Cable type tire bead and tire

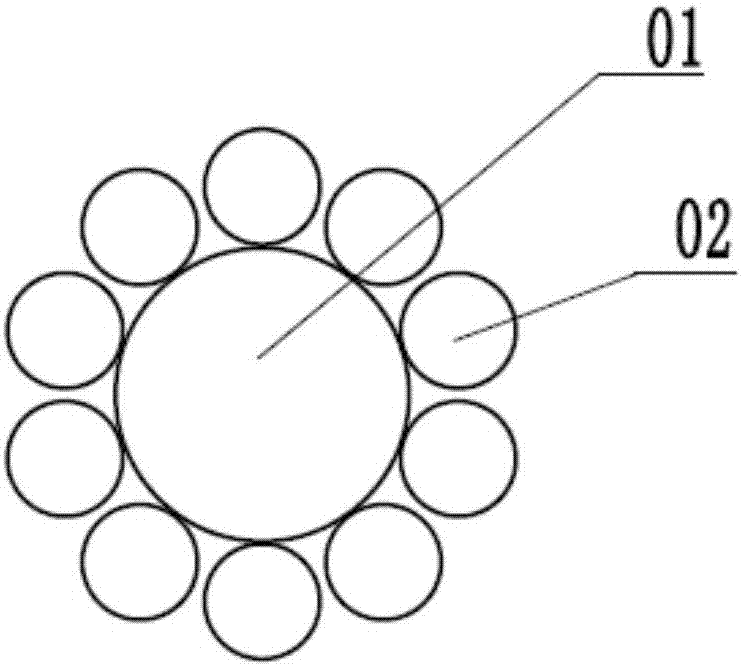

A bead and cable type technology, applied in tire parts, bead, textile cables, etc., can solve the problems of reducing the service life of the bead, large arrangement gap, low effective strength of the bead, etc., to extend the life of the bead, The effect of improving section strength and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as Figure 4 As shown, a cable-shaped bead has a specification of 1×φ5.00+(10)×(2.00×1.80), the core ring steel wire 31 is a round steel wire with a diameter of 5.00mm, and the outer winding steel wire 32 is a flat steel wire. The long axis is 2.00mm, the long axis is perpendicular to the radial direction of the bead section, the short axis is 1.80mm, and the short axis is parallel to the radial direction of the bead section. As shown in Table 1, compared with the prior art 1, the effective section strength of the cable bead in this embodiment is increased by 3.18%, the fatigue fracture retention is increased by 4.26%, and the cross-sectional diameter of the bead is reduced 3.78%.

[0042] Table 1

[0043]

[0044]

