Patents

Literature

80 results about "Ferric oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric oxalate, also known as iron(III) oxalate, is a chemical compound composed of ferric ions and oxalate ligands; it may also be regarded as the ferric salt of oxalic acid.

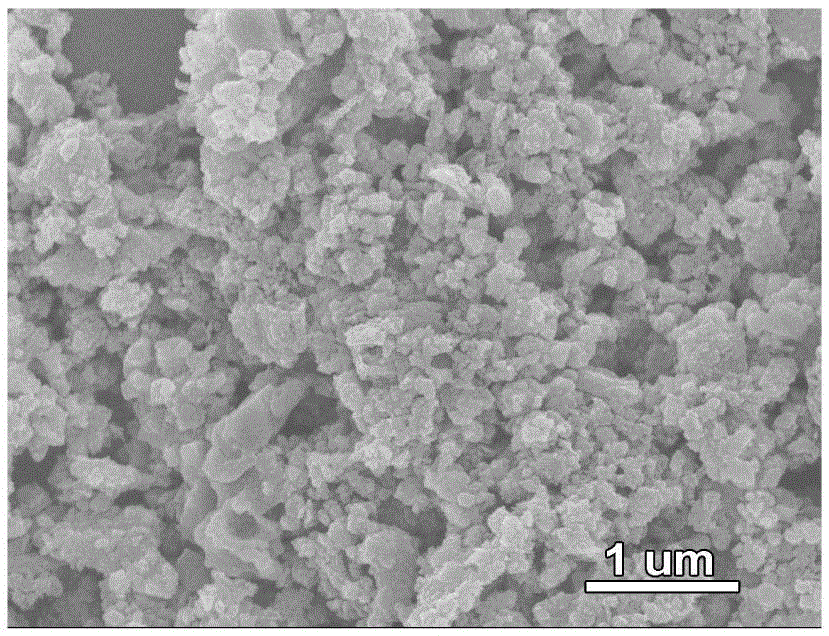

Superfine iron-copper alloy powder and preparation method thereof

The invention relates to superfine iron-copper alloy powder and a preparation method thereof. The superfine iron-copper alloy powder is prepared by using ferric oxalate powder at an industrial raw material stage and cupric oxide powder at an industrial raw material stage as raw materials through high-energy ball milling and hydrogen reduction and has a fisher particle size smaller than 1.0 microns and a oxygen content smaller than or equal to 0.5 percent by weight. The invention has the advantages that grains of the superfine iron-copper alloy powder are thinner, the physical and chemical properties are superior, and the manufacture cost is low.

Owner:惠州市新宏泰科技有限公司

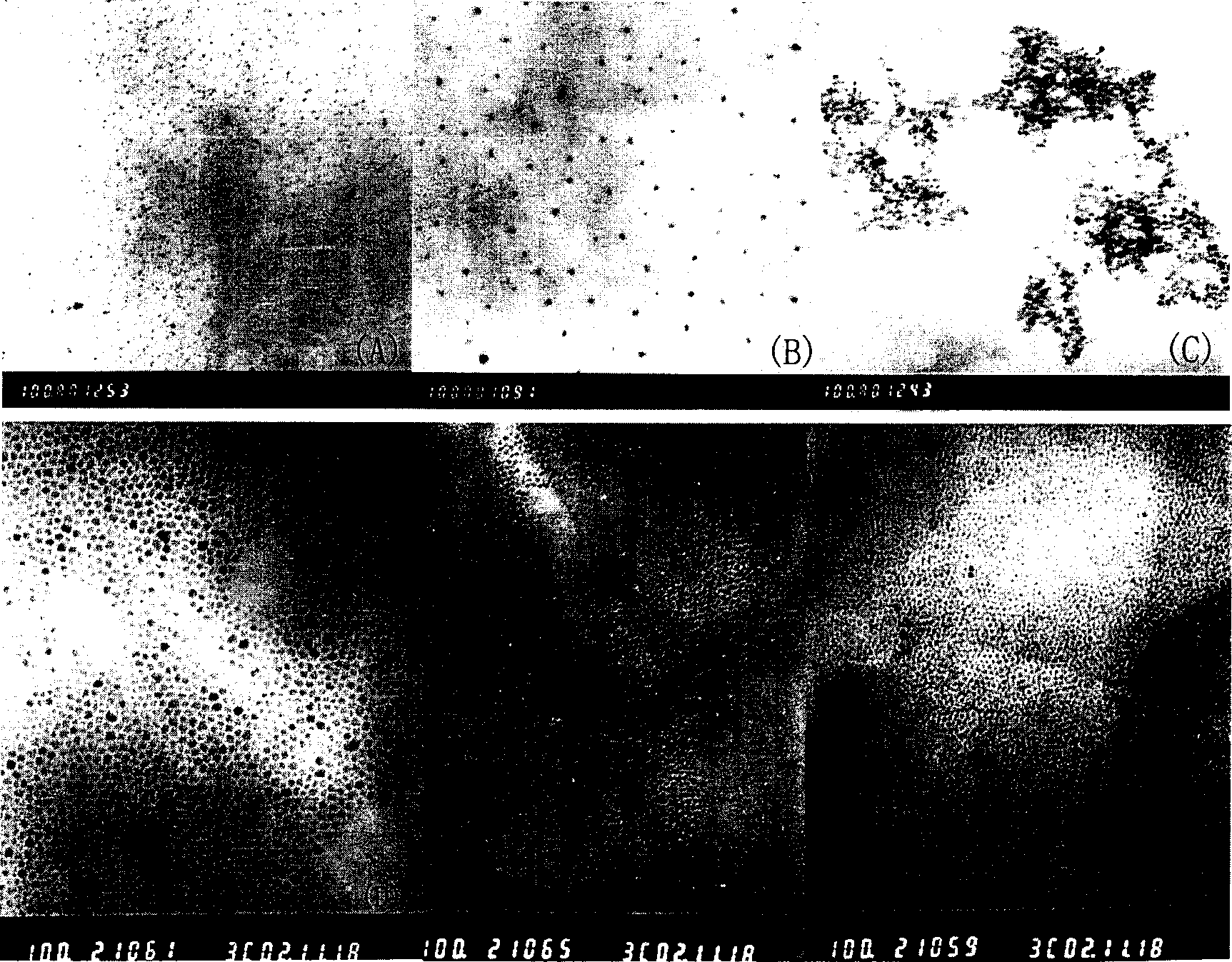

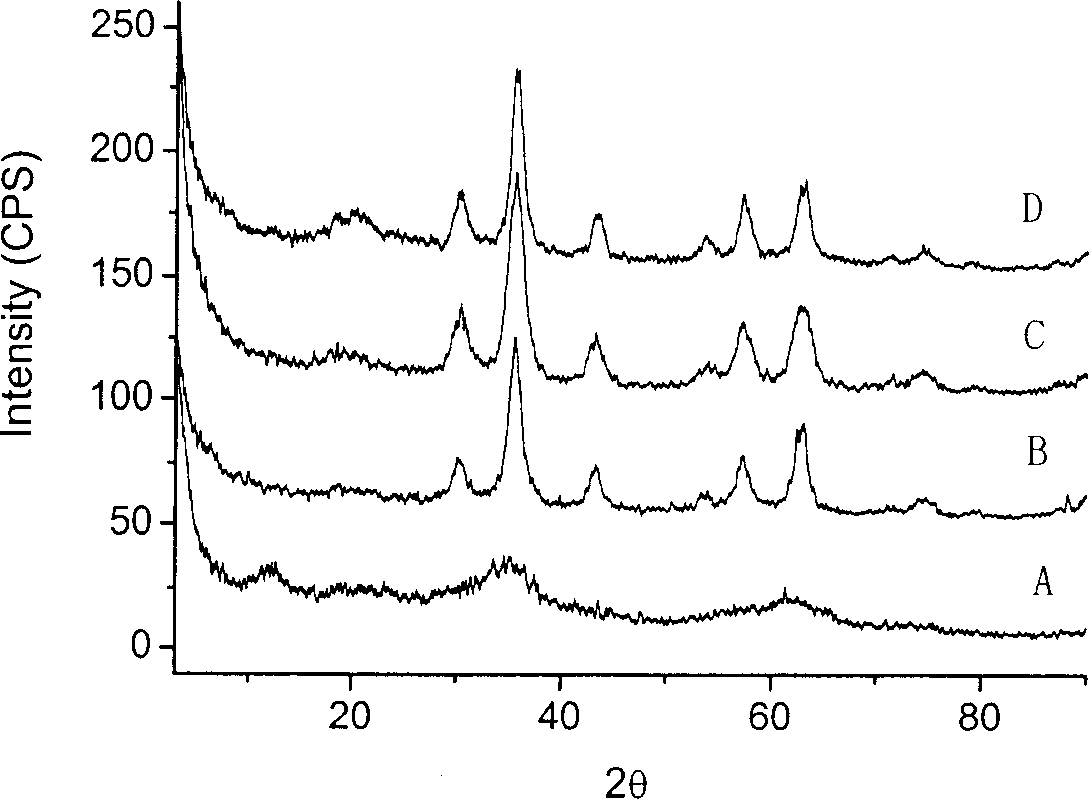

Method for producing water dispersing magnetic nano particle with high-crystallinity

InactiveCN1549283AUniform and controllable particle sizeHigh crystallinityNanostructure manufactureInductances/transformers/magnets manufactureFerric oxalateIron salts

The new method for preparing high crystallinity monodisperse water-soluble magnetic nano microparticles is characterized by that it selects the inorganic iron salts of anhydrous iron trichloride and iron chloride, etc. or metal organic iron compounds (such as iron pentacarbonyl, iron triacetylacetonate, iron biacetylacetonate, complex of cupferron and iron salt, iron octoate and ferric oxalate, etc.) as iron raw material, and utilizes high-temp. decomposition of them in high boiling point polar solvent (for example alpha-pyrrolidone and its derivatives (N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone, etc.), N,N-dimethyl-2-imidazolone, hexametapol, gamma-butyrolactone and its derivative and low molecular weight (molecular weight M is less than or equal to 5000) polyglycol and its derivatives) to prepare magnetic nano microparticles. Said invention can adopts different iron raw materials and high boiling point polar solvents so as to obtain different types of magnetic nano microparticles (Fe, Fe2O3 and Fe3O4) with different sizes and crystallinities and different crystal structures.

Owner:苏州欣影生物医药技术有限公司

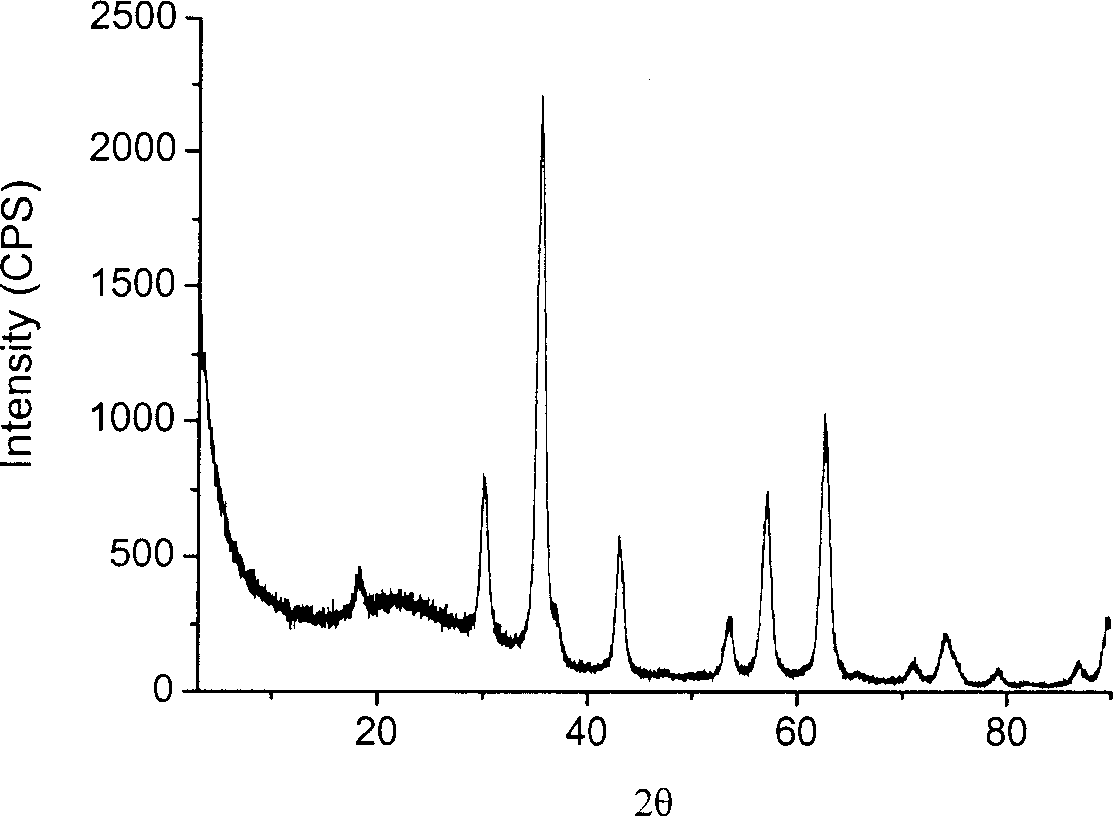

Method for preparing photoelectrode of alpha-iron oxide film by single-source precursor

InactiveCN105039938ASimple and fast operationLow costLiquid/solution decomposition chemical coatingElectrodesTin dioxideFerric oxalate

The invention provides a method for hydrothermal deposition of an iron oxide film through a one-step method by using single-source soluble complex iron salt as a precursor. The firm and compact iron oxide film is obtained through performing hydrothermal deposition onammonium ferric citrate or ammonium ferric oxalate serving as a raw material at a temperature of 90-200 DEG C. The iron oxide film, prepared by adopting the method, can be directly deposited on F-doped tin dioxide electric conducting glass, a surface-treated stainless steel substrate or common glass. The film obtained by being activated in the process that the iron oxide is reduced by ethanol and reoxidized has excellent photoelectric property. The method has the advantages that the concentration of other additives in solution does not need to be adjusted due to the fact that not many reaction precursors are used; the iron oxide film is directly obtained without adopting the process of annealing FeOOH and converting the annealed FeOOH into iron oxide, so that the manufacturing cost is reduced.

