Patents

Literature

406 results about "Oxychlorination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry oxychlorination is a process for making C-Cl bonds. In contrast with direct use of Cl₂, oxychlorination uses hydrogen chloride in combination with oxygen. This process is attractive industrially because hydrogen chloride is less expensive than chlorine.

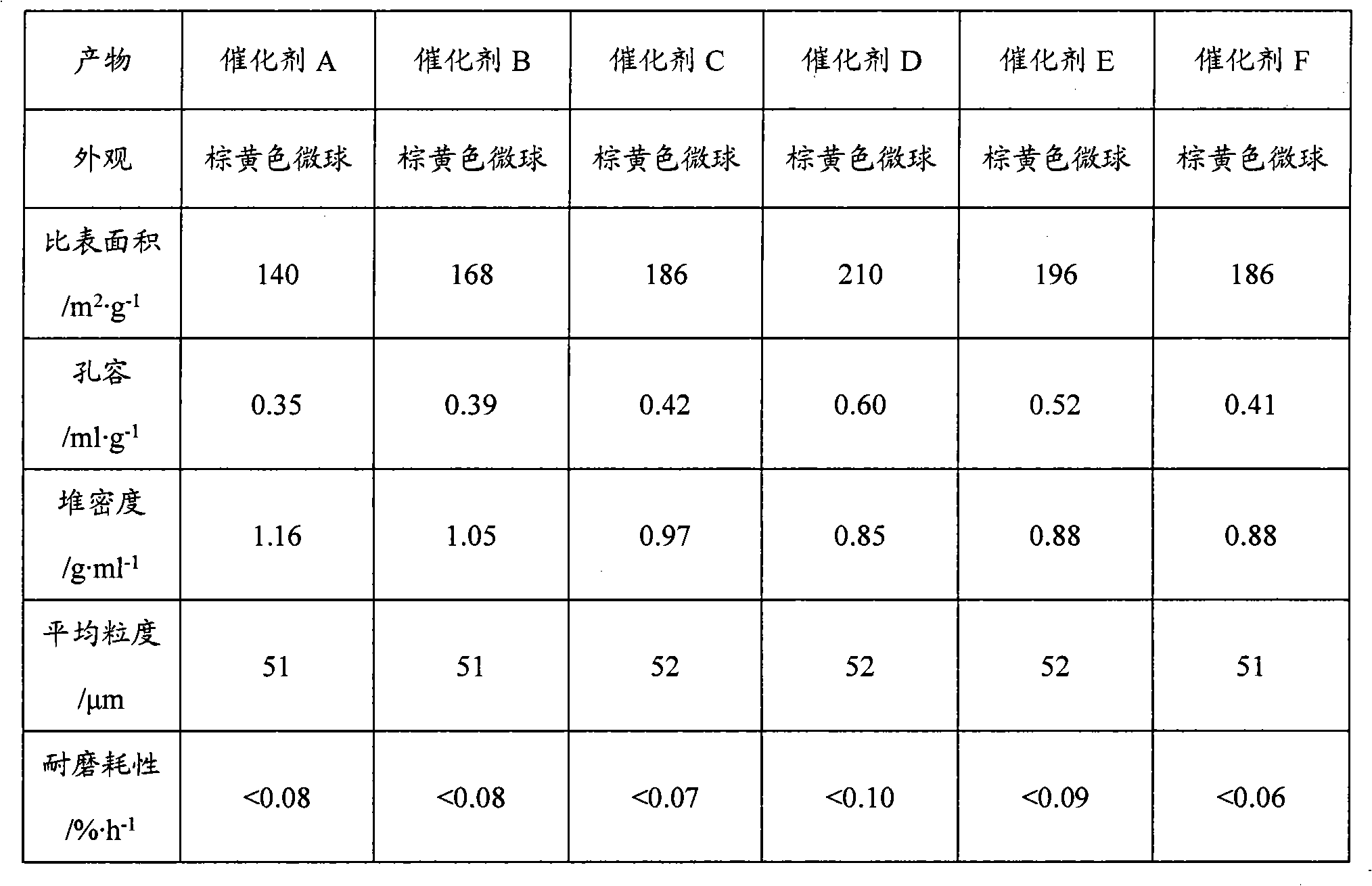

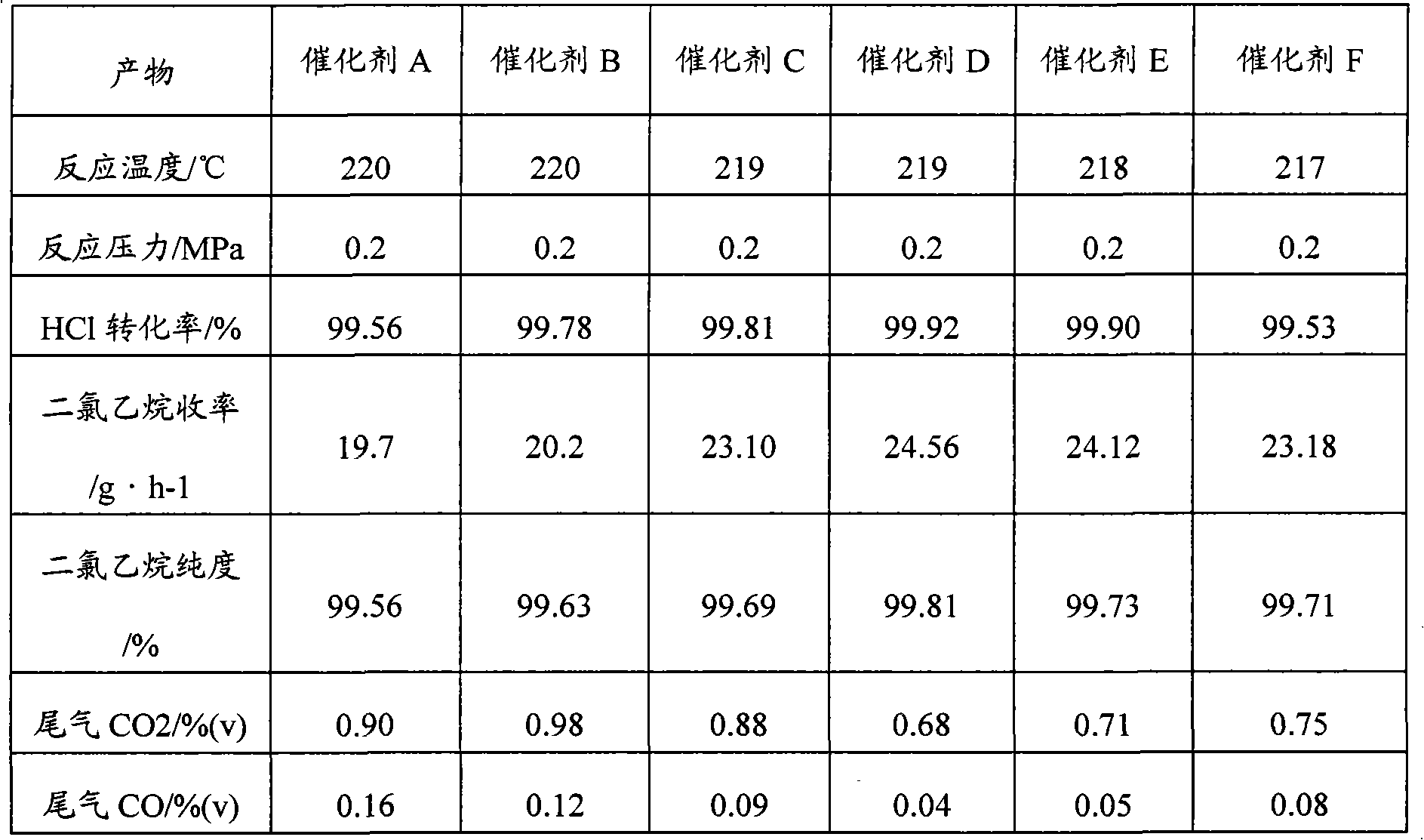

Microspherical ethylene oxychlorination catalyst preparation method

ActiveCN102049314AMaintain catalytic activityProblems Affecting Catalytic PerformanceCatalyst activation/preparationHalogenated hydrocarbon preparationTime extensionMicrosphere

The invention discloses a microspherical ethylene oxychlorination catalyst preparation method, which comprises the following six steps: solution preparation; precipitation and reaction; peptization; active component and assistant component homogenization; spray forming; and post-treatment. Solution of an active component and solution of an assistant component are dissolved in peptized pulp; a proper amount of dispersant and pore-expanding agent are added into the pulped sol solution to ensure the active component and the assistant component are uniformly distributed in the sol solution; the dispersant can prevent active and assistant component deposition caused by the prolongation of spray time; and the added proper amount of pore expanding agent can expand formed pore passage with a microspherical structure in a spraying process of the sol solution so as to improve the volume of the pore passage of a catalyst carrier and improve the pore volume and specific area of the catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

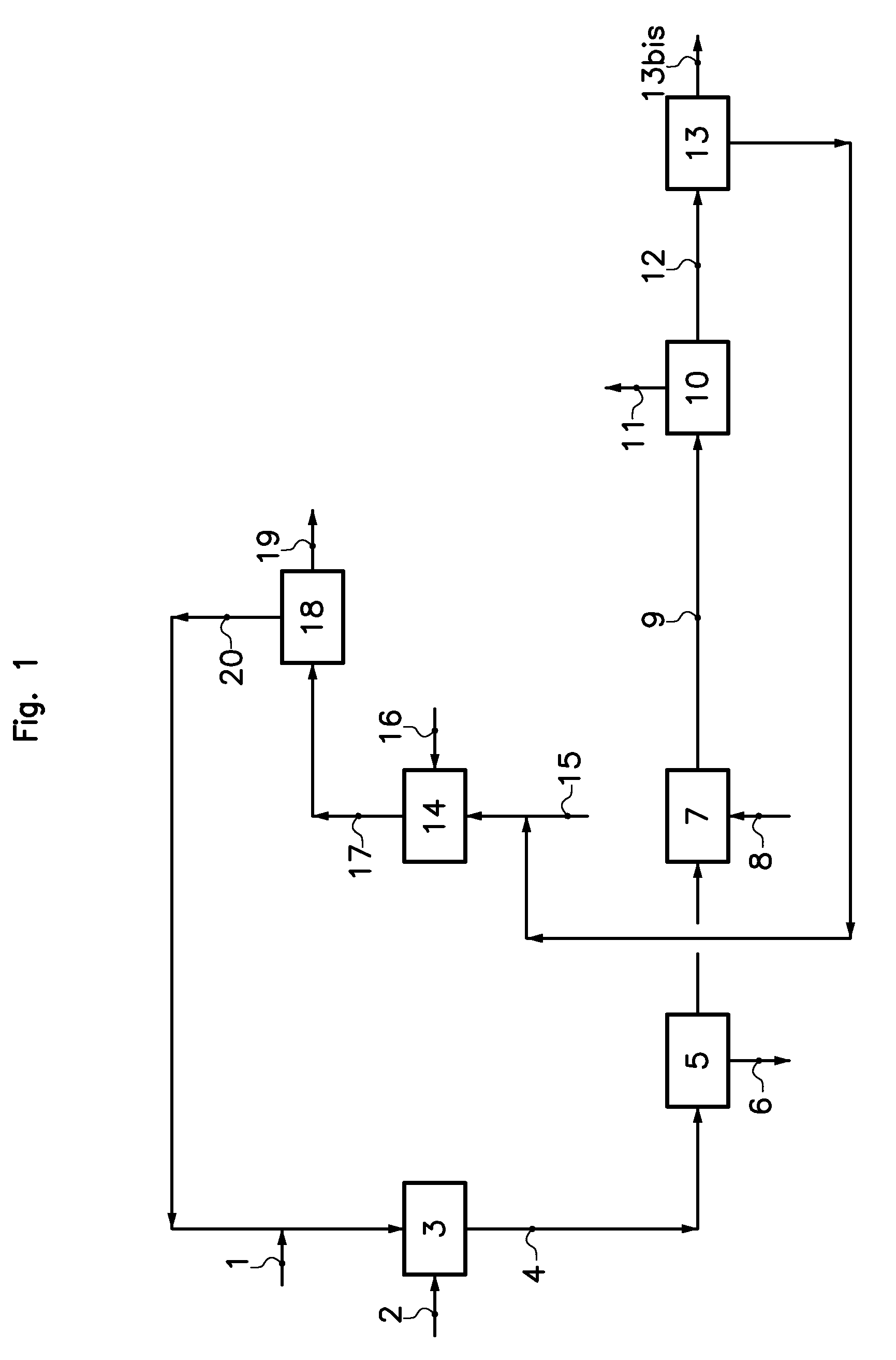

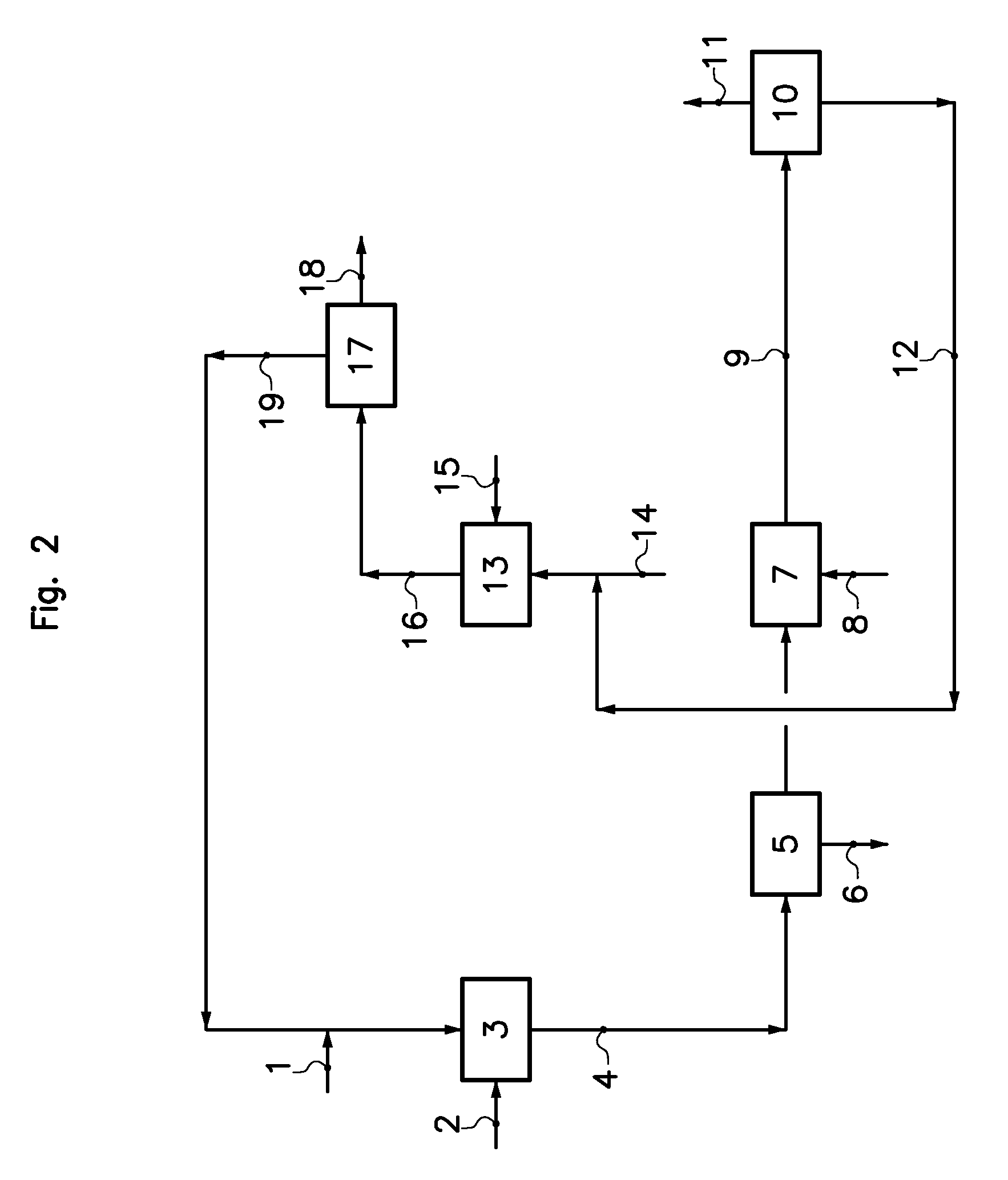

Process for the manufacture of 1,2-dichloroethane

InactiveUS8058490B2Low costHigh purityPreparation by hydrogen halide split-offChemical recyclingCatalytic oxidationEthane Dichloride

