Patents

Literature

43 results about "Aluminum Oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum oxalate is a strong dicarboxylic acid occurring in many plants and vegetables. It is produced in the body by metabolism of glyoxylic acid or ascorbic acid.

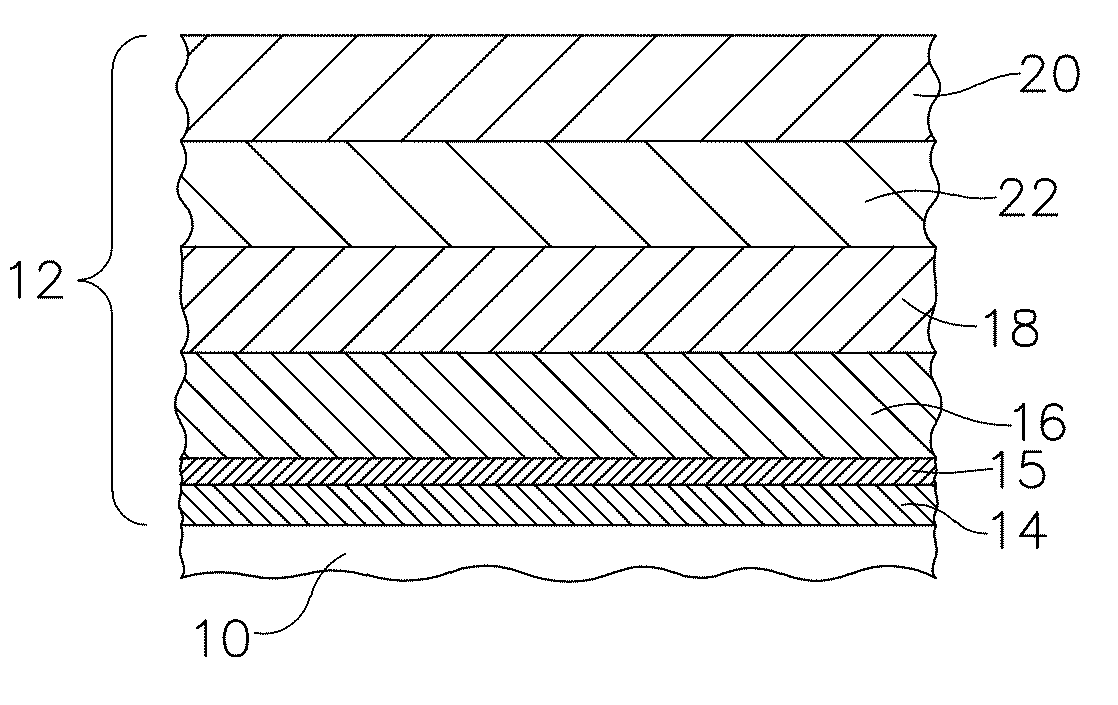

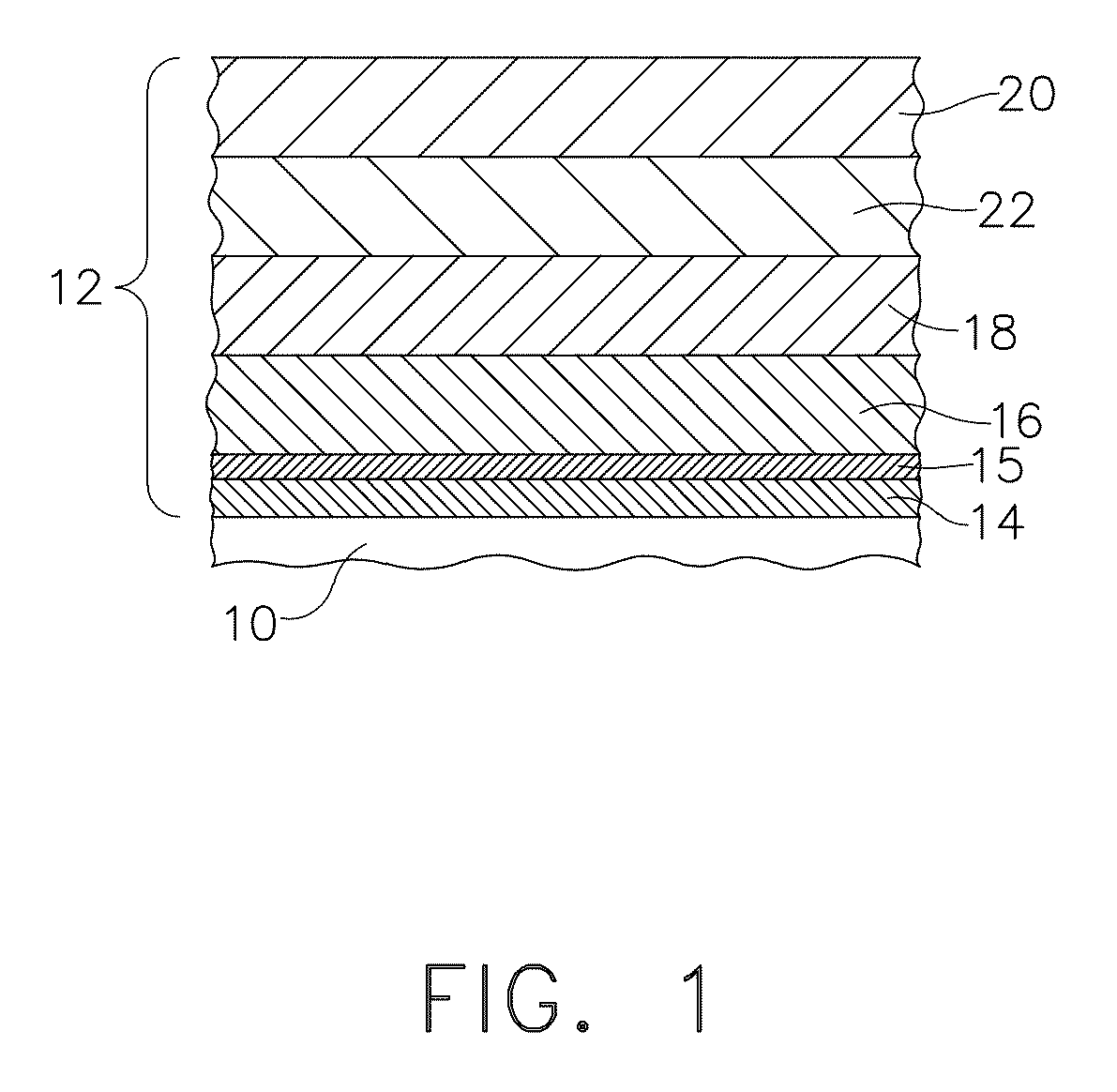

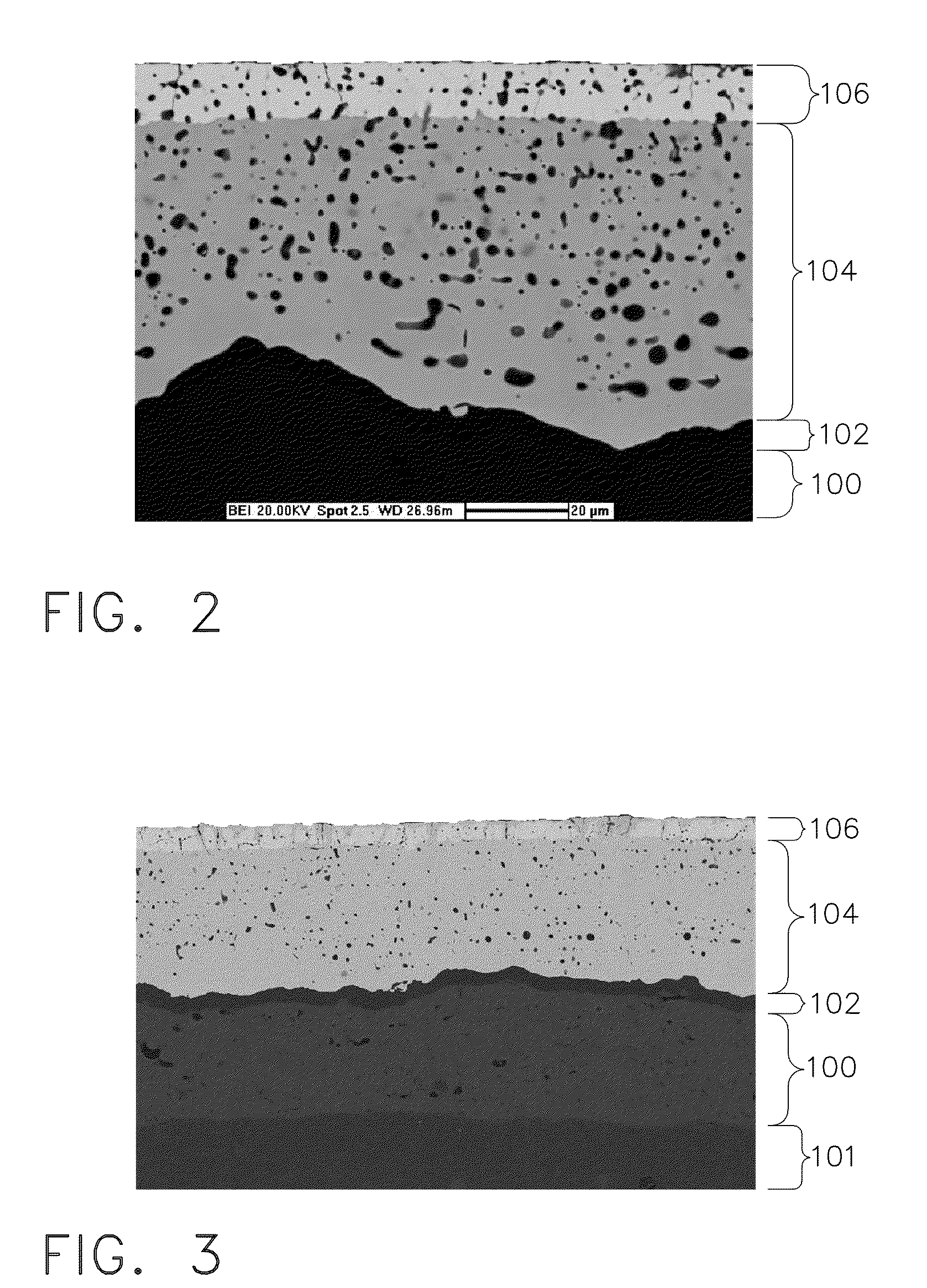

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

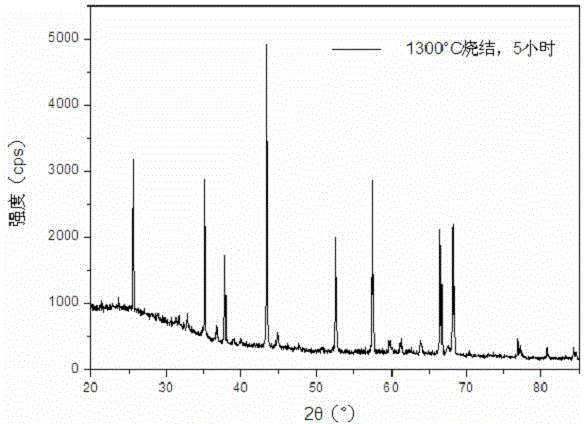

High temperature phase change heat storage material

ActiveCN109609099AHigh heat storage densityImprove thermal conductivityTransportation and packagingMetal-working apparatusSilicon alloyCopper oxide

Belonging to the technical field of ceramic materials, the invention provides a high temperature phase change heat storage material. The high temperature phase change heat storage material is preparedby the steps of: first, mixing quartz sand powder, corundum powder, copper oxide and zinc oxide evenly in proportion, conducting compression moulding, and then performing heat treatment to obtain a sieving material A; second, mixing the sieving material A, carbon black, silicon powder and aluminum oxalate evenly in proportion, and performing heat treatment to obtain an abrasive B; and third, mixing corundum particles, corundum powder, the abrasive B, aluminum-silicon alloy, silicon powder, silicon carbide powder and thermosetting phenolic resin evenly in proportion, conducting compression moulding, and then performing heat treatment to obtain a finished product. The high temperature phase change heat storage material prepared by the method provided by the invention has a working temperature above 600DEG C, and has the characteristics of large heat storage density, high heat conductivity coefficient, high compressive strength, high thermal shock stability, low production cost, simple process and the like.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