Owner:XUCHANG UNIV

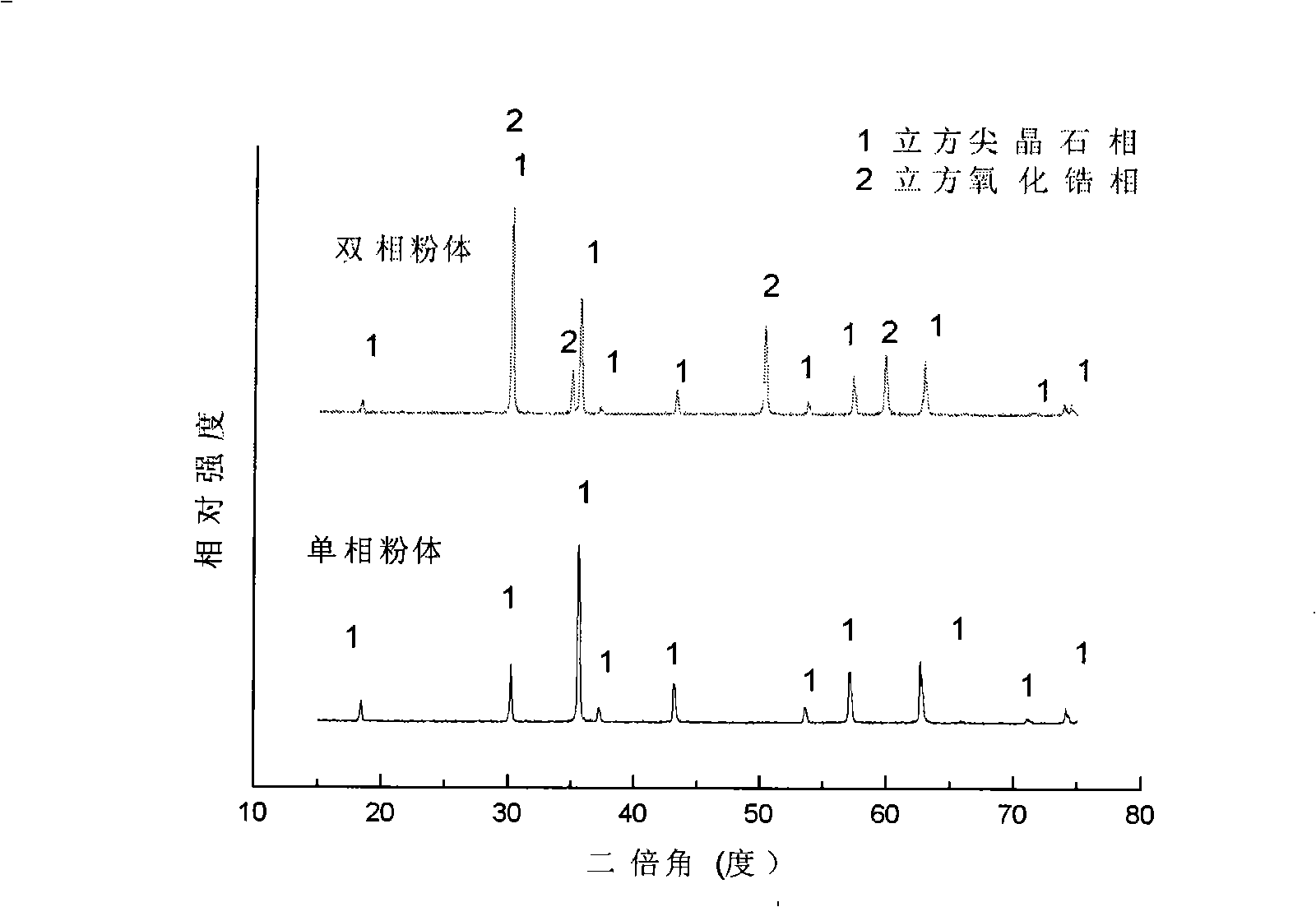

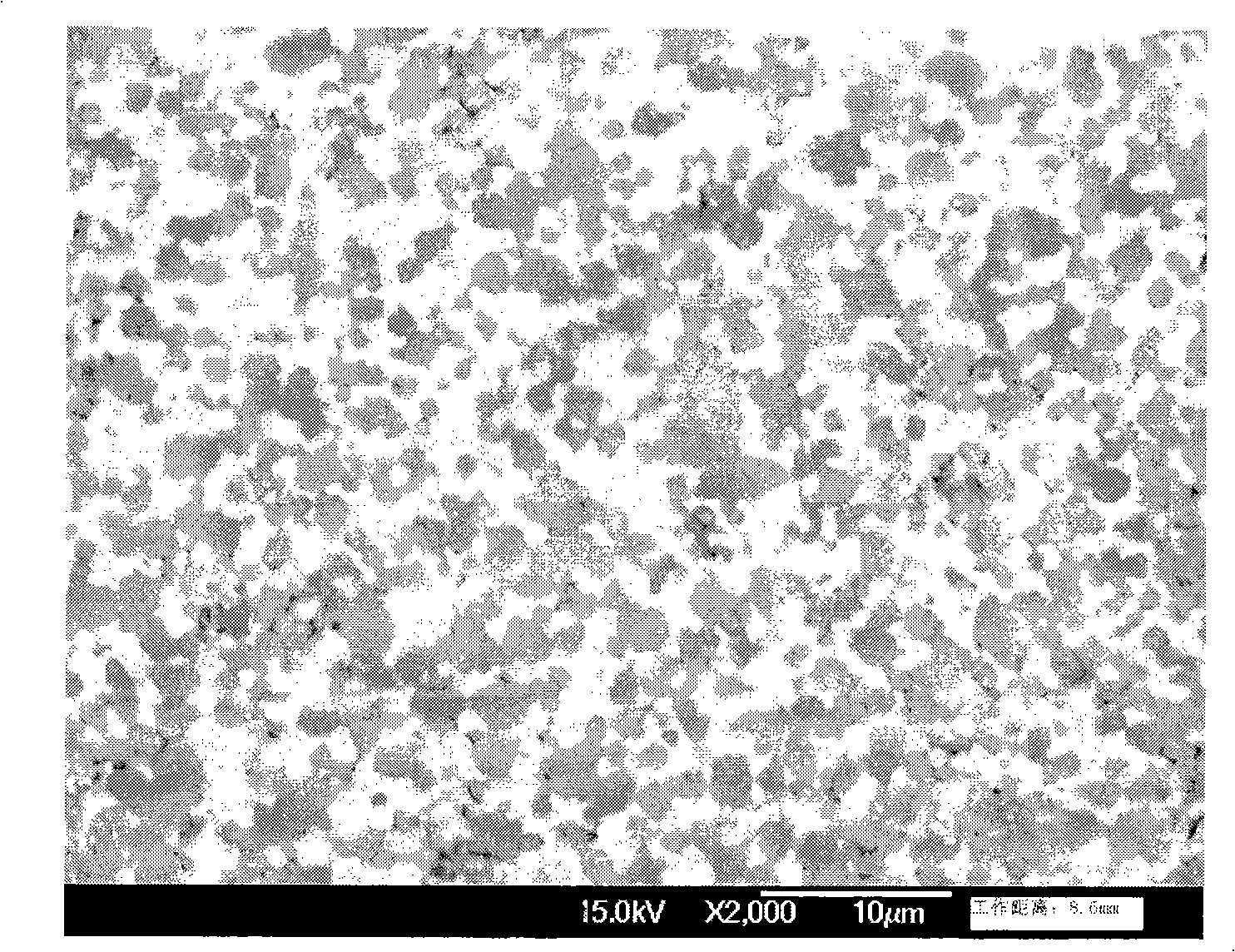

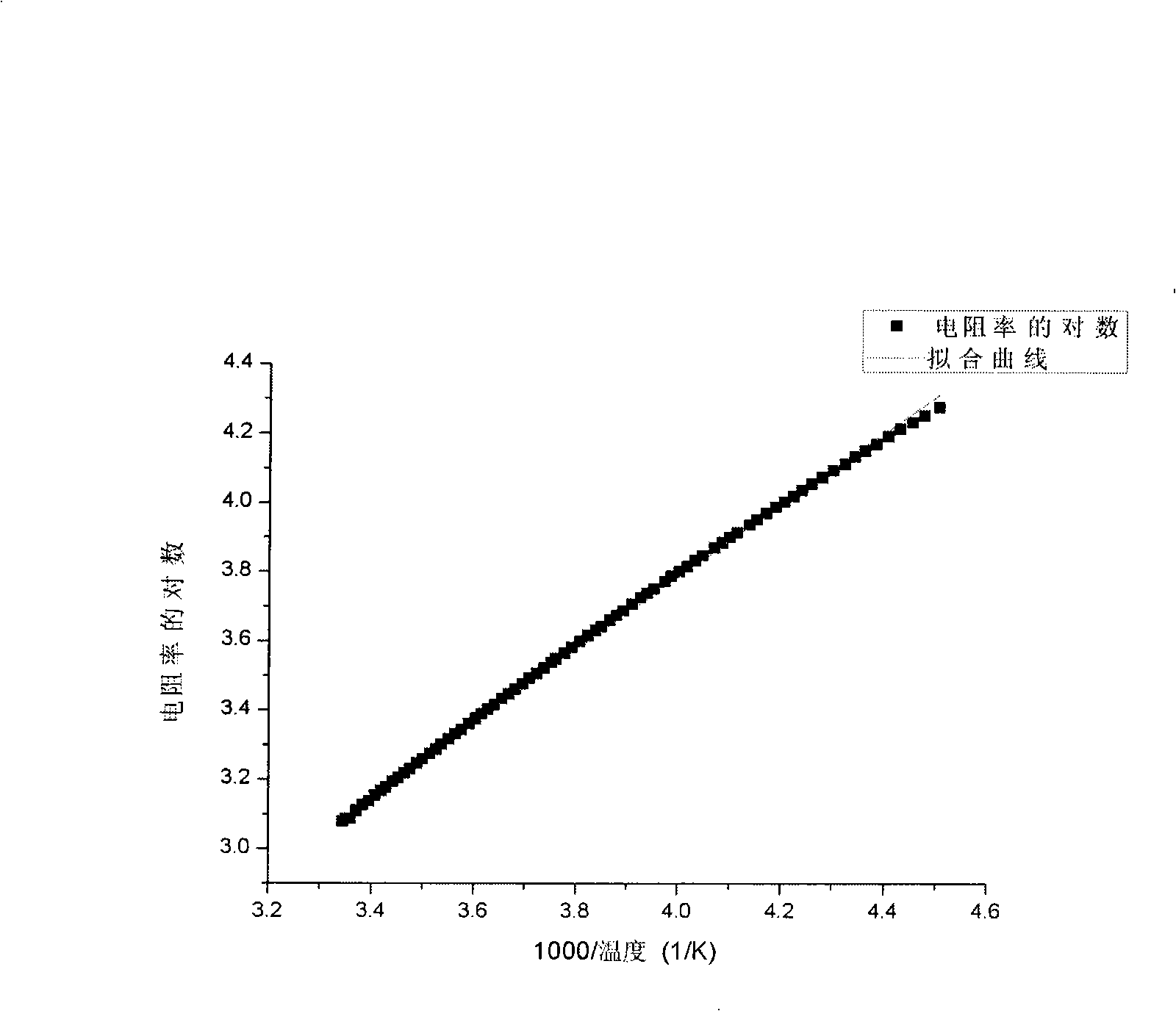

Negative temperature coefficient two-phase composite thermistor composition and preparation thereof

The invention discloses a negative temperature coefficient two-phase composite heat-sensitive material and a method for preparing the same characterized by mixing and milling the copper acetate, ferric oxalate, manganese acetate, nickel acetate and oxalate according to the mol ratio of 0.2-0.6: 1: 3.48-3.08: 1.32: 7.2, calcining the mixture after drying, mixing the prepared powder with partial stable cubic zirconia powder according to the mol ratio of 1: 1.5-4, getting two-phase composite powder after milling and drying, getting the negative temperature coefficient material with a relative density more than 94% after sintering. The material has a stable structure, a sintering temperature between 1200 and 1250 DEG C, a higher mechanical strength than the single-phase spinel ceramic, a B value less than 2800K, a resistivity of 1000omega.cm, a resistance drift less than 3% when accelerated ageing 1000 hours at 150 DEG C, a very good NTC property between -60 DEG C to +50 DEG C, and is suitable for the negative temperature coefficient heat sensitive sensor material in the modern aerostat.

Owner:HEFEI SENSING ELECTRONICS +1

Non-woven cloth suspension filler

InactiveCN102838203AChange propertiesImprove adhesionSustainable biological treatmentBiological water/sewage treatmentFerric oxalateAntioxidant

The invention discloses a non-woven cloth suspension filler which is prepared by the following constituents in parts by weight with the conventional method: 40-50 parts of polyethylene, 25-35 parts of polypropylene, 6-10 parts of carbon black, 3-7 parts of ferric oxalate, 4-6 parts of magnesium oxalate and 1-2 parts of antioxidant. The specific gravity of the non-woven cloth suspension filler is closed to that of water. No fixing support is required. The filler can suspend in the water in a pool with aeration stirring and is uniformly fluidized in the whole pool. The energy consumption is low, and the non-woven cloth suspension filler has a good prospect.

Owner:金宝玲

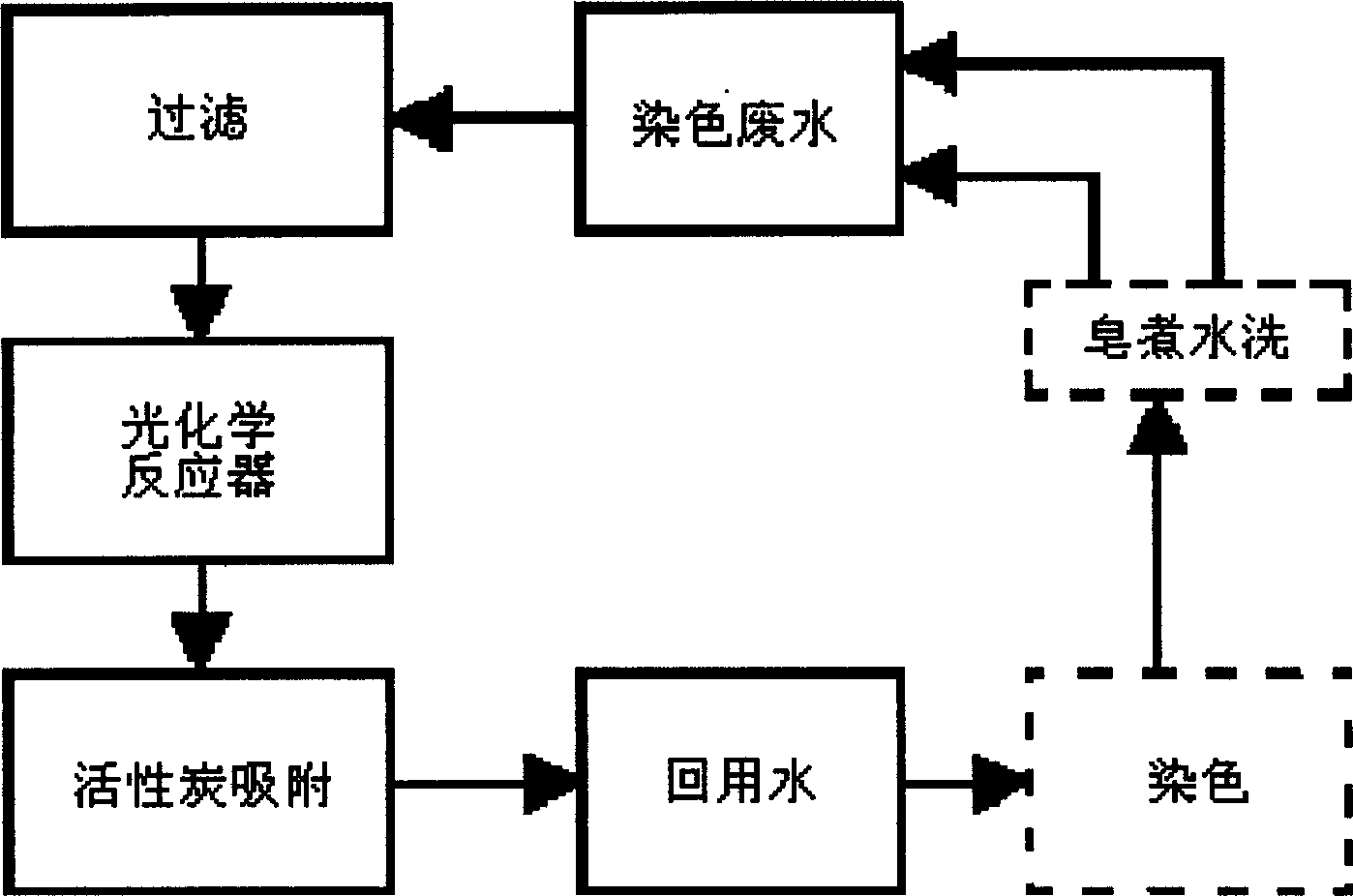

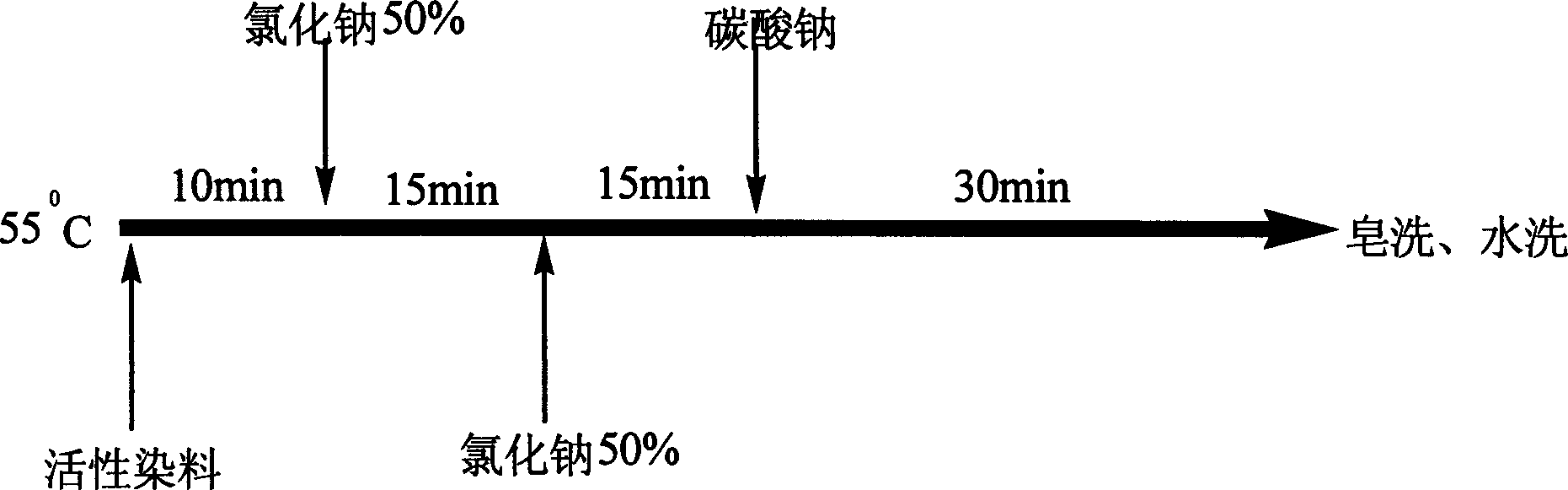

Dyeing waste-water decolorizing degradation, recovery and utilization

InactiveCN1778722AEmission reductionEffective in decolorization and degradationWater/sewage treatment by irradiationMultistage water/sewage treatmentFerric oxalateTemperature control

A dyeing waste water decolorizing degradation and reuse method is carried out by light-auxiliary oxidizing based on ferric oxalate / hydrogen peroxide system or light-auxiliary reducing based on hydroboron / sulfate by water-cooled temperature-controlled light chemical reactor, light chemical decolorizing degradation treating for filtered waste water, and passing degradated wasted water by active carbon adsorptive layer with thickness 80-100cm and flowing-speed 10-30ml / min.The active carbon is particular industrial waste water active carbon with size 3-5mm and density 0.45-0.50g / cm3, iodine adsorptive value is 850mg / g. It can be used for cotton fabrics.

