Preparation method of graphene/zirconium oxide nano-grade composite lubricating material

A technology of nanocomposite and lubricating materials, which is applied in lubricating compositions, base materials, petroleum industry, etc. It can solve the problems of zirconia/graphene nanocomposite application research that has not been reported publicly and the preparation process is cumbersome, and achieves significant friction Chemical properties, simple process, improved dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of preparation method of graphene / zirconia nanocomposite lubricating material

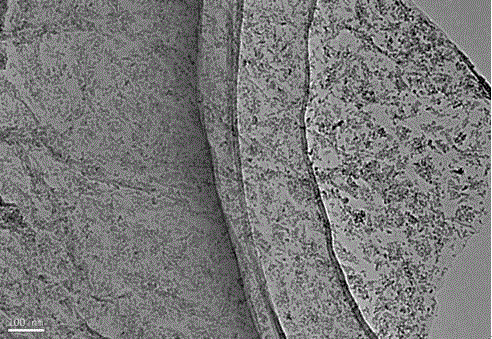

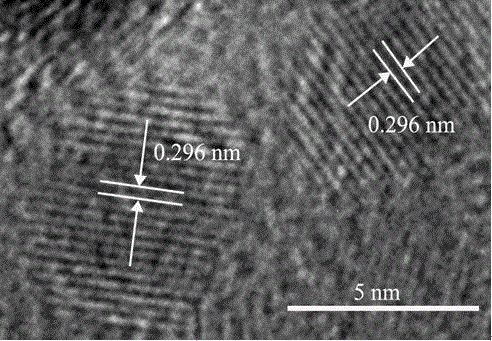

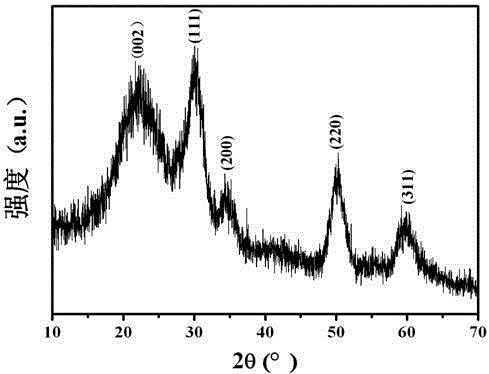

[0034] The raw materials are graphite oxide solution, zirconium oxychloride octahydrate, ultrapure water and hydrazine hydrate. The preparation process is as follows: firstly, the prepared graphite oxide solution is ultrasonically dispersed for 2 hours to obtain graphite oxide with only 1-2 layers of thickness. Then dilute its concentration to 2.33mg / mL; prepare a zirconium oxychloride solution with a concentration of 10mM at the same time, then measure 30mL each of the above-mentioned graphene oxide suspension and zirconium oxychloride solution, mix and stir evenly, And sonicate for 30 minutes, then add 1mL of hydrazine hydrate to the mixed solution, hydrothermally react at 180°C for 18h, wash the obtained black solid with ultrapure water, freeze-dry, and finally obtain graphene / oxide Zirconium nanocomposites.

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of graphene / zirconia nano lubricating material

[0036] The raw materials are graphite oxide solution, zirconium oxychloride octahydrate, ultrapure water and hydrazine hydrate. The preparation process is as follows: firstly, the prepared graphite oxide solution is ultrasonically dispersed for 2 hours to obtain graphite oxide with only 1-2 layers of thickness. ene suspension, and then dilute its concentration to 2.33mg / mL; prepare a zirconium oxychloride solution with a concentration of 10mM at the same time, then measure 40mL of the above-mentioned graphene oxide suspension and 20mL of the above-mentioned zirconium oxychloride solution, and The two were mixed and stirred evenly, and ultrasonically treated for 30 minutes, then 1 mL of hydrazine hydrate was added to the mixed solution, and the hydrothermal reaction was carried out at 180 °C for 18 hours, and the obtained black solid was washed with ultrapure water, freeze-dried, a...

Embodiment 3

[0037] Embodiment 3: a kind of preparation method of graphene / zirconia nano lubricating material

[0038] The raw materials are graphite oxide solution, zirconium oxychloride octahydrate, ultrapure water and hydrazine hydrate. The preparation process is as follows: firstly, the prepared graphite oxide solution is ultrasonically dispersed for 2 hours to obtain graphite oxide with only 1-2 layers of thickness. ene suspension, and then dilute its concentration to 2.33mg / mL; prepare a zirconium oxychloride solution with a concentration of 10mM; then measure 45mL of the above-mentioned graphene oxide suspension and 15mL of the above-mentioned zirconium oxychloride solution, and The two were mixed and stirred evenly, and ultrasonically treated for 30 minutes, then 1 mL of hydrazine hydrate was added to the mixed solution, and the hydrothermal reaction was carried out at 180 °C for 18 hours, and the obtained black solid was washed with ultrapure water, freeze-dried, and finally A gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com