Patents

Literature

49 results about "Cubic zirconia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cubic zirconia (CZ) is the cubic crystalline form of zirconium dioxide (ZrO₂). The synthesized material is hard and usually colorless, but may be made in a variety of different colors. It should not be confused with zircon, which is a zirconium silicate (ZrSiO₄). It is sometimes erroneously called cubic zirconium.

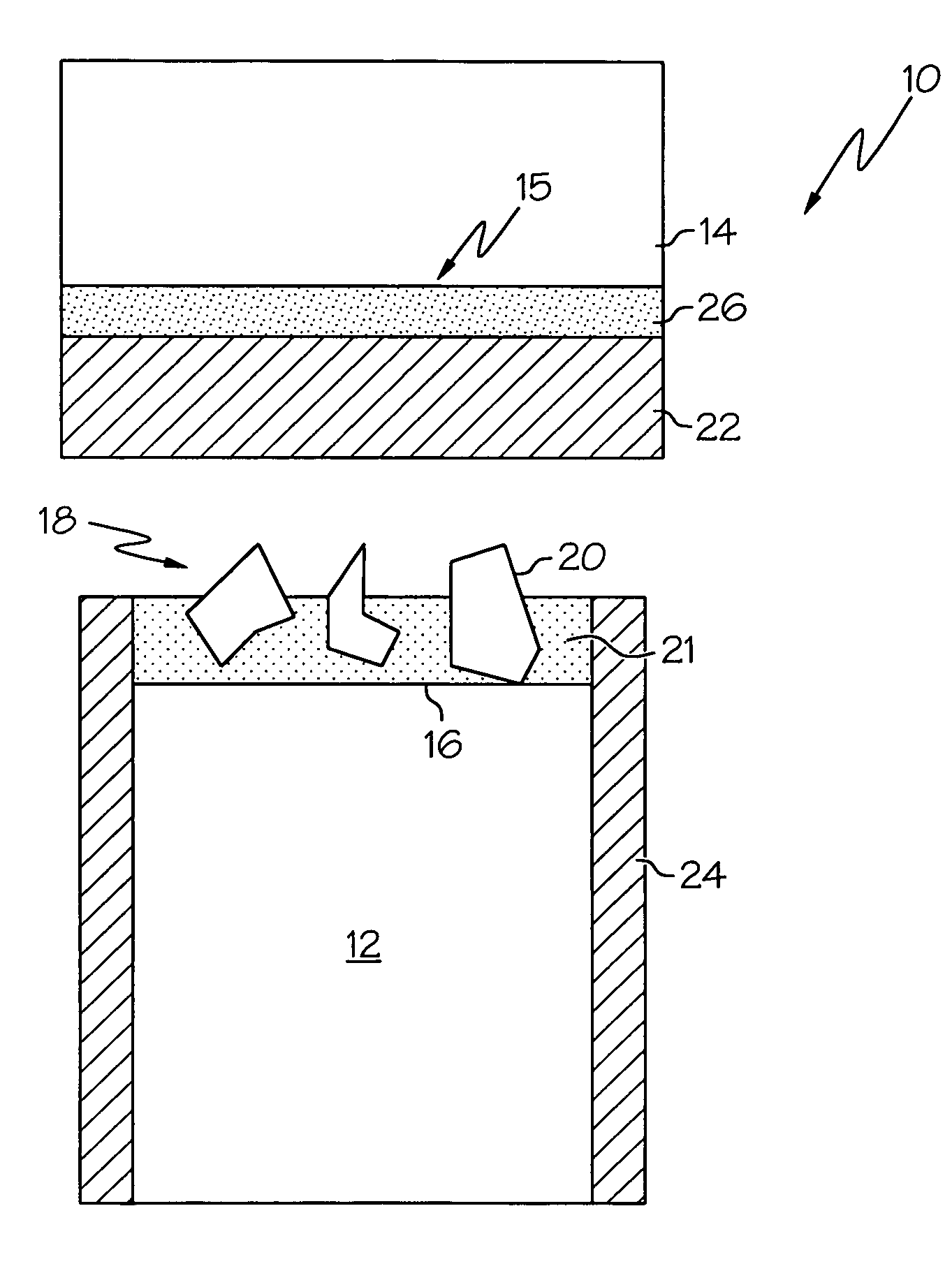

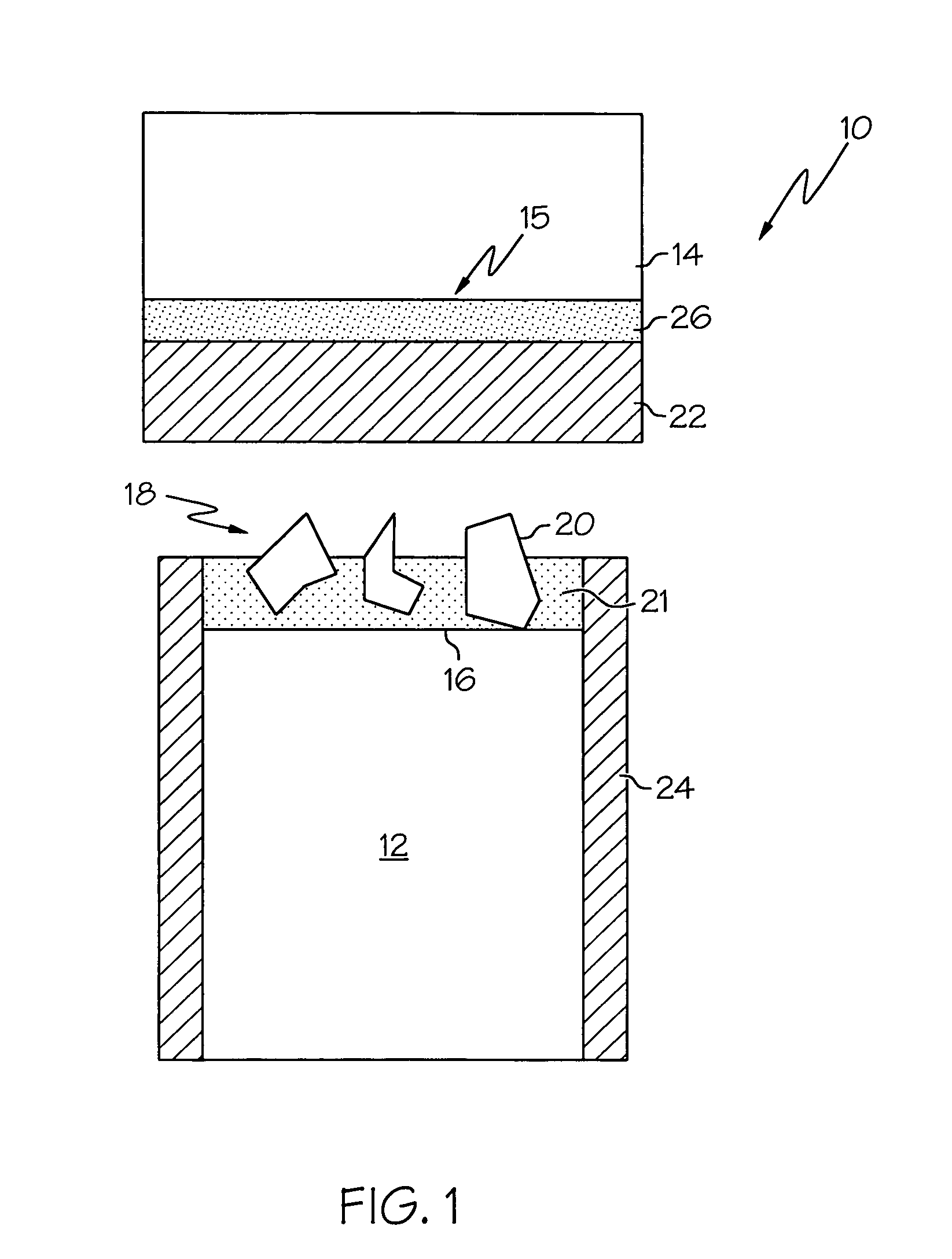

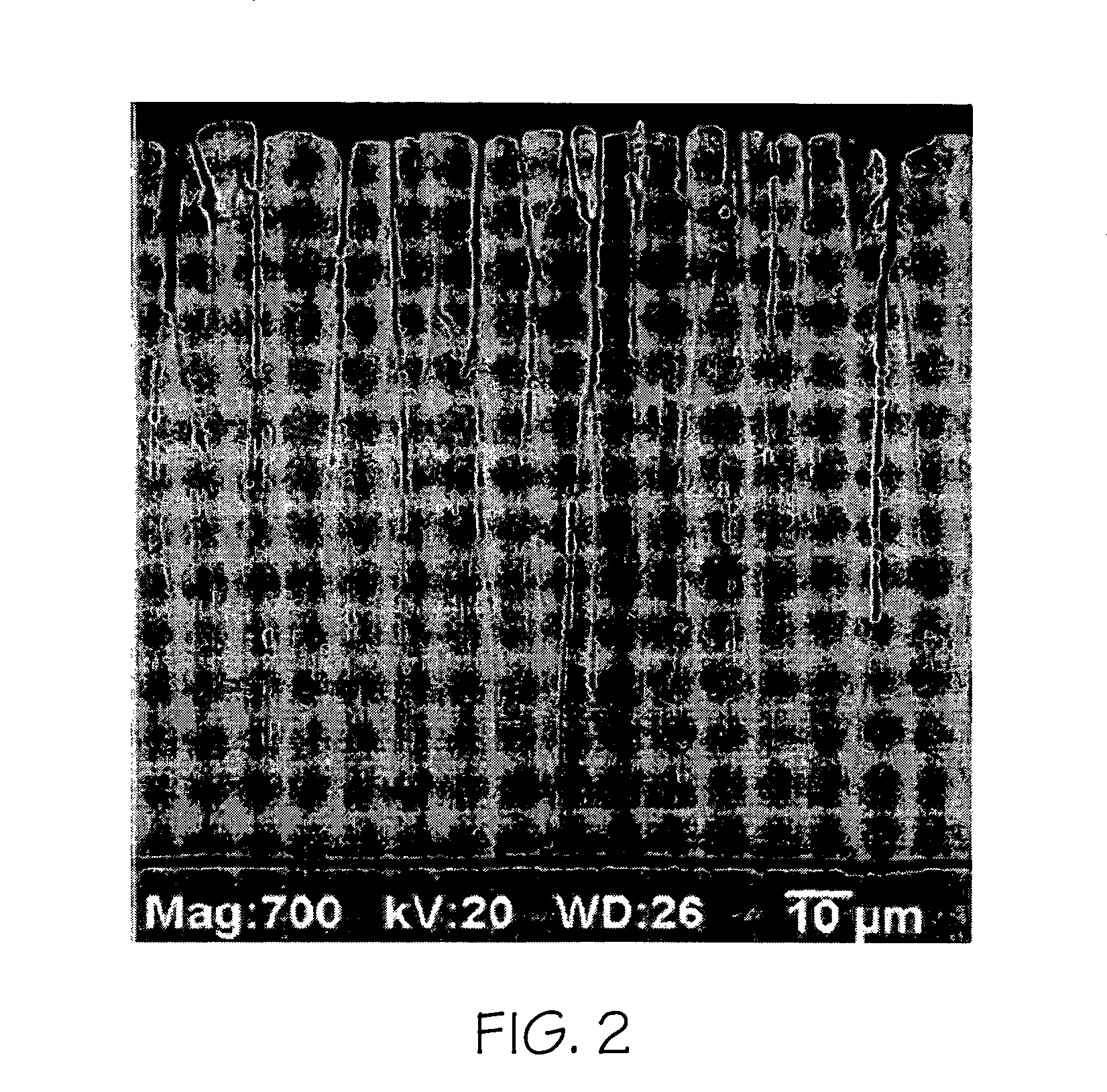

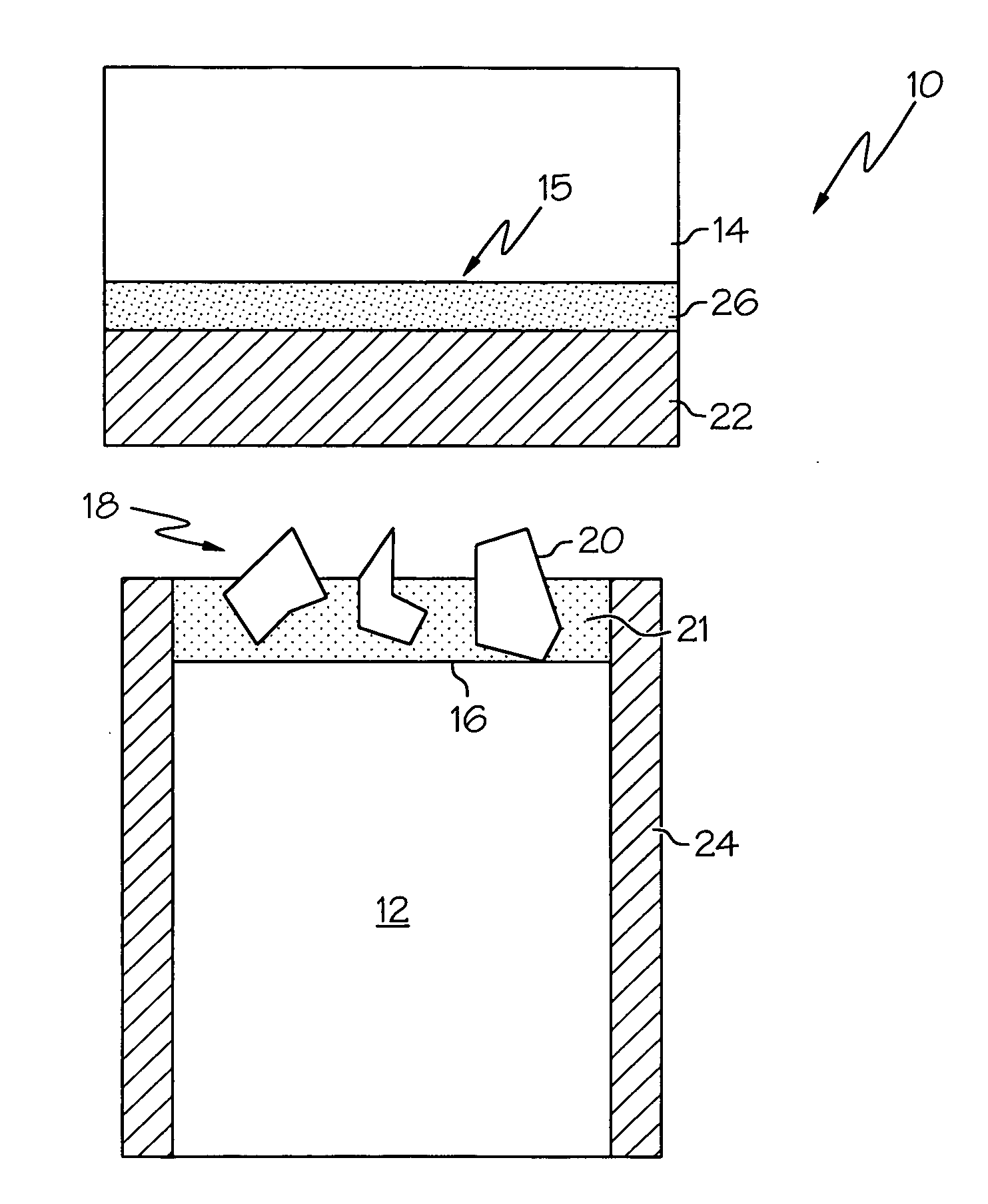

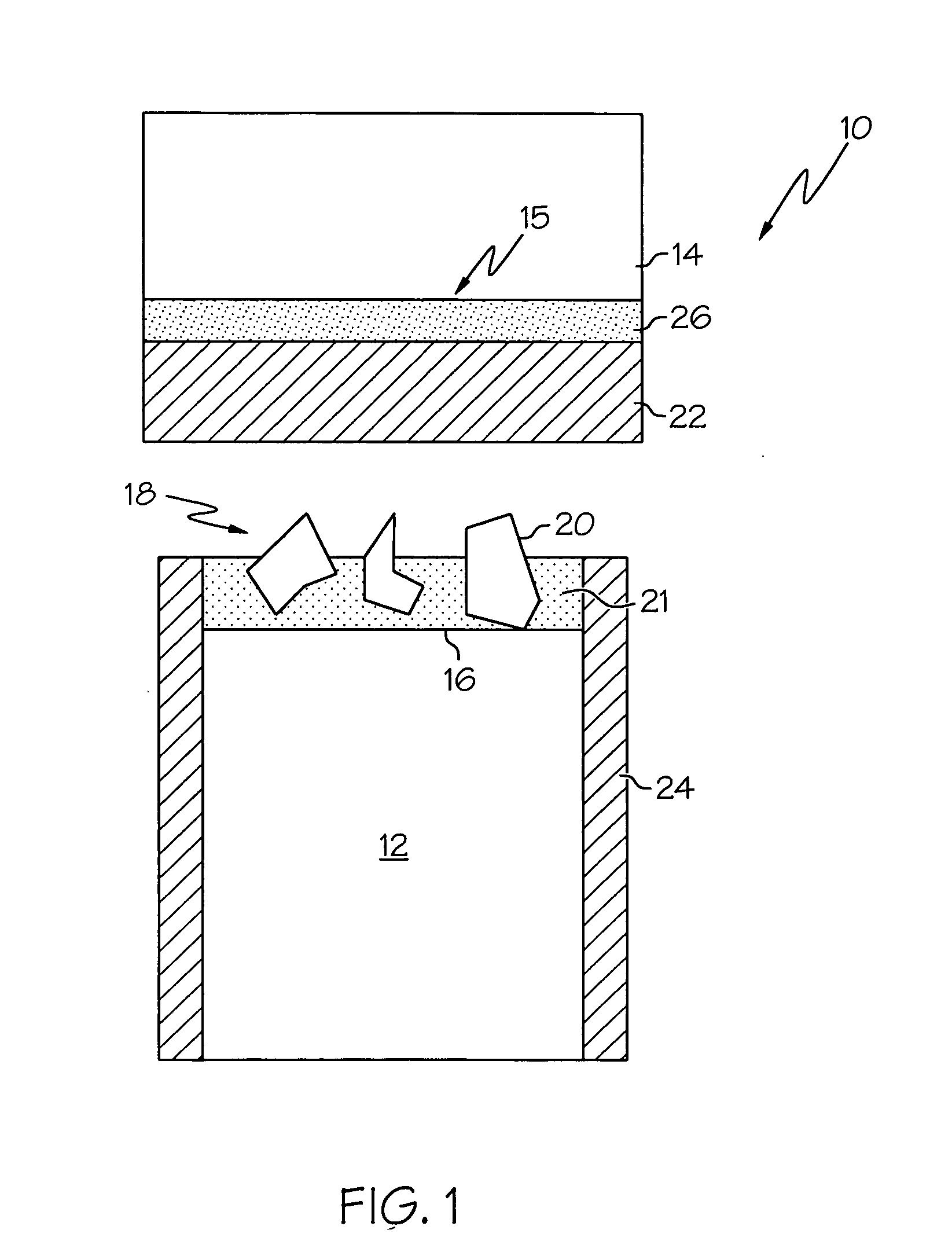

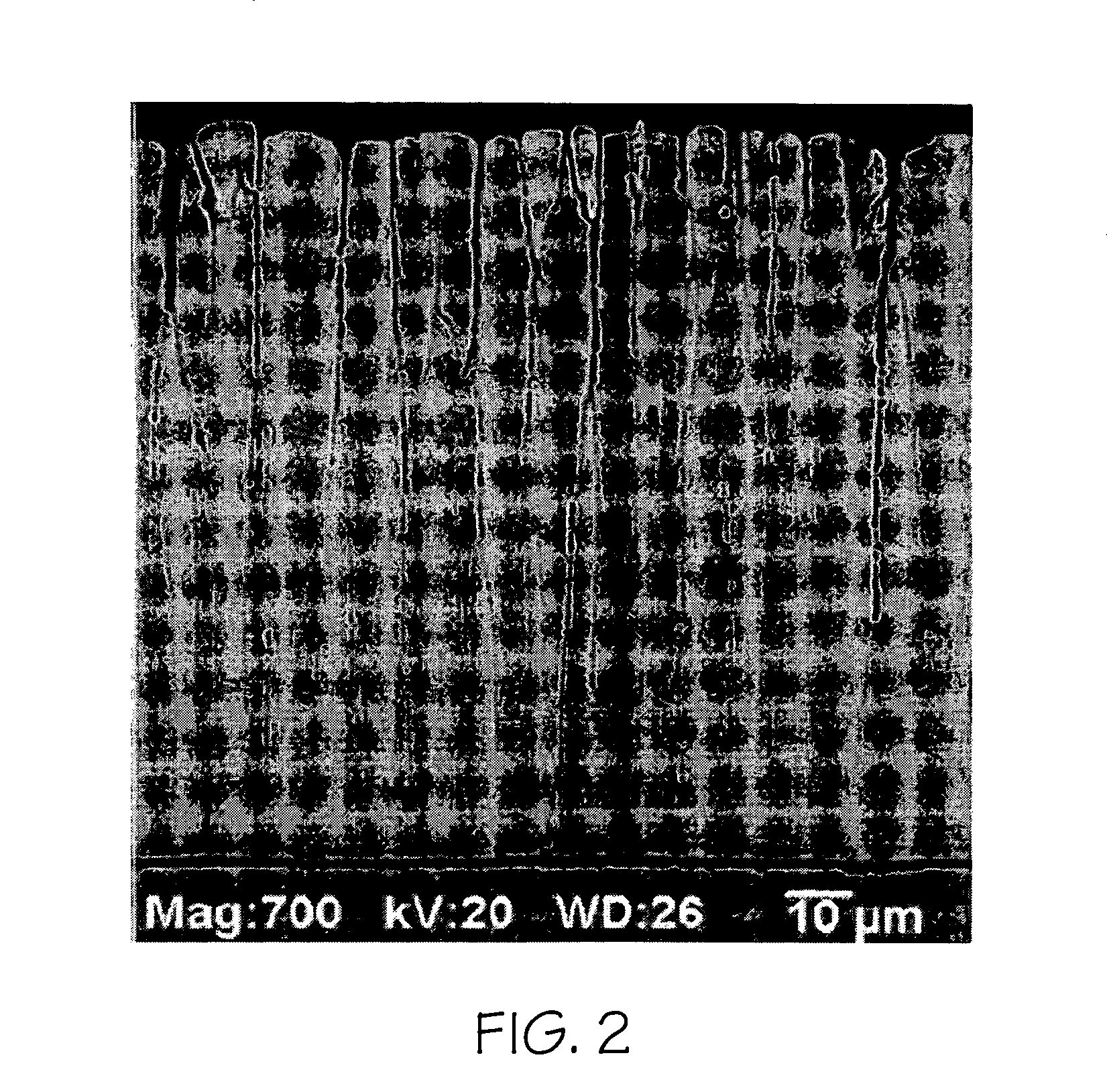

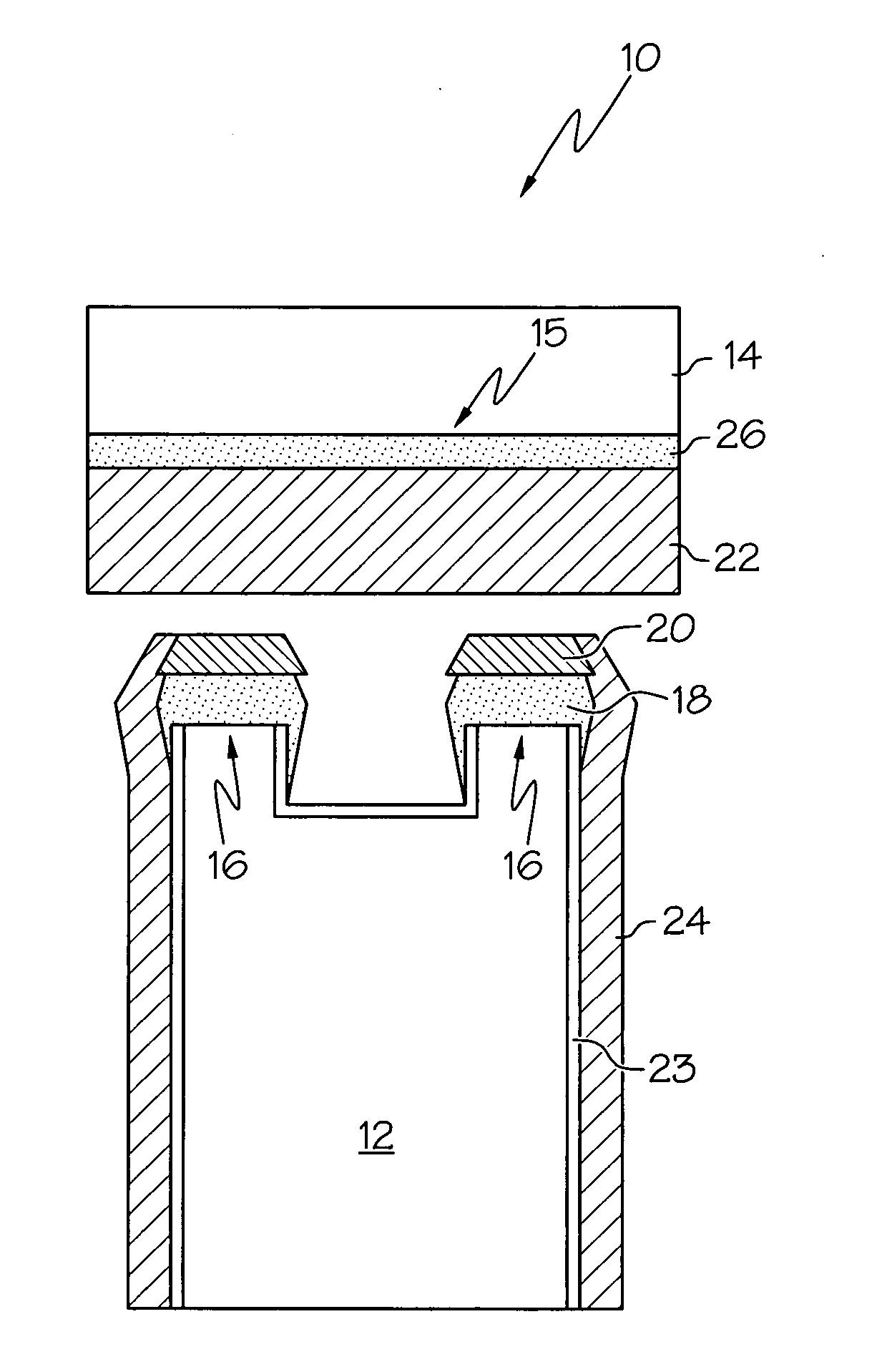

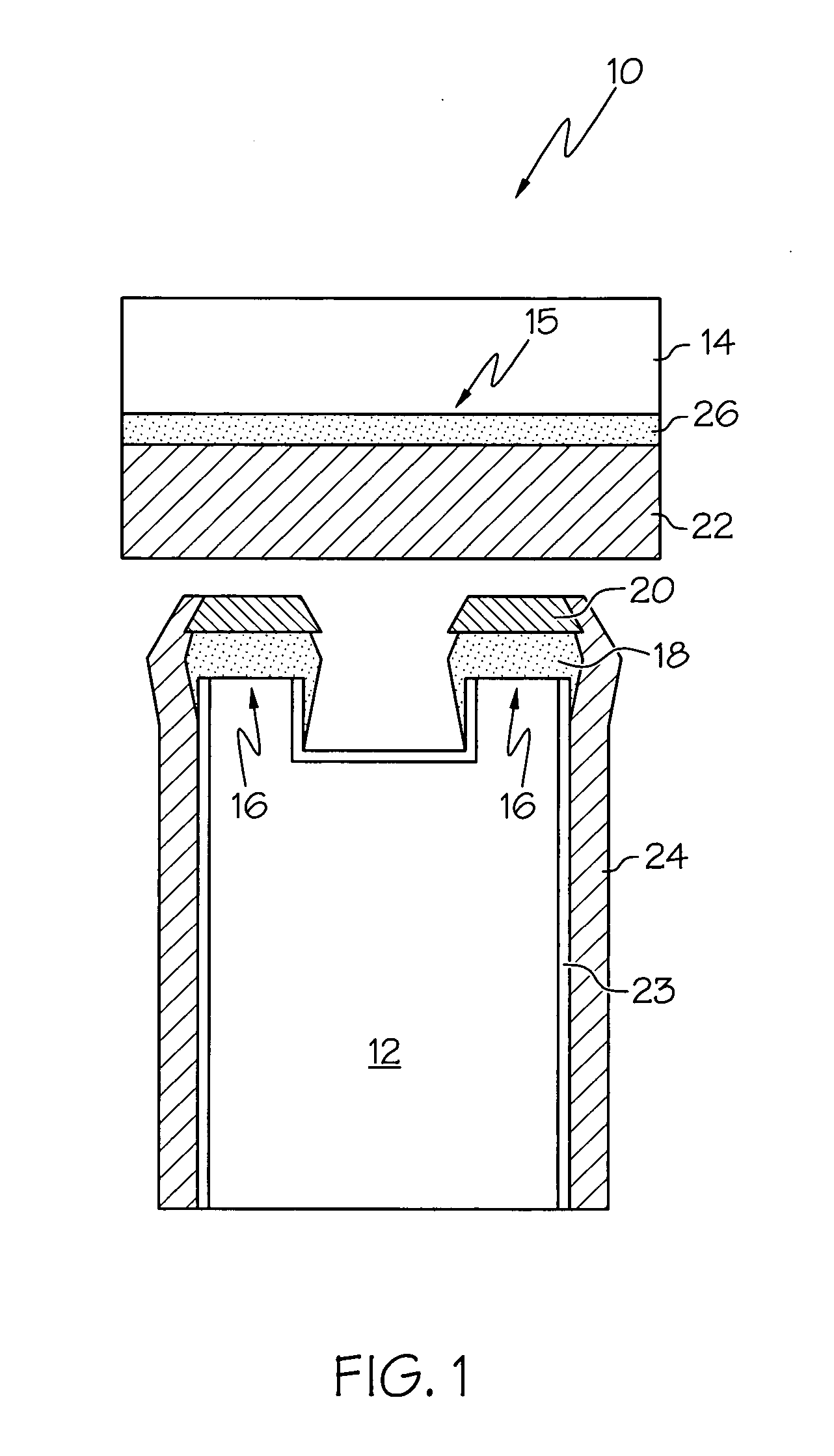