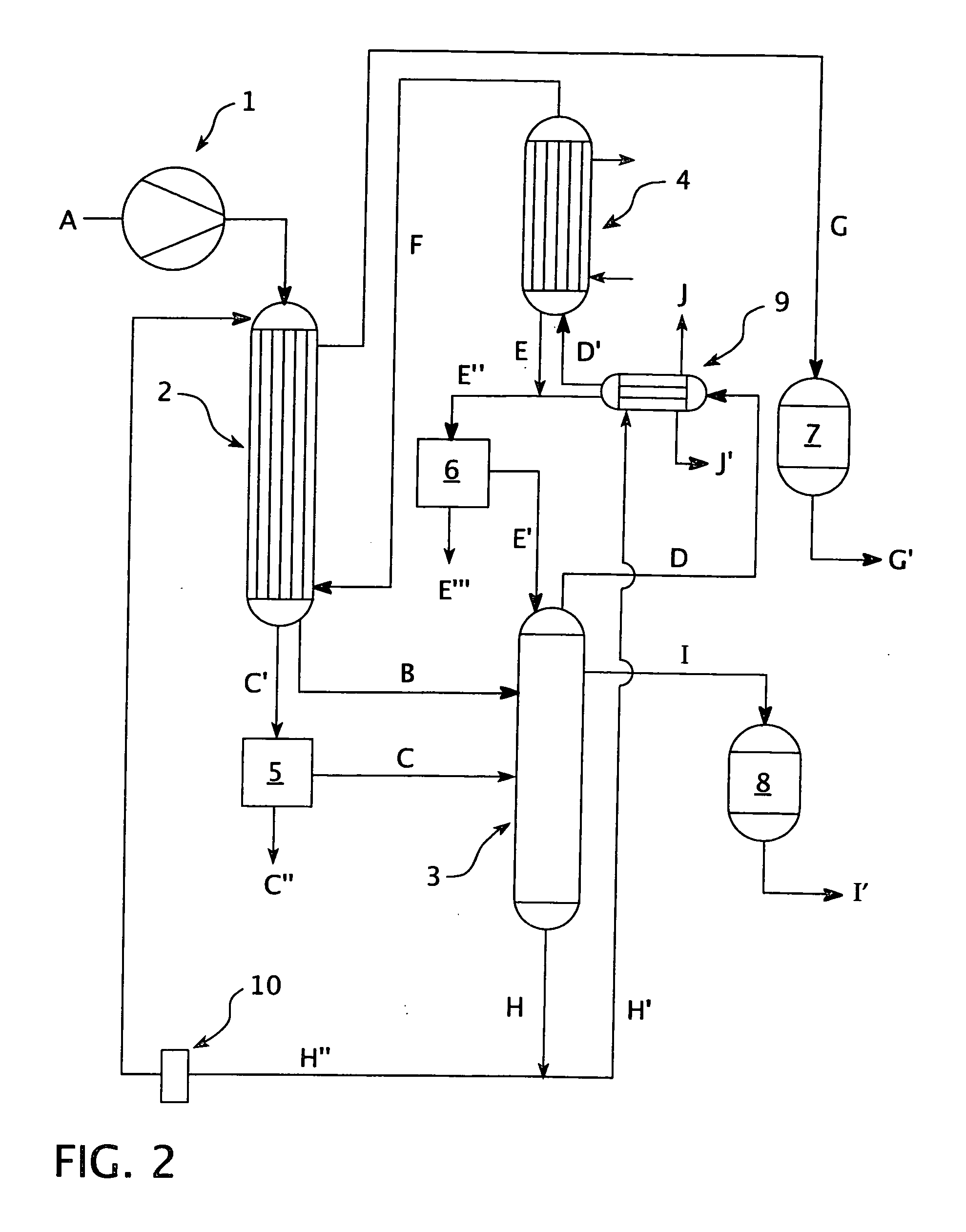

Process for the manufacture of 1,2-dichloroethane (DCE) starting from a stream of ethane which is subjected to a catalytic oxydehydrogenation (ODH) thus producing a gas mixture containing ethylene which is then dried and conveyed to a chlorination reactor supplied with a flow of chlorine so that at least 10% of the ethylene is converted to DCE. The stream of products derived from the chlorination reactor is then conveyed to an oxychlorination reactor in which the majority of the balance of ethylene is converted to DCE.

Owner:SOLVAY SA

Ethylene oxychlorination catalyst and its preparation method and application

ActiveCN100998942AIncrease throughputIncrease profitCatalyst activation/preparationHalogenated hydrocarbon preparationMicrosphereRare earth

A catalyst for the oxychlorinating reaction of ethene to prepare dichloroethane is composed of the carrier (aluminum oxide-titanium oxide microballs), primary active component (Cu) and secondary active component consisting of at least one of La, Ce, Nd, Pr and Y, one transition metal and at least one alkali metal. Its preparing process includes preparing carrier by codeposition, and dipping in active components.

Owner:CHINA PETROLEUM & CHEM CORP +1

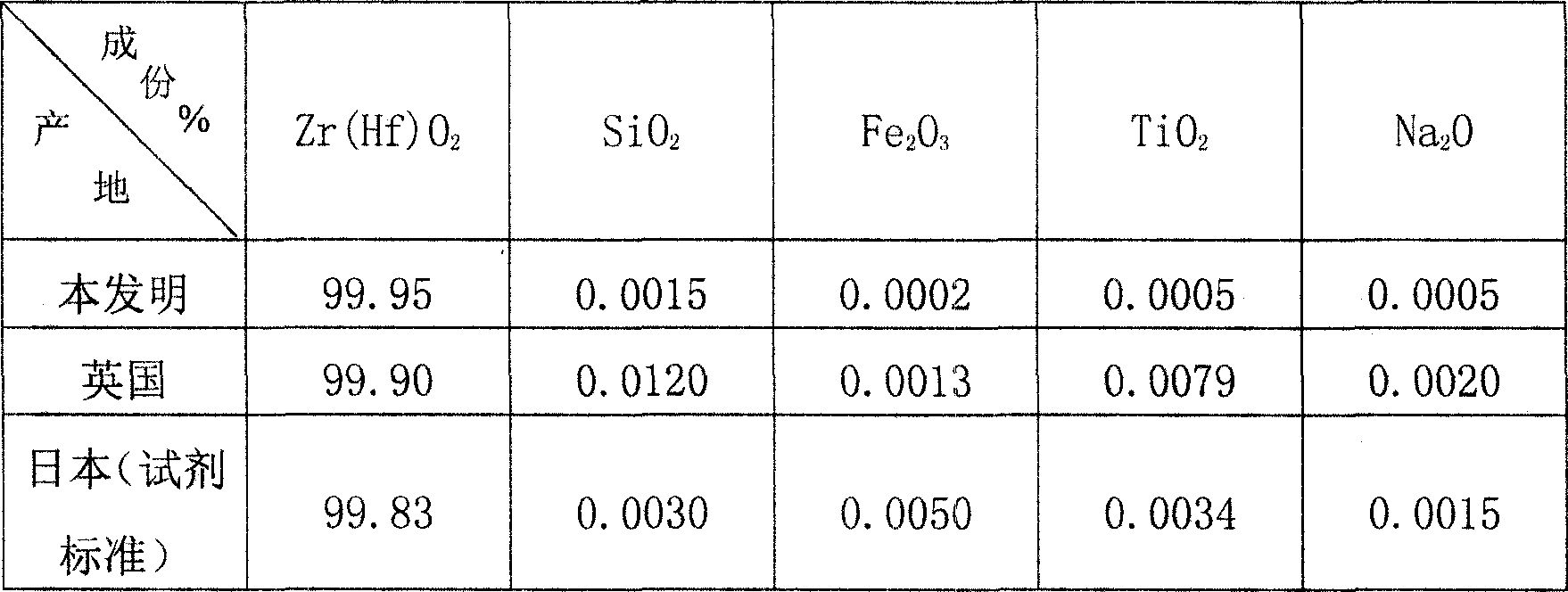

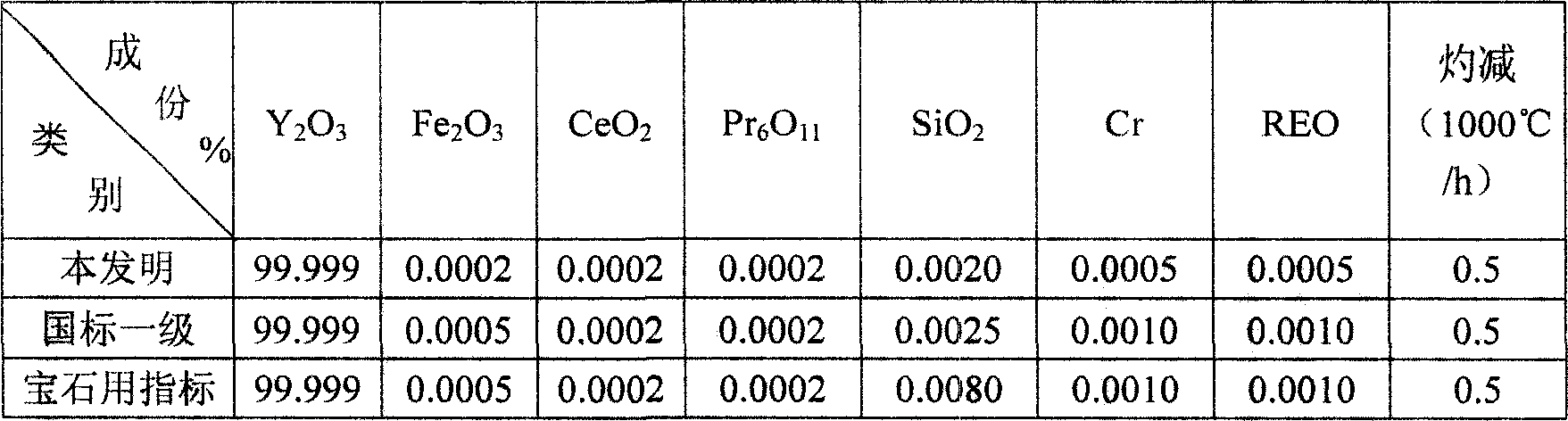

Process of preparing zirconia and yttria with Y-doped cubic zirconia powder

InactiveCN1986423AHigh metal contentLow priceRare earth metal compoundsZirconium oxidesOXALIC ACID DIHYDRATEPhysical chemistry

The process of preparing zirconia and yttria with Y-doped cubic zirconia powder includes the following steps: alkali fusing and sintering Y-doped cubic zirconia powder, water washing to eliminate sodium, acidifying and concentrating to obtain Zr crystal, oxychlorination to re-crystallize and purify, and high temperature calcining to obtain high purity jewel level zirconia; concentrating Y-containing mother liquid to crystallize zirconia, purifying high Y mother liquid, precipitating Y in oxalic acid solution, and high temperature calcining to obtain high purity jewel level yttria. The present invention has relatively low cost.

Owner:王必庆

Enhanced process for the purification of anhydrous hydrogen chloride gas

InactiveUS20070261437A1SolidificationChlorine/hydrogen-chloride purificationDeacon processHydrogen chloride

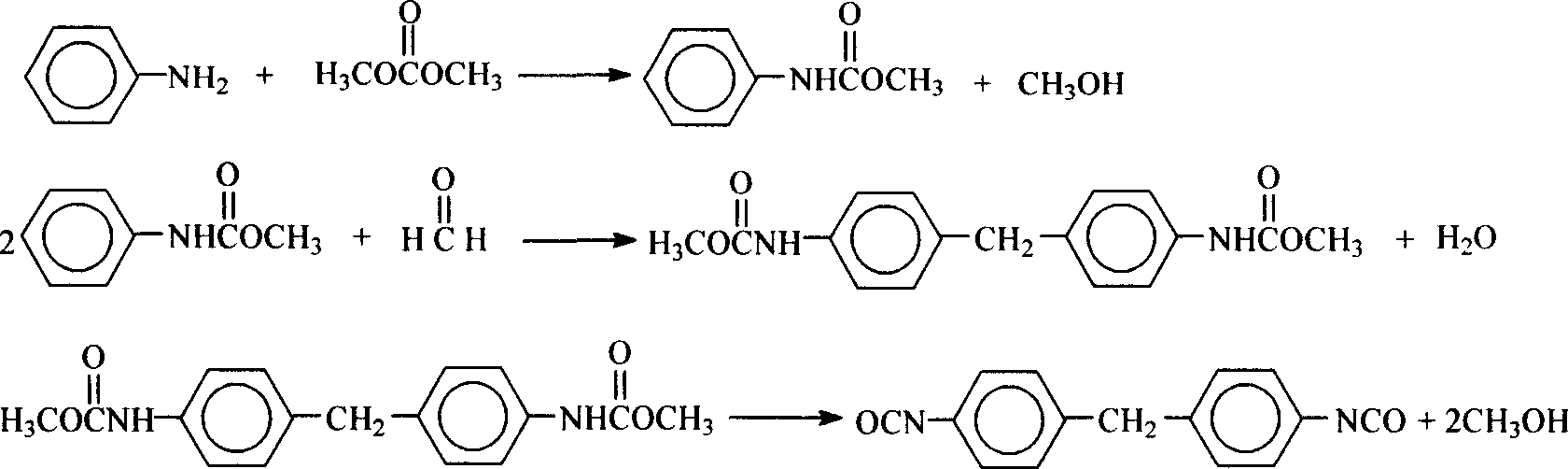

The present invention relates to a process for purifying anhydrous hydrogen chloride gas (“aHCl”), and preferably the anhydrous hydrogen chloride gas recovered from an isocyanate production process. In the process of the present invention, the content of chlorinated organics may be reduced from up to 1000 ppm by volume to below 10 ppb by volume levels. Generally, the process of the invention allows for chlorinated organic levels to be reduced to from 1 to 100 ppb, rendering the treated hydrogen chloride gas usable in a catalytic oxychlorination process or a Deacon process. The treated gas is also suitable for absorption in water or dilute hydrochloric acid.

Owner:BAYER MATERIALSCIENCE AG +2

High purity ultra fine zirconium biboride powder and its preparation method

The present invention relates to a high-purity ultrafine zirconium diboride powder material and its preparation method. It is characterized by that the described powder material contains zirconium oxychloride, boron carbide powder and active carbon powder, their mole ratio is ZrOcl2:B4C:C=1:0.4-0.8:1.4-1.8. Its preparation method includes the following steps: firstly, mixing boron carbide powder, active carbon powder and water according to mixing ratio, regulating pH value to obtain mixed suspension; dissolving zirconium oxychloride in deionized water to obtain the zirconium oxychloride solution; mixing the above-mentioned suspension and zirconium oxychloride solution, adding ammonia water, making the zirconium oxychloride be fully hydrolyzed and precipitated; making suspension undergo the processes of solid-liquor separation, waster-washing, removing NH4+ and Cl-, drying and sieving; then placing the powder material into a vacuum furnace to make reaction synthesis, its synthesis temperature is 1500-1600 deg.C, heat-insulating for 0.5-4 h; grinding powder and sieving so as to obtain the invented powder material.

Owner:칭다오정왕철강수통제주식유한회사

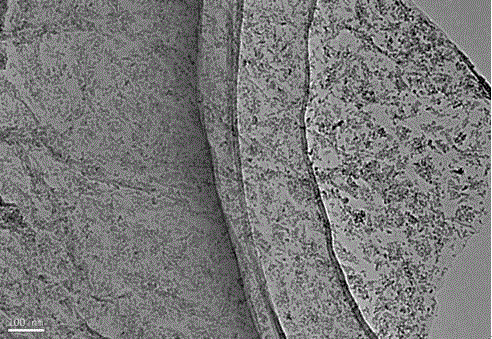

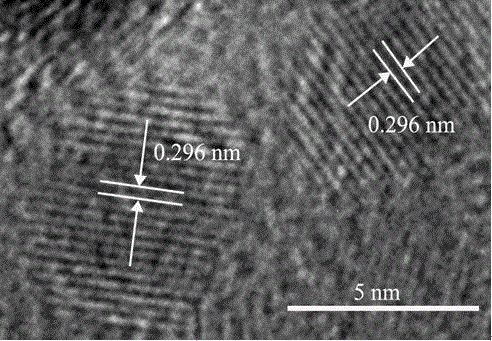

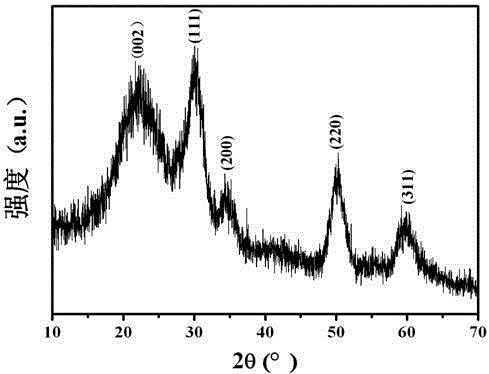

Preparation method of graphene/zirconium oxide nano-grade composite lubricating material

InactiveCN105219478ASimple processShorten the production cycleBase-materialsFreeze-dryingZirconium oxychloride

The invention discloses a preparation method of a graphene / zirconium oxide nano-grade composite lubricating material. The method comprises the following steps: a graphite oxide solution is subjected to ultrasonic treatment for 1-2h, such that a uniformly dispersed graphene oxide suspension liquid with thickness of 1-2 layers is obtained; the suspension liquid is diluted with ultrapure water; zirconium oxychloride octahydrate is dissolved in ultrapure water, such that a zirconium oxychloride solution is prepared; the diluted graphene oxide suspension liquid is mixed with the zirconium oxychloride solution, and the mixture is uniformly mixed by stirring; the mixture is subjected to ultrasonic treatment for 10-30min; hydrazine hydrate is added into the mixed liquid, and a reaction is carried out under a hydrothermal condition, wherein a reaction temperature is 150-220 DEG C and a reaction time is 18-24h; a black solid product obtained after the reaction is repeatedly washed with ultrapure water, and is subjected to freeze drying for 6-12h, such that the graphene / zirconium oxide nano-grade composite lubricating material with zirconium oxide nano-particles uniformly distributed on graphene surface is obtained. The preparation method provided by the invention has the advantages of simple process, easy operation, low cost, high product purity, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Supercritical hydrothermal synthesis method of nanometer zirconium oxide powder

ActiveCN103058277AFine particleNarrow particle size distributionMaterial nanotechnologyBulk chemical productionOxalateGranularity

The invention relates to a supercritical hydrothermal synthesis method of nanometer zirconium oxide powder. The method comprises the following steps of: respectively dissolving oxalic acid and a soluble zirconium compound in water, adding the zirconium oxide solution into the oxalic acid solution under a stirring condition, performing precipitation reaction to obtain white zirconium oxalate precipitate; washing and drying the zirconium oxalate precipitate and then performing thermal decomposition reaction, and performing wet-type grinding on the thermally decomposed product to obtain nanometer-grade dispersed slurry; and performing supercritical hydrothermal reaction on the nanometer slurry to obtain the nanometer zirconium oxide powder. The nanometer zirconium oxide powder prepared by using the method has the advantages of fine grain, narrow granularity distribution, good stability and high purity.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

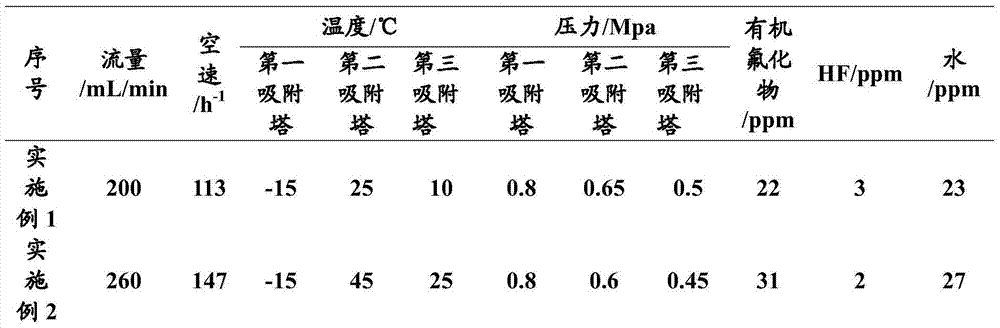

Method for purifying byproduct hydrogen chloride in fluorinated alkane production

ActiveCN103588173AIncrease added valueChlorine/hydrogen-chloride purificationDispersed particle separationSorbentSilica gel

The invention relates to a method for purifying a byproduct hydrogen chloride in fluorinated alkane production. The method comprises the following steps: sequentially passing the byproduct in fluorinated alkane production through a first absorption tower filled with an activated carbon absorbent, a second absorption tower filled with an aluminum oxide absorbent, and a third absorption tower filled with a molecular sieve absorbent and a silica gel absorbent, so as to obtain a hydrogen chloride product, wherein the weight content of the hydrogen chloride in the hydrogen chloride product is less than 5 ppm, the weight content of an organic fluoride is less than 50 ppm, and the weight content of water is less than 50 ppm. The purified hydrogen chloride gas can be used for synthesizing products such as vinyl chloride monomers, metal chloride, chlorocarbon and trichlorosilane, and raw materials for preparing chlorine in a oxychlorination mode, the application range of the byproduct hydrogen chloride gas is widened, the additional value is improved, and compared with the conventional process that the hydrogen chloride gas is converted into a byproduct hydrochloric acid, the method has remarkable economic benefits.

