Cerium stabilized cubic zirconia ceramic material and preparation method thereof

A technology of cubic zirconia and ceramic materials, applied in the field of cubic zirconia ceramic materials and their preparation, can solve the problems of mechanical property degradation, limited use environment temperature, etc., and achieves lower sintering temperature, full stability cost, stable zirconia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

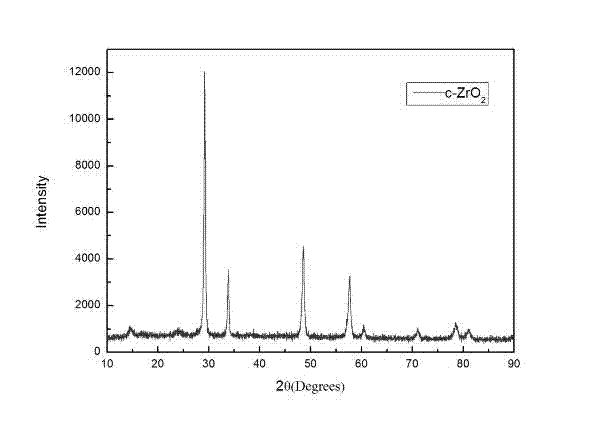

Image

Examples

Embodiment 1

[0028] In this embodiment, the specific process steps for preparing a cerium-stabilized cubic zirconia ceramic material are as follows:

[0029] (1) Sample weighing: Commercial zirconia ceramic powder and titanium oxide powder are used, of which 95wt% zirconia commercial powder and 5wt% titanium dioxide;

[0030] (2) Mixing: Put the weighed powder, absolute alcohol and ball mill into the ball mill tank for mixing. The ratio of material to ball is 1.5:1, and the mass ratio of alcohol powder to material is 4:1;

[0031] (3) Ball milling: ball mill the mixture, the speed of the ball mill is 50 rpm, and the milling time is 10 hours;

[0032] (4) Drying: Dry the ball-milled powder in an oven at a temperature of 100°C;

[0033] (5) Calcination: place the dried powder in a muffle furnace for calcination, the calcination temperature is 1000°C, and the holding time is 5h;

[0034] (6) Secondary ball milling: place the calcined powder in the ball mill again for ball milling, and t...

Embodiment 2

[0041] The process steps of this example are exactly the same as those of Example 1 above, the difference is that zirconia commercial powder is 90wt%, titanium dioxide is 10wt%, the sintering temperature is 1600°C, and the holding time is 5h, and a cerium-stabilized cubic zirconia ceramic material is obtained. .

Embodiment 3

[0043] The process steps of this example are exactly the same as those of Example 1 above, the difference is that zirconia commercial powder is 92wt%, titanium dioxide is 8wt%, the sintering temperature is 1600°C, and the holding time is 5h, and a cerium-stabilized cubic zirconia ceramic material is obtained. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com