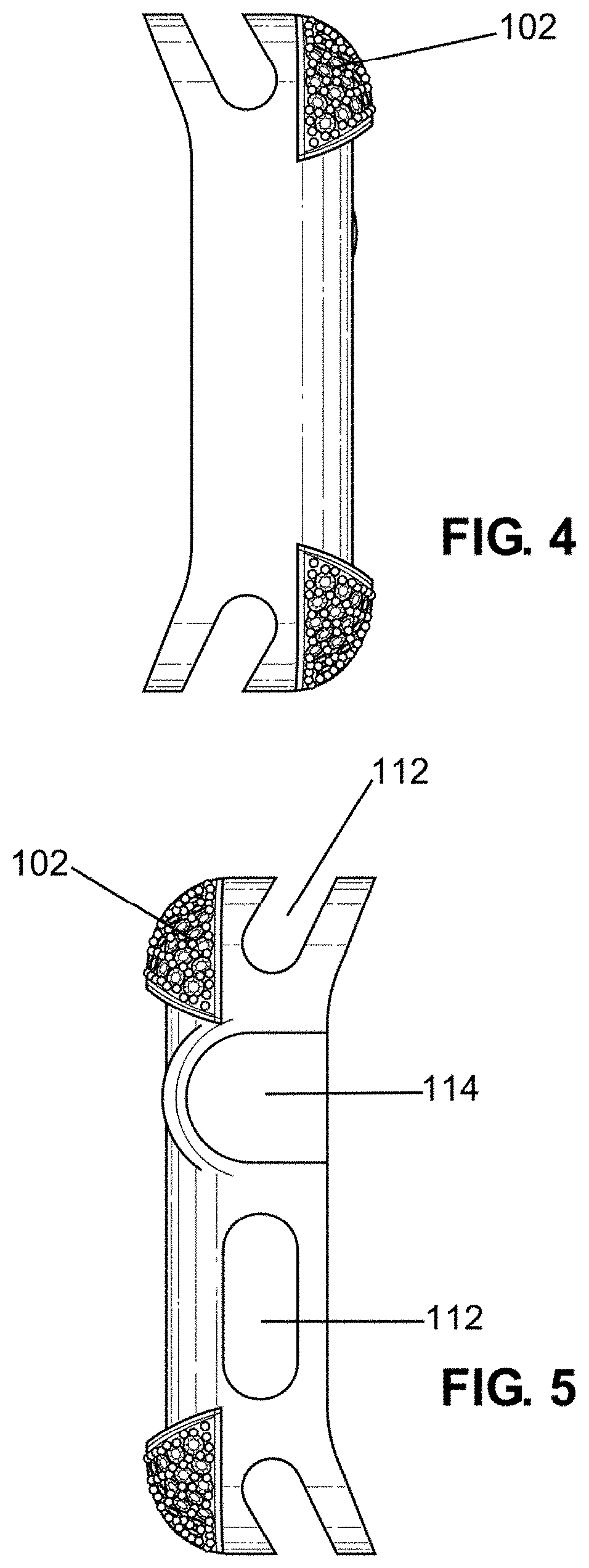

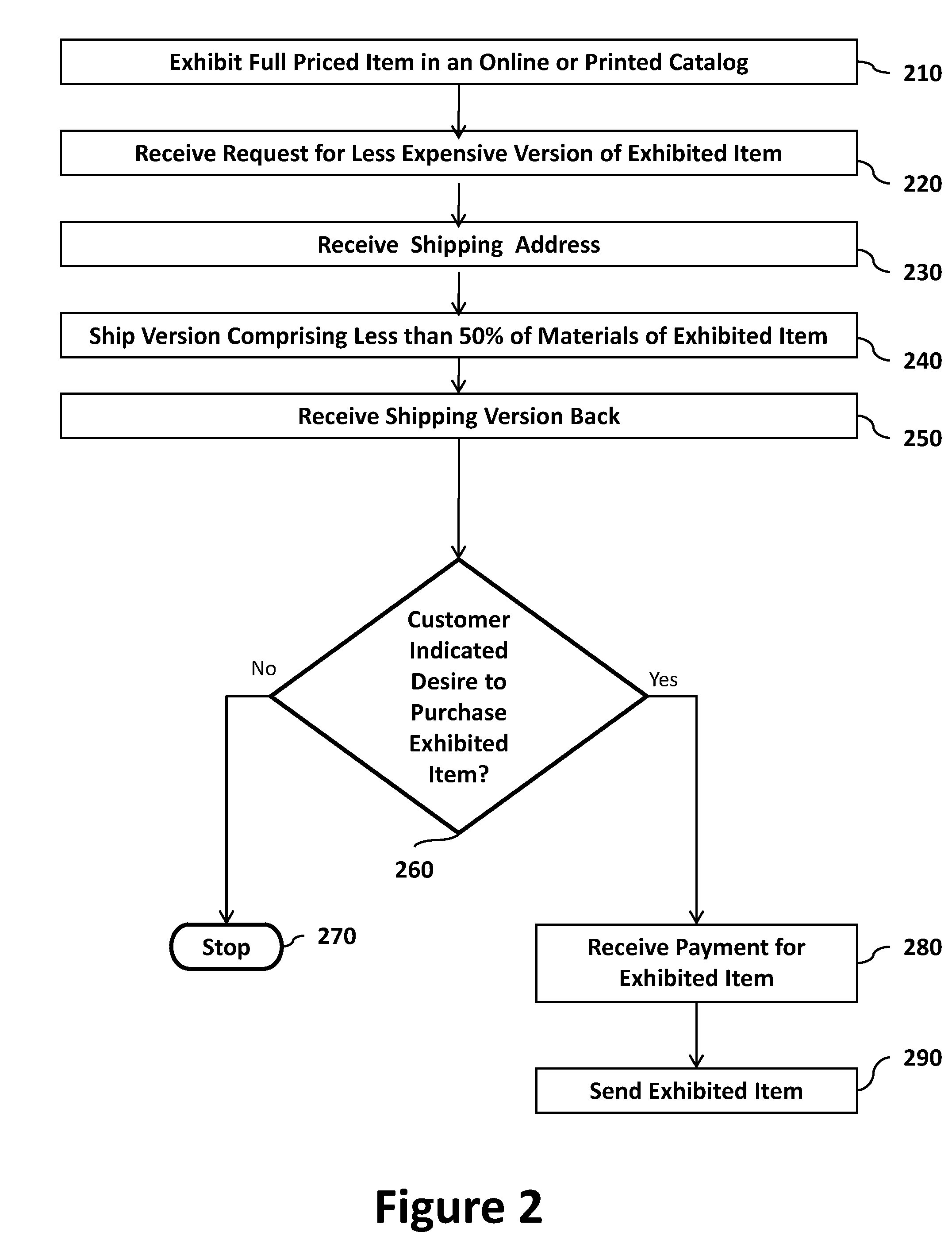

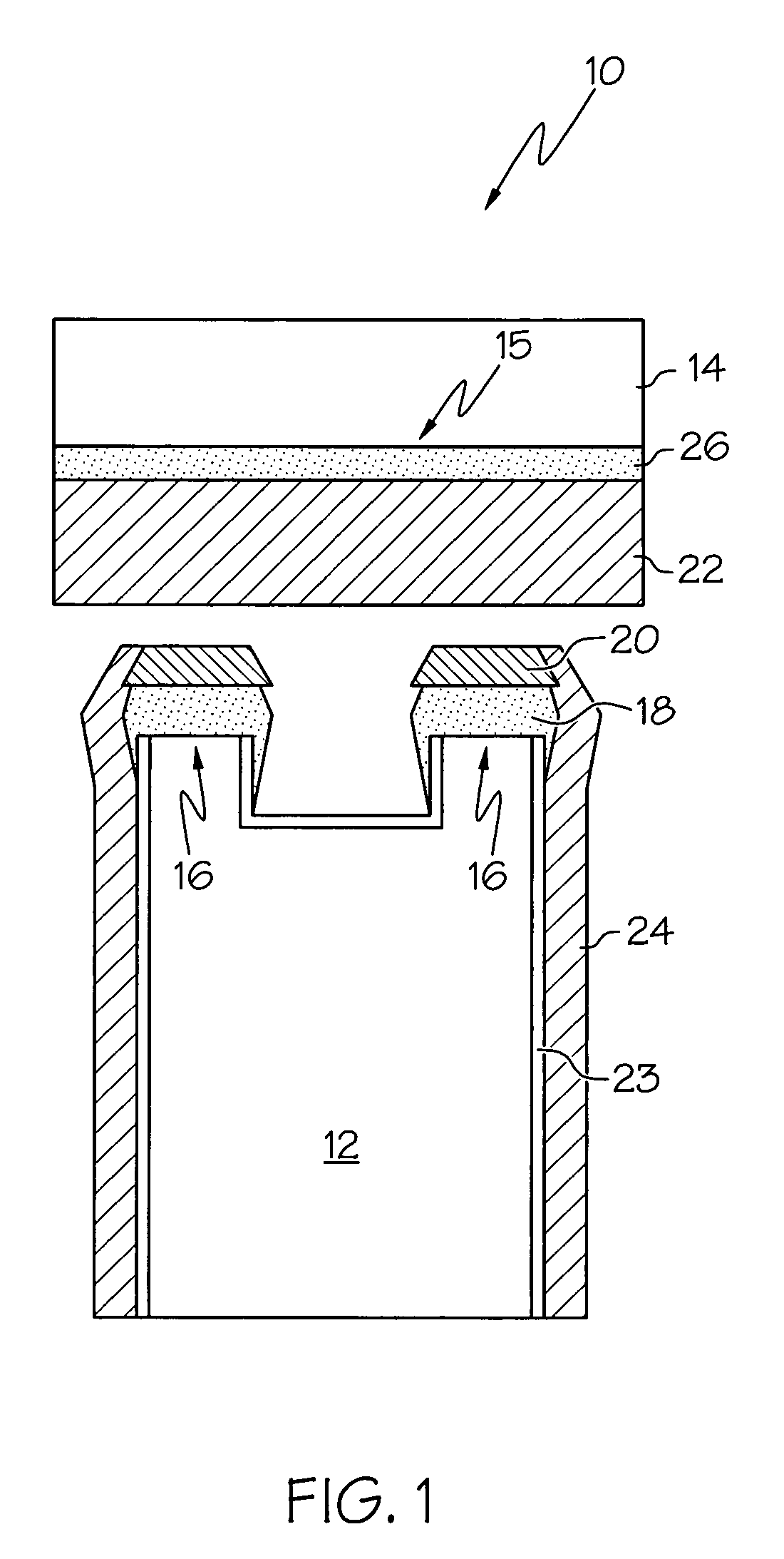

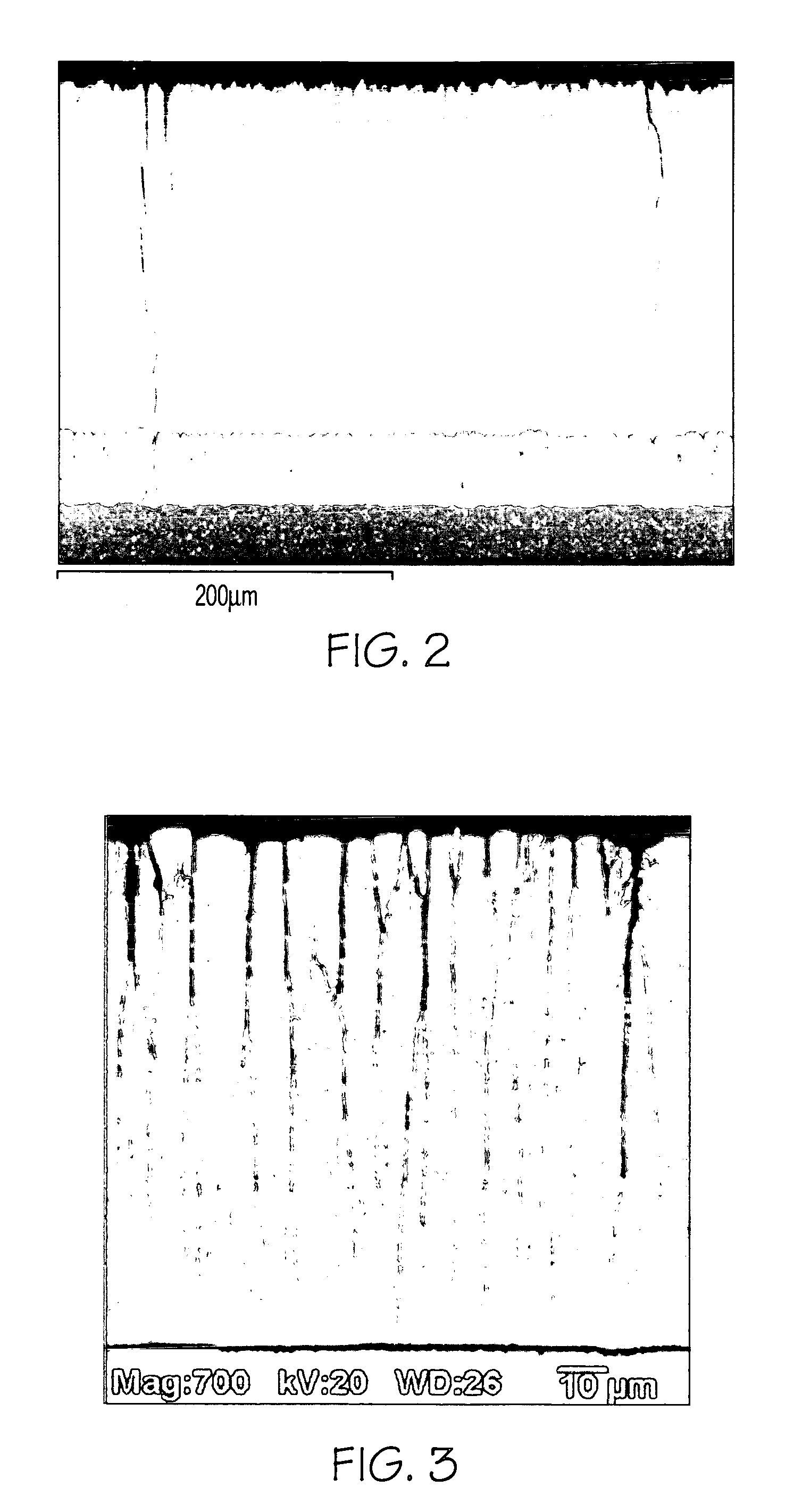

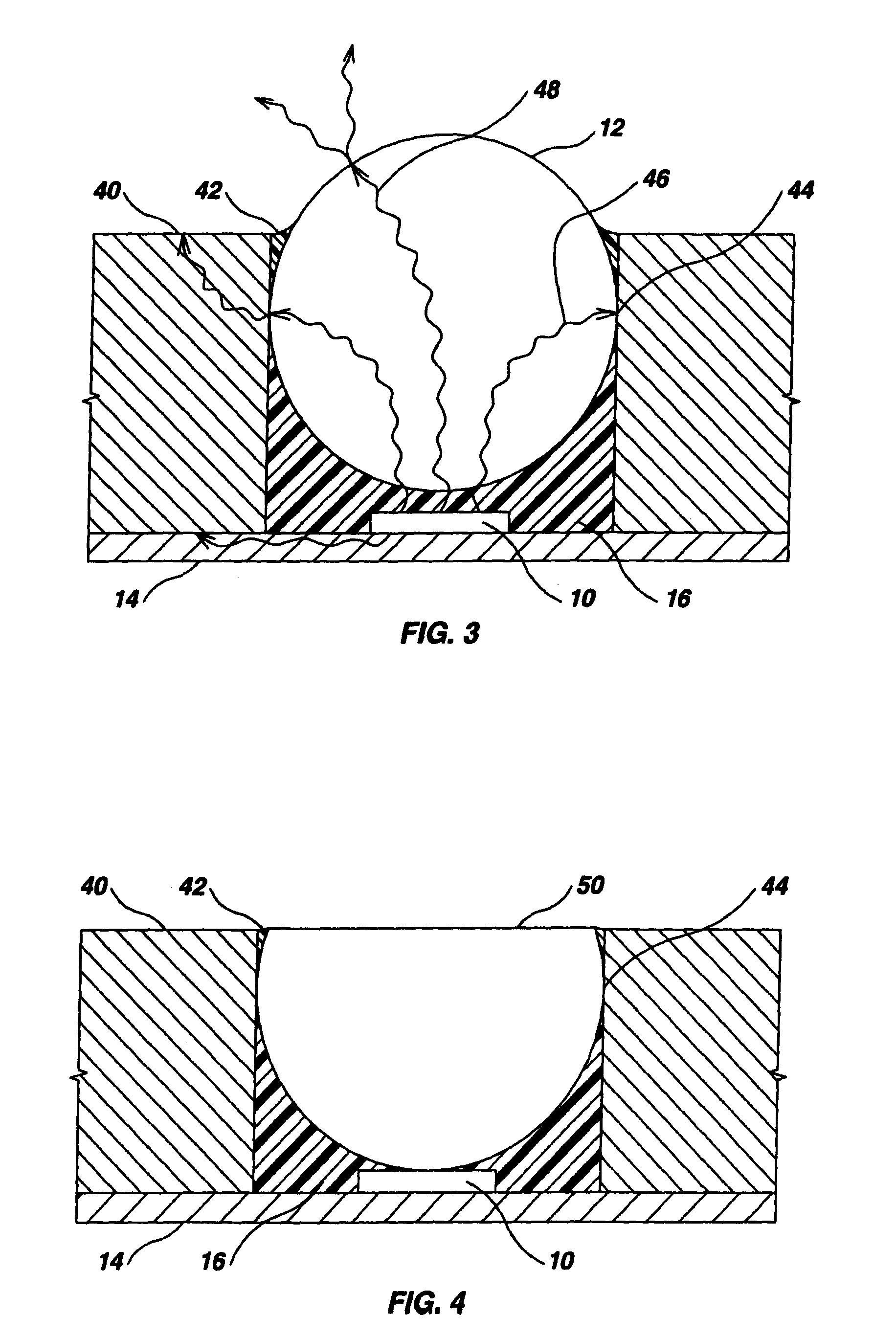

Turbine blade tip and shroud clearance control coating system

A turbine blade tip and shroud clearance control coating system comprising an abrasive blade tip coating and an abradable shroud coating are provided. The abrasive layer may comprise abrasive particles of cubic zirconia, cubic hafnia or mixtures thereof, and the abradable layer may be a nanolaminate thermal barrier coating that is softer than the abrasive layer. The invention further provides an alternate coating system comprising an abradable blade tip coating and an abrasive shroud coating.