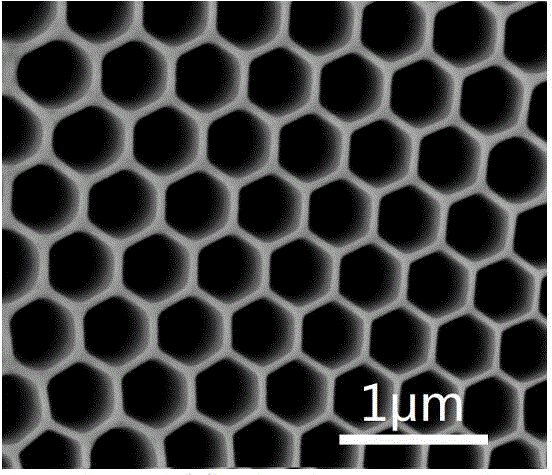

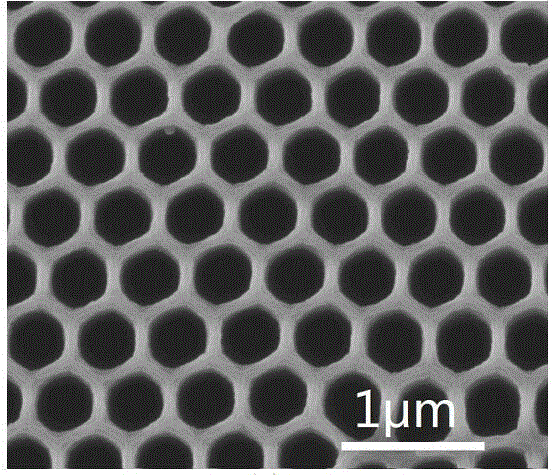

Preparation method of porous alpha-alumina membrane

A preparation method of a porous alpha-alumina membrane comprises the following steps: carrying out an annealing and electric polishing pretreatment on a high purity aluminum foil; taking the processed aluminum foil as the positive electrode, and graphite as the negative electrode, then carrying out two-step positive electrode oxidation in a mixed solution of phosphoric acid and aluminum oxalate to obtain an aluminum-base-containing porous anodic alumina membrane; subjecting the obtained aluminum-base-containing porous anodic aluminum membrane to a pore enlarging treatment; then subjecting the pore-enlarged aluminum-base-containing porous anodic alumina membrane to a water boiling treatment or a hydrothermal treatment; then removing the aluminum base from the aluminum-base-containing porous anodic alumina membrane, which has been treated by water boiling or a hydrothermal treatment; using a sodium citrate solution to remove the baffle layer and alumina hydrate on the external layer of the porous alumina membrane from the aluminum-base-free porous anodic alumina membrane so as to form a periodical hexahedral densely-arranged alumina through hole structure finally; and sintering the prepared alumina membrane with a periodical hexahedral densely-arranged alumina through hole structure in a muffle furnace at a high temperature so as to obtain porous alpha-alumina membrane.