Owner:太仓中化环保化工有限公司

Cerium oxide and zirconium oxide based sosoloid catalyst, preparation method and application thereof

InactiveCN101607195AImprove catalytic performanceImprove thermal stabilityDispersed particle separationCatalyst activation/preparationZirconium hydrideCerium(IV) oxide

The invention relates to a catalytic material for purifying tail gas of an automobile, in particular to a cerium oxide and zirconium oxide based sosoloid catalyst, a preparation method and application thereof. The cerium oxide and zirconium oxide based sosoloid catalyst comprises 50-79.5wt% of zirconium oxide, 20-49.5wt% of cerium oxide and 0.5-25wt% of oxides of other elements, wherein the zirconium oxide, the cerium oxide and the oxides of other elements is present in a sosoloid form, and the oxides of other elements are one or more oxides of lanthanons except cerium. The preparation method is as follows: continuous coprecipitation is carried out on zirconium oxychloride, saline solution of cerium and saline solution of lanthanons except cerium to obtain the cerium oxide and zirconium oxide based sosoloid catalyst. In the invention, by adding the zirconium oxide and the oxides of the lanthanons except cerium, the prepared cerium oxide and zirconium oxide based sosoloid catalyst has favorable catalytic performance and greatly improved thermal stability. The preparation method can prepare the cerium oxide and zirconium oxide based sosoloid catalyst under relatively lower temperature and normal pressure.

Owner:顾冬萍

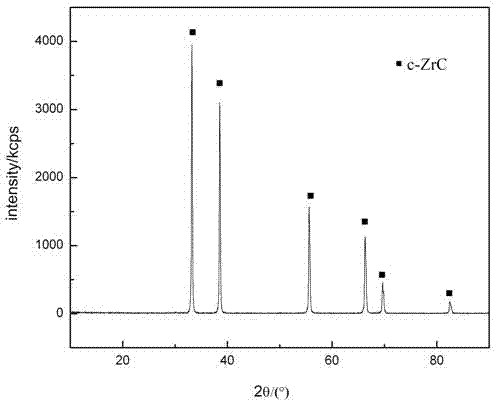

Preparation method of zirconium carbide ceramic powder

A preparation method of zirconium carbide ceramic powder belongs to the preparation field of ceramic powder. By improving a raw material mixing method and enabling subparticles with smaller particle size to be directly contacted and reacted, reaction activity of precursors is improved, thereby helping to enable the precursors to be compounded to high-purity fine-grained ceramic powder at a low temperature. A zirconium source is zirconium nitrate or zirconium oxychloride, a carbon source is glucose, and additives are carbamide, ammonium nitrate and hydrogen nitrate. Molar ratio of the zirconium source to the carbon source (Zr: C) is 1: 5-18. Molar ratio of +5 valence of nitrogen and -3 valence of nitrogen is N +5: N-3 = 1: 0.1-10. The particle size of the zirconium source and the carbon source in the precursors is small, mixing is even, reaction activity is good, carbothermic reduction reaction temperature can be lowered, reaction rate can be improved, and nano-level zirconium carbide ceramic powder with good dispersibility can be prepared. In addition, a variety of raw material sources are available, price is low, production cost is low, and prepared zirconium carbide nano-powder is stable in property, simple in production process and capable of achieving mass production.

Owner:UNIV OF SCI & TECH BEIJING

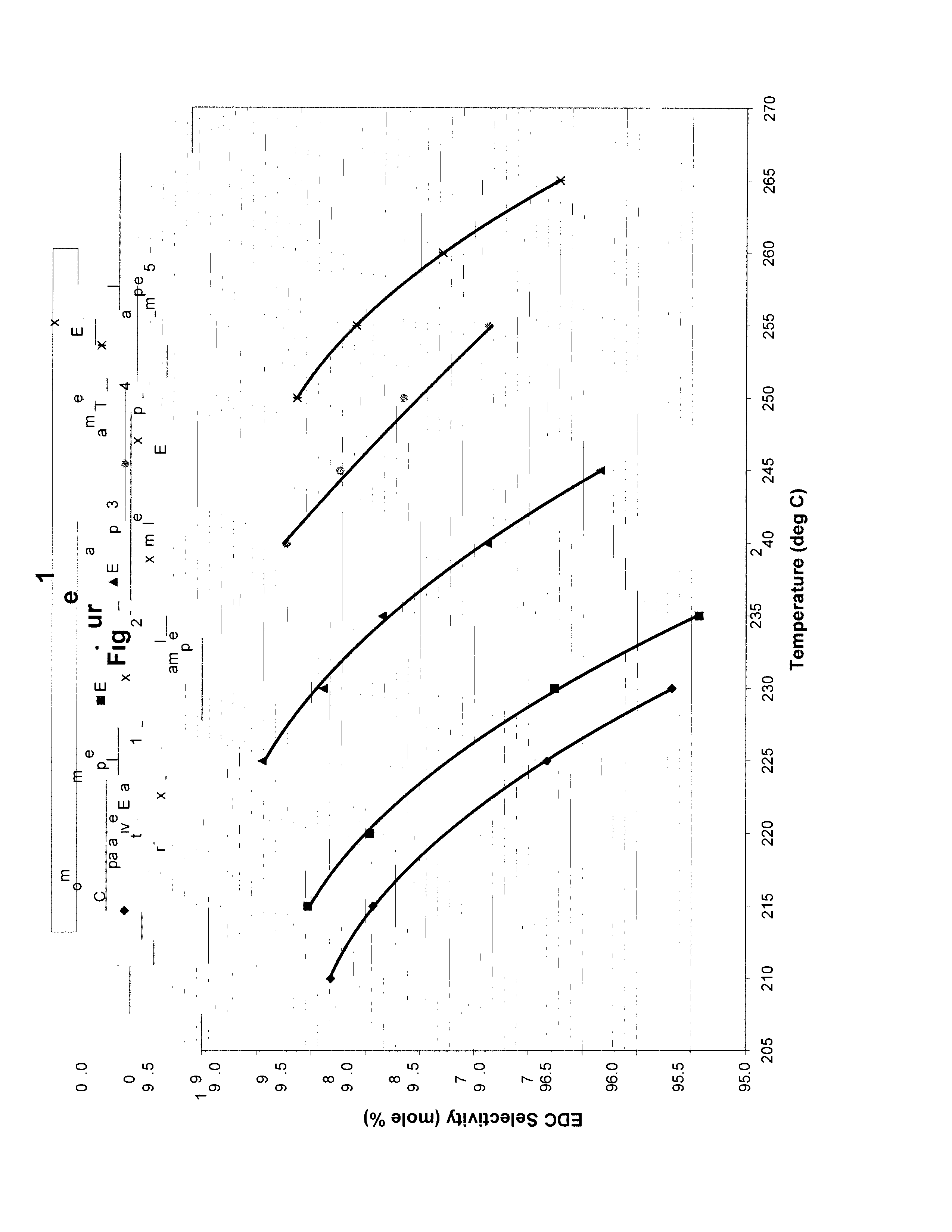

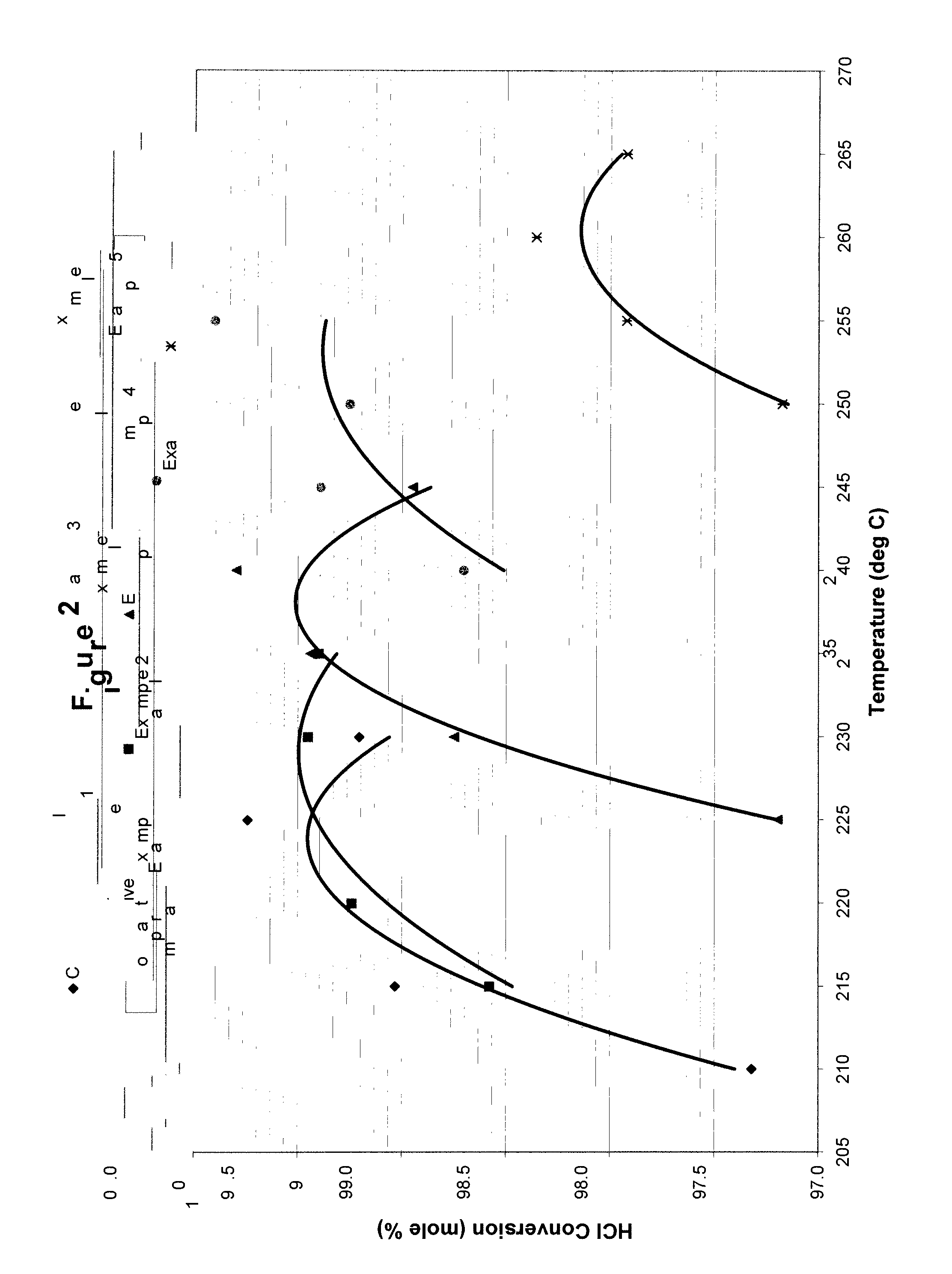

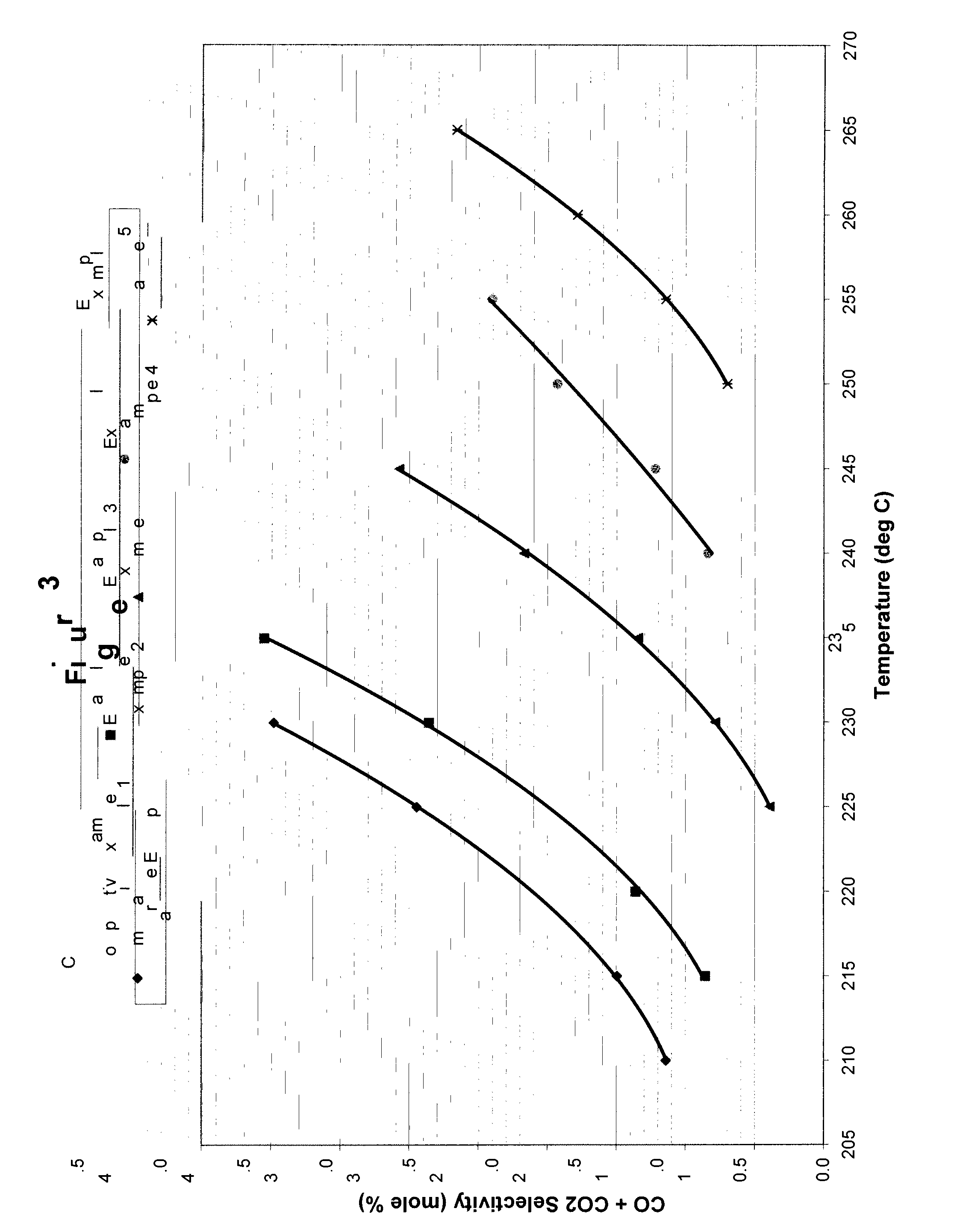

Catalyst compositions and process for oxychlorination

ActiveUS20070112235A1Increase optimal operating temperatureSacrificing catalyst performanceHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsChemical compositionDiluent

Oxychlorination catalyst compositions which include a catalytically effective amount of an oxychlorination catalyst and a diluent having certain chemical composition and / or physical properties are disclosed. Processes using such oxychlorination catalyst compositions are also described. Some oxychlorination catalyst compositions and processes disclosed herein can increase the optimal operating temperature, and thereby increase the production capacity of an existing reactor, such as a fluid-bed reactor, compared to other oxychlorination catalyst compositions.

