Zirconium Oxide Sheet Used For Solid Oxide Type Fuel Cell And Solid Oxide Type Fuel Cell Monocell Comprising Same

A solid oxide and fuel cell technology, which is applied in the direction of solid electrolyte fuel cells, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of increased electrolyte sheet resistance and reduced battery power generation performance, so as to reduce cracking, Excellent power generation performance and excellent battery strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Examples are given below to further specifically illustrate the present invention. The present invention is not limited to the following examples, and can be implemented with appropriate changes within the scope of the above-mentioned and following purposes, and these are also included in the technical scope of the present invention.

[0115] 1. Evaluation method of raw material powder

[0116]

[0117] Using nitrogen as an adsorbed molecule, the specific surface area of the powder was measured by the BET method. As a measurement device, Macsorb HM-1210 manufactured by Mountech Corporation was used. One sample was measured at three points, and the average value thereof was defined as the specific surface area.

[0118]

[0119] The aqueous solution which added 0.2 mass % of sodium metaphosphate as a dispersant to distilled water was used as a dispersion medium using laser diffraction / scattering type particle size distribution measuring apparatus "LA-920" manufac...

preparation example 1~4、7

[0124] Commercially available 8 mol% YSZ powder (manufactured by Daiichi Rare Elements Chemical Industry Co., Ltd. Name "HSY-8", specific surface area: 9m 2 / g, D50: 0.48μm) for heat treatment.

[0125] A wet medium circulating bead mill (manufactured by Ashizawa Finetech Co., Ltd.) dedicated to nanoparticle dispersion was used, and 4 kg of the above-mentioned heat-treated YSZ powder and 6 kg of pure water as a dispersion medium were charged thereinto as a raw material powder slurry. 4 kg of zirconia media (specific gravity: 6) having a diameter of 0.5 mm were thrown thereinto as grinding media. The power of the mill motor was adjusted, and the stirring power was 0.5kWh / kg-2kWh / kg, and the peripheral speed (ω) of the tip of the stirring blade was 8 m / s-10 m / s for pulverization. The slurry obtained by this wet pulverization was placed in a 10-liter rotary evaporator, and octanol equivalent to the slurry was added, and water was distilled off while heating and reducing pressur...

preparation example 5~6

[0127] 10Sc1CeSZ powder stabilized with commercially available 10 mol% scandium oxide and 1 mol% ceria at a temperature of 1250°C using a rotary furnace in which the core tube material is alumina Product name "10Sc1CeSZ", specific surface area: 11m 2 / g, D50: 0.6 μm, D90: 1.27 μm) were heat-treated, pulverized and dried in the same manner as in the above-mentioned Preparation Examples 1 to 4, and 7 to prepare a cubic-system stabilized ScCeSZ powder B1250. In addition, using a high-efficiency wet pulverizer (manufactured by Kotobuki Engineering & Manufacturing Co., Ltd., trade name: Apex Mill, model: AMV-1), the above-mentioned ScCeSZ powder without heat treatment was pulverized and dried in the same manner as above to prepare Cubic and stabilized ScCeSZ powder BNC. Table 1 shows the physical properties of these powders.

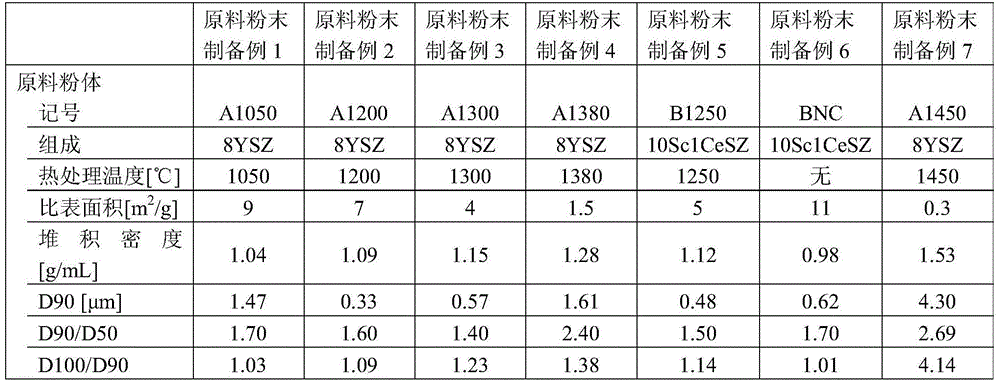

[0128] 【Table 1】

[0129]

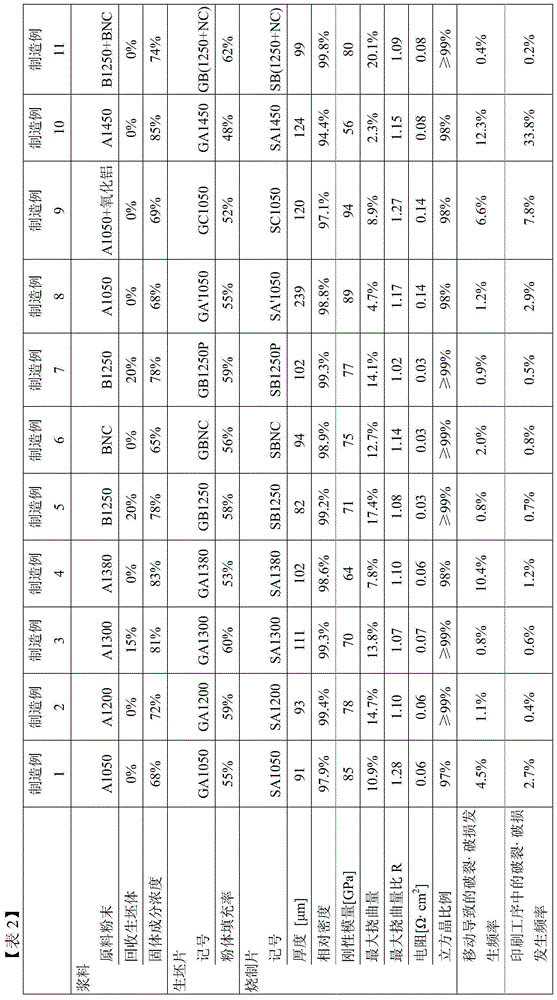

[0130] 3. Fabrication of Zirconia Sheets

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com