Preparation method of zirconium oxide crystal

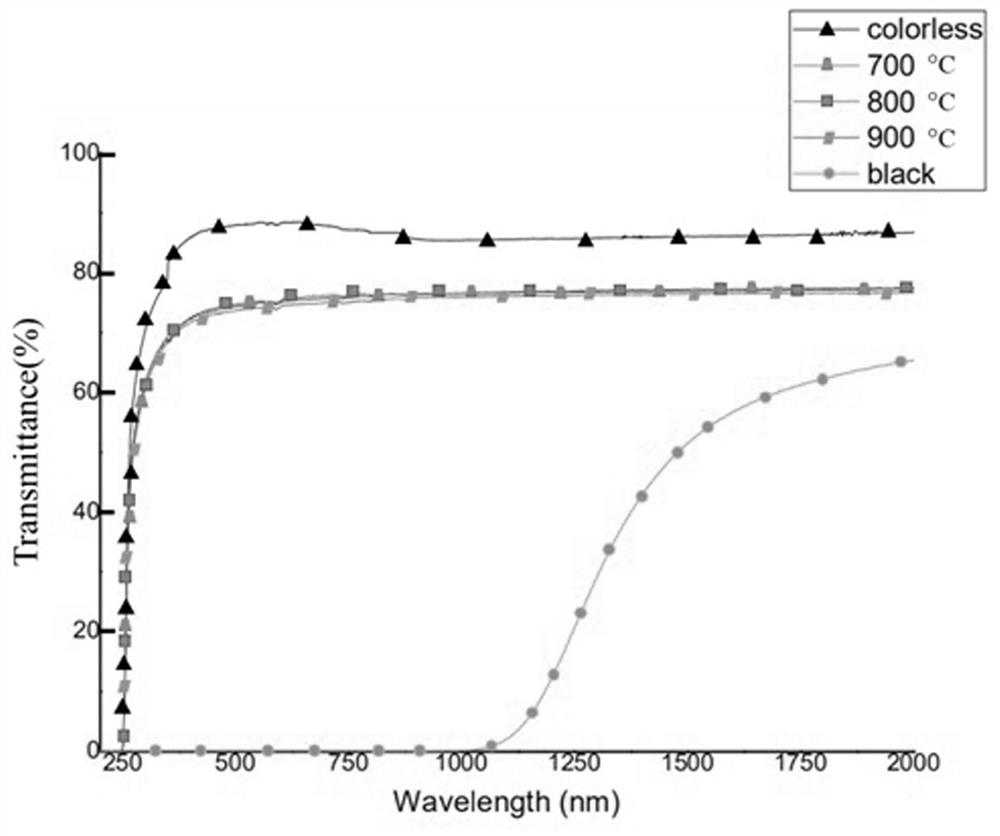

A zirconia and crystal technology, applied in the field of zirconia crystal preparation, can solve the problems of unsuitability for sunlight receivers, low absorption, etc., and achieve the effects of reducing the difficulty of growth, large size and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing zirconia crystals, comprising the steps of:

[0033] (1) ZrO 2 and Y 2 o 3 The powders are mixed in a molar ratio of 9:1 to obtain a mixture;

[0034] (2) Put the mixture obtained in step (1) into a cold crucible surrounded by copper tubes, because ZrO 2 Conductivity is only available above 1200°C, therefore, use cold crucible induction heating to smelt ZrO 2 At the same time, metal zirconium is added as "melting metal", the amount of metal zirconium added is 1% of the total weight of the mixture, the cross-sectional shape of metal zirconium is circular, and the thickness is 0.5mm; 1min, the metal zirconium is melted, forming a small "melting zone", making the surrounding ZrO 2 The temperature of the powder rises above 1200°C, making it a conductor, and under the action of a high-frequency induced magnetic field, ZrO 2 The powder is heated and melted, and the melt close to the crucible wall is first solidified to form a drum-like ZrO under t...

Embodiment 2

[0040] A method for preparing zirconia crystals, comprising the steps of:

[0041] (1) ZrO 2 and Y 2 o 3 The powders are mixed at a molar ratio of 8:1 to obtain a mixture;

[0042] (2) Put the mixture obtained in step (1) into a cold crucible surrounded by copper tubes, because ZrO 2 Conductivity is only available above 1200°C, therefore, use cold crucible induction heating to smelt ZrO 2 At the same time, metal zirconium is added as "melt-inducing metal". The amount of metal zirconium added is 3% of the total weight of the mixture. The cross-sectional shape of metal zirconium is rectangular and the thickness is 0.8mm; Min, the metal zirconium is melted to form a small "melting zone", so that the temperature of the surrounding ZrO2 powder rises above 1200 ° C, making it a conductor. Under the action of the high-frequency induced magnetic field, the ZrO2 powder is heated and melted. Under the cooling effect of the water-cooled copper tube, the melt first solidifies to form...

Embodiment 3

[0048] A method for preparing zirconia crystals, comprising the steps of:

[0049] (1) ZrO 2 and Y 2 o 3 The powders are mixed in a molar ratio of 7:1 to obtain a mixture;

[0050] (2) Put the mixture obtained in step (1) into a cold crucible surrounded by copper tubes, because ZrO 2 Conductivity is only available above 1200°C, therefore, use cold crucible induction heating to smelt ZrO 2 At the same time, metal zirconium is added as "melting metal", the amount of metal zirconium added is 5% of the total weight of the mixture, the cross-section shape of metal zirconium is square, and the thickness is 1mm; min, metal zirconium is melted, forming a small "melting zone", making the surrounding ZrO 2 The temperature of the powder rises above 1200°C, making it a conductor, and under the action of a high-frequency induced magnetic field, ZrO 2 The powder is heated and melted, and the melt close to the crucible wall is first solidified to form a drum-like ZrO under the action o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com