Technology for producing polymeric material polyvinyl chloride from crude vinyl chloride

A polymer material, polyvinyl chloride technology, applied in the field of polymer material science and engineering, can solve the problems of reduced output, high operating costs, long compression time, etc., to avoid excessive evaporation, improve the site environment, and avoid energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

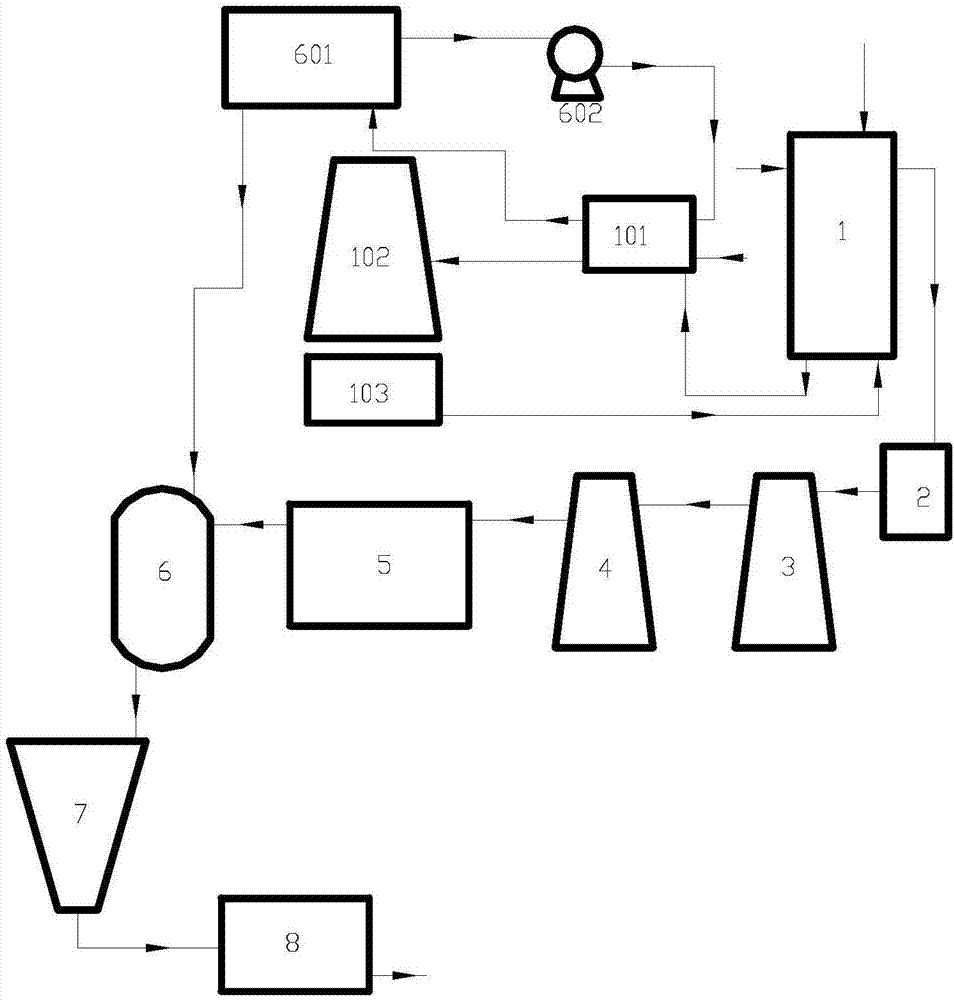

Image

Examples

Embodiment 1

[0028] A process for preparing polyvinyl chloride from crude vinyl chloride, comprising the following sections:

[0029] (1) Crude section: Acetylene gas and hydrogen chloride gas react in the converter to generate crude vinyl chloride gas, and the hot water after absorbing the heat of reaction in the shell of the converter is all returned to the hot water tank as the heat source for the converter, resulting in The hot water tank is excessively evaporated, and 10-15 liters of hot desalinated water must be added to the hot water tank every 24 hours to ensure the normal progress of the converter reaction;

[0030] (2) Refining section: the crude vinyl chloride gas is demercurized, acid recovered, alkali washed, compressed, and rectified to obtain refined vinyl chloride gas, and the compression equipment is a piston compressor;

[0031] (3) Polymerization section: Refined vinyl chloride gas enters the polymerization kettle to undergo polymerization reaction to obtain polyvinyl ch...

Embodiment 2

[0033] A process for preparing polyvinyl chloride from crude vinyl chloride, comprising the following sections:

[0034] (1) Crude section: Acetylene gas and hydrogen chloride gas react in the converter to generate crude vinyl chloride gas, and the hot water after absorbing the heat of reaction in the shell of the converter enters the upper part of the steam absorption tower after exchanging heat with the heat exchanger After absorbing the heat evaporated from the hot water tank of the converter, it flows into the hot water tank of the converter, which not only ensures that the temperature of the hot water tank meets the temperature requirements of the conversion process (90-100°C), but also avoids excessive evaporation of the hot water tank, and there is no need to replenish the hot water tank The desalinated water also ensures the normal progress of the reaction in the converter, and the heat exchanged by the heat exchanger is used for heating the cold desalted water in the f...

Embodiment 3

[0038] A process for preparing polyvinyl chloride from crude vinyl chloride, comprising the following sections:

[0039] (1) Crude section: Acetylene gas and hydrogen chloride gas react in the converter to generate crude vinyl chloride gas, and the hot water after absorbing the heat of reaction in the shell of the converter enters the upper part of the steam absorption tower after exchanging heat with the heat exchanger After absorbing the heat evaporated from the hot water tank of the converter, it flows into the hot water tank of the converter;

[0040] (2) Refining section: the crude vinyl chloride gas is demercurized, acid recovered, alkali washed, compressed, and rectified to obtain refined vinyl chloride gas, and the compression equipment is a screw compressor;

[0041] (3) Polymerization section: Refined vinyl chloride gas enters the polymerization kettle to undergo polymerization reaction to obtain polyvinyl chloride. The heating of the cold desalted water utilizes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com