Large-load hydraulic bidirectional loading apparatus

A two-way loading, large load technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems that affect the service life and efficiency, complex structure, wear and other problems, so as to improve the effective working efficiency, expand the scope of application, increase the The effect of the application function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

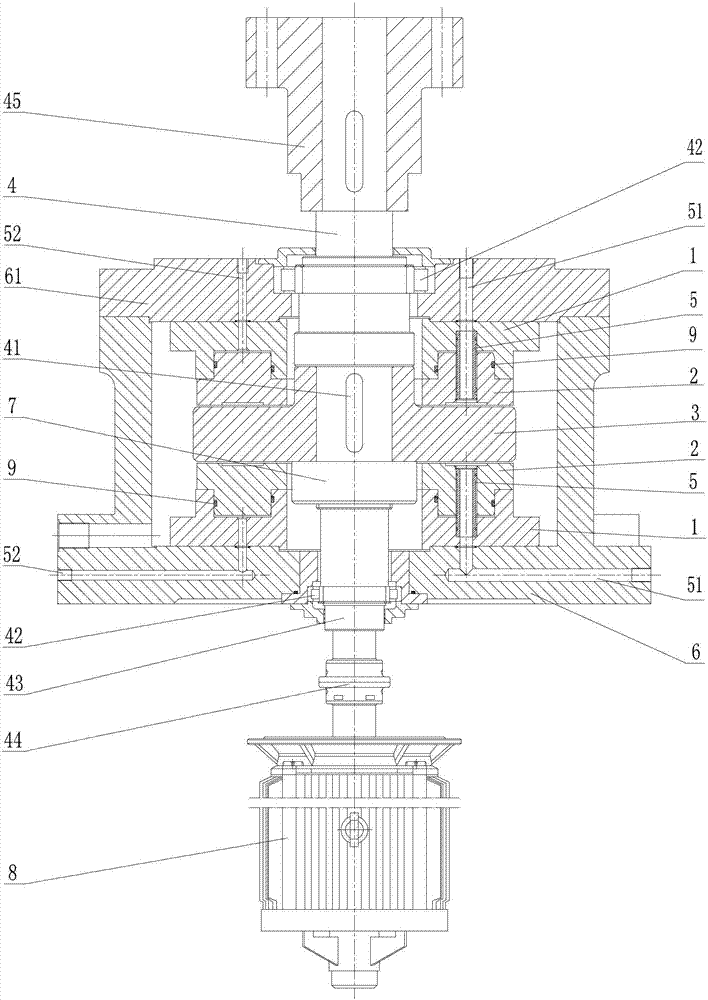

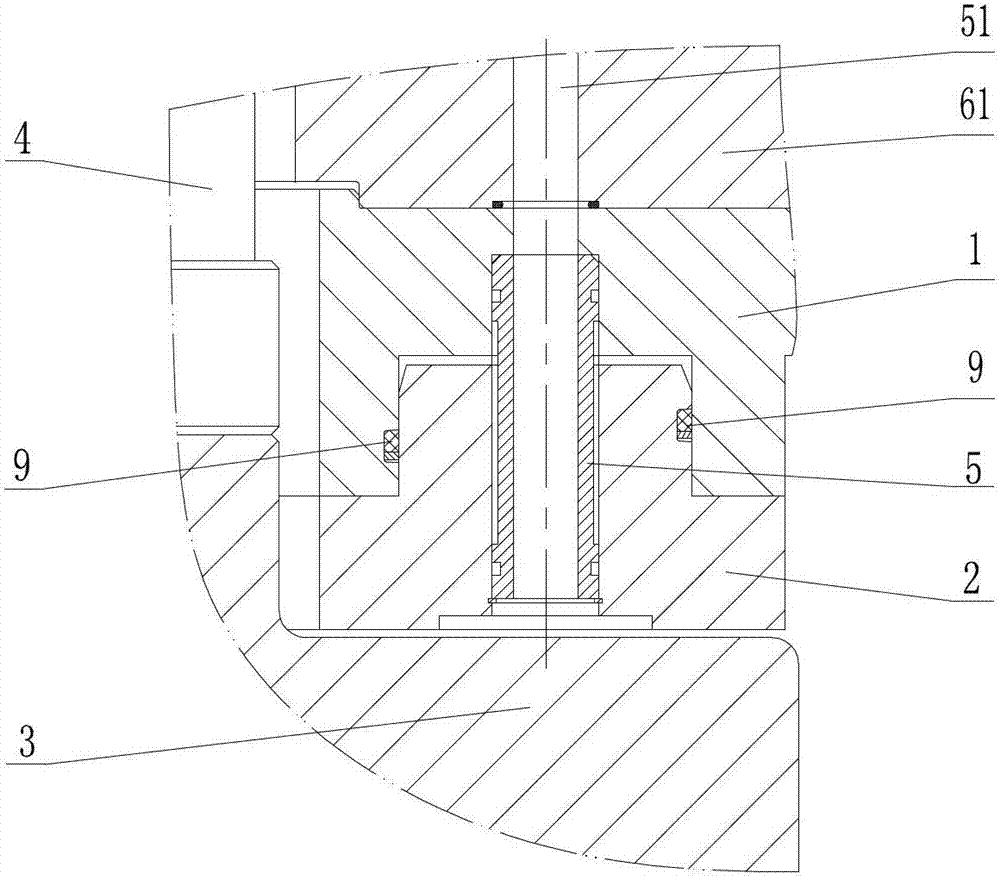

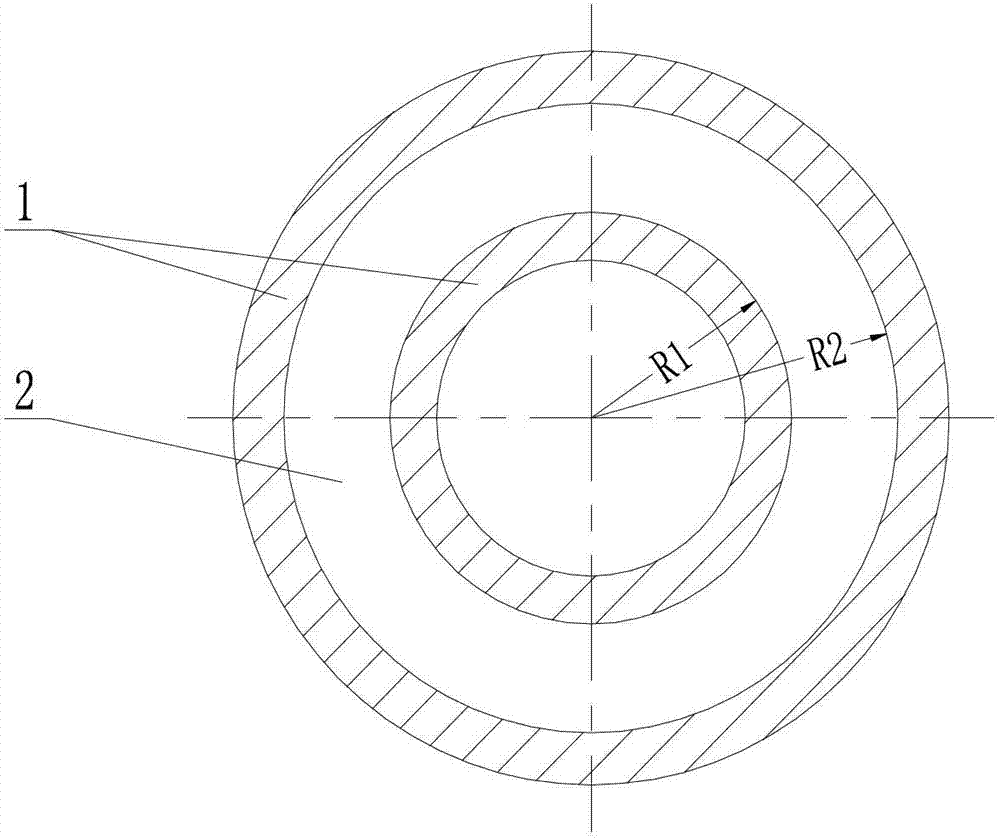

[0031] As shown in the accompanying drawings, a large-load hydraulic two-way loading device mainly includes follow-up cylinders 2 respectively arranged in the load cylinder 1 and symmetrically distributed along the axial direction of the thrust plate 3, and between the follow-up cylinder 2 and the load cylinder 1 Several oil pipes 5 are set, and the box body 6 and the box cover 61 are respectively provided with an oil passage A51 and an oil passage B52. The output also has independent loading and rotating functions. The oil passage A51 runs through the surface of the thrust plate 3 through the loading cylinder 1, the oil passage 5 and the follower cylinder 2, and the oil passage B52 passes through the loading cylinder 1 and the follower cylinder 1. The joint interface of the oil cylinder 2, the thrust plate 3 is fixedly connected to the thrust shaft 4 through the key 41 and the locking device 7, and the thrust shaft 4 is respectively installed on the flange seat 43 and the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com