Oxalic acid infusion process for removing film iron on silica sand surface

A leaching method, oxalic acid technology, applied in the direction of silicon oxide, etc., can solve the problems of high power consumption, dangerous operation process, unsatisfactory mechanical scrubbing effect, etc., and achieve the effect of excellent iron removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

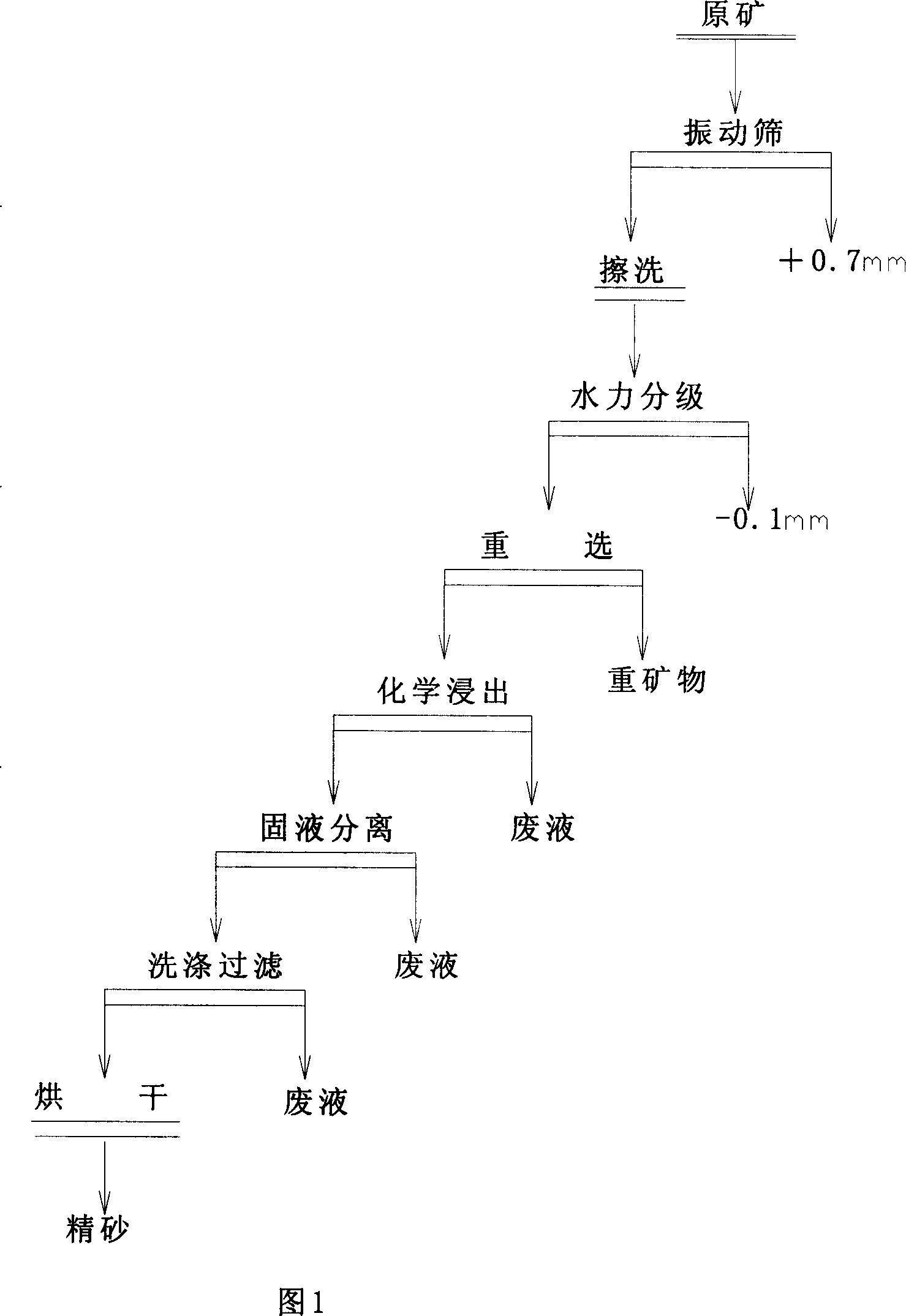

[0019] An oxalic acid leaching method for removing iron from natural silica sand to produce high-quality silica sand for float glass. The process flow is shown in Figure 1.

[0020] Source of raw material: Dalin quartz sand in Horqin area of Inner Mongolia is used as raw material, maximum particle size: 1.0mm, iron content (Fe 2 o 3 )0.34%, the process steps are as follows:

[0021] 1. Screening: Since the float glass requires the particle size range of raw materials to be 0.7-0.1mm, it is screened first, and the sieve hole size is 0.7mm;

[0022] 2. Mechanical scrubbing: Use a conventional impeller scrubbing machine to mechanically scrub the mixture of sand and water. The purpose is to dissociate impurities such as clay adhering to the surface of the silica sand from the surface of the silica sand. The scrubbing time is 10 minutes, and the weight concentration of the pulp is 50%;

[0023] 3. Desliming: Use a hydraulic classifier to separate the scrubbed clay and particle...

