Method for preparing polycarbonate catalyzed by ionic liquid

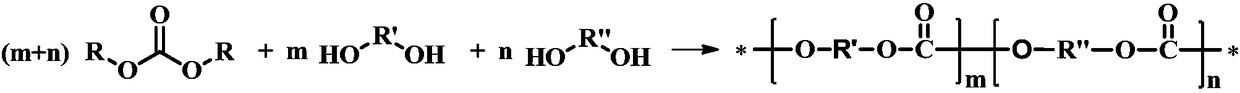

A polycarbonate, catalytic preparation technology, applied in clean catalysis, green field, can solve residual problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

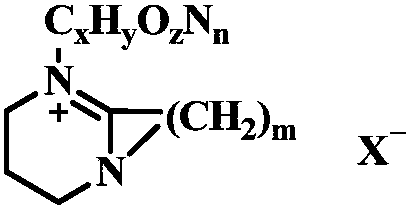

[0028]

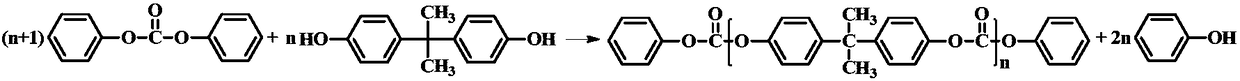

[0029] Implementation method: in the transesterification stage, under normal pressure, 6.85g (0.030mol) of bisphenol A and 6.75g (0.032mol) of diphenyl carbonate were heated to 150°C under a nitrogen atmosphere to melt them, and 3.18×10 -3 g (5×10 of the amount of bisphenol A substance -2 %) of acetic acidated 1,8-diazabicyclo(5,4,0)undec-7-ene, and reacted under nitrogen atmosphere for 11min to synthesize the prepolymer; -5 MPa, at a reaction temperature of 260° C., react for 20 minutes to obtain polycarbonate. After the reaction, it was cooled to room temperature under vacuum, dissolved in chloroform and precipitated in anhydrous methanol. The yield of gained polycarbonate is 97%, and molecular weight is 3.3 * 10 4 .

Embodiment 2

[0031] Same as Example 1, the catalyst used is benzoated 1,8-diazabicyclo(5,4,0) undec-7-ene 4.11×10 - 3 g (5×10 of the amount of bisphenol A substance -2 %), its structural formula is Other conditions remain unchanged, the yield of the obtained polycarbonate is 98%, and the molecular weight is 2.4×10 4 .

Embodiment 3

[0033] Same as Example 1, the catalyst used is lactated 1,8-diazabicyclo(5,4,0) undec-7-ene (3.63×10 - 3 g, 5 x 10 of the amount of bisphenol A substance -2 %), its structural formula is Other conditions remain unchanged, the yield of the obtained polycarbonate is 96%, and the molecular weight is 2.7×10 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com