Patents

Literature

57results about How to "Lower energy consumption ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

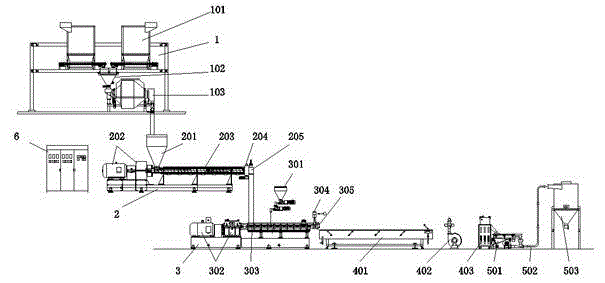

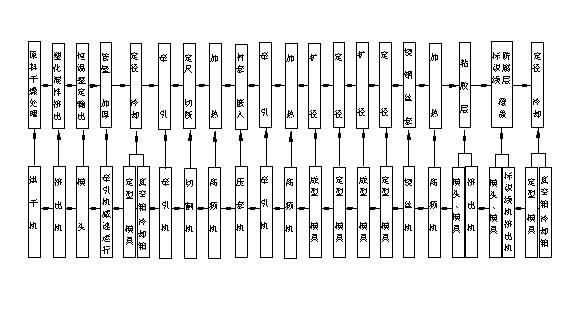

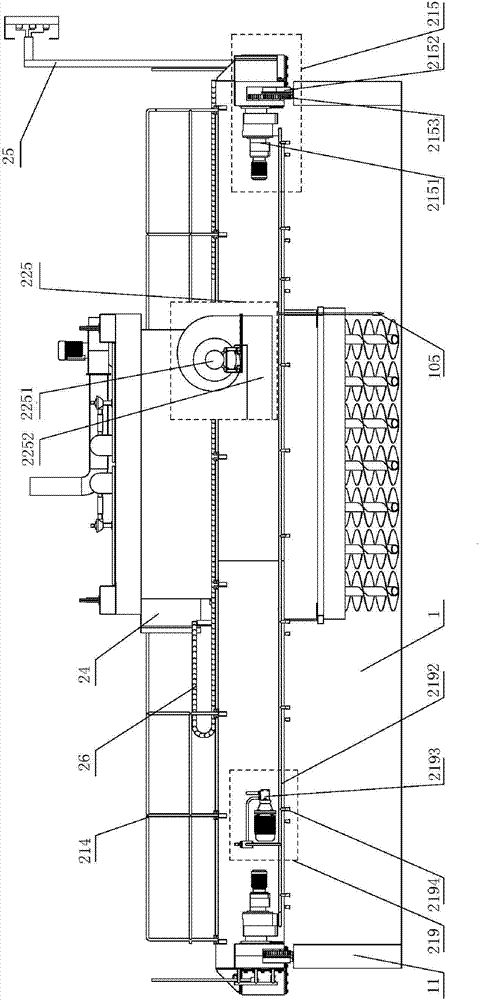

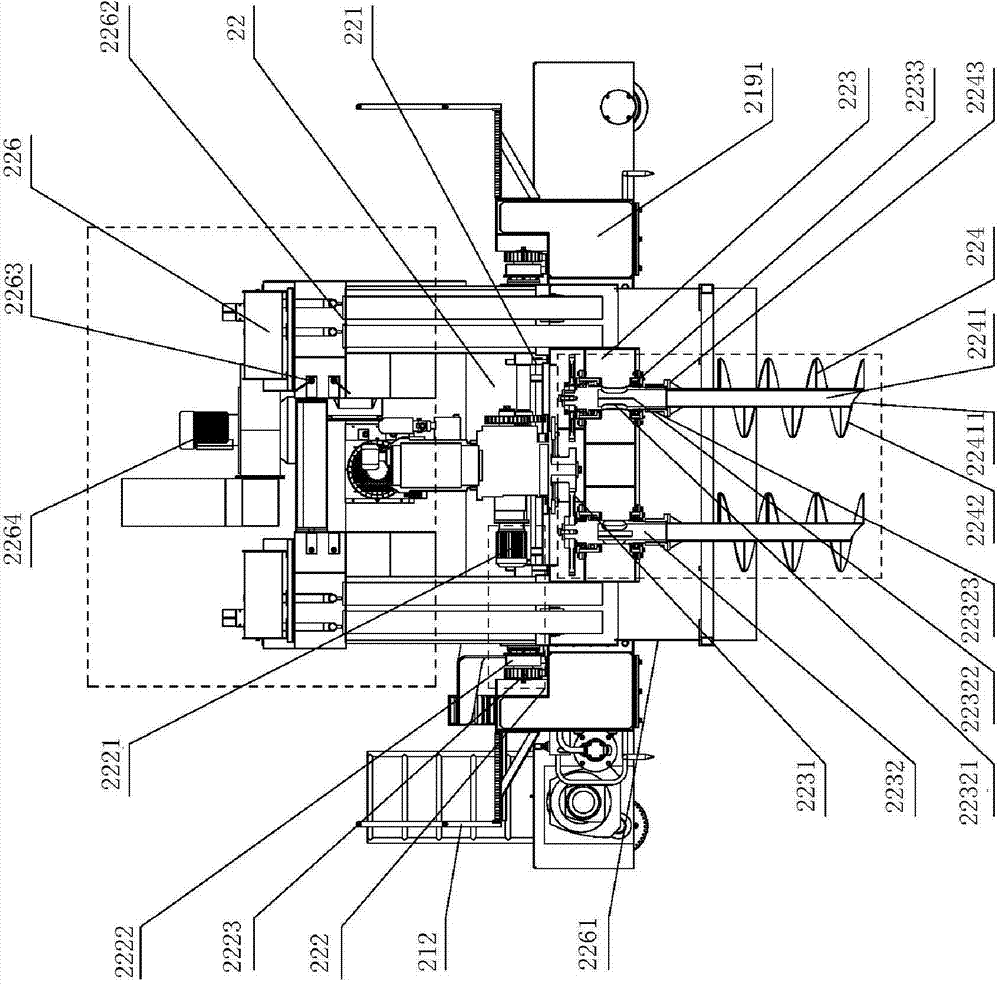

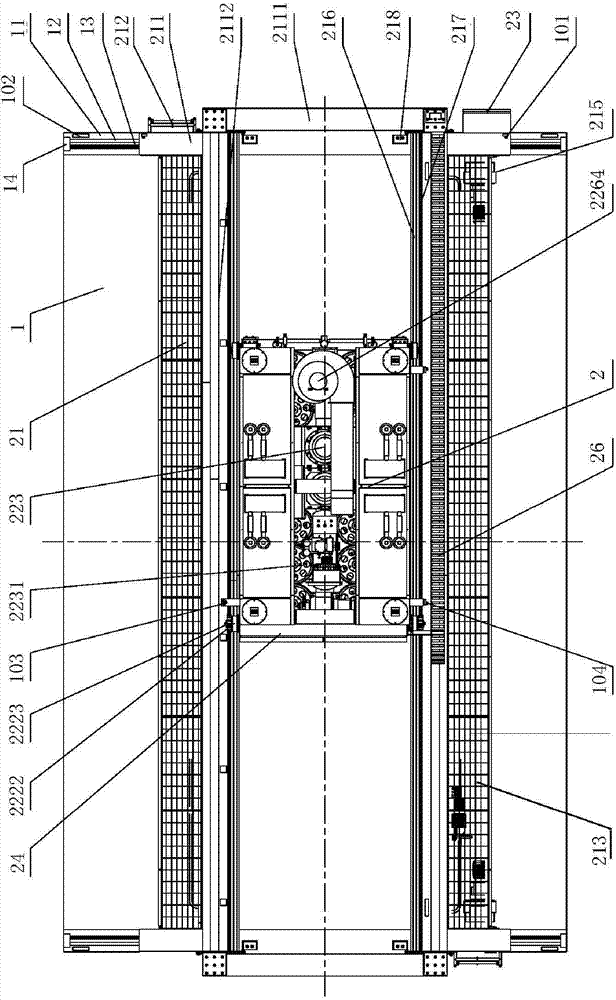

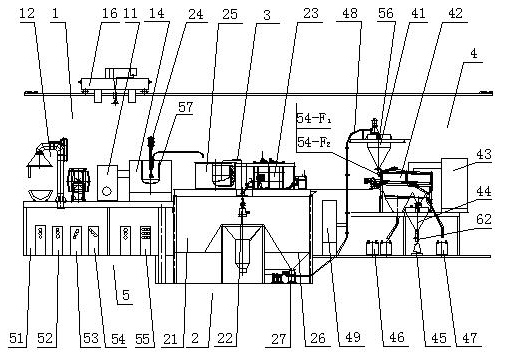

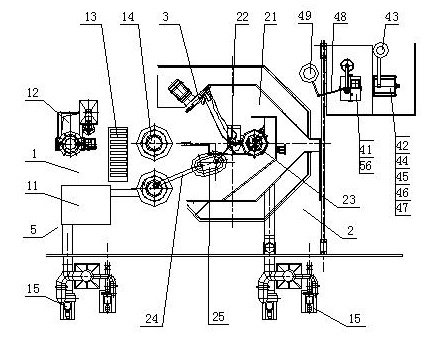

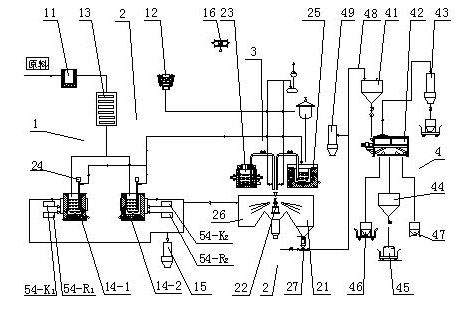

Efficient and energy-saving waste plastic recycling and granulating complete device

InactiveCN104162941AImprove the mixing effectLower energy consumption ratioCoatingsUnit deviceMaterial resources

The invention discloses an efficient and energy-saving waste plastic recycling and granulating complete device, which is characterized by comprising a main control device and a raw material supply device, an extrusion machine unit device, a granulating auxiliary device and a product conveying device, which are connected in sequence, wherein the extrusion machine unit device comprises a single-screw extrusion machine unit and a double-screw extrusion machine unit which are connected in sequence; the single-screw extrusion machine unit is connected with the raw material supply device; the product conveying device comprises a layering vibration screen, a conveying device and a drying and homogenizing material bin which is provided with a matched stirring screw rod; the drying and homogenizing material bin is used for drying by hot air. The efficient and energy-saving waste plastic recycling and granulating complete device has the beneficial effect that the comprehensive requirements of automation, efficiency, energy saving and environment friendliness are met; the production mode and economical benefit of the waste plastic recycling industry can be improved from every aspects and great manpower and material resources are saved.

Owner:江苏诚盟装备股份有限公司

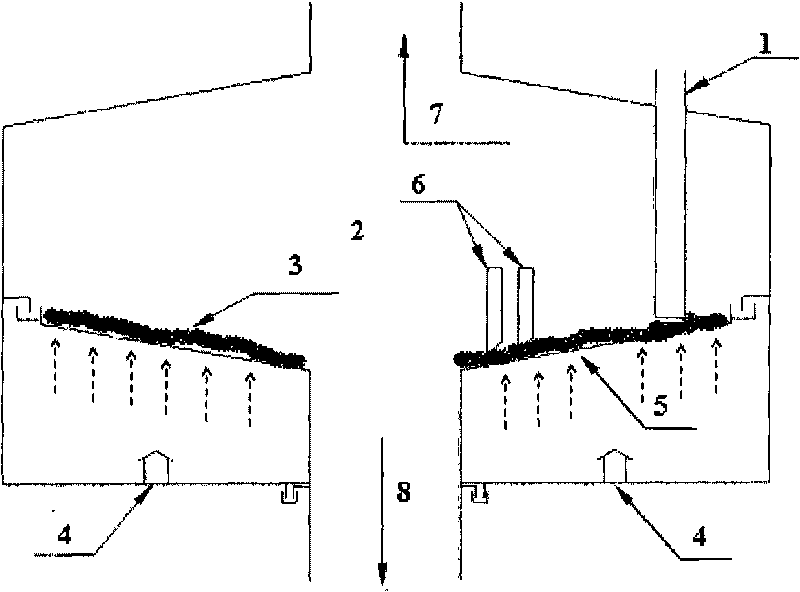

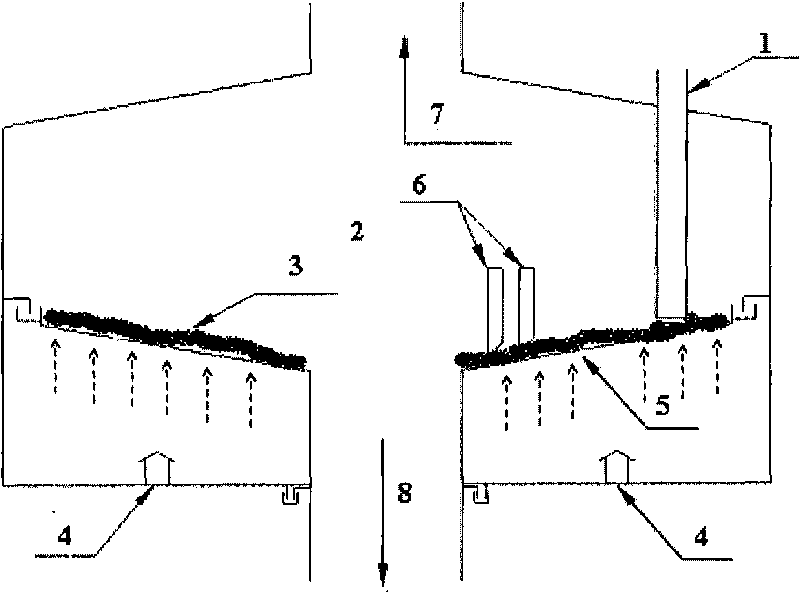

Process for upgrading low-rank coal in an internally heating way with heated gas carrier

InactiveCN101701158ALower energy consumption ratioImprove thermal efficiencyDirect heating destructive distillationSolid fuelsFlue gasProduct gas

The invention discloses a process for upgrading low-rank coal in an internally heating way with the heated gas carrier, comprising the following steps: (1) the crushed and screened raw coal is added to a rotating furnace grate arranged at the bottom of a reactor through a raw coal feeding elephant trunk; (2) hypoxic heated gas enters the reactor from a heating gas inlet arranged below the reactor to directly contact the raw coal sample and transfer heat to the raw coal sample through a hole chiseled on the rotating furnace grate, and the hypoxic heated gas and the raw coal sample are dried and subjected to the pyrolysis reaction; and (3) after a certain time of reaction, with the rotation of the rotating furnace grate, the processed raw coal sample is fixed on a plow-type mechanical stirrer which is arranged above the rotating furnace grate and is pushed to a discharge opening, and the tail gases of the heated gas are discharged out of a gas exhausting opening. The invention uses the hypoxic cyclic flue gas as the heat source to distill the low-rank coal and ensures that the hypoxic cyclic flue gas directly exchanges heat with the solid low-rank coal, thereby having high thermal efficiency and low energy consumption ratio. In addition, the invention has low requirement for the size of the granules of the processed low-rank coal and wide application range and can effectively reduce the content of the dust in the tail gases to be good for the transportation of the final product.

Owner:HUNAN HUAYIN ENERGY TECH

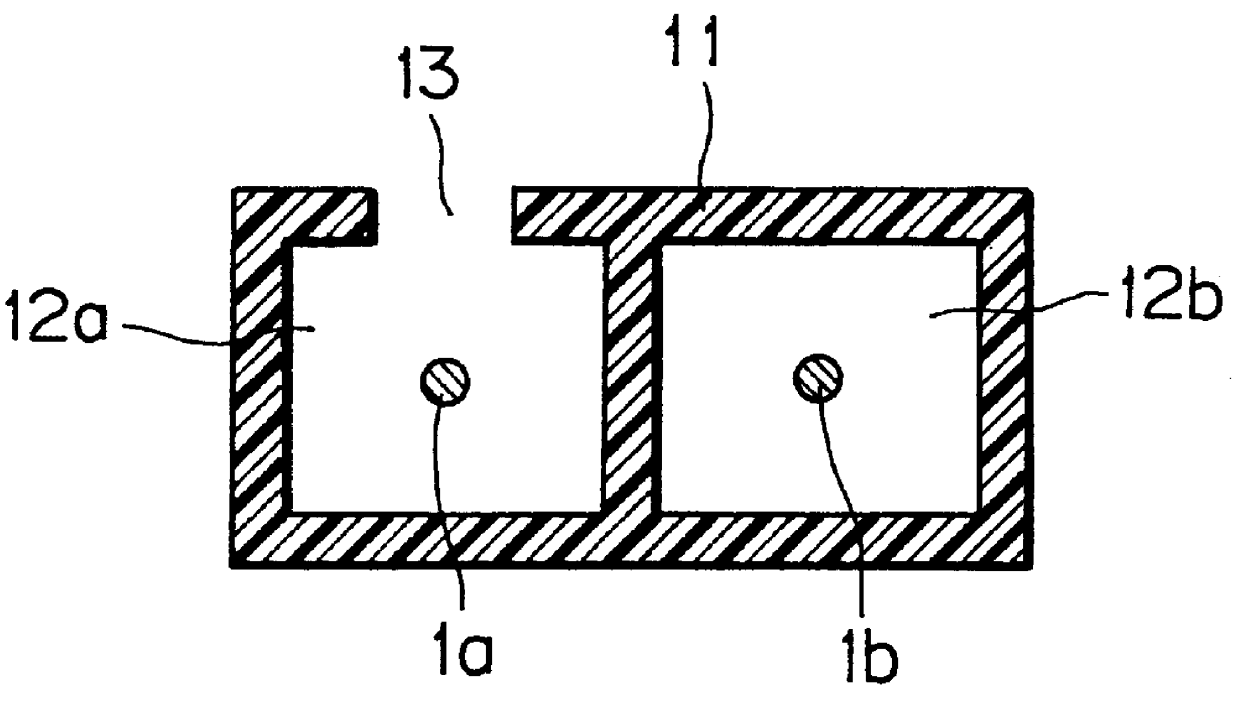

Toughening furnace for continuously producing half strengthened glass and production method of toughening furnace

InactiveCN103121793AAchieve continuous heatingImprove flatnessGlass tempering apparatusGlass productionSingle chamberToughened glass

The invention provides a toughening furnace for continuously producing half strengthened glass and a production method of the toughening furnace. The toughening furnace is characterized by comprising a feeding area, a heating area and the like arranged orderly, wherein the feeding area has a two-way feeding function; and the heating area comprises a first heating section, a second heating section and a third heating section. The production method of the toughening furnace comprises the following steps of heating treatment, cooling treatment and the like. The toughening furnace has the beneficial effects that the heating area is divided into three heating sections; the length of each heating section is 10m; the length of the heating area is greater than that of like product; the three heating sections adopt different temperature to heat; the glass can finish the heating requirement of the half strengthened glass after passing through the three heating sections; conveying for a plurality of times is not needed; and the rear glass does not need to wait in the feeding area, so that continuous heating of the glass is achieved; and the work efficiency is improved. The production efficiency of the toughening furnace is 3.5 times that of a common double-chamber toughening furnace, and is 5.5 times that of a common single-chamber furnace; and the energy consumption of each square meter of glass is reduced by about 39% in comparison with that of the common toughening furnace.

