Construction method of opening locked steel tube pilecofferdam

A construction method and technology of steel pipe piles, which can be applied in basic structure engineering, architecture, bridge construction, etc., can solve the problem that the bending modulus of steel sheet pile cofferdam cannot meet the required section resistance moment, and it is difficult for large tugboats and floating cranes to enter , Intensive construction can not be carried out and other problems, to achieve the effect of high rigidity, strong sealing, simple and convenient support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

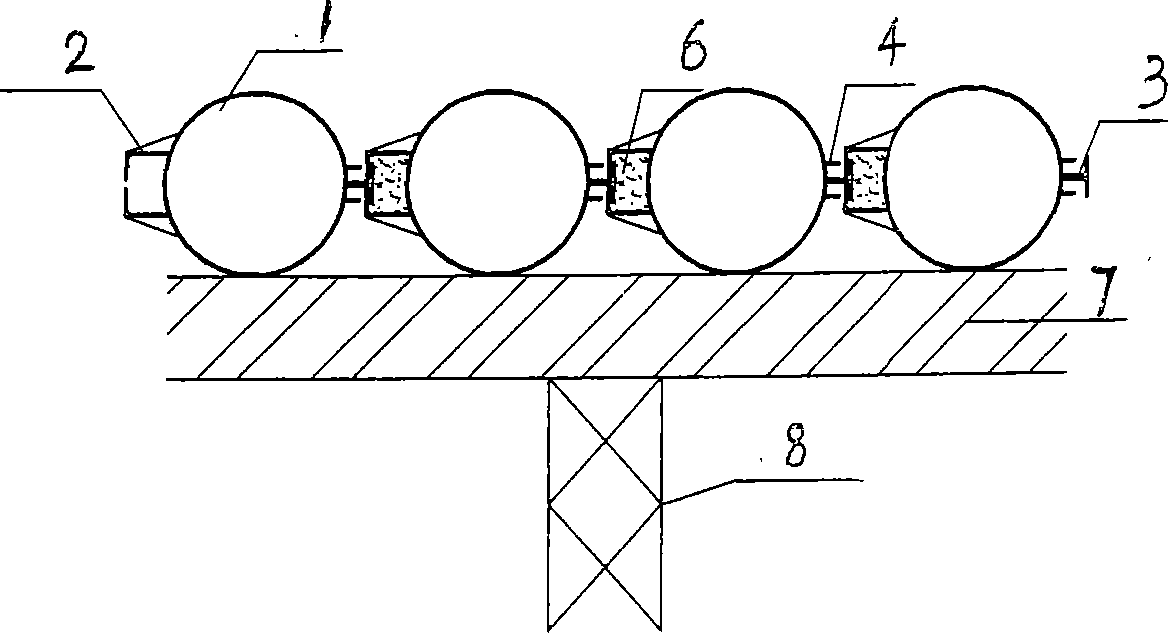

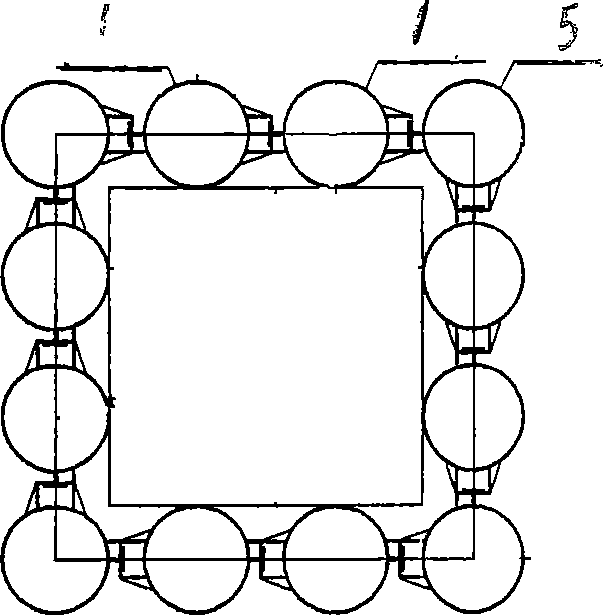

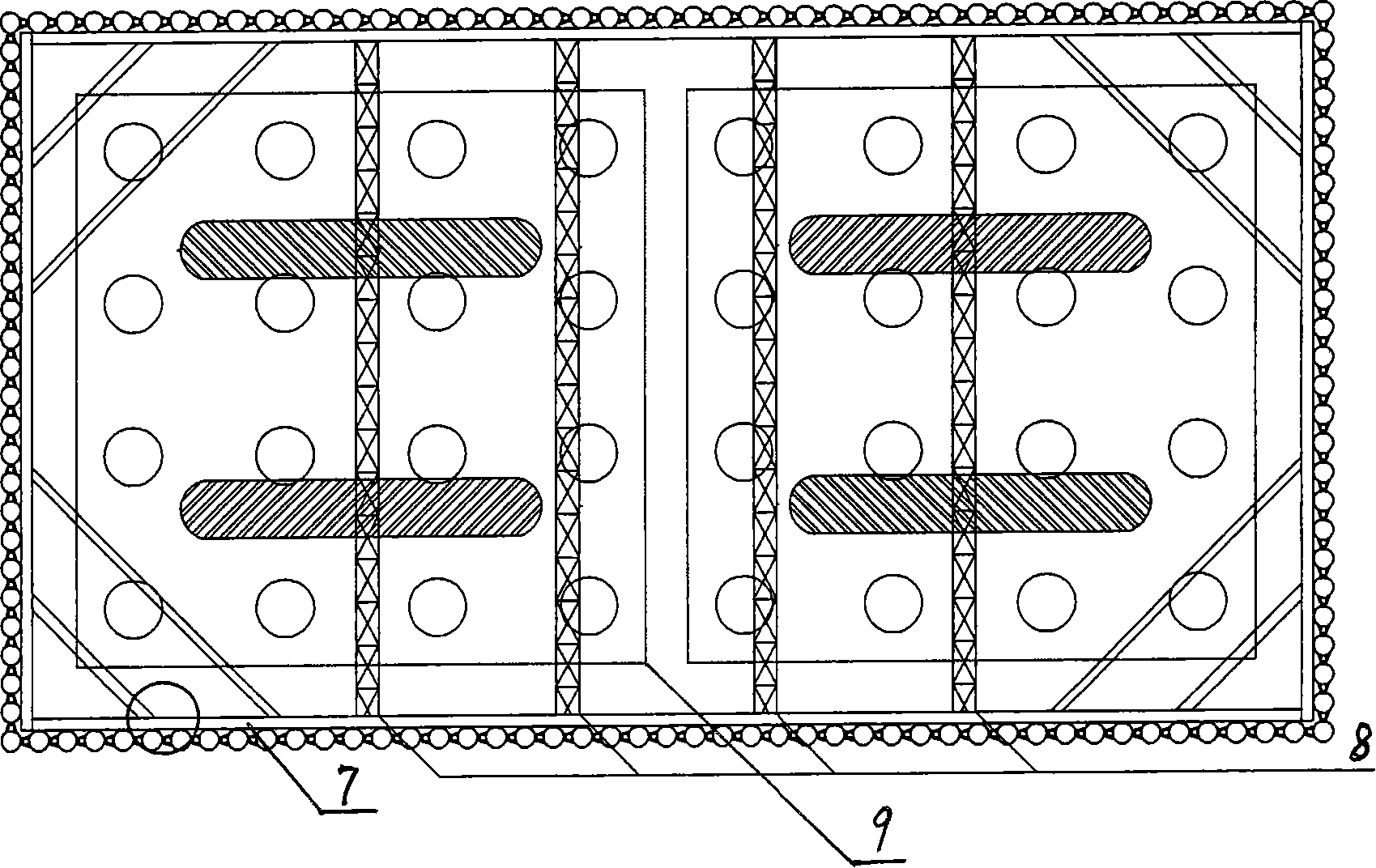

[0022] A method for constructing a cofferdam of interlocking steel pipe piles, which is carried out according to the following steps: ①Processing steel pipe columns: such as figure 1 As shown: the female buckle 2 and the male buckle 3 are respectively processed on the spiral tube 1; the male and female buckles are made of unequal angle steel, which not only saves materials, but also solves the problem of small locking space. In order to ensure the accuracy of positioning during the insertion and driving of steel pipe piles and the space position of the inner cavity of the box, we added a stopper 4 in the design. The above-mentioned male buckle and the female buckle are made of unequal angle steel and the axial bearings of the male buckle and the female buckle are 180°, and the corner pipe 5 is 90°. ② if figure 2 As shown: the steel pipe columns are connected to each other from the beginning along the surrounding of the cap to form a whole steel pipe column, and each one is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com