Owner:常毅

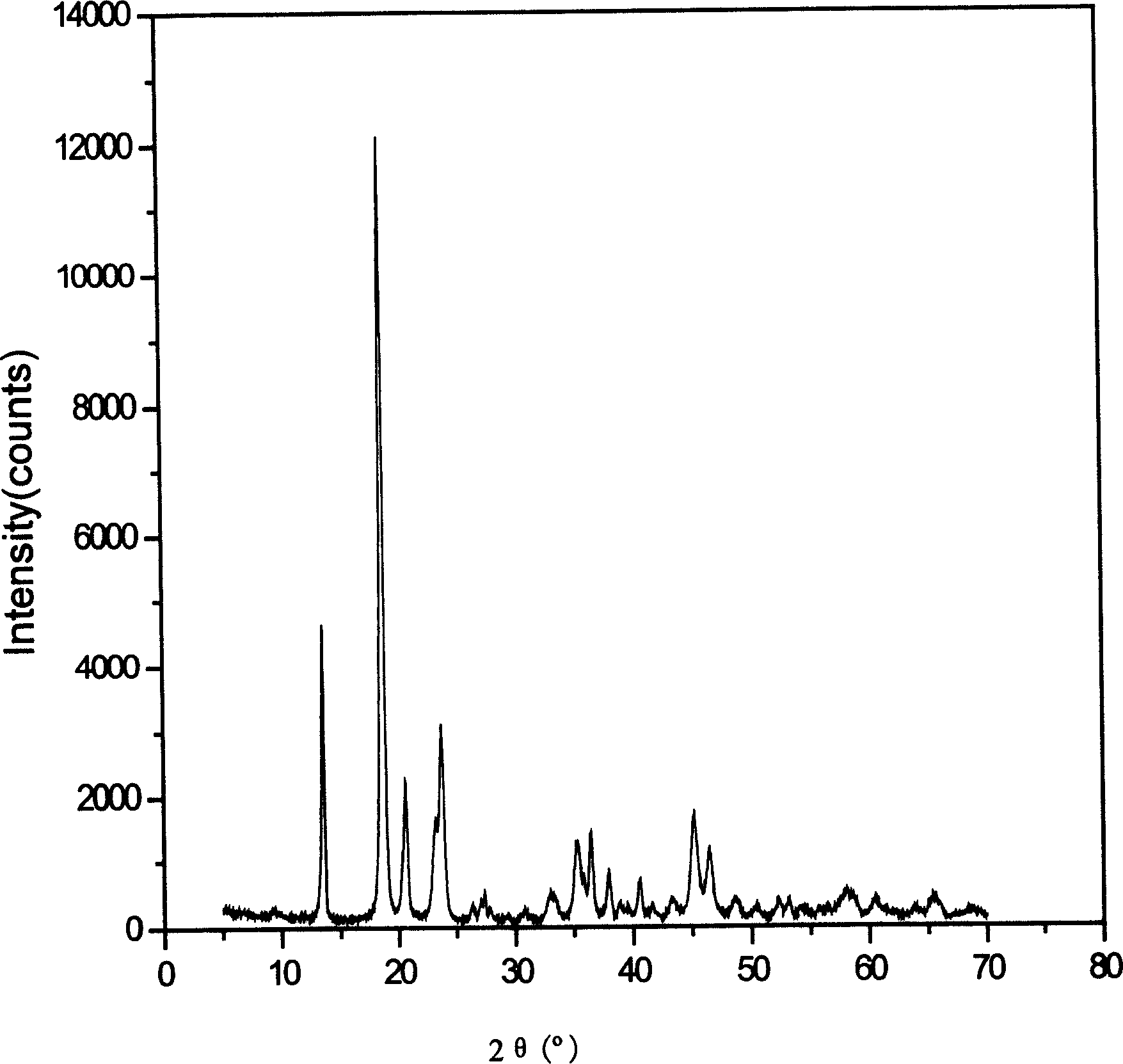

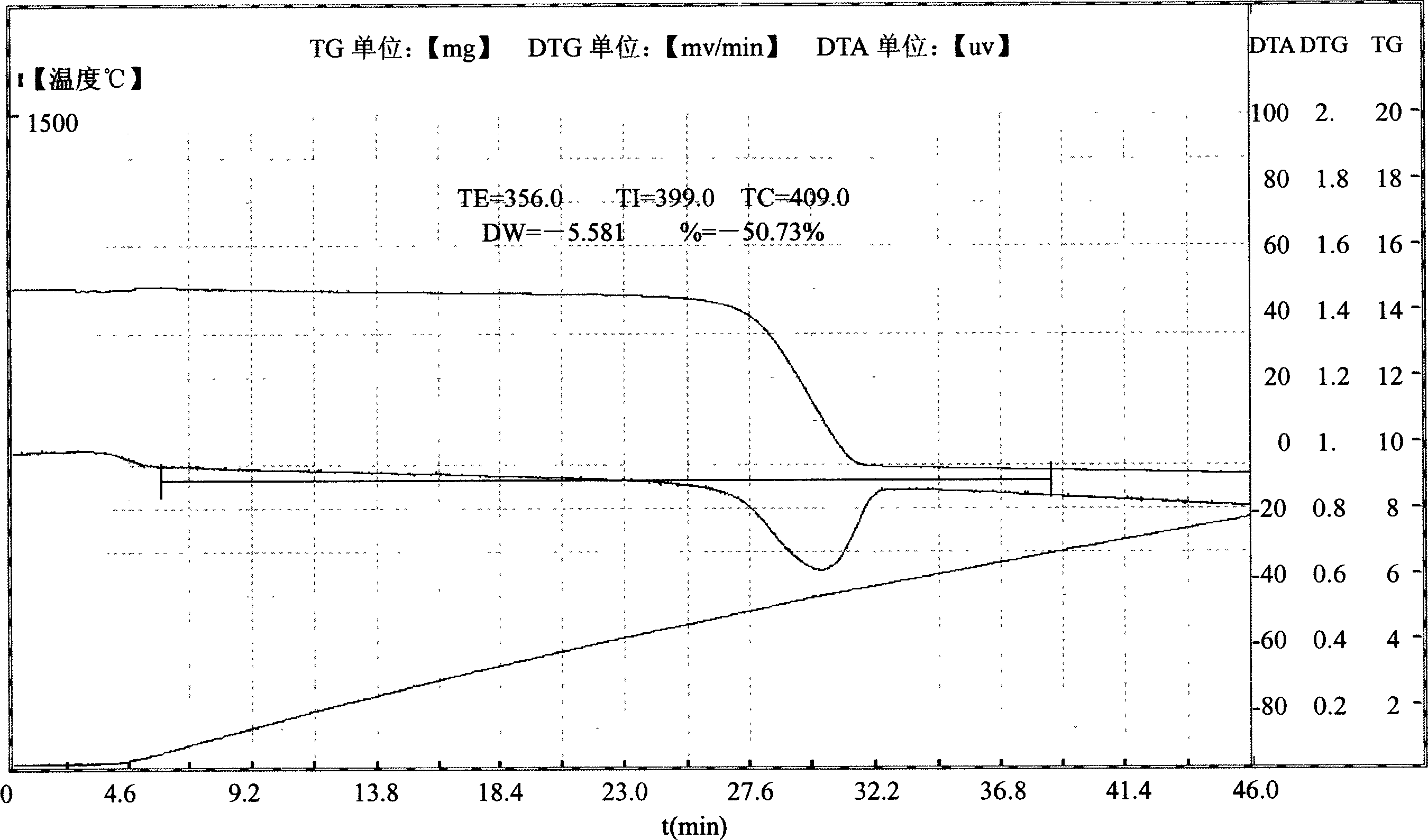

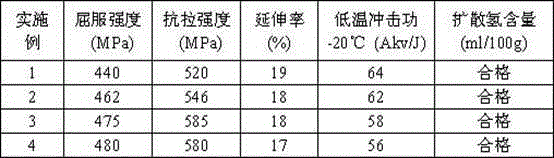

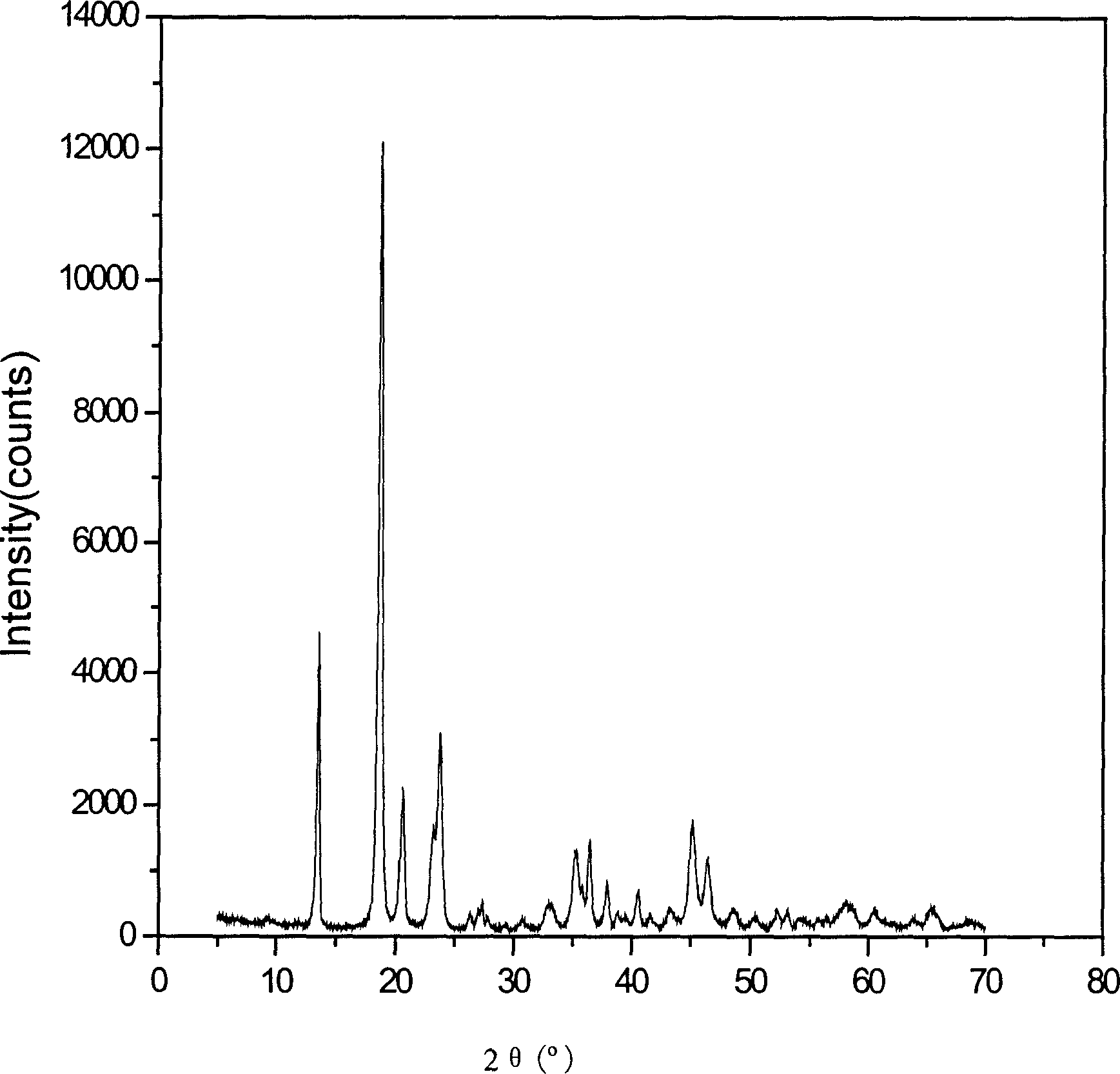

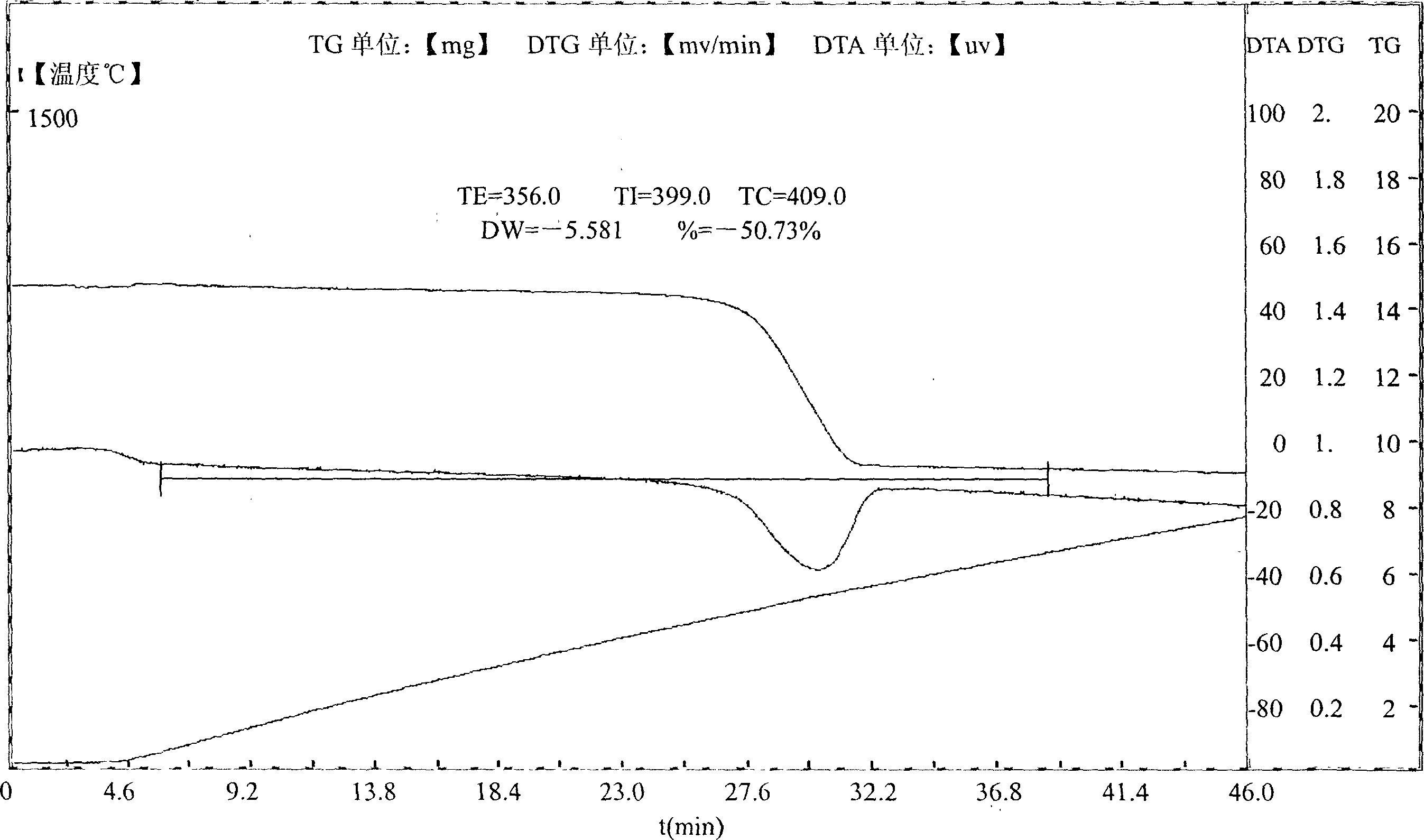

Hydroxy aluminium oxalate, and its preparing method and hydroxy aluminium oxalate as fire retardant

InactiveCN1640865ASimple structureEasy to operateCarboxylic acid salt preparationThermoplasticDecomposition

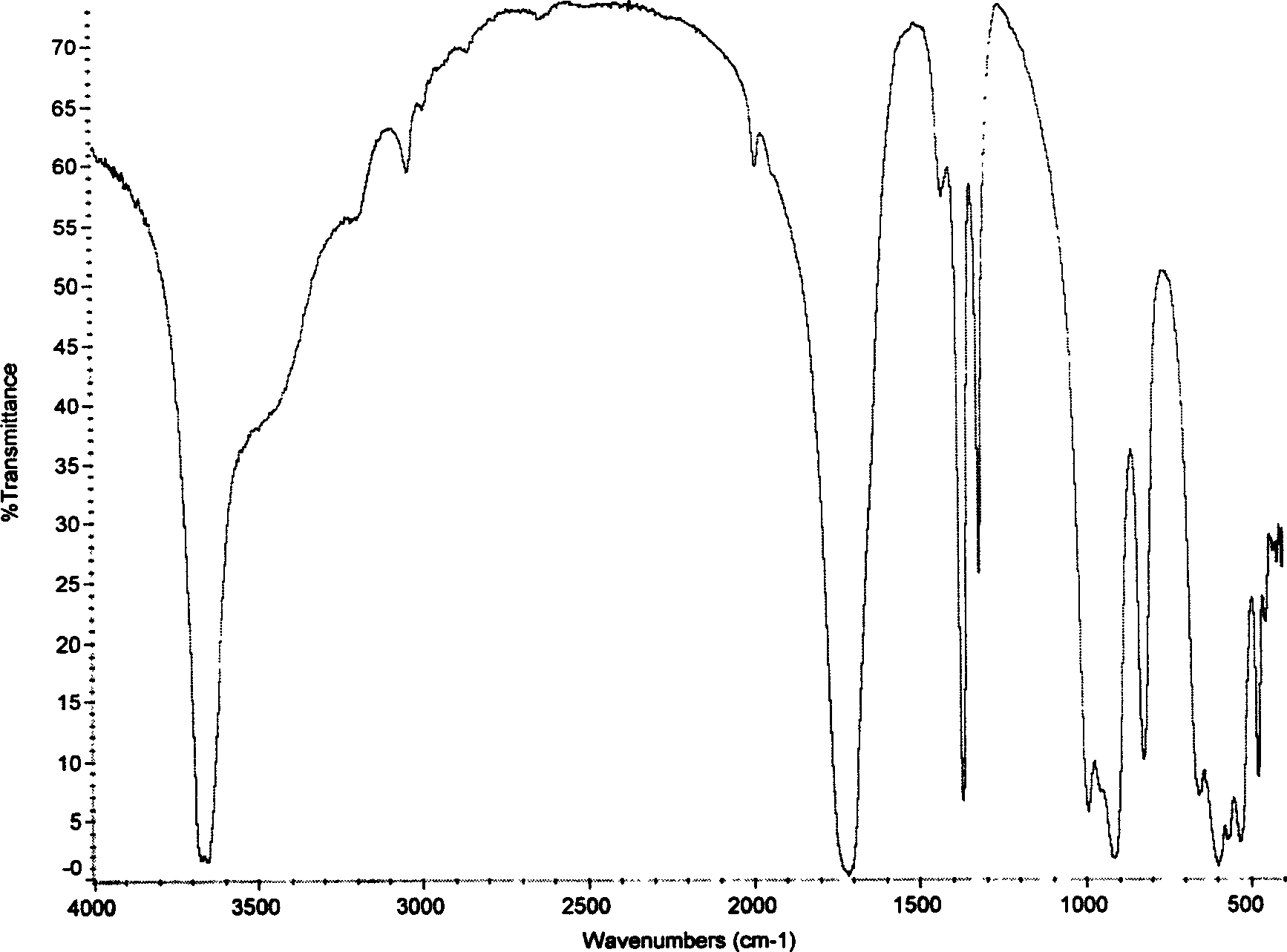

The present invention is the aluminum hydroxyoxalate and its preparation process. Aluminum hydroxyoxalate is used as fire retardant, and has molecular expression of Al2(C2O4)(OH)4, and X-ray diffraction spectrum with strong diffraction peaks at D values one 6.5149, 4.7263 and 4.2957 angstrom. Aluminum hydroxyoxalate is prepared through carbonization and decomposition and modification treatment, and through further crystal form controlling treatment, aluminum hydroxyoxalate with high dispersivity and complete crystal form may be obtained. Aluminum hydroxyoxalate has minimum one-dimensional size controlled in 40 nanometers to several microns, extrapolation onset weight-loss temperature higher than 340 deg.c, and weight-loss rate before 500 deg.c up to 51 %. As one kind of green fire retardant, aluminum hydroxyoxalate may be used in thermoplastic plastic and other polymer material with processing temperature over 210 deg.c.

Owner:BEIJING UNIV OF CHEM TECH

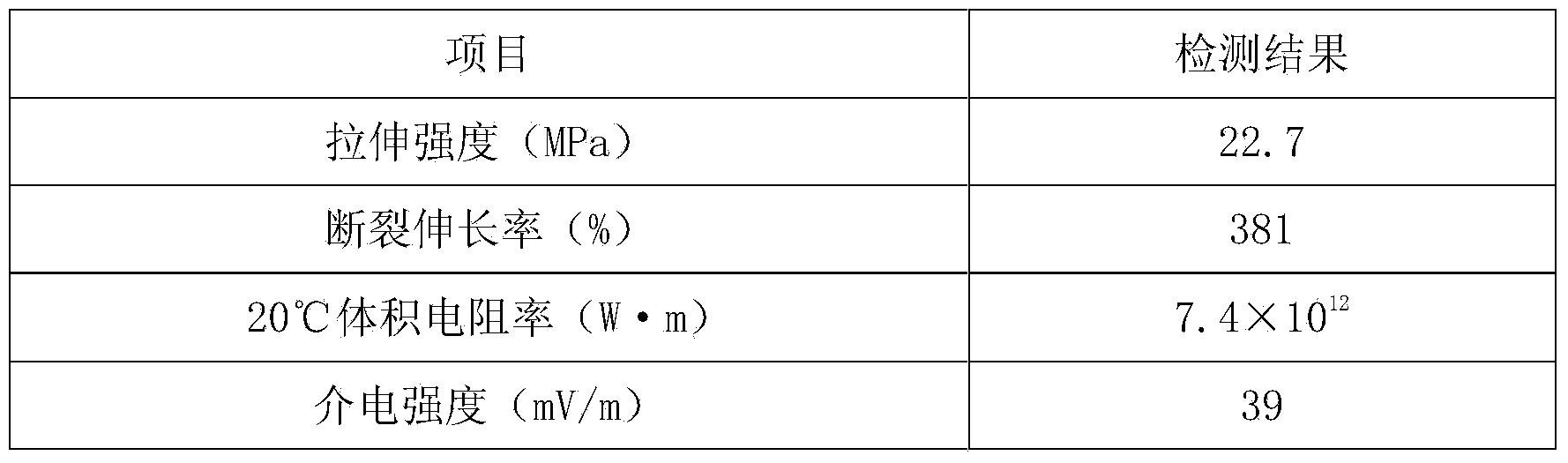

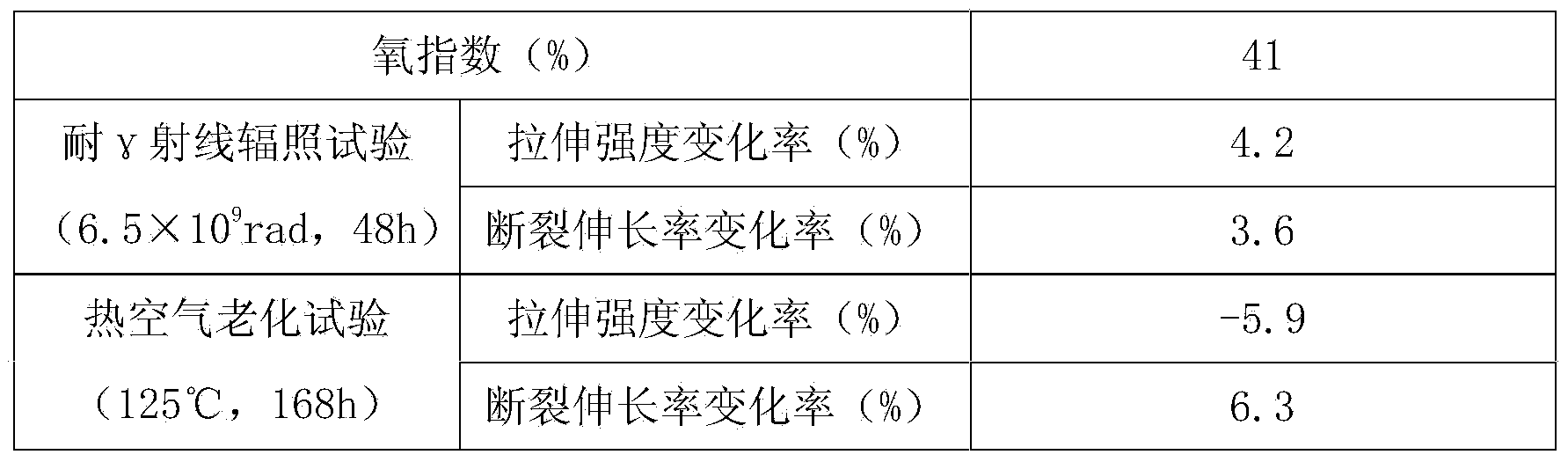

Communication optical fiber cable jacket material for nuclear power station and preparation method of communication optical fiber cable jacket