Owner:天津南玻节能玻璃有限公司 +2

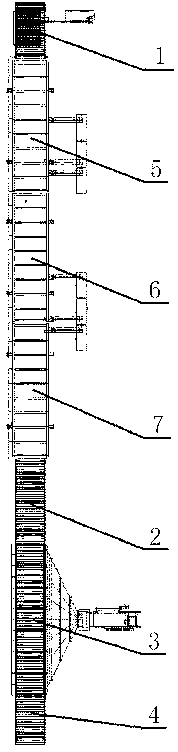

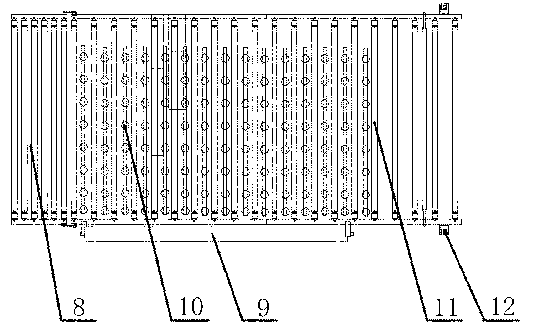

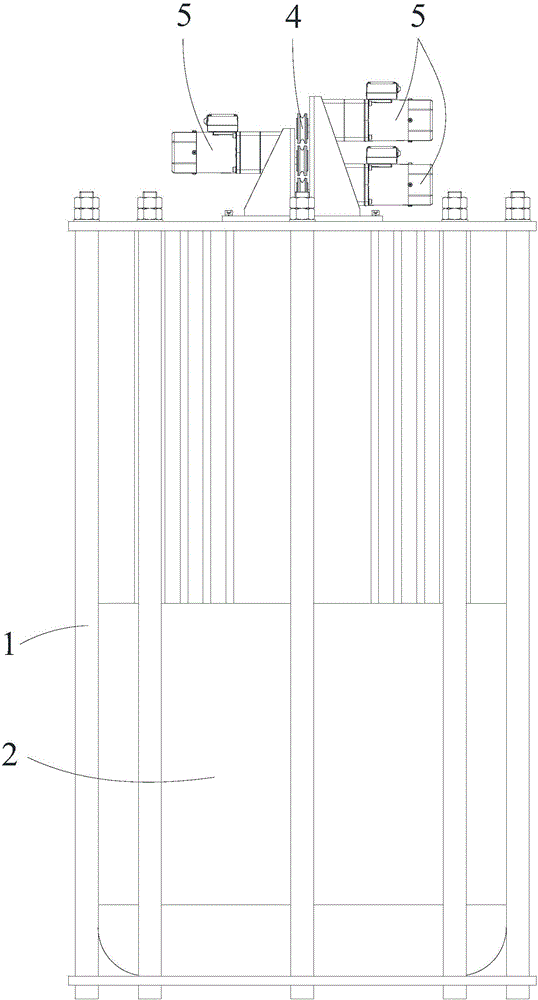

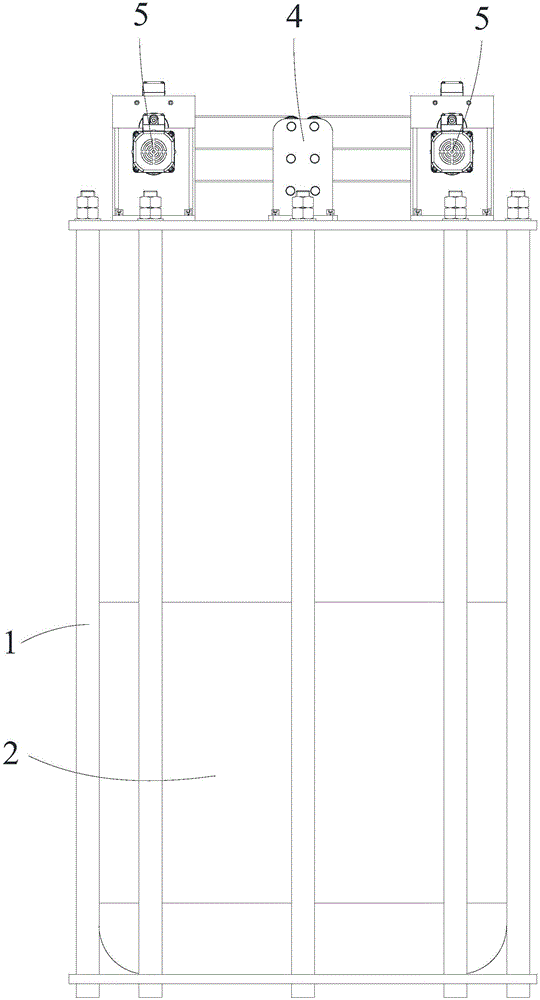

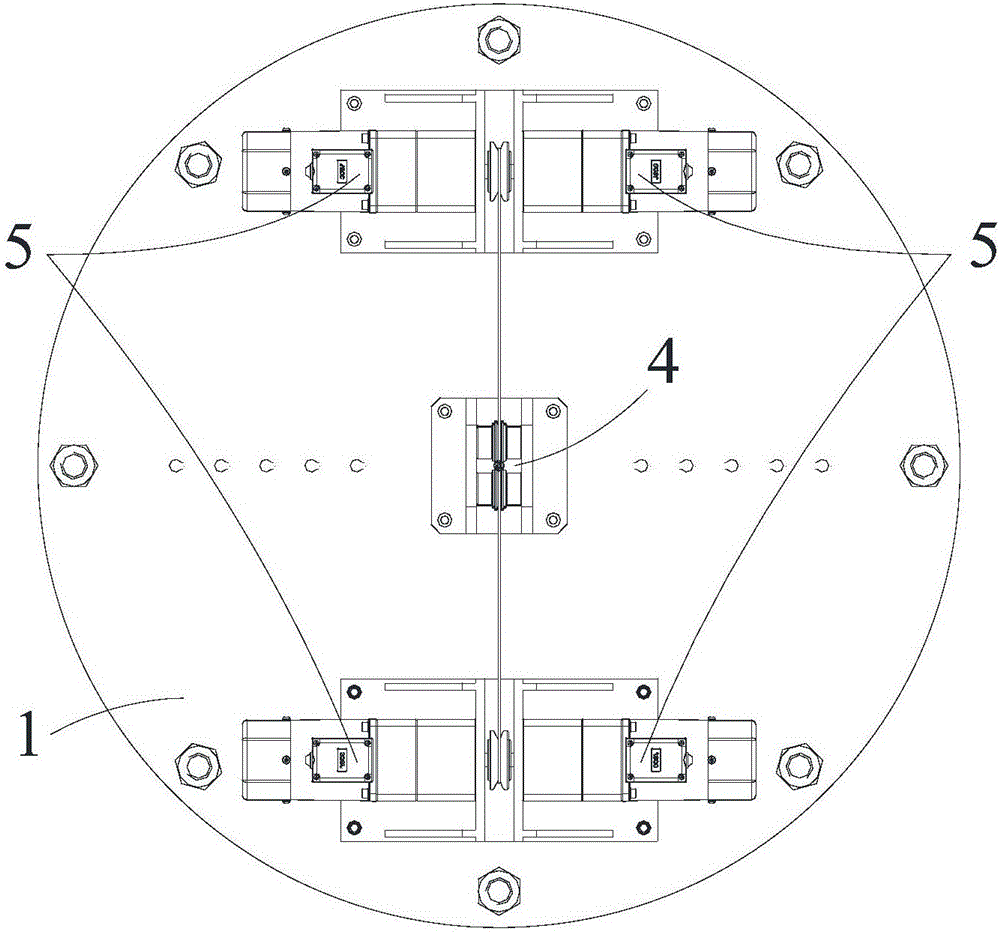

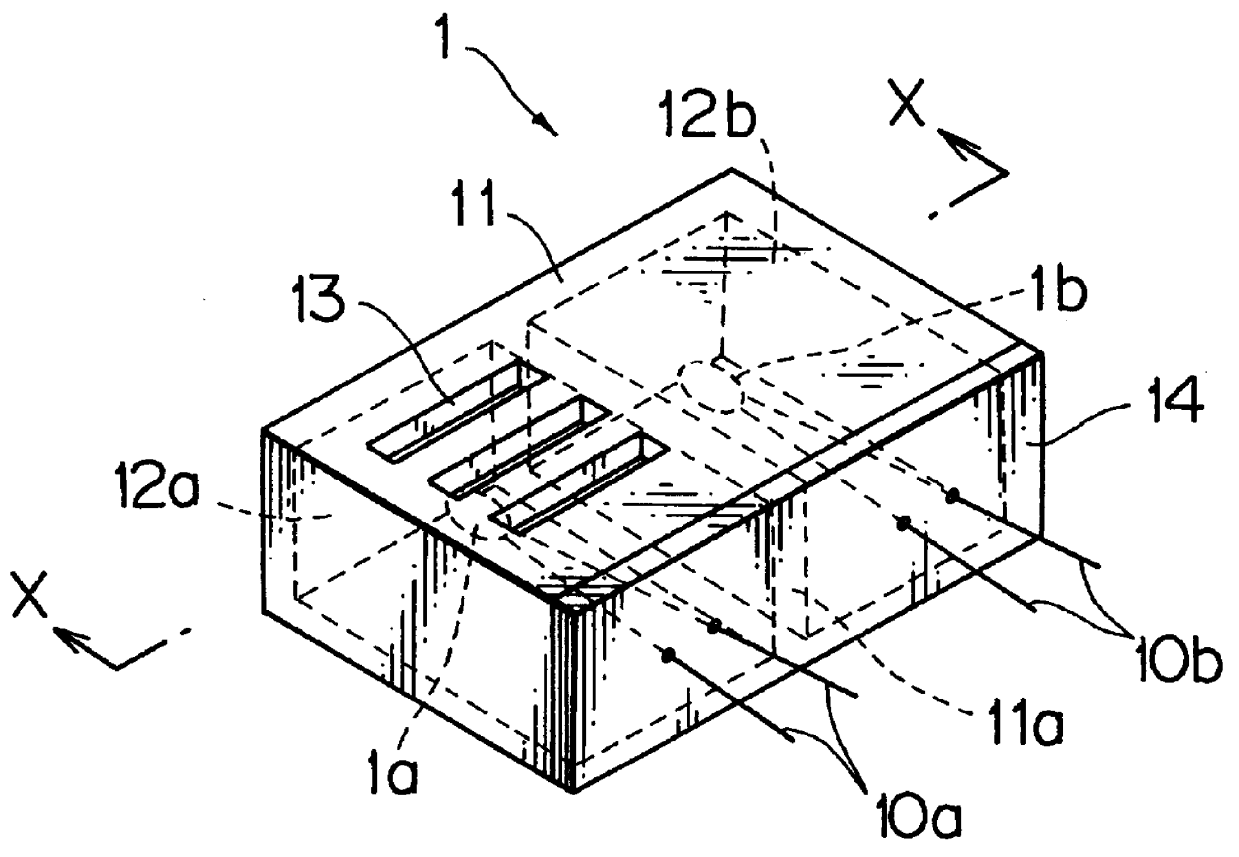

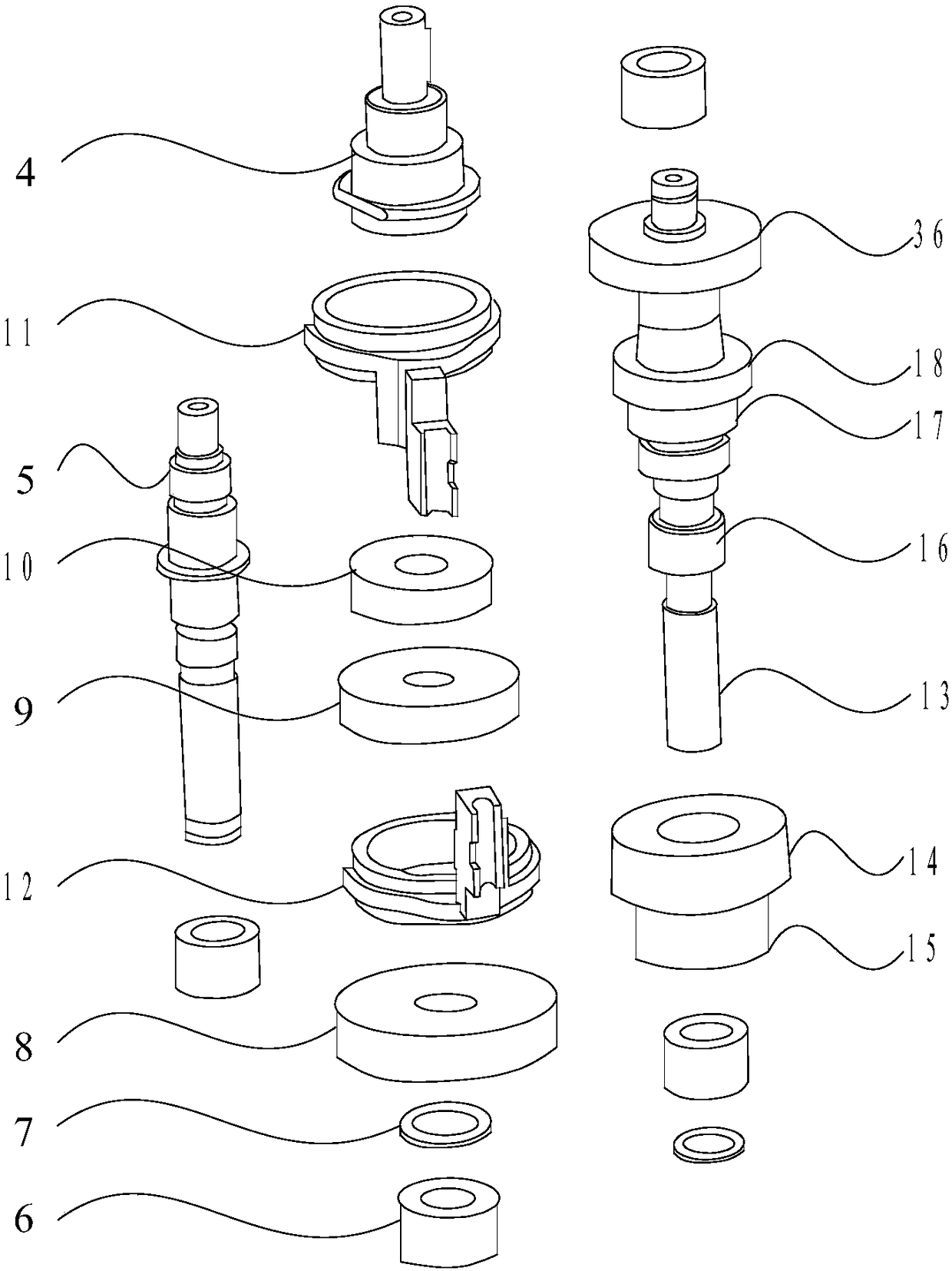

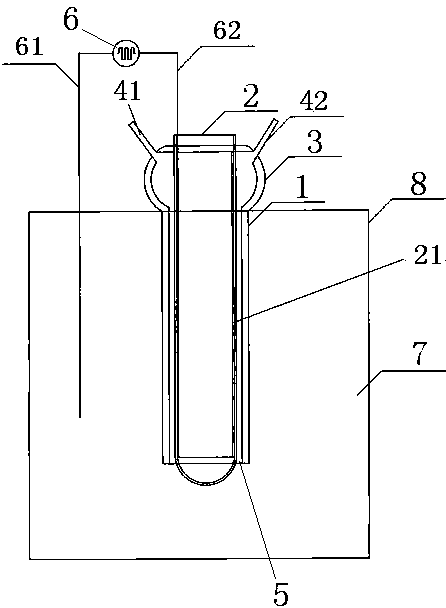

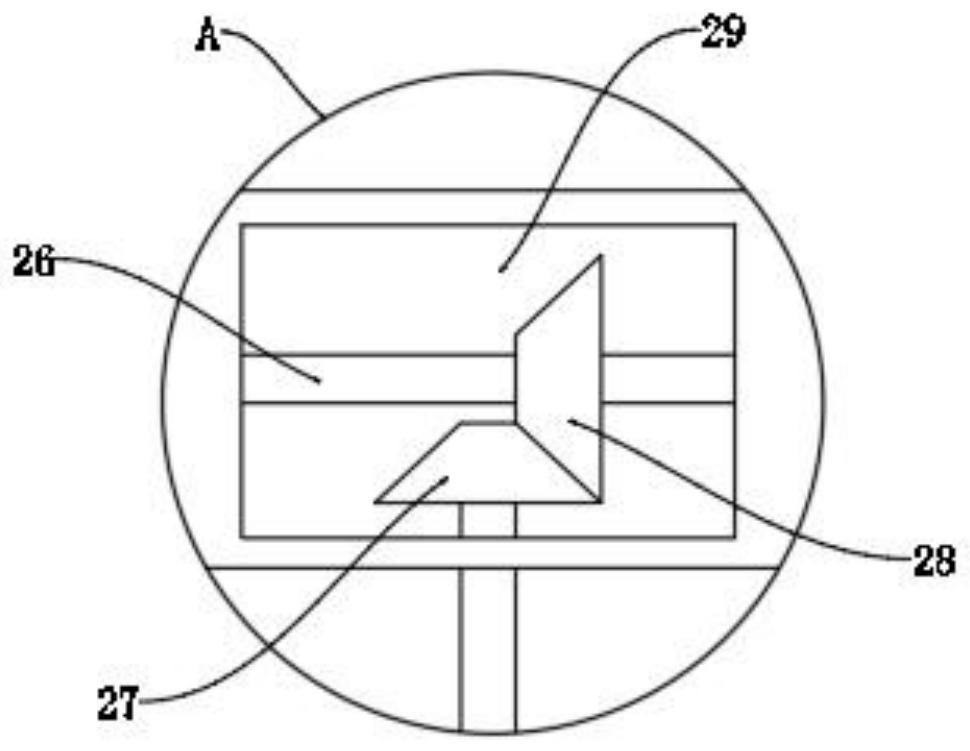

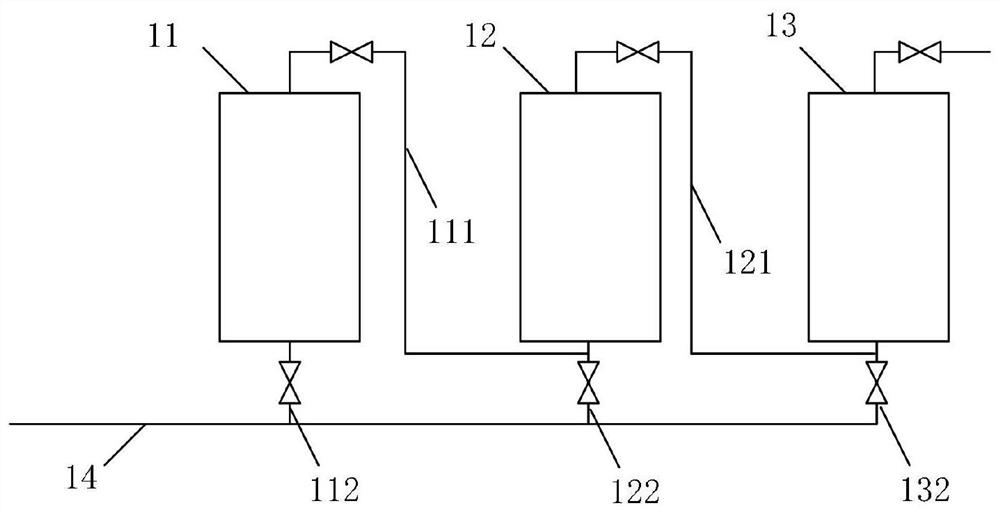

Displacement chromatography hydrogen isotope separation device

ActiveCN106693703AExtend effective lifeExtended service lifeIsotope separationDesorptionDisplacement chromatography

The invention discloses a displacement chromatography hydrogen isotope separation device which comprises a rack as well as a cooling part, a separation column, an air supply part, an air collection part, a lifting part and a driving part. By adopting the displacement chromatography hydrogen isotope separation device disclosed by the invention, different adsorption functions that hydrogen and hydrogen isotope are replaced and separated by using a separation material can be achieved, the lifting part is driven by the driving part to precisely control the lifting position of the separation column, and then the separation column can be descended or lifted off the cooling part, so that adsorption or desorption of hydrogen isotope by the separation material under different temperature conditions can be achieved, a high retention rate of deuterium-tritium isotope in the separation material can be ensured, and a deuterium-tritium isotope gas obtained through final separation and selection is relatively high in purity; compared with the prior art, the device needs no parts for introducing deuterium or separating deuterium, meanwhile deuterium and tritium do not need to be replaced by introducing hydrogen after the separation material is in saturation adsorption of hydrogen, and in addition, the device is simple in structure, low in energy consumption rate, simple in process and low in cost.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

