Microspherical ethylene oxychlorination catalyst preparation method

An ethylene oxychlorination catalyst, spherical technology, applied in the field of preparation of ethylene oxychlorination catalysts, can solve the problems of loss, reduction of catalyst effective specific surface area, uneven dispersion of active components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

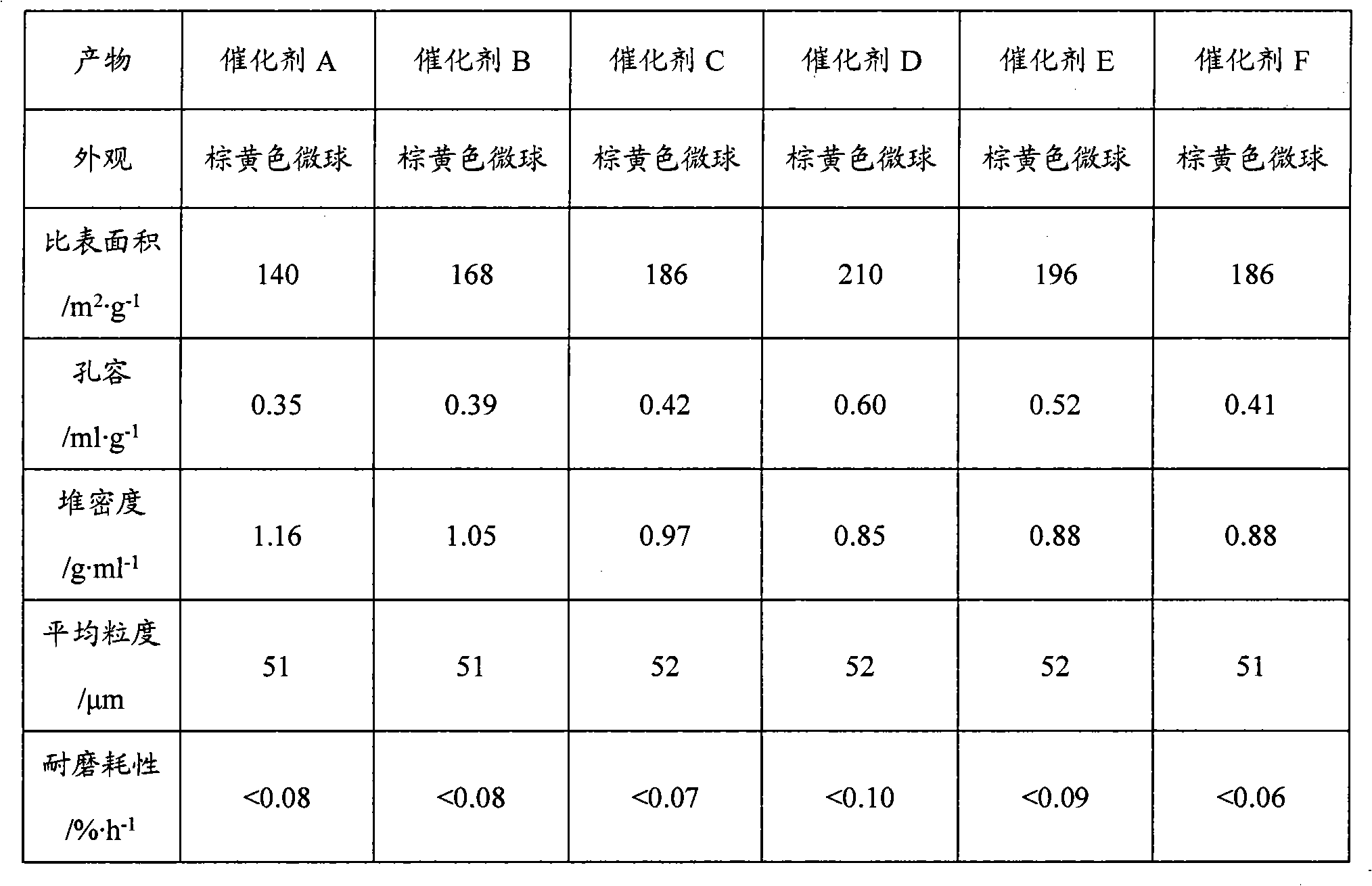

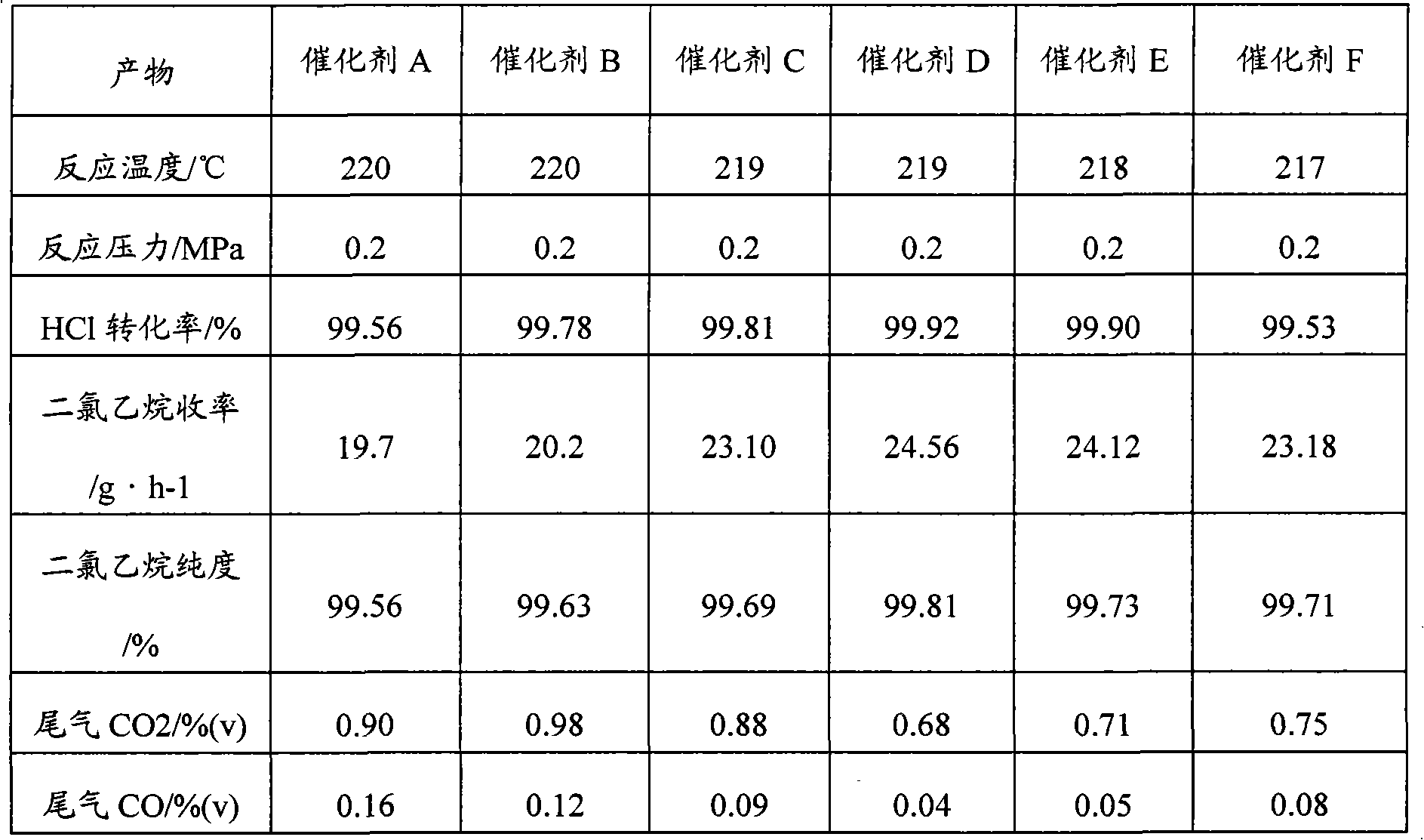

Examples

Embodiment 1

[0055] Weigh 1000g of aluminum hydroxide powder, add it to 1200ml of 30% sodium hydroxide solution by mass, set the temperature at 95°C for reaction, and prepare aluminum oxide and sodium hydroxide with a weight percentage of 1.15% Sodium metaaluminate solution;

[0056] The preparation mass percentage concentration is the hydrochloric acid solution of 25%;

[0057] Preparation mass percentage concentration is the cupric chloride active component solution of 20%;

[0058] A magnesium chloride additive solution with a mass percentage concentration of 30% is prepared.

[0059] Using the one-way method, place 1000ml of the sodium metaaluminate solution in a self-made precipitation kettle with a stirrer, gradually add 1200ml of hydrochloric acid solution with a mass percentage concentration of 25%, and turn on the stirrer to stir it for 5h. Precipitation reaction, in which the reaction temperature is set at 30°C and the pH value is 9; after the reaction is completed, the precipi...

Embodiment 2

[0065] Weigh 1000g of aluminum hydroxide powder, add it to 800ml of sodium hydroxide solution with a concentration of 30% by mass, set the temperature to 125°C for reaction, and prepare aluminum oxide and sodium hydroxide with a weight percentage of 2.25% Sodium metaaluminate solution;