Embodiment 2

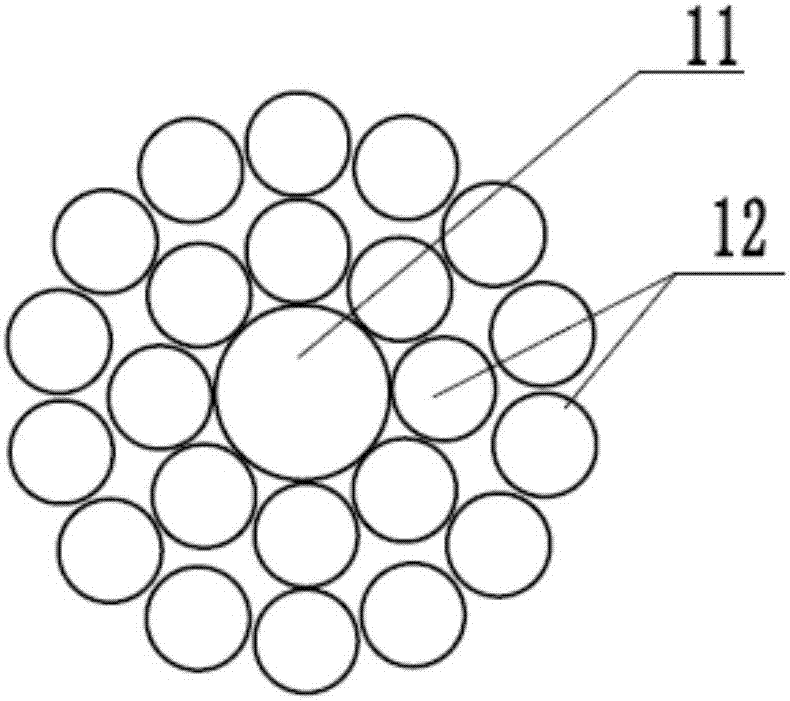

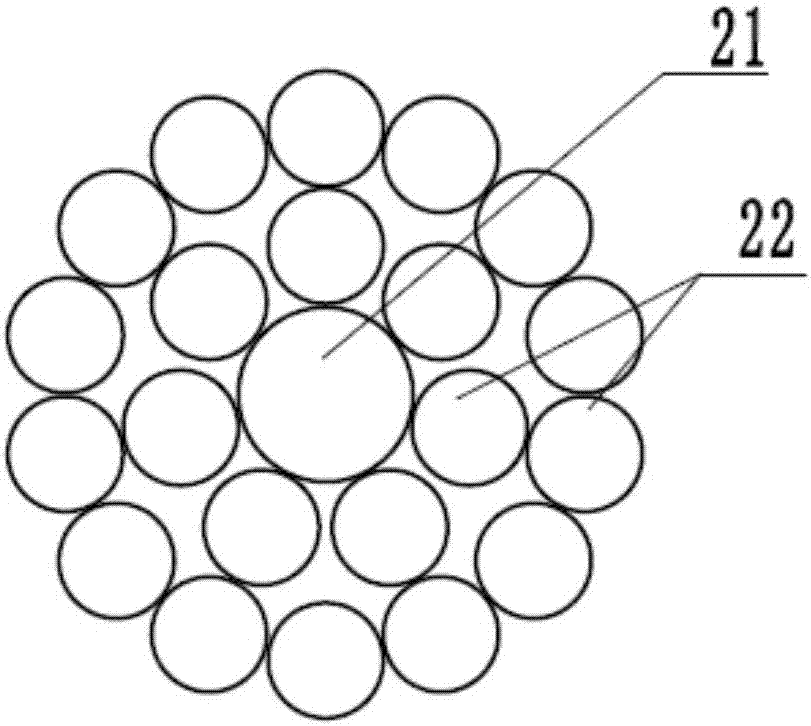

[0046] Such as Figure 5 and 6 As shown, a cable-shaped bead has a specification of 1×φ3.00+(7+12)×(1.98×1.70), the core ring steel wire 41 is a round steel wire with a diameter of 3.00mm, and the outer winding steel wire 42 is flat The steel wire has a long axis of 1.98 mm, the long axis is perpendicular to the radial direction of the bead section, and its short axis is 1.70 mm, and the short axis is parallel to the radial direction of the bead section. Along the radial direction of the bead section, the winding direction of the outer winding wire 42 of the first layer is the S direction, and the winding direction of the outer winding wire 42 of the second layer is the Z direction. As shown in Table 2, compared with prior art 2, the effective section strength of the cable bead in this embodiment is increased by 2.16%, the fatigue fracture retention is increased by 7.95%, and the cross-sectional diameter of the bead is reduced 2.64%.

Embodiment 3

[0048] The difference from Example 2 is that the winding direction of the outer winding wire of the first layer is the S direction from the inside to the outside along the radial direction of the bead section, and the winding direction of the outer winding wire of the second layer is the S direction. As shown in Table 2, compared with prior art 2, the effective section strength of the cable bead in this embodiment is increased by 2.16%, the fatigue fracture retention is increased by 7.95%, and the cross-sectional diameter of the bead is reduced 2.64%.

[0049] Table 2

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com