Owner:OXY VINYLS LP

Catalytic Oxychlorination

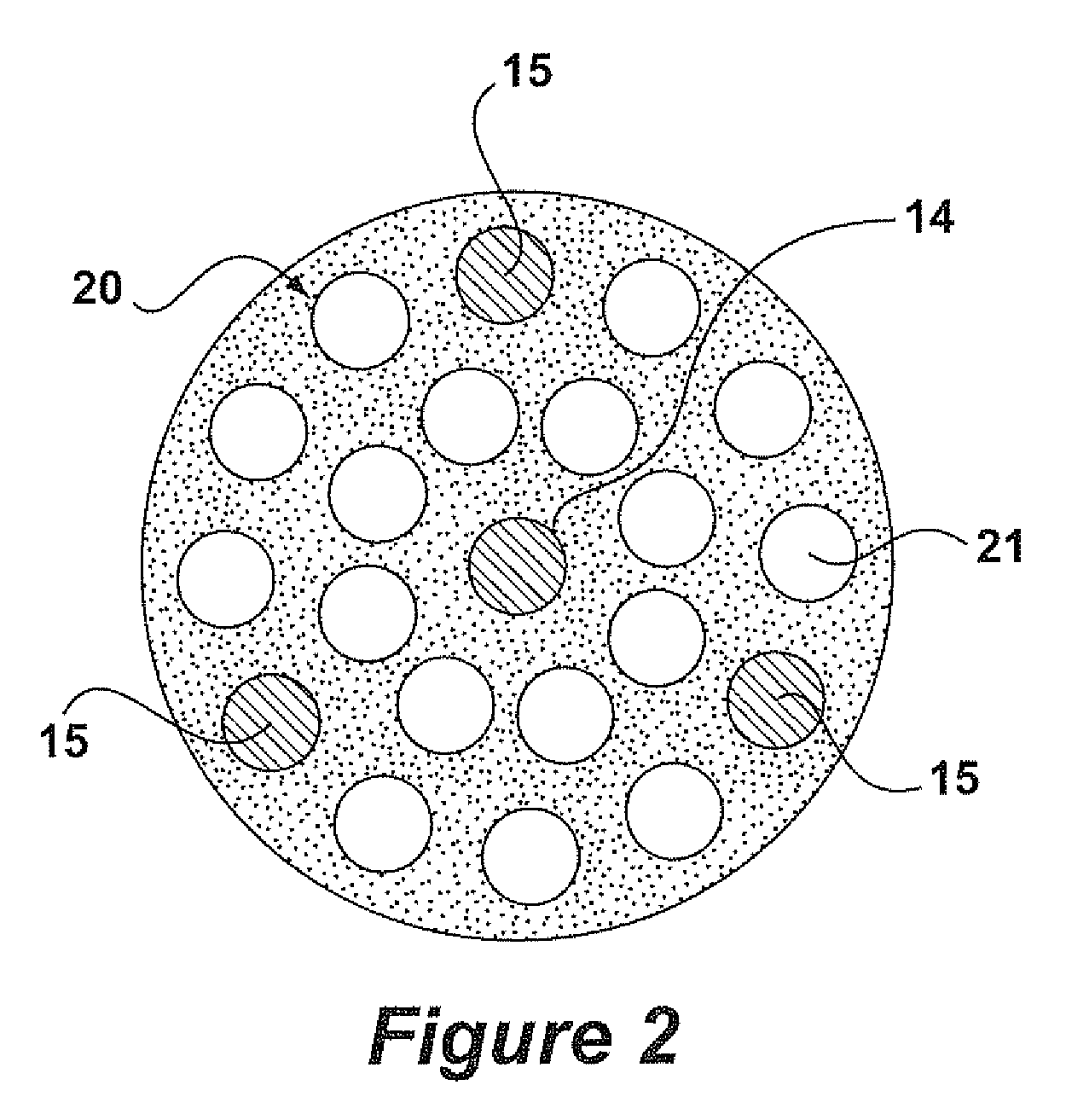

ActiveUS20090054708A1Preparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsRare earthMetal

Catalyst compositions for use in oxychlorination reactions, in particular the oxychlorination of ethylene, are disclosed. The catalyst compositions are in the form of particles suitable for use in fluid bed reactors, in particular baffled fluid bed reactors.Compared to prior art oxychlorination catalyst materials the catalyst particles disclosed herein have a reduced tendency to stick together under oxychlorination reaction conditions.Preferred catalyst materials comprise from 5.5 wt % to 14 wt % Cu. They may further comprise an earth alkali metal, such as Mg, and / or a rare earth metal. Preferred compositions contain less than 1 wt % of an alkali metal, which preferably is K

Owner:ALBEMARLE NETHERLANDS BV

Method for preparing load-type zirconium oxide and its using method

The present invention relates to a preparation method of loaded type zirconium oxide catalyst and its application. Its preparation method is characterized by that it utilizes equivoluminal impregnation process or overimpregnation process; the weight percentage content of zirconium oxide in catalyst whole body is 0.1-50%; carrier can be silicon oxide, aluminium oxide, titanium oxide, magnesium oxide, molecular sieve, active carbon or montmorillonite; it uses zirconium oxychloride or zirconyl nitrate to prepare impregnation solution and makes impregnation, then makes drying and roasting processes so as to obtain the invented loaded type zirconium oxide catalyst. Said catalyst can be used in methylcarbonate amine decomposition process process to synthesize methyl carbanilate.

Owner:HEBEI UNIV OF TECH

Preparation method of sulfadoxine

A preparation method of sulfadoxine belongs to the field of sulfanilamide antimicrobial drug preparation. Cyclization reaction comprises the following steps of: firstly pouring a sodium methoxide solution into a reactive pan, then successively adding methanamide and methyl ethyl methoxymalonate, keeping warm, recovering methanol, cooling for crystallization, drying by centrifugation, discharging,and drying to obtain 5-methoxy-4,6-disodium dihydroxypyrimidine; Chlorination reaction comprises the following steps of: firstly putting phosphorus oxychloride into a reaction vessel for heating, adding 5-methoxy-4,6-disodium dihydroxypyrimidine into the reaction vessel to react, decompressing and recovering phosphorus oxychloride until the material is dry, cooling, adding trichloro ethylene withuniformly stirring, putting into a hydrolysis pan for hydrolyzation, collecting a trichloro ethylene layer after standing and delaminating, followed by a neutralization reaction, controlling pH value, washing, removing a water layer, recovering trichloro ethylene, and releasing crystals to obtain 5-methoxy-4,6-dichloropyrimidine. The preparation method provided by the invention can be used to guarantee the product purity, prolong the service life of equipment, avoid the damage to the environment and human body, reduce emission, and save energy, and accords with foreign pharmacopoeia standard requirements.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

Coarse-grained sphere-like zirconium hydroxide with large specific surface area and preparation method of zirconium hydroxide

ActiveCN105502490ALow impurity contentUniform particle sizeZirconium compoundsZirconium hydridePotassium hydroxide

The invention discloses coarse-grained sphere-like zirconium hydroxide with large specific surface area. Zirconium hydroxide adopts a sphere-like structure in shape, the grain size D10 is larger than or equal to 8 mu m, the diameter D50 is larger than or equal to 30 mu m and smaller than or equal to 40 mu m, the diameter D90 is smaller than or equal to 80 mu m, the specific surface area is larger than or equal to 550 m<2> / g, the pore volume is 0.20-0.25 cm<3>, the pore diameter is 2.0-2.4 nm, and the phosphorus / sulfur dynamic adsorption capacity of zirconium hydroxide is larger than 1 mmol / g. The invention further provides a preparation method of coarse-grained sphere-like zirconium hydroxide with the large specific surface area. According to the method, zirconium oxychloride reacts with SO4<2->, a product reacts with potassium hydroxide or sodium hydroxide, and zirconium hydroxide is directly prepared; ammonium ions are avoided effectively, and the prepared product contains few impurities and is uniform in grain size, large in specific surface area and high in activity. With adoption of the coarse-grained sphere-like structure, the product can be applied to phosphorous removal through dynamic adsorption for hemodialysis and can effectively reduce osmotic pressure.

Owner:JIANGXI KINGAN HI TECH

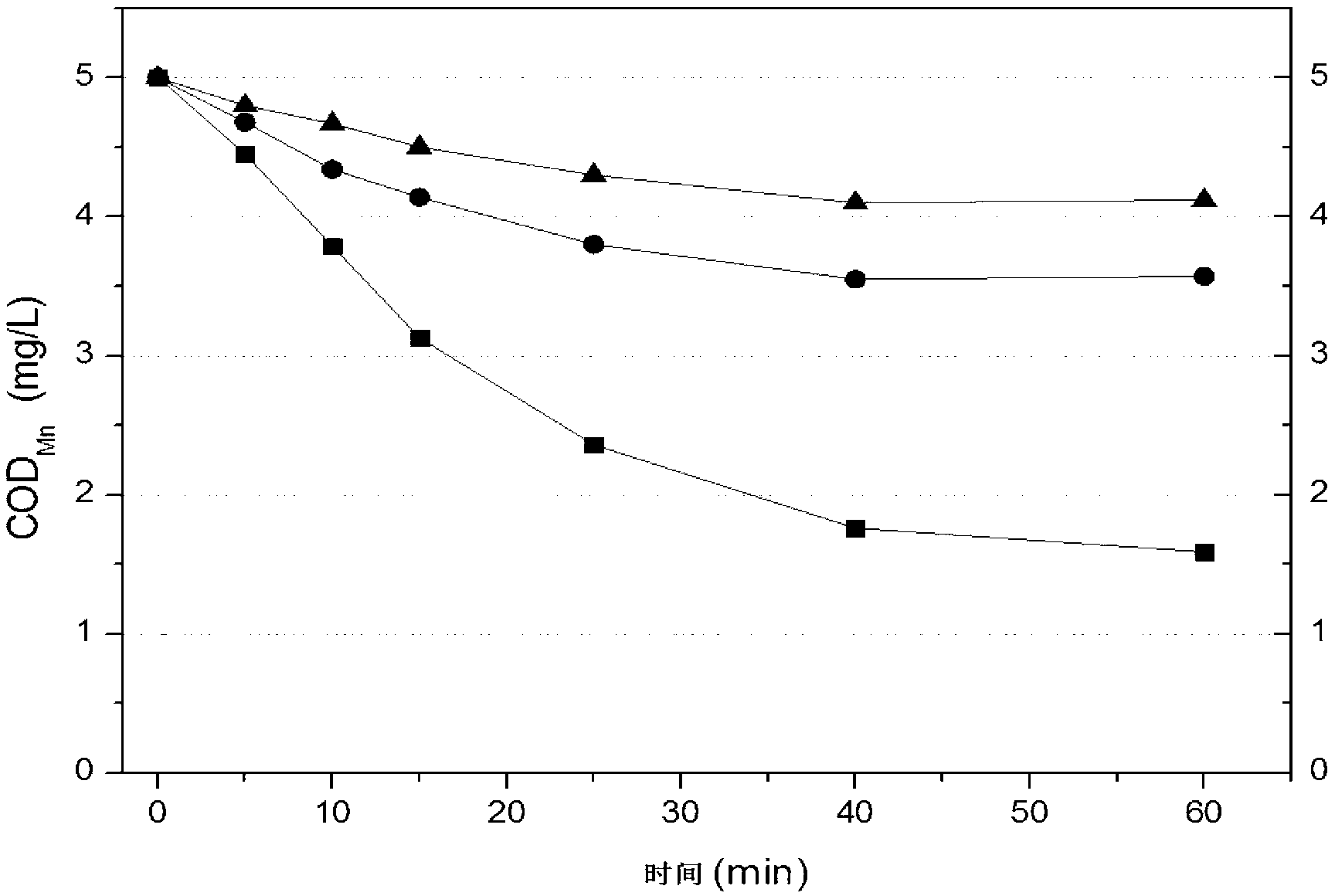

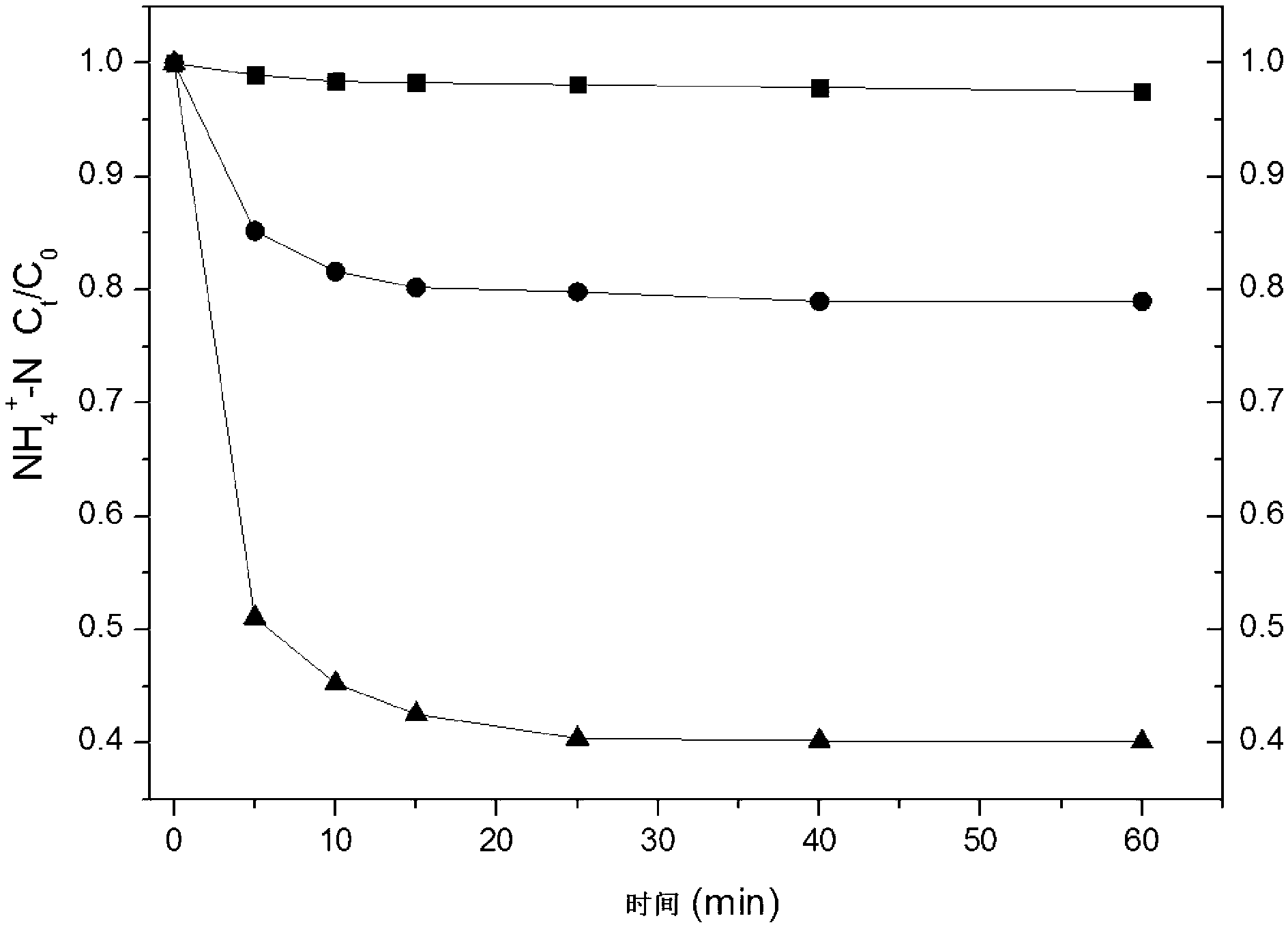

Water treatment method for simultaneously eliminating dissolved organic matters and ammonia nitrogen

InactiveCN103241827AEasy to handleEfficient removalWater/sewage treatment by irradiationWater contaminantsSolubilityEthyl Chloride

The invention discloses a water treatment method for simultaneously eliminating dissolved organic matters and ammonia nitrogen, relates to a water treatment method, and aims at solving the problem that dissolved organic matters and ammonia nitrogen cannot be simultaneously eliminated by using a water treatment method. The water treatment method comprises the following steps of: adding an oxidant into a water sample to be treated, and subsequently carrying out ultraviolet irradiation, and reacting for 2-60min so as to accomplish the water treatment method for simultaneously eliminating the dissolved organic matters and the ammonia nitrogen, wherein the oxidant is hypochlorous acid or sodium hypochlorite, and the addition amount is on the basis that the mass ratio of the chlorine element to the nitrogen element in the water sample to be treated is (0.5-6):1. According to the water treatment method, photocatalysis is coupled with an oxychlorination technique, so that the treatment performance on a composite polluted water body is enhanced, and the dissolved organic matters and the ammonia nitrogen in water are effectively and simultaneously eliminated. The water treatment method is applied to the field of water treatment.