Owner:TIANJIN POLYTECHNIC UNIV

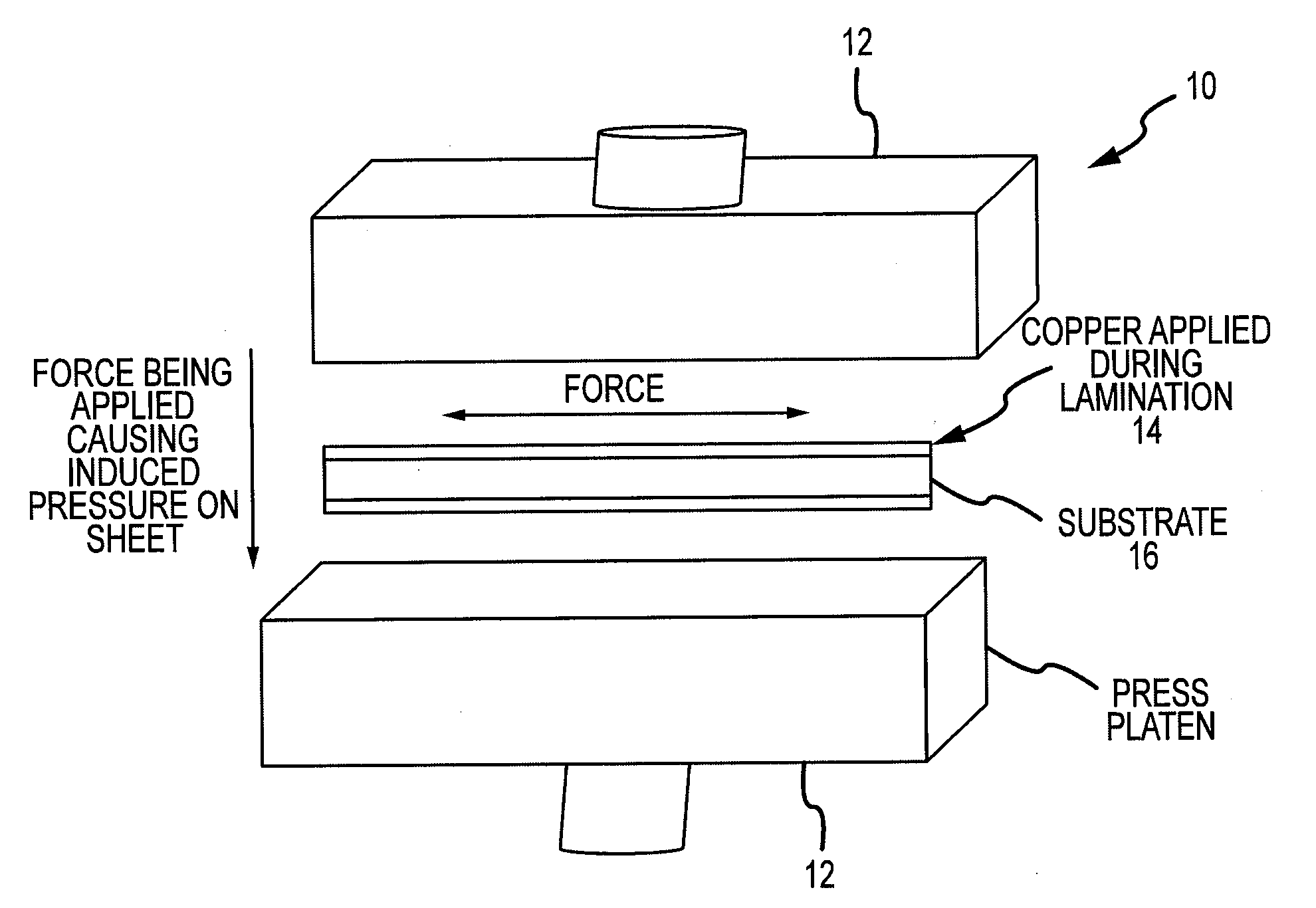

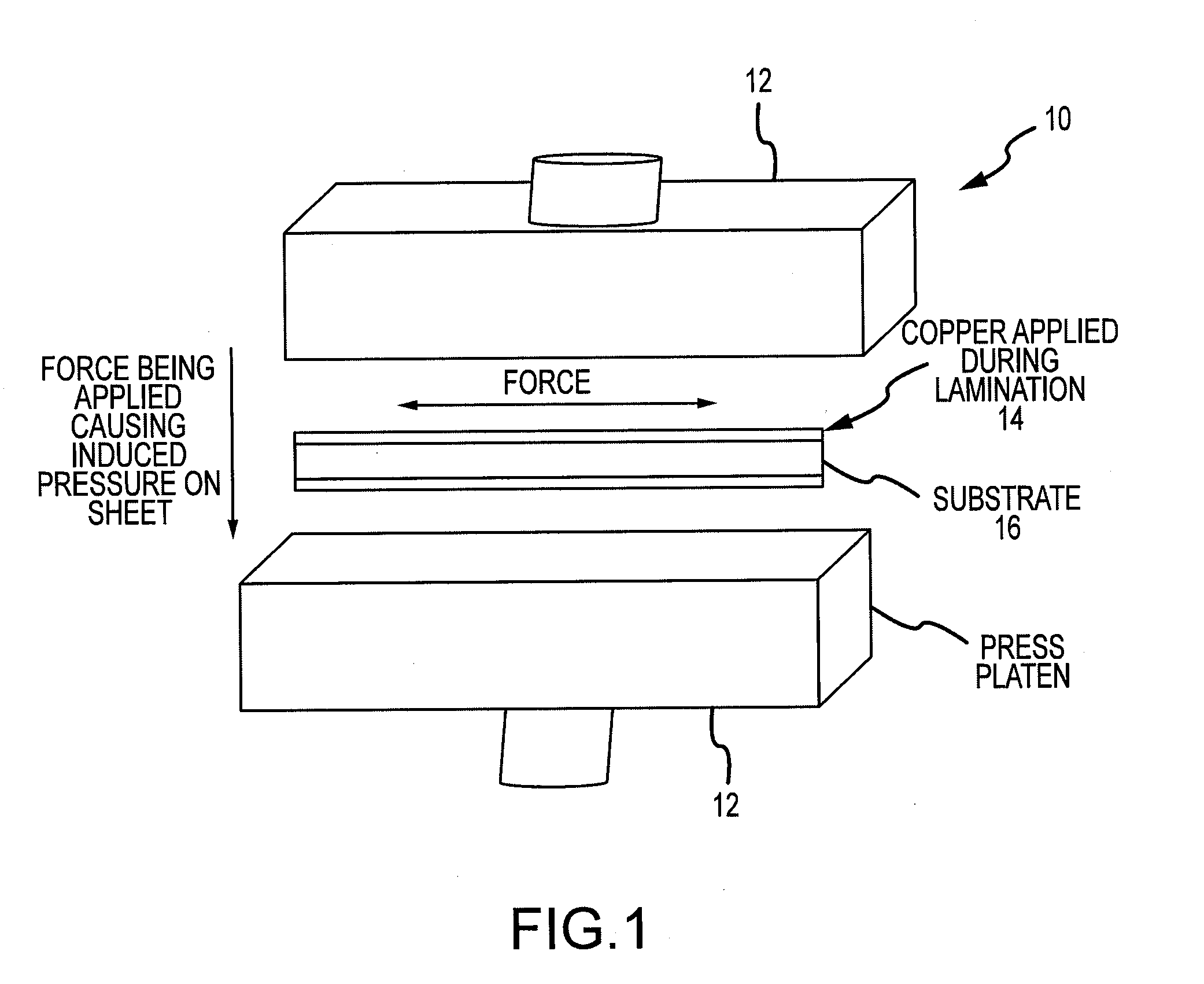

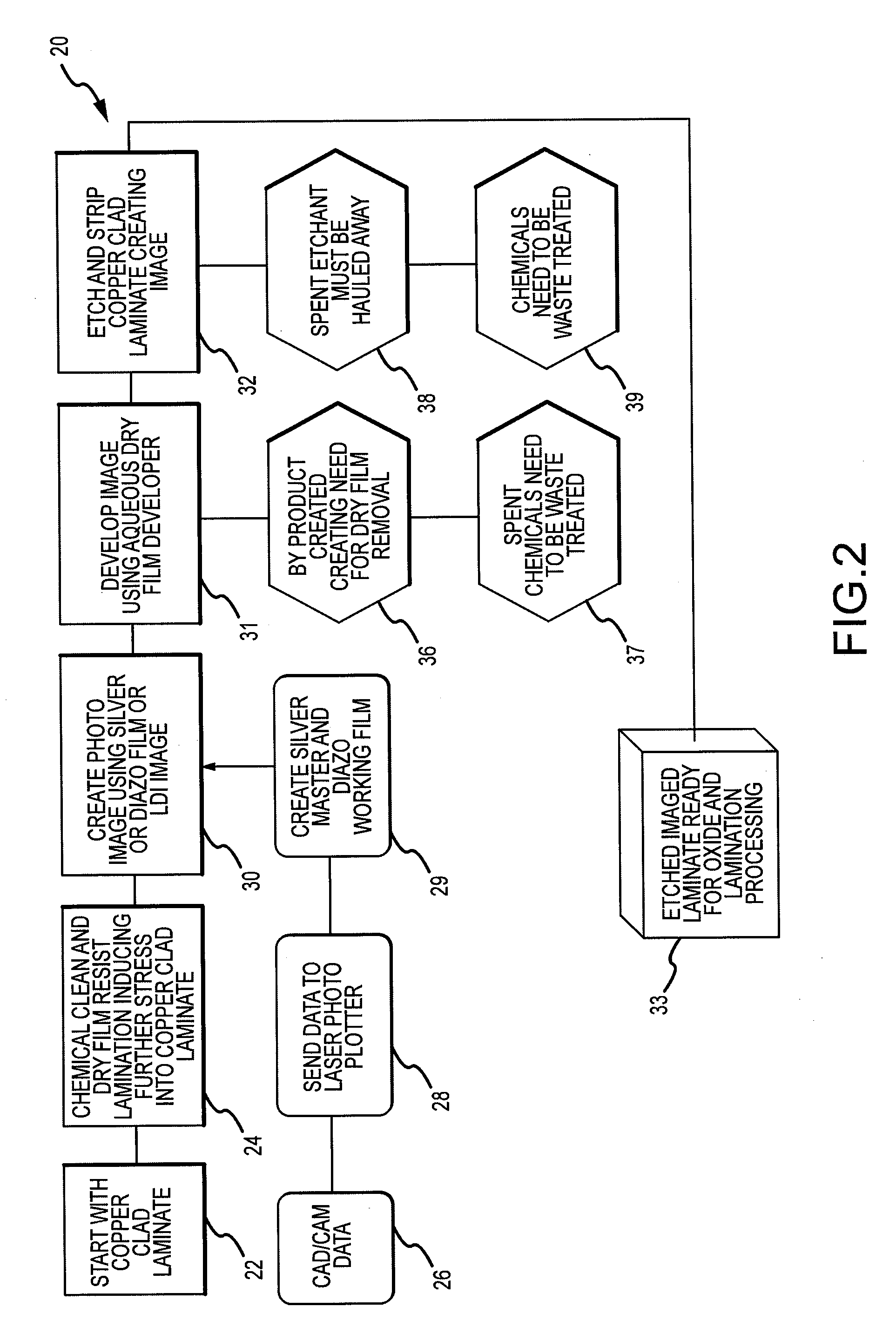

Direct emulsion process for making printed circuits

InactiveUS20090020314A1Eliminate needSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusFerric oxalateEmulsion

A direct emulsion process for making printed circuits and printed circuit boards which includes coating a non-metallized substrate with a solution which creates a light sensitive surface on the substrate, imaging the coated substrate with a circuit design, developing the imaged substrate, and directly plating the developed image onto the coated substrate. Coating solutions which work particularly well in this process include a ferric oxalate and palladium emulsion or a silver based emulsion.

Owner:EARTHONE CIRCUIT TECH CORP +1

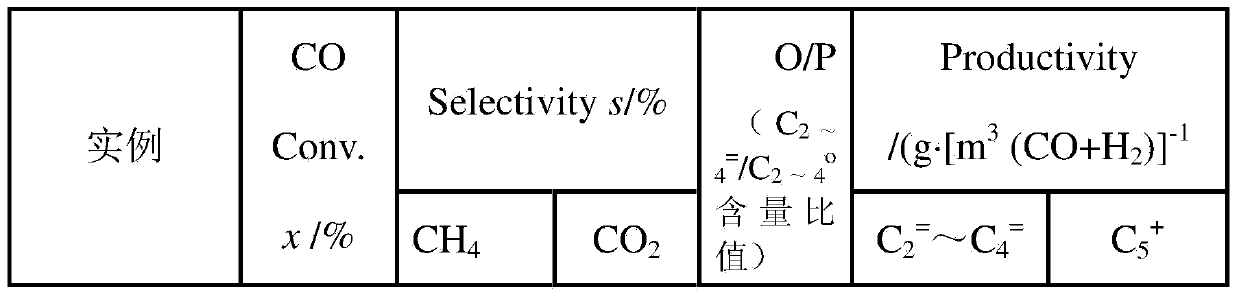

A preparing method of a catalyst used for preparing low-carbon olefins from synthetic gas and applications of the catalyst

InactiveCN103990464AShort cycleReduce energy consumptionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsFerric oxalatePotassium

The invention relates to a preparing method of a catalyst used for preparing low-carbon olefins from synthetic gas and applications of the catalyst. Active components of the catalyst are Fe and Zr. Assistants of the catalyst are Zn and K. The catalyst comprises 20-80 wt% of the Fe, 20-80 wt% of the Zr, 5-20 wt% of the Zn, and 0.5-5 wt% of the K. The catalyst is prepared by a microwave hydrothermal method and a dipping method. Urea is adopted as a precipitator. An active component ferric salt is one selected from ferric nitrate and ferric oxalate. A zircon salt is one selected from zirconium oxychloride, zirconium nitrate and zirconium oxynitrate. An assistant zinc salt is selected from zinc nitrate and a potassium salt is selected from potassium carbonate. Compared with the prior art, the catalyst has characteristics of cheap and easily available raw materials, simple preparation process, short cycle, low energy consumption, good repeatability, low cost and suitability for industrial production. The CO conversion per pass is higher than 93%. The olefin-alkyl (O / P) ratio is higher than 4.80. The yield of C2-C4 olefins can reach 68.15-72.38 g / [m<3>(CO+H2)]. CH4, CO2 and C<5><+> can be maintained in a relatively low value. The reaction products are well distributed. The utilization rate of the synthetic gas is increased.

Owner:NINGXIA UNIVERSITY

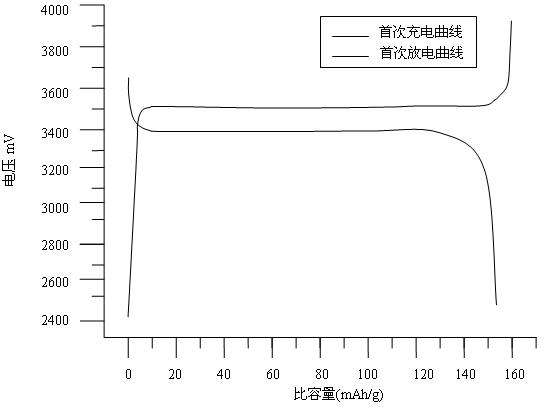

Preparation method of lithium ion battery anode materials mixed with stibium and barium

InactiveCN103066297AHigh specific capacityImprove cycle performanceCell electrodesFerric oxalateElectrical battery

The invention discloses a preparation method of lithium ion battery anode materials mixed with stibium and barium. Plasma materials with micrometer diameters can be obtained after diammonium hydrogen phosphate, ferric oxalate, carbonic acid lithium, antimony trioxide, barium hydroxide, and yttrium oxide are mixed and ball-milled. Nanometer precursors can be obtained after the plasma materials are filtrated, washed and dried. The lithium ion battery anode materials mixed with the stibium and the barium can be obtained after the nanometer precursors are sintered. With utilizing lithium iron phosphate composite materials, a lithium ion battery can use a special ratio and a ternary-form sintering method, wherein the lithium ion battery is prepared by the preparation method of the lithium ion battery anode materials mixed with the stibium and the barium. Antimony, barium, rare earth element yttrium, and the like can be mixed in the lithium iron phosphate composite materials and property of the lithium iron phosphate composite materials can be changed. The lithium iron phosphate composite materials mixed with the stibium and the barium is high in energy density and good in electrical conductivity when applied in the lithium ion battery. Therefore, the lithium ion battery is high in specific capacity and stable in cycle property.