[0066] The preparation mass percentage concentration is the hydrochloric acid solution of 40%;

[0067] Preparation mass percentage concentration is the cupric chloride active component solution of 20%;

[0068] The preparation mass percent concentration is the magnesium chloride auxiliary solution of 30%;

[0069] A potassium chloride additive solution with a mass percent concentration of 30% was prepared.

[0070] Using the one-way method, place 1000ml of the sodium metaaluminate solution in a self-made precipitation kettle with a stirrer, gradually add 980ml of hydrochloric acid solution with a mass percent concentration of 40%, and turn on the stirrer to stir it for 0.5h Carry out a pre...

Embodiment 3

[0076] Weigh 1000g of aluminum hydroxide powder, add it to 1100ml of sodium hydroxide solution with a mass percent concentration of 30%, set the temperature at 105°C for 2 hours, and prepare aluminum oxide and sodium hydroxide with a weight percent of 1.8 % sodium metaaluminate solution;

[0077] The preparation mass percentage concentration is the nitric acid solution of 40%;

[0078] Preparation mass percentage concentration is the cupric chloride active component solution of 20%;

[0079] The preparation mass percent concentration is the magnesium chloride auxiliary solution of 30%;

[0080] Prepare a solution of cerium nitrate additive with a mass percent concentration of 30%.

[0081] Using the co-current method, 1000ml of the sodium metaaluminate solution and 940ml of nitric acid solution with a mass percent concentration of 40% were gradually added to the self-made precipitation kettle with agitator at the same time, and the agitator was turned on to stir it for 1.0h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com