Owner:HARBIN INST OF TECH

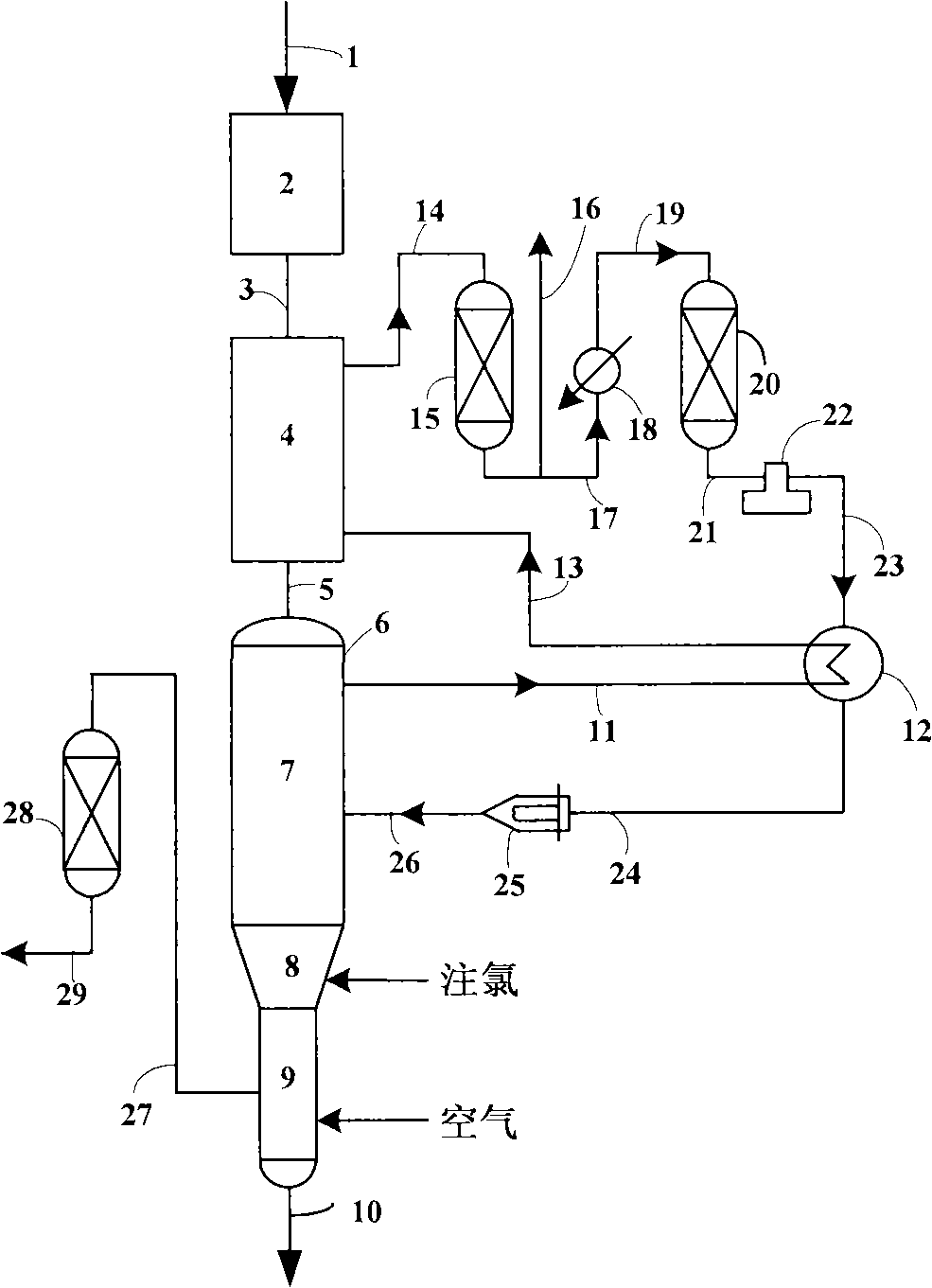

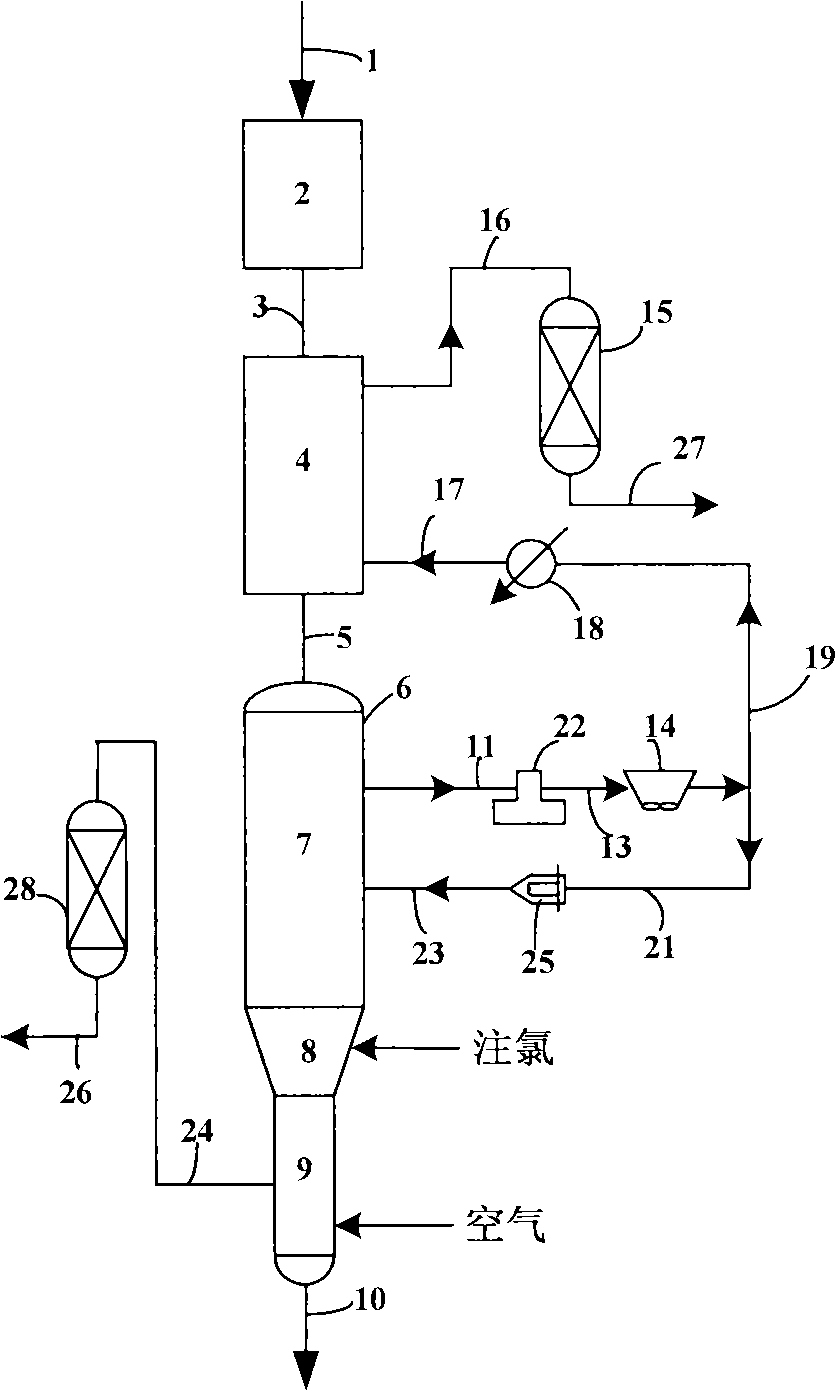

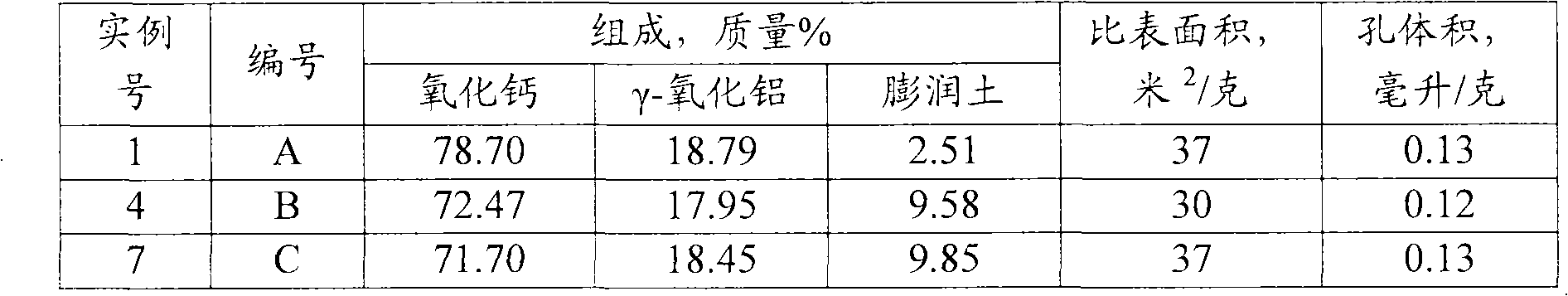

Method for dechlorinating gas discharged from continuous reforming regenerator

ActiveCN101569830AImprove stabilityNot easy to slimeCatalytic naphtha reformingDispersed particle separationSodium BentoniteEnvironmental engineering

The invention relates to a method for dechlorinating gas discharged from a continuous reforming regenerator, comprising the following steps: absorbing chloride in gas discharged from a coke-burning zone and an oxychlorination zone of the continuous reforming regenerator through a bed for catalyst to be regenerated and a bed for solid dechlorinating agent, wherein the bed for catalyst to be regenerated and the bed for solid dechlorinating agent are arranged between a gas-solid separator and a regenerator in sequence; eliminating one part of gas discharged from the bed for catalyst to be regenerated from a system, and returning the other part of the gas to the coke-burning zone of the continuous reforming regenerator; enabling gas discharged from a roasting zone of the continuous reforming regenerator to enter another dechlorinating pot filled with solid dechlorinating agent to absorb chloride therein and eliminating the gas from the system, wherein the solid dechlorinating agent comprises 50-88 percent of alkaline earth oxide by weight, 10-40 percent of alumina by weight and 2-30 percent of bentonite by weight. With the method for dechlorinating gas discharged from a continuous reforming regenerator, the gas discharged from the continuous reforming regenerator can be dechlorinated, and agent to be regenerated can absorb a certain amount of chlorine to reduce the amount of chlorine injected in the regeneration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ion sieve for extracting uranium from water body and preparation method thereof

InactiveCN103894155AOther chemical processesRadioactive decontaminationPhosphomolybdic acidHydroxylamine

The invention provides an ion sieve for extracting uranium from a water body and a preparation method thereof. The ion sieve is prepared from pyrophosphate, molybdate, zirconium oxychloride, hexadecyl trimethyl ammonium bromide, acrylonitrile, and hydroxylamine hydrochloride. The preparation method comprises the steps: preparing a hydrogen ion exchanger of zirconyl-molybdopyrophosphate polyoxometalate by using zirconium oxychloride, the molybdate and the pyrophosphate, introducing a defined amount of uranium ions to the hydrogen ion exchanger, extracting through immobilizing the uranium ions, and baking for forming; then radiating and activating, making a product obtained by radiating and activating react with hexadecyl trimethyl ammonium bromide for performing organic modification, and then adding acrylonitrile and hydroxylamine hydrochloride for performing amine oximation; finally, performing solid-liquid separation, and then performing steps of high-temperature sintering, cooling and grinding, and the like to obtain the ion sieve for extracting uranium from the water body. The prepared ion sieve has a most suitable crystal structure of receiving the uranium ions, shows an efficient selective effect, and has a chelation function and a good selectivity to the uranium ions.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