Owner:SHANGHAI JINZHONG INFORMATION TECH

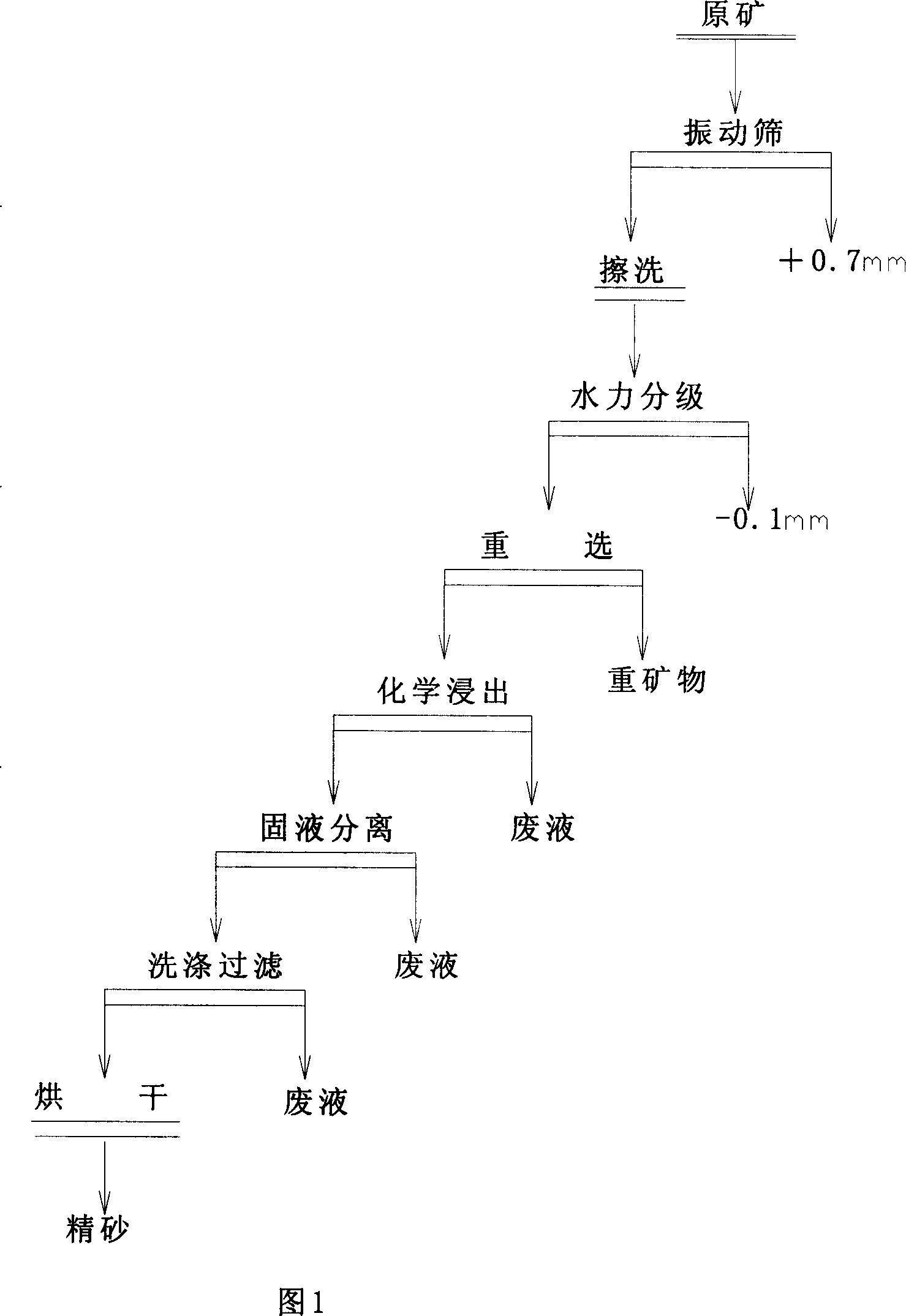

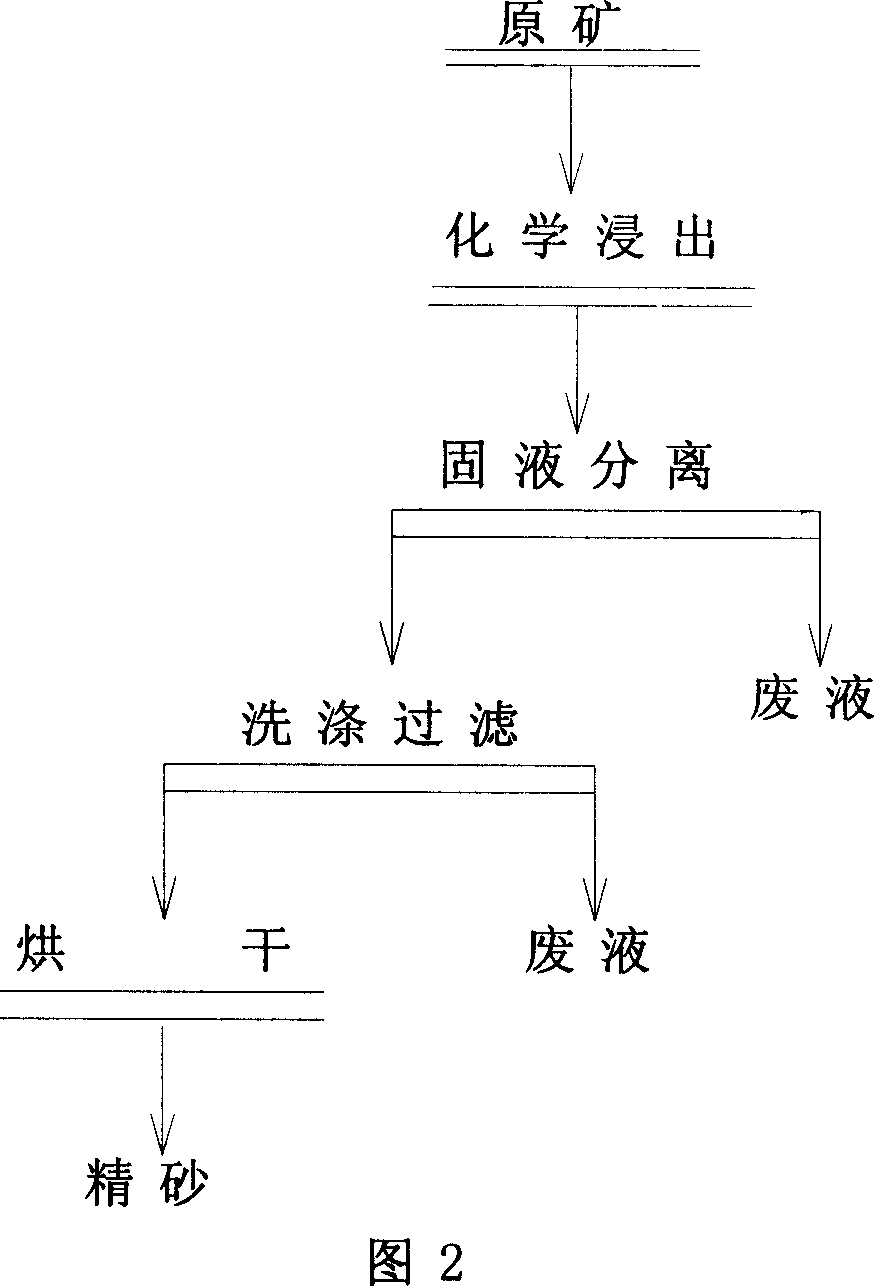

Oxalic acid infusion process for removing film iron on silica sand surface

InactiveCN1962437AEfficient removalExcellent iron removal efficiencySilicon oxidesFerric oxalateSilicon

The invention discloses an oxalic acid leaching method on the silica sand surface film iron, which comprises the following steps: placing silica sand with film iron on the surface in the oxalic acid solution with density at 1-10%; making the quality rate of oxalic acid solution and silica sand more than 100: 100; heating to 80-90 Deg C; stirring fitfully; dissolving film iron on the silica sand by oxalic acid to form ferric oxalate after 1-5h; proceeding solid-liquid separation; washing through clean water; filtering to obtain the product.

Owner:YANSHAN UNIV

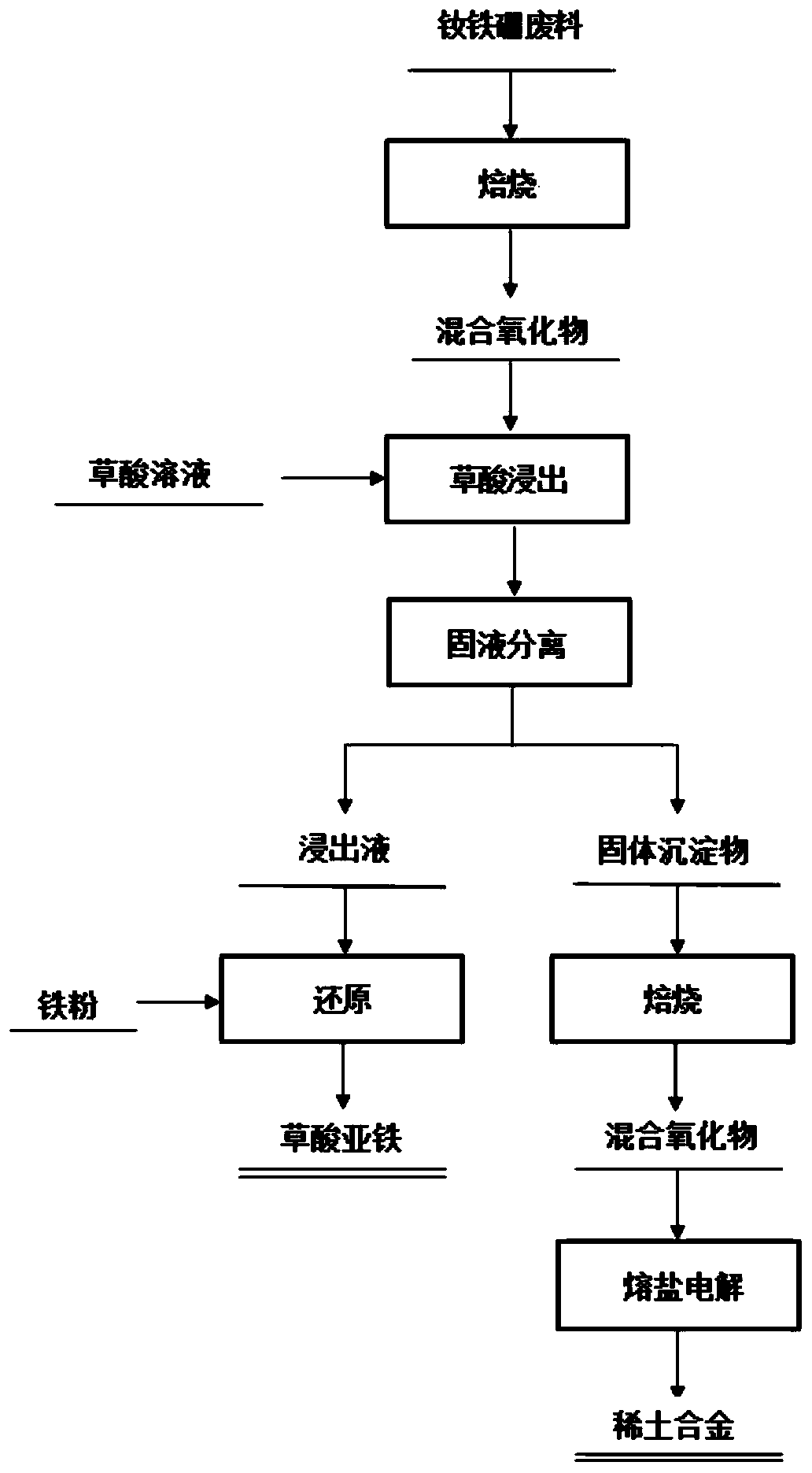

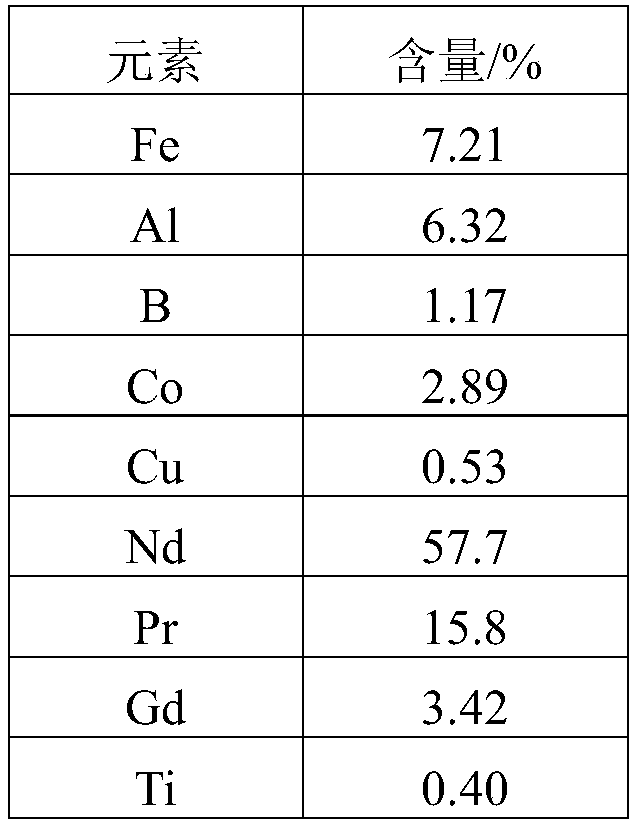

Method for synchronously and efficiently extracting high-value recycled rare earth and iron in neodymium-iron-boron waste

ActiveCN110607537AEasy to operateEfficient extraction and high process operabilityOrganic compound preparationCarboxylic acid salt preparationFerric oxalateElectrolysis

The invention belongs to the technical field of recycling of industrial waste, and particularly relates to a method for synchronously and efficiently extracting high-value recycled rare earth and ironfrom neodymium-iron-boron waste. According to the method, an oxidation product obtained after the neodymium-iron-boron waste is subjected to oxidative roasting is reacted with an oxalic acid solution, a leaching solution containing ferric oxalate and a solid precipitate mainly contains oxalic acid rare earth can be obtained, then iron reduction and molten salt electrolysis treatment are carried out only on the leaching solution and the precipitate respectively, and rare earth alloy for producing neodymium-iron-boron materials and ferrous oxalate used in the lithium battery material productioncan be obtained. According to the method, only the oxalic acid solution is used as a leaching agent and a precipitant, and leaching of iron and transformation of rare earth can be completed in one step, so that the purpose of synchronous realization of efficient extraction and high-value reuse of iron and rare earth is achieved, in the case of the method, the extraction process is short, the environment-friendly effect is achieved, high-value products can be effectively recovered and obtained, and extremely high process operability is achieved.

Owner:赣州稀土友力科技开发有限公司

Brown fused alumina-containing high-strength wear-resistant daily ceramic product

The invention relates to a daily ceramic product, and particularly relates to a brown fused alumina-containing high-strength wear-resistant daily ceramic product and a preparation process thereof. The ceramic product is prepared from the following raw materials in parts by weight: 50-55 parts of clay, 10-15 parts of brown fused alumina, 12-14 parts of cubic boron nitride, 1-2 parts of aluminum powder, 2-3 parts of copper powder, 1-2 parts of nickel powder, 5-6 parts of aluminum oxide powder, 2-3 parts of carbon black, 1-2 parts of ferric oxalate, 2-3 parts of ferroferric oxide, 1-2 parts of silver nitrate, 1-2 parts of alum, 1-2 parts of iron ore slag powder and 7-9 parts of auxiliaries. According to the ceramic product provided by the invention, by adding the raw materials with high strength and good wear resistance such as brown fused alumina and cubic boron nitride, the strength and wear resistance of the green body are improved; in combination with other raw materials, the prepared ceramic product has the advantages of good hardness and strength, high tensile strength, good thermal stability, dense glaze, uniform color, beautiful appearance and durability and great practical value.

