Supercritical hydrothermal synthesis method of nanometer zirconium oxide powder

A nano-zirconia, supercritical water technology, applied in zirconia, nanotechnology, nanotechnology and other directions, can solve the problems of abnormal growth of powder particles, unavoidable grain growth, long reaction time, etc., to achieve narrow particle size distribution, Good stability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A nano-zirconia powder supercritical hydrothermal synthesis method, the synthesis steps are:

[0023] 1) Dissolving the oxalic acid and the soluble zirconium compound in water respectively at a temperature of 60-80°C to obtain an oxalic acid solution with a molar concentration of 0.4-2.5 mol / L and a zirconium compound solution with a molar concentration of 0.1-2.0 mol / L;

[0024] 2) Under stirring, add the zirconium compound solution into the oxalic acid solution for precipitation reaction to obtain white zirconium oxalate precipitate, the molar ratio of oxalic acid to zirconium ions is ≥2.0;

[0025] 3) The obtained zirconium oxalate precipitate is washed and then dried, and then thermally decomposed after drying. The thermal decomposition reaction temperature is 360°C-470°C, and the thermal decomposition reaction time is 0.5-1h;

[0026] 4) The product after the thermal decomposition reaction is subjected to wet pulverization to obtain nano-scale dispersion slurry;

...

Embodiment

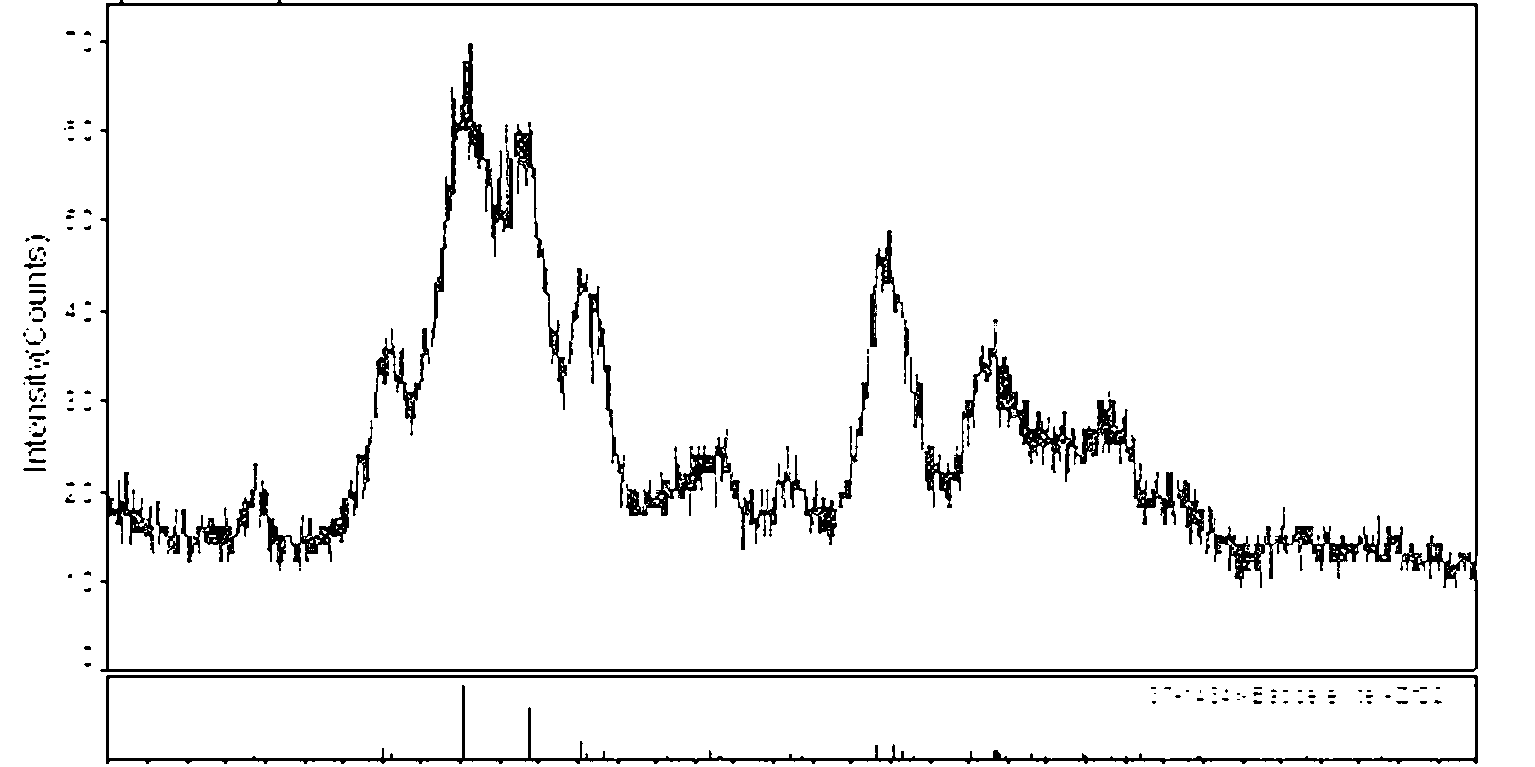

[0038] Weigh 322 g of zirconium oxychloride octahydrate and 270 g of oxalic acid, dissolve them in 600 ml and 1000 ml of pure water respectively at 70°C, add the zirconium oxychloride solution into the oxalic acid solution under stirring to form a white precipitate; Wash until the chloride ion content is less than 100ppm, then dry, heat at 400°C for 40 minutes after drying, then transfer to a planetary mill, control the material-water ratio = 1:2, and grind at 300 rpm for 7 hours; grind the Slurry transfer adopts continuous supercritical hydrothermal synthesis equipment for reaction (reaction temperature = 420°C, reaction pressure = 30Mpa, reaction time = 30 seconds), the product obtained by the reaction is washed several times with pure water and dried to measure the specific surface area and XRD, specific surface area=117.45m2 / g, XRD measurement shows that the crystal phase of the product is a monoclinic phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com