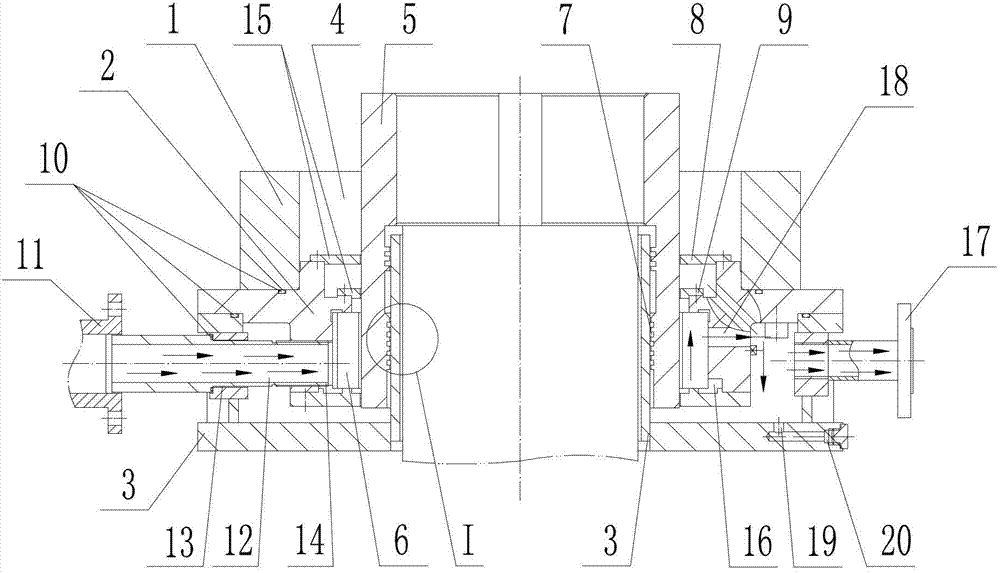

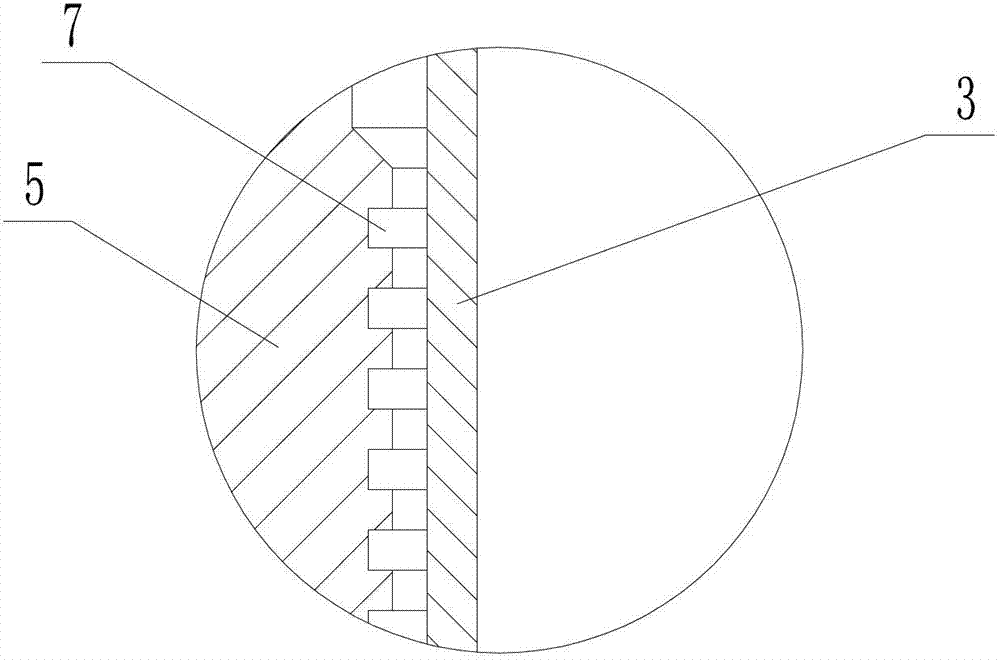

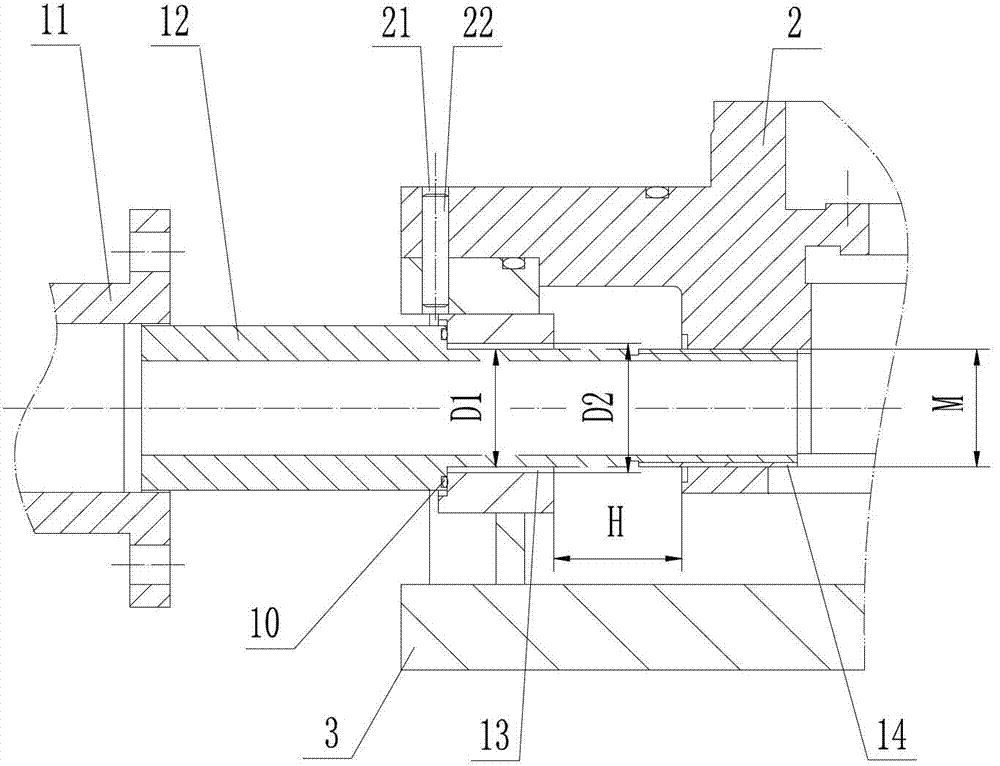

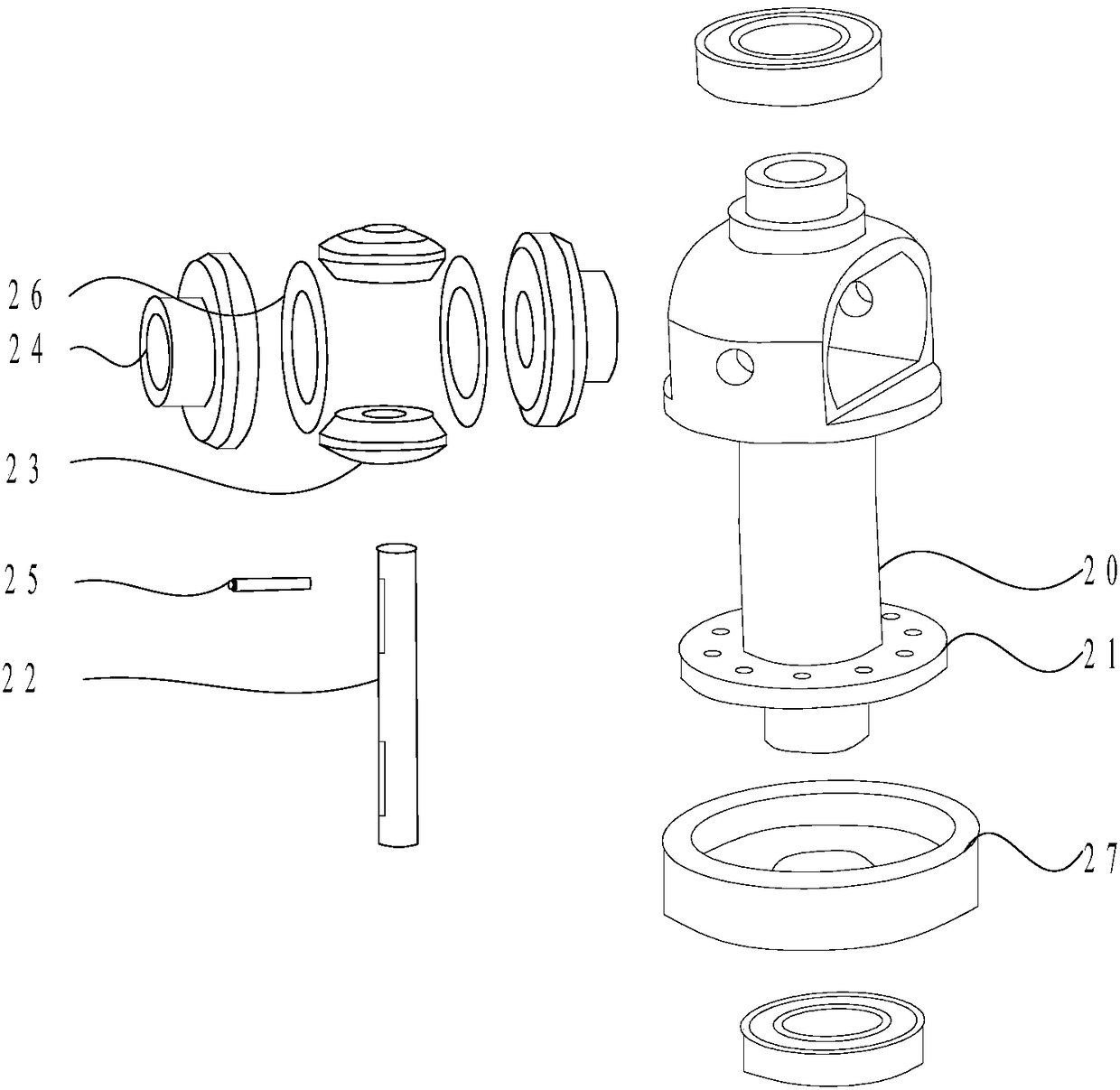

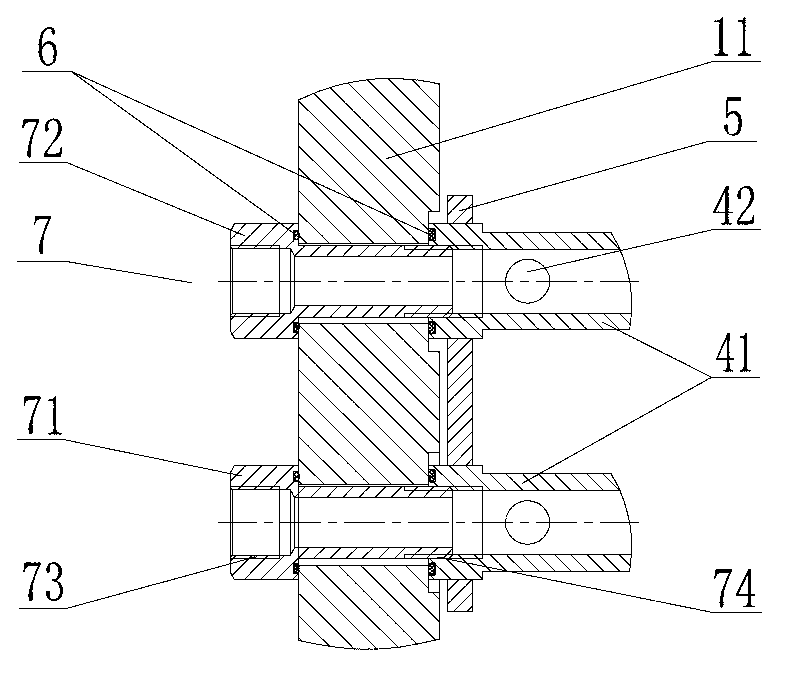

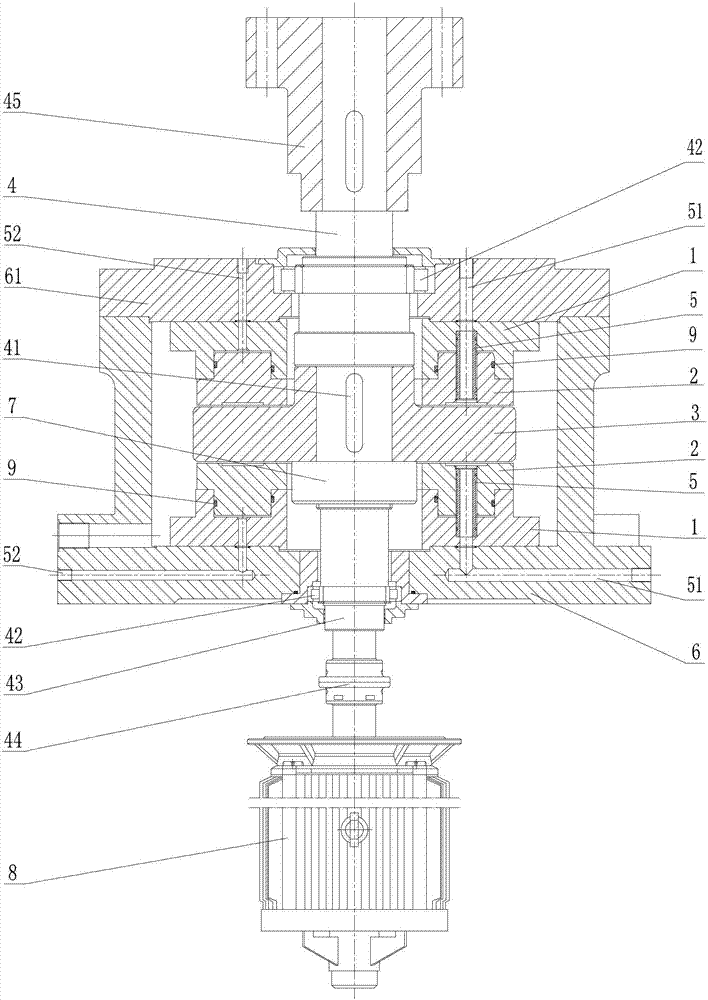

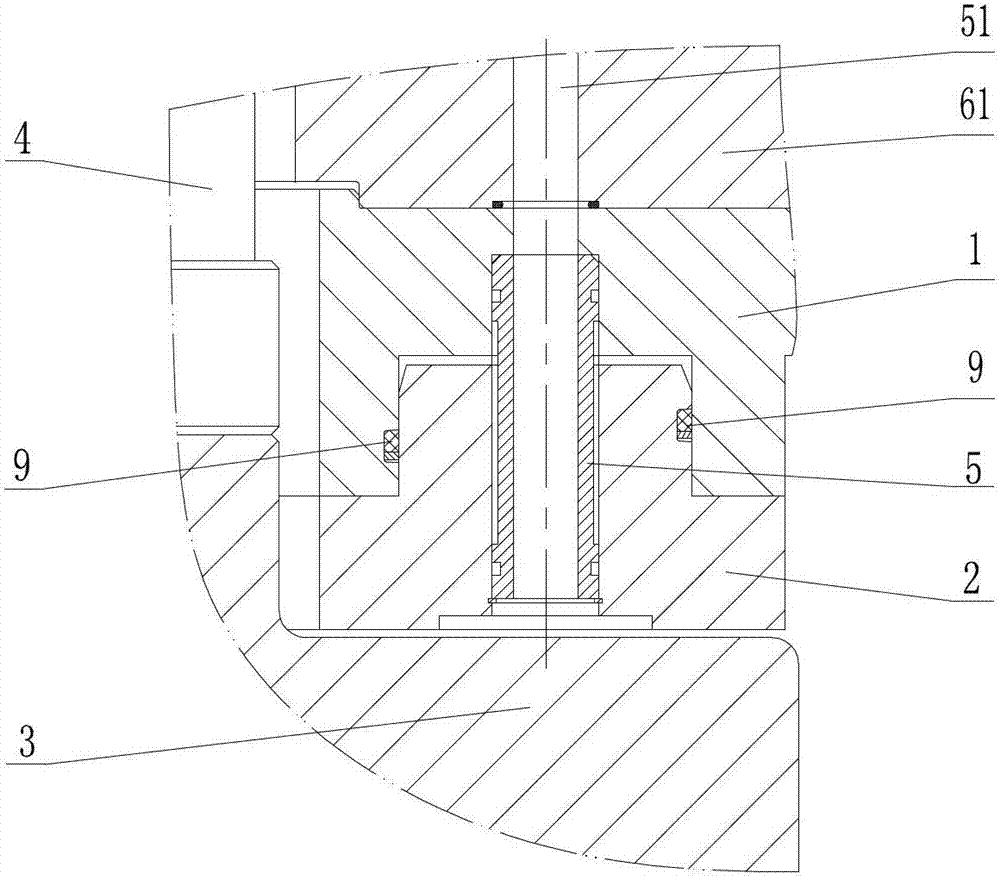

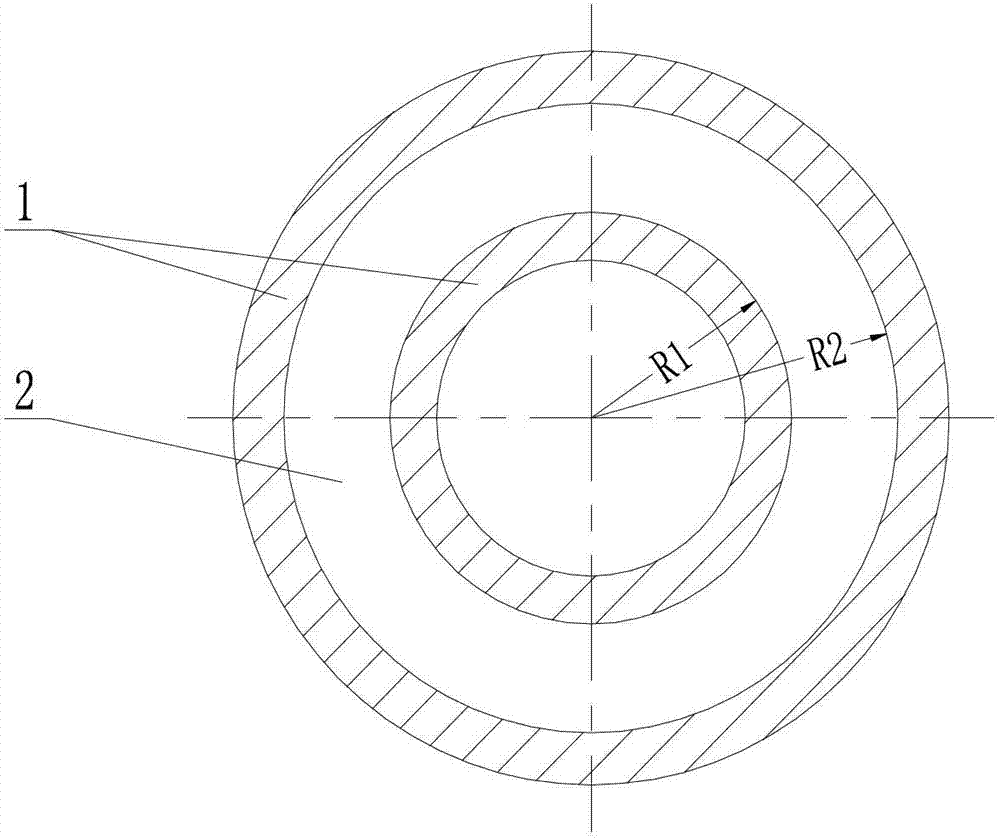

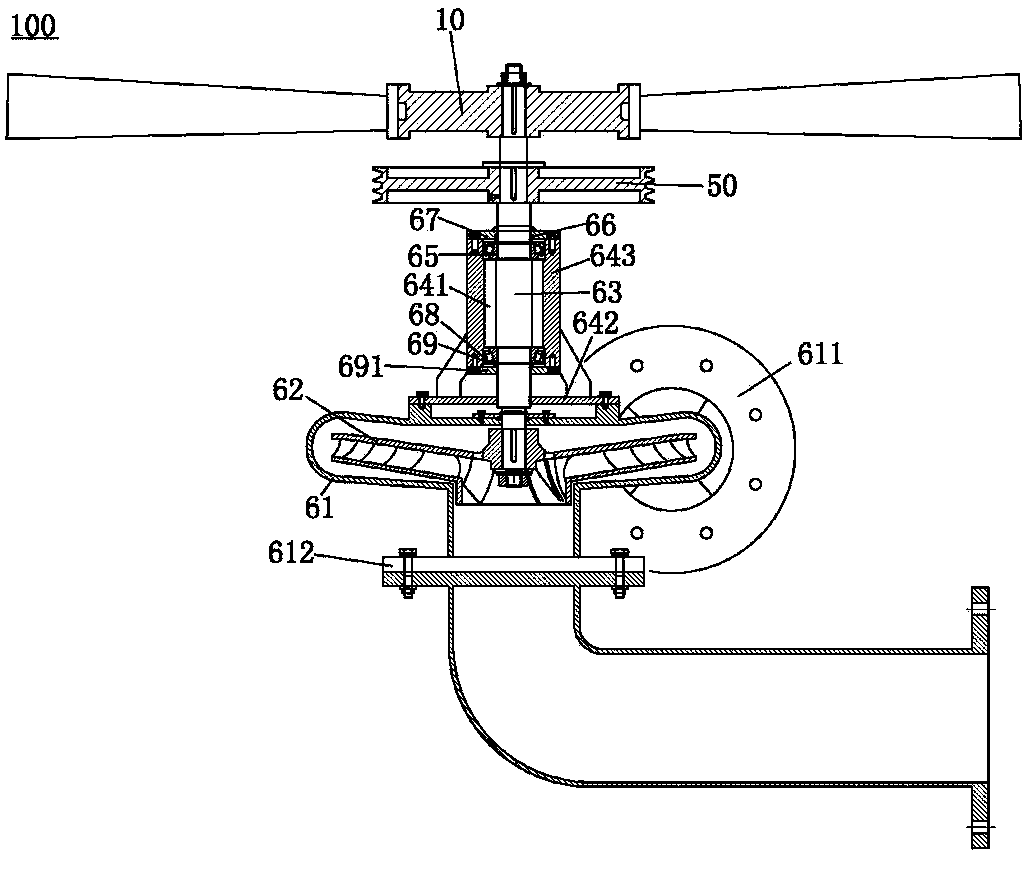

Lubricant circulating device based on sliding bearing and manufacturing process of lubricant circulating device

ActiveCN102829314AExpand the scope of applicationImprove cooling effectBearing coolingEngine lubricationPower equipmentHeavy load

The invention discloses a lubricant circulating device based on a sliding bearing, as well as a manufacturing process of the lubricant circulating device. The lubricant circulating device essentially consists of a bearing bracket, a guide base and an oil tank; an oil transportation duct which is connected to a port of a cold oil inputting pipe penetrates a duct mounting hole of the oil tank and is connected to a thread hole of the guide base, and is communicated with a cold oil storing cavity; a hot oil outputting pipe is connected to the oil tank and is communicated with an oil returning hole, thereby forming a system-cold oil-hot oil / cold oil-lubricant circulating-inputting / outputting loop; meanwhile, under the synchronous control of various corresponding equipment, the scheme of arranging the lubricant circulating inputting / outputting loop system is implemented. Through the lubricant circulating device, the sliding bearing which is matched with the motor, the water pump and other host equipment is not only compactly structured but is adaptive to the high-speed operation of the host equipment, and the sliding bearing cannot change the connecting and mounting size of the original machine and can ensure the circulation of the lubricant; the bearing bush can not generate heat; the equipment system is stable, reliable and safe in operation; the lubricant circulating device is suitable to be used as a supporting product of various power equipment, especially for as a supporting product of various heavy-load engineering machineries.