Owner:安徽省含山瓷业股份有限公司

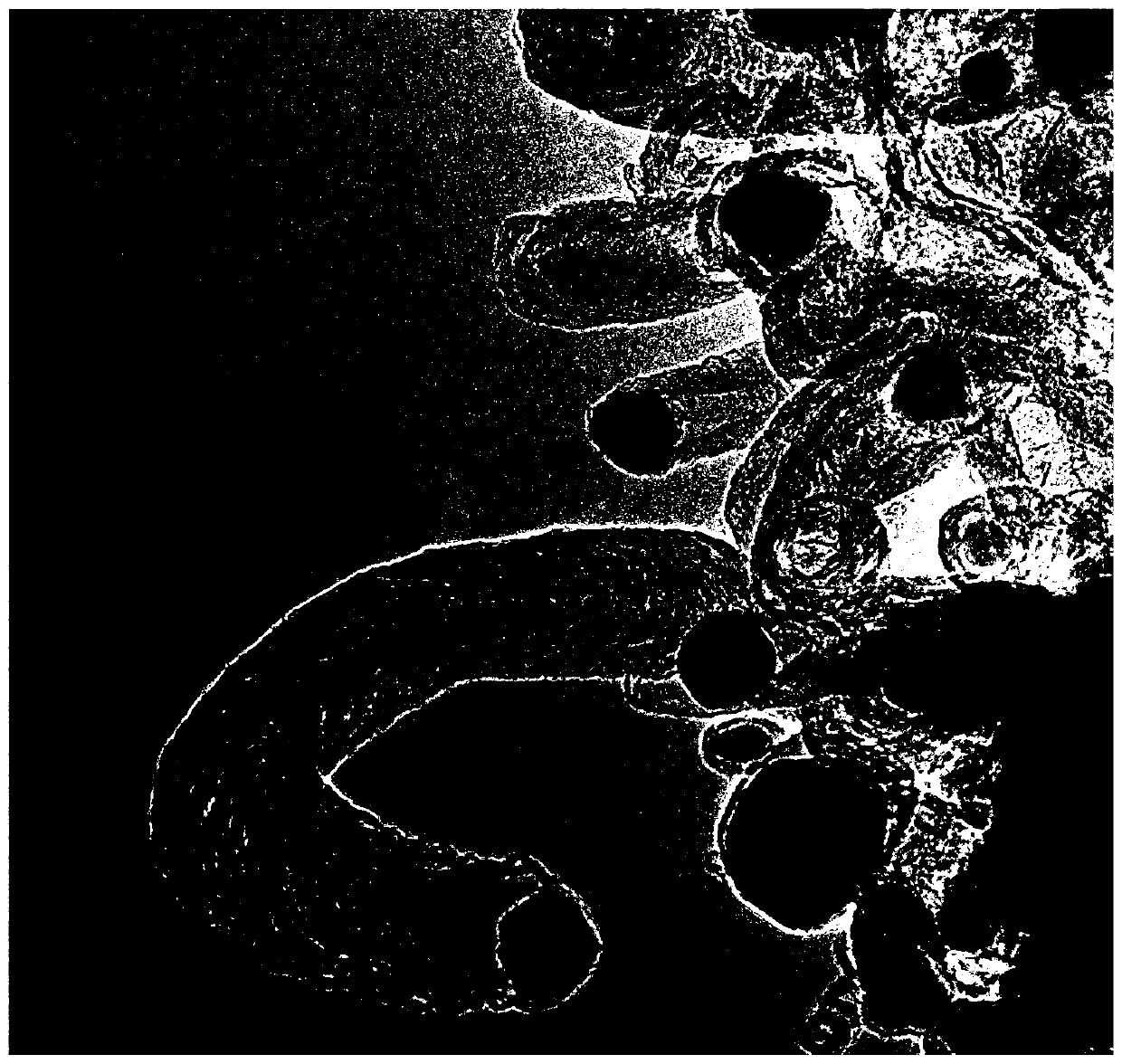

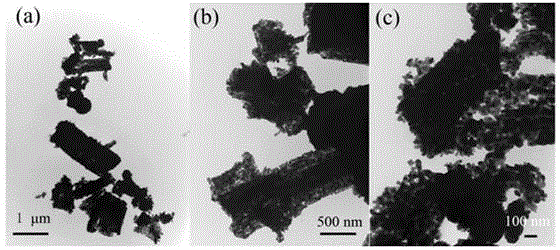

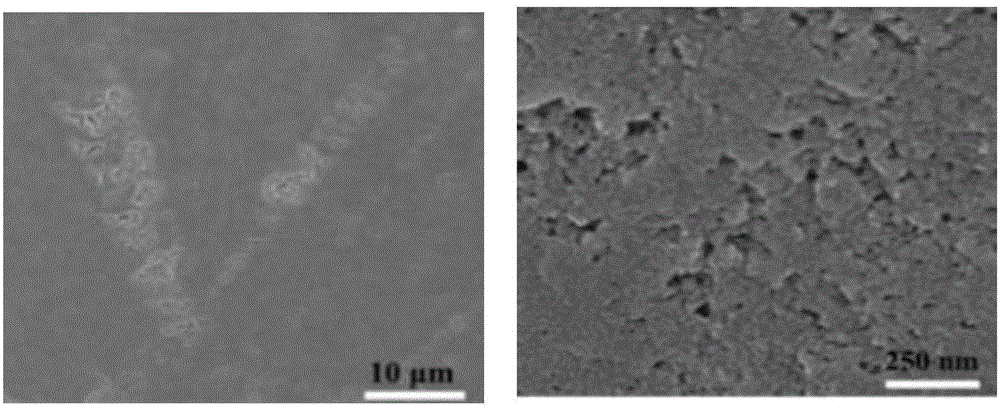

Iron nickel sulfide nano material and preparation method and application thereof

ActiveCN110224126AImprove conductivityImprove structural stabilityMaterial nanotechnologyCell electrodesFerric oxalateHigh sodium

The invention discloses an iron nickel sulfide nano material and a preparation method and an application thereof. The preparation method comprises the following steps: 1) ammonium ferric oxalate, nickel nitrate, methyl imidazole and urea are mixed according to a mass ratio of 1:1:1:(1-7) and ground to obtain a mixture A; 2) the mixture A is loaded into a homogeneous reactor for hydrothermal reaction, evaporated and collected to obtain a product B; 3) the product B is thermally treated in a low temperature tube furnace to obtain a product C; 4) the product C is mixed with thioacetamide and ground to obtain a mixture D; 5) the mixture D is thermally treated in the low temperature tube furnace to obtain the iron nickel sulfide nano material. The bimetallic iron nickel sulfide prepared by theinvention produces carbon nanotubes under the action of metal co-catalysis which significantly improve the electrical conductivity of the material in the process of charge and discharge and improve the structural stability of the material, and has extremely high sodium ion storage performance, high charge and discharge capacity and good rate performance.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of lithium titanate composite cathode material of lithium battery

ActiveCN106711420ACompatible with fast charging performanceHigh specific capacityVehicle seatsCell electrodesFerric oxalateOxide composite

The invention relates to a preparation method of a lithium titanate composite cathode material of a lithium battery, and belongs to the technical field of cathode materials of lithium ion batteries. The method comprises the steps that a lithium titanate precursor is prepared; soluble ferric salt is added to oxalic acid mixed with the lithium titanate precursor; a suspension of ferric oxalate and the lithium titanate precursor is prepared by a precipitation method; and finally high-temperature treatment is performed on mixed powder to obtain the lithium titanate and ferric oxide composite cathode material. The lithium titanate composite cathode material prepared by the method has the rapid charging performance of a lithium titanate material and the high specific capacity performance of ferric oxide; the cost is low; a technology is simple; and industrial production is facilitated.

Owner:四川国创成电池材料有限公司

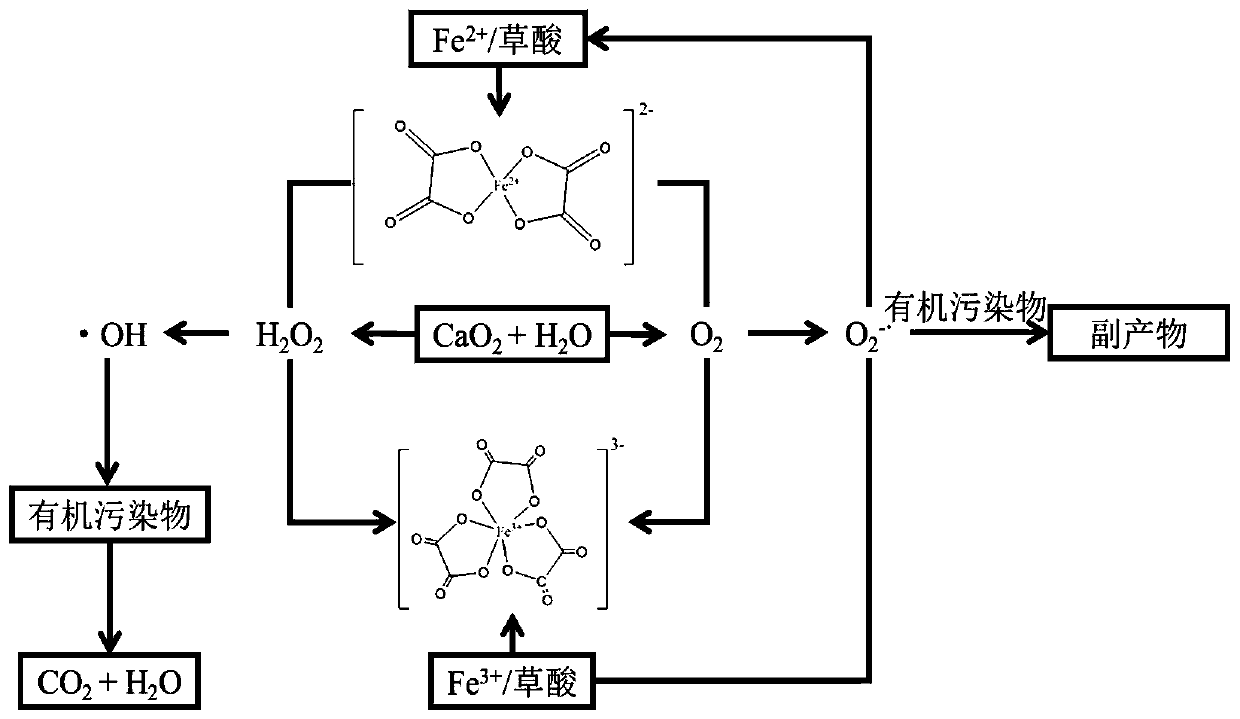

Method for treating organic waste water by iron complexing Fenton reaction

InactiveCN109734172AImprove degradation rateExtension of timeWater contaminantsWater/sewage treatment by oxidationFerric oxalateDecomposition

The invention provides a method for treating organic waste water by an iron complexing Fenton reaction, and belongs to the field of environmental waste water treatment. The method includes the following steps: sequentially adding oxalic acid, FeSO4*7H2O and calcium peroxide into organic waste water for degradation reaction. In the method, the oxalic acid and the FeSO4*7H2O can generate a ferric oxalate complex; calcium peroxide is a solid source of hydrogen peroxide, which is convenient for transportation and storage; the ferric oxalate complex reacts with CaO2 to obtain a Fenton-like system,which can promote stable generation of *OH, avoid disproportionation and decomposition of H2O2, and improve the utilization rate of H2O2; and meanwhile, the addition of the oxalic acid can prolong theexistence time of free Fe2+ / Fe3+ and further reduce the precipitation of iron mud, and thus the removal efficiency of organic matters in waste water by the Fenton-like system is improved. Compared with the traditional Fenton method, the method can be applied to organic waste water with a pH value of 3-11.

Owner:YANSHAN UNIV

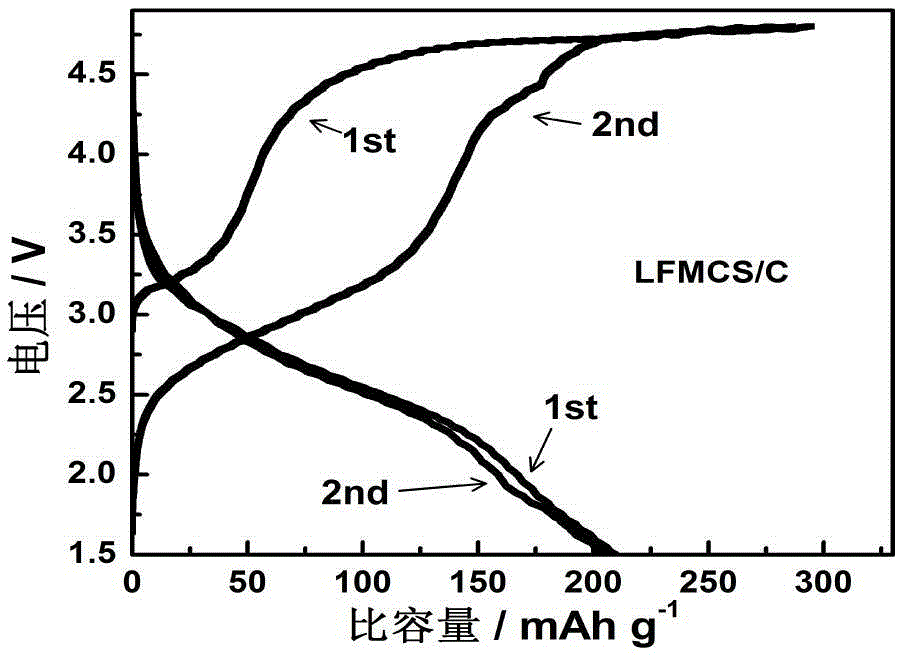

Ternary silicate composite cathode material and preparation method therefor

ActiveCN105375029ALow costNo pollution in the processNon-aqueous electrolyte accumulator electrodesFerric oxalateArgon atmosphere

The invention provides a ternary silicate composite cathode material. The cathode material is carbon-coated ternary silicate having the specific structural formula: LixFe alpha M1 beta M2 gamma SiO4 / C, wherein x is greater than or equal to 2.0 and less than or equal to 2.1; alpha+ beta+ gamma is equal to 1; alpha is greater than or equal to 0.2; beta is greater than or equal to 0.2; gamma is greater than or equal to 0.2; M1 and M2 are transitional metal elements; the preparation method is as follows specifically: putting lithium carbonate, ferric oxalate and two kinds of M1 and M2 sources containing different transitional metals into a container, and taking absolute ethyl alcohol as the medium for stirring for 30-180 min, and then adding ethyl silicate to obtain mixed liquid; drying the mixed liquid to obtain a dry material; adding the carbon source into the dry material, taking acetone as the medium, performing ball milling, and sintering in a nitrogen or argon atmosphere to obtain a target product; stirring the product with acetylene black and polyvinylidene fluoride in N-methyl pyrrolidone, and coating an aluminum foil with the stirred product, and then performing drying, film stamping and film pressing to obtain the ternary silicate composite cathode material plate. The preparation method is low in cost, pollution-free, low in harmful gas emission in the synthetic process, and excellent in the electrochemical performance of the material.

Owner:CHINA THREE GORGES UNIV

Breeding cattle feed and preparation method thereof

InactiveCN105614080AIncrease appetiteEnhance physical fitnessFood processingAnimal feeding stuffFerric oxalateVitamin C

The present invention provides a breeding cattle feed and a preparation method thereof. The breeding cattle feed comprises the following components in parts by weight: 20-30 parts of corn, 5-8 parts of soybeans, 10-15 parts of sweet potato residues, 5-6 parts of radix polygalae, 1-1.5 parts of poria cocos, 0.6-2 parts of radix rehmanniae, 0.1-1.3 parts of caulis polygoni multiflori, 0.6-1 part of fructus schisandrae chinensis, 6-15 parts of amino acid compositions, 1-9 parts of shell powder, 2-7 parts of shrimp powder, 1-5 parts of silkworm chrysalis, 1-2 parts of vitamin A, 0.5-1.2 parts of vitamin C, 0.6-1 part of vitamin E, 5-15 parts of ferric oxalate, 8-12 parts of zinc oxalate, 3-6 parts of calcium dihydrogen phosphate, 2-3 parts of whey powder and 6-20 parts of water. The provided feed is full of nutrition and good in absorption, can effectively improve the appetite of the breeding cattle, enhance physical fitness and disease resistance of the breeding cattle, improve semen quality of the breeding cattle, effectively increase sperm motility and density, effectively improve breeding rate, at the same time reduce breeding costs and increase incomes.

