Method for preparing nanocrystalline zirconium carbide powder

A technology of zirconium carbide and nanocrystals, which is applied in the field of ceramic materials, can solve the problems of uneven particle size, complex reaction process, and high energy consumption, etc., and achieve easy large-scale production, simple preparation process, and uniform grain size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for preparing nanocrystalline zirconium carbide powder, the method comprising the following processes and steps:

[0018] (1) Zirconium oxychloride, sucrose, and ammonia water are used as raw materials, and polyethylene glycol 6000 is used as a dispersant. First mix absolute ethanol and water at a volume ratio of 5:1, and add polyethylene glycol 6000 with a total amount of alcohol and water of 1 wt%, and then add 0.05mol zirconium oxychloride to the mixed solution of absolute ethanol and water , stirred for 1 hour, slowly added 17ml of ammonia water into the mixture through a separatory funnel, then added 0.02mol of sucrose into the mixture, stirred at room temperature for 3 hours, after fully reacting, dried at 60°C, ground and pressed into a green body.

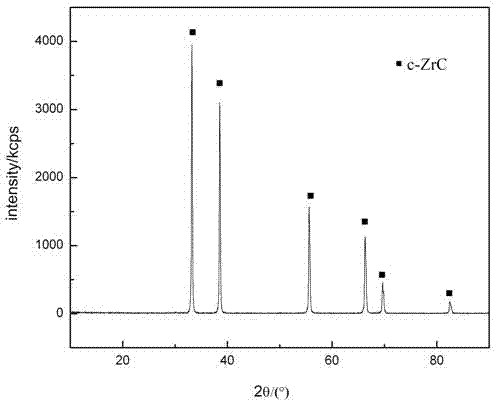

[0019] (2) Place the green body in a high-temperature tube furnace to embed activated carbon, and synthesize it through a high-temperature reaction at 1550°C under the protection of a high-purity argon atmos...

Embodiment 2

[0022] A method for preparing nanocrystalline zirconium carbide powder, the method comprising the following processes and steps:

[0023] (1) Zirconium oxychloride, sucrose, and ammonia water are used as raw materials, and polyethylene glycol 6000 is used as a dispersant. First mix absolute ethanol and water at a volume ratio of 3:1, and add polyethylene glycol 6000 with a total amount of alcohol and water of 1.5wt%, and then add 0.05mol zirconium oxychloride to the mixed solution of absolute ethanol and water , stir for 1 hour, slowly drop 23ml of ammonia water into the mixture through a separatory funnel, then add 0.05mol sucrose into the mixture, stir at room temperature for 3 hours, after fully reacting, dry at 60°C, grind and press into a green body .

[0024] (2) Place the green body in a high-temperature tube furnace to embed activated carbon, and synthesize it through a high-temperature reaction at 1650°C under the protection of a high-purity argon atmosphere, keep it...

Embodiment 3

[0026] A method for preparing nanocrystalline zirconium carbide powder, the method comprising the following processes and steps:

[0027] (1) Zirconium oxychloride, sucrose, and ammonia water are used as raw materials, and polyethylene glycol 6000 is used as a dispersant. First mix absolute ethanol and water at a volume ratio of 8:1, and add polyethylene glycol 6000 with a total amount of alcohol and water of 0.5wt%, and then add 0.05mol zirconium oxychloride to the mixed solution of absolute ethanol and water , stir for 1 hour, slowly drop 20ml of ammonia water into the mixture through a separatory funnel, then add 0.04mol sucrose into the mixture, stir at room temperature for 3 hours, after fully reacting, dry at 60°C, grind and press into a green body .

[0028] (2) Place the green body in a high-temperature tube furnace to embed activated carbon, and synthesize it through a high-temperature reaction at 1600°C under the protection of a high-purity argon atmosphere, keep it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com