Owner:HUNAN CHONGDE IND TECH

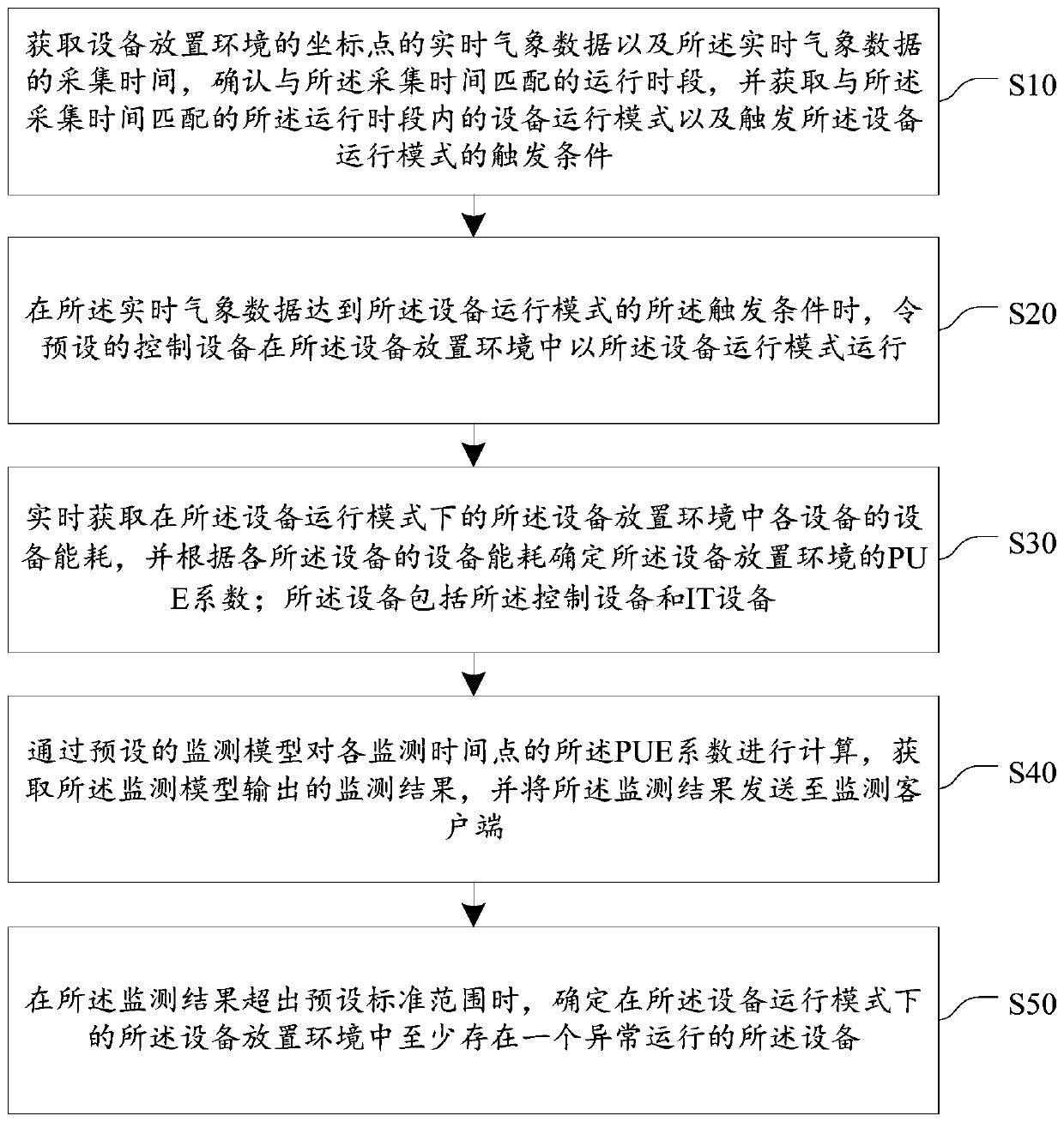

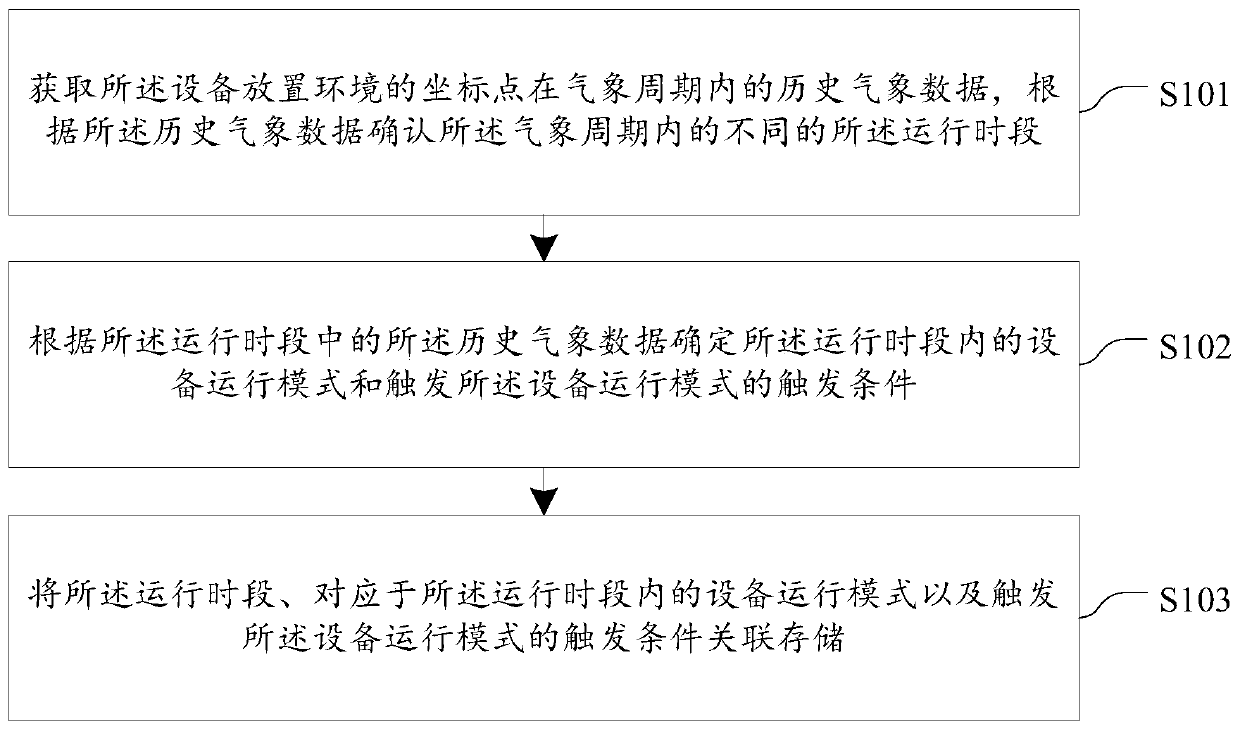

Equipment operation and monitoring method, device, equipment and medium

ActiveCN110442170AImprove operational efficiencyHigh degree of greeningIndication of weather conditions using multiple variablesSimultaneous control of multiple variablesAcquisition timeOperation mode

The invention discloses an equipment operation and monitoring method, a device, equipment and a medium. The method includes the following steps of: acquiring real-time meteorological data and an acquisition time thereof, confirming an operation period matched with the acquisition time, and acquiring a corresponding equipment operation mode and a trigger condition thereof; when the real-time meteorological data reaches a trigger condition, instructing control equipment to operate in an equipment operation mode in an equipment placement environment; obtaining the energy consumption of each pieceof equipment in the equipment placement environment in the equipment operation mode, and determining the PUE of the equipment placement environment; calculating the PUE of each monitoring time pointthrough a monitoring model, and obtaining a monitoring result; and when the monitoring result exceeds the preset standard range, determining that at least one piece of equipment in an abnormal operation state exists. According to the scheme of the invention, the intelligent operation of the equipment is realized; and meanwhile, abnormalities can be found and processed in time according to the PUEof the equipment placement environment during the operation of the intelligent monitoring equipment, the energy consumption ratio of the equipment placement environment is reduced, and thus the greening degree of the equipment placement environment is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

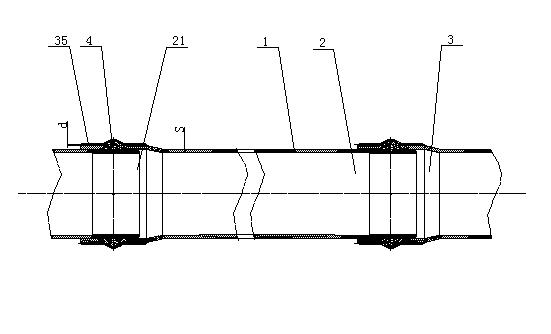

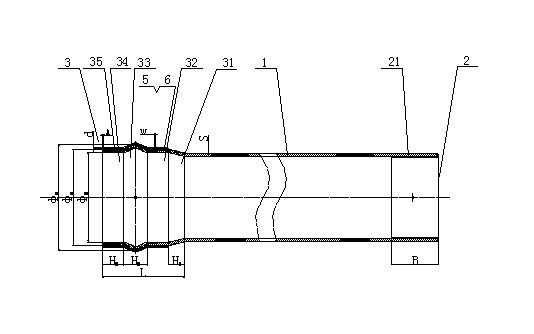

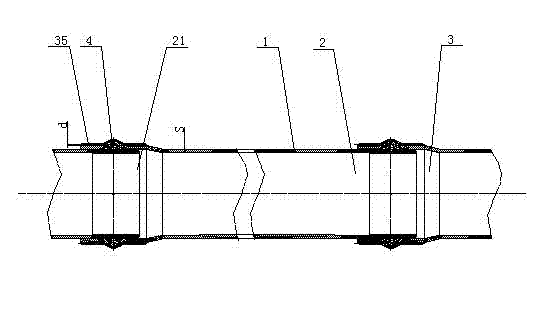

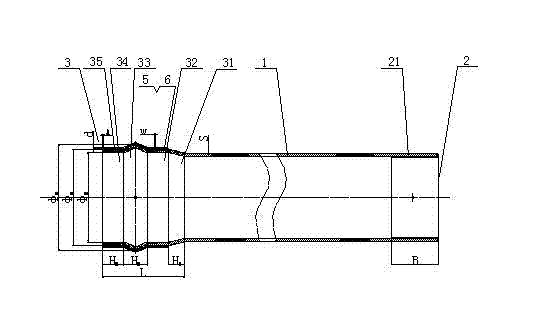

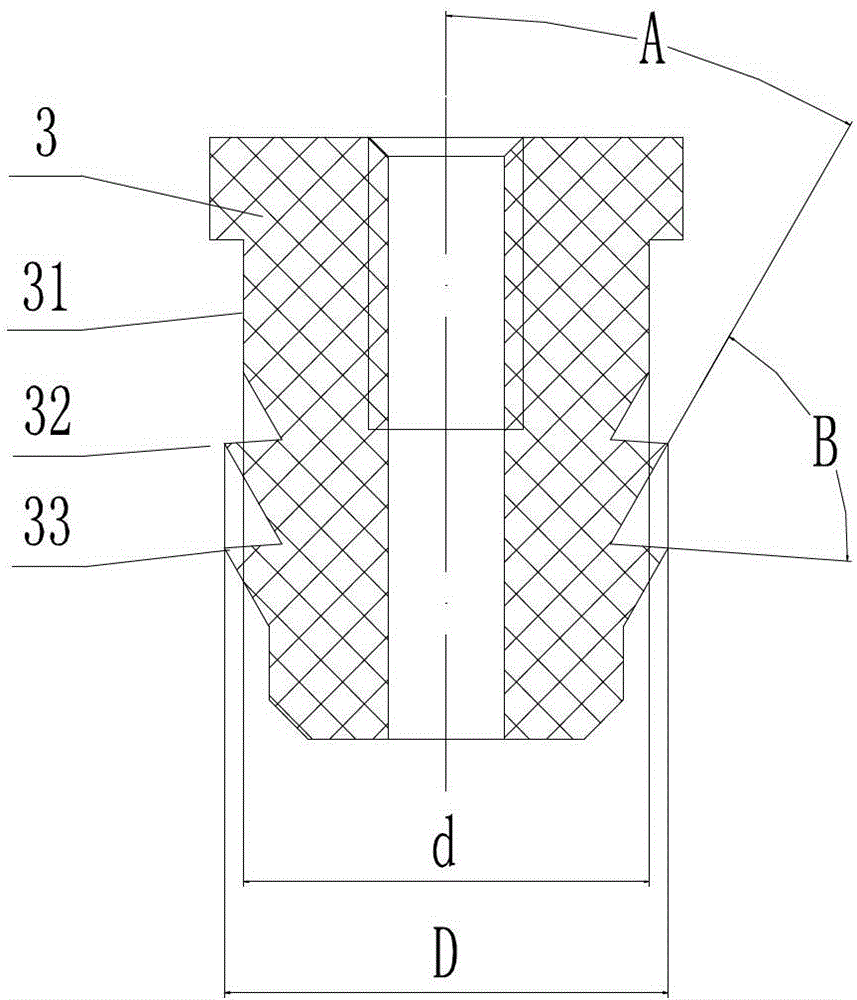

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356ASimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubePolyvinyl chloride

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell and spigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube, a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system to be difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

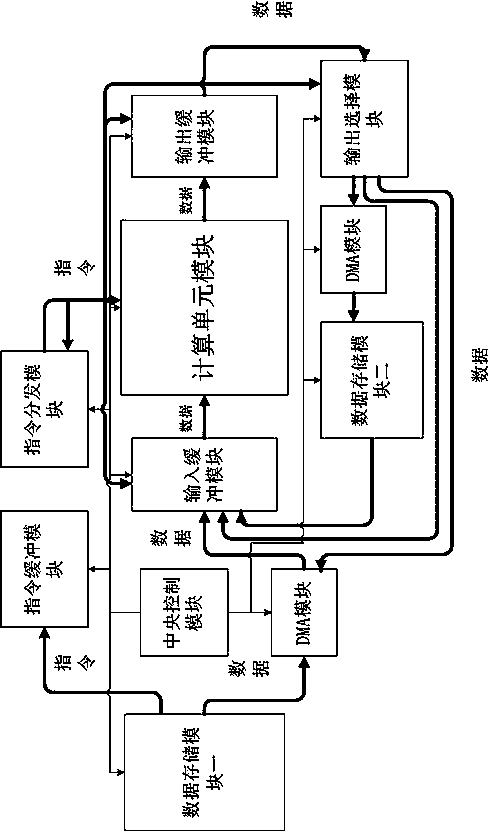

A convolutional neural network instruction data storage system and method

ActiveCN109542513AImprove work efficiencyAchieve decompositionRegister arrangementsNeural architecturesData accessComputer module

The invention discloses a convolutional neural network instruction data storage system and method, and belongs to data processing of artificial intelligence, the technical problem to be solved by theinvention is how to efficiently, orderly and conveniently increase the number of model layers of the convolution neural network, data access with exponential growth in the number of convolution kernelweights. The technical scheme adopted is as follows: a convolutional neural network instruction data storage system is provided. The system includes a computing unit module, an input buffer module, an output buffer module, an output selection module, an instruction distribution module, a first data storage module, a second data storage module and a central control module; the central control module is respectively connected to and control the central control module, The calculation unit module, the input buffer module, the output buffer module, the output selection module, the instruction distribution module, the first data storage module and the second data storage module. The invention also discloses a convolutional neural network instruction data storage method.

Owner:SHANDONG INSPUR SCI RES INST CO LTD

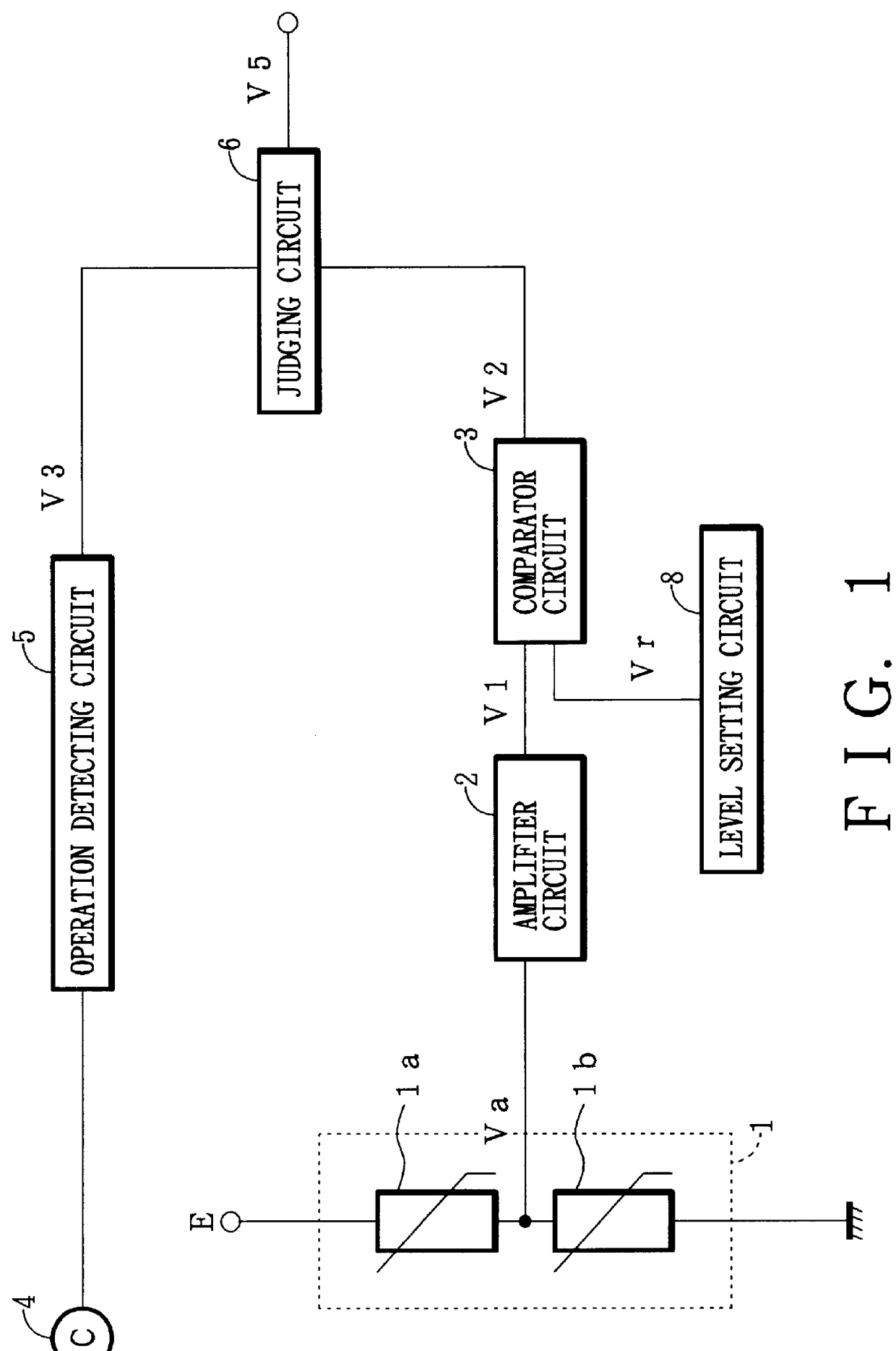

Frost detecting device

InactiveUS6038872ARule out the possibilityAccurate detectionLighting and heating apparatusAuxillary controllers with auxillary heating devicesFrostComparators circuits

PCT No. PCT / JP96 / 03486 Sec. 371 Date Jun. 12, 1998 Sec. 102(e) Date Jun. 12, 1998 PCT Filed Nov. 28, 1996 PCT Pub. No. WO97 / 24568 PCT Pub. Date Jul. 10, 1997A frost detecting device including a frost detector which detects the amount of frost from the temperature difference between a detecting thermal sensitive element and a compensating thermal sensitive element is provided. The frost detecting device includes: a frost detector 1 made up of a detecting thermal sensitive element and a compensating thermal sensitive element; an amplifier circuit 2 for amplifying an output signal from the frost detector 1; a comparator circuit 3 for comparing an output voltage from the amplifier circuit 2 with a set level; an operation detecting circuit 5 for detecting operating conditions of a compressor and a cooling fan 4; and a judging circuit 6 for detecting the amount of frost in accordance with output voltages from the operation detecting circuit 5 and the comparator circuit 3. The output from the comparator circuit 3 is used to detect the amount of frost only when the compressor and the cooling fan 4 are both in operation.