The invention discloses a communication optical fiber cable jacket material for a nuclear power station and a preparation method of the communication optical fiber cable jacket material. The communication optical fiber cable jacket material is prepared from the following raw materials in parts by weight: 58-74 parts of polyimide, 32-56 parts of poly(ether ether ketone), 18-26 parts of aluminum borate whisker, 12-16 parts of molybdenum disilicide, 10-15 parts of flint clay powder, 10-15 parts of butyl acetyl ricinoleate, 15-25 parts of PPL, 2-3 parts of cyanuric acid lead, 1-2 parts of bismuth neodecanoate, 10-15 parts of diethyl glutarate, 1-2 parts of dodecanethiol dibutyltin, 3-6 parts of ethylene bis stearamide, 4-8 parts of aluminum oxalate, 2-3 parts of butyl hydroxyanisole, 3-6 parts of melamine pyrophosphate, 5-10 parts of trioctyl trimellitate, and 1-2 parts of 2-(2'-hydroxy-3',5'-diamyl phenyl) benzotriazole. The jacket material disclosed by the invention is high in irradiation resistance, can keep the tensile strength and the breaking elongation to be 90% above after gamma ray irradiation which is highly up to 6.5*10<9> rad, and is excellent in heat resistance, fire resistance, oil resistance and corrosion resistance, long in service life and capable of being widely applied to manufacturing of the communication optical fiber cable jacket for the nuclear power station.

Owner:安徽电信器材贸易工业有限责任公司

Method for removing thiophene sulfur in fuel oil

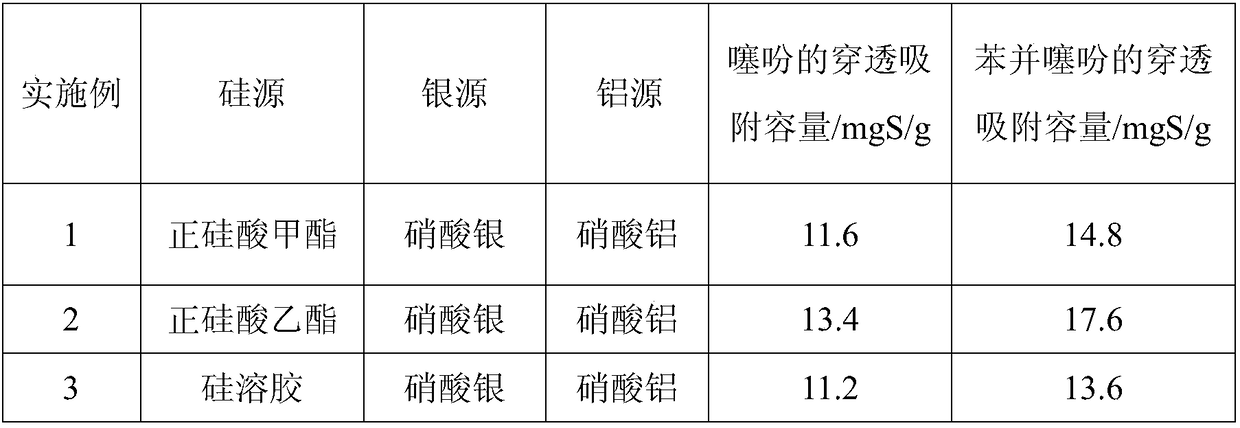

InactiveCN108192656AHigh porosityLarge specific surface areaHydrocarbon oils refiningHydrocarbon oils treatment productsSorbentFixed bed

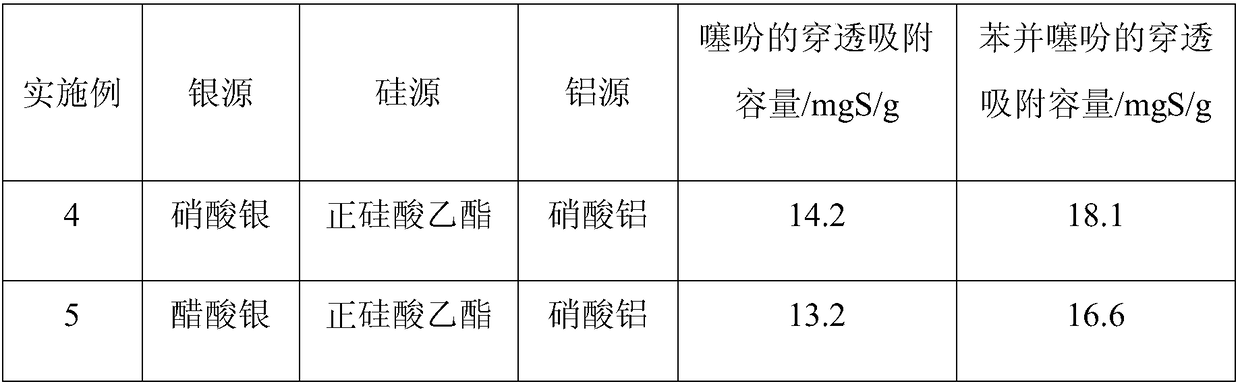

The invention discloses a method for removing thiophene sulfur in fuel oil and belongs to the technical field of fuel oil processing. The method comprises the following steps: using tetramethyl orthosilicate, tetraethyl orthosilicate, silica sol, water glass or the like as a silicon source; using silver acetate, silver nitrate or the like as a silver source; using aluminum nitrate, aluminum acetate or aluminum oxalate as an aluminum source; preparing an Ag2O / SiO2-Al2O3 composite aerogel with a sol-gel-atmospheric pressure drying method; quantitatively filling in a fixed bed adsorption device;injecting a simulated gasoline containing thiophene sulfur at a certain temperature and space velocity; and collecting the adsorbed simulated gasoline at a lower outlet of a reaction device for chromatographic analysis. Results show that the Ag2O / SiO2-Al2O3 composite aerogel has good adsorption performance for thiophene sulfur; an Ag2O / SiO2-Al2O3 composite aerogel adsorbent in the invention is simple in preparation method, low in cost, capable of being repeatedly used, high in economic efficiency, environmentally friendly, mild in adsorption condition and low in requirement on adsorption equipment.

Owner:ZHEJIANG UNIV OF TECH

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

ActiveUS20110217511A1Improve surface roughnessPretreated surfacesRecord information storageIron saltsNickel salt

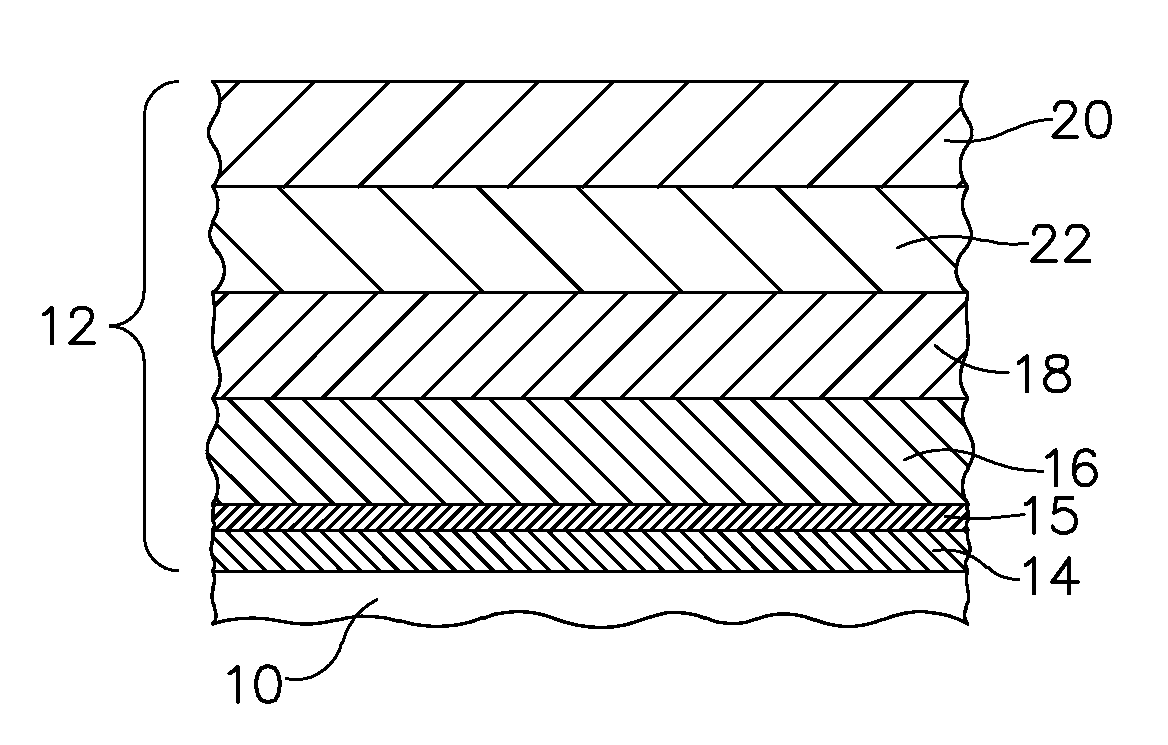

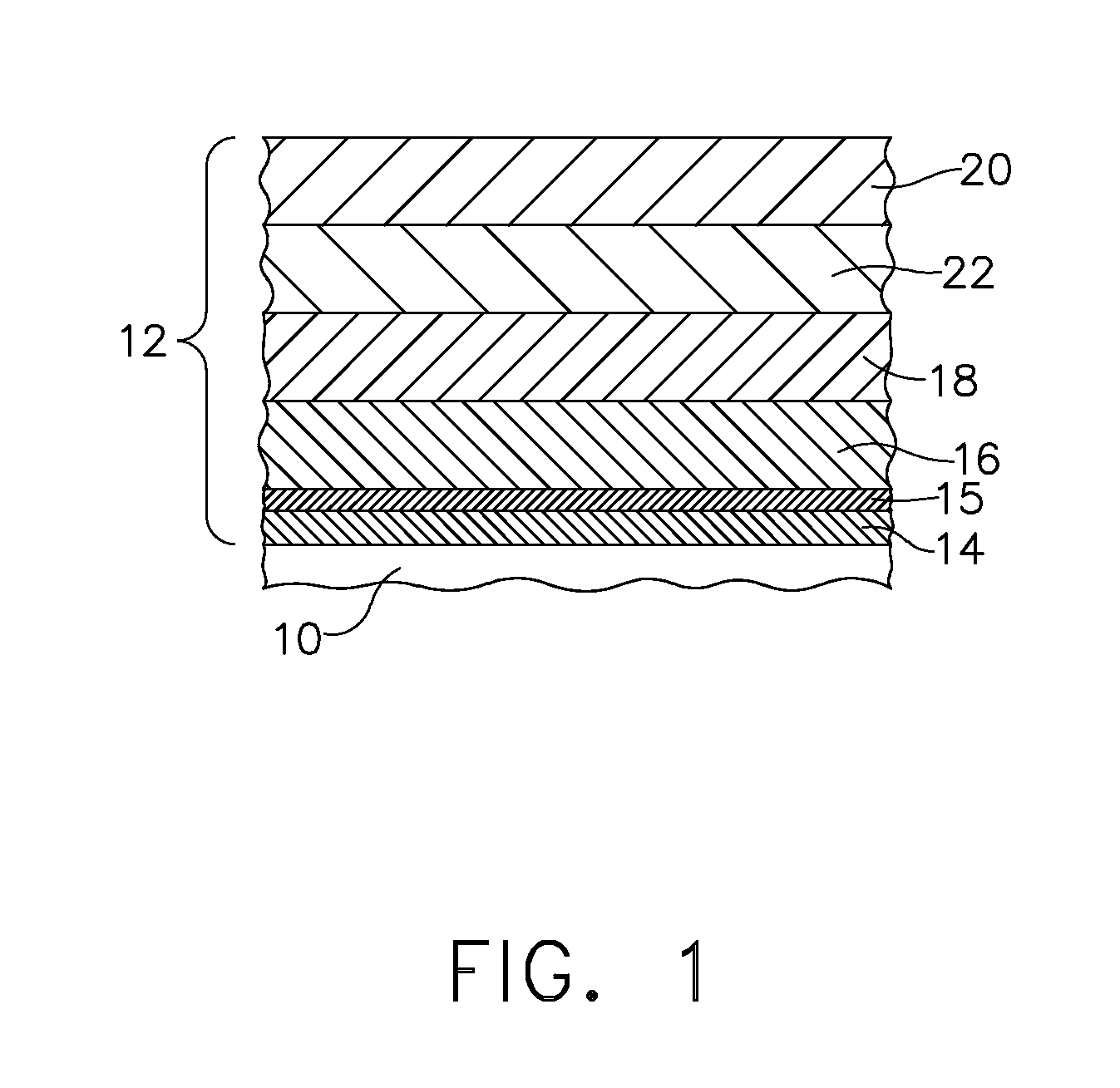

Methods for improving surface roughness of an environmental barrier coating involving providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness wherein the slurry includes water; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, water soluble iron salts, water soluble gallium salts, water soluble aluminum salts, water soluble nickel salts, water titanium salts, water soluble boron salts, and water soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