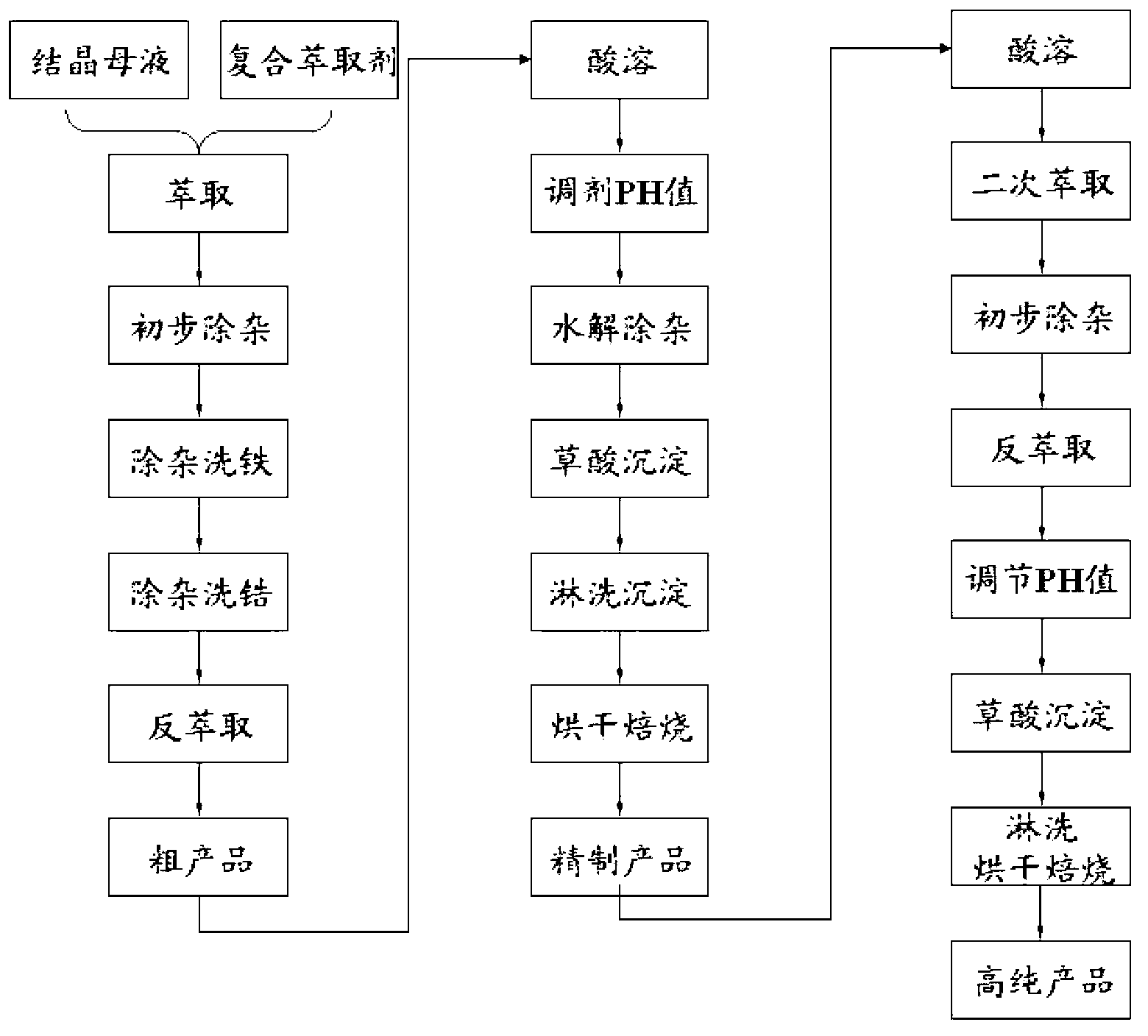

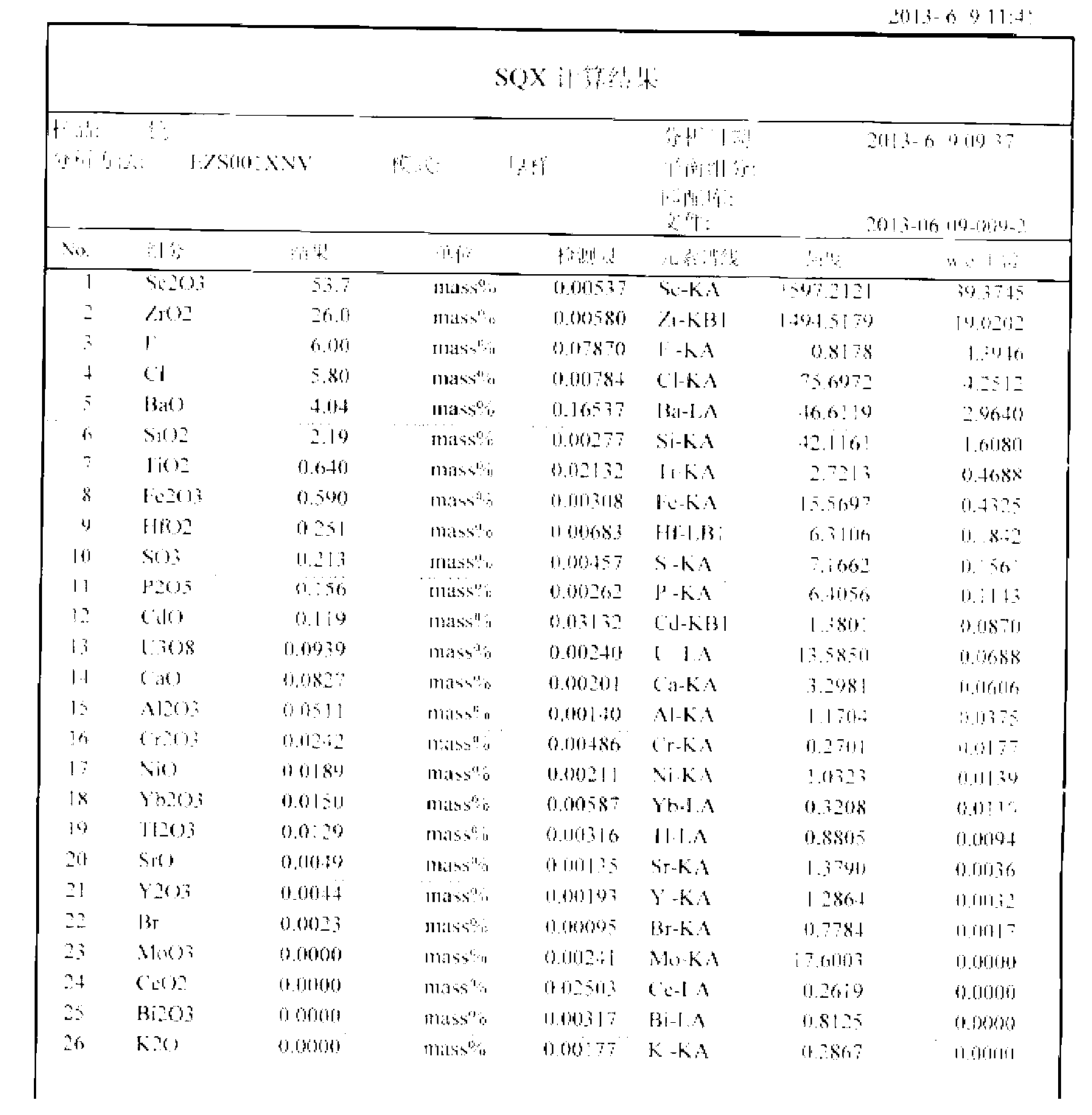

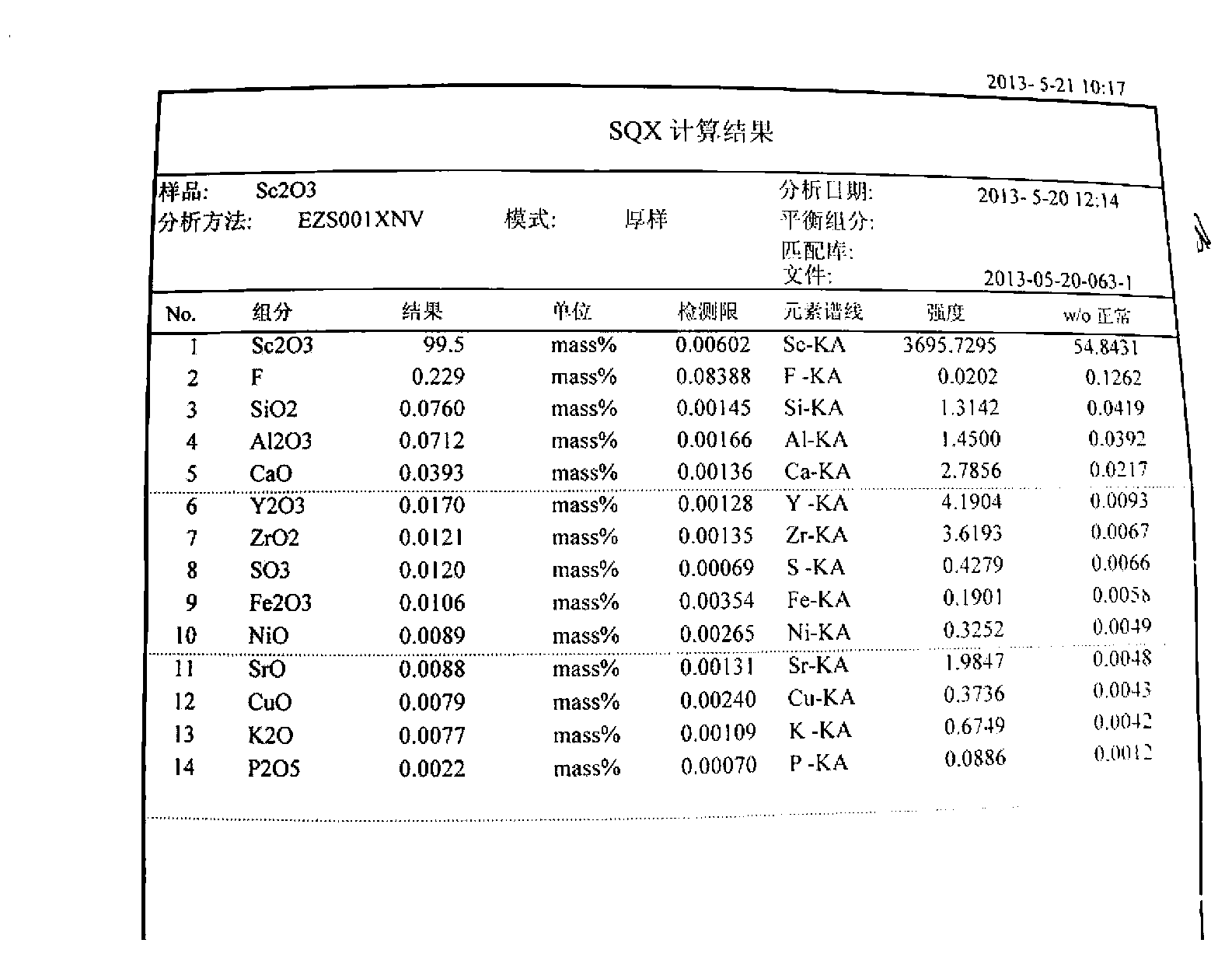

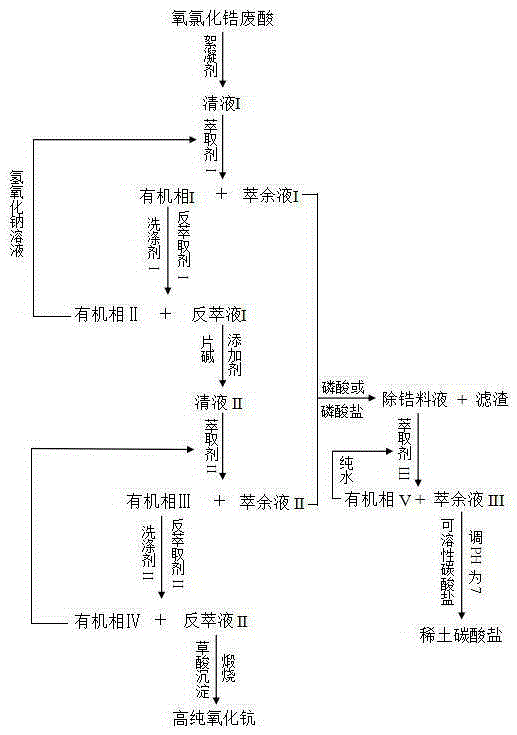

Method for extracting scandium oxide from zirconium oxychloride waste acid

ActiveCN103318940ALiquid solutions solvent extractionRare earth metal compoundsZirconium oxychlorideScandium oxide

The invention provides a method for extracting scandium oxide from zirconium oxychloride waste acid. The method comprises the steps of: a) extracting zirconium oxychloride waste acid by utilizing an extractant I to obtain an organic phase I, wherein the extractant I comprises P204, tributyl phosphate, a modifier and a diluting agent I; b) washing the organic phase I by using a washing liquid I, to obtain an organic phase II, wherein the washing liquid I is water or a diluted acid solution; c) washing the organic phase II by utilizing washing liquid II to obtain an organic phase III, wherein the washing liquid II is a mixed solution of hydrogen peroxide and diluted acid; d) washing the organic phase III by utilizing a washing liquid III to obtain an organic phase IV; and 3) backextracting the organic phase IV by taking an alkaline solution as a back-extractant, filtering and roasting a water phase to obtain scandium oxide. Compared with the prior art, the method is lower in cost and higher in recovery rate by taking P204 and tributyl phosphate as extractants.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of zirconium oxide structural ceramics

The invention relates to a preparation method of zirconium oxide structural ceramics, which comprises the following steps: mixing yttrium-oxide-dope zirconium oxide ceramic powder and a binding agent, wherein the binding agent accounts for 10-25 wt% of the mixture; blending the mixture; and carrying out CIM injection molding and vacuum hot-pressed sintering to obtain the zirconium oxide structural ceramics of which the density is up to 6.05-6.1g / cm<3>, the hardness is up to 1050-1400HV and the heat conductivity coefficient is up to 2.3-3W / (m.k). The yttrium-oxide-dope zirconium oxide ceramic powder is prepared by the following steps: carrying out a chemical coprecipitation method to obtain a precipitate, wherein zirconium oxychloride and yttrium nitrate are used as the raw materials, sodium hydroxide is used as a precipitant, and ammonium citrate is used as a dispersant; and washing the precipitate, drying, and presintering to obtain the yttrium-oxide-dope zirconium oxide ceramic powder.

Owner:JIANGXI UNIV OF SCI & TECH

Mercury chloride catalyst regenerated by oxychlorination method

InactiveCN101288850AEliminate poisonEliminate carbon depositsPhysical/chemical process catalystsCyclic processAdditional values

The invention discloses a chlorine-oxidation method for regenerating mercuric chloride catalyst, comprising the steps as follows: (1) screening; (2) activation reaction: 1000kg of screened waste mercuric chloride catalyst which complies with the requirement of particle size (the content of mercuric chloride is 3.0-4.5%) is taken as benchmark, arranged in an activator and prepared as dipping solution in a material distribution container I. The dipping solution is pumped into the activator, dipped and activated for 30 minutes under the conditions of the temperature of 15-40 DEG C and 0.1MPa of normal pressure, arranged in the material distribution container I, and pumped into the activator after 1-3kg of chlorine is pumped into the dipping solution, so as to complete a dipping and circulation process; the dipping and circulation process is repeated till that the colour of the dipping solution turns from green to pale brownish yellow; the dipping solution is then arranged in the material distribution container I and taken as circulation motor liquor used for the next material distribution; (3) dipping and adsorbing; (4) drying and cooling. The method of the invention has the advantages of short process flow, lower energy consumption, higher recovery and utilization additional value and utilization ratio of effective component, lower production cost and being more beneficial to environmental protection.

Owner:WANSHAN HONGJING MERCURY

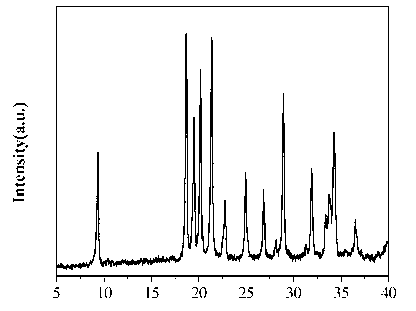

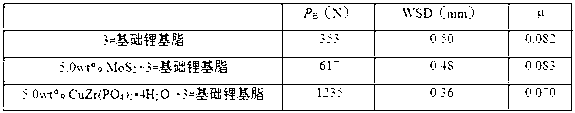

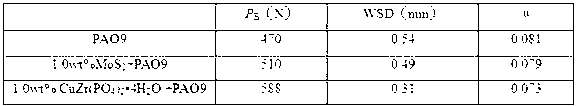

Preparation method and application method of CuZr(PO4)2*4H2O material

InactiveCN103072965AReduce pollutionThe synthesis process is simpleAdditivesPhosphorus compoundsO-Phosphoric AcidCopper nitrate

The invention discloses a preparation method and an application method of a CuZr(PO4)2*4H2O material, and belongs to the field of inorganic functional materials. The preparation method and the application method are characterized in that the CuZr(PO4)2*4H2O material is directly prepared by a hydrothermal synthesis method, and further applied to the field of lubrication. The preparation method comprises the steps that one of a zirconium oxychloride solution and a zirconium nitrate solution with a molar concentration of 1.0-4.0mol / L is mixed with one of a copper chloride solution, a copper acetate solution and a copper nitrate solution with a molar concentration of 1.0-4.0mol / L on the condition that a molar ratio of Cu to Zr is 0.8-3.0, and stirred uniformly; then a pH value of a system is adjusted to be 0.5-5 with 85% of phosphoric acid solution by mass percent; stirring is conducted for 10-20min; blue gel is obtained, sealed in a polytetrafluoroethylene lining reaction kettle, and crystallized in a drying oven at 100-220 DEG C for 12-200h; a product is washed to be neutral with distilled water by a centrifuge, and dried at a room temperature; and the CuZr(PO4)2*4H2O material is obtained. The material is directly added to lubricant base oil to serve as a lubricant additive in an ultrasonic, heating and stirring, or three-roller grinding mode, and has good bearing capability, abrasion resistance and antifriction capability.