Owner:ISHIZUKI ELECTRONICS

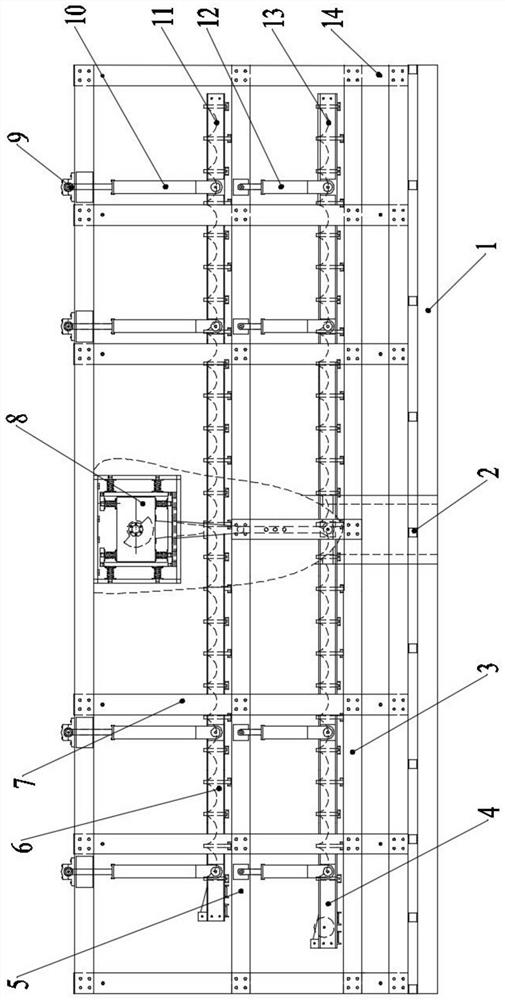

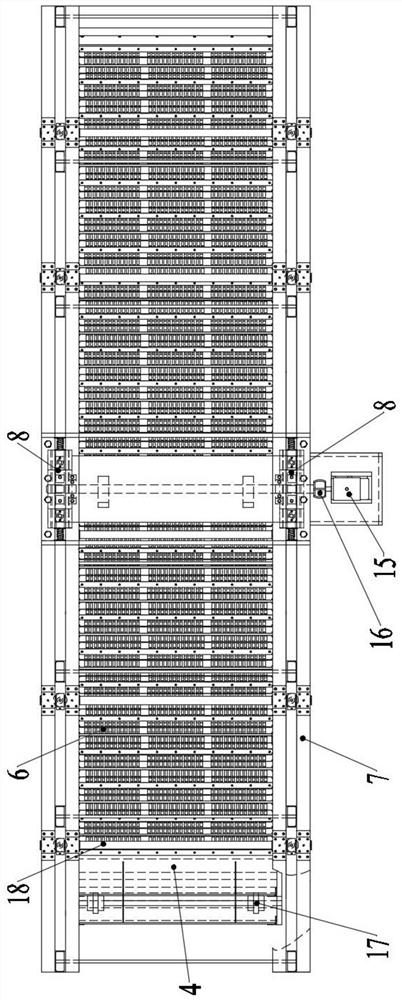

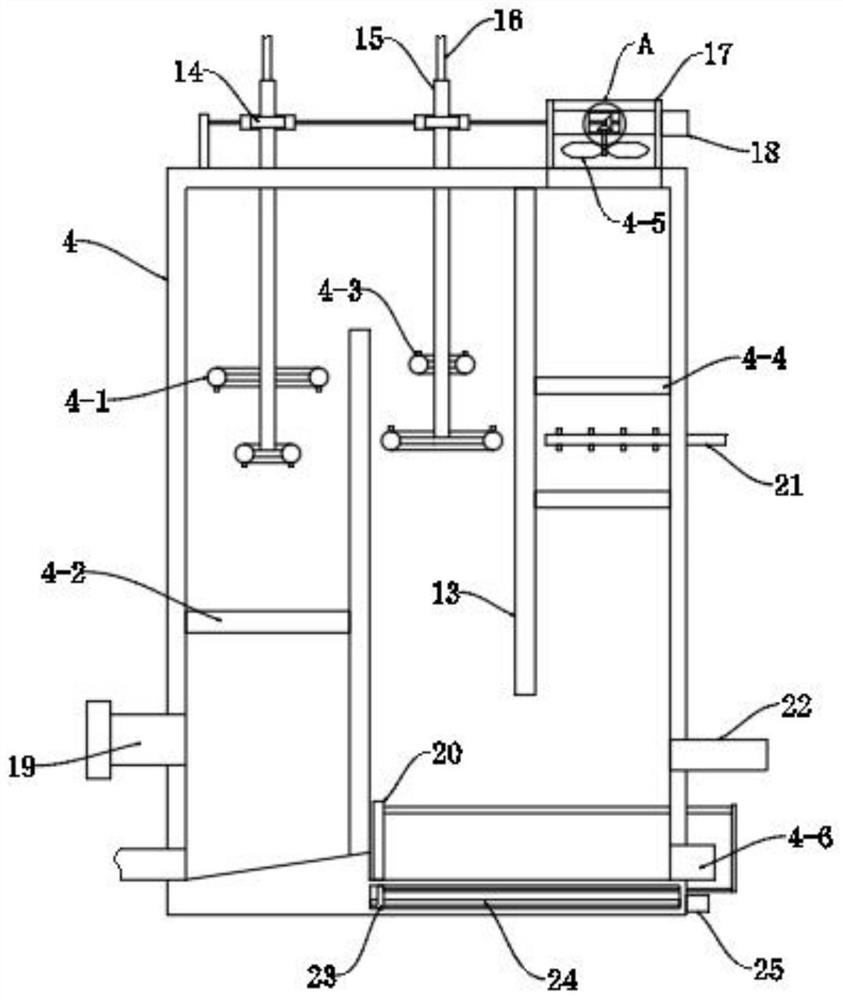

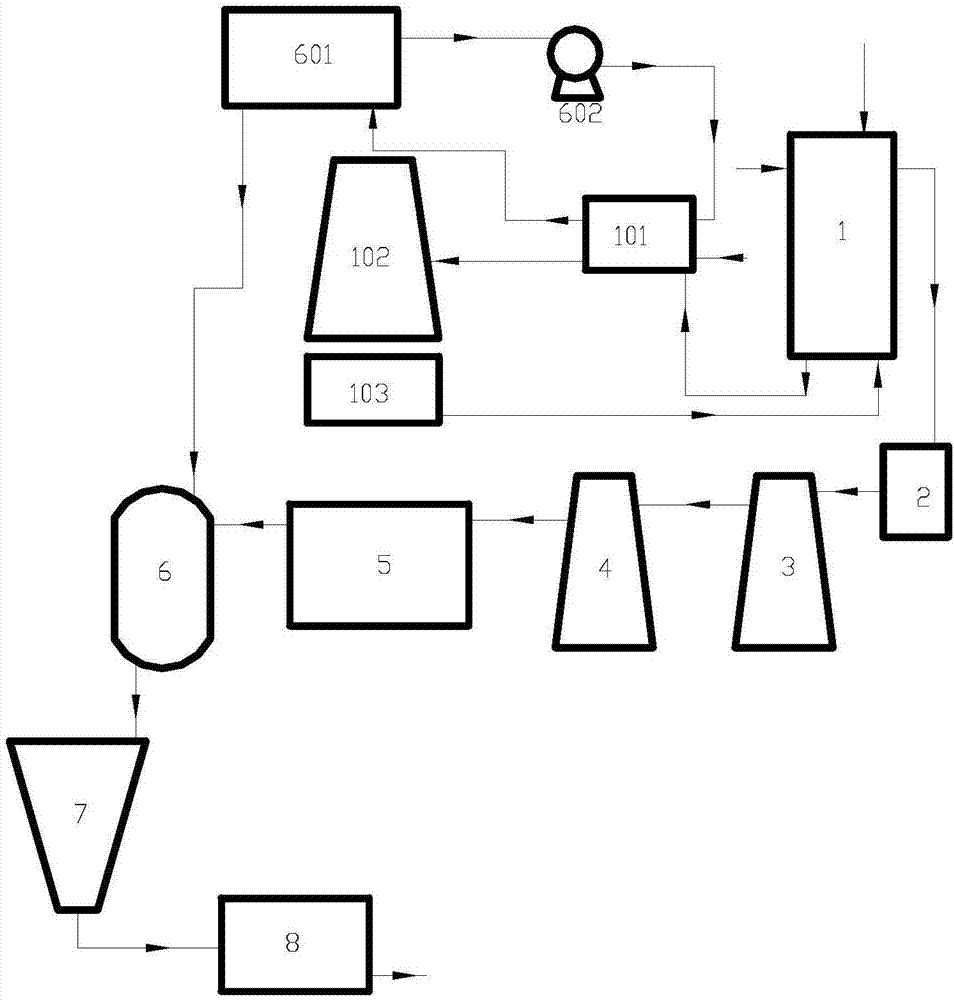

Trestle-type floatation helical fermentation system and operating control method thereof

ActiveCN104725089ALow investment costTo achieve harmonious developmentBio-organic fraction processingClimate change adaptationDrive shaftAgricultural engineering

The invention relates to a trestle-type floatation helical fermentation system and an operating control method thereof. The trestle-type floatation helical fermentation system comprises a fermentation tank and a trestle-type floatation helical fermentation turner which is installed on the fermentation tank and can make a reciprocating movement along the fermentation tank, wherein the trestle-type floatation helical fermentation turner comprises a mobile trestle and a helical turning vehicle which is installed on a trestle cross beam of the mobile trestle and can make a reciprocating movement along the mobile trestle; the width of the fermentation tank 10-45m, and the length is 50-500m; the helical turning vehicle is provided with a turning transmission gear, a ventilation aeration device and a hollow helical turning shaft; the ventilation aeration device is provided with a ventilating duct composed of a closed inner cavity of the helical turning vehicle machine frame; the turning transmission gear is provided with a hollow transmission shaft with a closed upper end and an open lower end; the hollow transmission shaft penetrates through the ventilating duct, and the axial wall in the ventilating duct is provided with ventilating holes communicated the ventilating duct; and the hollow helical stirring shaft is connected to the lower end of the hollow transmission shaft.

Owner:GUANGXI LIYUANBAO SCI & TECH

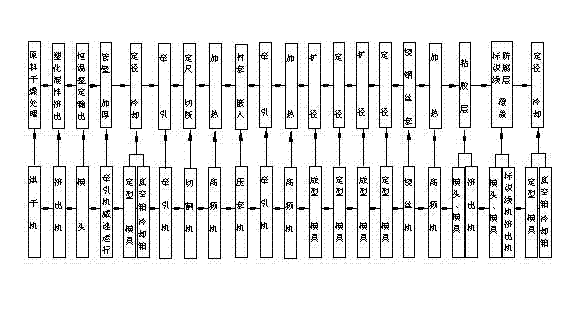

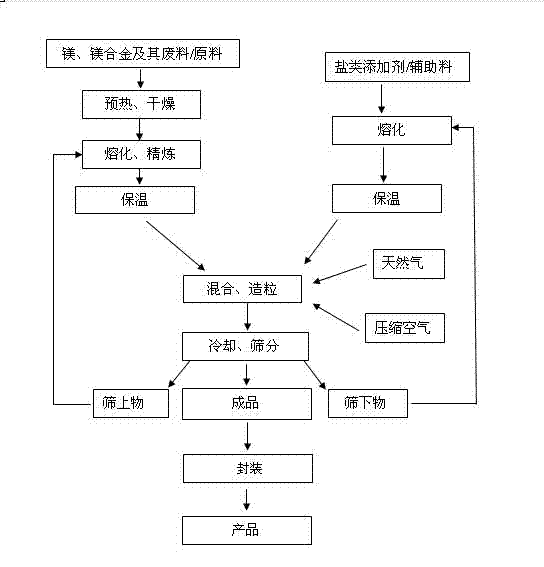

Magnesium, magnesium alloy and wastes thereof based production line for producing particle magnesium desulfurizing agent/particle magnesium alloy desulfurizing agent

InactiveCN101974665ASolve comprehensive problems such as increased use costsSimple structureGas emission reductionSiphonAutomatic control

The invention relates to a magnesium, magnesium alloy and wastes thereof based production line for producing a particle magnesium desulfurizing agent / particle magnesium alloy desulfurizing agent, adopting the technical scheme which comprises a raw material preheating and refining system, a granulating and injecting system, a vacuum siphon system, a sieving and finished product processing system and an automatic control and operation system. The production line overcomes the defects of high energy consumption, serious environmental pollution, dangers caused by easy incontrollable operation of a material carrying tank, poor safety and product consistency and low repeatability due to the adoption of a crucible electric furnace as well as the defects of serious waste of a magnesium resource, high maintenance cost of equipment, overhigh reject ratio and the like by mechanically cutting and clamping magnesium ingots / magnesium alloy in the traditional particle magnesium / particle magnesium alloy production equipment using a fusion method, thereby solving the comprehensive problems of improved using cost and the like. The production line is suitable for producing molten iron preprocessing desulfurizing agent, molten steel deep-desulfurizing agent and cast iron mixed modifier in steel smelting as well as magnesium / magnesium alloy desulfurizing agent for producing Fe-Si-Mg and Fe-Si-Ca intermediate alloy in silicon iron fusion.

Owner:HUNAN S R M SCI & TECH

Cottonseed meal puffing and detoxifying method

InactiveCN103875999AImprove removal efficiencyLess loss of effective nutrientsAnimal feeding stuffFood shapingRevolutions per minuteWater content

The invention discloses a cottonseed meal puffing and detoxifying method. The method comprises the following steps: (1) mixing, adding water and a detoxifying agent into cottonseed meal with the shell amount of 8-12 percent, and uniformly mixing, wherein the moisture content of the cottonseed meal is 20-40 percent, and the addition amount of the detoxifying agent refers to 15g / kg of urea and 5g / kg of ferrous sulfate; (2) puffing, wherein the cottonseed meal is subjected to the effects of high temperature, high pressure and high shear force in an extrusion cavity of a puffing machine under the conditions that the puffing temperature is 120-130 DEG C and the rotating speed of a screw rod is 180 revolutions per minute, changes of physical and chemical performances and organization structures during mixing, gluing and gelatinizing are caused, and free gossypol is inactivated under the effects of high temperature, high pressure, moisture and detoxifying agent; and (3) drying, namely performing drying treatment on the detoxified cottonseed meal materials. The method is good in detoxification effect, low in loss of effective nutritional ingredients in the cottonseed meal, high in palatability, low in cost, simple and convenient to operate, high in production efficiency and suitable for industrial application.

Owner:上海兆极环境科技有限公司

Drive axle assembly of variable-speed electric vehicle

PendingCN108591399ASolve the following technical problemsLower performance requirementsGearingGearing detailsGear wheelElectric vehicle

The invention discloses a drive axle assembly of a variable-speed electric vehicle. The drive axle assembly comprises a transmission, a differential mechanism assembly and a clutch, wherein the transmission comprises a first shaft, a second shaft and a middle shaft, wherein the axis of the first shaft and the axis of the second shaft are located on the same straight line, the second shaft is inserted into the first shaft, the middle shaft is located below the first shaft and the second shaft, and a large gear of a reduction gear set on the middle shaft is connected with a primary reduction main gear of the second shaft; a second-stage speed reducing driven gear on the differential mechanism assembly is connected with a small gear of the speed reducing gear set on the middle shaft, and thefirst shaft is connected in an clutch internal gear of the clutch. According to the assembly, the structure is adopted by the drive axle assembly of the variable-speed electric vehicle, so that the using performance of the electric vehicle is effectively improved, so that the structure of the driving axle is compact, the driving axle can adapt to multiple road conditions, and the endurance mileageof the whole vehicle is increased.

Owner:保定市信达车桥配件制造有限公司

Oil-water cooler used for sliding bearing

The invention discloses an oil-water cooler used for a sliding bearing. According to the oil-water cooler, a bearing oil tank is adopted as a middle connector; a plurality layers of cooler tubes are arranged in a spiral manner at the periphery of the joint part of a radial tile in the center inside the bearing oil tank and a rotational member thrust head connected with a host machine rotor; the connection joint of the cooler tubes is horizontally arranged and is connected with a transit water tube joint which penetrates through a box body wall, a connecting plate and a sealing ring, so that the technical scheme that the cooler tubes are communicated with a water supply system outside the bearing oil tank is realized. Defects that in the conventional upper intake and outtake water oil-water cooler used for a bearing, the corrosion of a cooler pipeline is accelerated as the cooling water remained inside the cooler cannot be discharged in time when a machine set is shut down for a long time, and that the cooler pipeline cracks as the cooling water is frozen in low temperature, are avoided, and the problems that the lubrication cooling effect is poor, the tile of the bearing is combusted and the like caused by the defects of a high position intake and outtake water oil-water cooler are solved, and therefore, the oil-water cooler is applicable to products in match with various power equipment, and in particular applicable to products in match with various heavy-load machines.

