Preparation method of spun-laced regenerated leather for automotive interior surface

A technology for automotive interiors and recycled leather, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problem of not using the material preparation stage to provide more direct and powerful help to the material forming stage, and lack of material preparation and molding. Planning, low production efficiency and other issues, to achieve the effect of environmental protection, enriching categories, and reducing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

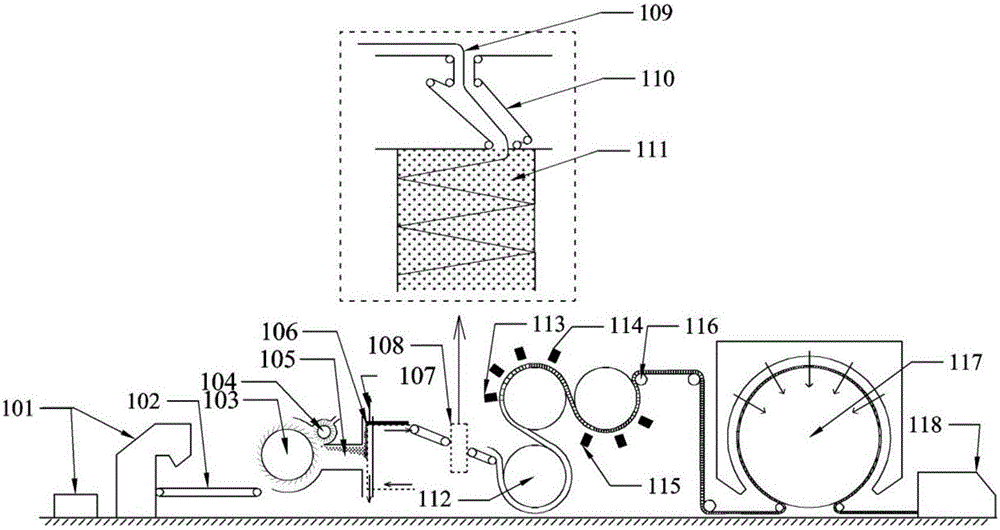

[0049] (1) 60Kg of cowhide fiber prepared by cowhide leftovers with a water content of 15% and 9Kg of 4080 fiber with a skin-core structure are accurately weighed, and are sent into the opener 101 for mixing and opening.

[0050] (2) Feed mixed fibers for air-forming. A layer of continuous 4080 fiber mat with a thickness of 50 μm is pre-laid on the output curtain, and then a four-curtain cross-folding method is used to lay the web on the 4080 fiber mat. Divide the one-way trip of the net-laying trolley into five sections, the length ratio is 1:2:4:2:1, and the corresponding speed ratio of the net-laying trolley is 1.12:1.06:1:1.06:1.12.

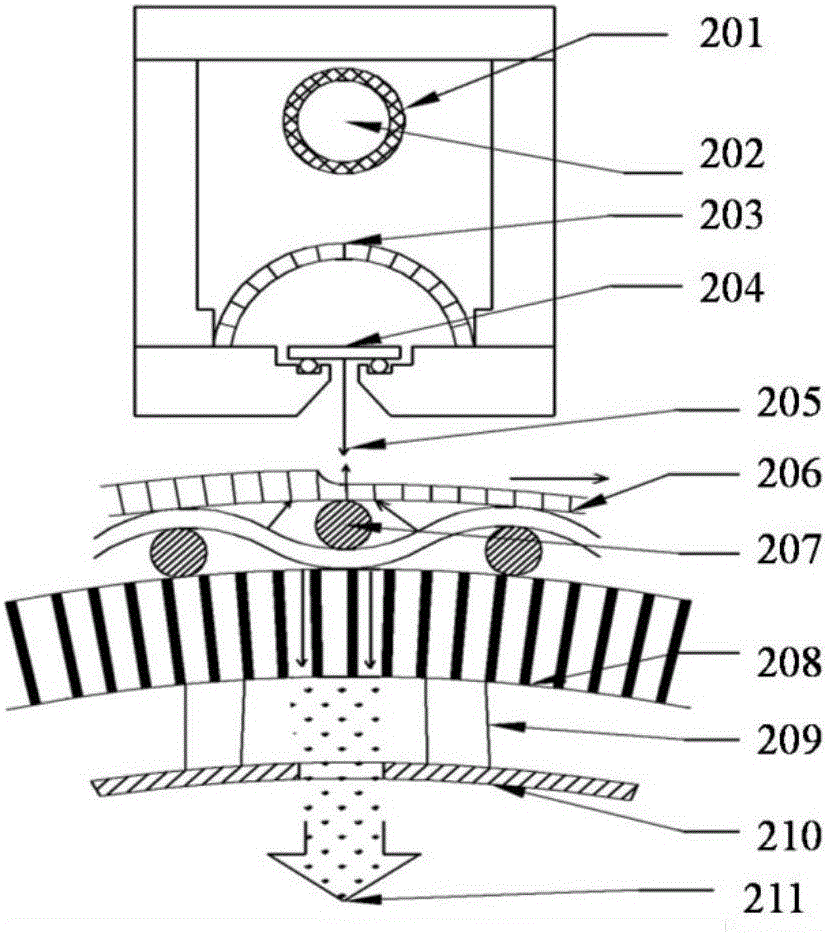

[0051] (3) Before the laid fiber web is sent to the spunlace area for reinforcement, it is pre-humidified by the clamping pre-humidification method of the perforated roller and the net delivery curtain.

[0052] (4) The pre-wetted fiber net enters the spunlace area, and a total of seven spunlaces are used. The hole diameter of the orifice pl...

Embodiment 2

[0057] (1) Accurately weigh 60Kg of fibers prepared from cowhide leftovers with a water content of 20% and 12Kg of N720 fibers with a sheath-core structure, and carry out rough opening and fine opening respectively after mixing.

[0058] (2) Feed the mixed fiber and card it into a web.

[0059] (3) if figure 1 As shown in 108, a layer of N720 fiber mat with a thickness of 30 μm is pre-laid on the output curtain, and then the N720 fiber mat is laid on the N720 fiber mat by double-clamping method. Divide the one-way trip of the net-laying trolley into five sections, the length ratio is 1:2:4:2:1, and the corresponding speed ratio of the net-laying trolley is 1.12:1.06:1:1.06:1.12.

[0060] (4) Before the spunlace reinforcement of the paved fiber web, it is pre-humidified by double-net clamping, and the pressure of the pre-wet spunlace 113 is 25 bar.

[0061] (5) The pre-wetted fiber net enters the spunlace area, and a total of seven spunlaces are used. The hole diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com