Marbled glass ceramics directly employing fusion blast furnace slag and preparation method of marbled glass ceramics

A glass-ceramic and blast furnace slag technology, applied in the field of waste resource utilization, can solve the problems of reducing the added value of products, reducing the utilization efficiency of blast furnace slag, affecting the decorative effect, etc. Deterministic influence, the effect of shortening the blending time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

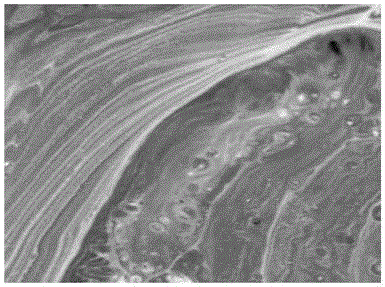

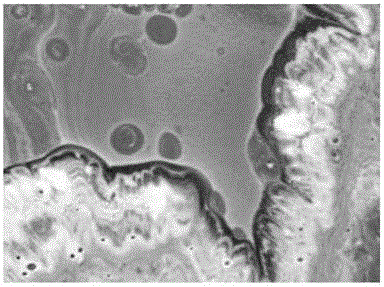

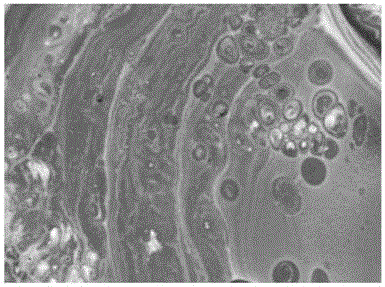

Image

Examples

Embodiment 1

[0040] A streaked glass-ceramic directly using molten blast furnace slag, the raw material composition and preparation method are as follows:

[0041] a. In terms of parts by mass, the amount of molten blast furnace slag added to the raw material is 55 parts, and the other auxiliary materials include: 19.5 parts of quartz sand, 5.5 parts of limestone, 5 parts of soda ash, 4 parts of potassium carbonate, 1 part of zinc oxide, diphosphate 4 parts of hydrogen ammonia, 1.5 parts of spodumene, 2.5 parts of sodium fluorosilicate, 1 part of sodium fluoroaluminate, and 1 part of borax; the blast furnace slag used in this embodiment consists of: SiO 2 (36wt%), CaO (38wt%), Al 2 o 3 (15wt%), MgO (10wt%), TiO 2 (0.5wt%), Fe 2 o 3 (0.5wt%);

[0042] b. Feed the uniformly mixed auxiliary materials from the feeding machine 1 through the auxiliary material feeding port 2 to the melting part 9 of the glass kiln, the melting temperature is 1500 °C, and the melting time is 10 hours; the mo...

Embodiment 2

[0047] A streaked glass-ceramic directly using molten blast furnace slag, the raw material composition and preparation method are as follows:

[0048] a. In terms of parts by mass, the amount of blast furnace slag mixed into the glass-ceramic raw material is 65 parts, and the other auxiliary materials include: 15.25 parts of quartz sand, 1 part of limestone, 2 parts of soda ash, 5 parts of potassium carbonate, 3 parts of zinc oxide, phosphoric acid 1 part of dihydroammonia, 2 parts of spodumene, 3.5 parts of sodium fluorosilicate, 1.5 parts of sodium fluoroaluminate, 0.75 parts of borax; the applicable blast furnace slag composition is: SiO 2 (33wt%), CaO (41wt%), Al 2 o 3 (18wt%), MgO (7wt%), TiO 2 (0.7wt%), Fe 2 o 3 (0.3wt%);

[0049] b. Feed the uniformly mixed auxiliary materials from the feeding machine 1 through the auxiliary material feeding port 2 to the melting part 9 of the glass kiln, the melting temperature is 1450 °C, and the melting time is 12 hours; the mol...

Embodiment 3

[0054] A streaked glass-ceramic directly using molten blast furnace slag, the raw material composition and preparation method are as follows:

[0055] a. In terms of parts by mass, the amount of blast furnace slag added to the glass-ceramic raw material is 75 parts, and other auxiliary materials include: 8.5 parts of quartz sand, 0.5 part of limestone, 1 part of soda ash, 2 parts of potassium carbonate, 4 parts of zinc oxide, phosphoric acid 2 parts of dihydroammonia, 1 part of spodumene, 5 parts of sodium fluorosilicate, 0.5 parts of sodium fluoroaluminate, and 0.5 parts of borax; the applicable blast furnace slag composition is: SiO 2 (31wt%), CaO (43wt%), Al 2 o 3 (17wt%), MgO (8wt%), TiO 2 (0.8wt%), Fe 2 o 3 (0.2wt%);

[0056] b. Feed the uniformly mixed auxiliary materials from the feeding machine 1 through the auxiliary material feeding port 2 to the melting part 9 of the glass kiln, the melting temperature is 1540 ° C, and the melting time is 8 hours; the molten bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com