Owner:青岛博泰美联化工技术有限公司

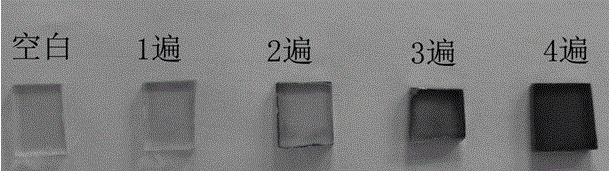

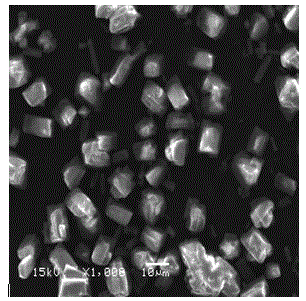

Preparation method of lithium iron phosphate precursor

InactiveCN106915734AHigh purityUniform crystal formPhosphorus compoundsBulk chemical productionFerric oxalateSodium phosphates

The invention relates to a preparation method of a lithium iron phosphate precursor. The method includes the steps of: subjecting ferric oxalate to temperature-programmed calcination to obtain anhydrous ferric oxalate; crushing the anhydrous ferric oxalate and performing sieving, then according to the mass of the sieved anhydrous ferric oxalate, using supercritical water to perform washing 3 times so as to obtain ferric oxalate powder; putting the ferric oxalate powder into a reactor, introducing oxygen, and carrying out full reaction for 5min so as to obtain purified ferric oxalate; adding sodium phosphate into phosphoric acid for acidification, and adjusting the pH so as to obtain a sodium phosphate solution; transferring the purified ferric oxalate and the sodium phosphate solution into a hydrothermal high temperature and high pressure kettle, then adding iron phosphate seed crystal to carry out reaction for 14h, thus obtaining iron phosphate crystals; adding a dispersant into the iron phosphate crystals, and fully mixing the substances, thus obtaining a lithium iron phosphate precursor. The preparation method of the lithium iron phosphate precursor provided by the invention has the characteristics of simple production process and mild reaction conditions, and the precursor product has high purity, regular shape and good consistency, thus being capable of realizing industrial production.

Owner:沧州凯盛达新能源科技有限公司

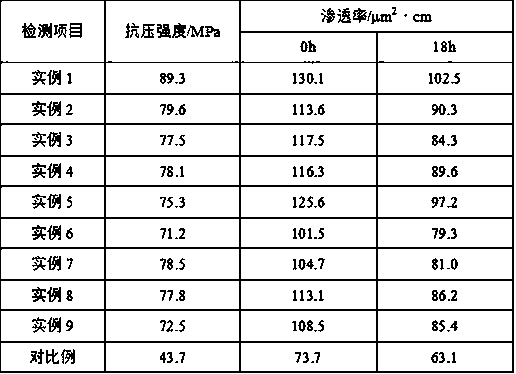

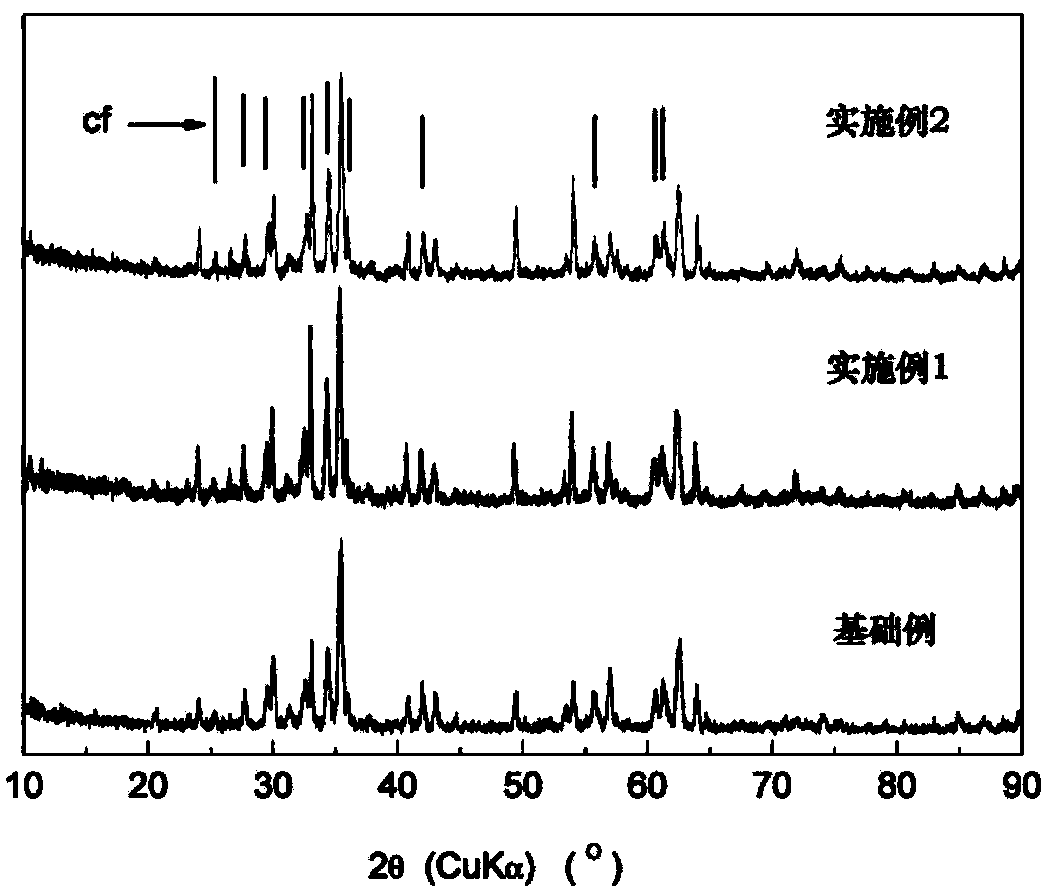

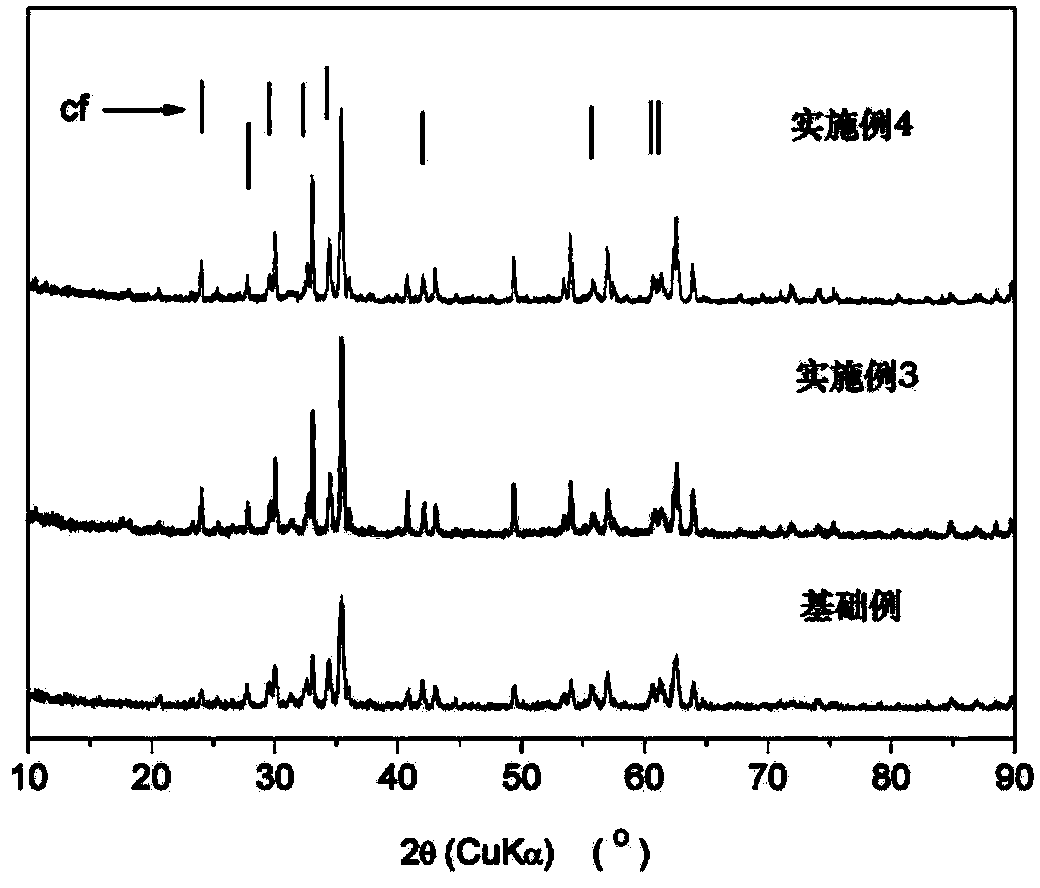

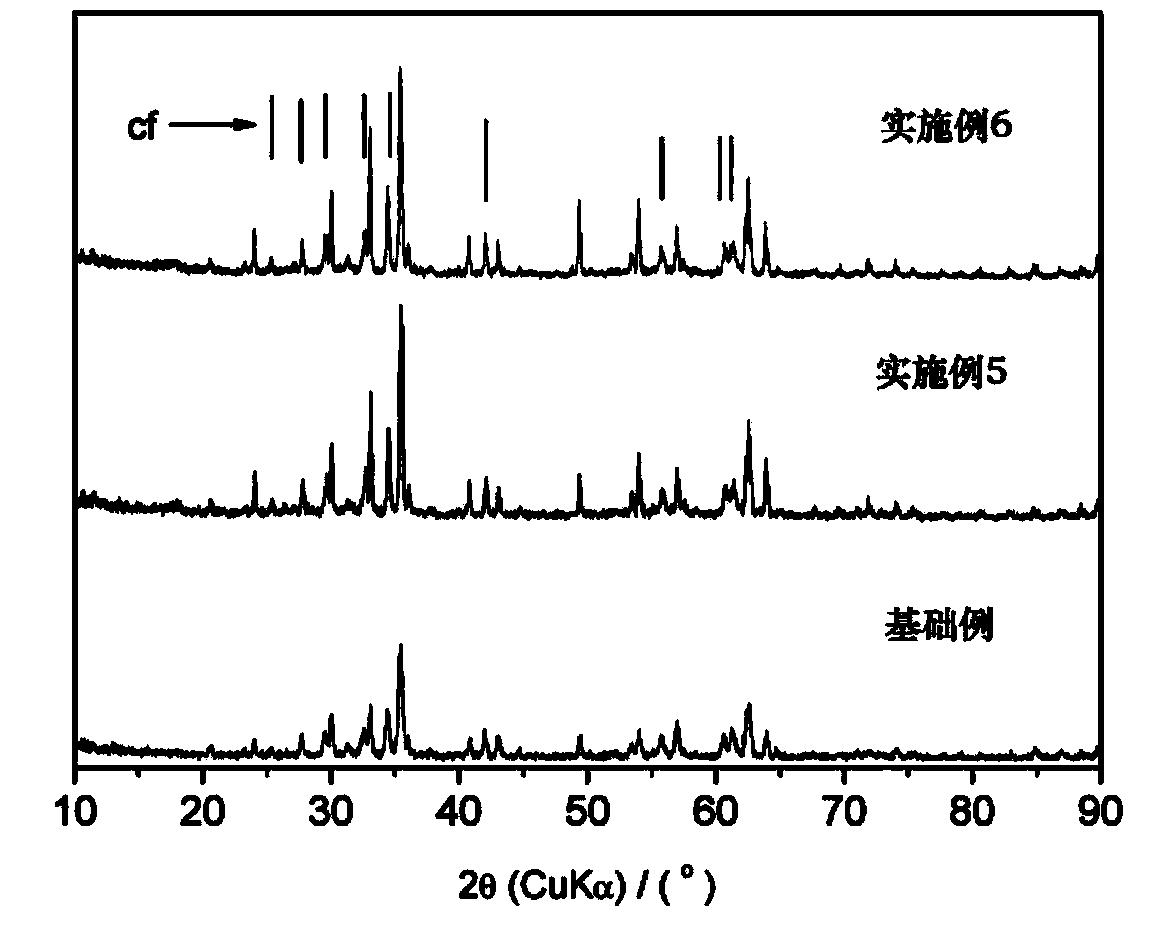

Ceramsite fracturing propping agent preparation method

InactiveCN108892485ASystem rate increaseHigh porosityFluid removalDrilling compositionFerric oxalateFiber

The invention belongs to the technical field of well drilling auxiliary agents and discloses a ceramsite fracturing propping agent preparation method. The method includes steps: subjecting albite, bauxite, kaolin, coal ash, dolomite, potassium permanganate, cryolite, low-melting-point alloy powder, graphite, cupric oxalate, ferric oxalate, calcium carbonate and modified bamboo fiber powder to mixed ball milling, and filtering through a 120-mesh screen to obtain mixed powder; stirring and mixing sodium fluoride solution and peach gum liquid according to a mass ratio of 1:20-1:30 to obtain mixedslurry; mixing mixed powder with mixed slurry according to a mass ratio of 3:2-3:1, granulating, drying, carbonizing and sintering to obtain a blank material; stirring and mixing the blank material with modified sodium alginate liquid according to a mass ratio of 1:20-1:30, filtering and drying to obtain a ceramsite fracturing propping agent. Mechanical properties and permeability of the ceramsite fracturing propping agent are both improved effectively.

Owner:邹峰

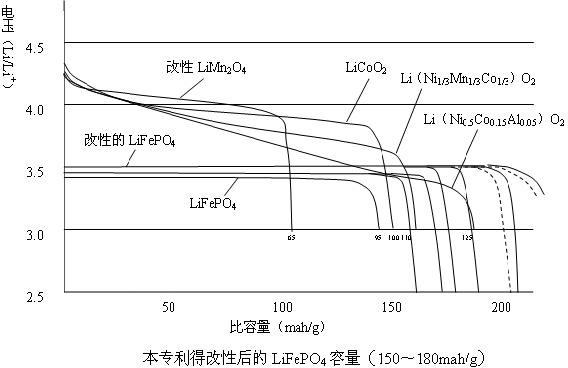

Comprehensive modification method for synthesis of lithium iron phosphate

The invention discloses a comprehensive modification method for the synthesis of lithium iron phosphate, comprising the following steps of: taking iron trioxide with a lower price as an iron source to replace expensive ferric oxalate and ferrous acetate; preparing a LiFePO4 / C material by an improved high-temperature solid phase method and combining synthesis, surface modification (carbon covering) and inner doping (phase doping) to finish the process. By utilizing the synthesis to be newly combined with the external modification and the inner doping, the cost is reduced. The battery does not contain any heavy metal and rare metal (a nickel-metal hydride battery needs the rare metal) and has no toxin (passing SGS (Societe Generale De Surveillance) authentication) and no pollution, so that the battery is the absolute green and environment-friendly battery. A lead-acid battery contains a lot of lead and secondary pollution to the environment is caused if the abandoned lead-acid battery is not properly processed; and no matter whether a lithium iron phosphate material is used for production or use, no pollution is caused, so that the battery is listed into an '863' National High-tech Development Plan during a;Twelfth Five-Year' period and is a project which is supported and encouraged to be developed by the country.