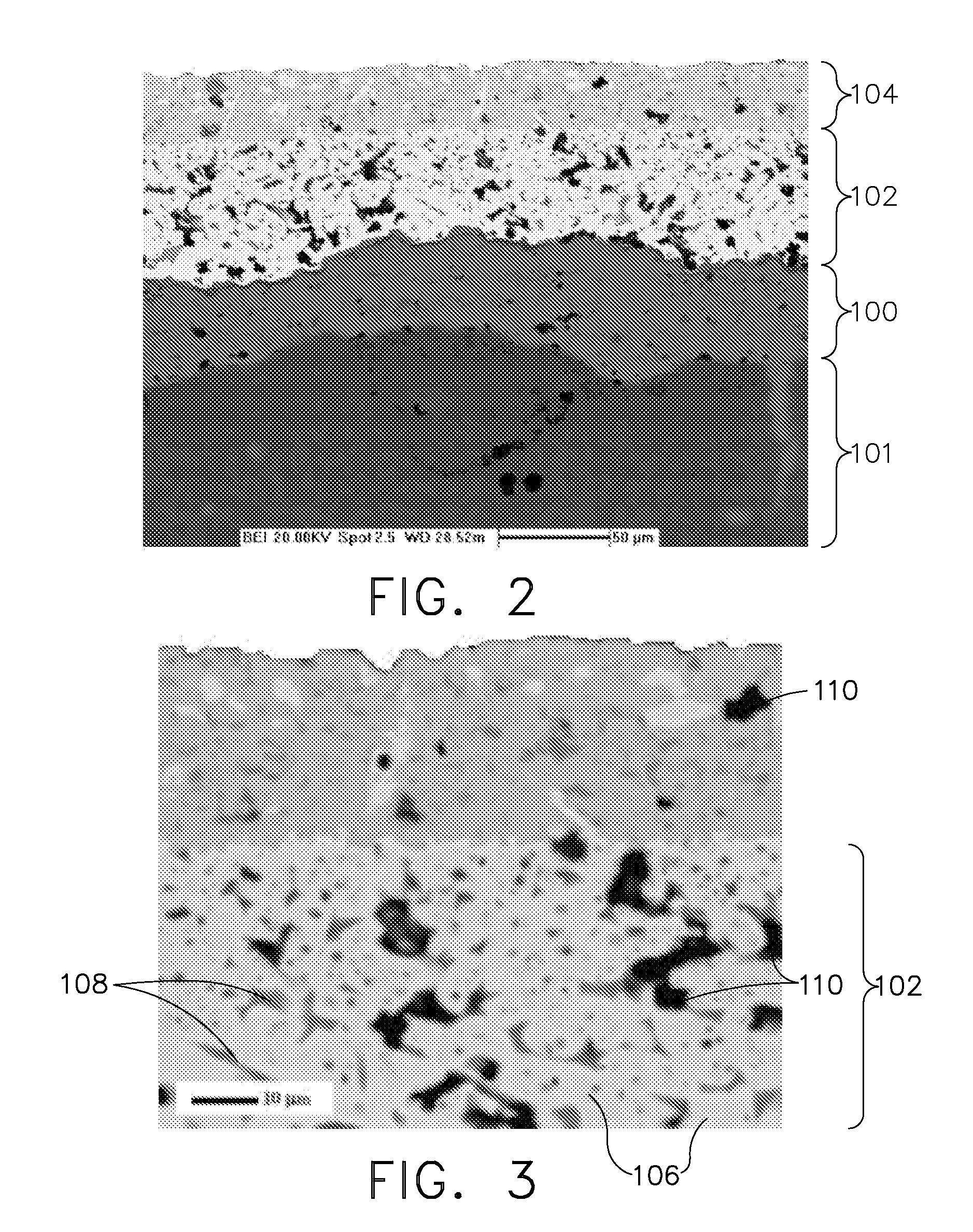

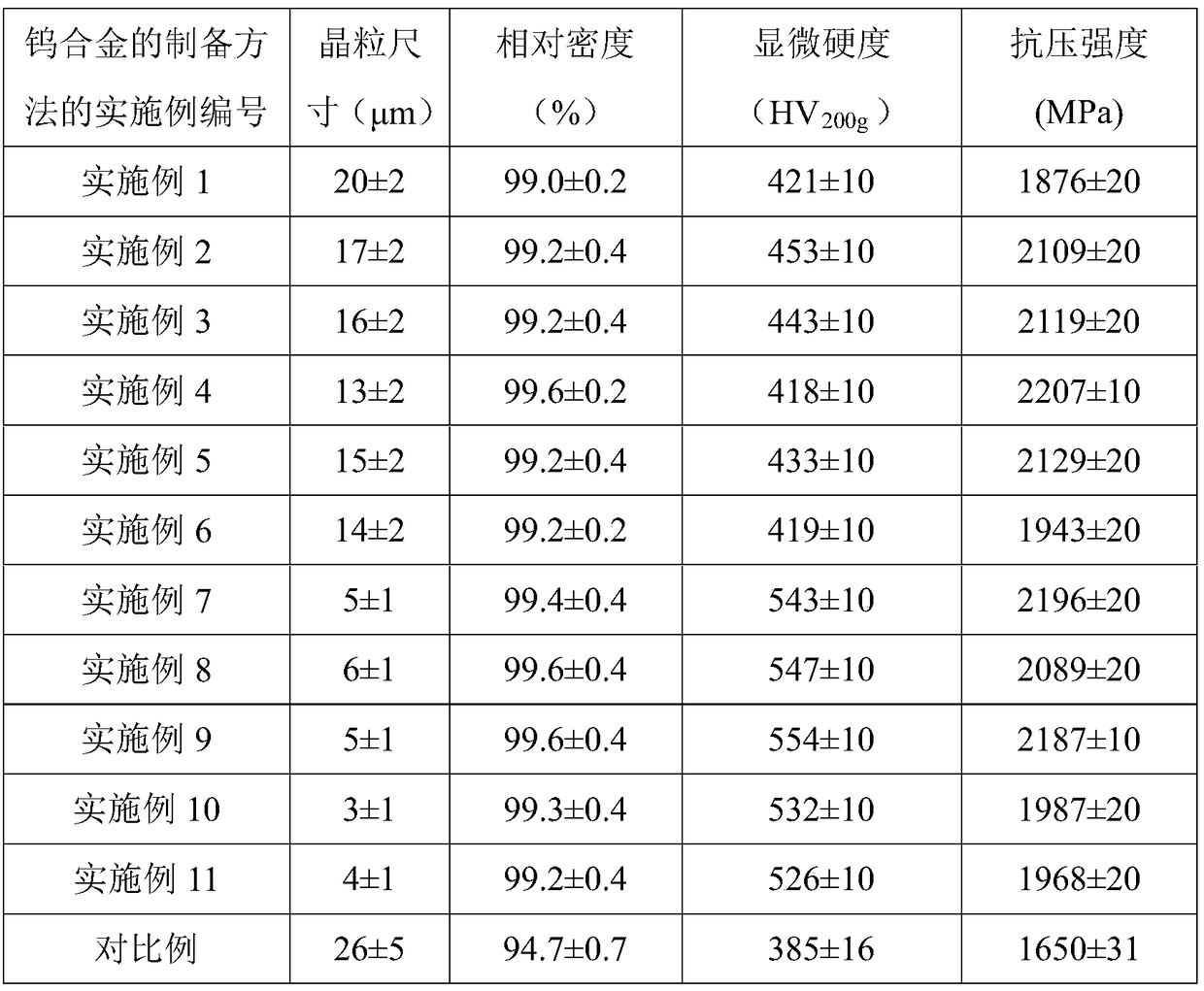

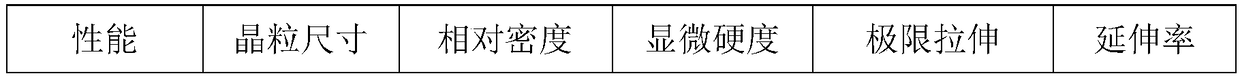

Preparation method of tungsten alloy precursor composite powder, ceramic aluminum oxide enhanced tungsten alloy and preparation method thereof

ActiveCN109182812AImprove wear and erosion resistanceSolve the Coarse Grain of Dispersion Reinforced Tungsten AlloyTungstate ionAluminum Ion

The invention relates to a preparation method of tungsten alloy precursor composite powder, a ceramic aluminum oxide enhanced tungsten alloy and a preparation method of the ceramic aluminum oxide enhanced tungsten alloy, and belongs to the technical field of tungsten alloy. The preparation method of the tungsten alloy precursor composite powder comprises the steps that ammonium metatungstate and amixed solution of soluble aluminum salt are provided, oxalic acid is added into the mixed solution till pH is not larger than 1.5, a complex reaction is carried out, a solvent is removed, and mixed powder is obtained. According to the preparation method, the pH is adjusted through oxalic acid after liquid-liquid mixing, hydrogen ions and tungstate ions in the solution will react to generate tungstate precipitate; oxalate ions and aluminum ions react to generate aluminum oxalate precipitate, serious segregation caused by the mass difference of tungsten atomic nucleuses and aluminum atomic nucleuses can be avoided, the uniformity degree of tungstic acid and aluminum oxalate in the obtained powder is improved, molecular mixing is achieved, and a raw material base is provided for improving high-temperature wear-resisting erosion-resistance performance of tungsten alloy.