Owner:HONEYWELL INT INC

Turbine blade tip and shroud clearance control coating system

A turbine blade tip and shroud clearance control coating system comprising an abrasive blade tip coating and an abradable shroud coating are provided. The abrasive layer may comprise abrasive particles of cubic zirconia, cubic hafnia or mixtures thereof, and the abradable layer may be a nanolaminate thermal barrier coating that is softer than the abrasive layer. The invention further provides an alternate coating system comprising an abradable blade tip coating and an abrasive shroud coating.

Owner:HONEYWELL INT INC

Turbine blade tip and shroud clearance control coating system

A turbine blade tip and shroud clearance control coating system comprising a dense abrasive blade tip layer and an abradable shroud layer are provided. The dense abrasive coating may comprise cubic zirconia, hafnia or mixtures thereof and the abradable layer may be a nanolaminate thermal barrier coating that is softer than the dense abrasive layer.

Owner:HONEYWELL INT INC

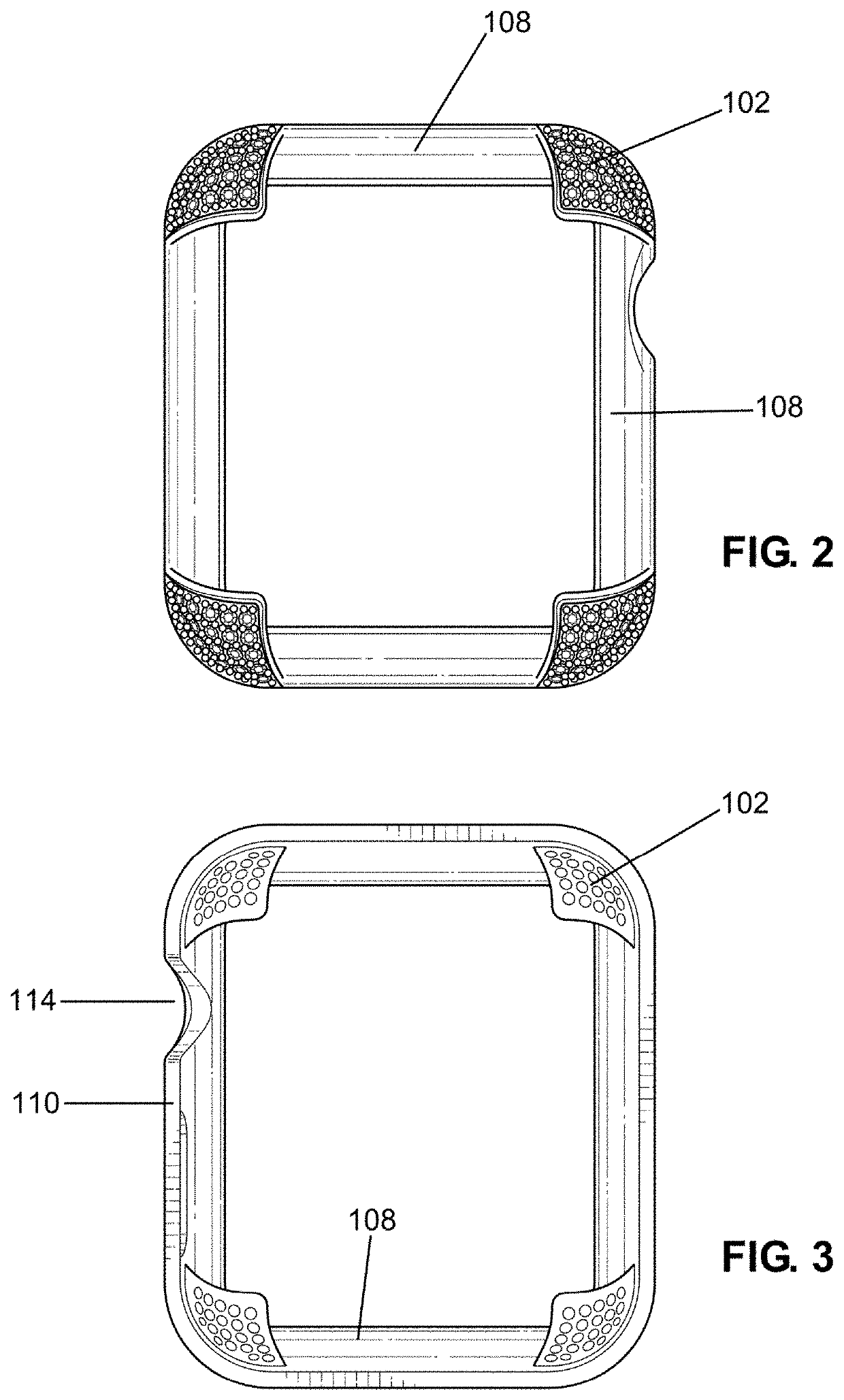

Smartwatch cover

InactiveUS20190369563A1Avoid contactProvide protectionEngine sealsElectronic time-piece structural detailsMechanical engineeringCubic zirconia

A watchcase cover has a top wall configured to reveal a watch face at a top side of a watchcase and the top wall comprising a top surface comprising decorative elements. Side walls of the case align with side walls of the watchcase and the side walls include: at least one cutout revealing a watch control positioned at the watchcase, and at least two strap apertures configured to receive a watch strap connected to the watchcase. The top wall and the side walls together define a major opening configured to receive the watchcase. The decorative elements may comprise cubic zirconia. A gasket is positioned at a junction of an interior surface of the top wall and interior surfaces of the side walls.

Owner:PRIME ART & JEWEL

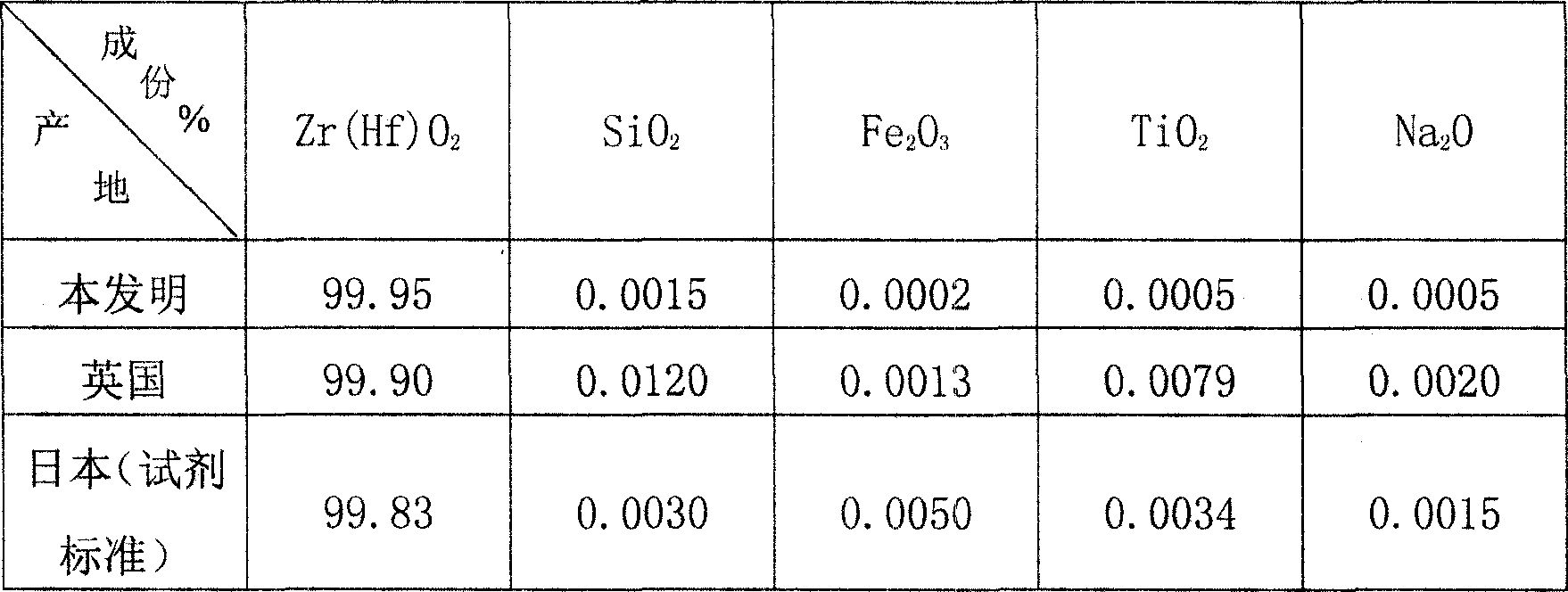

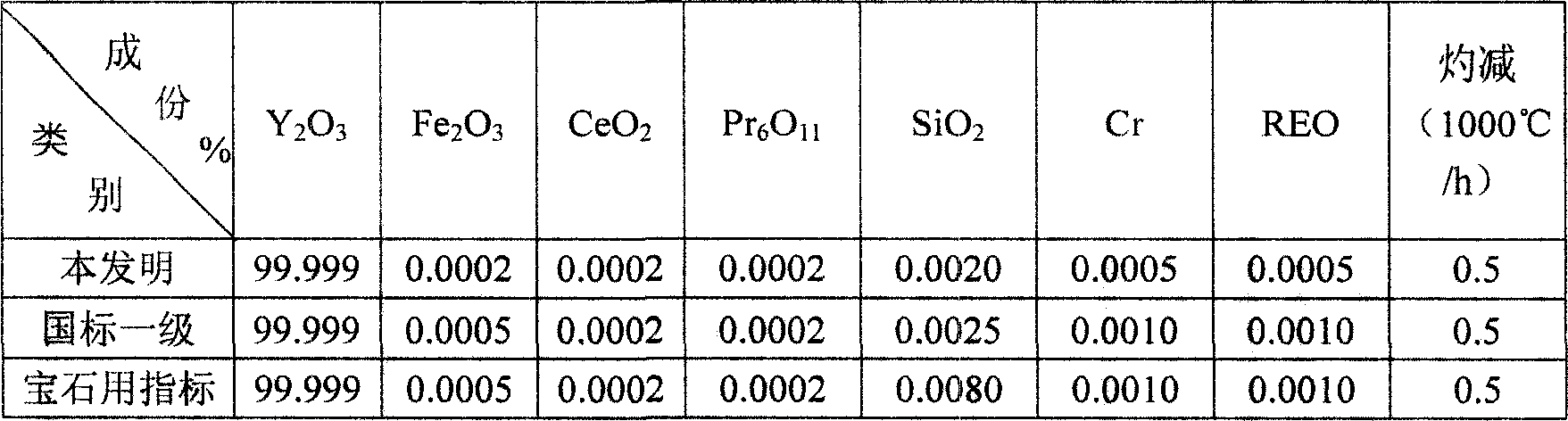

Process of preparing zirconia and yttria with Y-doped cubic zirconia powder

InactiveCN1986423AHigh metal contentLow priceRare earth metal compoundsZirconium oxidesOXALIC ACID DIHYDRATEPhysical chemistry

The process of preparing zirconia and yttria with Y-doped cubic zirconia powder includes the following steps: alkali fusing and sintering Y-doped cubic zirconia powder, water washing to eliminate sodium, acidifying and concentrating to obtain Zr crystal, oxychlorination to re-crystallize and purify, and high temperature calcining to obtain high purity jewel level zirconia; concentrating Y-containing mother liquid to crystallize zirconia, purifying high Y mother liquid, precipitating Y in oxalic acid solution, and high temperature calcining to obtain high purity jewel level yttria. The present invention has relatively low cost.

Owner:王必庆

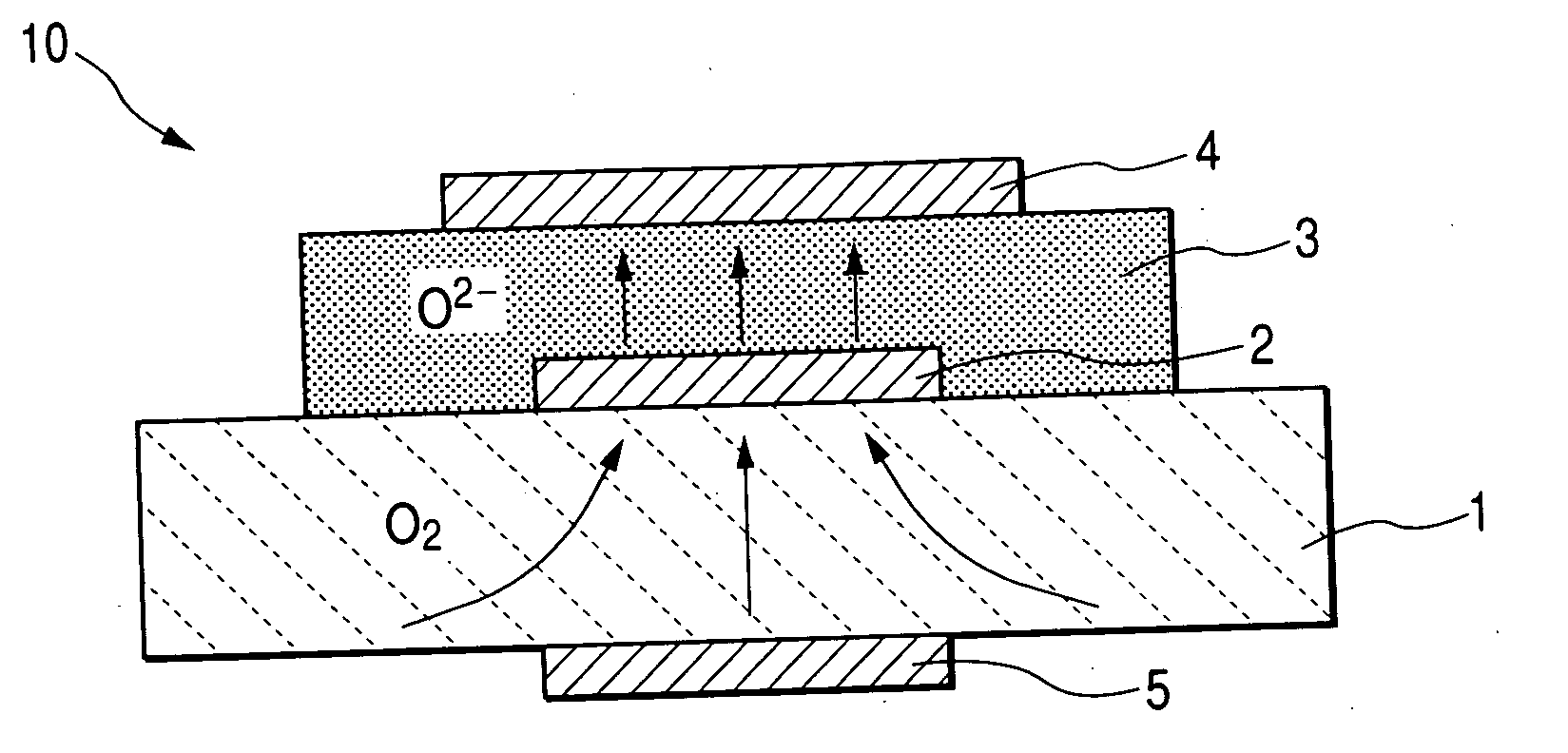

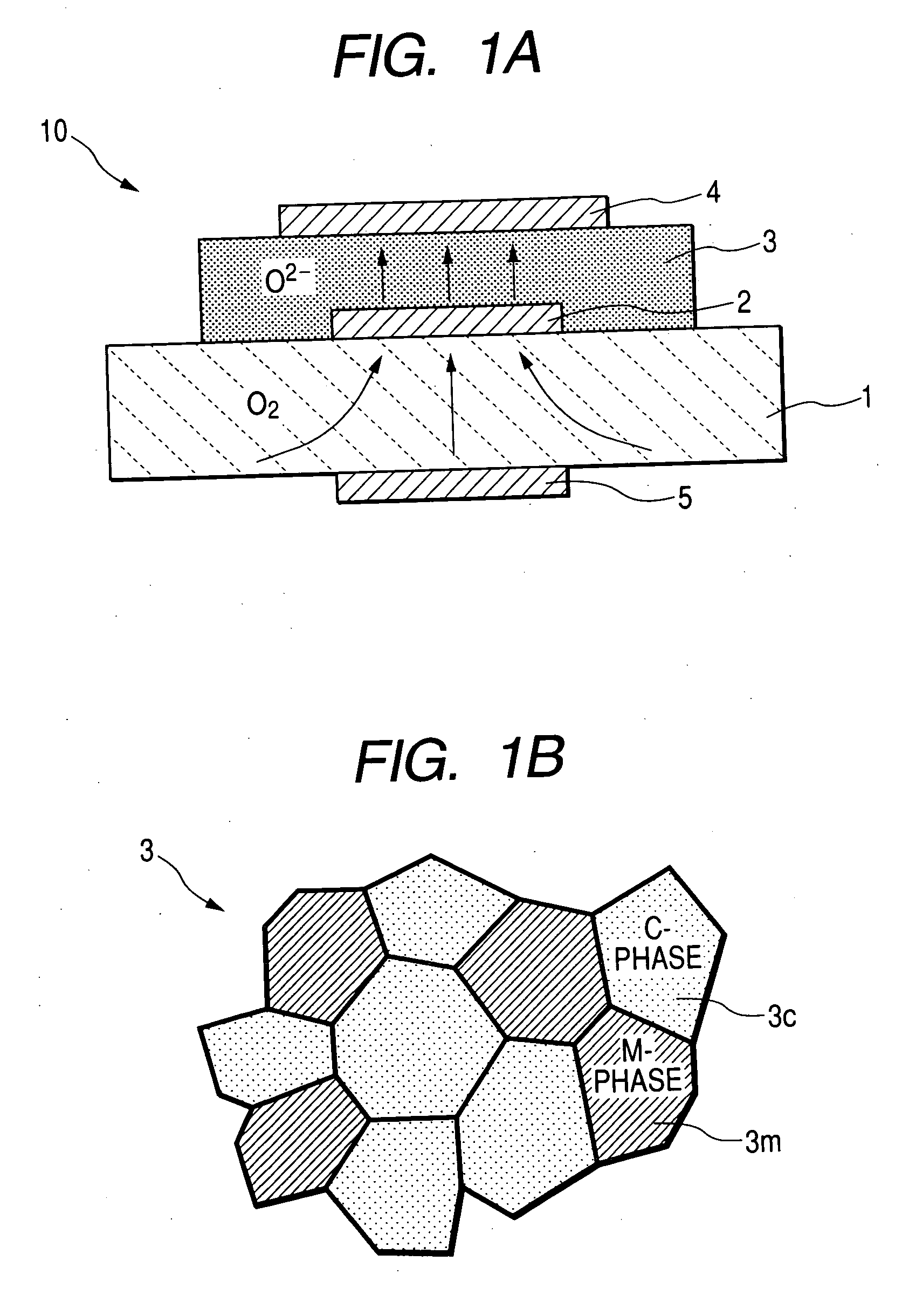

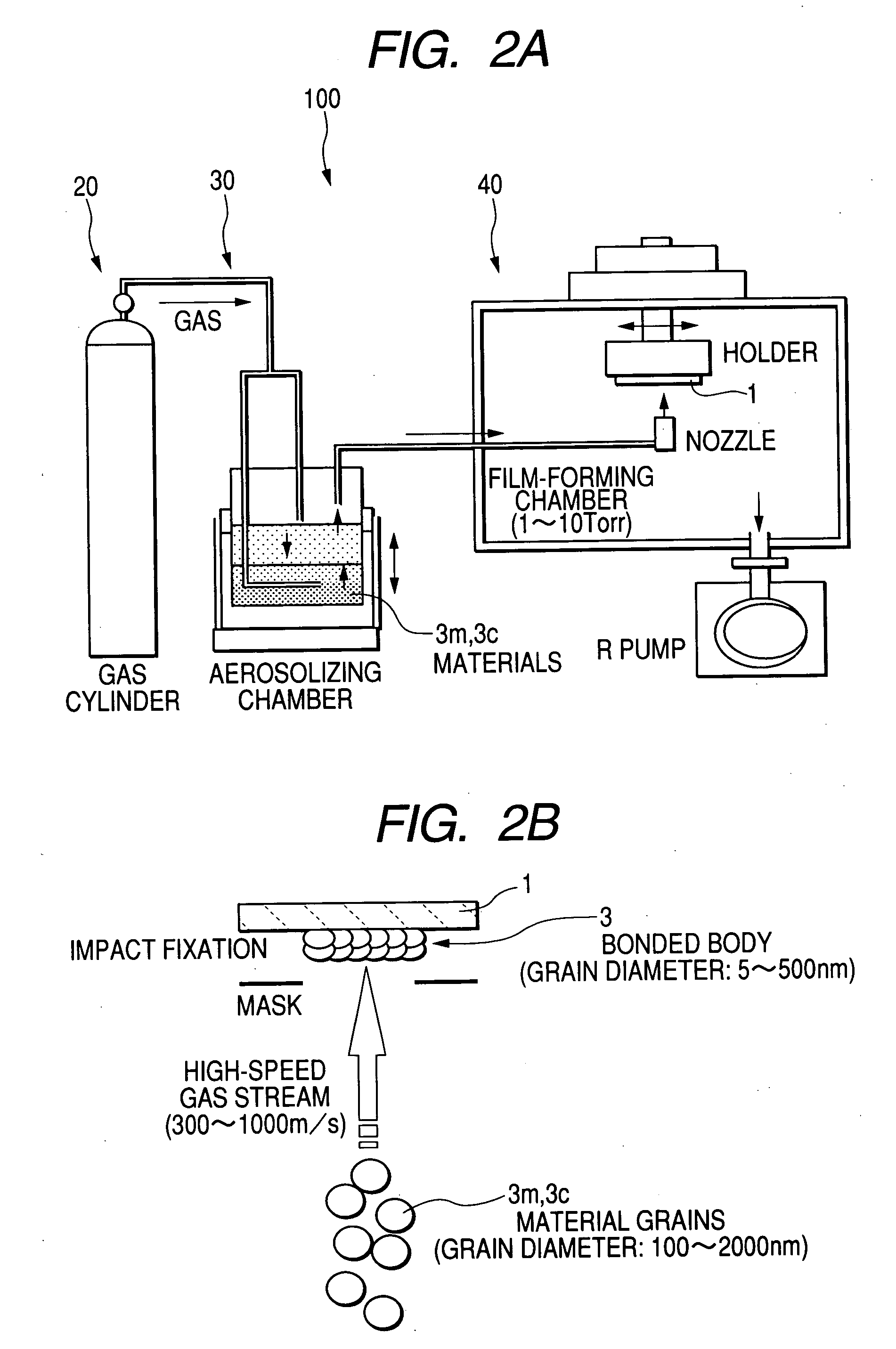

Zirconia structural body and manufacturing method of the same

InactiveUS20060009344A1Improve reliabilityImprove responseMaterial analysis by electric/magnetic meansSuperimposed coating processCubic zirconiaCrystallite

A zirconia structural body includes a substrate having one surface on which a first electrode, a zirconia layer, and a second electrode are successively laminated. The zirconia layer is a bonded body of mixture consisting of monoclinic zirconia crystal grains and cubic zirconia crystal grains.