Owner:TAIYUAN UNIV OF TECH

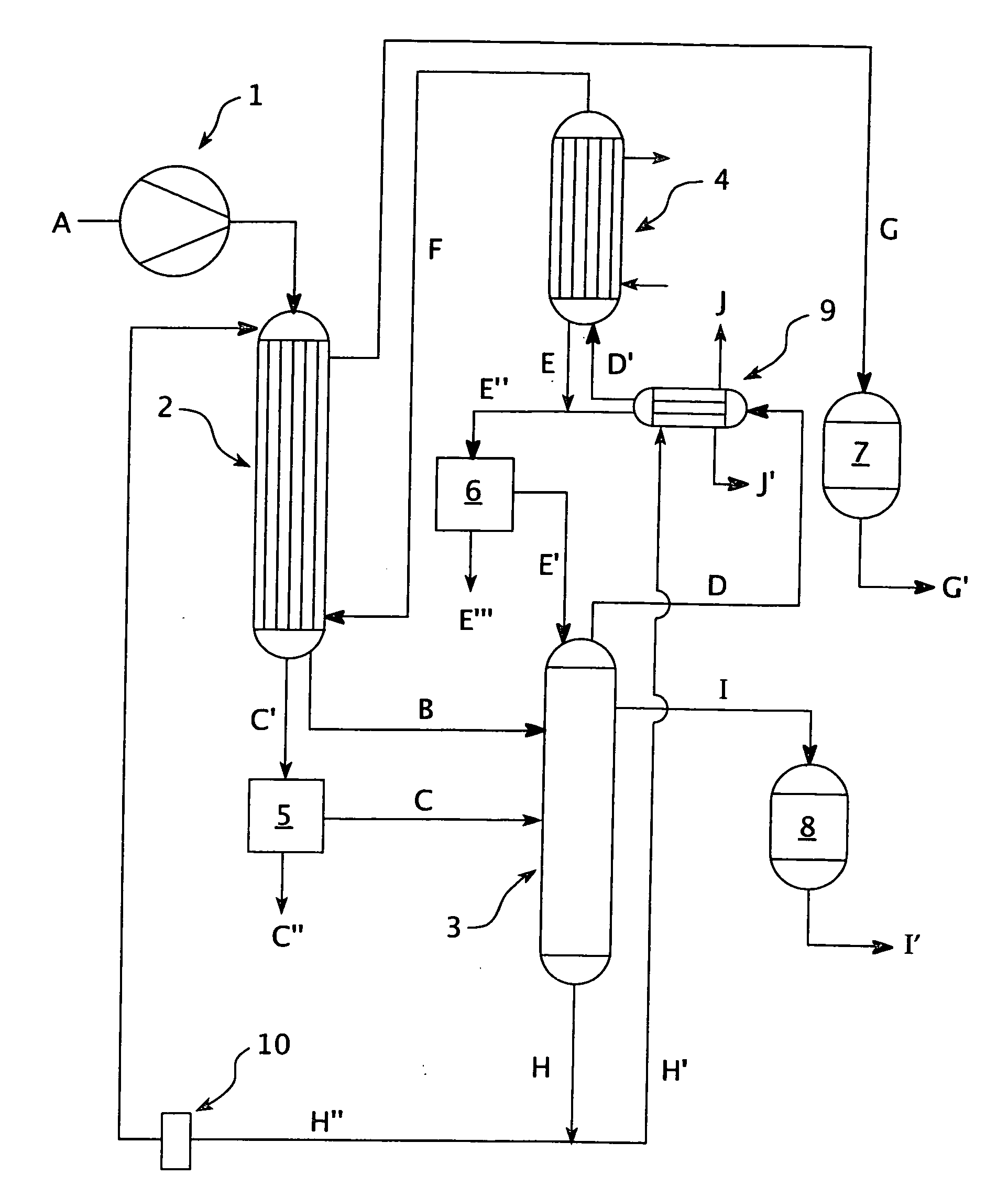

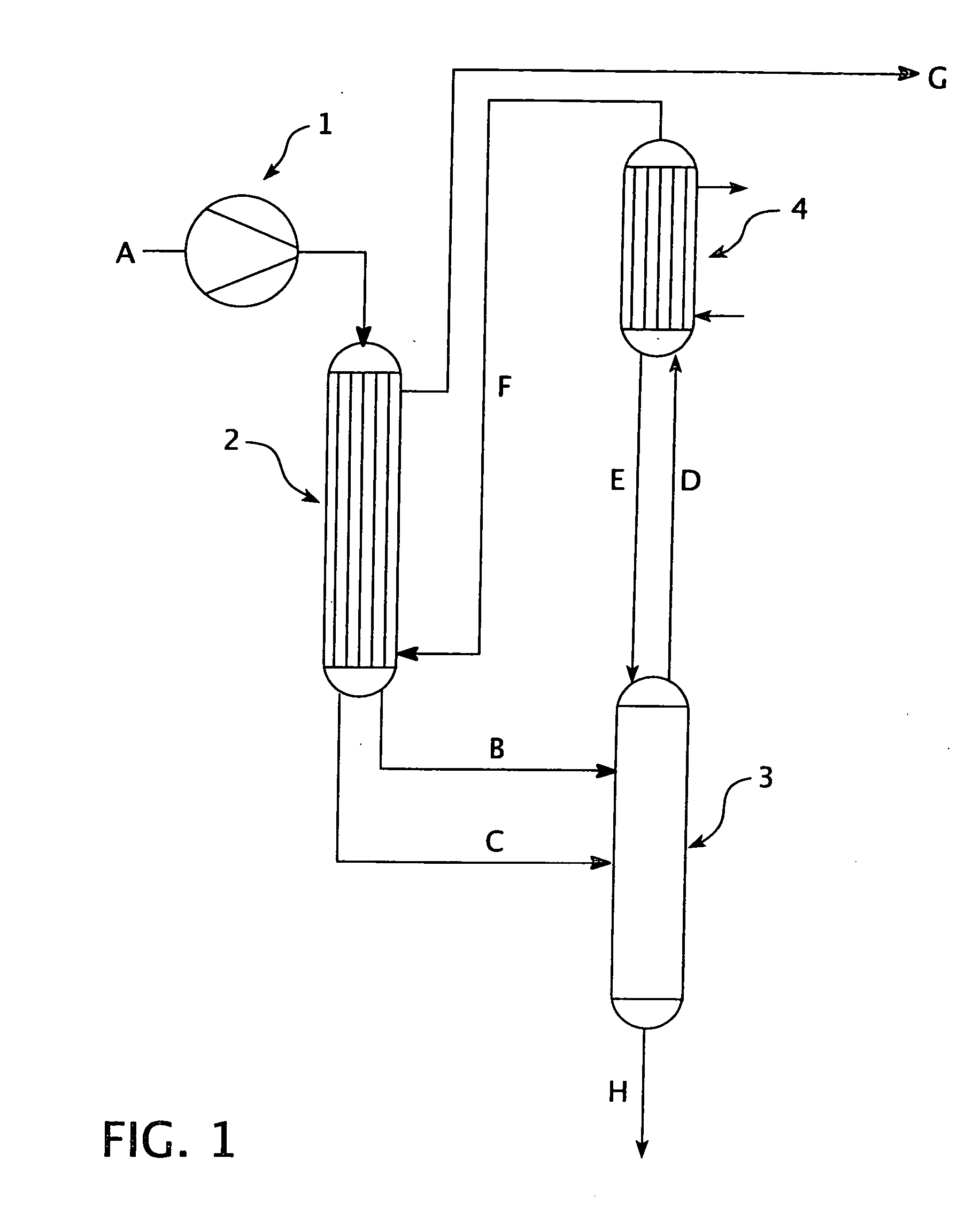

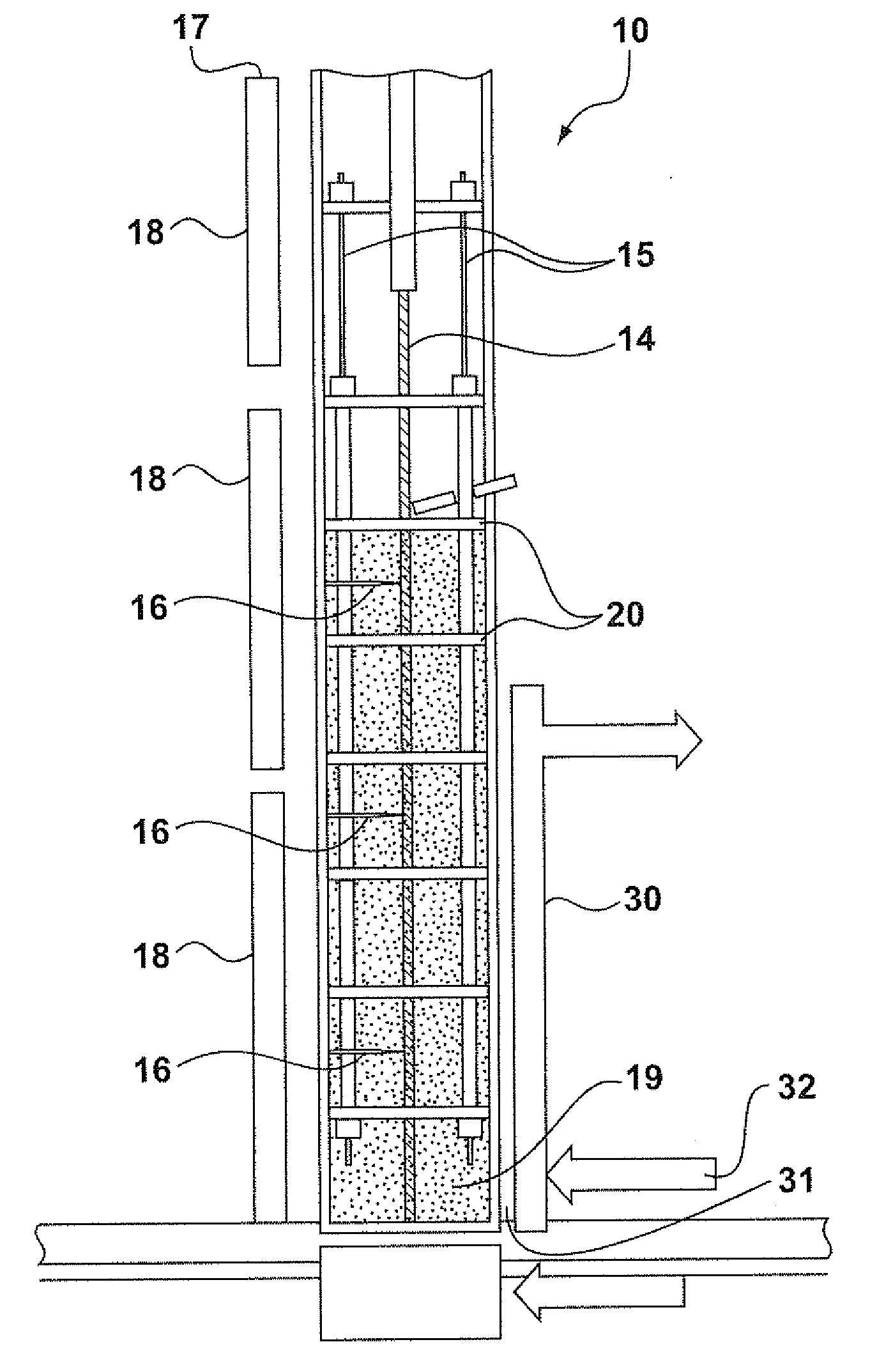

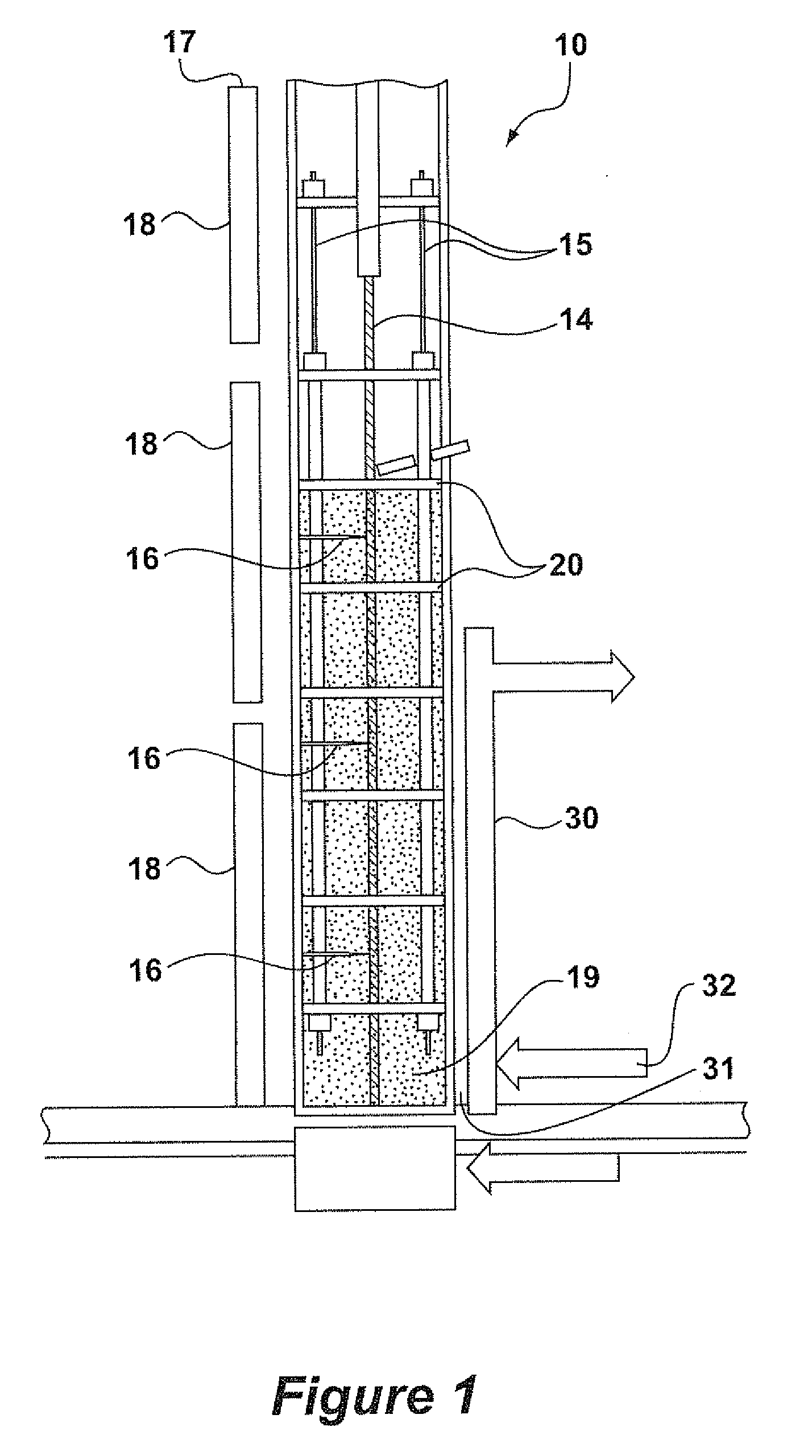

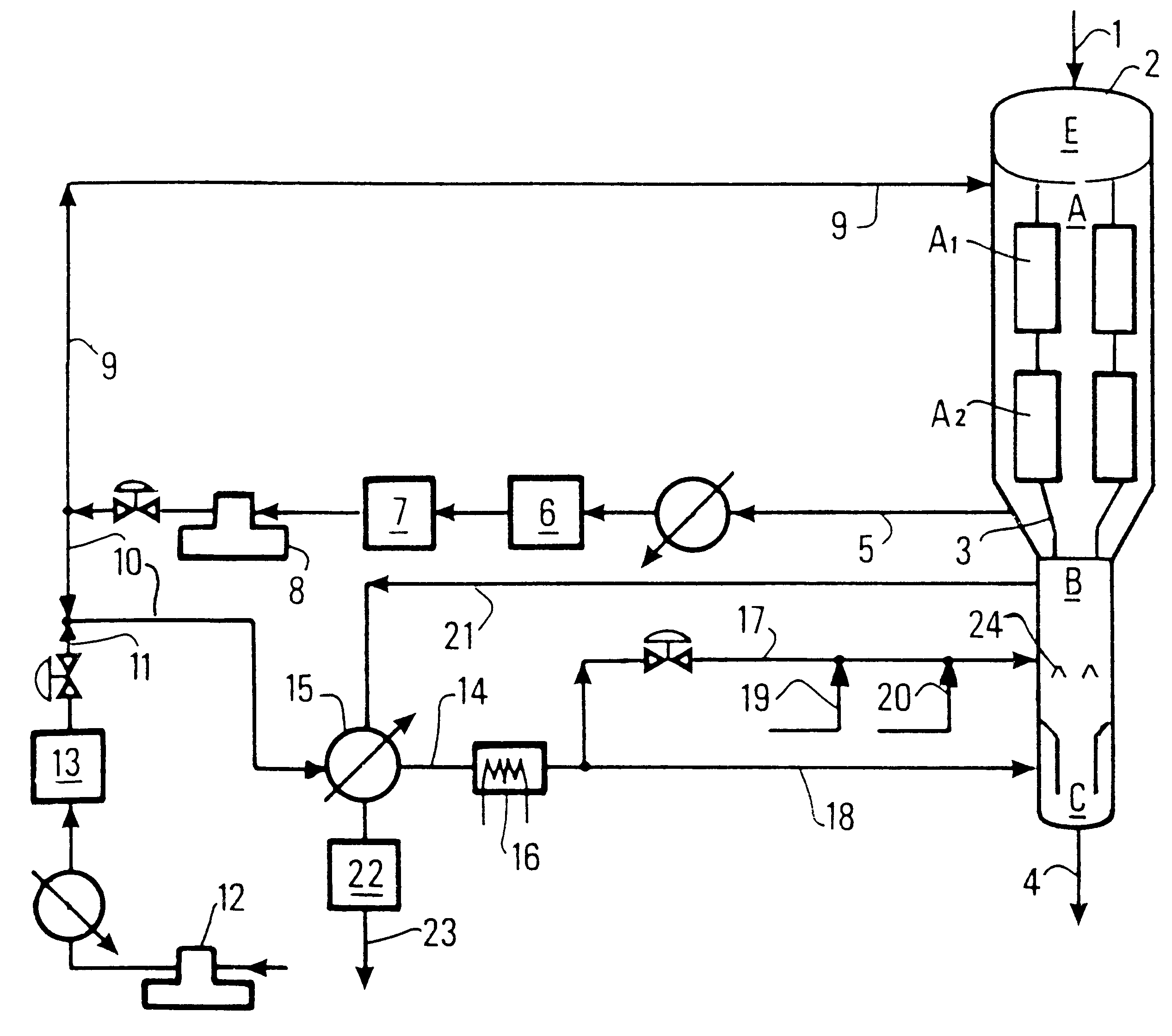

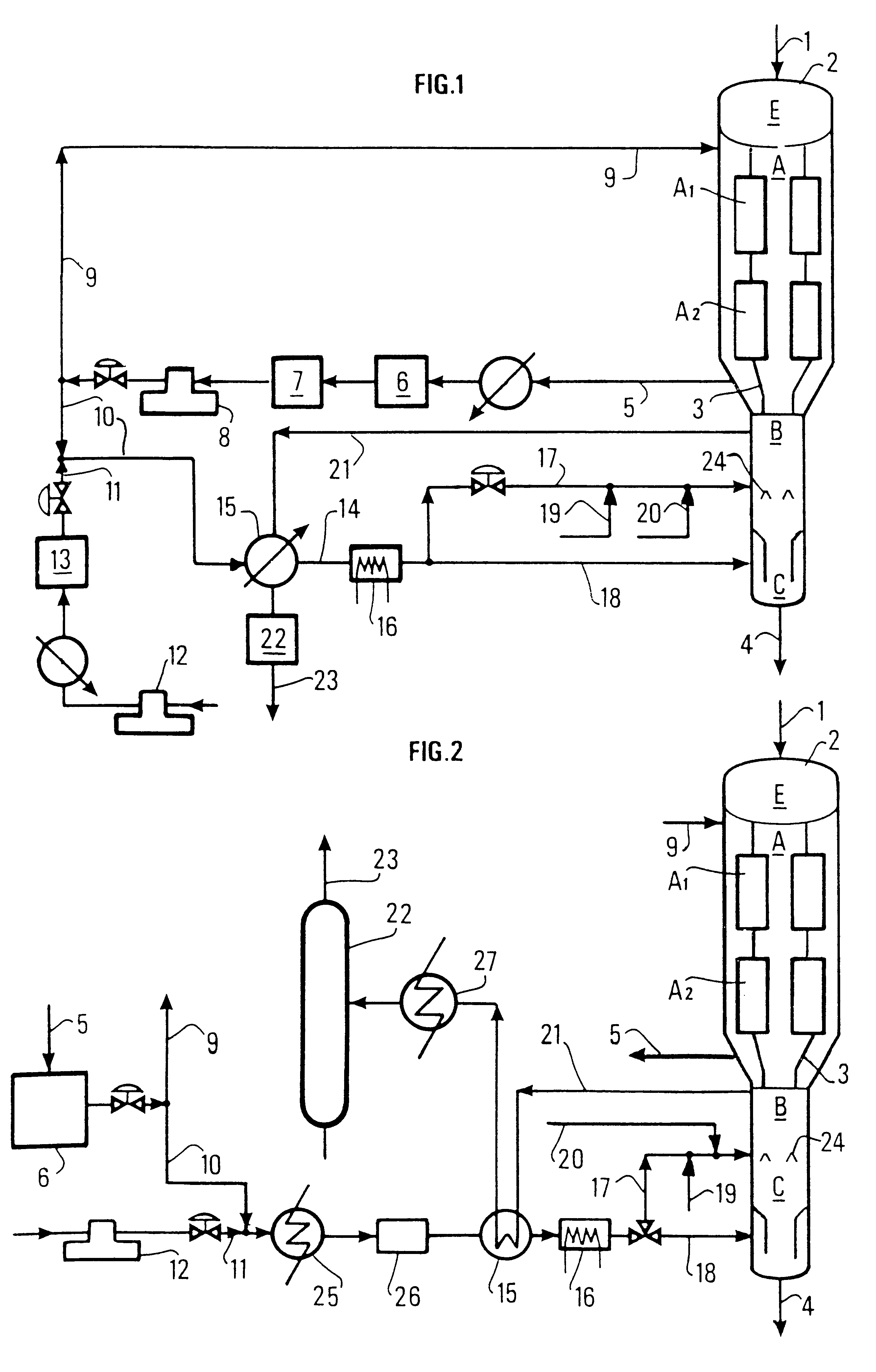

Vessel for regenerating a catalyst for the production of aromatic compounds or for reforming, with improved oxychlorination

A vessel for regenerating a catalyst for reforming or for aromatic compound production comprising a support, at least one noble metal and chlorine, the catalyst being in the form of a moving bed, said vessel comprising at least one combustion zone (A) provided with at least one conduit (9) for introducing oxygen gas and at least one conduit (5) for evacuating gasses from the combustion step, at least one oxychlorination zone (B) and at least one calcining zone (C) provided with at least one conduit (18) for introducing an oxygen-containing gas, said vessel also comprising at least one conduit (1) for introducing catalyst into the vessel, at least one conduit (3) for introducing catalyst from the combustion zone into the following oxychlorination zone (B), and at least one conduit (21) for evacuating gases from the oxychlorination zone comprising at least one means (20) for introducing least one chlorinating agent and at least one means (19) for introducing water and at least one means (17) for introducing an oxygen containing gas.