Owner:HENAN UNIV OF SCI & TECH

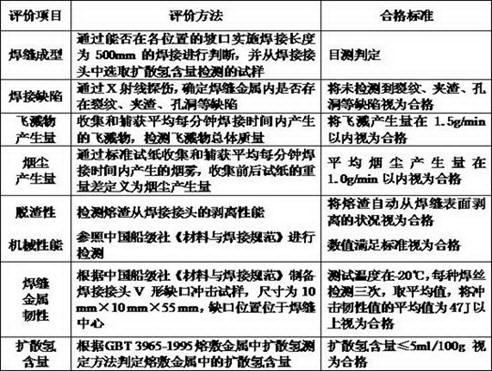

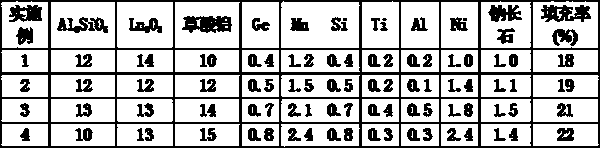

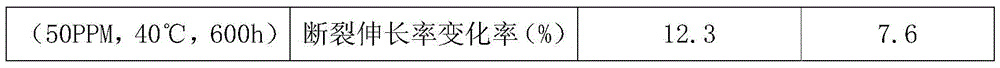

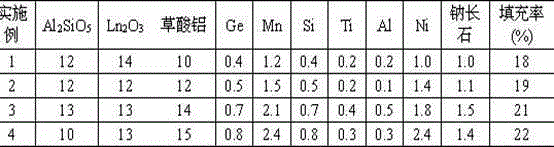

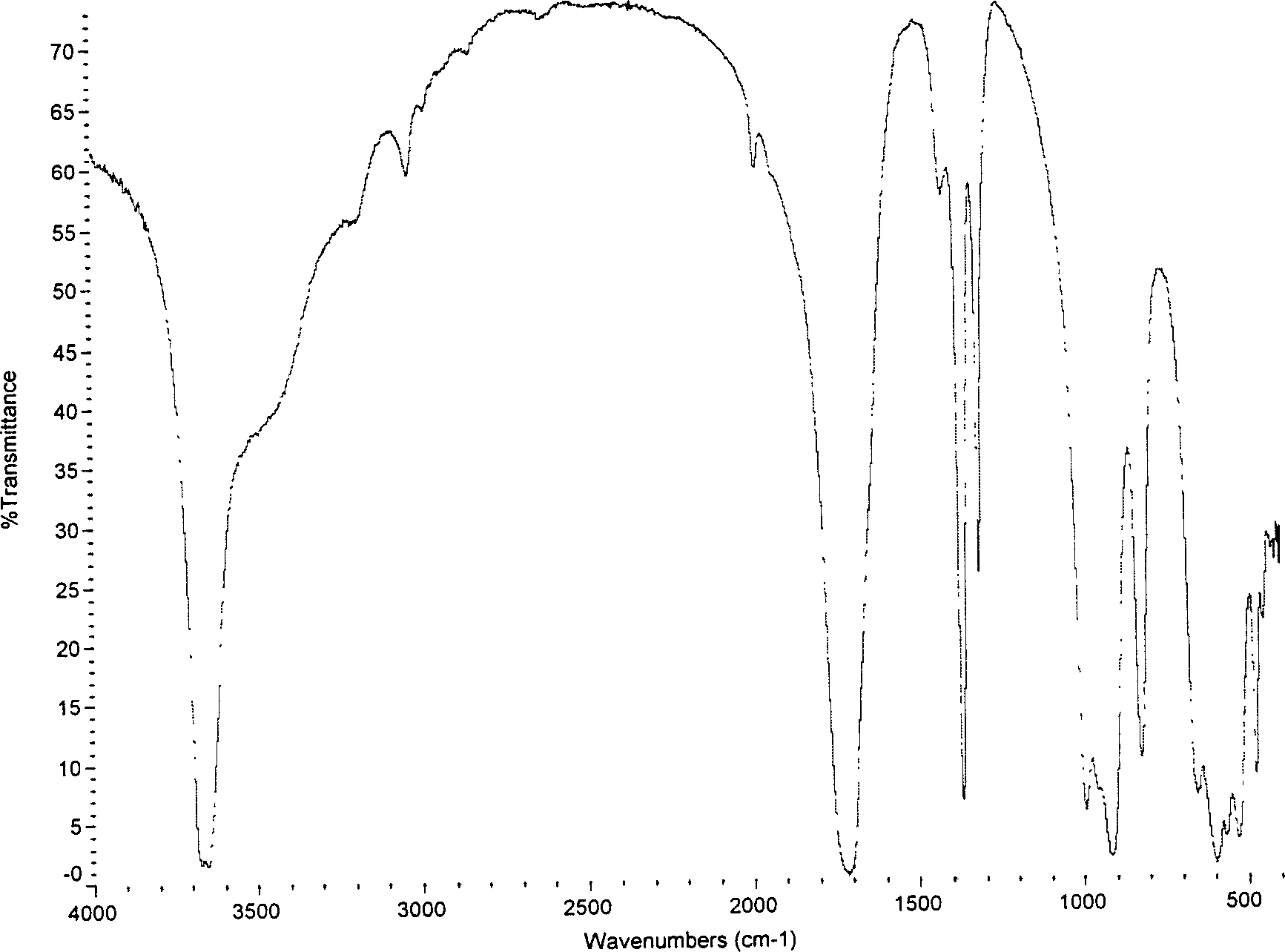

Self-protection flux-cored wire applicable for pipeline steel welding

InactiveCN104043912AHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaIron powderMolten bath

The invention discloses a self-protection flux-cored wire applicable for pipeline steel welding. The self-protection flux-cored wire consists of a steel band and flux core powder, and is characterized in that the flux core powder comprises the following chemical components in mass percentage: 20-26% of slagging constituent, 10-15% of gas forming agent aluminum oxalate, 0.4-0.8% of Ge, 1.2-2.4% of Mn, 0.4-0.8% of Si, 0.2-0.4% of Ti, 0.1-0.5% of Al, 1.0-2.4% of Ni, 1.0-1.5% of soda feldspar, and the balance of iron powder; the flux core filling rate is 18-22%. The invention provides the self-protection flux-cored wire specially aiming at pipeline steel, a lot of smoke and harmful gas cannot be produced in the welding process, the spatter phenomenon is reduced in the welding process, the arcs are maintained to be stable, no obvious pore is formed in the surface, the contents of nitrogen and oxygen in a molten bath are reduced, the weld metal structure refinement and the uniform distribution are ensured, and the low temperature impact toughness is high. The self-protection flux-cored wire is applicable for the welding of high-strength steel with certain intensity, and the field operation requirements of outdoor large-pipe diameter pipeline steel can be particularly met.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Preparation method of tungsten alloy precursor compound powder, tungsten alloy and preparation method of tungsten alloy

The invention relates to a preparation method of tungsten alloy precursor compound powder, a tungsten alloy and a preparation method of the tungsten alloy, and belongs to the technical field of high-temperature structural materials. The preparation method of the tungsten alloy precursor compound powder comprises the following steps that a mixed dispersion solution of ammonium paratungstate, soluble ferric salt, soluble nickel salt and soluble aluminum salt is provided; the pH of the mixed dispersion solution is adjusted to be not higher than 1.5 by the aid of oxalic acid, after complete reaction, mixed powder is obtained through removal of a solvent, and then the tungsten alloy precursor compound powder is obtained. According to the preparation method of the tungsten alloy precursor compound powder, the pH of the mixed dispersion solution is adjusted by the aid of the oxalic acid, newly-produced tungstic acid, ferric oxalate, nickel oxalate and aluminum oxalate are subjected to commonreaction and co-precipitation, thus the uniformity and the consistency of various components of the mixed powder are improved, refined crystalline strengthening and dispersion strengthening of the tungsten alloy can be realized by the aid of the obtained compound powder, the toughness of the tungsten alloy can be improved while the strength of the tungsten alloy is substantially improved, and thenano ceramic particle dispersion reinforced high-strength and high-toughness tungsten alloy can be prepared from the compound powder.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing vanadyl oxalate from vanadium slag through short process

ActiveCN110358926AInhibit entryReduce manufacturing costOrganic compound preparationCarboxylic acid salt preparationSolubilitySlag

The invention discloses a method for preparing vanadyl oxalate from vanadium slag through a short process, and belongs to the technical field of preparation for vanadyl oxalate. The method for preparing vanadyl oxalate from the vanadium slag through the short process comprises the following steps: roasting the vanadium slag to obtain roasted clinker; adding water and oxalic acid into the roasted clinker, and leaching and filtering; and concentrating and crystallizing a filtrate, and then carrying out solid-liquid separation to obtain vanadyl oxalate solid. According to the method for preparingvanadyl oxalate from the vanadium slag through the short process, oxalic acid is taken as a leaching agent, and on one hand, an acidic environment is provided for dissolving out vanadium from the clinker; and on the other hand, ferrous oxalate, calcium oxalate, manganese oxalate, magnesium oxalate and aluminum oxalate which have extremely low solubility are formed with iron, calcium, manganese, magnesium and aluminum in the clinker, and then the impurity elements are prevented from entering a leaching solution, so that one-step completion of leaching for vanadium and separation for the impurities is realized, and short process and low production cost are achieved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Preparation method for ternary composite cathode material for germanium-coated lithium ion battery

The invention relates to a preparation method for a ternary composite cathode material for a germanium-coated lithium ion battery. The chemical formula of the cathode material is LiNi1-x-yAlxCoyO2-zFz, wherein x is 0.26 to 0.32, y is 0.18 to 0.22, and z is 0.005 to 0.01. The method comprises the following steps: (1) preparing nickel oxalate, aluminum oxalate and cobalt oxalate into a mixed solution, adding argon into the prepared metal ion solution, stirring, heating, instilling a KOH solution into a stirred reactor very slowly to produce (Ni1-x-yAlxCoy)(OH)2 sedimentation, filtering, washing, and drying so as to obtain a granulous (Ni1-x-yAlxCoy)(OH)2 precursor; (2) respectively weighing the precursor, lithium hydroxide and lithium fluoride, performing ball-milling, drying, and sintering so as to obtain the ternary composite cathode material LiNi1-x-yAlxCoyO2-zFz; (3) obtaining germanium oxide coated LiNi1-x-yAlxCoyO2-zFz through the adoption of germanium sol coating. According to the preparation method for the cathode material, a wet method is adopted to prepare the ternary material precursor so as to obtain higher energy density and material activity; a solid phase sintering method is adopted to dope F in the material to further improve the stability of the material, and finally the germanium coating is adopted to improve the overall performance of the material.

Owner:山东毅聪新能源有限公司

High-insulativity halogen-free flame-retardant insulation material for household appliances and preparation method thereof

InactiveCN104893086AImprove insulation performanceImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethyleneSilanes

The invention relates to a high-insulativity halogen-free flame-retardant insulation material for household appliances. The high-insulativity halogen-free flame-retardant insulation material is prepared by adopting the following raw materials in parts by weight: 3 to 4 parts of calcined pottery clay, 8 to 9 parts of thermoplasticity polyimide, 5 to 6 parts of nano hydroxyl aluminum oxalate, 10 to 15 parts of low-density polyethylene resin, 0.3 to 0.4 part of vinyl trimethoxy silane, 0.04 to 0.08 part of dicumyl peroxide, 0.01 to 0.02 part of n-butyltin dilaurate, 50 to 60 parts of magnesium hydroxide, 60 to 65 parts of EVA and 20 to 23 parts of high-density polyethylene resin. According to the insulation material, inorganic flame-retardant filler is modified in a cross-linking manner by utilizing raw materials such as the low-density polyethylene, so that the compatibility of the flame-retardant filler and a resin base material is improved, and the fracturing is prevented; by utilizing the calcined pottery clay, the thermoplasticity polyimide and the nano hydroxyl aluminum oxalate, the insulation performance and the flame-retardant property of the insulation material can be improved, and the safety can be improved; and the insulation material can be used for a high-power household appliance wire harness and is long in service life and high in safety.