Owner:HUNAN CHONGDE IND TECH

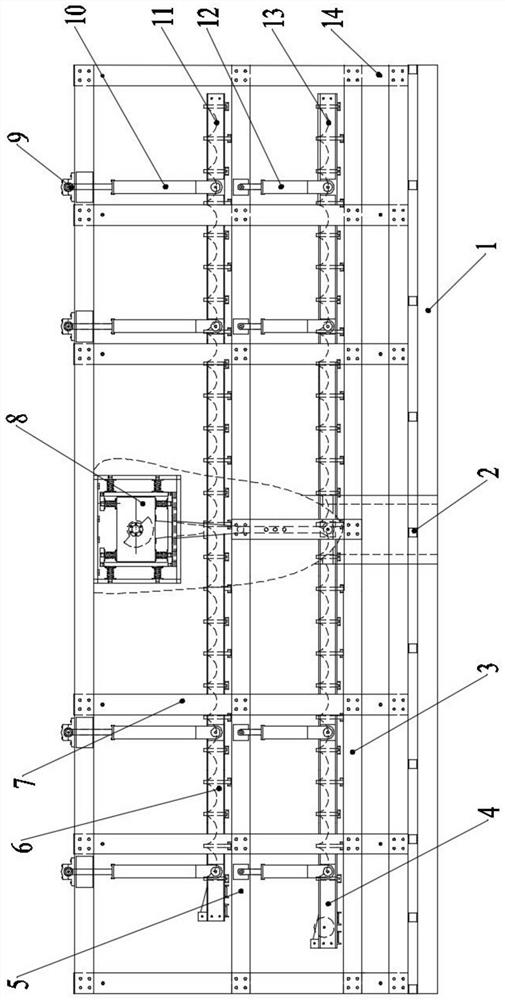

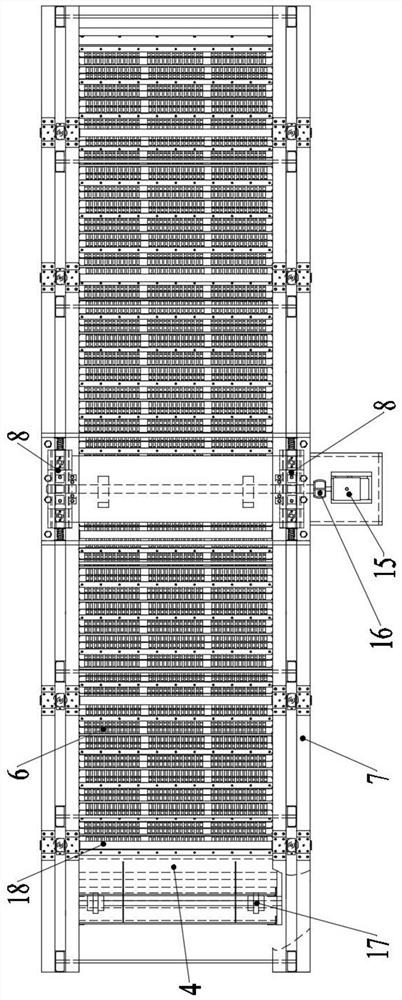

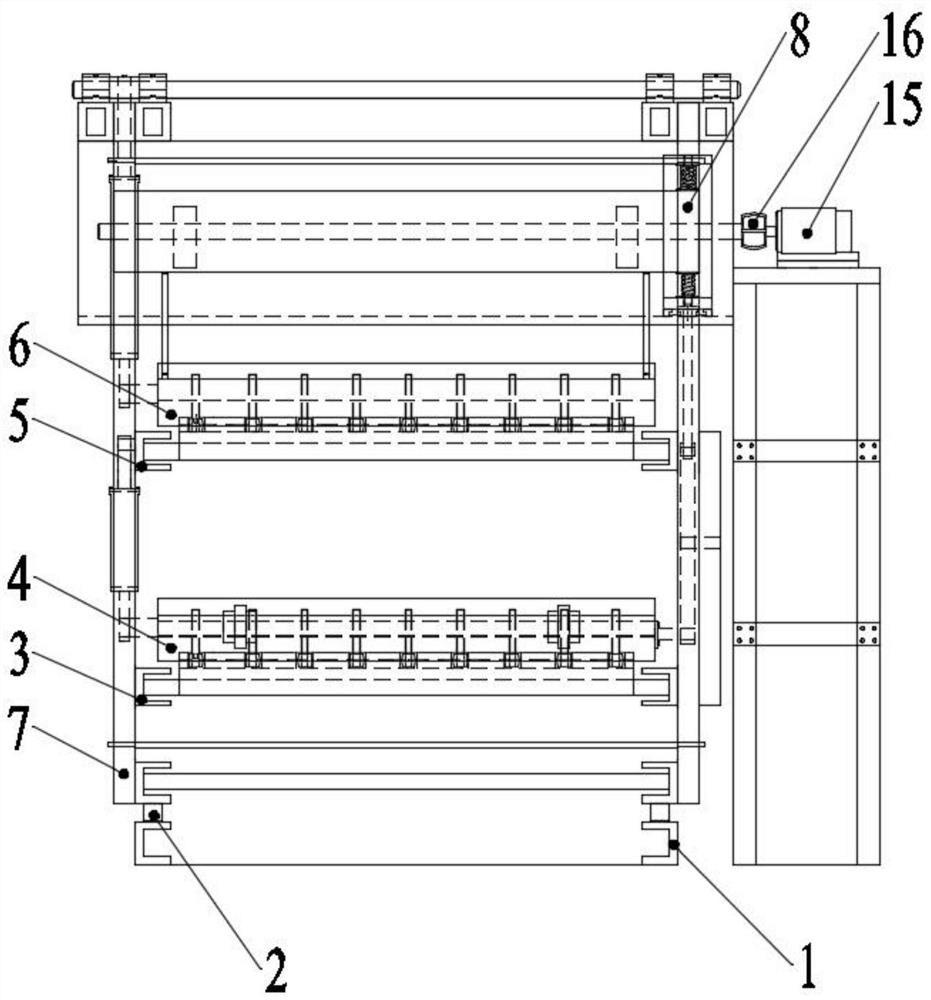

Efficient double-layer multistage vibrating screen

ActiveCN112642702ARealize the supporting roleAchieve vibration dampingSievingScreeningStructural engineeringElectrical and Electronics engineering

The invention discloses an efficient double-layer multistage vibrating screen which comprises a base, a rack, an upper-layer fixed screen box, an upper-layer floating screen box, a lower-layer fixed screen box, a lower-layer floating screen box and a vibration excitation movement device. The upper-layer floating screen box and the lower-layer floating screen box are suspended and mounted on the rack through multiple upper-layer elastic suspension rods and lower-layer elastic suspension rods which are symmetrically arranged left and right, and flexible screens are connected between two adjacent screen supporting frames of the upper-layer fixed screen box and the upper-layer floating screen box and two adjacent screen supporting frames of the lower-layer fixed screen box and the lower-layer floating screen box. The vibration excitation movement device comprises an eccentric vibration excitation shaft, a driving vibration exciter, a driven vibration exciter, spring guide devices, a fixing frame, an up-down limiting guide sliding mechanism, an upper-layer transmission rod, a lower-layer transmission rod and a steering rod. According to the efficient double-layer multistage vibrating screen, on the premise that material particles can be better, rapidly and comprehensively screened in a layered manner, dry type efficient screening of materials large in viscosity and difficult to screen can be achieved, the fine particle material screening probability is increased, and the efficient double-layer multistage vibrating screen is particularly suitable for raw coal grading screening in the coal dressing process.

Owner:CHINA UNIV OF MINING & TECH

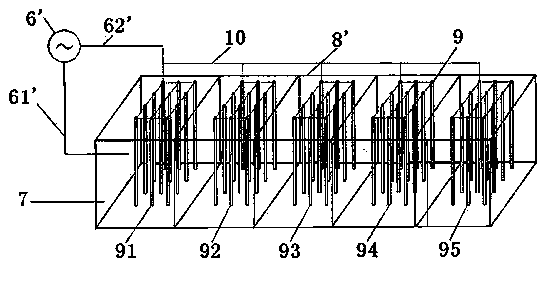

Normal-pressure normal-temperature high-frequency water low-temperature plasma generator

InactiveCN104270882APromote generationLower energy consumption ratioPlasma techniqueHazardous substanceEngineering

The invention relates to a normal-pressure normal-temperature high-frequency water low-temperature plasma generator which comprises one or more than two electrodes. The electrode is inserted into an outer insulation tube through an inner insulation tube with the inner wall coated with a conductive film, the distance between the inner wall of the outer tube and the outer wall of the inner tube is not larger than 5 mm, an air uniformizing chamber is arranged on the upper portion of the outer tube and can be placed underwater or exposed out of the water face, a ground terminal of an output pole of an alternating current power supply is inserted into liquid, the other pole of the alternating current power supply is connected into a conductive layer of the inner tube, the potential difference of the two poles is not smaller than 1 KV, and the frequency ranges from 1 KHz to 50 KHz. Low-temperature plasma meeting the industrialization requirement can be generated continuously and stably, organic matter and other toxic and harmful substances in water are directly decomposed and treated, the water reaches the standard, no chemical is added, and no toxic or harmful by-product is generated after treatment. The electrode can be directly placed in the treated water, occupied space is small, energy consumption is low, the early investment cost and running cost are low, and the advantages of being efficient, saving energy and being environmentally friendly are achieved.

Owner:赵岳虎 +4

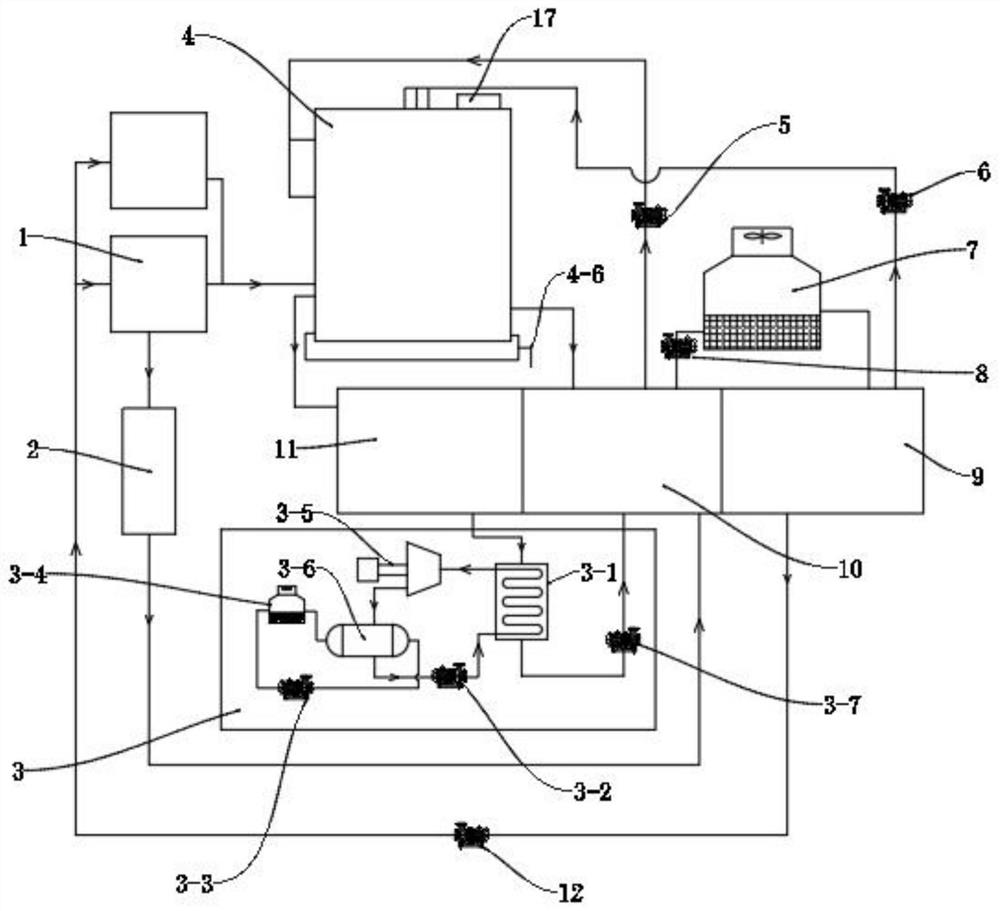

Heat accumulating type steel slag heat stewing waste heat ORC power generation system and device

PendingCN111608759ALower energy consumption ratioEmission reductionSteam engine plantsProcess efficiency improvementSlagPollutant emissions

The invention discloses a heat accumulating type steel slag heat stewing waste heat ORC power generation system and device. The heat accumulating type steel slag heat stewing waste heat ORC power generation system comprises a plurality of heat stewing pools, the heat stewing pools are connected with horizontal flow sedimentation pools, the horizontal flow sedimentation pools are connected with a water return pool, the two sides of the water return pool are provided with a heat accumulating pool and a cold water pool, the heat accumulating pool and the water return pool are connected with an ORC generator set, the cold water pool is connected with the plurality of heat stewing pools, the water return pool is connected with a cooling mechanism, the water return pool is connected with a spraywashing condensing tower through a first-stage spray pump, the cold water pool is connected with the spray washing condensing tower through a second-stage spray pump, and the cold water pool is connected with the plurality of heat stewing pools through a heat stewing water pump. The system is reasonable in structure, discontinuous steam generated by hot stewing of steel slag is recycled, and theenergy consumption ratio of iron and steel enterprises is reduced; and meanwhile, dust carried in steam can be effectively eliminated, the problem of white smoke elimination is solved, pollutant emission of the iron and steel enterprises is reduced, and the purification degree of industrial tail gas is further improved.

Owner:XINXING HEBEI ENG & RES INC

Large-load hydraulic bidirectional loading apparatus

The invention relates to a large-load hydraulic bidirectional loading apparatus. According to the invention, servo cylinders respectively positioned in a loading cylinder and symmetrically and axially distributed along a thrust plate are adopted. A plurality of oil duct pipes are arranged between the servo cylinders and the loading cylinder. An oil channel A and an oil channel B are respectively arranged at a box body and a box cover. The oil channel A penetrates the surface of the thrust plate through the loading cylinder, the oil duct pipes, and the servo cylinders. The oil channel B penetrates a bonding interface of the loading cylinder and the servo cylinders through the loading cylinder. One end of a thrust shaft is connected to a driving apparatus through a coupler, and inputs power. The other end of the thrust shaft outputs power through a flange plate. With existing large-load thrust loading apparatuses, mechanical loading or electric loading is adopted, such that an interface of rotation parts can easily get abraded, and service life and efficiency are influenced. Further more, independent function requirements of heavy load and high-speed rotation can not be satisfied simultaneously by mechanical loading and electric loading, and a structure is complex. With the apparatus provided by the invention, the defects are overcome. The apparatus is suitable to be used as a matched loading apparatus in industries such as mining, electricity, coal, metallurgy, transportation, chemical industry, water conservancy, machine tools, and the like.