Embodiment 2

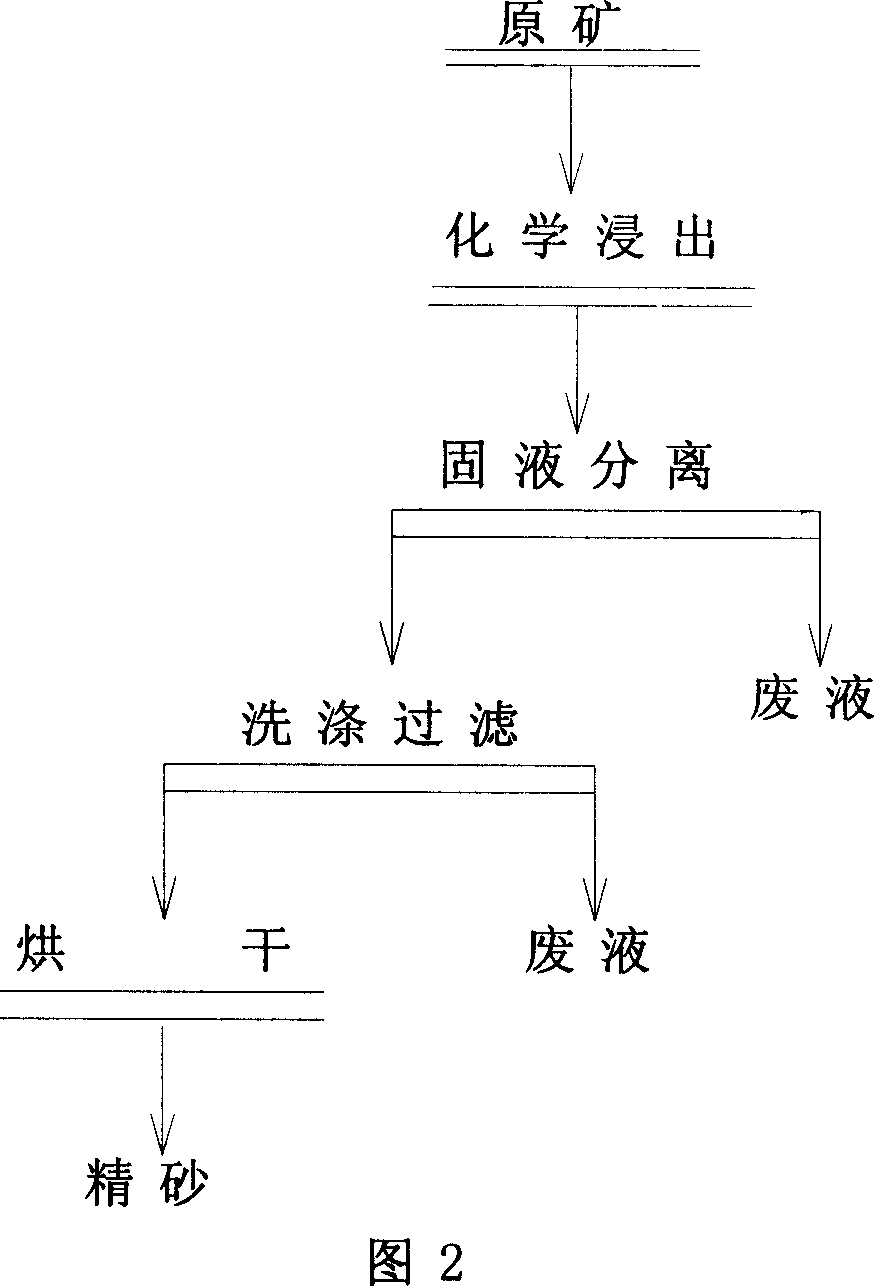

[0030] A method for removing iron by leaching silica sand with oxalic acid on artificial silica sand, using quartz sandstone as raw material, the process flow chart is shown in Figure 2.

[0031] Raw material: Quartz sandstone from Luanxian County, Hebei Province, which has been crushed, screened, magnetically separated, and classified in advance. The particle size range: 0.6-0.1mm. 2 o 3 Total): 0.075%, the process steps are as follows:

[0032] 1. Oxalic acid leaching: place the silica sand in an oxalic acid solution at a temperature of 82°C, the concentration of oxalic acid is 6%, the ratio of the oxalic acid solution to the quartz sand is 100:60, stir properly, and the leaching time is 3 hours;

[0033] 2. Solid-liquid separation: solid-liquid separation of oxalic acid and silica sand;

[0034] 3. Washing and filtering: wash the silica sand several times with clean water;

[0035] 4. Drying: Dry the silica sand until the water content is less than 5%.

[0036] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com