Owner:ZHUZHOU TAIHE HIGH TECH

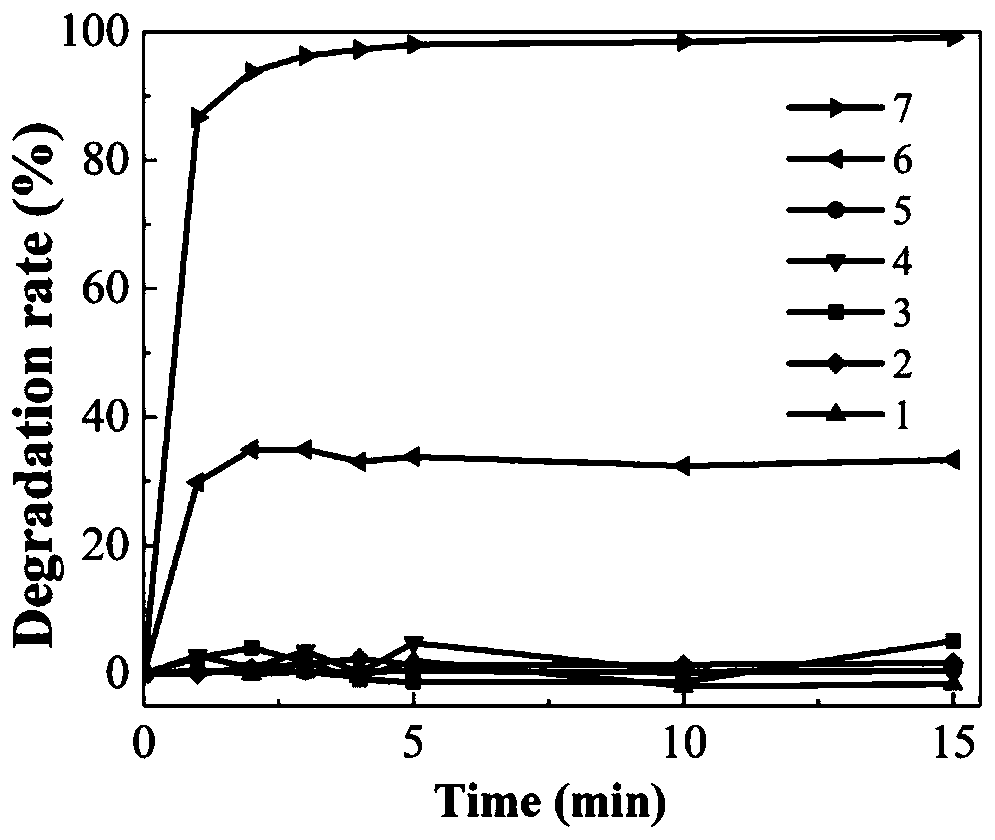

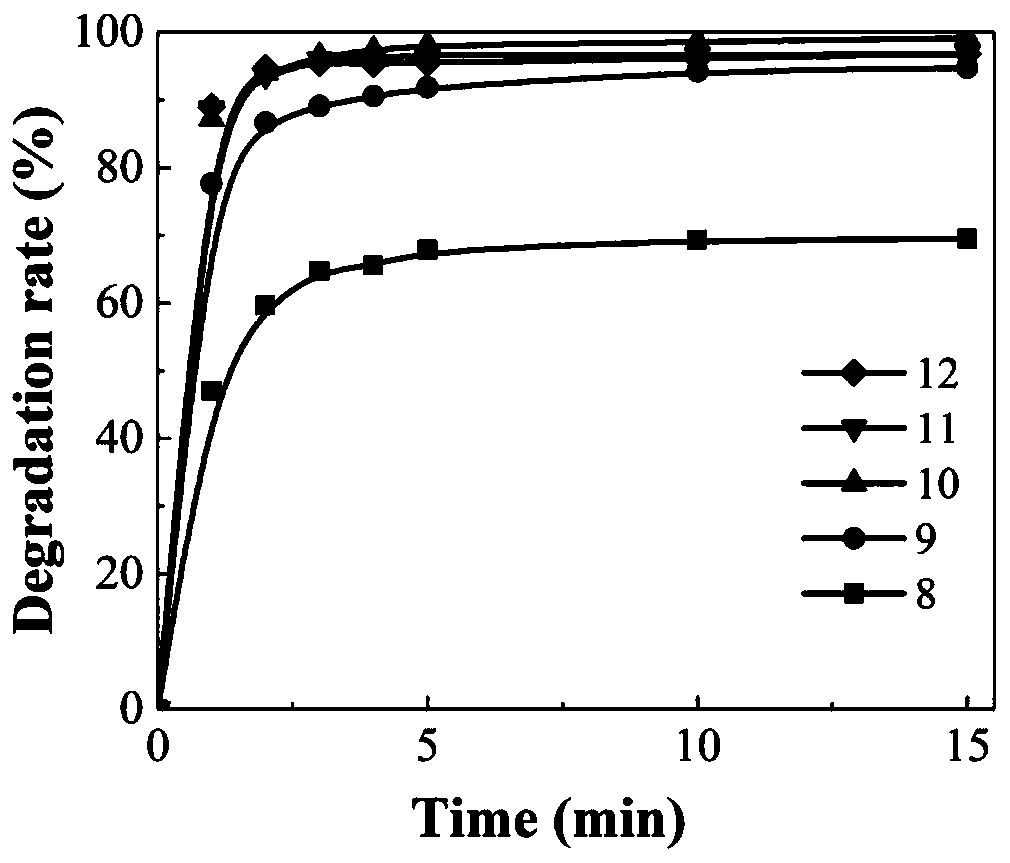

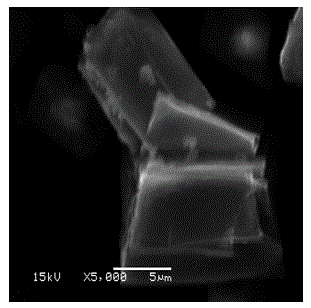

Preparation method of visible light activated brick-shaped nano-copper ferrite photocatalyst and application thereof

InactiveCN103055864ASimple preparation processEasy to operateWater/sewage treatment by irradiationWater contaminantsFerric oxalateBrick

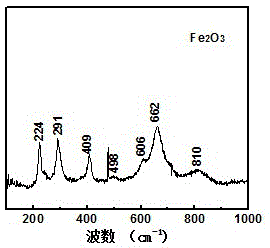

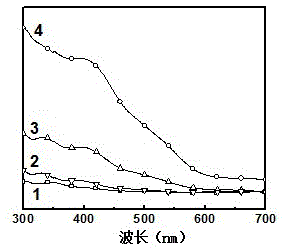

The invention relates to a preparation method of visible light activated brick-shaped nano-copper ferrite photocatalyst and an application thereof. The preparation method comprises the following steps: preparing precursor solution, comprising respectively taking 100mL 0.1M copper sulfate solution, 100mL 0.2M ferrous sulfate solution and 100mL 0.1M sodium oxalate solution, mixing the solutions and then magnetically stirring for 0.5-1h at the temperature of 75-85 DEG C so that the mixture is completely mixed, generating precursor solution of light yellow nantokite ferric oxalate, and continuously stirring till no precipitate is generated; after naturally cooling, carrying out centrifuging, deionized water washing and absolute ethyl alcohol washing, and then carrying out drying processing so as to obtain the precursor powder of light yellow nantokite ferric oxalate; and calcining for 1.5-2.5h in the air at the temperature of 300-700 DEG C so as to obtain brown copper ferrite sample.

Owner:LIAONING NORMAL UNIVERSITY

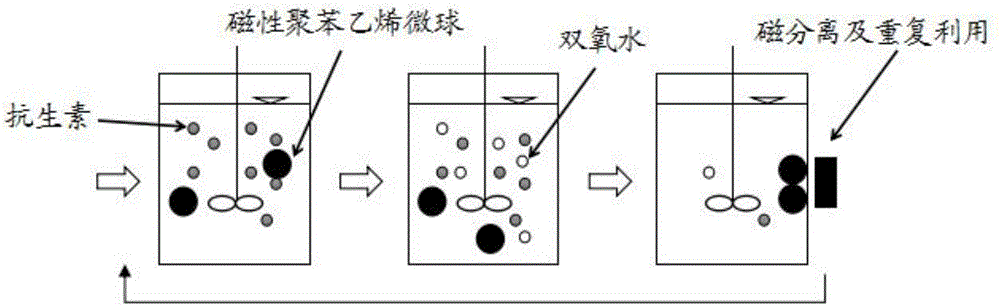

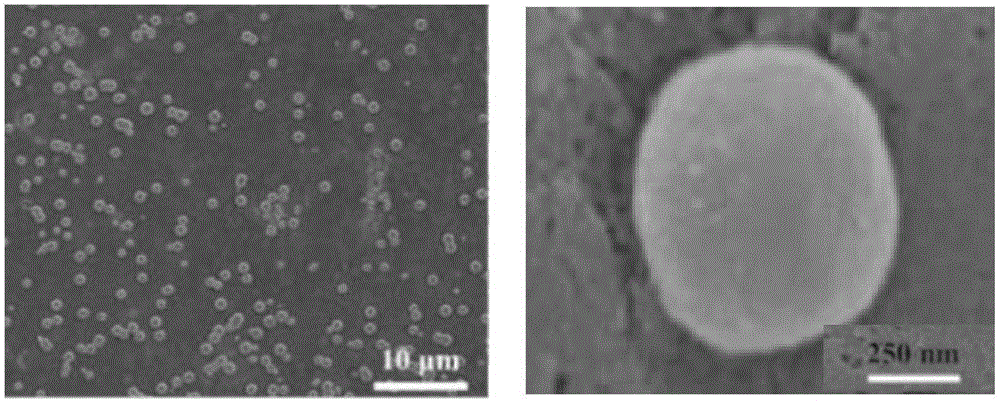

Magnetic micro-sphere, method for preparing same and application of magnetic micro-sphere to treating antibiotic wastewater

InactiveCN106475071AEasy to operateLow costOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsIonChemistry

The invention provides a method for preparing a magnetic micro-sphere. The method includes modifying a chloromethyl polystyrene micro-sphere by the aid of ethylenediamine and chloroacetate to obtain a modified polystyrene micro-sphere; mixing ammonium ferrie oxalate, surfactants, ion buffering agents and alcohol organic solvents with one another to obtain ammonium ferrie oxalate solution; mixing the modified polystyrene micro-sphere and the ammonium ferrie oxalate solution with each other to obtain a mixture and carrying out pre-reaction on the mixture under an oxygen isolation condition; carrying out solvothermal reaction on a pre-reaction product to obtain the magnetic micro-sphere. The method for preparing the magnetic micro-sphere has the advantages that the method is easy to implement and low in cost, antibiotic wastewater can be effectively treated by the magnetic micro-sphere prepared by the aid of the method, and the magnetic micro-sphere can be recycled; 90% of tetracycline can be adsorbed and degraded in 2 h under the condition that 2 g of magnetic micro-sphere and an appropriate quantity of hydrogen peroxide are added into each liter of to-be-treated antibiotic wastewater which is 100 mg / L tetracycline aqueous solution.

Owner:TSINGHUA UNIV

Compound flux of high-MgO sinter ore, and preparation method and application of the compound flux

The invention relates to a compound flux of high-MgO sinter ore, and a preparation method and application of the compound flux, belongs to the field of hematite sintering. The compound flux comprises a MgO source and a water-soluble additive, wherein the water-soluble additive is a combination of one or more than one of boric anhydride, calcium chloride, ferric oxalate, iron nitrate and ammonium ferrie oxalate. The preparation method comprises the following steps: first, dissolving the water-soluble additive in water; then, pouring the MgO source material to realize that the additive is uniformly adhered on the surfaces of the MgO source particles; putting into a drying oven below the temperature of 95 DEG C for drying, thereby obtaining the compound flux of the high-MgO sinter ore. During sintering, the compound flux, the hematite and the lime flux are mixed together to serve as the MgO flux, so that the MgO content in the sinter ore can be increased to 4 percent. Meanwhile, the additive has a low melting point, the sintering mineralization rate is improved, and as a result, reasonable mineral composition and phase structure can be obtained, the sinter ore strength and high-temperature metallurgical property can be improved, also, the finished product ratio and drum rotating index are obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

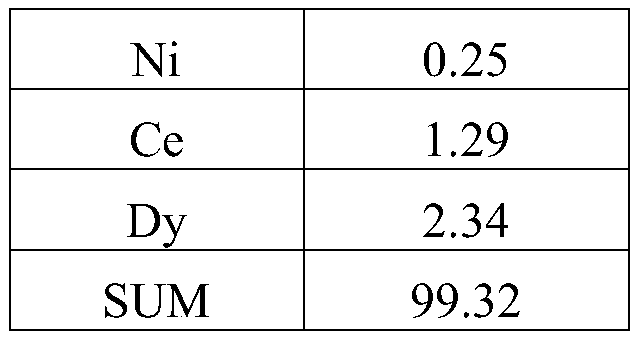

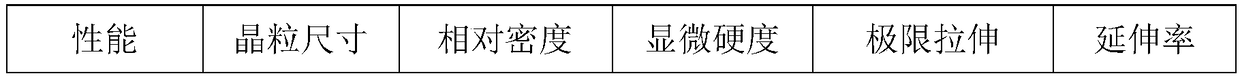

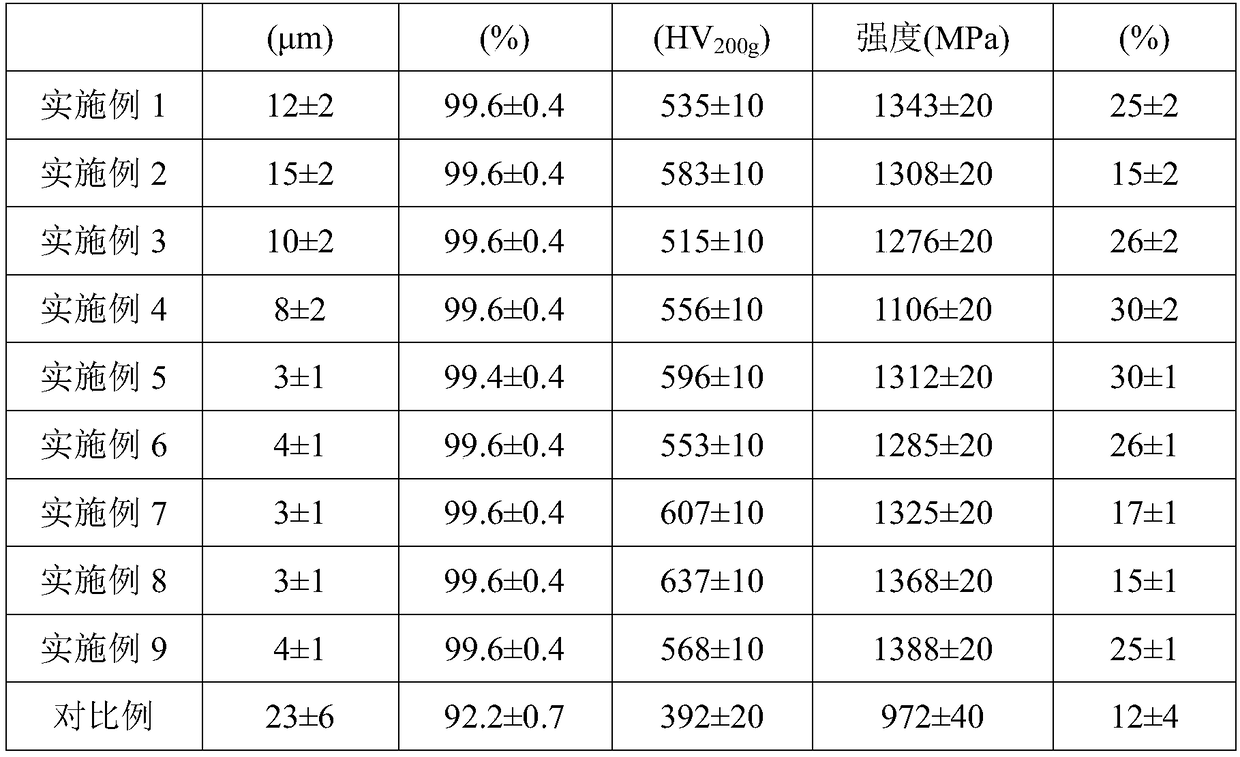

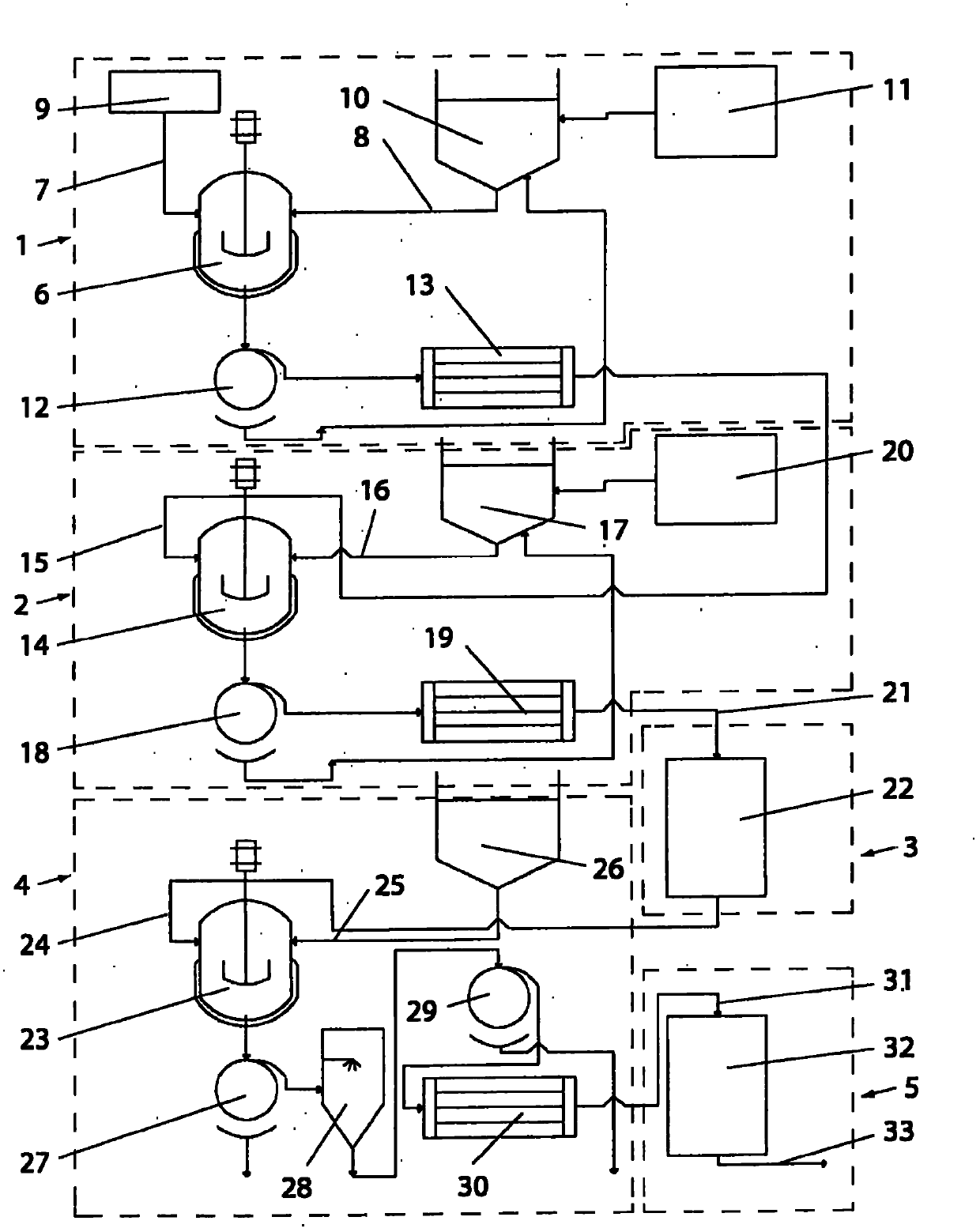

Preparation method of tungsten alloy precursor compound powder, tungsten alloy and preparation method of tungsten alloy

The invention relates to a preparation method of tungsten alloy precursor compound powder, a tungsten alloy and a preparation method of the tungsten alloy, and belongs to the technical field of high-temperature structural materials. The preparation method of the tungsten alloy precursor compound powder comprises the following steps that a mixed dispersion solution of ammonium paratungstate, soluble ferric salt, soluble nickel salt and soluble aluminum salt is provided; the pH of the mixed dispersion solution is adjusted to be not higher than 1.5 by the aid of oxalic acid, after complete reaction, mixed powder is obtained through removal of a solvent, and then the tungsten alloy precursor compound powder is obtained. According to the preparation method of the tungsten alloy precursor compound powder, the pH of the mixed dispersion solution is adjusted by the aid of the oxalic acid, newly-produced tungstic acid, ferric oxalate, nickel oxalate and aluminum oxalate are subjected to commonreaction and co-precipitation, thus the uniformity and the consistency of various components of the mixed powder are improved, refined crystalline strengthening and dispersion strengthening of the tungsten alloy can be realized by the aid of the obtained compound powder, the toughness of the tungsten alloy can be improved while the strength of the tungsten alloy is substantially improved, and thenano ceramic particle dispersion reinforced high-strength and high-toughness tungsten alloy can be prepared from the compound powder.