Owner:DENSO CORP

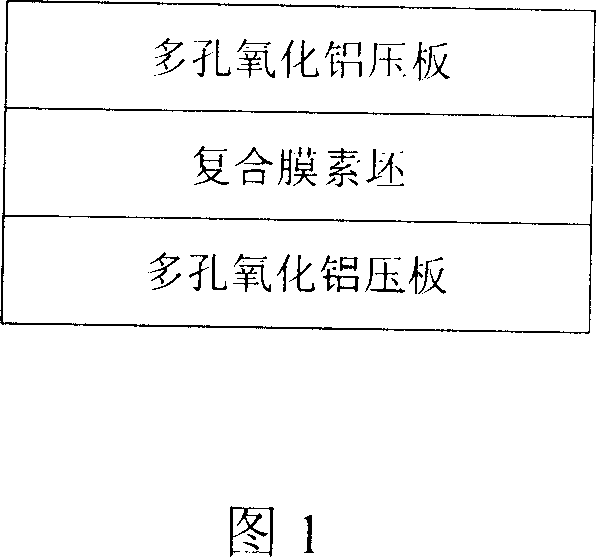

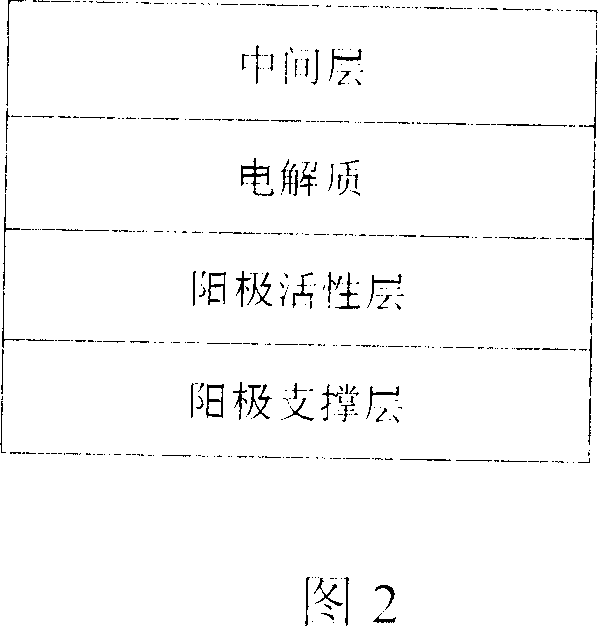

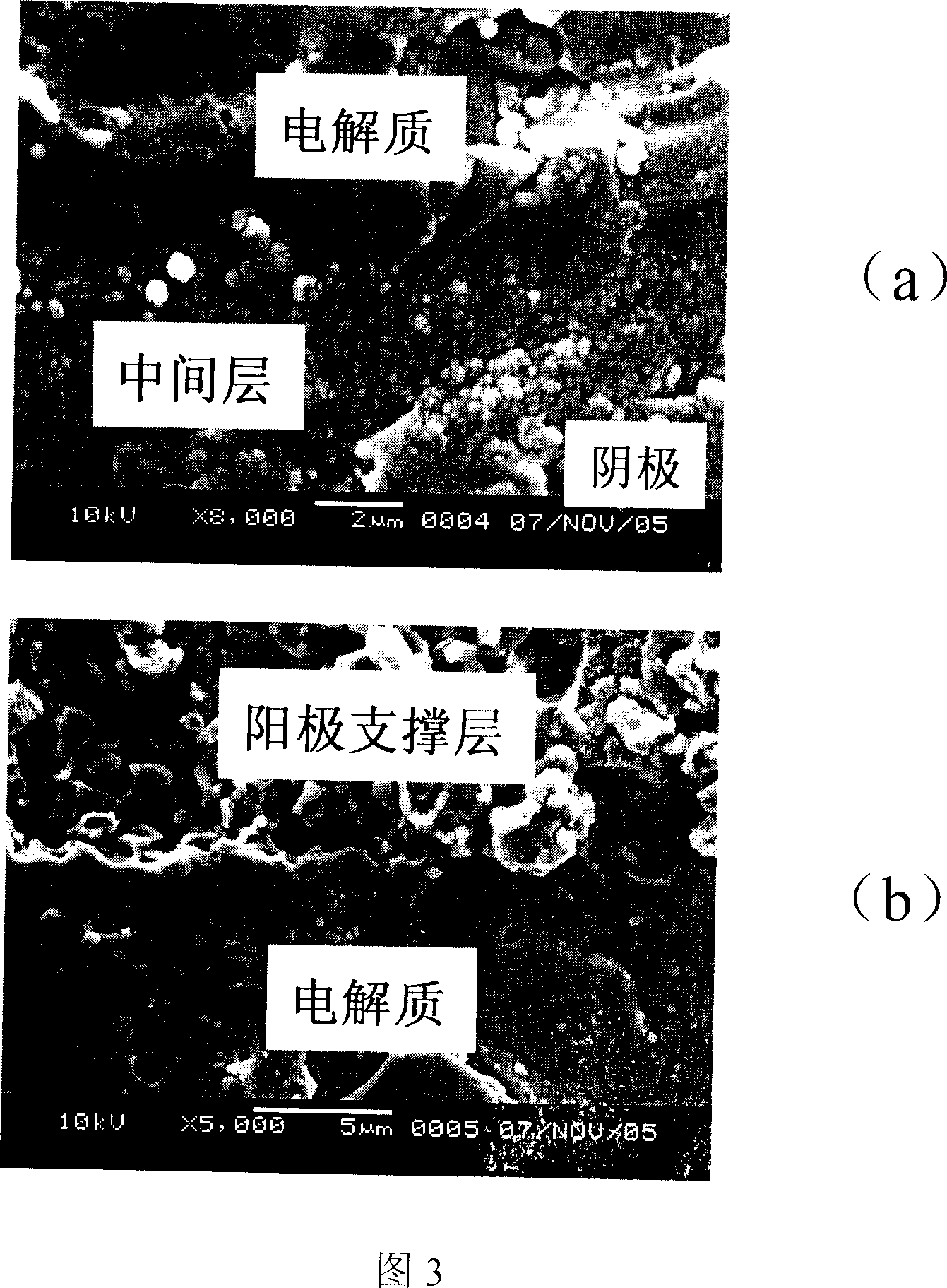

Anode supporting solid electrolyte compound film for solid oxide fuel battery and its preparing method

InactiveCN1925200AEasy to adjustControl thicknessCell electrodesSolid electrolyte fuel cellsFuel cellsGadolinium

This invention relates to solid oxidation fuel battery anode supportive electrolyte compound film, which comprises the following layers: anode supportive layer by NiO-YSZ of 3mol%Y<2>O<3; anode active layer by NiO-SSZ; solid electrolyte layer of SSZ 9mol% scandium oxide with total stable zircite and middle layer of CGO mixed with 20mol% cerium oxide.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

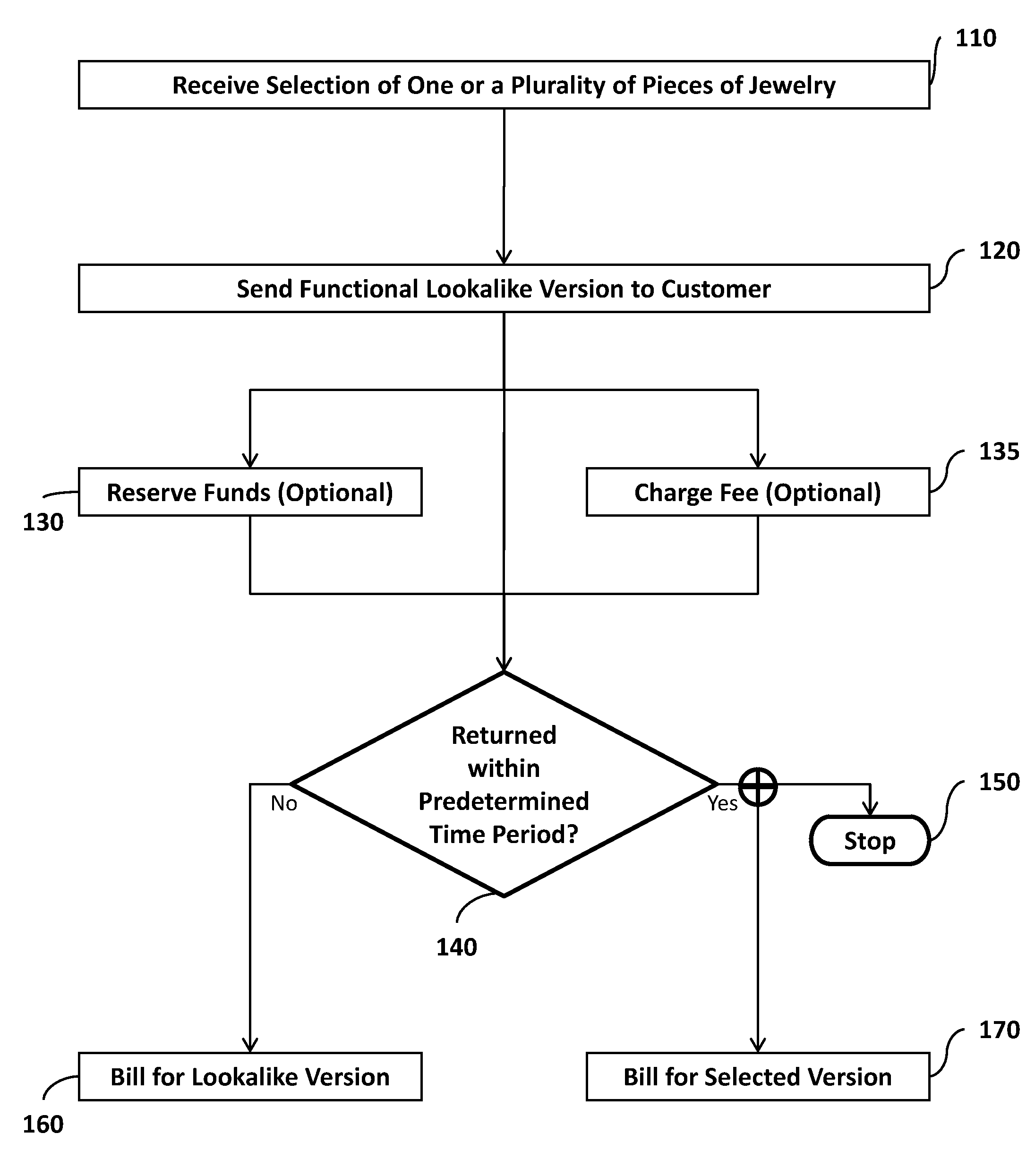

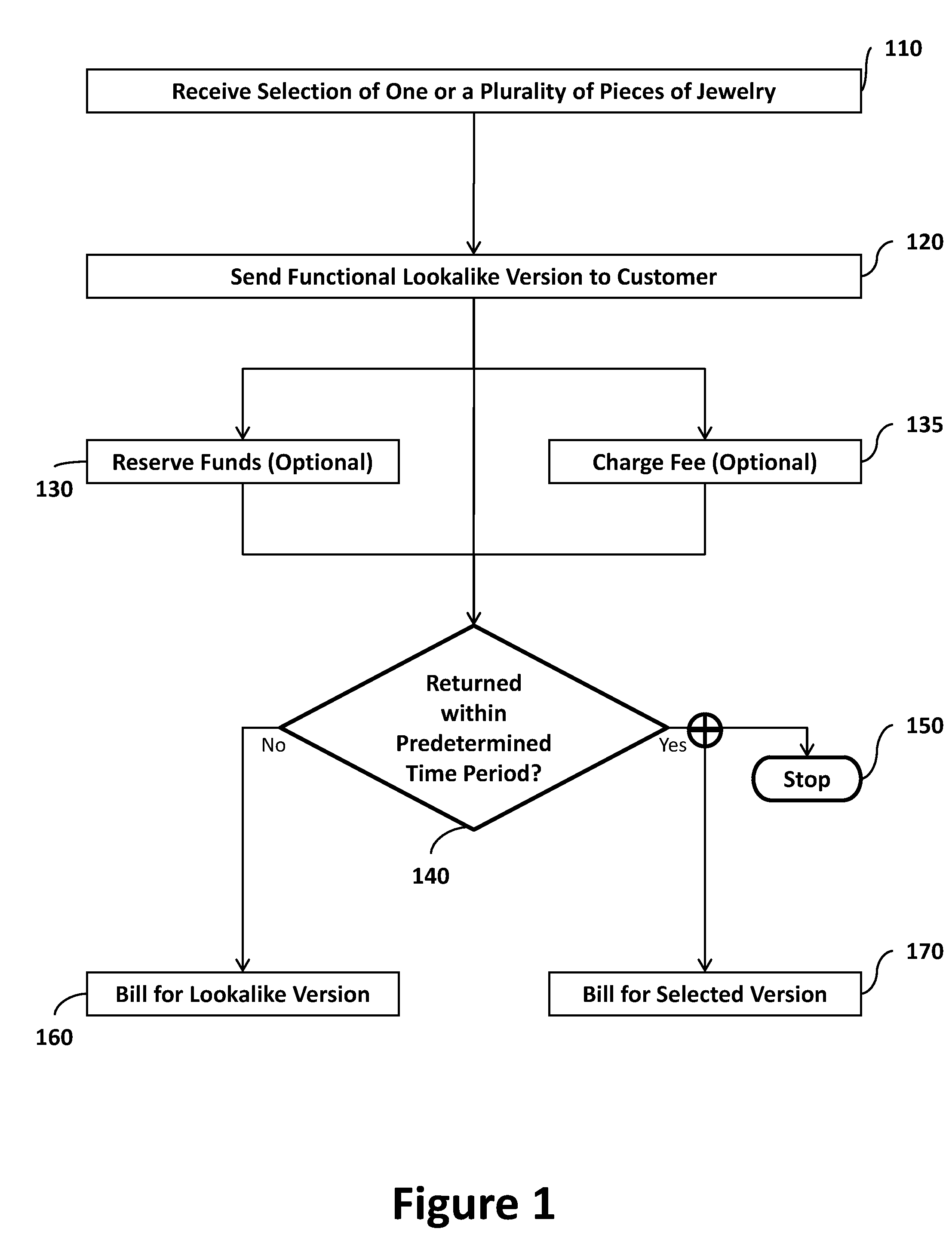

Look-alike Tryout of Mail Order Product Before Purchase

The disclosed technology comprises a method of providing a functional version of a product to a potential buyer via postal services. The potential buyer may try out the product for a limited amount of time, and then return same to the seller or pay for the look-alike product / purchase the actual product. This method may be used with jewelry, clothing, electronics, and other items. For example, in an embodiment of the disclosed technology, a buyer may desire to try 1, 2, 3 or more diamond rings with gold bands. A cubic zirconia ring with a silver or copper alloy band may be sent to the potential buyer via mail or a courier to try out for a limited time period, during which he / she can decide whether to purchase the real product. In this manner, risk of loss of goods to the seller is lessened, and the ability to touch and feel a product which functions like the original is granted to the potential buyer before making a purchase.

Owner:RENDLER YONAH

Turbine blade tip and shroud clearance control coating system

A turbine blade tip and shroud clearance control coating system comprising a dense abrasive blade tip layer and an abradable shroud layer are provided. The dense abrasive coating may comprise cubic zirconia, hafnia or mixtures thereof and the abradable layer may be a nanolaminate thermal barrier coating that is softer than the dense abrasive layer.

Owner:HONEYWELL INT INC

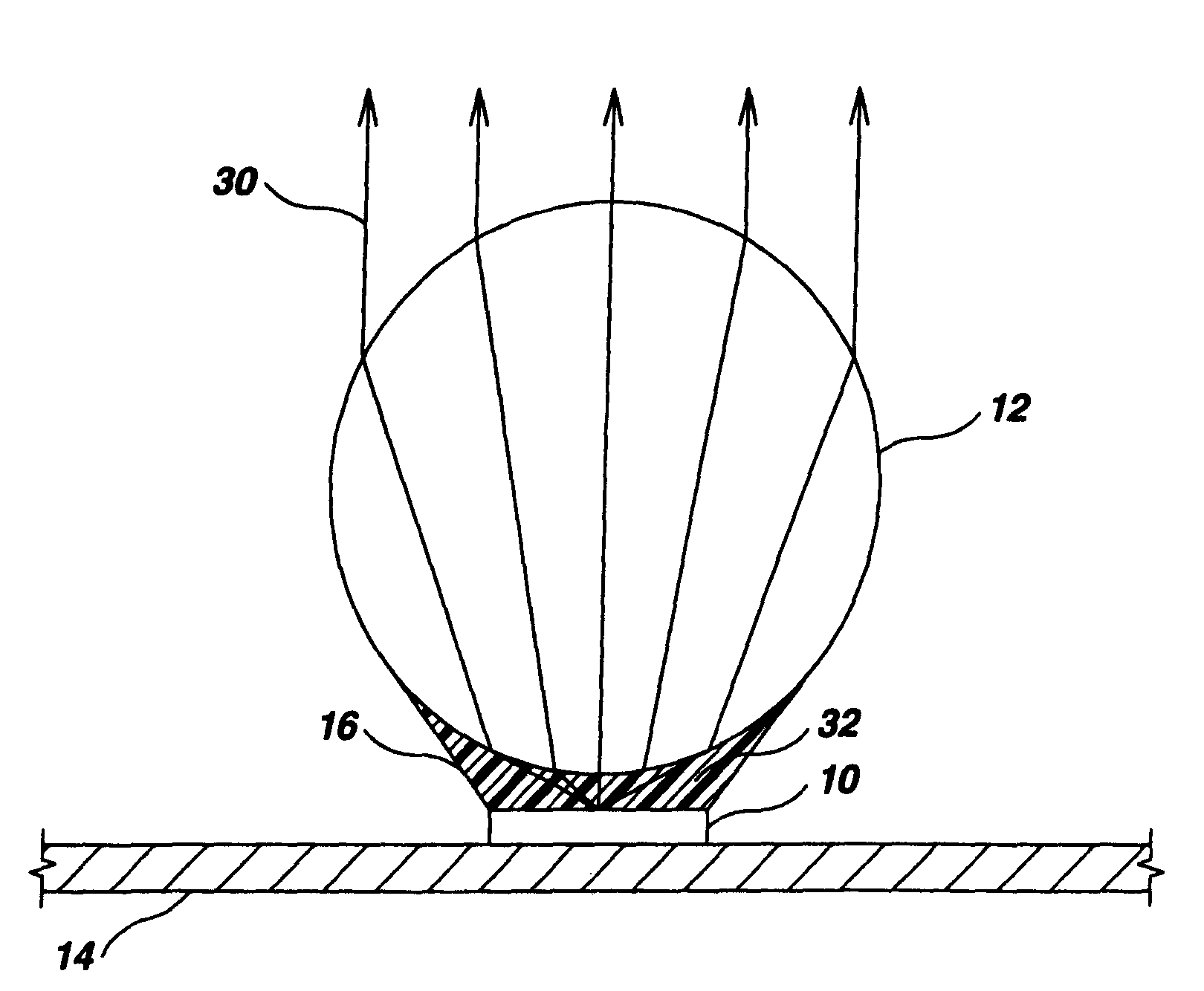

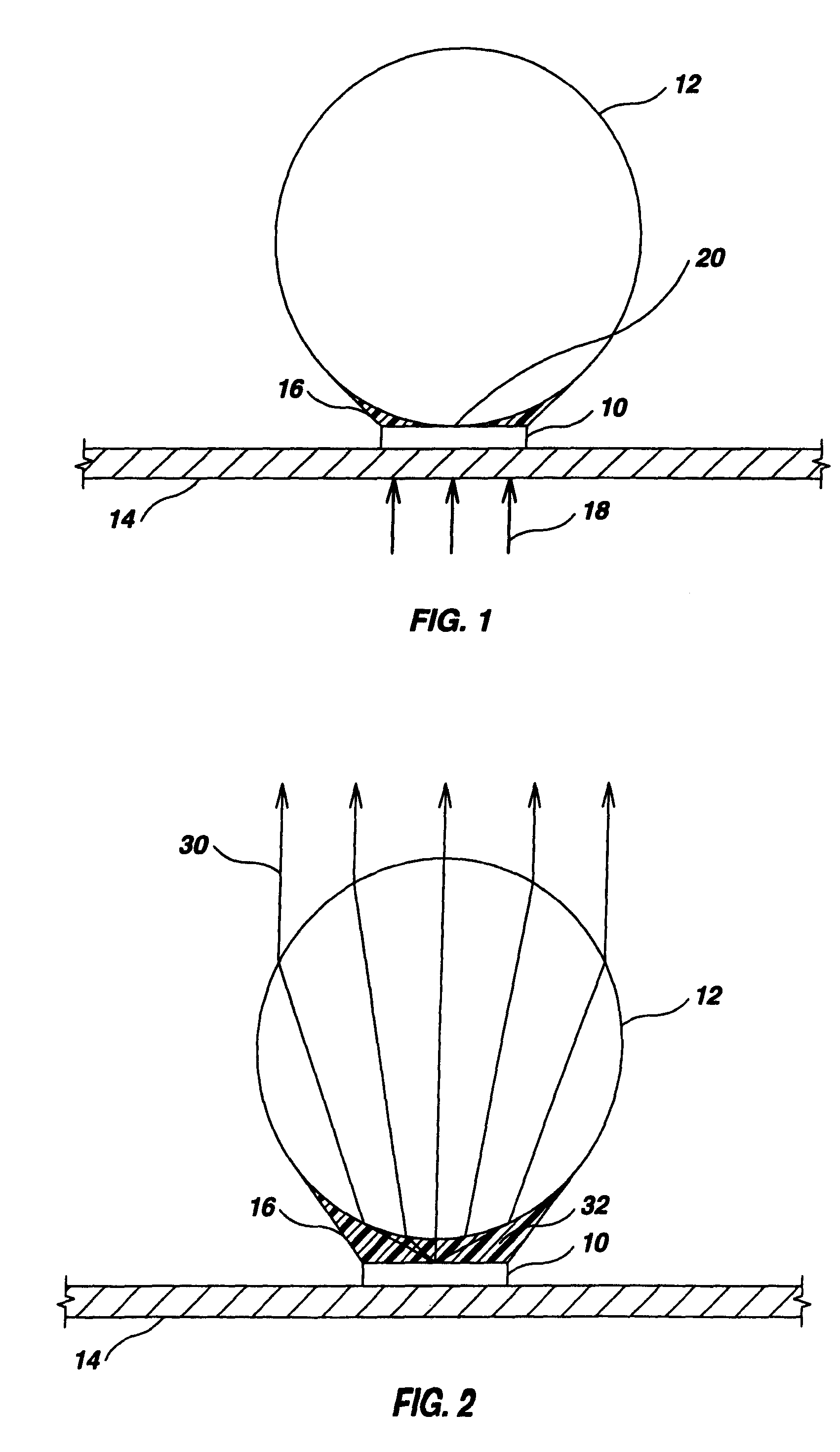

LED Illumination Device with Cubic Zirconia Lens

A lens element has a curved surface mounted adjacent an LED for improving the light transmission efficiency and the dispersal pattern of radiation emitted by the LED.