Owner:HUNAN CHONGDE IND TECH

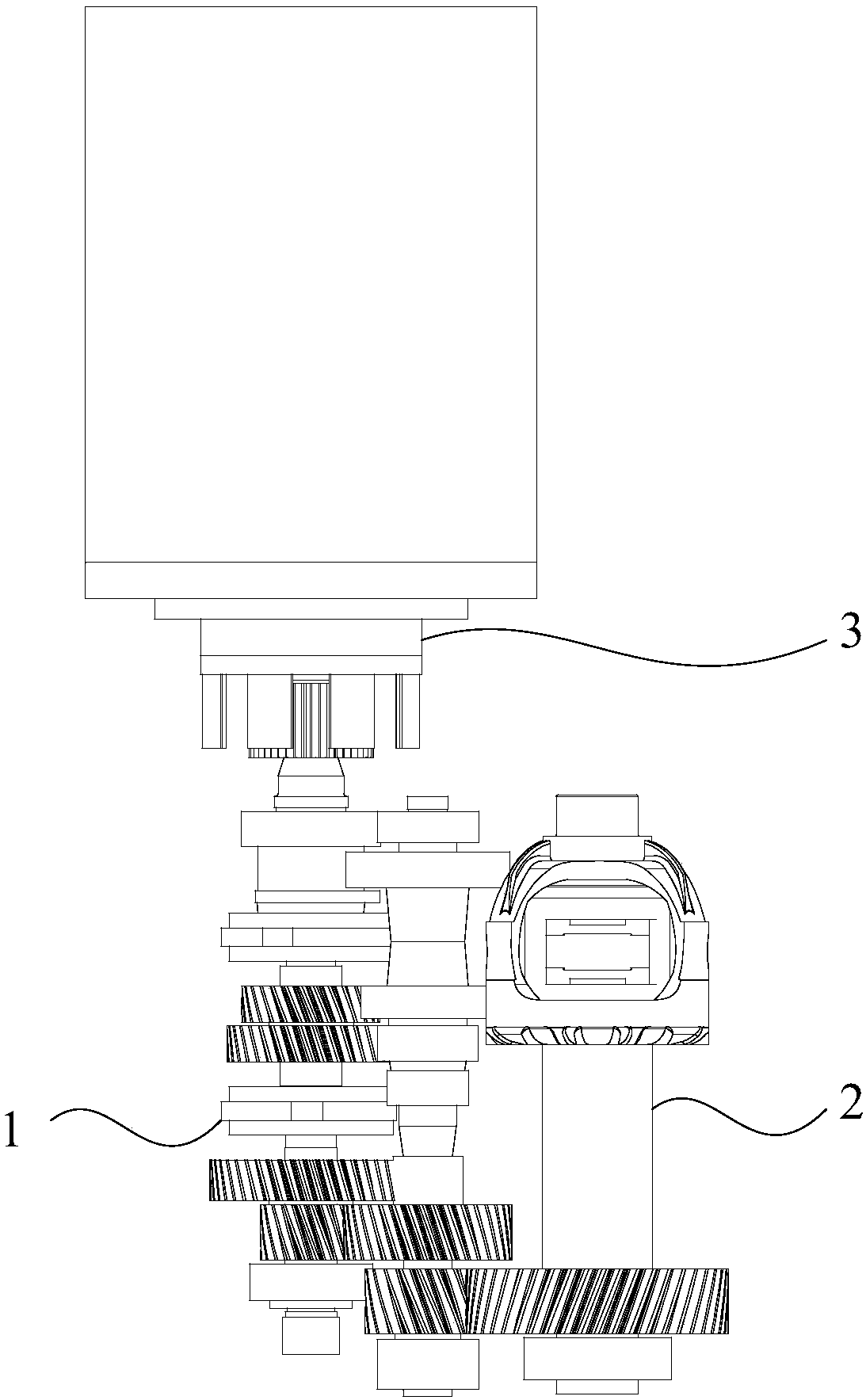

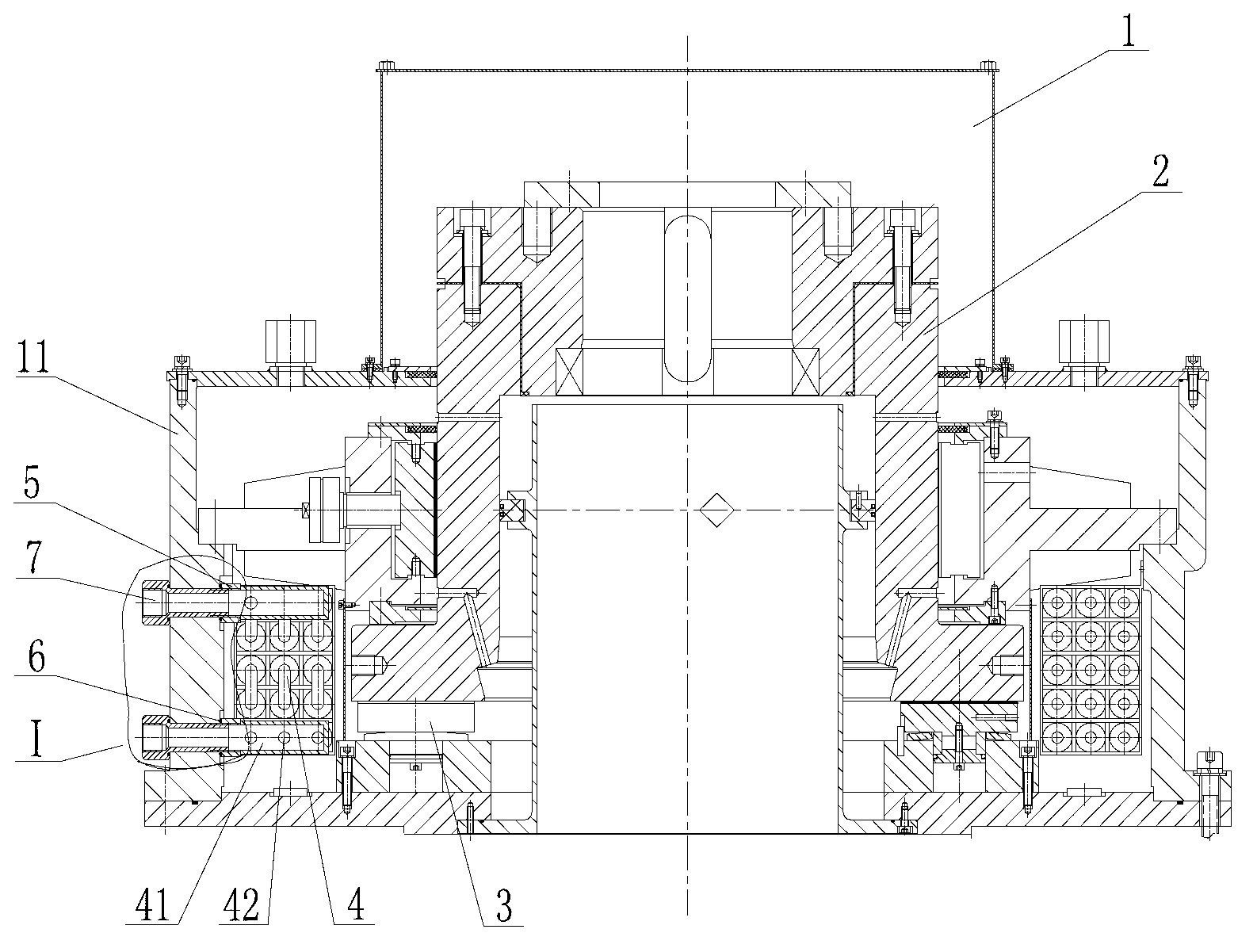

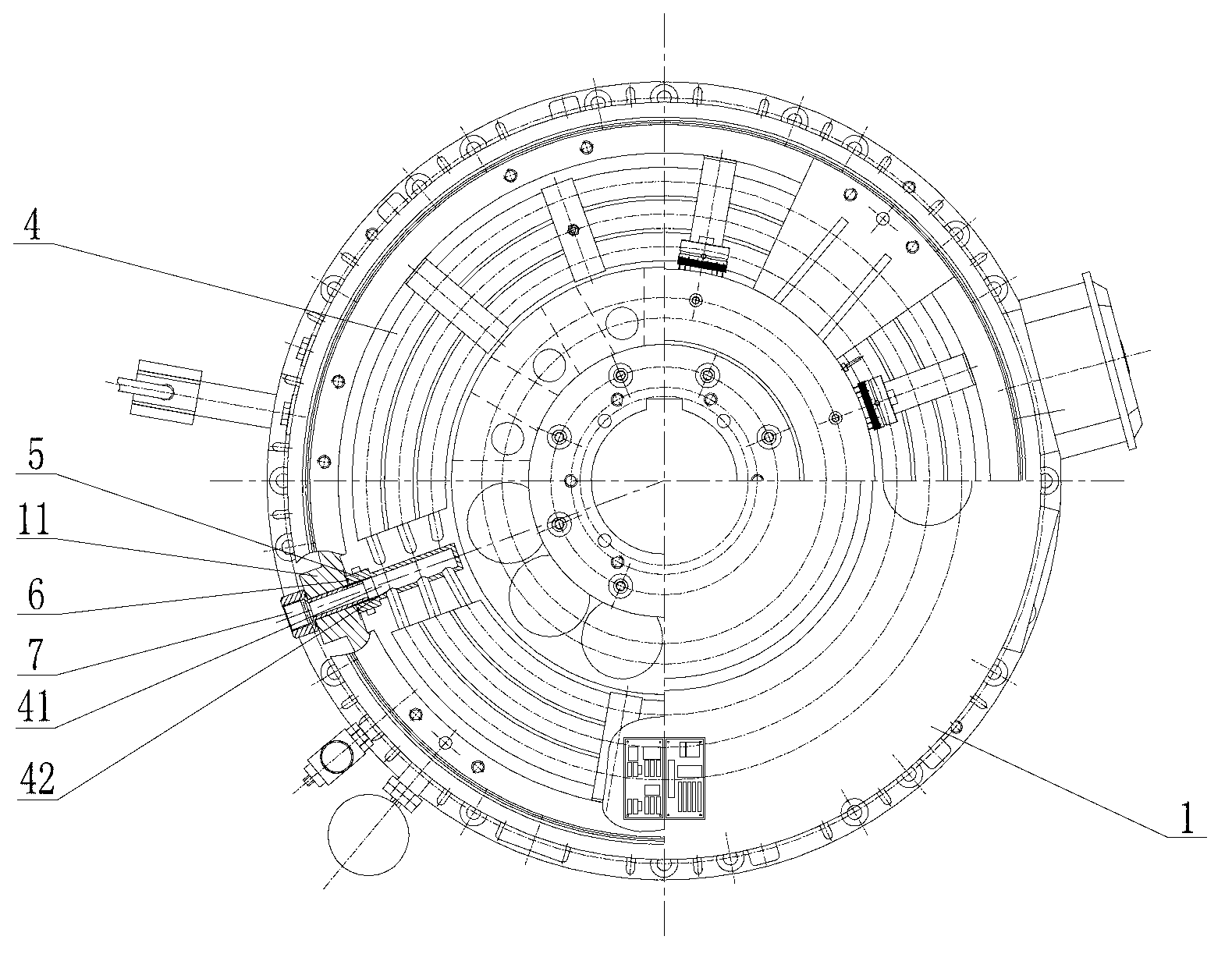

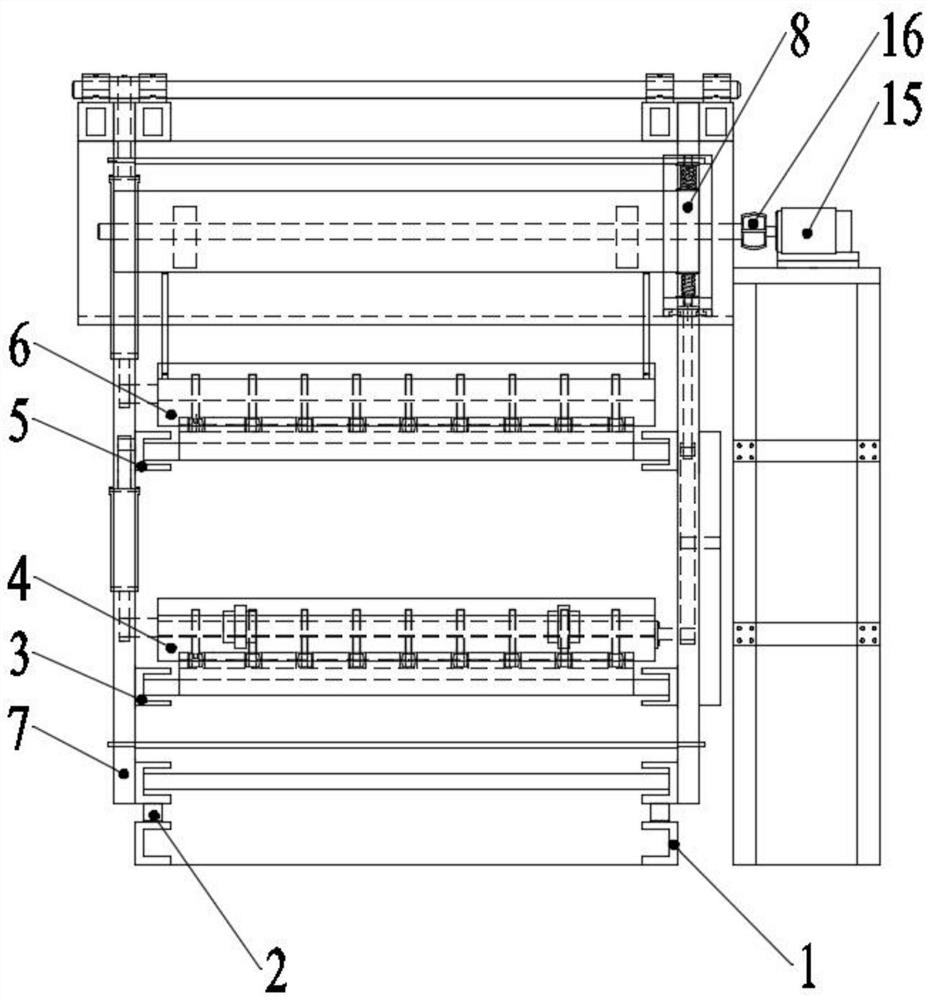

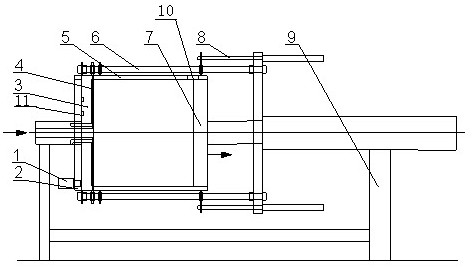

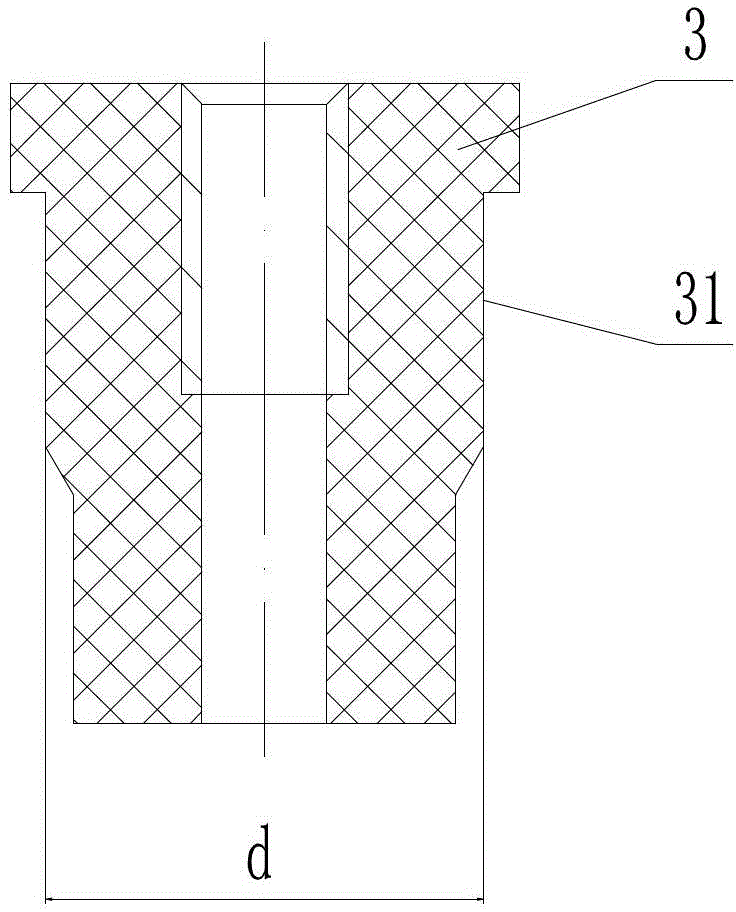

Sludge filter press

PendingCN111847829AReduce moisture contentAdd lessSludge treatmentSpecific water treatment objectivesGear driveSludge

The invention discloses a sludge filter press. The sludge filter press comprises a driving motor 1, a driving planetary gear 2, a filter plate 3, filter cloth 4, a piston cylinder 5, a connecting rod6, a pressing plate hydraulic system 7, a piston cylinder hydraulic system 8 and a bracket 9; the filter plate is oppositely arranged on one side of the driving planetary gear; the filter cloth coatsthe filter plate; piston cylinders are fixedly mounted at two ends of the filter plate; a filtrate outlet is formed in the filter plate; the pressing plate hydraulic system is arranged on the side face of the piston cylinder. The filter plate, the piston cylinder and the pressing plate hydraulic system are fixedly connected through the connecting rod to form a fixed assembly body; the piston cylinder hydraulic system is mounted at the end part of the connecting rod; the driving planetary gear drives a subsequent rotating part to rotate; the pressing plate hydraulic system realizes horizontal reciprocating piston motion of a pressing plate through a pipeline hydraulic system of the pressing plate hydraulic system, sludge is subjected to filter pressing from the sludge with the water contentof 99%-98% to the sludge with the water content of 55%-75%, so that the purpose of sludge reduction is achieved, the structure is simple, the automation degree is high, and 24-hour continuous operation is realized.

Owner:江苏康泰环保装备有限公司

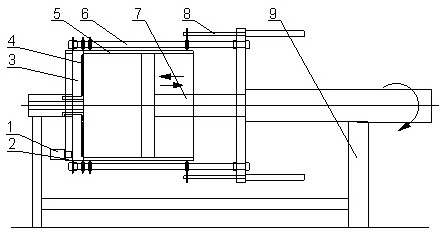

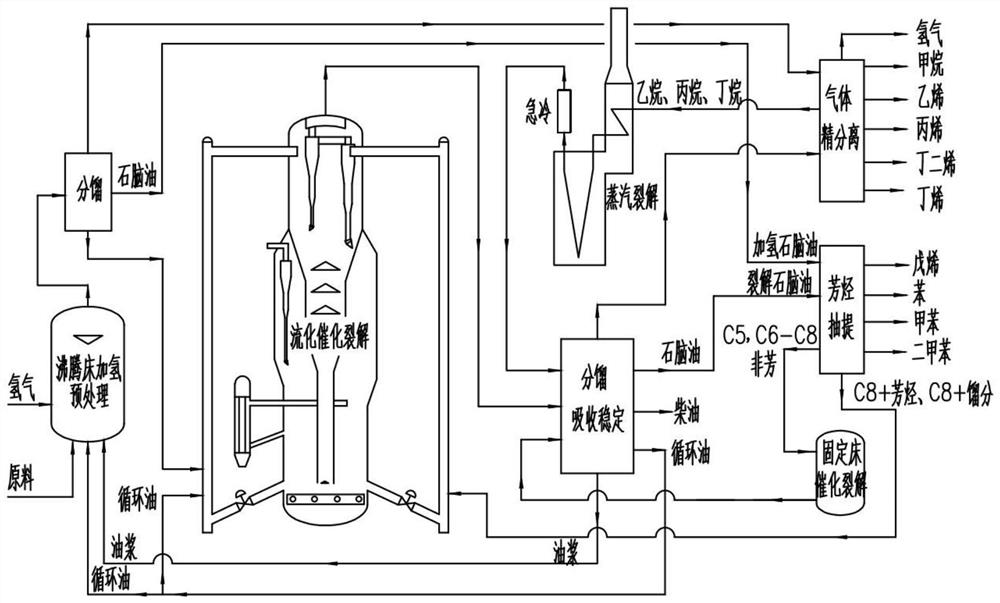

A processing technology for producing olefins and aromatics from inferior heavy oil

ActiveCN110591759BExtended operating cycleEnsuring Hydrogenation EfficiencyTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkanePtru catalyst

Owner:上海竣铭化工工程设计有限公司

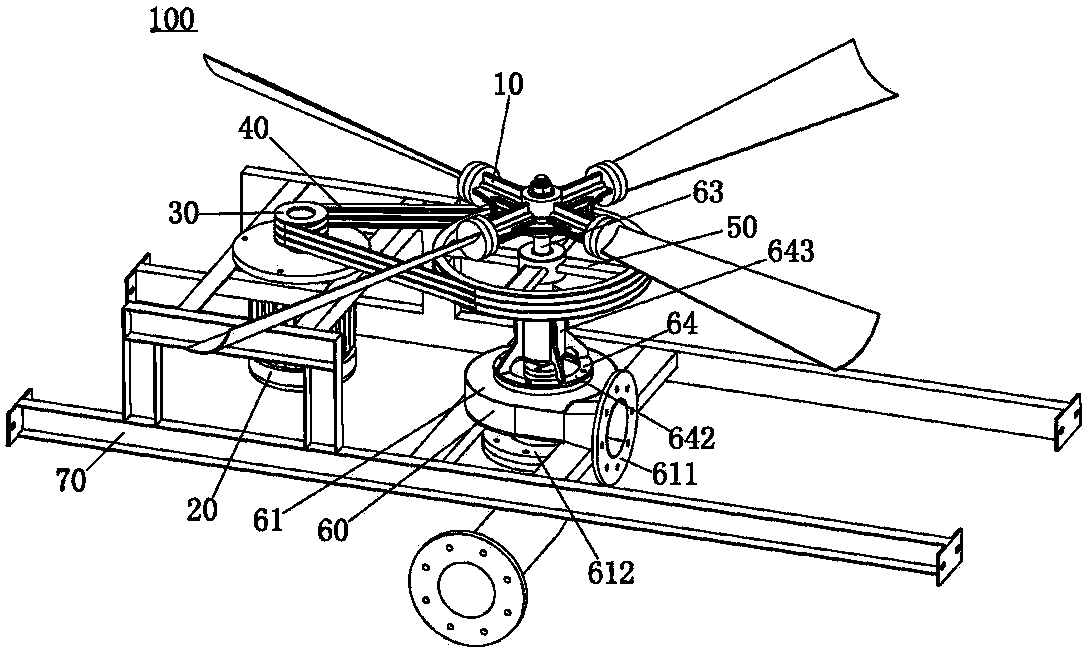

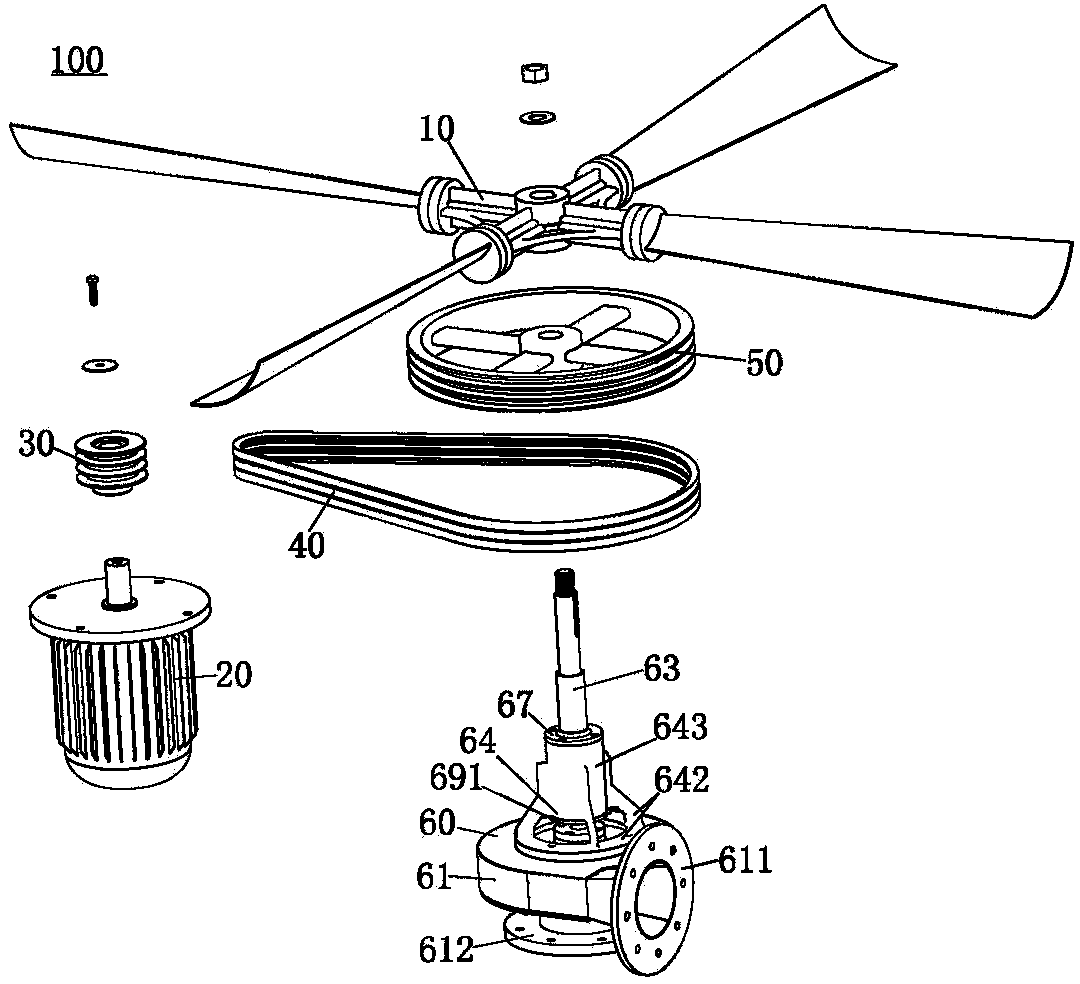

Hybrid power type water evaporation condenser fan

InactiveCN104214113AFlexible and practical drive modeLower energy consumption ratioHydro energy generationEngine componentsImpellerDrive wheel

The invention discloses a hybrid power type water evaporation condenser fan, which comprises a fan body, a motor, a driving wheel, a belt, a driven wheel and a water turbine, wherein the water turbine is provided with a machine casing, an impeller, a center rotary shaft and a shaft seat, the impeller is arranged in an inner cavity of the machine casing, the shaft seat covers the upper end of the machine casing, the shaft seat is provided with a vertical shaft seat through hole, the upper end of the center rotary shaft is rotationally and fixedly inserted into the shaft seat through hole and extends out of the shaft seat, the lower end of the center rotary shaft extends into the inner cavity of the machine casing and is fixedly connected with the center rotary shaft of the impeller, the machine casing is provided with a water inlet port and a water outlet port which are communicated with the inner cavity of the machine casing, the driving wheel is fixedly connected to an output shaft of the motor, the fan body and the driven wheel are sequentially and fixedly connected with the upper end of the center rotary shaft from top to bottom, and the belt is wound at the exteriors of the driving wheel and the driven wheel. The hybrid power type water evaporation condenser fan has the advantages that the two driving methods of motor driving and water turbine driving are adopted, and are flexible and practical, and the energy consumption ratio can be economically and conveniently decreased.

Owner:GUANGDONG FEIYANG IND GRP

Technology for producing polymeric material polyvinyl chloride from crude vinyl chloride

ActiveCN106866860AAvoid wastingNo leakagePreparation by halogen halide additionChemical industryWater useWater discharge

The invention discloses a technology for producing polymeric material polyvinyl chloride from crude vinyl chloride. The technology comprises a crude product preparation process, a purifying process and a polymerization process, and hot water discharged from the shell of a converter in the crude product preparation process undergoes heat exchange through a heat exchanger, then enters the upper portion of a steam absorption tower, absorbs heat evaporated by a hot water tank in the converter, and automatically flows into the hot water tank of the converter as a heat source for assisting a reaction in the converter; a compression device of crude vinyl chloride gas in the purifying process selects a screw compressor; and cold desalinized water in the polymerization process undergoes heat exchange in the heat exchanger in the crude product preparation process to prepare hot desalinized water used for polymerization, and a cooling medium of a polymerization kettle comprises circulating water and 7 DEG C refrigerated water. The technology has the advantages of simple and reasonable design, effective utilization of the vinyl chloride conversion heat, energy saving and consumption reduction, realization of high automation degree and low energy consumption due to the compression device selecting the screw compressor, and realization of the shortening of the polymerization reaction time of the polymerization kettle, output improvement and benefit increase due to the reasonable selection of the cooling medium of the polymerization kettle at different temperatures.

