Method for purifying byproduct hydrogen chloride in fluorinated alkane production

A technology of fluorinated alkane and purification method, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, chemical instruments and methods, etc., can solve the problems of catalyst deactivation, poisoning, etc., to increase added value, expand application scope, and significantly economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

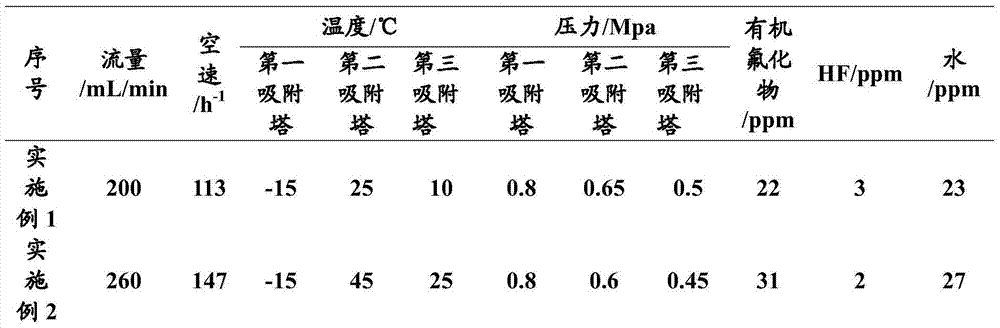

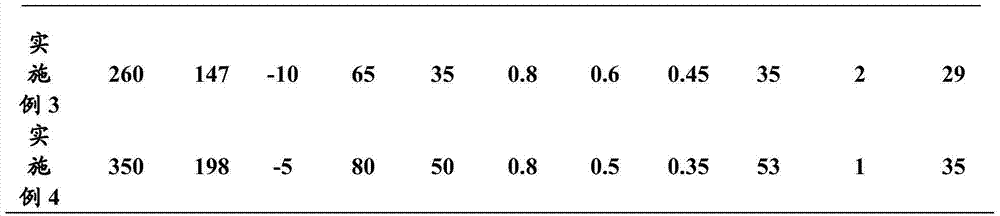

Embodiment 1 to 4

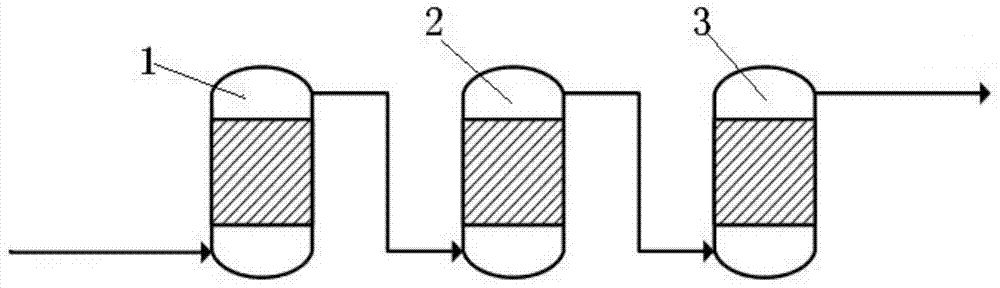

[0031] Connect the first adsorption tower 1, the second adsorption tower 2, and the third adsorption tower 3 with the specifications of DN15mm×600mm in series, and the specific surface area of 100mL filled in the three adsorption towers is 1100m 2 / g of Norit GCN48 activated carbon, the specific surface area of 100mL is greater than 200m 2 / g of granular activated alumina, 40mL of 3A molecular sieve + 60mL of silica gel adsorbent.

[0032] Such as figure 1As shown, in the experimental process, the by-products in the device for producing HFC-134a are sequentially passed through the first adsorption tower 1, the second adsorption tower 2, and the third adsorption tower 3 from bottom to top. After the adsorption tower 3, samples are taken to analyze the content of each impurity. The flow rate of the by-products in the device for producing HFC-134a into the adsorption towers, the adsorption pressure in each adsorption tower, the adsorption temperature and the operating space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com