Preparation method of black yttrium-stabilized zirconium oxide powder

A technology of yttrium-stabilized zirconia and zirconia, which is applied in the direction of zirconia, can solve the problems of difficult procurement of raw materials and high energy consumption in the preparation process, and achieve the effects of no surface defects, good processability, and soft and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

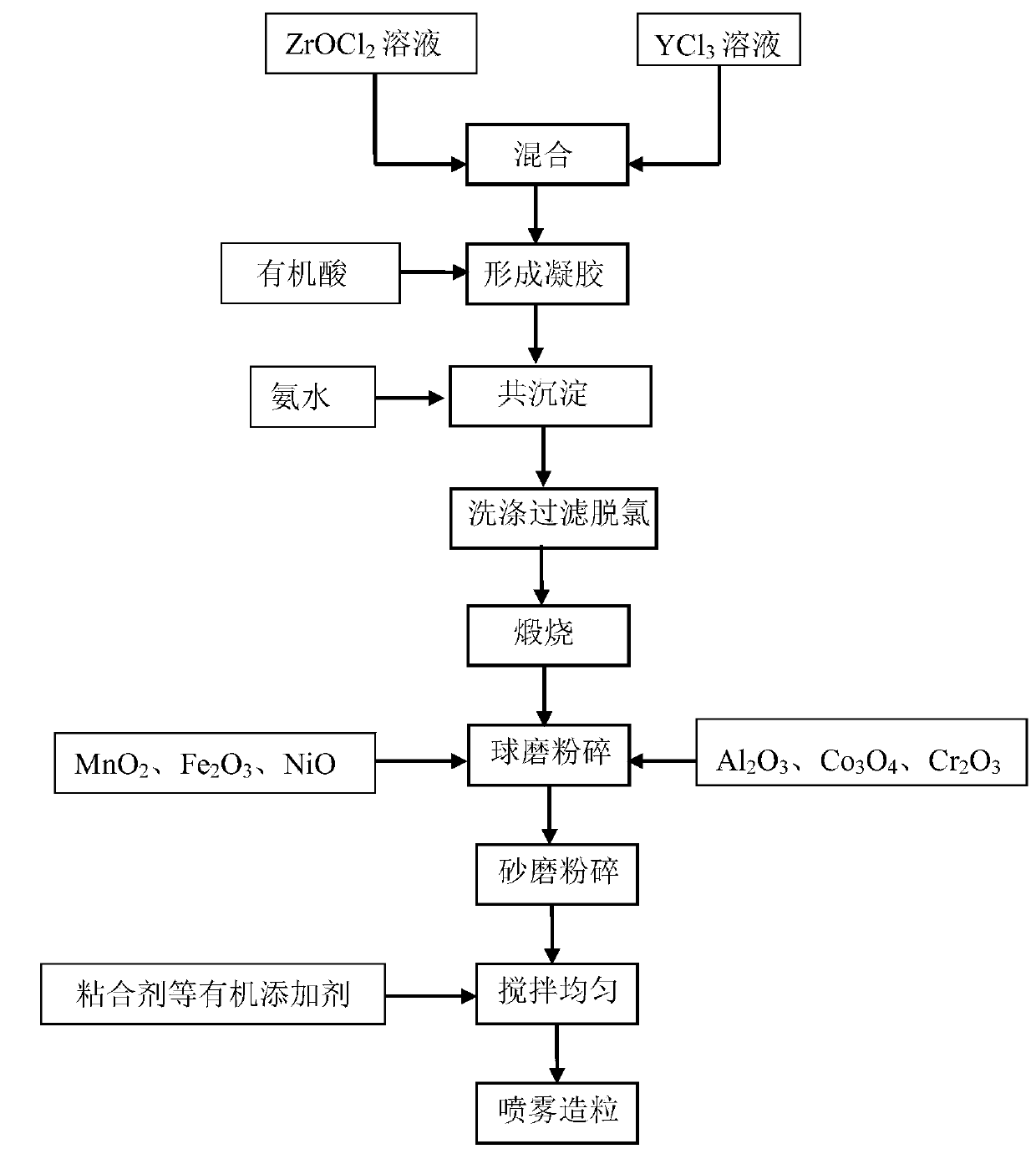

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the black yttrium-stabilized zirconia powder with an yttrium oxide content of 2.1mol described in Example 1 consists of the following steps:

[0040] ① Preparation of zirconium oxychloride octahydrate solution

[0041] Weigh zirconium oxychloride octahydrate (ZrOCl) with zirconia content of 36.00%. 2 ·8H 2 O) 2138kg, be dissolved in 10690L pure water and stir evenly, the concentration of zirconia in this solution is 6.0%;

[0042] ② Preparation of yttrium chloride solution

[0043] Add 30.4 kg of yttrium trioxide into 98 kg of 30.00% hydrochloric acid solution, stir to dissolve, add 40 L of pure water, the concentration of yttrium trichloride in this solution is converted to a concentration of 18.0% of yttrium trioxide;

[0044] ③ Pour the prepared zirconium oxychloride octahydrate solution and yttrium trichloride solution into the neutralization kettle, mix well, add 400kg of organic acid with a content of 20.0%, heat to 140°C, keep it warm...

Embodiment 2

[0049] The preparation method of the black yttrium-stabilized zirconia powder with the yttrium oxide content of 2.6mol described in the present embodiment 2 consists of the following steps:

[0050] ① Preparation of zirconium oxychloride octahydrate solution

[0051] Weigh zirconium oxychloride octahydrate (ZrOCl) with zirconia content of 36.00%. 2 ·8H 2 O) 2118kg, dissolved in 10590m 3 Stir evenly in pure water, the concentration of zirconia in this solution is 6.0%;

[0052] ② Preparation of yttrium chloride solution

[0053] Add 37.36 kg of diyttrium trioxide into 110 kg of 30.00% hydrochloric acid solution, stir to dissolve, add 60 L of pure water, the concentration of yttrium trichloride in this solution is converted to 18.0% of diyttrium trioxide;

[0054] ③ Pour the prepared zirconium oxychloride octahydrate solution and yttrium trichloride solution into the neutralization kettle, mix well, add 400kg of organic acid with a content of 20.0%, heat to 145°C, keep it wa...

Embodiment 3

[0059] The preparation method of the black yttrium-stabilized zirconia powder with an yttrium oxide content of 3.2mol described in Example 3 consists of the following steps:

[0060] ① Preparation of zirconium oxychloride octahydrate solution

[0061] Weigh zirconium oxychloride octahydrate (ZrOCl) with zirconia content of 36.00%. 2 ·8H 2 O) 2096kg, dissolved in 10477L pure water and stirred evenly, the concentration of zirconia in this solution is 6.0%;

[0062] ② Preparation of yttrium chloride solution

[0063] Add 45.6 kg of yttrium trioxide into 130 kg of 30.00% hydrochloric acid solution, stir to dissolve, add 78 L of pure water, the concentration of yttrium trichloride in this solution is converted to a concentration of 18.0% of yttrium trioxide;

[0064] ③ Pour the prepared zirconium oxychloride octahydrate solution and yttrium trichloride solution into the neutralization kettle, mix well, add 400kg of organic acid with a content of 20.0%, heat to 135°C, keep it war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com