Owner:DEEPSEA POWER & LIGHT

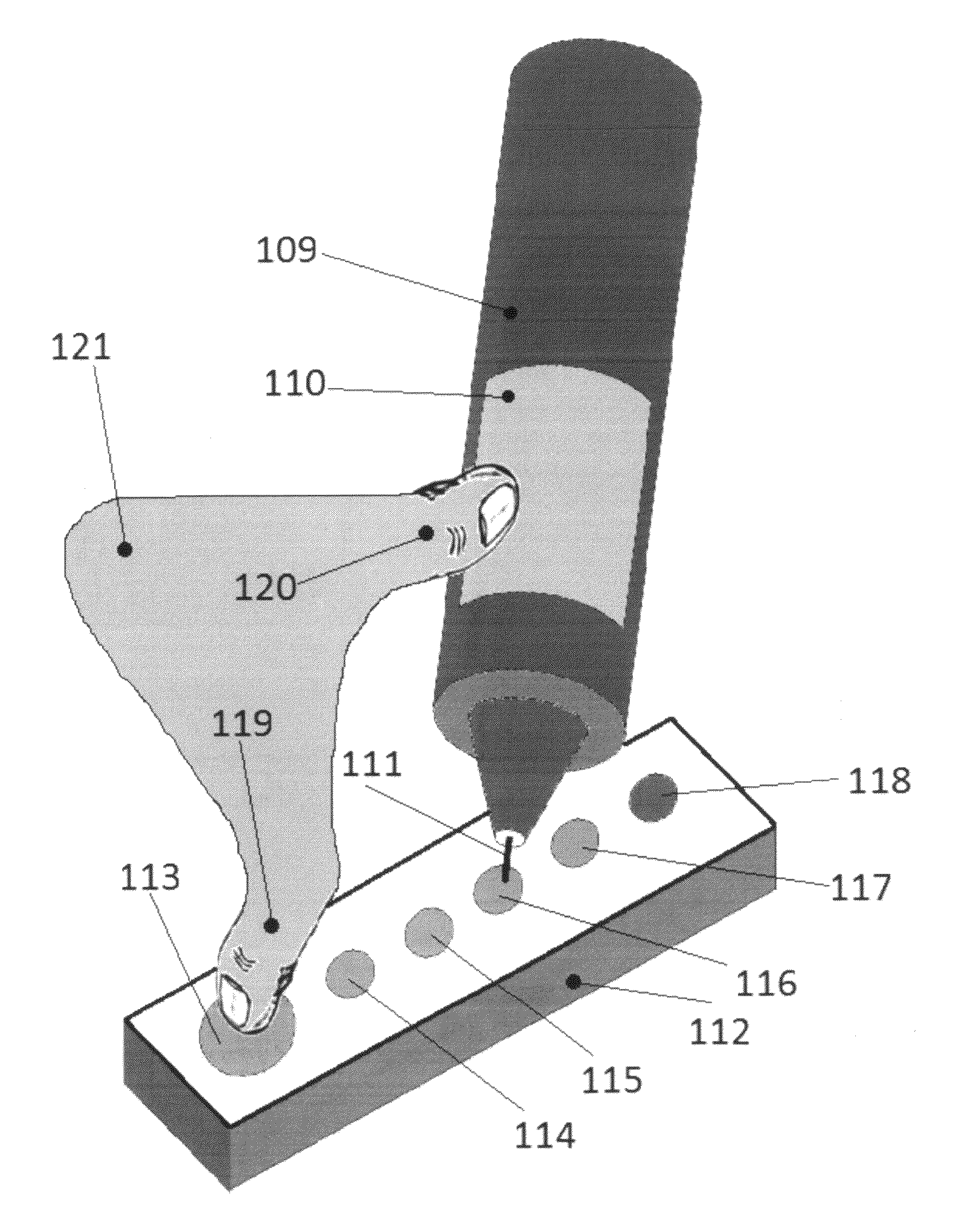

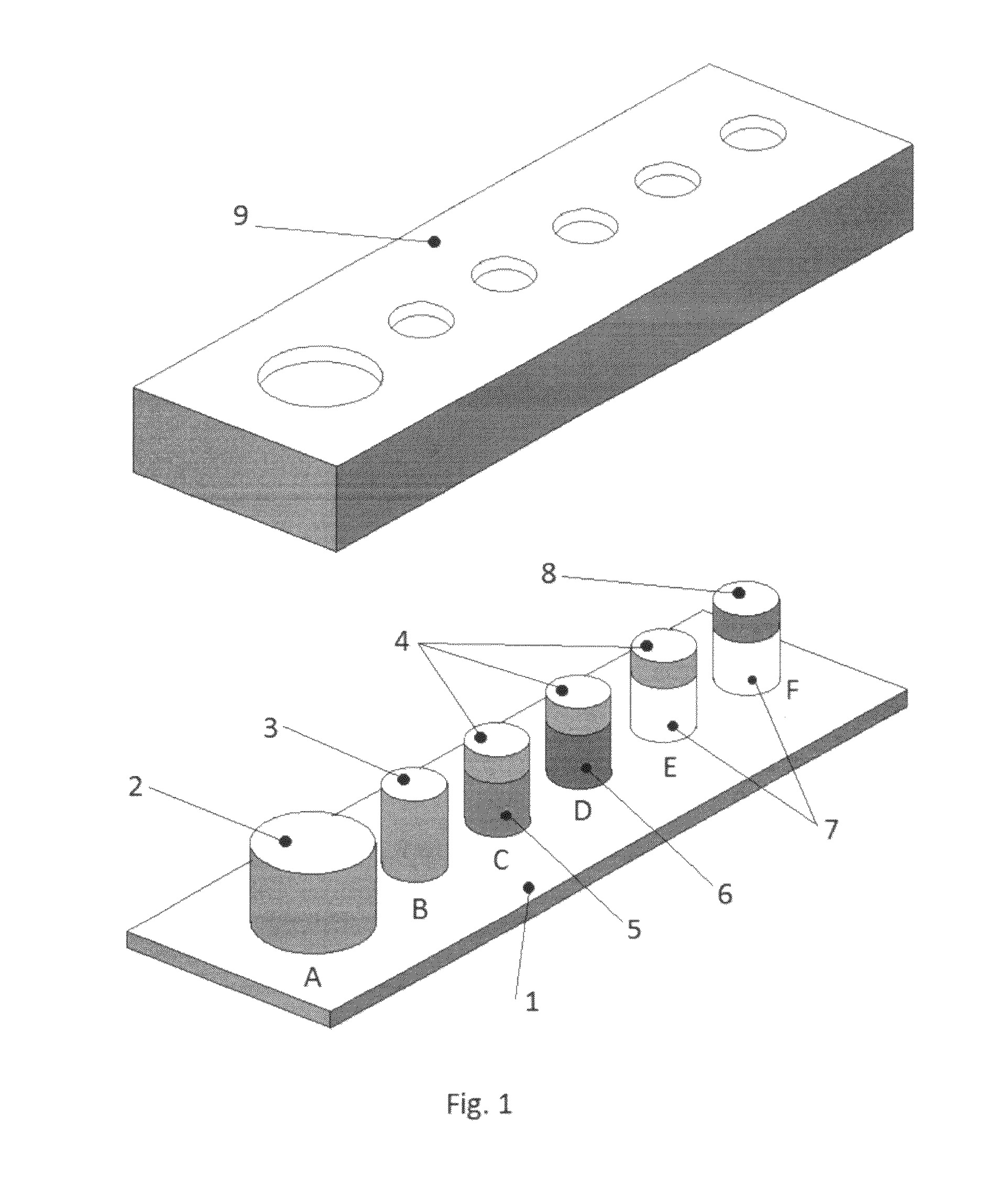

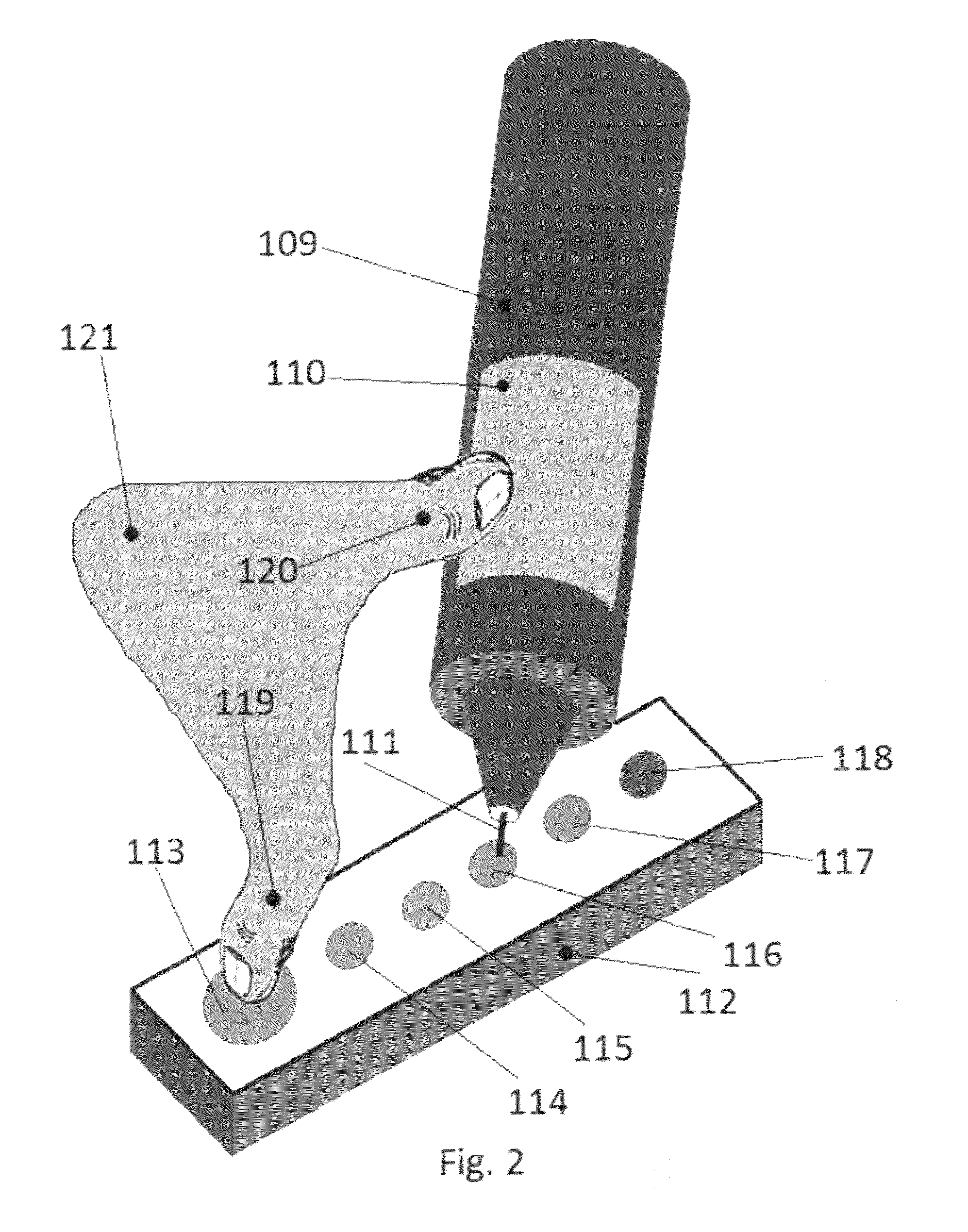

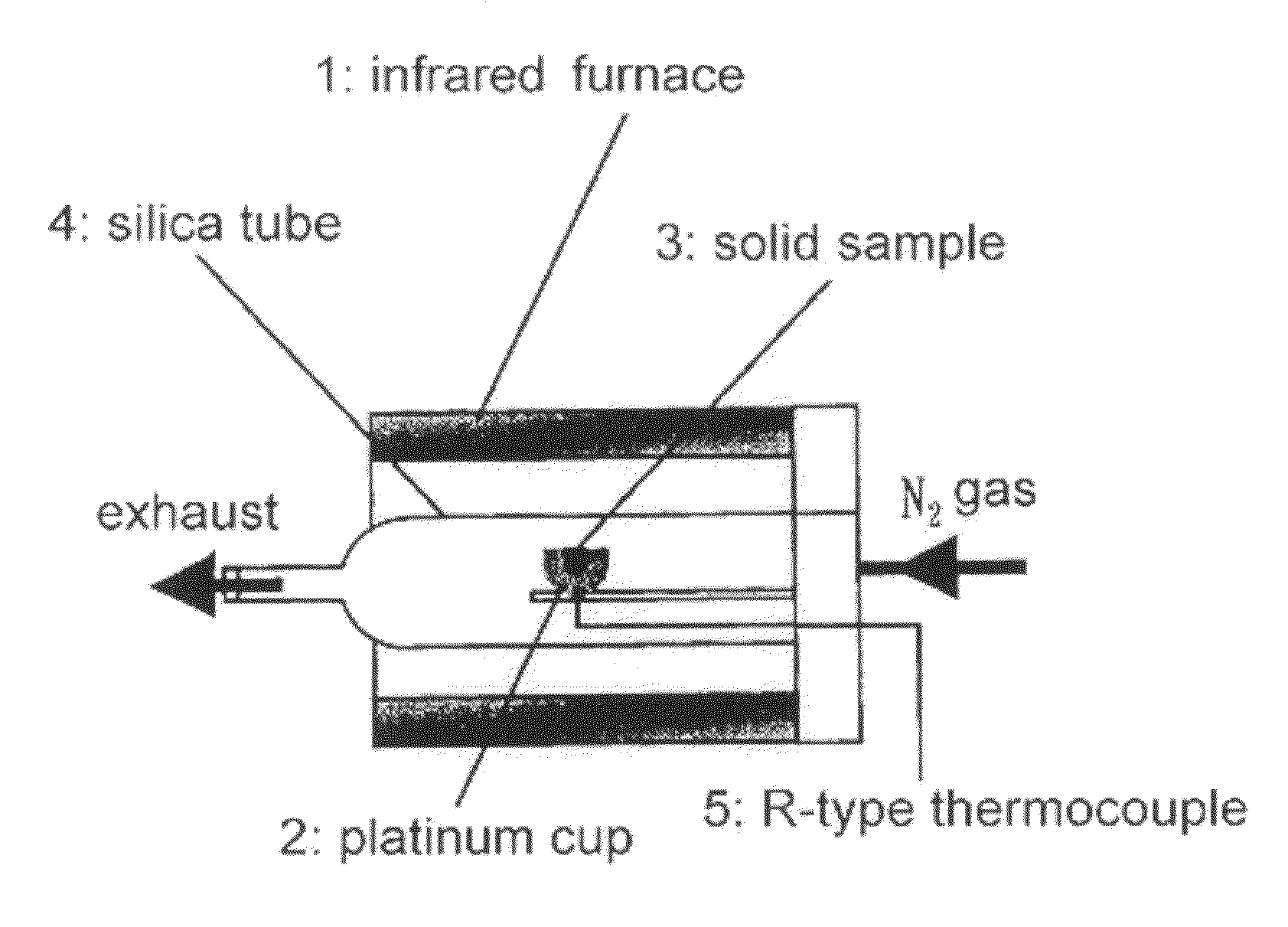

Apparatus for simulating thermal conductivity and electrical resistance of diamonds and their substitutes

InactiveUS8278906B2Resistance/reactance/impedenceElectrical testingElectrical resistance and conductanceMoissanite

The invention relates to substitutes of real gems for the purpose of calibrating of commercial diamond testers and for verification of their correct operation. Suggested apparatus consists of a set of objects, which are made of cheap materials like brass, stainless steel, and electrically conductive rubber, and which exhibit combination of thermal and electric conductivities typical for diamonds and their popular imitations like moissanites, cubic zirconia, and others.