Owner:SICHUAN YONGXIANG CO LTD

A high-efficiency double-layer multi-stage vibrating screen

ActiveCN112642702BFast layered screeningFast and comprehensive layered screeningSievingScreeningStructural engineeringVibration exciter

The invention discloses a high-efficiency double-layer multi-stage vibrating screen, which comprises a base, a frame, an upper fixed screen box, an upper floating screen box, a lower fixed screen box, a lower floating screen box and an exciting motion device; the upper floating screen box and The lower floating screen box is suspended and installed on the frame by a plurality of symmetrically arranged upper elastic suspension rods and lower elastic suspension rods respectively. The upper fixed screen box, upper floating screen box, lower fixed screen box and lower floating screen box are adjacent A flexible screen is connected between the two screen support frames; the vibration excitation device includes an eccentric excitation shaft, an active vibration exciter, a driven vibration exciter, a spring guide, a fixed frame, an upper and lower limit guide sliding mechanism, Upper drive rod, lower drive rod and steering rod. The invention can realize dry efficient screening of difficult-to-sieve materials with high viscosity and improve the probability of fine particle materials to be screened under the premise of better, rapid and comprehensive layered screening of material particles, and is especially suitable for the coal preparation process Raw coal classification and screening.

Owner:CHINA UNIV OF MINING & TECH

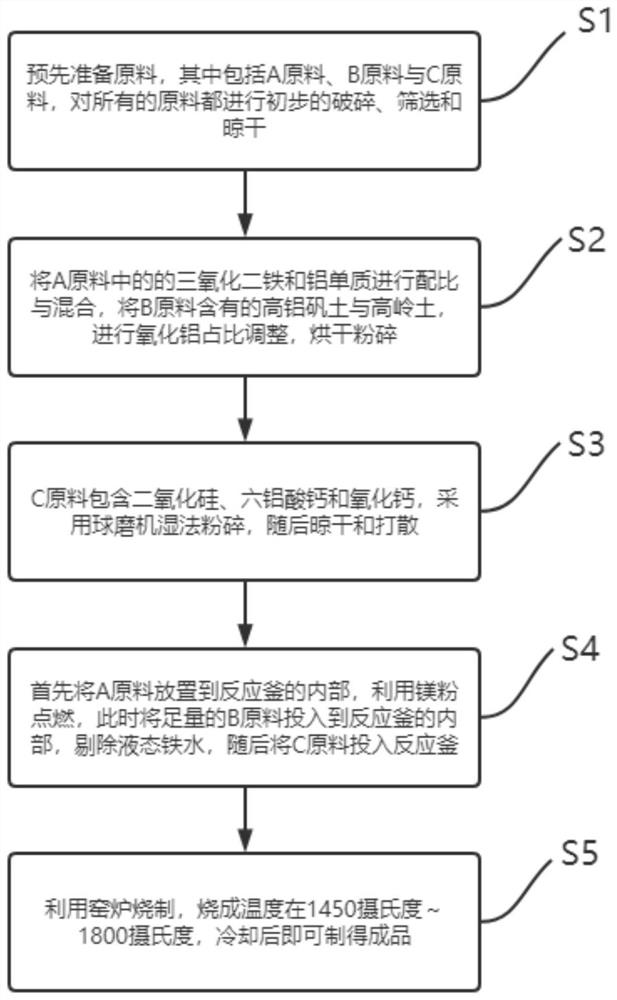

High-stability low-cost preparation process of artificially synthesized mullite

PendingCN114524667ALower energy consumption ratioReduce production energy consumption ratioChemical industryBrown iron oxideAluminothermic reaction

The invention discloses a high-stability and low-cost preparation process of artificially synthesized mullite, and belongs to the technical field of mullites.The high-stability and low-cost preparation process of the artificially synthesized mullite comprises the following steps that 1, raw materials including a raw material A, a raw material B and a raw material C are prepared in advance, and all the raw materials are preliminarily crushed, screened and air-dried; step 2, proportioning and mixing the ferric oxide and the aluminum elementary substance in the raw material A, adjusting the proportion of aluminum oxide in the high bauxite and the kaolin in the raw material B, and drying and crushing. According to the present invention, by combining the aluminothermic reaction generated by the aluminum elementary substance and the iron oxide, the preliminary hot melting of a variety of raw materials can be achieved, and in the subsequent furnace kiln sintering process, the heating energy consumption ratio is saved, the mullite production energy consumption ratio can be reduced, the generation of a large amount of waste gas is not generated, and the actual environmental protection performance is high; the proportion of aluminum oxide is matched by utilizing multiple raw materials.

Owner:江苏新时高温材料股份有限公司

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356BSimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubeSystem maintenance

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell andspigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube,a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system tobe difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

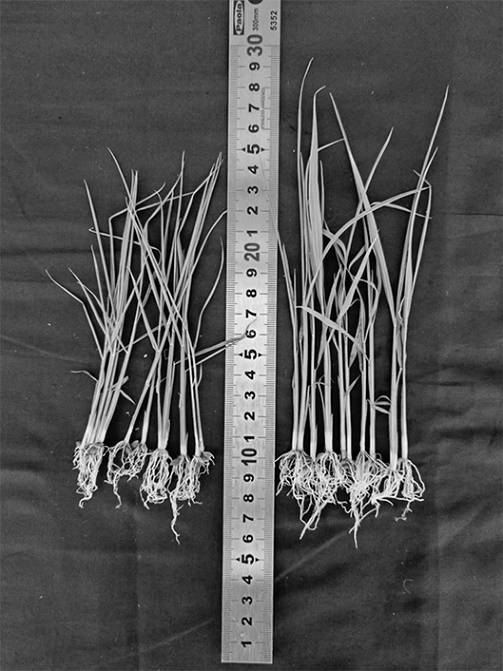

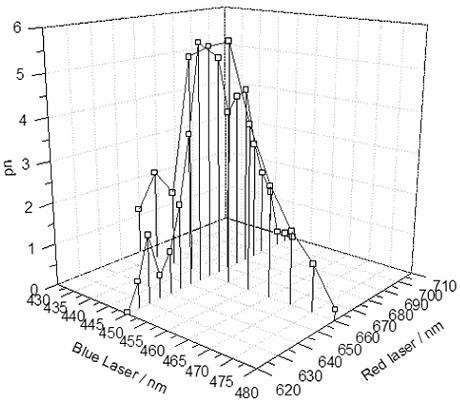

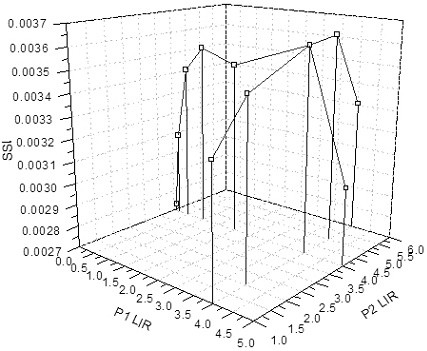

Laser seedling raising method and rice cultivation method based on the same

ActiveCN114521410BLower energy consumption ratioImprove light utilizationSaving energy measuresHorticulture methodsRed laserLasing wavelength

The invention belongs to the technical field of planting, and in particular relates to a laser seedling breeding method and a rice breeding method based on the method. The method includes: irradiating the rice in the seedling growth stage; the laser seedling raising light field is composed of a blue laser and a red laser, the blue laser has a wavelength of 445-455 nm, and the red laser has a wavelength of 655-455 nm. 665 nm, the light intensity of the laser seedling light field is 0.1-2.0 μmol m ‑2 ·s ‑1 , the single-day irradiation time is less than or equal to 16 h; the light intensity ratio of the red and blue lasers is (0.5~4): 1 after the rice seedlings emerge to the three-leaf stage; the rice is from the three-leaf stage to the seedlings For transplanting, the intensity ratio of red and blue laser light is (2~5):1. The invention reduces the energy consumption ratio and improves the light utilization rate through the laser light supplement, and can save more than 60% of energy in the field of agricultural planting supplement light, resulting in a very significant energy saving effect.

Owner:浙江长芯光电科技有限公司

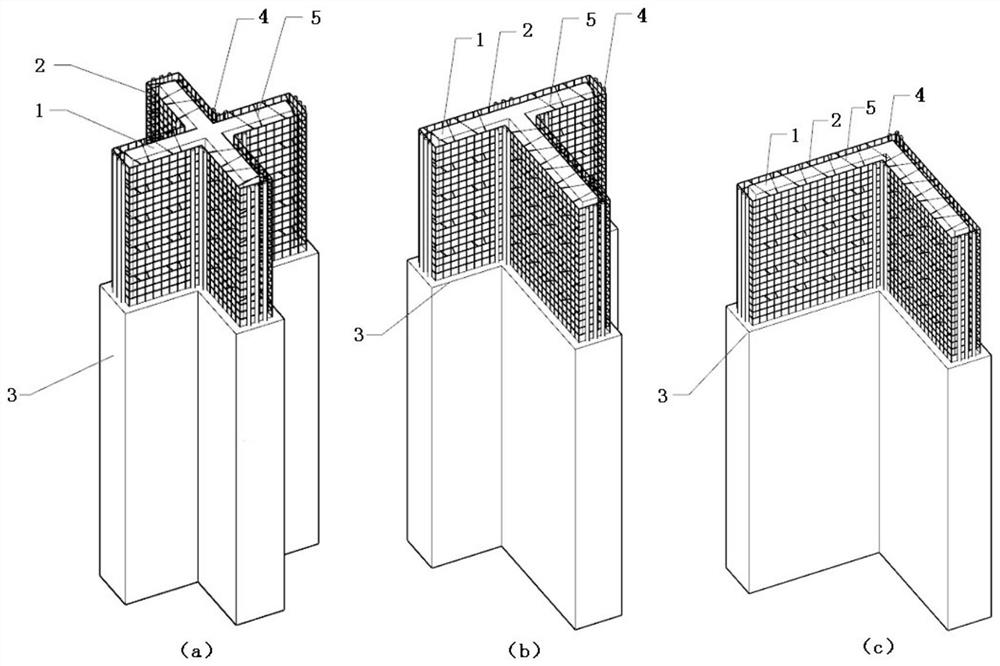

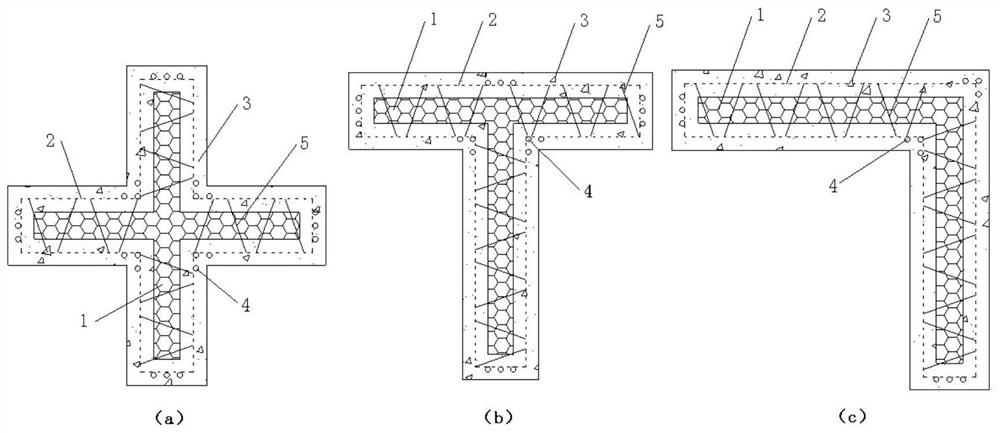

Desert sand lightweight aggregate concrete special-shaped column structure with built-in insulation board and construction process of desert sand lightweight aggregate concrete special-shaped column structure

ActiveCN113175156AImprove ductilityImprove crack resistanceStrutsHeat proofingExpanded clay aggregateColumn structure

The invention provides a desert sand lightweight aggregate concrete special-shaped column structure with a built-in insulation board. The desert sand lightweight aggregate concrete special-shaped column structure comprises the special-shaped insulation board, a steel wire net frame is arranged on the periphery of the special-shaped insulation board, a gap is reserved between the steel wire net frame and the special-shaped insulation board, and the height of the steel wire net frame is equal to that of the special-shaped insulation board. Longitudinal tensional bars are arranged at the section center and the outer side of the limb end of the steel wire net frame along the height in a pass-length mode. Oblique inserting wires horizontally penetrate through the special-shaped insulation board layer by layer, the two ends of the oblique inserting wires are connected with the steel wire net frame, and desert sand ceramsite lightweight aggregate concrete matched with the special-shaped insulation board is poured on the inner side and the outer side of the steel wire net frame. The steel wire net frame and the insulation board are connected and then placed in a special-shaped column mold, the desert sand ceramsite lightweight aggregate concrete is poured, curing and demolding are carried out, and the lightweight aggregate concrete steel wire net frame insulation board special-shaped column structure is obtained. The manufacturing cost is low, the material source is wide, the manufacturing process is simple, and the working efficiency can be remarkably improved.

Owner:SHIHEZI UNIVERSITY

Polyester chip for producing automotive interior fiber and preparation method thereof

The invention discloses a polyester chip for producing automobile interior decoration fibers and a preparation method thereof. Firstly, the polyester chip that meets the technical requirements is synthesized: using a two-pot process semi-continuous polymerization reaction device, by introducing isocyanate in the esterification reaction Construct and replace carboxylic acid to reduce the melting point of the product to the target range, and then add reactive catalyst, stabilizer, auxiliary materials, etc. in the polycondensation reaction to control the reaction temperature and vacuum degree, and the final synthetic intrinsic viscosity is 0.730‑0.740dl / g The target polyester chip base material; the synthesized product is passed through the solid phase drum device water steam crystallization process to complete the pre-crystallization of the polyester chip; the pre-crystallized polyester chip is obtained by temperature control without cooling down. The continuous negative pressure processing technology completes the drying of polyester chips. After drying, the water content of polyester chips is not higher than 0.05%, and the intrinsic viscosity is not lower than 0.715dl / g. Through the above three steps, the special polyester chips for automotive interior fibers that meet the requirements of industrial production can be prepared.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

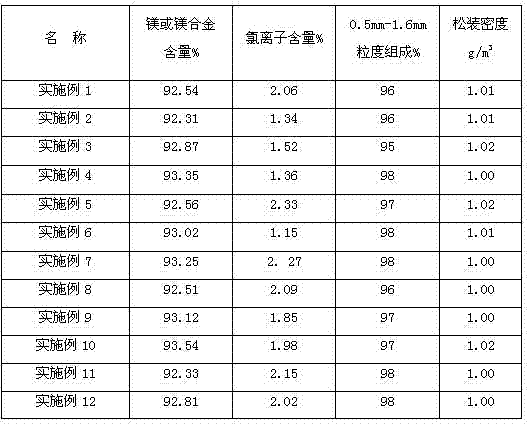

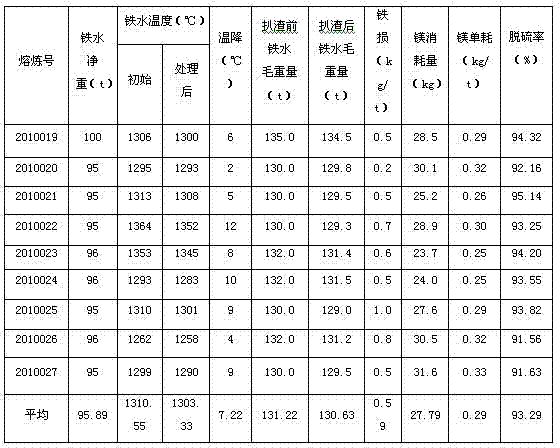

Particle magnesium desulfurizer/particle magnesium alloy desulfurizer based on magnesium, magnesium alloy and waste materials thereof and preparation method

The invention relates to a particle magnesium desulfurizer / particle magnesium alloy desulfurizer based on magnesium, magnesium alloy and waste materials thereof and a preparation method. In the invention, with magnesium, a magnesium waste material or a magnesium alloy and a magnesium alloy waste material as raw materials, and with a salt additive as an auxiliary material, a composition mixing 93%of magnesium solution or magnesium alloy solution and 7% of salt solution is formed, wherein the salt solution comprises the following components and contents: 50-65% of sodium chloride, 30-45% of potassium chloride and 2-5% of magnesium chloride; and a matched scheme combining with a production line and a production process is adopted. In the invention, the comprehensive problems of high energy consumption, serious pollution, poor safety, serious resource waste, high equipment failure, too many substandard products, high production equipment investment, low output, loose finished product surface structure, low compactedness, easy falling, easy moisture absorption, influences on steel output and quality, great magnesium resource loss, low utilization rate and the like in the traditional finished particle magnesium product and production thereof are overcome; the particle magnesium desulfurizer / particle magnesium alloy desulfurizer is widely applied to molten iron pretreatment desulfurization and molten steel deep desulfurization in iron and steel smelting and utilized as a component of a cast iron mixed denaturing agent and an intermediate alloy in the production of fusion ferrosilicon.

Owner:HUNAN S R M SCI & TECH

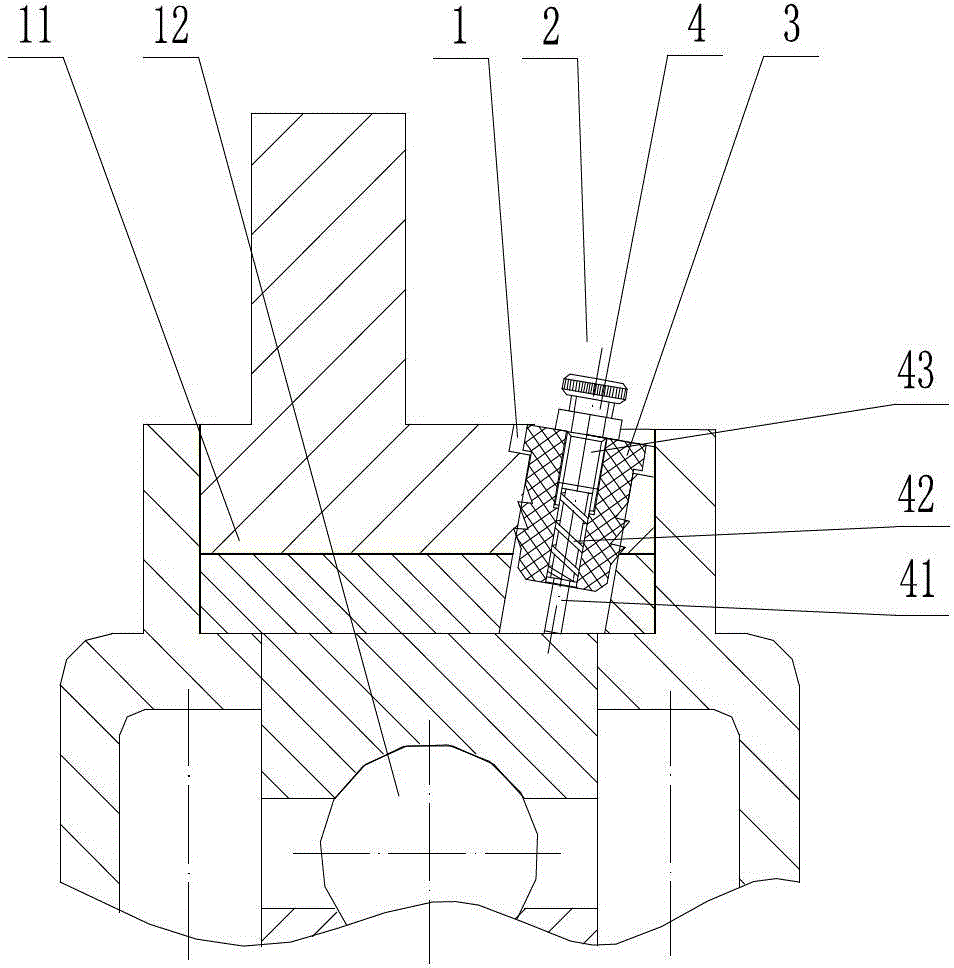

Locking gear insulation temperature measuring device for motor end cover

ActiveCN103066760BEasy to processOvercome the defect of easy looseningStructural associationSupports/enclosures/casingsEngineeringElectrical and Electronics engineering

Owner:HUNAN CHONGDE IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com