Shape modification and reinforcement of columns confined with FRP composites

a technology of composites and columns, applied in the field of shape modification and reinforcement of columns confined with frp composites, can solve the problems of composite structure, non-uniform gap thickness, non-uniform thickness of the non-shrink or expansive portion of the core,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

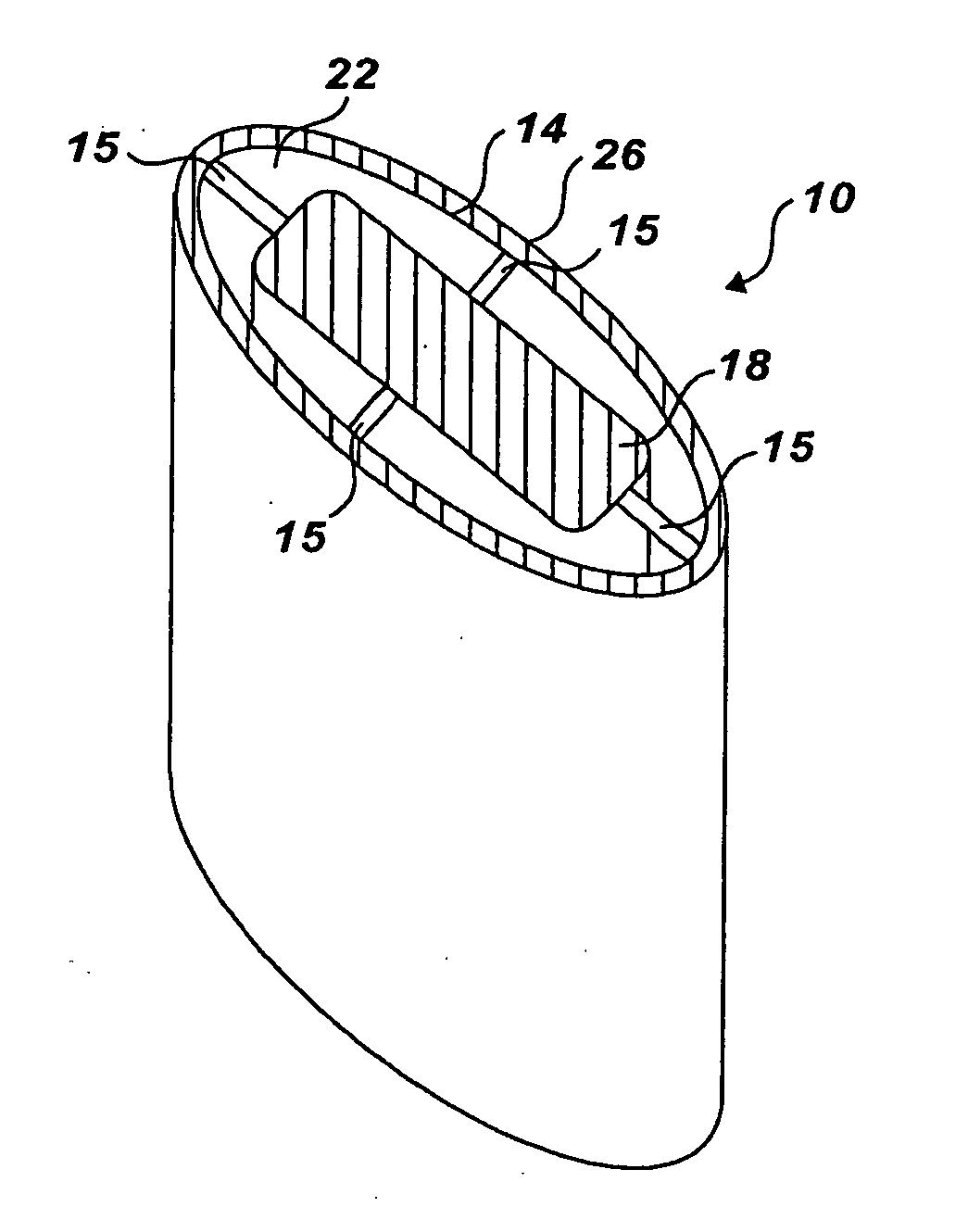

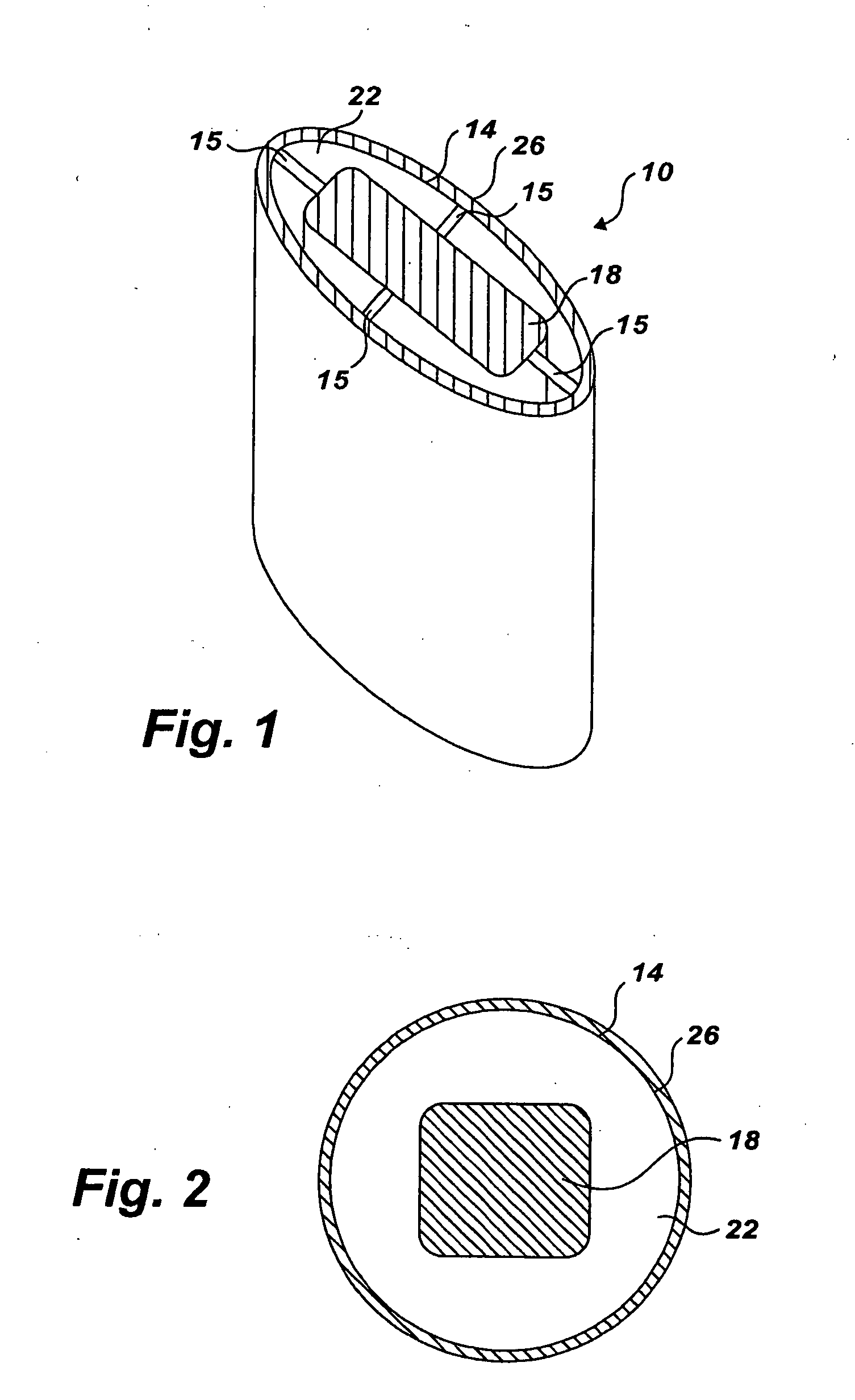

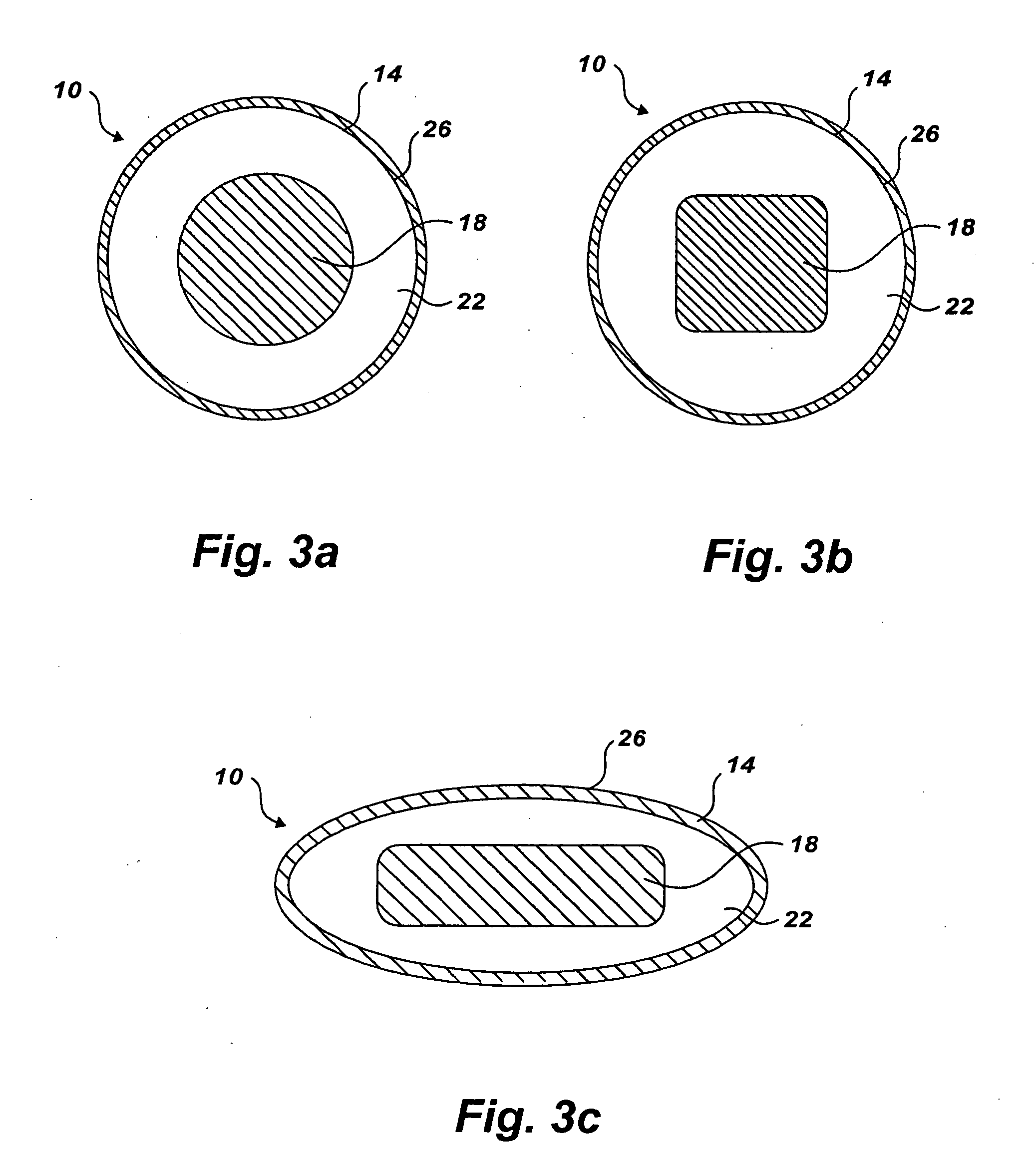

Image

Examples

examples

[0113] The following examples illustrate exemplary embodiments of the invention. However, it is to be understood that the following is only exemplary or illustrative of the application of the principles of the present invention. Numerous modifications and alternative compositions, methods, and systems may be devised by those skilled in the art without departing from the spirit and scope of the present invention. The appended claims are intended to cover such modifications and arrangements. Thus, while the present invention has been described above with particularity, the following examples provide further detail in connection with what is presently deemed to be practical embodiments of the invention.

[0114] In the following examples, the radii of curvature for the 90 degree corners of the square and rectangular columns were designed to be ¾ in. This would allow modification of existing columns, taking into account typical existing steel reinforcement at 90 degree corners. Expansive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com