Owner:TRI ELECTRONICS

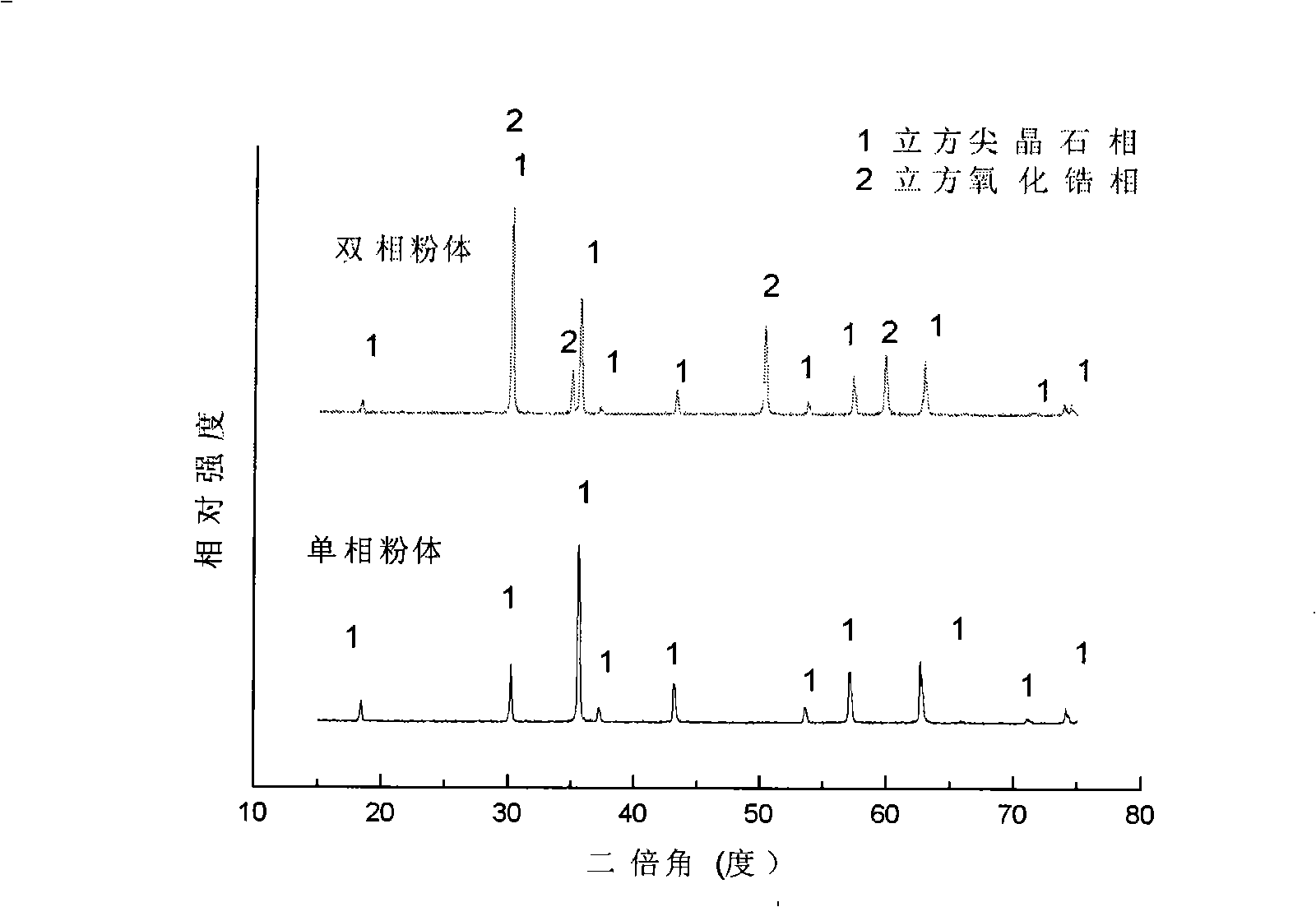

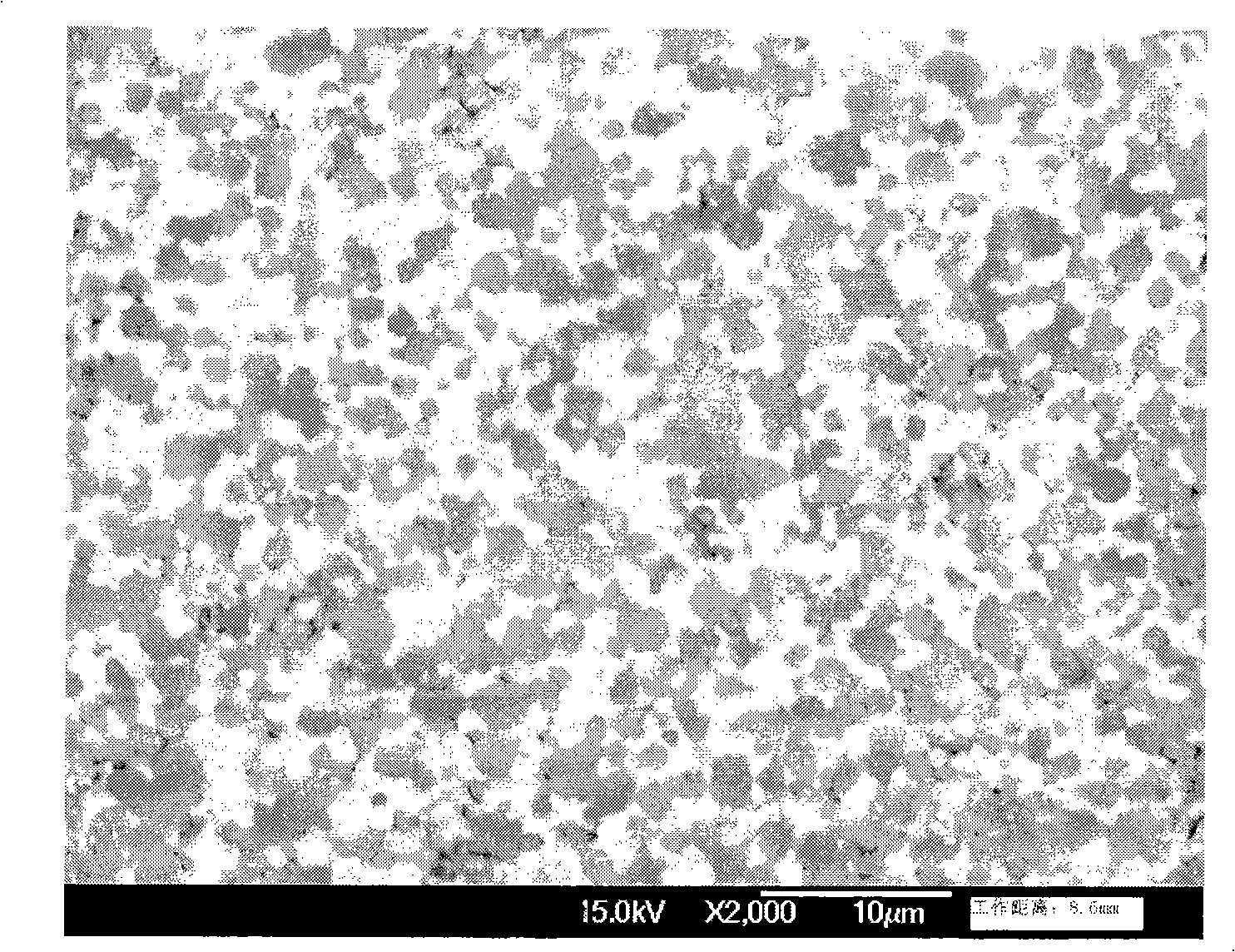

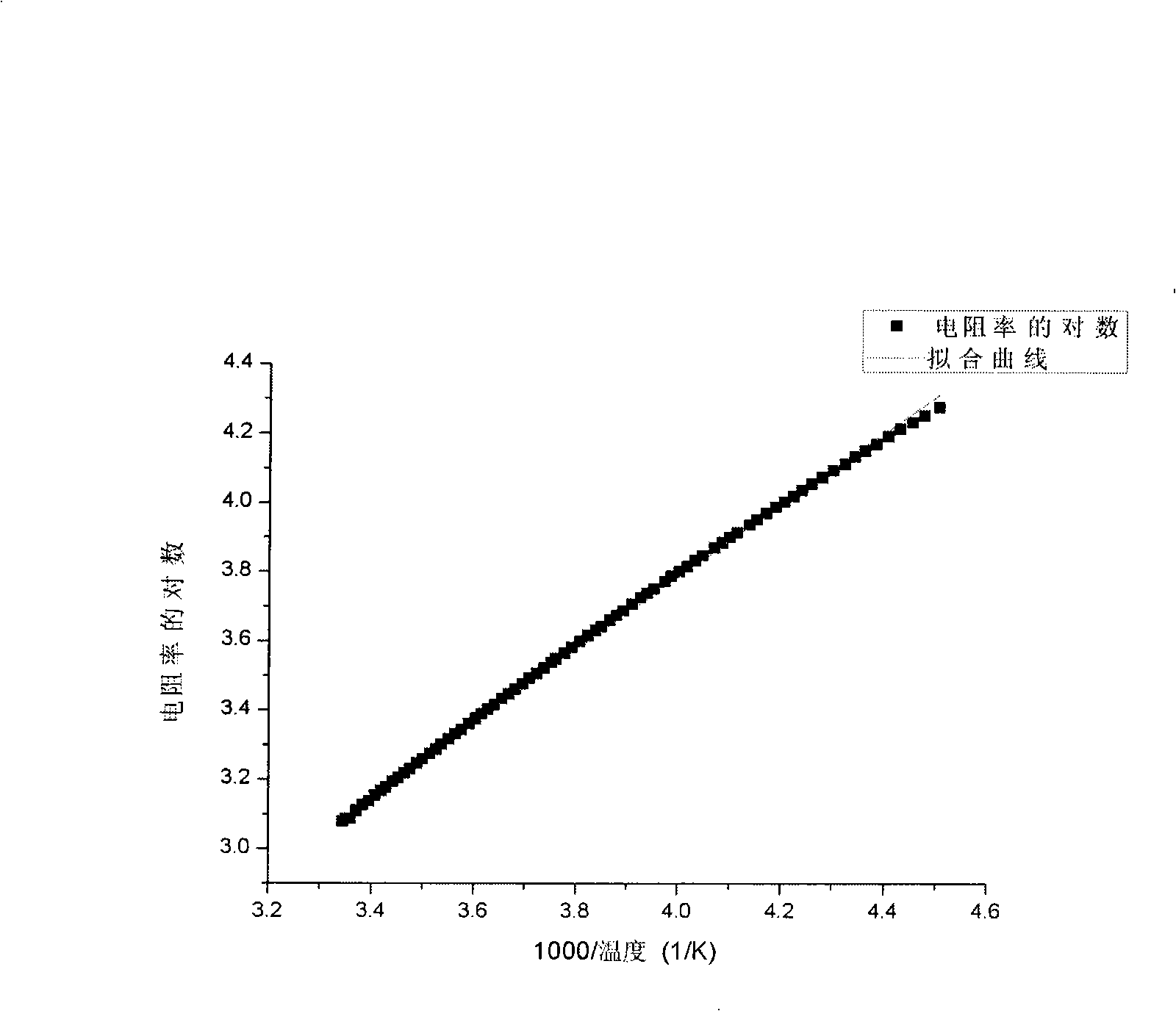

Negative temperature coefficient two-phase composite thermistor composition and preparation thereof

The invention discloses a negative temperature coefficient two-phase composite heat-sensitive material and a method for preparing the same characterized by mixing and milling the copper acetate, ferric oxalate, manganese acetate, nickel acetate and oxalate according to the mol ratio of 0.2-0.6: 1: 3.48-3.08: 1.32: 7.2, calcining the mixture after drying, mixing the prepared powder with partial stable cubic zirconia powder according to the mol ratio of 1: 1.5-4, getting two-phase composite powder after milling and drying, getting the negative temperature coefficient material with a relative density more than 94% after sintering. The material has a stable structure, a sintering temperature between 1200 and 1250 DEG C, a higher mechanical strength than the single-phase spinel ceramic, a B value less than 2800K, a resistivity of 1000omega.cm, a resistance drift less than 3% when accelerated ageing 1000 hours at 150 DEG C, a very good NTC property between -60 DEG C to +50 DEG C, and is suitable for the negative temperature coefficient heat sensitive sensor material in the modern aerostat.

Owner:HEFEI SENSING ELECTRONICS +1

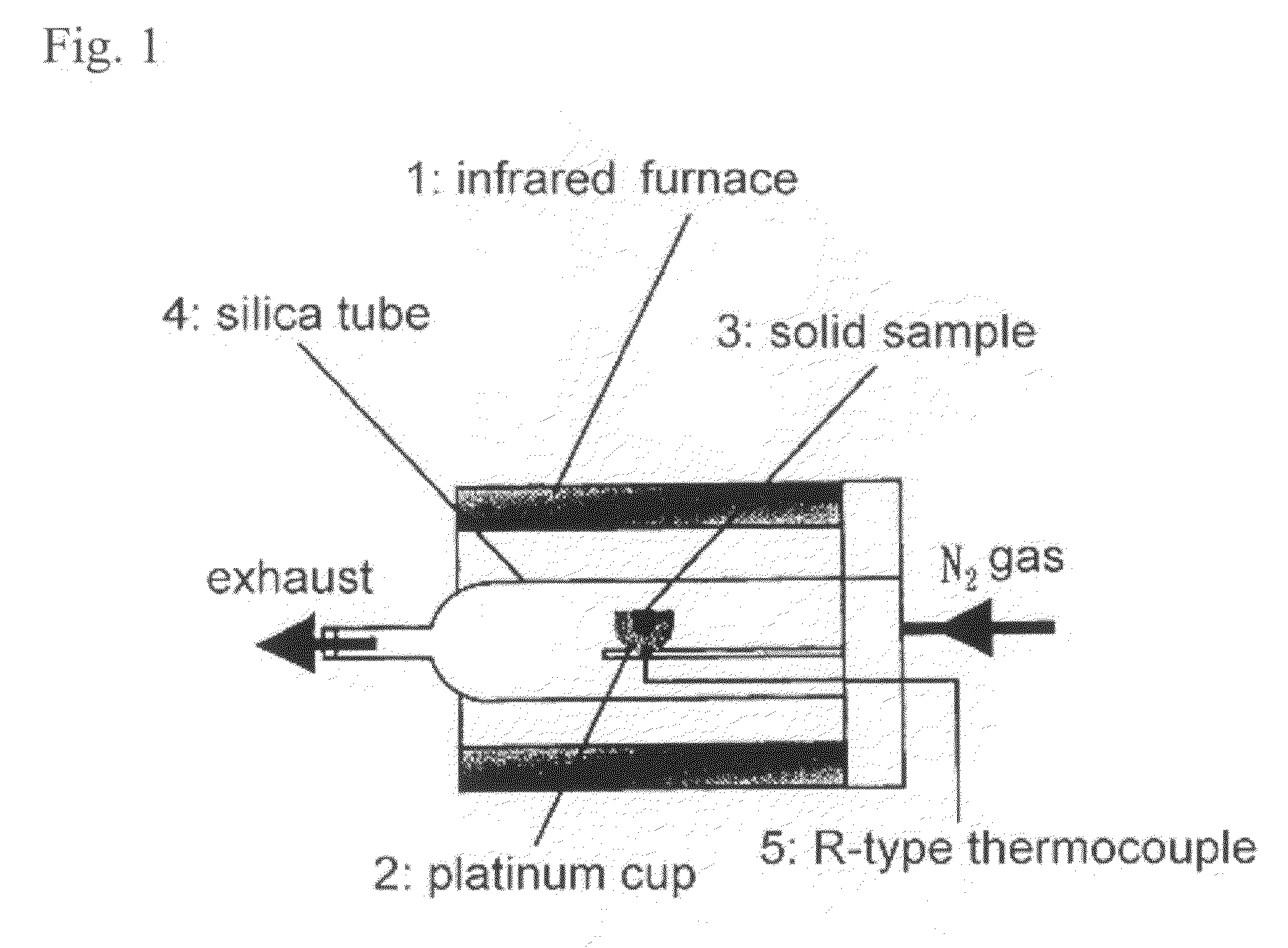

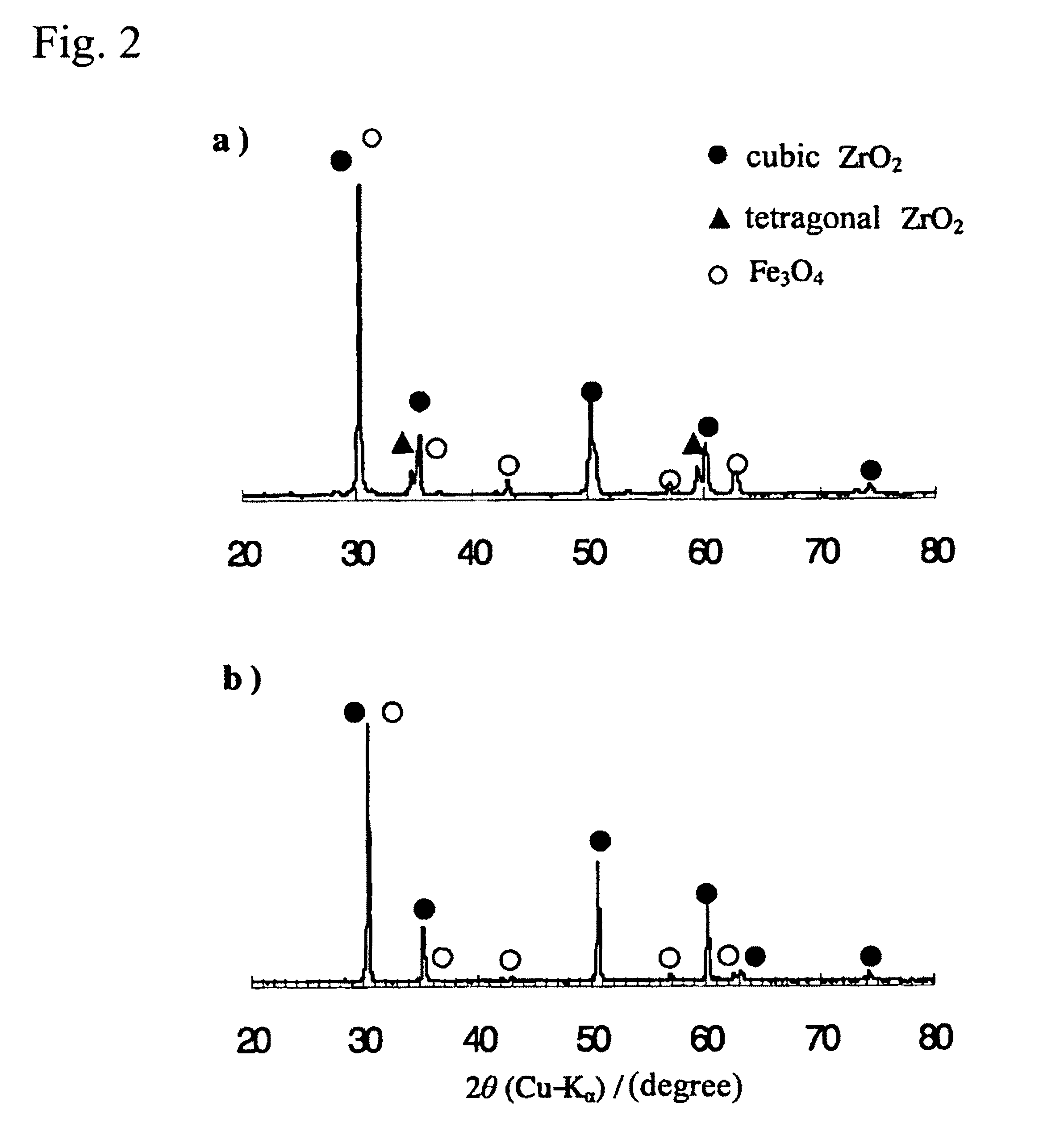

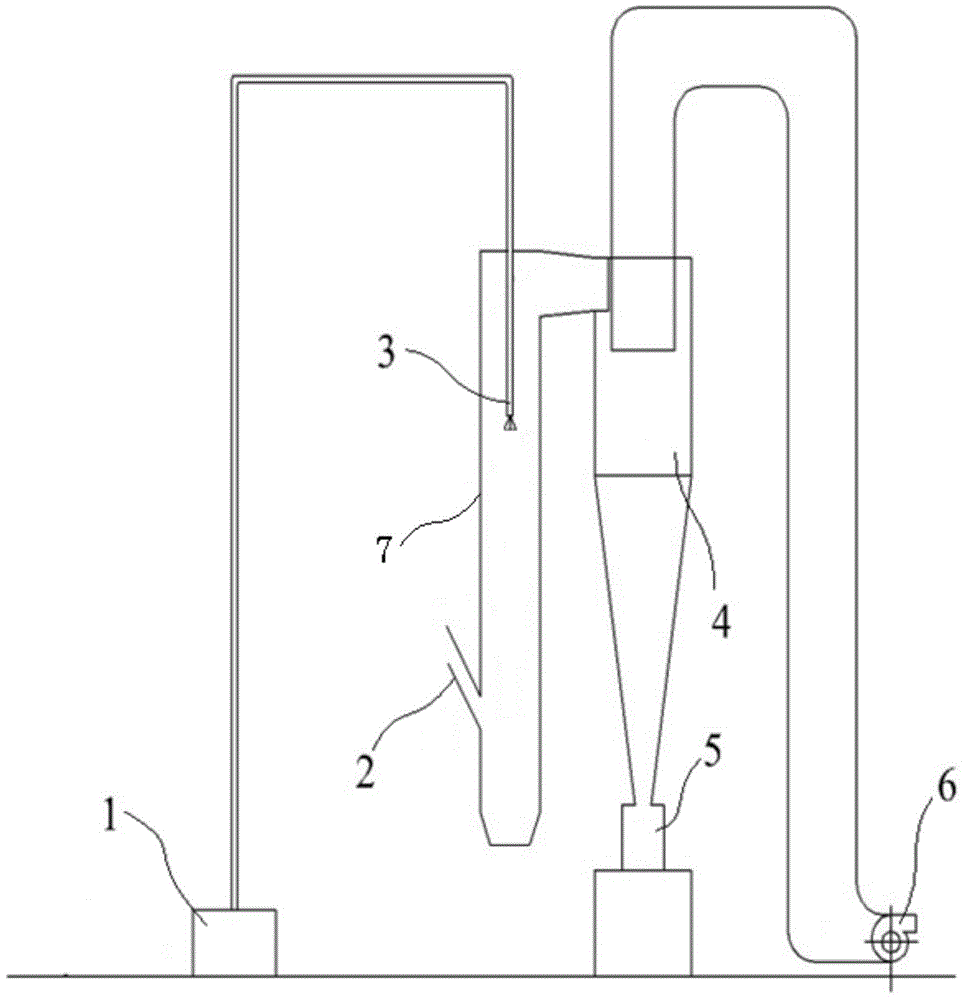

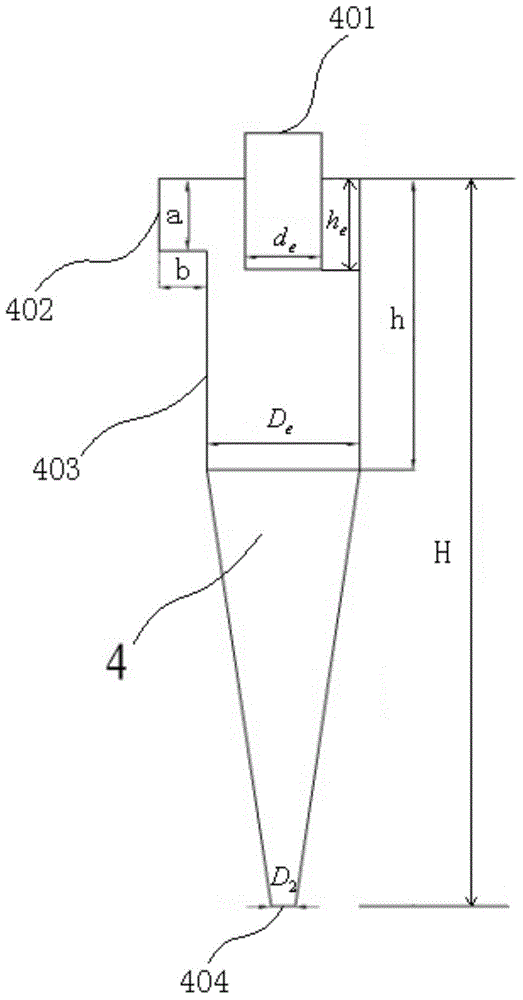

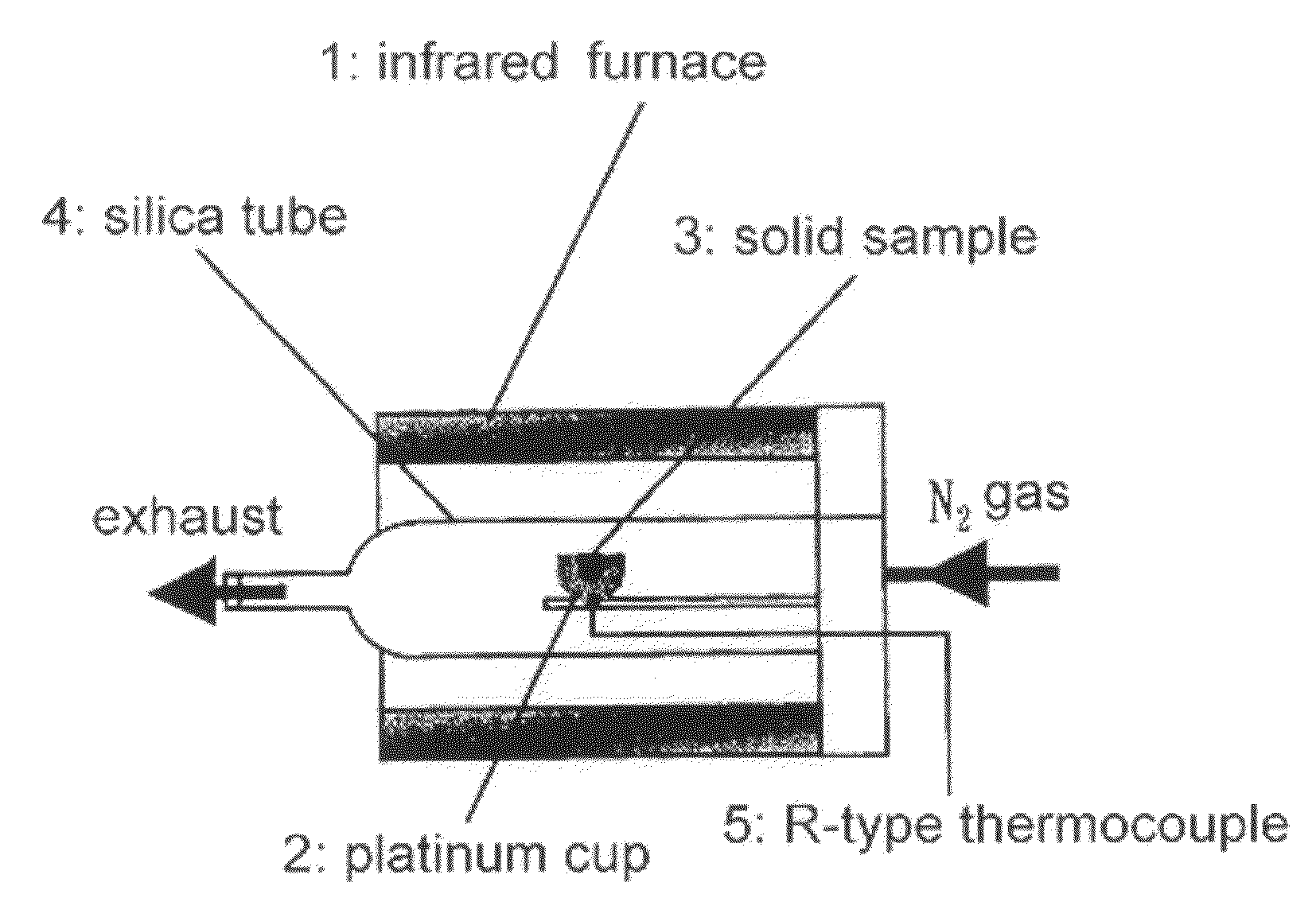

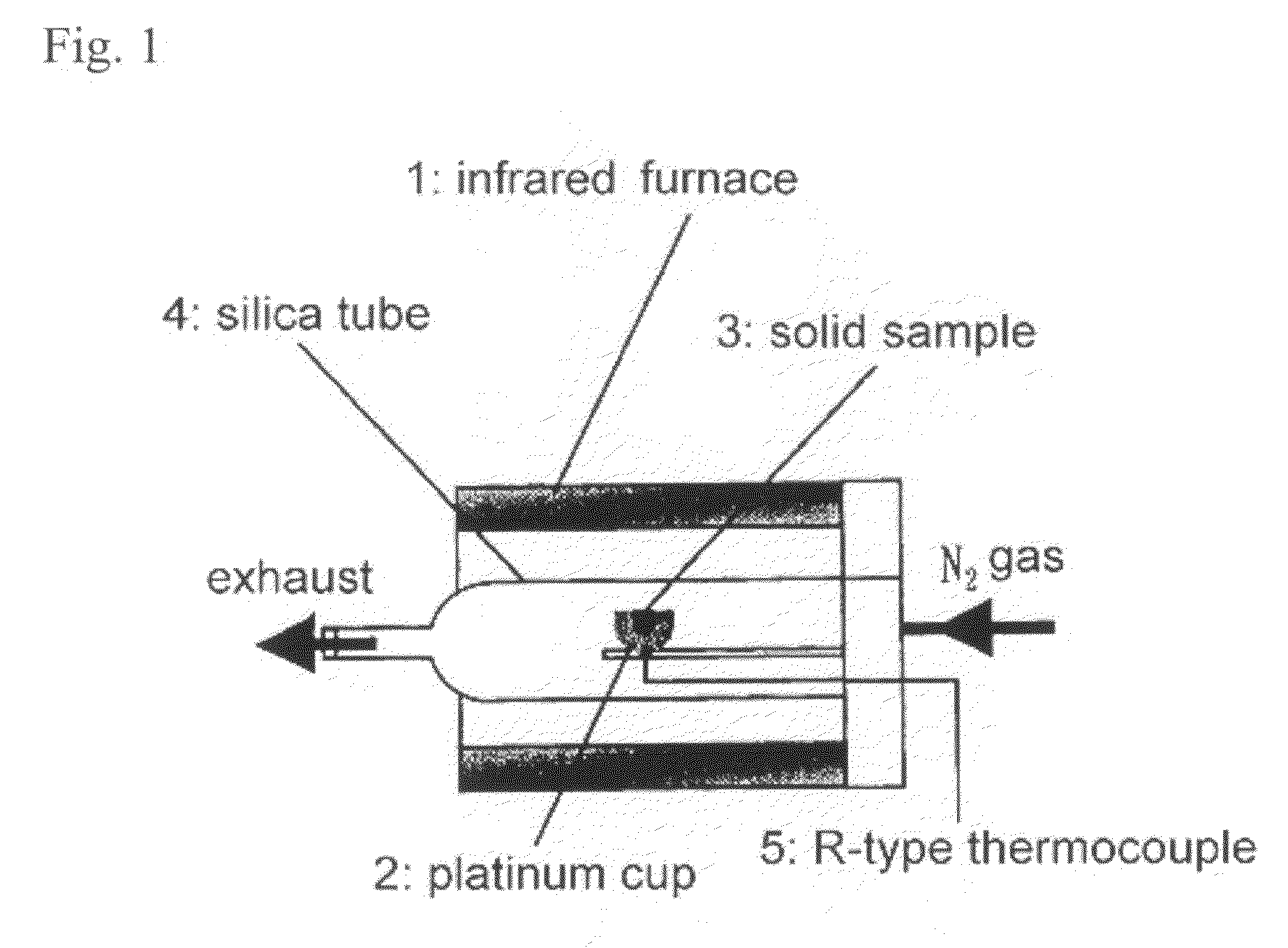

Reactive working material for use in hydrogen production by decomposition of water

InactiveUS8110174B2Preventing ferriteGrowth inhibitionIron oxides/hydroxidesEnergy inputWater basedMetallurgy

Disclosed is a reactive working material for use in a process of producing hydrogen by splitting water based on a two-step thermochemical water-splitting cycle through the utilization of solar heat, industrial waste heat or the like, which comprises a ferrite fine powder and a cubic zirconia supporting the ferrite fine powder. This reactive working material makes it possible to prevent scaling off of the ferrite fine powder from the zirconia fine powder due to volumetric changes of the ferrite fine powder during repeated use, and suppress growth of FeO grains due to repetition of melting and solidification when used as a reactive working material for a cyclic reaction under a high temperature of 1400° C. or more.

