Method for preparing load-type zirconium oxide and its using method

An application method and catalyst technology are applied in the field of preparation of supported zirconia catalysts, which can solve the problems of unrecyclable homogeneous catalysts, difficult product separation, unfriendly environment, etc., and achieve easy regeneration and reuse, environmental friendliness and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

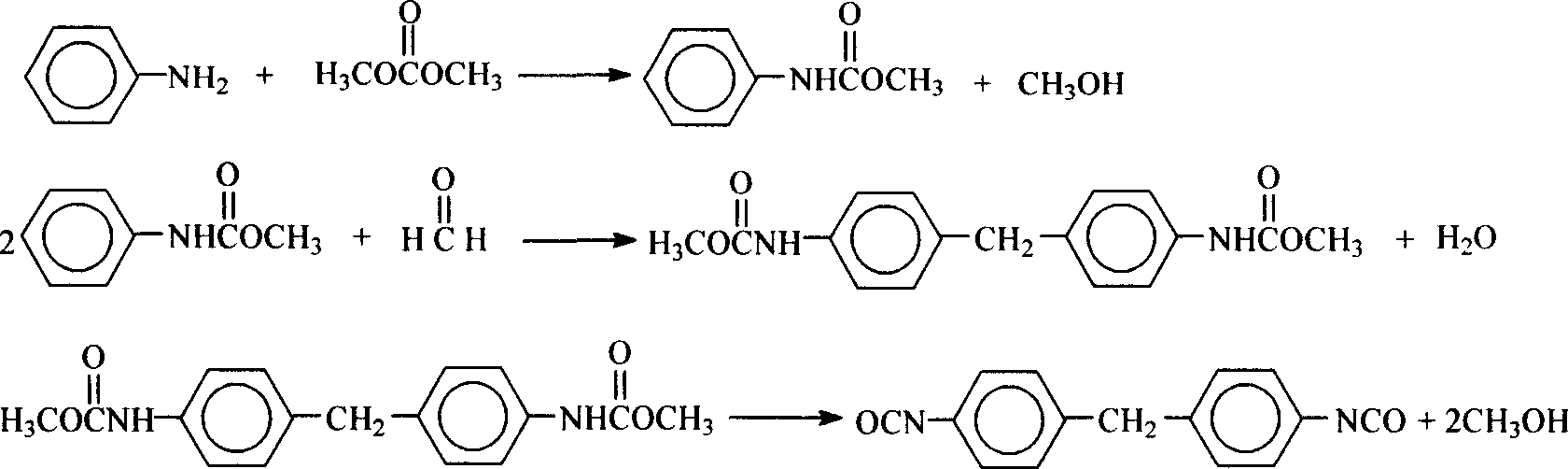

Method used

Image

Examples

Embodiment 1

[0038] (1) The weight percent content of selected zirconia in the whole catalyst is 5%;

[0039] (2) Weigh 5 grams of SiO 2, use deionized water to determine the volume of solution required for equal-volume impregnation to be 10 milliliters;

[0040] (3) Weigh 0.69 grams of ZrOCl 2 ·8H 2 O was dissolved in 10 ml of deionized water to prepare an impregnating solution;

[0041] (4) Add the impregnation solution prepared in step (3) dropwise to 5 grams of SiO taken by (2) 2 On, equal-volume impregnation for 24 hours, and vacuum-dried the impregnated carrier in a constant temperature water bath at 60°C for 2 hours;

[0042] (5) Calcining the impregnated and dried support obtained in step (4) in an air atmosphere at 500° C. in a muffle furnace for 5 hours to obtain the required supported zirconia catalyst of the present invention.

Embodiment 2

[0044] (1) The weight percent content of selected zirconia in the whole catalyst is 3%;

[0045] (2) Take 5 grams of SiO 2 , use deionized water to determine the volume of solution required for equal-volume impregnation to be 10 milliliters;

[0046] (3) Weigh 2 grams of ZrOCl 2 ·8H 2 O was dissolved in 50 ml of deionized water to prepare an impregnating solution;

[0047] (4) with 5 grams of SiO that (2) step claims 2 Place in the impregnating solution prepared in step (3), heat to 90°C, impregnate excessively for 24 hours, obtain the impregnated carrier by vacuum filtration, and vacuum-dry the impregnated carrier at 60°C for 3 hours;

[0048] (5) Calcining the impregnated and dried support obtained in step (4) in an air atmosphere at 500° C. in a muffle furnace for 5 hours to obtain the required supported zirconia catalyst of the present invention.

Embodiment 3-5

[0050] The preparation method is the same as in Example 1, except that the calcination temperatures in step (5) are changed to 400°C, 600°C, and 700°C, respectively, to prepare the respective required supported zirconia catalysts of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com