Owner:INST FR DU PETROLE

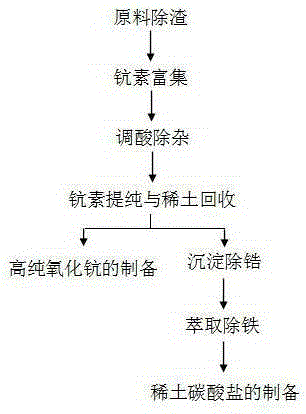

Method for extracting scandium and other rare earth from zirconium oxychloride acid pickle

ActiveCN105256143AReduce lossesRealize impurity removal and purificationProcess efficiency improvementOXALIC ACID DIHYDRATEHydrometallurgy

The invention discloses a method for extracting scandium and other rare earth from zirconium oxychloride acid pickle. The method comprises the following steps that (1), the zirconium oxychloride acid pickle is subjected to floculation adsorption slag removing, scandium element enrichment, acid modulation and impurity removing, scandium element purification and rare earth recycling, and high-purity scandium strip liquor and extraction raffinate containing rare earth are obtained; (2), the high-purity scandium strip liquor is subjected to oxalic acid precipitation and high-temperature calcination to prepare high-purity scandium oxide; and (3), the extraction raffinate containing the rare earth is subjected to precipitation zirconium removing, extraction iron removing and carbonate adding reactions to obtain rare earth carbonate. The method belongs to the technical field of hydrometallurgy and waste acid treatment and comprehensive utilization. According to the method, the high-purity scandium oxide powder with the grade being above 99.9% can be obtained; and meanwhile, the other rare earth is recycled in a manner of rare earth carbonate enriched products, the total recycling rate of the rare earth is larger than 80%, the investment is small, the manual requirement is small, the handling capacity is large, and industrial continuous production can be achieved.

Owner:全南晶环科技有限责任公司 +1

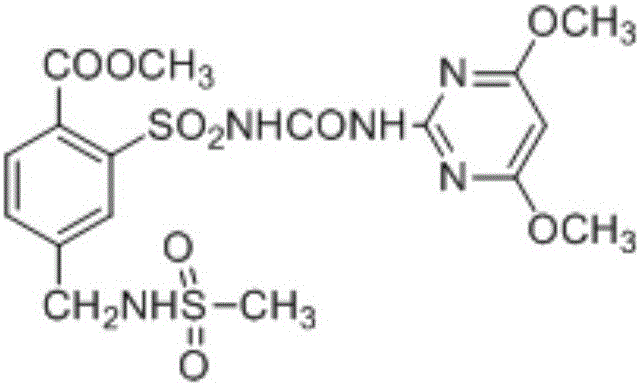

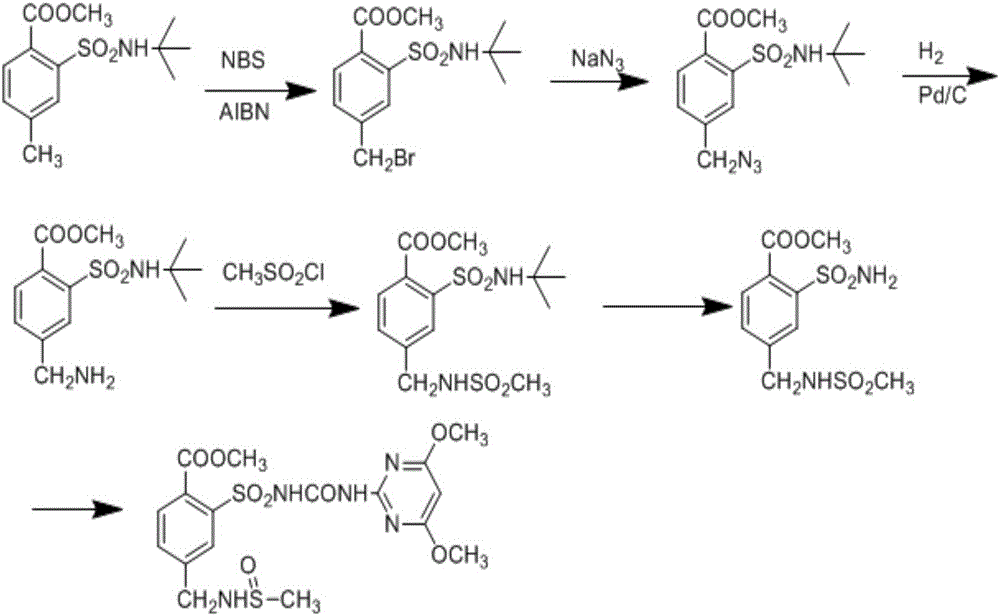

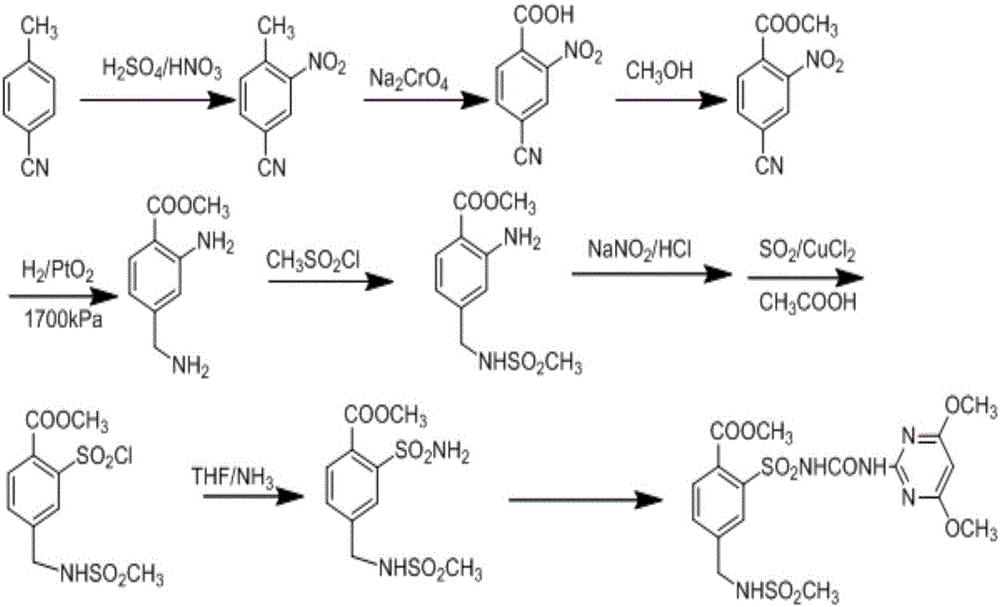

Preparation method of mesosulfuron

ActiveCN106243046ARaw materials are cheap and easy to getEasy to operateOrganic chemistrySynthesis methodsNitrogen

The invention discloses a synthesis method of mesosulfuron, and belongs to the fields of pesticide chemistry. The synthesis method is characterized in that mesosulfuron is prepared from 4-chloro-2-aminobenzoic acid through esterification, diazotization, sulfur dioxide introduction, oxychlorination, ammonification cyclization, nitrogen methylation, cyanidation, reduction, ring opening, mesylation and condensation. The method for synthesizing mesosulfuron has the advantages of cheap and easily available raw material, simplicity in operation, mild conditions, low device requirements, high yield, suitableness for industrial production, and strong practicality.

Owner:NANJING UNIV OF TECH

Catalysts for oxychlorination of ethylene to 1,2-dichlorethane

InactiveUS20060129008A1Satisfactory performanceSolution to short lifeHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsCopper atomEthane Dichloride

Catalysts for oxychlorination of ethylene to 1,2-dichlorethane, comprising compounds of copper and magnesium supported on gamma alumina, wherein the copper, expressed as metal, is present in a quantity from 7 to 12% by weight and the Mg / Cu ratio is from 0.05 to 1, wherein the distribution of copper in the catalyst particle is such that the ratio X / Y between the concentration of the copper atoms on the surface given by the Al / Cu ratio (X) on the surface (20-30 nm layer) and the concentration given by the Al / Cu ratio (Y) referred to the entire particle is greater than 1.3 and can reach 3.

Owner:SUD CHEM CATALYSTS ITAL SRL

Method for preparing nanocrystalline zirconium carbide powder

The invention relates to a method for preparing nanocrystalline zirconium carbide powder, which comprises the steps that zirconium oxychloride, ammonia water and cane sugar are used as raw materials; the zirconium oxychloride and the cane sugar are dissolved in the mixed solution of absolute ethyl alcohol and water according to a certain proportion; polyethylene glycol 6000 serving as a dispersing agent is added into the mixed solution, and then the ammonia water is dropwise added into the mixed solution for reaction to obtain zirconium hydroxide precipitation; the dried powder is pressed into green bodies; and the green bodies are baked in high-purity argon atmosphere at high temperature of 1500-1650 DEG C and then fully ground to obtain the nanocrystalline zirconium carbide powder. The method for preparing the nanocrystalline zirconium carbide powder has the advantages that the cost of the raw materials is low, the process is simple, the purity of the product is high, and the size of crystalline grains is uniform. The method for preparing the nanocrystalline zirconium carbide powder is favorable to large-scale production.

Owner:SHANGHAI UNIV

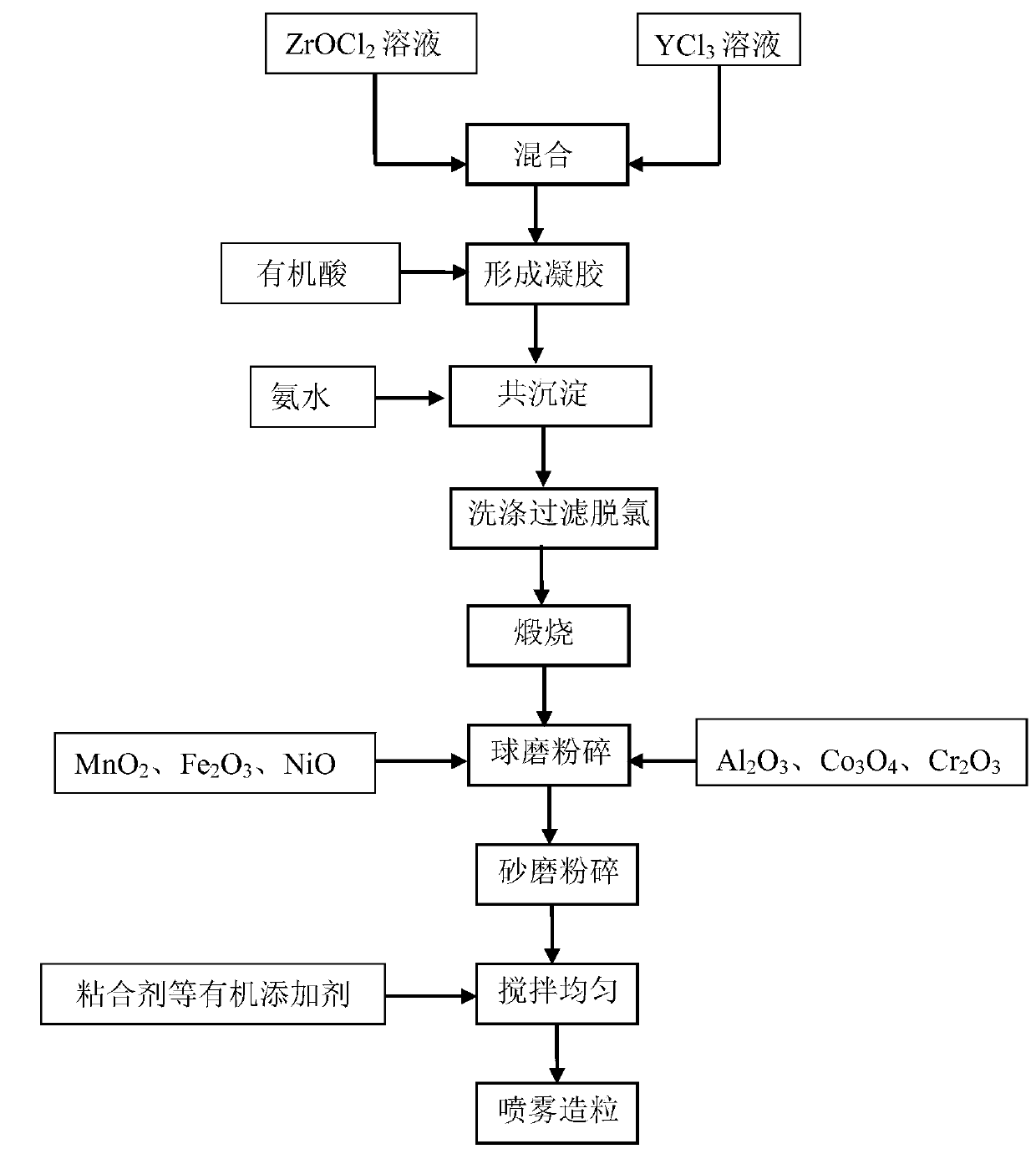

Preparation method of black yttrium-stabilized zirconium oxide powder

ActiveCN111204802AImprove stabilityUniform particle size distributionZirconium oxidesAdhesiveZirconium oxychloride

The invention belongs to the technical field of inorganic new materials, and particularly relates to a preparation method of black yttrium-stabilized zirconium oxide powder. The preparation method comprises the steps: mixing a zirconium oxychloride solution and a yttrium trichloride solution in a proportion; adding an organic acid to generate a gel, adding an ammonia water solution to neutralize and precipitate, washing, filtering and dechlorinating, calcining an obtained filter cake to obtain a precursor powder, adding a coloring agent and a binding agent, ball-milling, sanding and crushing,adding an adhesive and a release agent, uniformly mixing, spraying, granulating and drying to obtain the yttrium-stabilized zirconium oxide powder. The invention relates to the preparation method of black yttrium-stabilized zirconium oxide powder. The process is simple, the yield is high, the produced powder is good in stability, uniform in particle size distribution, good in flowability and stable in shrinkage rate; the sintering temperature is 1350 DEG C, which is 100 DEG C lower than the temperature of common zirconium oxide ceramic production, moulding is convenient, the blank strength ishigh, the processability is good, and black ceramic products prepared from the powder has the advantages of high strength, good toughness, good stability and the like.

Owner:长裕控股集团股份有限公司

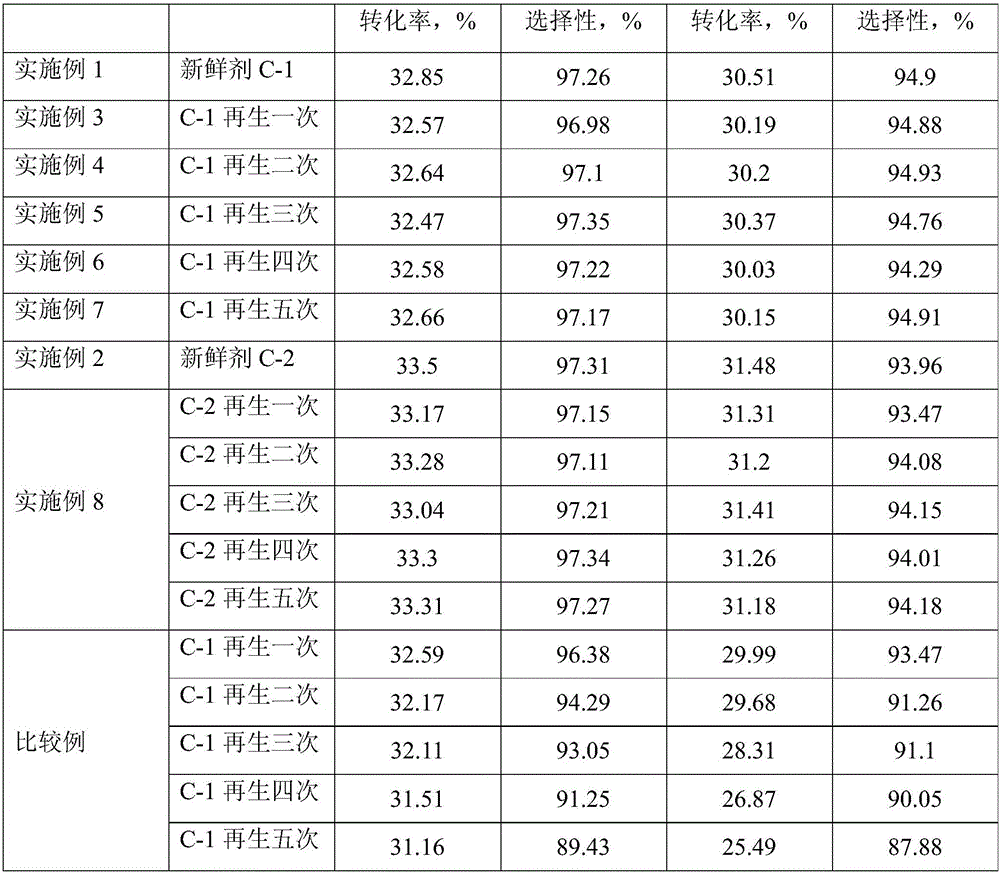

Regeneration method of paraffin dehydrogenation catalyst

InactiveCN105797788AAvoid gatheringReduce acidity changesCatalyst regeneration/reactivationHydrocarbonsWater vaporAir treatment

The invention discloses a regeneration method of a paraffin dehydrogenation catalyst. The method includes the following steps of firstly, carbon-burning an inactivated dehydrogenation catalyst in an oxygen-containing atmosphere; secondly, conducting oxychlorination treatment on the catalyst carbon-burned in the first step; thirdly, conducting vapor dechlorination treatment on the catalyst subjected to oxychlorination treatment in the second step; fourthly, conducting alkaline metal promoter compensation treatment on the catalyst subjected to vapor treatment in the third step; fifthly, conducting high-temperature air treatment on the catalyst obtained in the fourth step to obtain the regenerated catalyst. By means of the method, alkali metal lost in the reaction process and the regeneration process can be effectively compensated for, the dehydrogenation activity of the regenerated catalyst can reach the level of a fresh catalyst, operation is easy, and the service life of the catalyst is prolonged.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com