Owner:NIIGATA UNIVERSITY

Preparation method for submicron zirconia-toughened aluminium oxide powder and ceramic thereof

The invention discloses a preparation method for a submicron zirconia-toughened aluminium oxide powder and a ceramic thereof. The preparation method is characterized by comprising the following steps: (1) mixing industrial aluminium hydroxide, zirconium oxychloride, a composite mineralizer and a stabilizer for 1-2 hours; (2) heating to 1350-1500 DEG C at a heating speed of 3-5 DEG C and carrying out a calcining treatment for 2-8 hours to obtain ZTA powder; (3) mixing the ZTA powder, a dispersant and water and carrying out wet-method ball-milling, and carrying out spray-drying, thereby obtaining a submicron ZTA powder with the powder grain size D50 of 0.2-0.8mum. The obtained submicron ZTA powder is shaped into a ceramic biscuit, and the ceramic biscuit is sintered at a high temperature of 1500-1650 DEG C for 2-5 hours, so as to obtain a submicron ZTA ceramic with the relative density of 97-99%. The method is low in cost, simple in technique process, and convenient for realization of industrial production; the powder is small in raw crystalline grain size, narrow in distribution, and capable of being applied to the field of high-technology ceramics.

Owner:广西平果铝朗琨科技有限公司

Manufacture of synthetic quartz glass substrate

InactiveUS20130203324A1Conserve costIncrease costOther chemical processesLapping machinesRough surfaceSlurry

A rough surface of a starting synthetic quartz glass substrate is polished to a mirror finish, using a polishing slurry containing tetragonal or cubic zirconia.

Owner:SHIN ETSU CHEM IND CO LTD

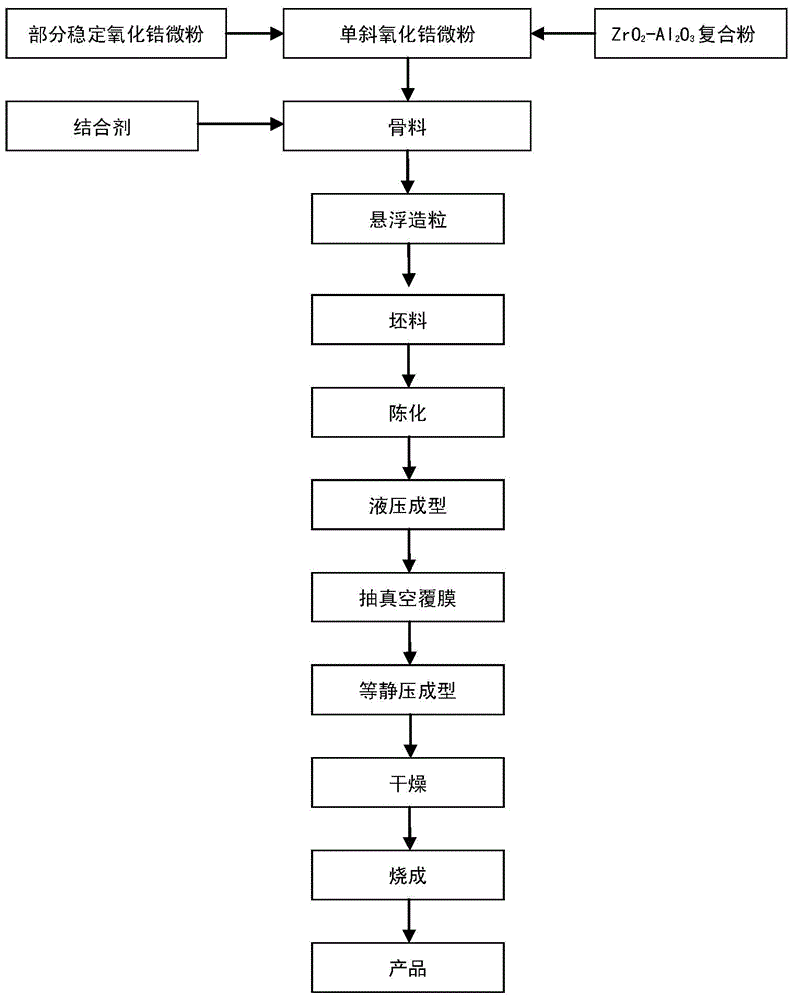

Method and device for preparing zirconia sizing nozzle with ZrO2-Al2O3 composite powder

The invention discloses a method and a device for preparing a zirconia sizing nozzle with ZrO2-Al2O3 composite powder. According to the method, an additive, a binding agent and a powder material are subjected to spray granulation, such that a particulate matter is obtained; the particulate matter is separated, such that a blank is obtained; the blank is fired under a temperature of 1700-1710 DEG C, such that the zirconia sizing nozzle is obtained. The powder material comprises partially stabilized zirconia, monoclinic zirconia and ZrO2-Al2O3 composite powder with a dosage ratio of (40-50):(50-60):(2-4). The binding agent is zirconia gel. The blank used in ceramic zirconia sizing nozzle compression molding is prepared with a suspended cyclic granulation process. The blank is subjected to aging, dehydration and molding, and is dried for 24h under a temperature of 105+ / -5 DEG C. the ceramic zirconia sizing nozzle is obtained after firing. Compared with that obtained with a common humidifying granulation process, the finished product of the sizing nozzle has a bulk density improved by 3-5%, a porosity reduced by 75-80%, and a service life of more than 40h.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

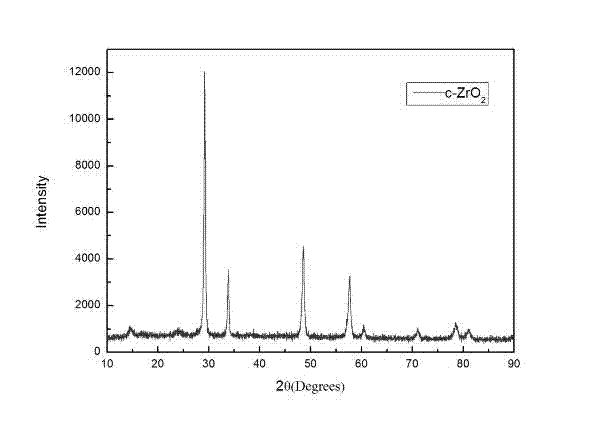

Cerium stabilized cubic zirconia ceramic material and preparation method thereof

The invention discloses a cerium stabilized cubic zirconia ceramic material and a preparation method of the cerium stabilized cubic zirconia ceramic material. The cerium stabilized cubic zirconia ceramic material comprises the following compositions: 90-100wt% of commercial zirconia powder (80 mol% of zirconia, 20 mol% of ceric oxide), and 0-10wt% of titanium dioxide.The sintering preparation method comprises the following steps of: (1) sampling; (2)mixing; (3) performing ball-milling; (4)drying; (5)incinerating; (6) performing secondary ball-milling; (7) discharging and drying; (8) pelleting; (9) molding by dry pressing; (10) performing isostatic cool pressing; (11) sintering with high temperature to obtain the ceric oxide stabilized cubic zirconia ceramic materiel. The cerium stabilized cubic zirconia ceramic material provided by the invention has the advantages of whole stability and low cost, and can be widely applied to the fields such as jewelries, oxygen sensors, sensitive elements and high temperature electrode materials.

Owner:SHANGHAI UNIV

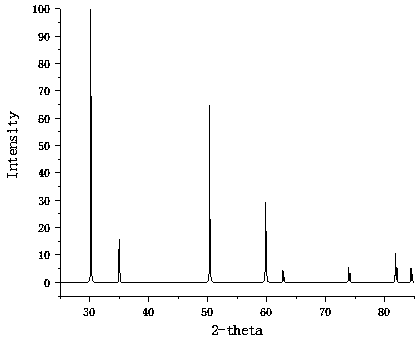

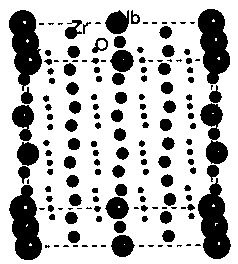

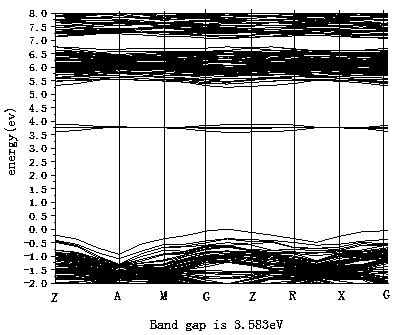

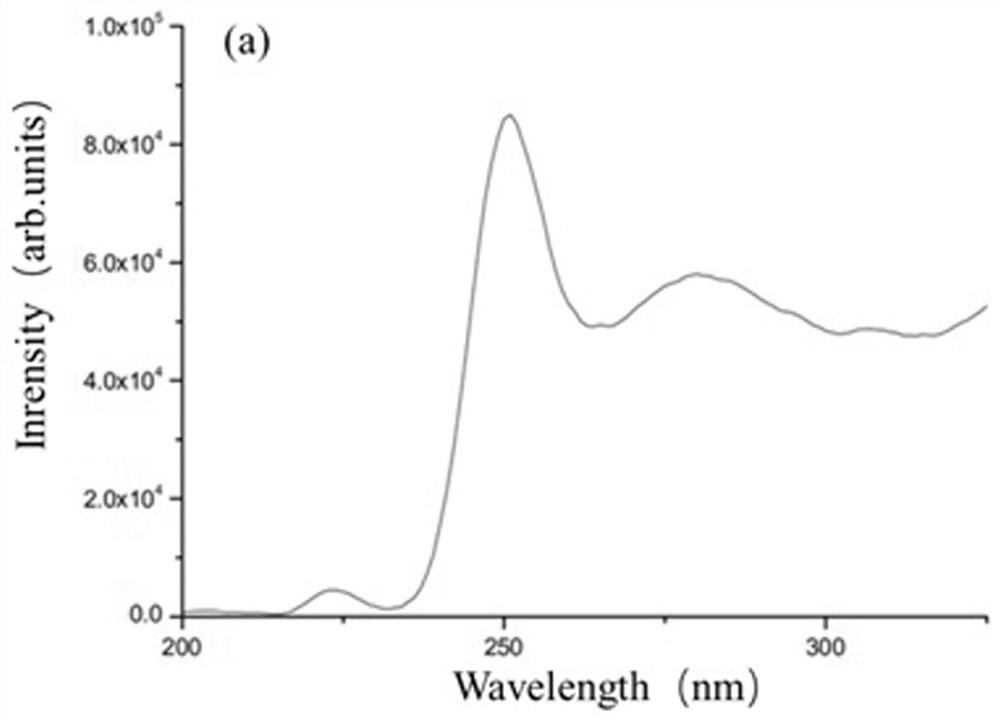

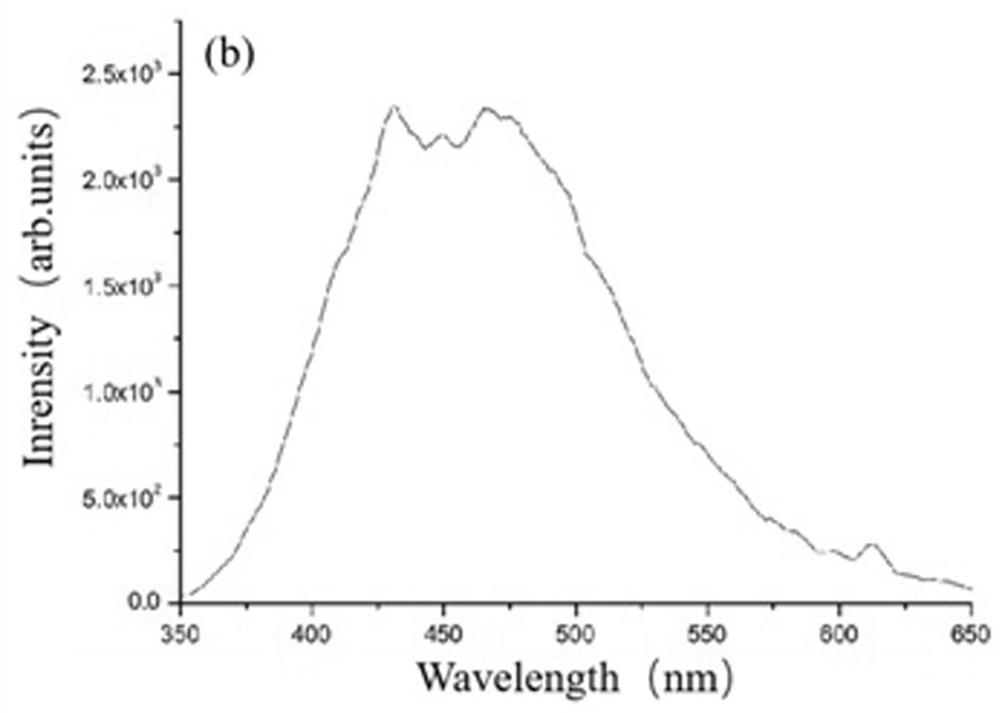

Simulation method for researching characteristics of cubic zirconium oxide doped Y and Nb composite material

ActiveCN109992867ALow costEasy to operateDesign optimisation/simulationSpecial data processing applicationsFirst principleDensity based

The invention discloses a simulation method for researching characteristics of cubic zirconium oxide doped Y and Nb composite material. A first principle based on a density functional theory is adopted. ZrO2 is taken as a matrix. Y and Nb doping of specific transition elements is carried out on the ZrO2. A rough model is established firstly, a stable crystal model is constructed through calculation, the energy band structure, the wave division state density and the optical characteristics of the ZrO2 are calculated and analyzed, and the method is low in cost, easy to operate, high in accuracy,wide in application range and good in repeatability. According to the method, a Y and Nb co-doped stable composite model is constructed for the first time. Changes of energy bands before and after acomposite system are given, and the change rule is revealed to analyze the change reason.Meanwhile, the optical property of the composite system is calculated, and a theoretical basis is laid for developing novel multifunctional crystal materials.

Owner:YANGEN UNIV

Molten glass conveying equipment element, method for producing molten glass conveying equipment element, and glass manufacturing apparatus

ActiveCN103687821AAvoid crackingAvoid deformationGlass furnace apparatusCeramicwareYttriumCubic zirconia

The present invention relates to a method for producing a molten glass conveying equipment element that comprises a conduit pipe structure for molten glass, said conduit pipe structure comprising at least one conduit pipe that is formed of platinum or a platinum alloy, a first ceramic structure arranged around the conduit pipe, and a second ceramic structure arranged around the first ceramic structure. The first ceramic structure is formed by filling the space between the conduit pipe and the second ceramic structure with a slurry material and sintering the slurry material at a temperature of 1,200-1,700 DEG C. The slurry material is obtained by blending first stabilized zirconia particles having a median diameter (D50) of 0.2-5 [mu]m and second stabilized zirconia particles having a median diameter (D50) of 0.2-2 mm so that the mass ratio of the first stabilized zirconia particles to the second stabilized zirconia particles (mass of first stabilized zirconia particles / mass of second stabilized zirconia particles) is 0.3-0.6. The first stabilized zirconia particles and the second stabilized zirconia particles respectively contain, in mass% relative to the total composition, 75 wt% or more of zirconium oxide, with the ratio of cubic zirconia in the zirconium oxide being 80 wt% or more, and 6-25 wt% in total of at least one oxide that serves as a stabilizer and is selected from the group consisting of yttrium oxide and cerium oxide.

Owner:ASAHI GLASS CO LTD

Abrasion-resistant tooth restoration material

InactiveCN106823003AHigh strengthPromote plasticizationImpression capsPharmaceutical delivery mechanismRare-earth elementAging resistance

The invention relates to an abrasion-resistant tooth restoration material. The abrasion-resistant tooth restoration material is prepared from the following components in parts by weight: 95 to 100 parts of polymethyl methacrylate, 1 to 3 parts of oxidized cubic zirconia powder, 1.5 to 4.5 parts of trace rare earth element, 0.2 to 2.5 parts of nanometer aluminum oxide, and 0.2 to 0.5 part of nanometer quartz powder. Compared with the frequently used material in the prior art, the prepared abrasion-resistant tooth restoration material has the advantages that the indexes of strength, aging resistance, luster, abrasion-resistant degree, plasticizing and the like are respectively improved, the material cost is low, and the economic and practical effects are realized.

Owner:桂林加宏汽车修理有限公司

Bright red cubic zirconium oxide crystal

InactiveCN107937982ASolve the puzzle where Big Red can't be coloredUnique formulaPolycrystalline material growthBy pulling from meltCeriumYttrium

The invention relates to a bright red cubic zirconium oxide crystal. The bright red cubic zirconium oxide crystal is prepared from the following formula raw materials: 89 to 94 percent of zirconium dioxide, 3 to 8 percent of yttrium oxide, 1.5 to 3 percent of rare earth dicerium trioxide or cerium dioxide and 1.5 to 4 percent of neodymium oxide. The bright red cubic zirconium oxide crystal can beprepared by the steps of mixing the above formula raw materials uniformly, placing the mixture into a crucible, smelting, performing crystal pulling and cooling. The formula is unique, the special formula and the proportion of a coloring agent are selected, the problem that the bright red cannot be colored when the raw materials are at high temperature of 2700 DEG C is solved successfully, the blank that no cubic zirconium oxide crystal serves as nature-imitated ruby is filled, and when the bright red cubic zirconium oxide crystal is used for producing the nature-imitated ruby, the color is beautiful and bright and the nature-imitated ruby can be compared favorably with the natural ruby.

Owner:冯春生

Reactive working material for use in hydrogen production by decomposition of water

ActiveUS20100119441A1Preventing ferriteGrowth inhibitionIron oxides/hydroxidesEnergy inputWater basedDecomposition

Disclosed is a reactive working material for use in a process of producing hydrogen by splitting water based on a two-step thermochemical water-splitting cycle through the utilization of solar heat, industrial waste heat or the like, which comprises a ferrite fine powder and a cubic zirconia supporting the ferrite fine powder. This reactive working material makes it possible to prevent scaling off of the ferrite fine powder from the zirconia fine powder due to volumetric changes of the ferrite fine powder during repeated use, and suppress growth of FeO grains due to repetition of melting and solidification when used as a reactive working material for a cyclic reaction under a high temperature of 1400° C. or more.

Owner:NIIGATA UNIVERSITY

Preparation method for cubic zirconia-beta phase silicon carbide complex phase high temperature resistance powder material

The invention relates to a preparation method for a cubic zirconia-beta phase silicon carbide complex phase high temperature resistance powder material, belonging to the technical field of the preparation of the high temperature resistance powder material. The preparation method is characterized by comprising the following steps of: using zirconia, zircon sand or zirconium silicate as main raw materials, carbon black, coke, graphite or activated carbon as reducing agents, magnesium oxide, calcium oxide, yttrium oxide or cerium oxide as additives, mixing the materials according to certain proportions, and then preparing the cubic zirconia-beta phase silicon carbide complex phase high temperature resistance powder material by adopting technological processes such as ball-milling, drying, molding and carbon thermal reduction. The preparation method for the cubic zirconia-beta phase silicon carbide complex phase high temperature resistance powder material has the advantages of short technological process, non-pollution, low energy consumption, lower cost and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Novel method of preparing cube zirconium oxide single crystal

InactiveCN1924115AImprove working conditionStable working conditionPolycrystalline material growthFrom frozen solutionsElectric arc furnaceMiddle frequency

The invention discloses a new manufacturing method of cubic zirconia monocrystal, which comprises the following steps: adopting electric arc furnace power as heating source; or mating electric arc furnace power and middle-frequency power as heating power; fusing zirconium dioxide in the water-cooled copple; combining with lifting crystal pulling technology to obtain the product.

Owner:冯春生

High-hardness high-strength high-transparency microcrystalline glass and preparation method and application thereof

InactiveCN110862233AHigh transparencyHigh hardnessTelephone set constructionsPhysical chemistrySpinel

The invention relates to high-hardness high-strength high-transparency microcrystalline glass and a preparation method and application thereof. The preparation method comprises the following steps: casting a mixture into glass, and carrying out crystallization treatment to obtain the microcrystalline glass, wherein the mixture mainly comprises Li2O, A2lO3, SiO2, CaO, SrO, ZnO, BaO, K2O, Na2O, ZrO2, Sb2O3 and NaCl; and the prepared microcrystalline glass is mainly composed of a glass matrix, spodumene crystals dispersed in the glass matrix and distributed in a dendritic manner, spinel crystalsdistributed in a granular manner and cubic zirconium oxide crystals distributed in a granular manner, and can be applied to preparation of high-strength wear-resistant transparent microcrystalline glass glaze and to preparation of mobile phone panels. The preparation method of the high-hardness high-strength high-transparency microcrystalline glass is simple and easy to implement, and has extremely high popularization value; and the prepared microcrystalline glass has the advantages of a low melting point, excellent forming processability and good application prospects.

