Preparation method for cubic zirconia-beta phase silicon carbide complex phase high temperature resistance powder material

A cubic zirconia powder material technology, applied in the field of high temperature resistant powder material preparation, can solve the problems of cubic zirconia powder easy to agglomerate, complex process, high cost, etc., to achieve high product added value, short process flow and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

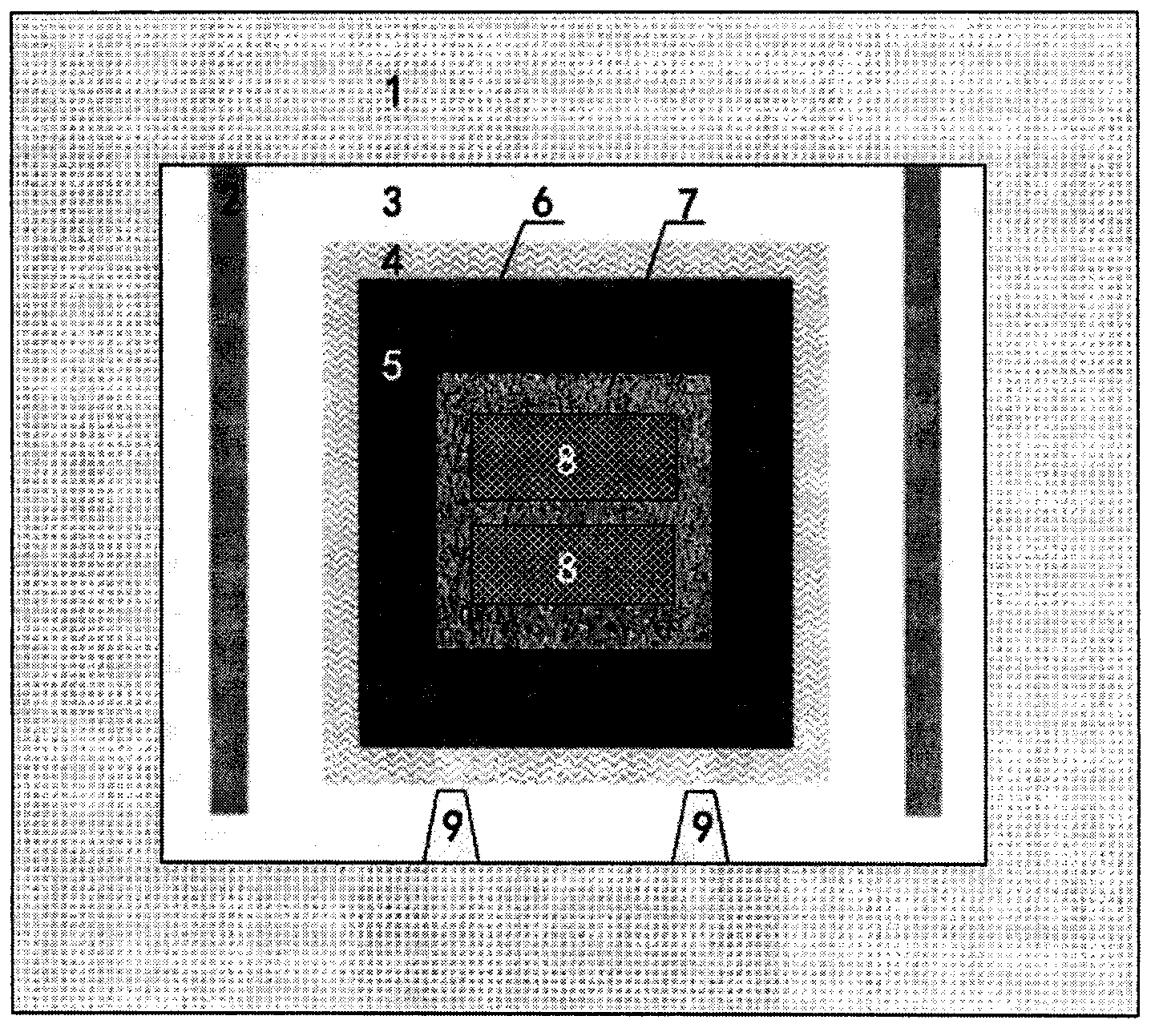

Image

Examples

Embodiment 1

[0021] Raw materials and ratio:

[0022] The particle size and quality requirements of zircon raw materials are, ZrSiO 4 The content is greater than 80% by mass, of which ZrO 2 The content is greater than 50% by mass, the particle size is ≤1mm; carbon black is used as the reducing agent, the particle size and quality requirements of the carbon black reducing agent are, the carbon content is greater than 98% by mass, and the particle size is ≤1μm The mass ratio of the added amount is 5:1; industrially pure yttrium oxide is used as an additive, and the added amount of the yttrium oxide is an additional 10% by mass.

[0023] crafting process:

[0024] The above-mentioned various raw materials are made into a sample green body of Φ20mm×20mm through batching, mixing, ball milling, drying, molding and other processes, and then the sample is placed in a coke-buried airtight high-temperature resistant In a sagger container, place the high temperature resistant container in a high t...

Embodiment 2

[0027] Raw materials and ratio:

[0028] The particle size and quality requirements of zircon sand raw materials are, ZrSiO 4 The content is greater than 95% by mass, of which ZrO 2 The content is greater than 60% by mass, and the particle size is ≤1mm; activated carbon is selected as the reducing agent, and the particle size and quality requirements are that the carbon content in the activated carbon is greater than 98% by mass, and the particle size is ≤1μm; the mass of zircon and activated carbon added The ratio is 5:1; industrial pure magnesia is used as an additive, and the amount of magnesia added is an additional 8wt% by mass.

[0029] crafting process:

[0030] The above-mentioned various raw materials are made into a sample green body of Φ20mm×20mm through batching, mixing, ball milling, drying, molding and other processes, and the sample is placed in an open graphite crucible, and then the graphite crucible is placed in argon gas. After being kept at 1650°C for 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com