Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

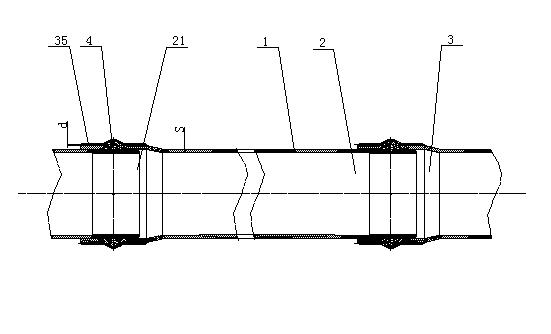

A socket and reinforced technology, which is applied in the field of steel wire reinforced socket and socket composite plastic pipes and the manufacturing process thereof, can solve the maintenance difficulties of water supply, gas supply and liquid supply systems, the socket and socket can not meet the connection quality requirements, and the production cost. With the high cost of raw materials, it can improve the quality of connection and installation, the effect of fusion welding is remarkable, and the construction period and maintenance cost can be saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

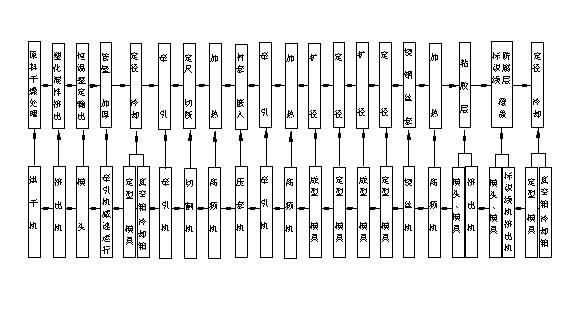

Method used

Image

Examples

Embodiment approach 1

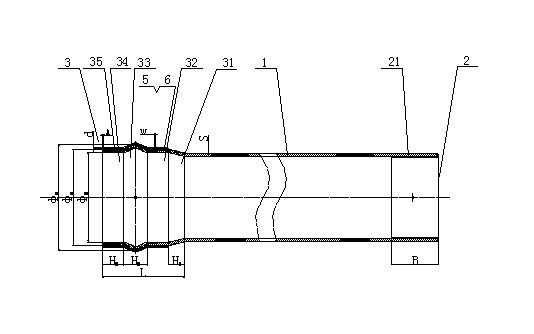

[0058] Embodiment 1 is the value range of each corresponding ratio for the nominal outer diameter of 110 mm to 1000 mm and the nominal pressure PN of 0.8 MPa, see Figure 4 That is, chart 4-a; this embodiment provides the steel wire diameter d of the steel wire sleeve 35 and the wall thickness S of the pipe wall 1 and the inner diameter φ of the round pipe B34 1 With round pipe B34 outer diameter φ 2 With arc tube 33 outer diameter φ 3 with round tube B34 long H 1 with arc tube 33 long H 2 with conical tube 31 long H 3 The value range of the corresponding ratio with the length L of the outer bearing socket 3 is: the steel wire diameter d of the steel wire sleeve 35 and the wall thickness S of the pipe wall 1 and the inner diameter φ of the round pipe B34 1 With round pipe B34 outer diameter φ 2 With arc tube 33 outer diameter φ 3 with round tube B34 long H 1 with arc tube 33 long H 2 with conical tube 31 long H 3 The corresponding ratio to the length L of the outer so...

Embodiment approach 2

[0059] Embodiment 2 is the value range of each corresponding ratio of the nominal outer diameter of 110 mm to 1000 mm and the nominal pressure PN of 1.0 MPa, see Figure 5 That is, chart 4-b; this embodiment provides the steel wire diameter d of the steel wire sleeve 35 and the wall thickness S of the pipe wall 1 and the inner diameter φ of the round pipe B34 1 With round pipe B34 outer diameter φ 2 With arc tube 33 outer diameter φ 3 with round tube B34 long H 1 with arc tube 33 long H 2 with conical tube 31 long H 3 The corresponding ratio to the length L of the outer socket 3 is d0.7~1.2mm: S5~43mm:φ 1 112~1008mm: φ 2 117~1051mm: φ 3 132~1182mm: H 1 21~185mm: H 2 36~319mm: H 3 23~208mm: L129~1156mm.

Embodiment approach 3

[0060] Embodiment 3 is the value range of each corresponding ratio for the nominal outer diameter of 110 mm to 1000 mm and the nominal pressure PN of 1.25 MPa, see Figure 6 That is, chart 4-c; this embodiment provides the steel wire diameter d of the steel wire sleeve 35 and the wall thickness S of the pipe wall 1 and the inner diameter φ of the round pipe B34 1 With round pipe B34 outer diameter φ 2 With arc tube 33 outer diameter φ 3 with round tube B34 long H 1 with arc tube 33 long H 2 with conical tube 31 long H 3 The corresponding ratio to the length L of the outer socket 3 is d0.7~1.2mm: S5.5~48mm:φ 1 112~1008mm: φ2 118~1056mm: φ 3 132~1188mm: H 1 20~186mm: H 2 36~321mm: H 3 23~209mm: L129~1162mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com