Owner:赵国祥

Production method of electrically melt yttrium oxide stabilized zirconia granulation powder

The invention discloses a production method of electrically melt yttrium oxide stabilized zirconia granulation powder which is profitable, green and environmentally friendly. The method comprises the following steps: adding zircon sand and Y-doped cubic zirconia powder (or Y-Zr powder) in reducing agent for mixing and electric smelting or directly adding baddeleyite for mixing and electric smelting, cooling, performing coarse crushing and fine crushing, screening, performing coarse grinding and fine grinding, performing wet grinding to generate pulp, performing surface modification, performing spray granulation, mixing evenly and packaging. The method of the invention uses Y-Zr powder as raw material, the technical process is simple and easy, the method does not discharge waste water, waste gas and waste residue; the equipment investment is less, the product quality meets user requirements, the production process does not adopt secondary electric smelting and high-temperature heat treatment and add stabilizing agent; and under the same conditions, compared with the stabilized Zr and granulation powder thereof which are produced by the current and popular technology, the granulation powder quality is higher, the performance is better and the cost is reduced by 30-40%.

Owner:王必庆

Scalpel blade and preparation method thereof

InactiveCN105598457AHigh hardnessHigh strengthTransportation and packagingMetal-working apparatusStrontium titanateSesquioxide

The invention discloses a scalpel blade and a preparation method of the scalpel blade. The scalpel blade is prepared from the following raw material in parts by weight: 78-80 parts of cubic boron nitride, 50-52 parts of cubic zirconia, 38-40 parts of strontium titanate, 6-8 parts of tungsten carbide, 10-12 parts of aluminum oxide, 1-3 parts of iron sesquioxide, 2-4 parts of silicon nitride, 6-8 parts of zirconium nitride, 2-4 parts of molybdenum disilicide, 4-6 parts of tantalum carbide, 2-4 parts of titanium nitride, 12-14 parts of titanium dioxide, 10-12 parts of polymerized rosin, 8-10 parts of copal resin, 6-8 parts of graphite powder, 1-3 parts of samarium oxide, 1-3 parts of nickel oxide, 15-17 parts of quartz sand, 1-3 parts of zinc oxide and 17-19 parts of silver paste. The scalpel blade has high strength.

Owner:刘三光

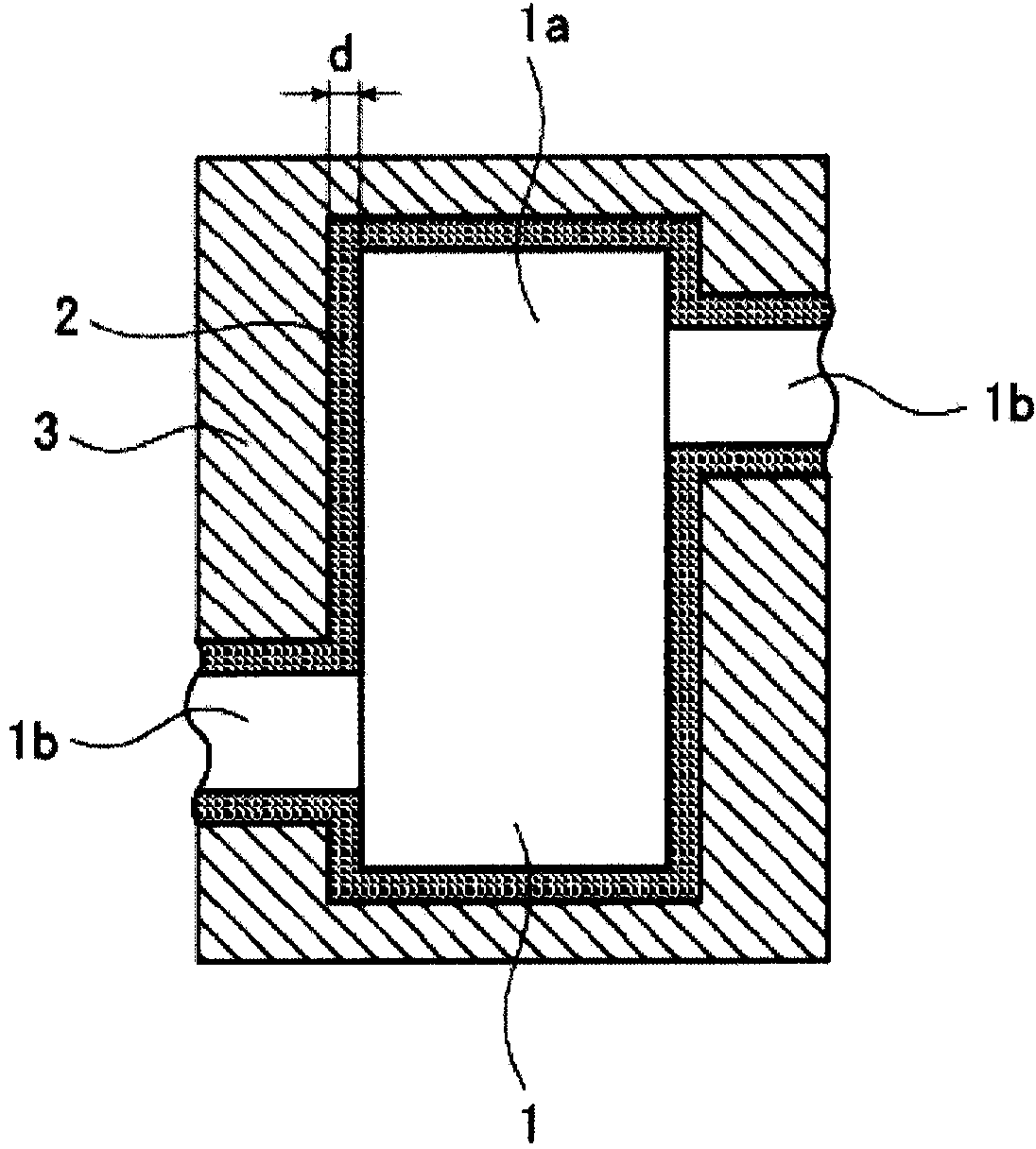

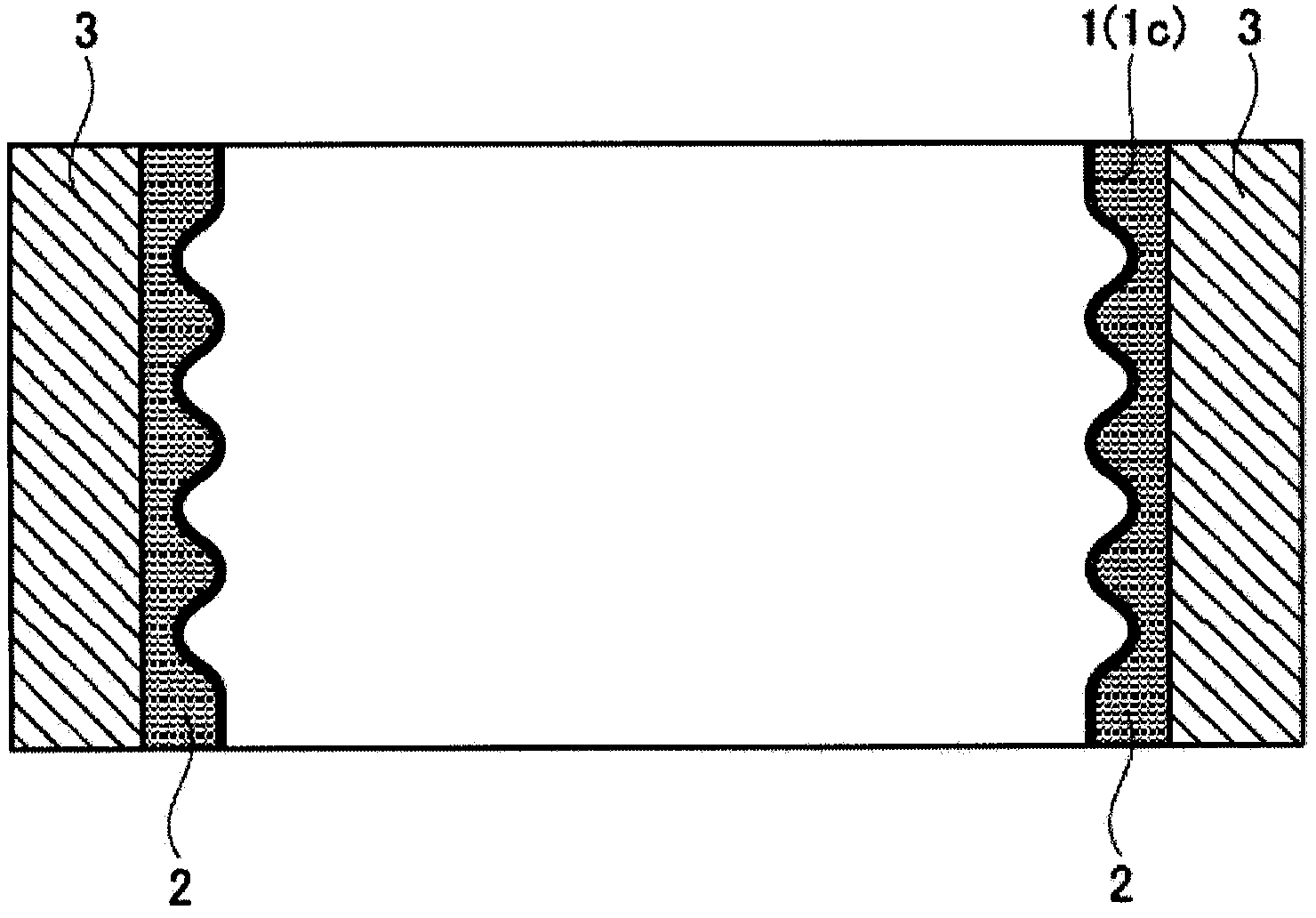

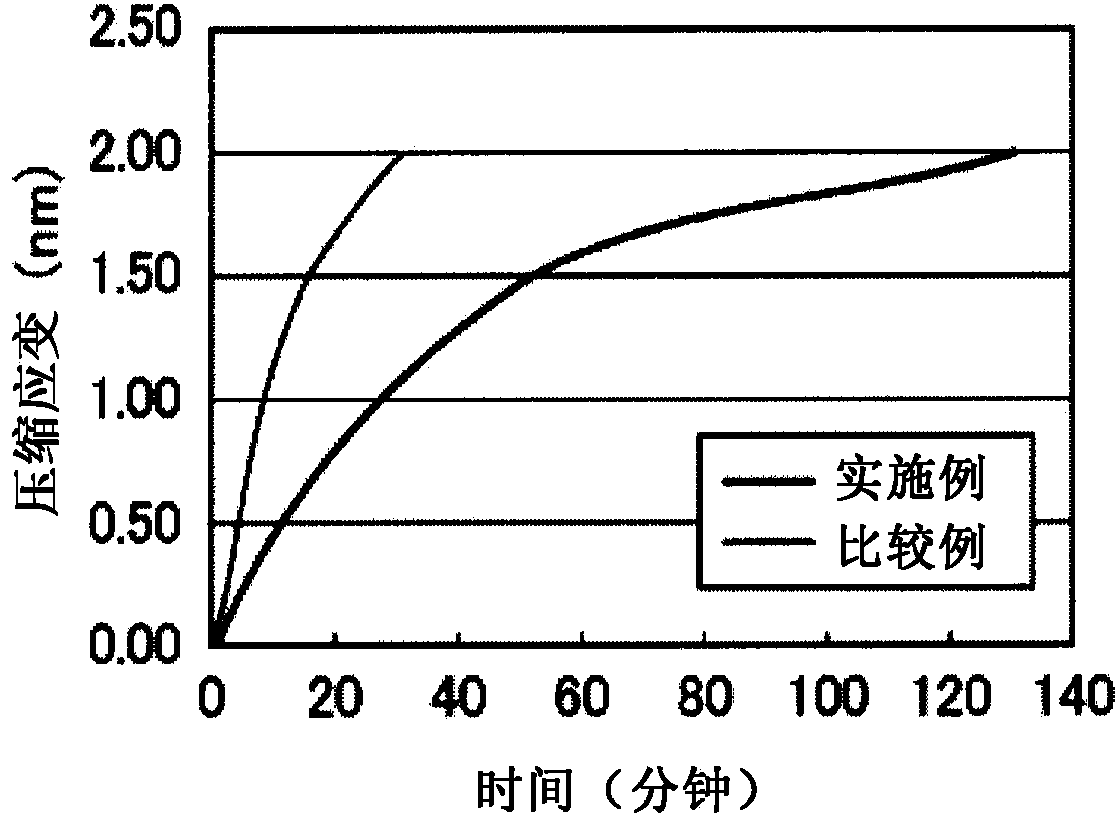

Zirconium Oxide Sheet Used For Solid Oxide Type Fuel Cell And Solid Oxide Type Fuel Cell Monocell Comprising Same

InactiveCN104659397AHigh strengthImprove power generation effectFinal product manufactureSolid electrolyte fuel cellsFuel cellsEngineering

The present invention provides a zirconium oxide sheet used for a solid oxide type fuel cell and a solid oxide type fuel cell monocell comprising the same, aims to provide the zirconium oxide sheet which is suitable for being used as a solid oxide type fuel cell electrolyte sheet reducing the cracking along with a carrying operation and during the manufacture process of the zirconium oxide sheet and the manufacture process of using the zirconium oxide sheet as an electrolyte cell, even though the resistance of the zirconium oxide sheet is low. The present invention also aims to provide the solid oxide type fuel cell monocell comprising the zirconium oxide sheet as the electrolyte. The zirconium oxide sheet used for the solid oxide type fuel cell of the present invention is characterized by comprising an oxide of a zirconium oxide system, wherein the oxide of the zirconium oxide system takes the cubic zirconia as the main component, the thickness of the zirconium oxide sheet is between 50 micrometers and 120 micrometer, and the cracking maximum flexural amount in a four-point bending test is 10-30%. The solid oxide type fuel cell monocell of the present invention is characterized by comprising the zirconium oxide sheet as the electrolyte.

Owner:NIPPON SHOKUBAI CO LTD

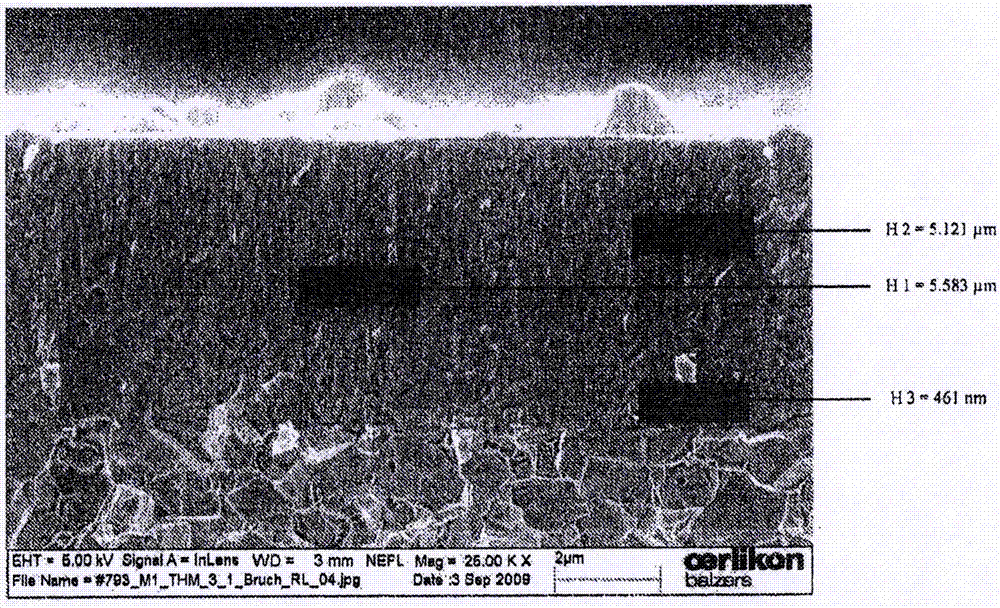

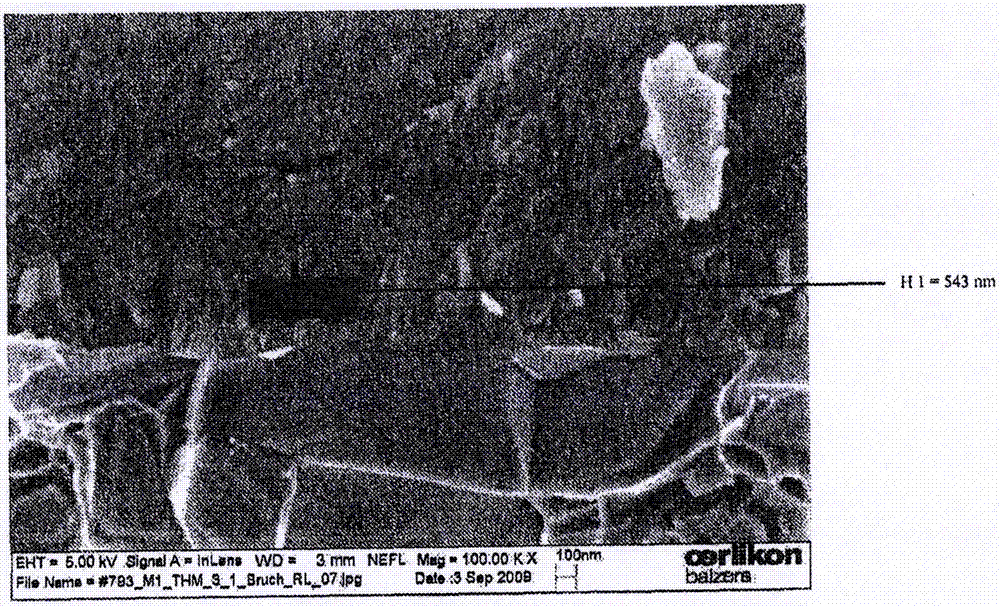

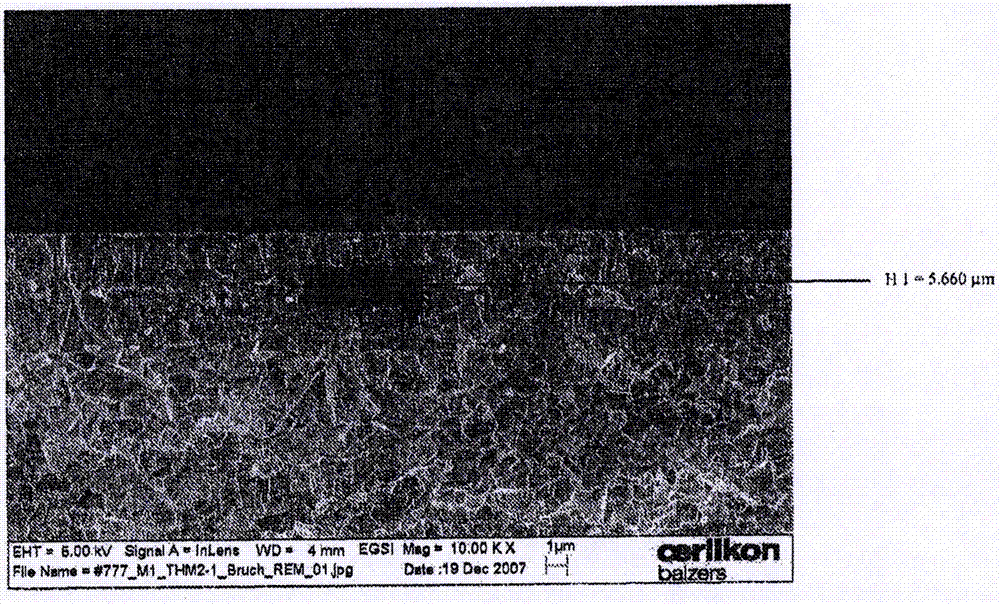

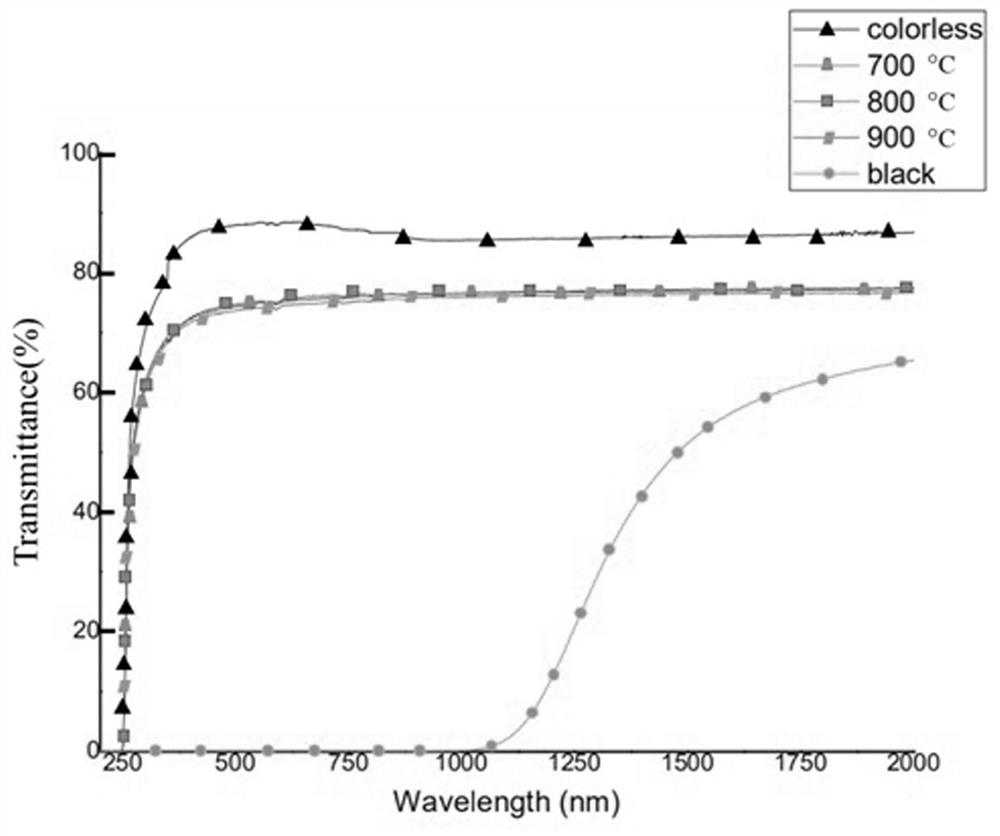

Method for producing cubic zirconia layers

In order to produce zirconia-based layers on a deposition substrate, wherein reactive spark deposition using pulsed spark current and / or the application of a magnetic field that is perpendicular to the spark target are employed, a mixed target comprising elemental zirconium and at least one stabilizer is used, or a zirconium target comprising elemental zirconium is used, wherein in addition to oxygen, nitrogen is used as the reactive gas. As an alternative, it is also possible, combined with the use of the mixed target, to use nitrogen as the reactive gas in addition to oxygen.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Preparation method of zirconium oxide crystal

PendingCN112695375ANo pollution in the processPromote growthPolycrystalline material growthAfter-treatment detailsReduction treatmentCrucible

The invention discloses a preparation method of zirconium oxide crystal, and belongs to the field of preparation of metal oxide functional materials. Yttrium oxide and zirconium oxide are mixed in proportion and ground into uniform powder, the cubic zirconium oxide crystal is prepared through a cold crucible method, then reduction treatment is conducted, and the black cubic zirconium oxide crystal can be obtained. The material can realize large-size rapid crystallization growth and is suitable for large-scale production, the crucible material can be recycled as a raw material and the cost is saved, and the obtained crystal has a large crystal size and a high crystallinity.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com