Owner:合肥得润电子器件有限公司

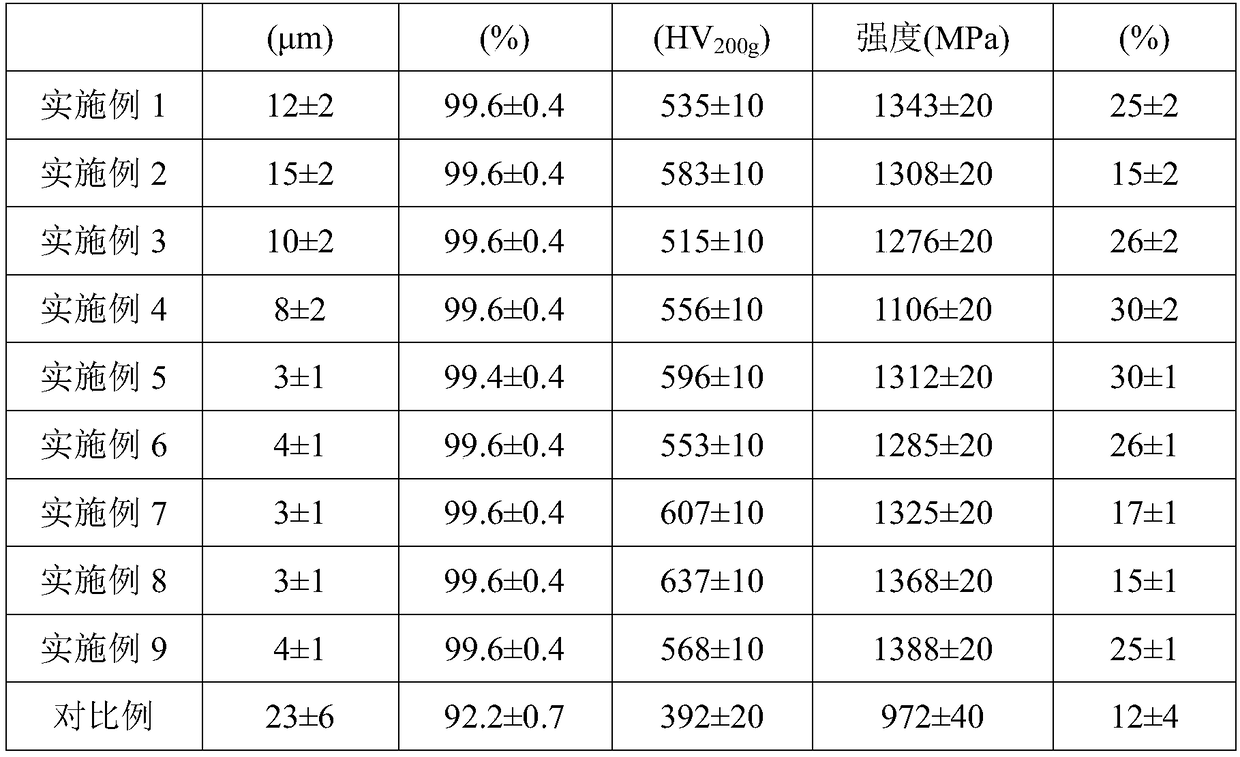

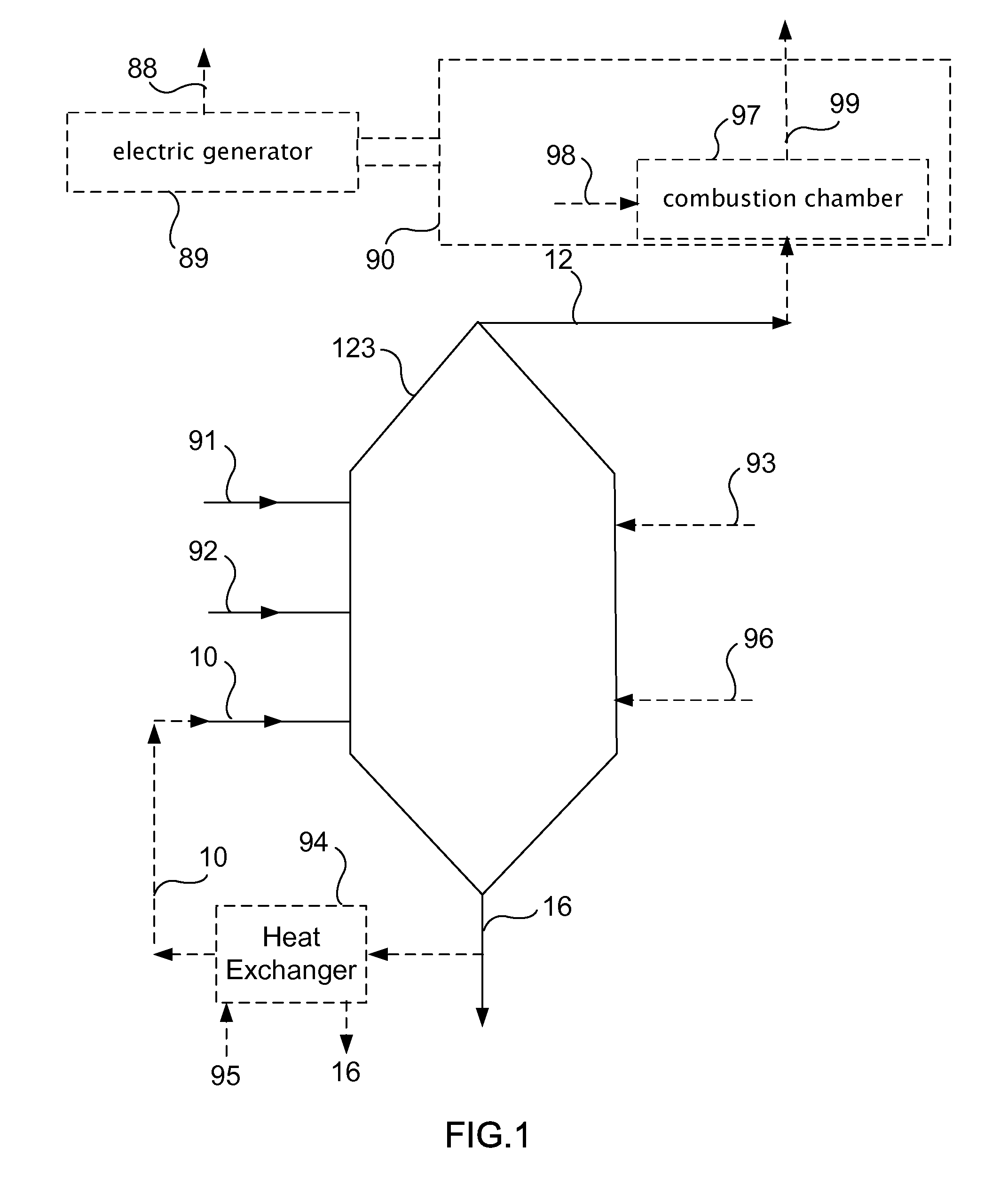

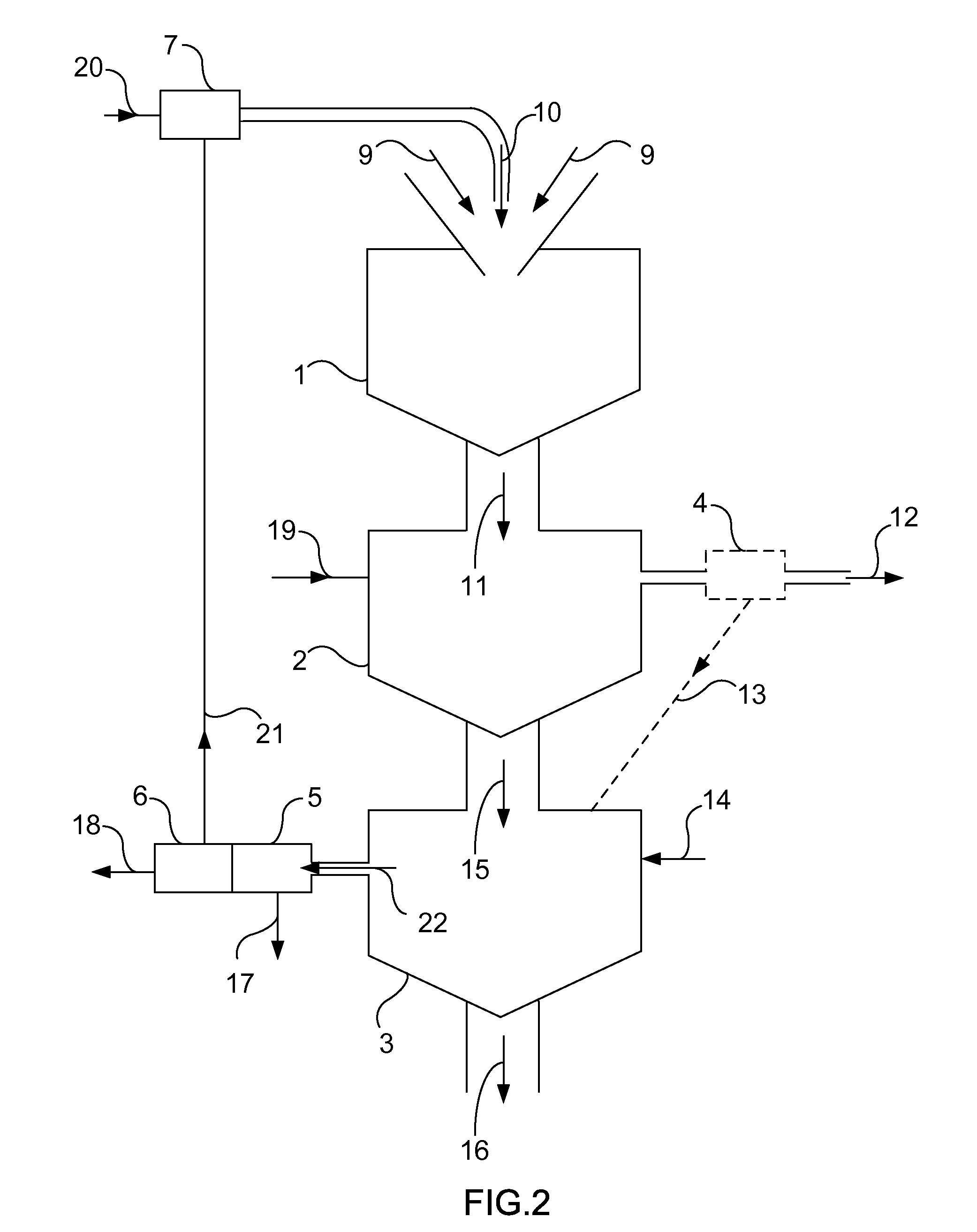

Process for converting carbon dioxide from coal utilization to a solid ash

InactiveUS20100178239A1High yieldFinal product manufactureGasification processes detailsCombustion chamberHigh pressure

A process for conversion of coal in a reaction vessel comprises steps of: admixing coal and powdered alumina clay to form reactants; injecting the reactants with a high-pressure steam jet into the reaction vessel; and producing aluminum oxalate ash and hydrogen. Preferably, the reaction vessel is pressurized to maximize the production of aluminum oxalate and hydrogen. Optionally, the process includes adding calcium carbonate if not present in the clay. The reactants in the reaction vessel are typically maintained a temperature of about 2,000 degrees Kelvin and a pressure of about 1 mega Pascals. To save energy, the process may include preheating water with the aluminum oxalate ash to aid in creating pressurized steam. The hydrogen may be mixed with air and burned in a combustion chamber, such as is found within a gas turbine-generator unit to produce electricity. Optionally the reactants may include an aqueous sodium hydroxide.

Owner:HCE

Flame retardant, transparent and heat insulating nano glass coating and preparation method thereof

InactiveCN105838213ASmall water absorptionEvenly dispersedFireproof paintsAnti-corrosive paintsPotassium persulfateUltraviolet lights

The invention discloses a flame retardant, transparent and heat insulating nano glass coating .The flame retardant, transparent and heat insulating nano glass coating is prepared from, by weight, 20-21 parts of nano antimony tin oxide, 0.2-0.3 part of a dispersing agent SN-5040, 79-81 parts of waterborne polyurethane resin, 30-35 parts of deionized water, 40-50 parts of N, N'-dimethylformamide, 20-22 parts of a sulfuric acid solution with the concentration being 20%, 20-22 parts of perfluoro caprylic acid, 3-4 parts of methyl methacrylate, 0.1-0.2 part of potassium persulfate, 3-3.5 parts of isocyanate, 0.4-0.5 part of sulfosalicylic acid, 0.3-0.4 part of edetic acid, 0.4-0.5 part of nano copper and 1.2-1.4 parts of a hydroxyl aluminum oxalate solution .According to the flame retardant, transparent and heat insulating nano glass coating, the sulfosalicylic acid and the edetic acid are utilized to modify the nano copper and the hydroxyl aluminum oxalate solution, the nano copper and hydroxyl aluminum oxalate are evenly dispersed in the coating, flame retardance and wear resistance are improved, and the shading property for ultraviolet light of the coating is further improved .

Owner:ANHUI RONGCHENG GLASS PROD CO LTD

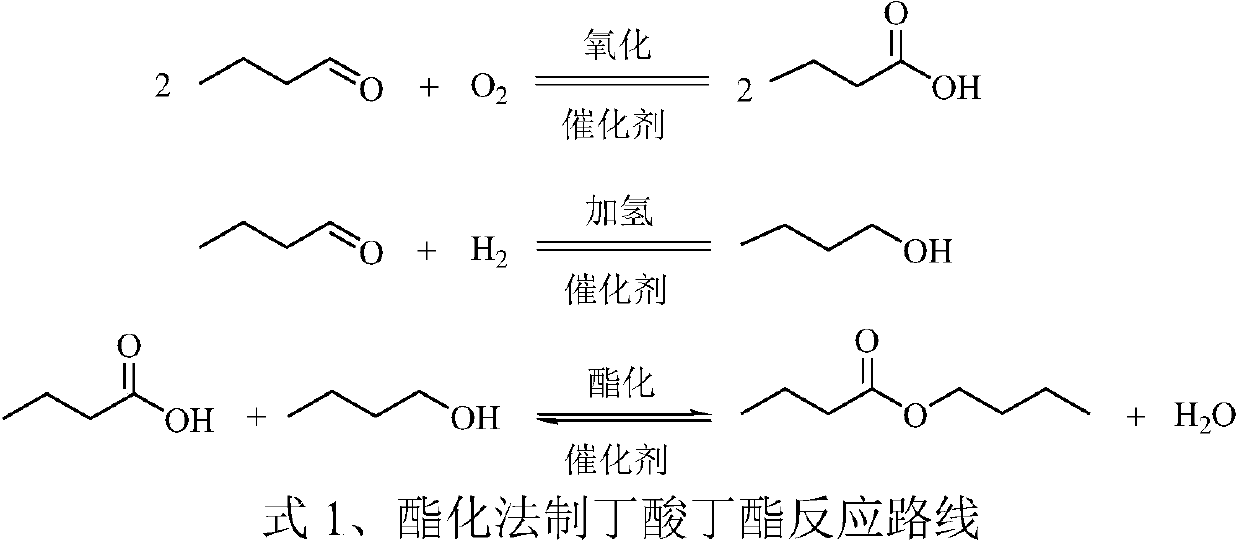

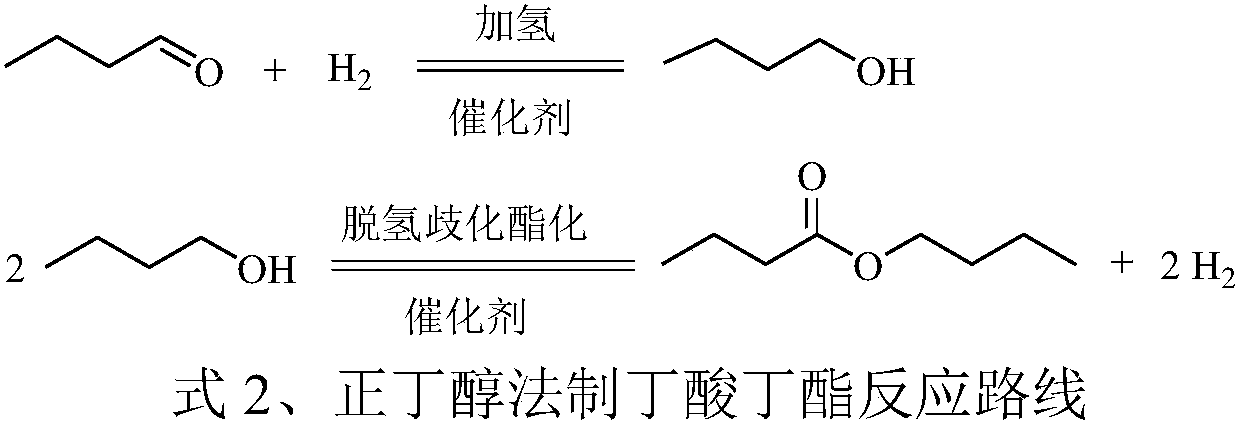

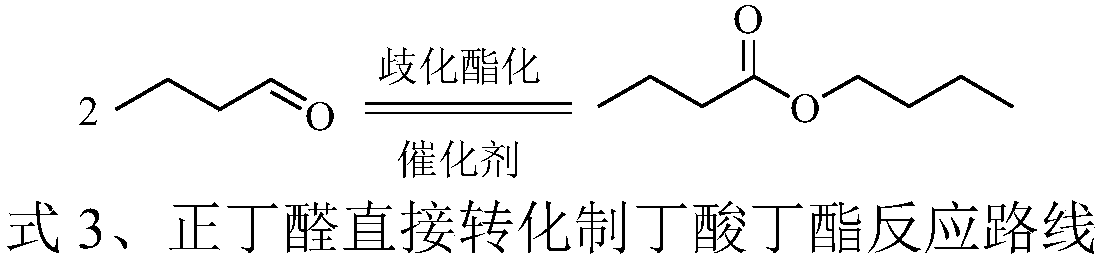

Method for preparing butyl butyrate through direct catalytic conversion of n-butyraldehyde

