Preparation method of gallium nitride film layer and substrate

A thin-film, gallium nitride technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of reducing the utilization rate of epitaxial materials, large lattice mismatch and thermal mismatch, and expensive SiC substrates, etc. problem, to achieve the effect of good thermal conductivity, small lattice mismatch, and regular connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method for preparing the gallium nitride thin film layer and the substrate provided by the present invention will be described in detail below with reference to the accompanying drawings.

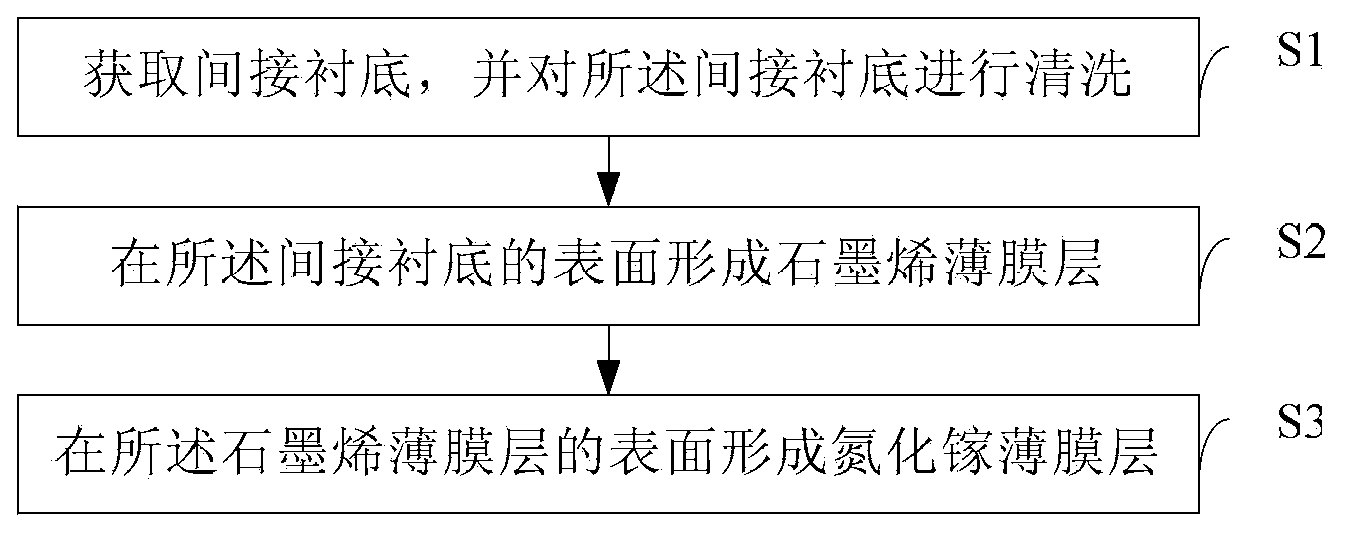

[0049] This embodiment provides a method for preparing a gallium nitride thin film layer. figure 1 It is a flowchart of a method for preparing a gallium nitride thin film layer according to an embodiment of the present invention. like figure 1 Shown, the preparation method of gallium nitride film layer comprises the following steps:

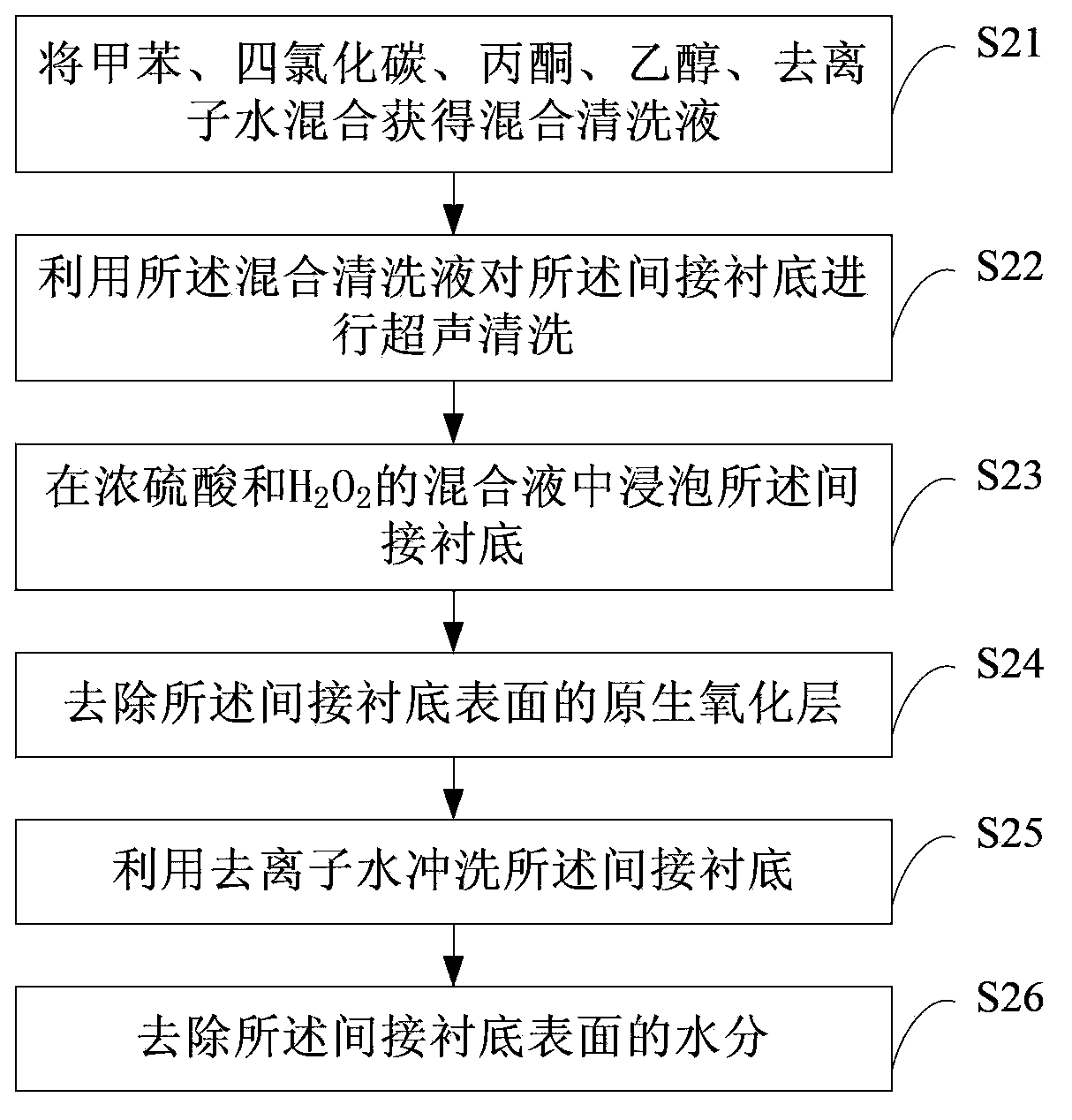

[0050] Step S1, obtaining an indirect substrate, and cleaning the indirect substrate.

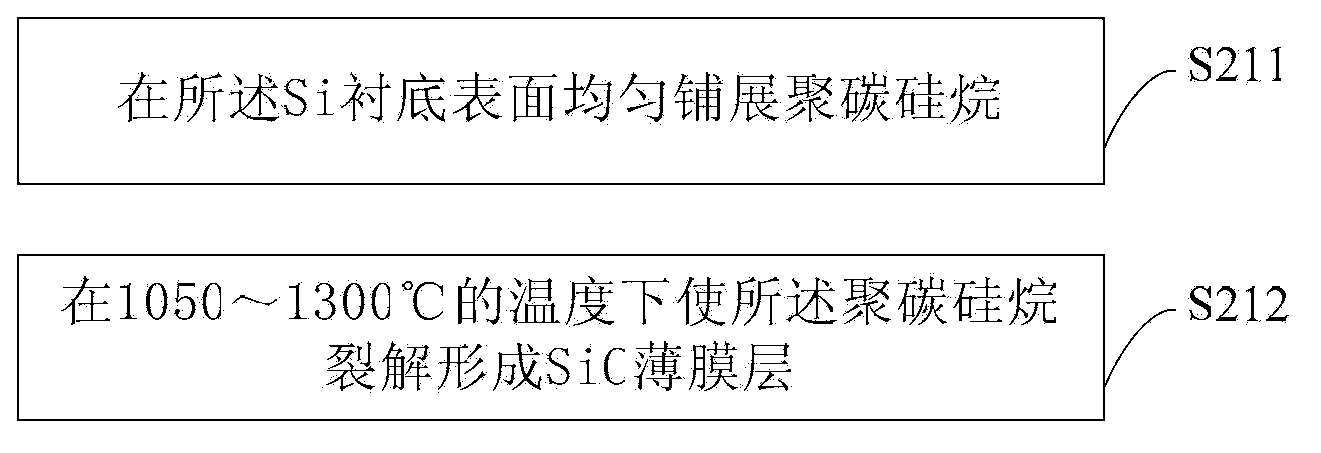

[0051] The indirect substrate can be sapphire substrate, SiC substrate, Si substrate, LiAlO 3 substrate or ZnO substrate. This embodiment takes the Si substrate as an example for illustration, as figure 2 Shown, the specific steps of cleaning Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com