Owner:HENAN UNIV OF SCI & TECH

Feed for poultry

InactiveCN105341453AAvoid cakingPrevent mildewAnimal feeding stuffAccessory food factorsFerric oxalatePolyethylene glycol

The invention provides a feed for poultry. The feed comprises the following components in parts by weight: 50-90 parts of corn flour, 15-35 parts of bran, 10-20 parts of soybean meal, 0.2-2 parts of ferric oxalate, 0.1-0.5 part of zinc oxalate, 0.1-0.8 part of nanometer copper oxide, 0.02-0.06 part of nanometer cobalt oxide, 0.01-0.06 part of magnesium chloride, 0.02-0.05 part of potassium iodide, 0.01-0.1 part of maltooligosaccharides, 0.05-0.2 part of isomaltooligosacharides, 0.05-0.5 part of cyclodextrin glucose, 0.01-0.5 part of polyethylene glycol fatty acid ester, 0.2-2 parts of triglyceride, 0.1-0.3 part of propylene glycol fatty acid ester, 3-5 parts of haw powder, 2-8 parts of carrot powder and 2-6 parts of attapulgite. The feed has the characteristics of being wide in application range, comprehensive in nutrition, good in absorbability, difficult to agglomerate, difficult to mildew and rot and the like.

Owner:李勇男

Method and apparatus for sorbent production, primarily for removing arsenic from drinking water

InactiveCN102006928ACheap and economical to produceReduce arsenic levelsOther chemical processesWater/sewage treatment by sorptionOXALIC ACID DIHYDRATEFerric oxalate

The object of the invention is method and apparatus for sorbent production. The method comprises the steps of saturating a moisture-absorbent, wettable organic support material with the aqueous solution of a water-soluble ferric salt, then filtering it and drying it to constant weight; saturating the support material with a stoichiometric quantity (computed relative to the iron content of the support material) of oxalic acid and / or water-soluble salt of oxalic acid, then filtering it and drying it to constant weight, while converting the iron ions to insoluble ferric oxalate; converting the saturated support material to activated carbon by anaerobic heating, then subjecting said saturated support material to anaerobic cooling, while the ferric oxalate is decomposed into iron and carbon dioxide; preoxidizing iron particles of the activated carbon by a water-soluble peroxide compound, filtering the activated carbon, and rinsing it to completely remove salt therefrom, then filtering it again and drying it; converting the iron hydroxide formed on the surface of the iron particles into magnetite by anaerobic heating of the activated carbon, and subsequently cooling in an anaerobic manner the thus produced sorbent to room temperature.

Owner:HM ELEKTRONIKAI LOGISZTIKAI & VAGYONKEZELO ZRT

Preparation method for lithium iron phosphate

ActiveCN102009971AAvoid malformed growthControl spherificationPhosphorus compoundsFerric oxalateLithium hydroxide

The invention discloses a preparation method for lithium iron phosphate. The method comprises the following steps: mixing high-purity phosphoric acid, lithium hydroxide and ferric oxalate; regulating the pH value to 5.0-6.0; drying the mixture at the temperature of 60-80 DEG C; heating the dried mixture to 300-400 DEG C at a rate of 5 DEG C / h in a reacting furnace; carrying out insulation reaction for 3 hours, and then cooling to room temperature; smashing the obtained mixture; evenly mixing the smashed mixture with lithium hydroxide, a carbon source and metallic oxides by a ball mill, and utilizing a colloid mill to pulp the blend at the temperature of 16-20 DEG C for 6-10 hours; and drying at the temperature of 60-80 DEG C, and sintering at the temperature of 600-800 DEG C for 3-6 hours in the reacting furnace in the presence of inert gas, thus preparing the lithium iron phosphate product. The preparation method is smart in concept and simple in process; and by means of the method, the stacking density and electrical conductivity of the lithium iron phosphate can be effectively improved.

Owner:李全东 +2

Superfine iron-copper alloy powder and preparation method thereof

Owner:惠州市新宏泰科技有限公司

Nano lithium iron silicate/graphene anode material for lithium battery and preparation method thereof

ActiveCN108123120ALowered intercalation barrierImprove the de-intercalation rateMaterial nanotechnologyCell electrodesFerric oxalateNickel–lithium battery

The invention provides a nano lithium iron silicate / graphene anode material for a lithium battery and a preparation method thereof. The preparation method comprises the following steps: mixing graphene oxide, ferric oxalate, lithium silicate and ammonia water; adding a dispersant for wet process ball-milling; and then carrying out thermal treatment to obtain nitrogen-doped lithium iron silicate / graphene. By performing replaced doping on graphene and lithium iron silicate through nitrogen atoms to replace carbon atoms in graphene and oxygen atoms in lithium iron silicate, the de-embedding potential barrier of lithium ions is reduced, and meanwhile, nitrogen atoms are introduced to form N-suspended keys in graphene, and the suspended keys after deep de-embedding of lithium ions and anions form weak covalent bond joint, so that the structural integrity of the anode material is kept. The method provided by the invention solves the problems that lithium ions of a conventional lithium iron silicate material are incompletely de-embedded, the capacity is low and the structure of the material after deep de-embedding collapses, the migration rate of lithium ions in the anode material is increased, and the discharge rate and the cycling stability of the battery are improved.

Owner:东营市广利临港产业园有限公司 +1

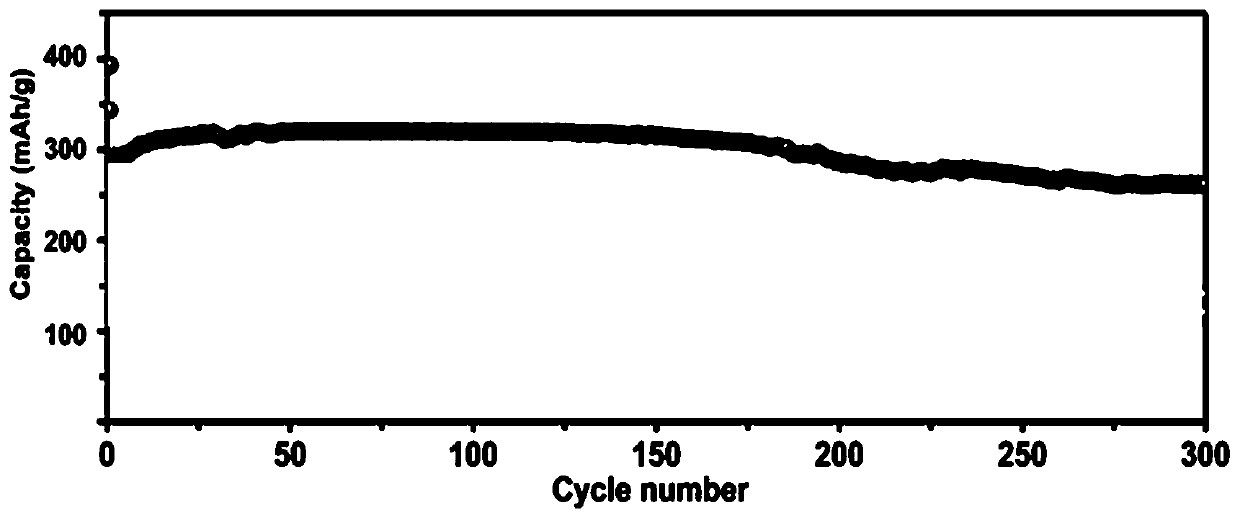

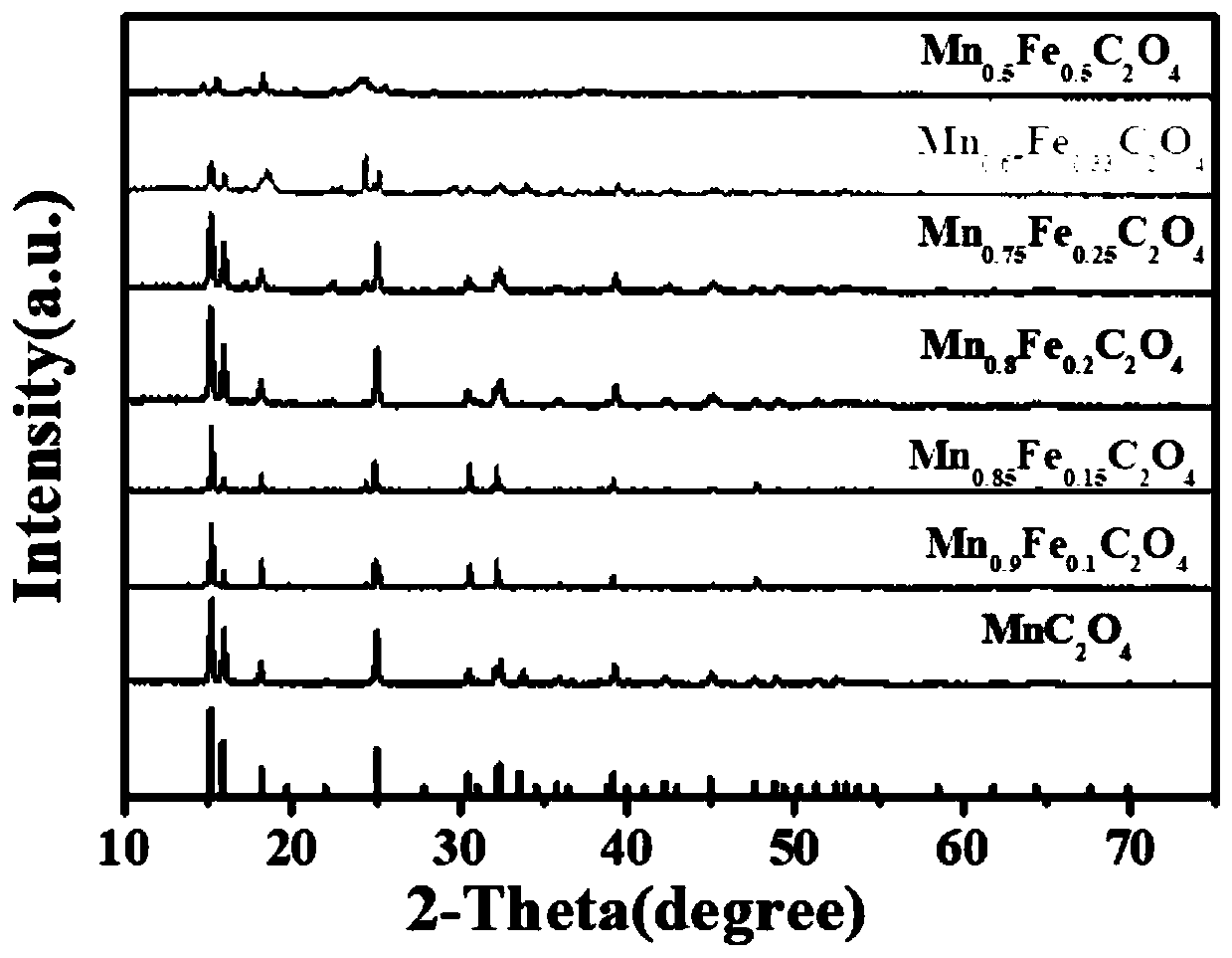

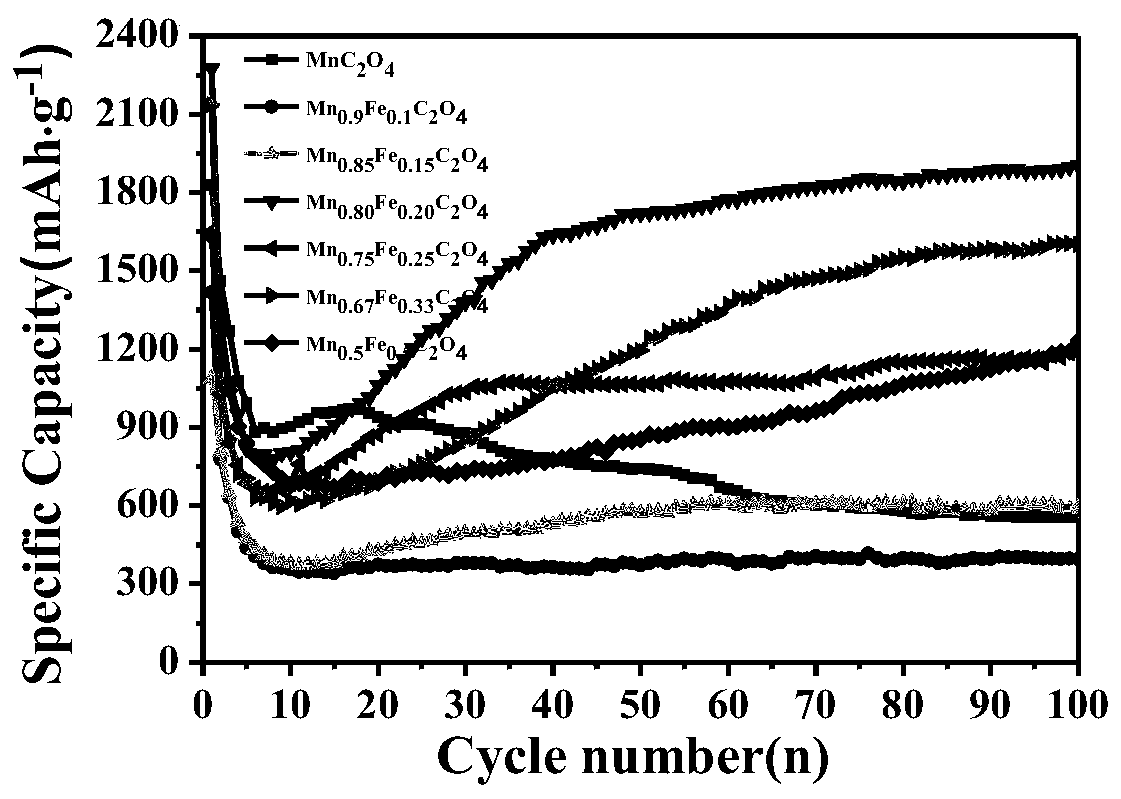

Synthesis method and application of lithium ion battery negative electrode active material Mn<x>Fe<1-x>C2O4

InactiveCN110729481AIncrease capacityThe synthesis method is simpleSecondary cellsNegative electrodesFerric oxalateManganese

The invention discloses a lithium ion battery negative electrode active material Mn<x>Fe<1-x>C2O4 and a synthesis method and application thereof. Manganese oxalate with a rod-like structure is prepared by adopting a hydrothermal or solvothermal method. In addition, a proper proportion of ferrite is doped, and a series of manganese ferric oxalate Mn<x>Fe<1-x>C2O4 materials which are modified from manganese oxalate and have different morphologies are obtained by adopting the same method. Tests in the application of the Mn<x>Fe<1-x>C2O4 materials in lithium ion batteries show that the reversiblespecific capacity is obviously improved and the cyclic stability is also significantly improved when the Mn<x>Fe<1-x>C2O4 material synthesized in the invention is used as a negative electrode active material, compared with pure-phase manganese oxalate. For example, Mn0. 8Fe0.2C2O4 prepared through doping can remarkably improve the capacity of lithium ion batteries, and shows most excellent cycle performance and rate capability. Therefore, the Mn<x>Fe<1-x>C2O4 is a potential lithium ion negative electrode material.

Owner:HUBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com