Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

A technology of ethylene copolymer emulsion and vinyl acetate, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, device for coating liquid on the surface, etc., can solve the problem of low bonding strength, poor water resistance, hand feeling Hard and other problems, to achieve the effect of good product performance, low glass transition temperature and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

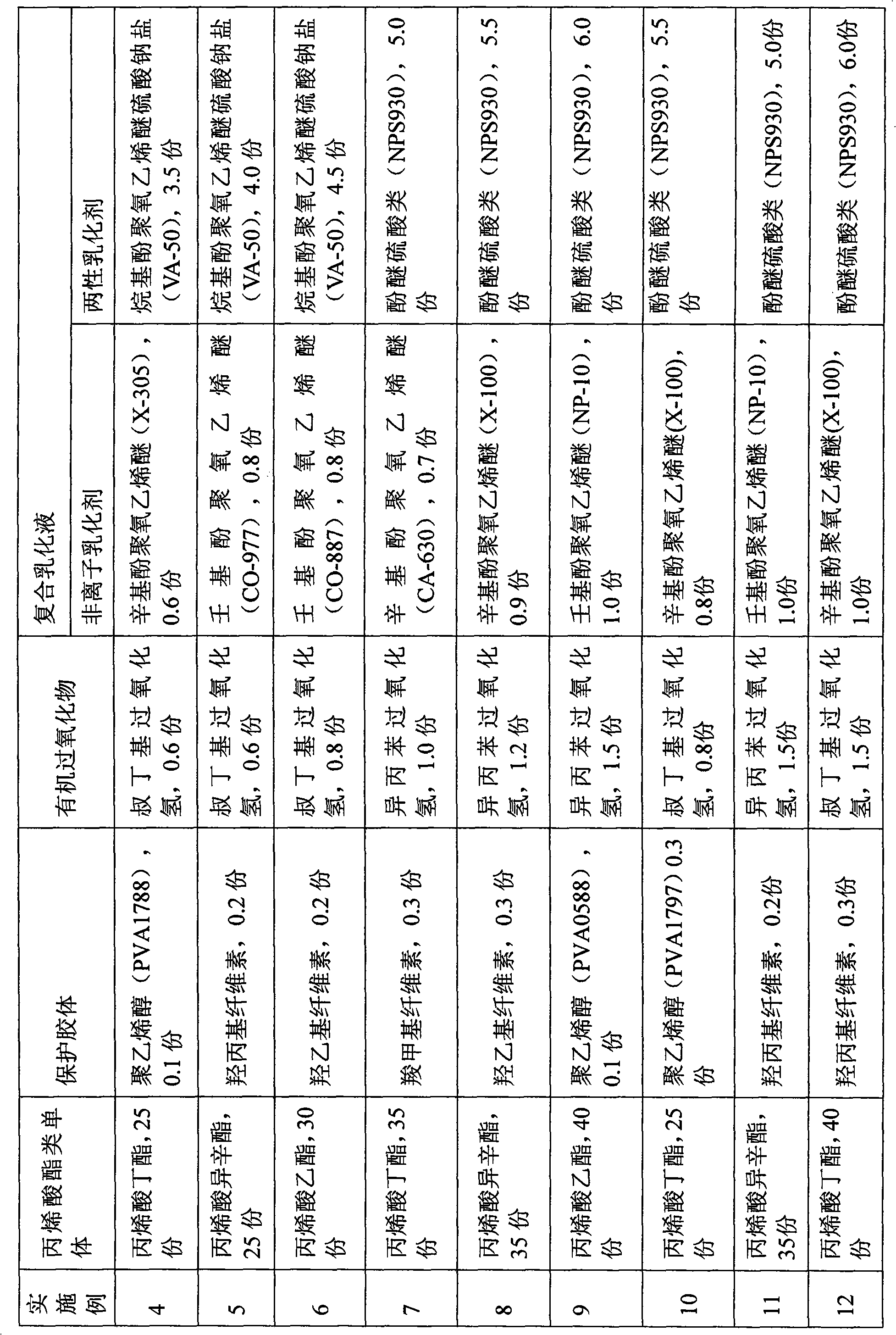

Examples

Embodiment 1

[0042] 1. Preparation of raw materials

[0043] 1) Preparation of pre-emulsion: add 80 parts of deionized water to the pre-emulsification tank, start the mixer, add 1.5 parts of composite emulsion (wherein the nonionic emulsifier is octylphenol polyoxyethylene ether (X-100), 0.3 parts , The amphoteric emulsifier is sodium alkylphenol polyoxyethylene ether sulfate (VA-50), 1.2 parts), 0.2 parts of sodium bicarbonate, 0.2 parts of sodium acetate, 5 parts of N-methylolacrylamide, after stirring and dissolving, Add 80 parts of vinyl acetate and 20 parts of butyl acrylate, and stir for 30 minutes to prepare a pre-emulsion;

[0044] 2) Prepare emulsifier solution: add 40 parts of deionized water, 0.1 part of hydroxyethyl cellulose, and 3.3 parts of compound emulsion into the emulsifier tank (the non-ionic emulsifier is octylphenol polyoxyethylene ether (X-100) , 0.5 parts, the amphoteric emulsifier is sodium alkylphenol polyoxyethylene ether sulfate (VA-50), 2.8 parts), start the agi...

Embodiment 2

[0051] Get 120 parts of deionized water, 0.3 part of carboxymethyl cellulose, 6 parts of composite emulsion (wherein the nonionic emulsifier is nonylphenol polyoxyethylene ether (CO-887), 0.8 part, and the amphoteric emulsifier is phenol ether sulfuric acid (NPS930), 5.2 parts), 1.2 parts cumene hydroperoxide, 0.5 parts zinc formaldehyde sulfoxylate, 0.4 parts sodium bicarbonate, 0.2 parts sodium acetate, 7 parts N-methylolacrylamide, 90 parts acetic acid Ethylene, 35 parts of isooctyl acrylate, 20 parts of ethylene, prepare the special VAE of electrostatic flocking with the method of embodiment 1, the result is as follows:

[0052] Exterior

[0053] Glass transition temperature °C

Embodiment 3

[0055] Get 140 parts of deionized water, 0.2 part of hydroxypropyl cellulose, 7 parts of composite emulsion (wherein nonionic emulsifier is octylphenol polyoxyethylene ether (CA-630), 1.0 part, amphoteric emulsifier is alkylphenol Polyoxyethylene ether sulfate sodium salt (VA-50), 6.0 parts), 1.5 parts of tert-butyl hydroperoxide, 0.7 parts of zinc formaldehyde sulfoxylate, 0.3 parts of sodium bicarbonate, 0.4 parts of sodium acetate, 4 parts of N-hydroxy Methacrylamide, 120 parts of vinyl acetate, 40 parts of ethyl acrylate, 30 parts of ethylene, prepare the special VAE for electrostatic flocking with the method of embodiment 1, the result is as follows:

[0056] Exterior

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com