ActiveCN111217704AHigh selectivityShort routePreparation by aldehyde oxidation-reductionChemical recyclingPtru catalystReaction temperature

The invention relates to a method for preparing butyl butyrate by directly converting n-butyraldehyde. According to the method, n-butyraldehyde is used as a raw material, one or more than two of organic dibasic acid aluminum or organic tribasic acid aluminum such as aluminum oxalate, aluminum citrate, aluminum tartrate, aluminum malate, aluminum adipate, aluminum heptanedioate, aluminum dodecanedioate and the like are used as catalysts, the use amount of the catalyst is 0.2-1.0% of the mass of the n-butyraldehyde, the reaction temperature is 0-20 DEG C, the reaction time is 0.5-2 hours, and the n-butyraldehyde conversion rate and the butyl butyrate selectivity can reach more than 99%. The method has the advantages of short route, good atom economy, mild reaction conditions, catalyst recyclability, high raw material conversion rate, high product selectivity and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

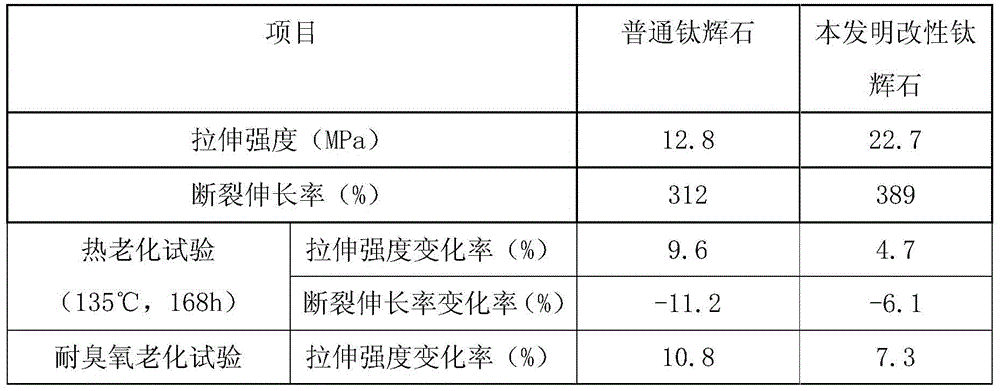

Modified titanaugite for high heat-resistance and anti-aging butadiene-acrylonitrile rubber cable material and preparation method thereof

InactiveCN105482189AHigh fillingImprove high temperature resistanceRubber insulatorsQuinoxalinePolymer science

The invention discloses modified titanaugite for a high heat-resistance and anti-aging butadiene-acrylonitrile rubber cable material and a preparation method thereof. The modified titanaugite is prepared from, by weight parts, 28-42 parts of titanaugite, 18-34 parts of crude ore red mud, 15-25 parts of sludge dry powder, 16-28 parts of polyphenyl quinoxaline, 14-22 parts of phosphonitrilic chloride trimer, 10-15 parts of epoxyfuroic-oleic poctyl, 3-7 parts of oleic acid triethanolamine, 4-8 parts of high molecular weight polybutylene, 2-4 parts of Vanadyl(IV) acetylacetonate, 5-10 parts of pentaerythritol ester of hydogenated rosin, 3-6 parts of hydroxyl aluminum oxalate, 1-2 parts of N- nitrosodimethylamine, 1-2 parts of 4,4'-diaminodiphenyl methane and 5-7 parts of compound additive. The modified titanaugite is applied to the butadiene-acrylonitrile rubber cable material, can remarkably improve the high heat resistance, acid resistance, corrosion resistance and the anti-aging performance of the butadiene-acrylonitrile rubber cable material and greatly improve the application range and the service life of the butadiene-acrylonitrile rubber cable material.

Owner:ZHONGGUAN CABLE CO LTD

A self-shielded flux-cored wire suitable for pipeline steel welding

A self-shielding flux-cored welding wire suitable for pipeline steel welding, consisting of a steel strip and flux-core powder, characterized in that the chemical composition and mass percentage of the powder are: 20-26% slagging agent, 10% aluminum oxalate gas-forming agent ~15%, Ge0.4~0.8%, Mn1.2~2.4%, Si0.4~0.8%, Ti0.2~0.4%, Al0.1~0.5%, Ni? 1.0~2.4%, albite 1.0~1.5%, the rest is iron powder, the powder filling rate is 18~22%. The invention provides a flux-cored welding wire for self-protection welding specially used for pipeline steel, which does not generate a large amount of smoke and harmful gas during the welding process, reduces splashing during the welding process, keeps the arc stable and has no obvious pores on the surface, and reduces the risk of melting. The content of nitrogen and oxygen in the pool ensures that the weld metal structure is refined and evenly distributed, and the low-temperature impact toughness is high. The invention is suitable for welding high-strength steel with a certain strength, and can especially meet the field operation requirements of outdoor large-diameter pipeline steel.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Phase change thermal storage material

ActiveCN109628068AHigh heat storage densityImprove thermal conductivityHeat-exchange elementsSilicon alloyVolumetric Mass Density

The invention relates to a phase change thermal storage material, and belongs to the technical field of ceramic materials. The material is prepared from the following steps that 1, quartz sand powder,corundum powder, copper oxide and zinc oxide are mixed to be uniform in proportion, compression moulding is conducted, then thermal treatment is conducted to obtain a screening material A; 2, the screening material A, carbon black and aluminum oxalate hydrate are mixed to be uniform in proportion, thermal treatment is conducted, and then an abrasive material B is obtained; 3, corundum particles,the corundum powder, the abrasive material B, an aluminium-silicon alloy and thermosetting phenolic resin are mixed to be uniform in proportion, compression moulding and thermal treatment are conducted, and a finished product is obtained. The phase change thermal storage material has the advantages of being large in thermal storage density, large in coefficient of thermal conductivity, high in compressive strength, high in thermal shock resistance, low in production cost, simple in process and the like.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

Hydroxy aluminium oxalate, and its preparing method and hydroxy aluminium oxalate as fire retardant

InactiveCN1247514CSimple structureEasy to operateCarboxylic acid salt preparationThermoplasticDecomposition

The present invention is the aluminum hydroxyoxalate and its preparation process. Aluminum hydroxyoxalate is used as fire retardant, and has molecular expression of Al2(C2O4)(OH)4, and X-ray diffraction spectrum with strong diffraction peaks at D values one 6.5149, 4.7263 and 4.2957 angstrom. Aluminum hydroxyoxalate is prepared through carbonization and decomposition and modification treatment, and through further crystal form controlling treatment, aluminum hydroxyoxalate with high dispersivity and complete crystal form may be obtained. Aluminum hydroxyoxalate has minimum one-dimensional size controlled in 40 nanometers to several microns, extrapolation onset weight-loss temperature higher than 340 deg.c, and weight-loss rate before 500 deg.c up to 51 %. As one kind of green fire retardant, aluminum hydroxyoxalate may be used in thermoplastic plastic and other polymer material with processing temperature over 210 deg.c.

Owner:BEIJING UNIV OF CHEM TECH

Refractory coating for components of and aluminum electrolysis cess

The present invention provides a refractory coating for a component of an electrolytic cell for the production of aluminum in which an aqueous slurry is prepared comprising particulate refractory material, e.g. TiB2, dispersed in an aluminum oxalate complex. The slurry is applied as a coating to the surface of the component, e.g. a cathode block, and dried to form a hard refractory surface on the component. The aluminum oxalate complex may be formed in situ during production of the slurry by mixing together oxalic acid and electrostatic precipitator dust comprising aluminum oxide. After the refractory coated component is immersed in a high temperature cryolite bath of an aluminum electrolysis cell, the aluminum oxalate complex is converted to alumina which bonds the refractory particles to the surface of the cell component.

Owner:ALCAN INT LTD

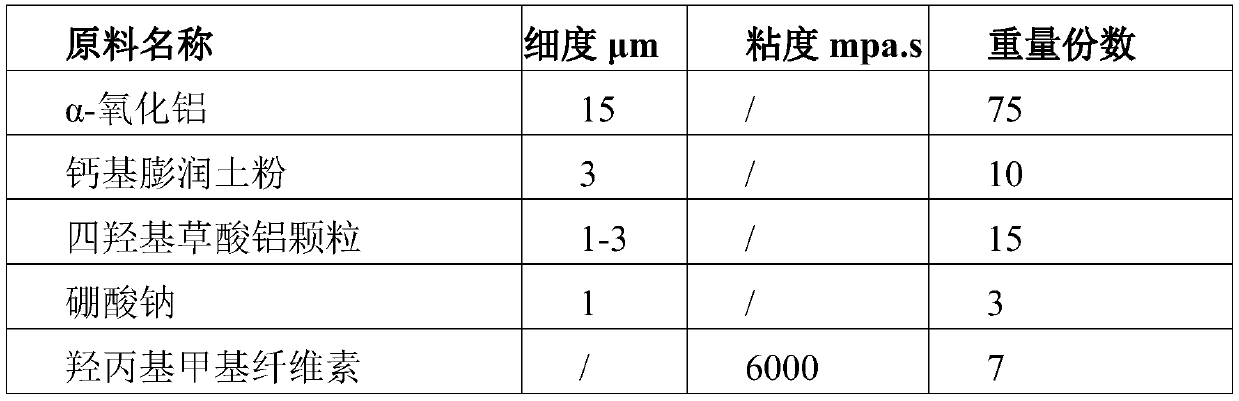

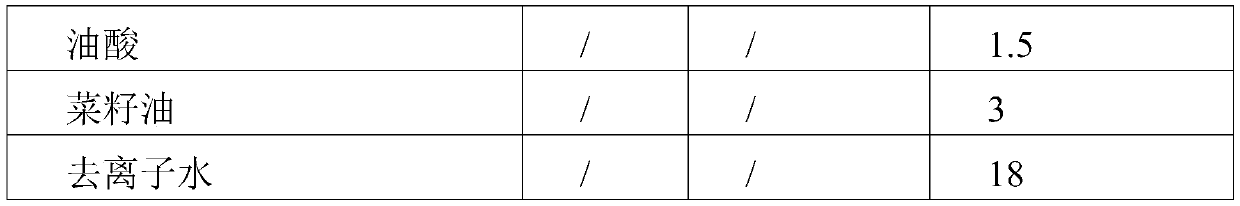

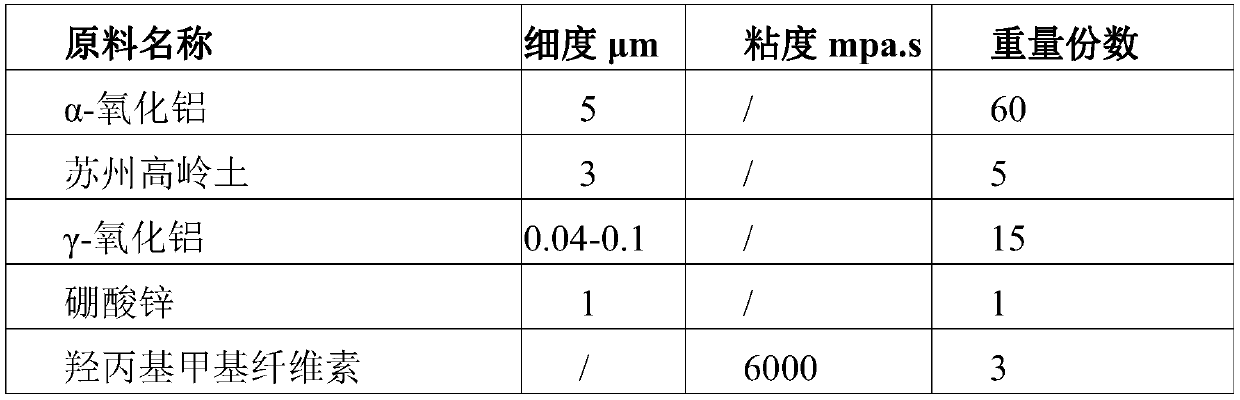

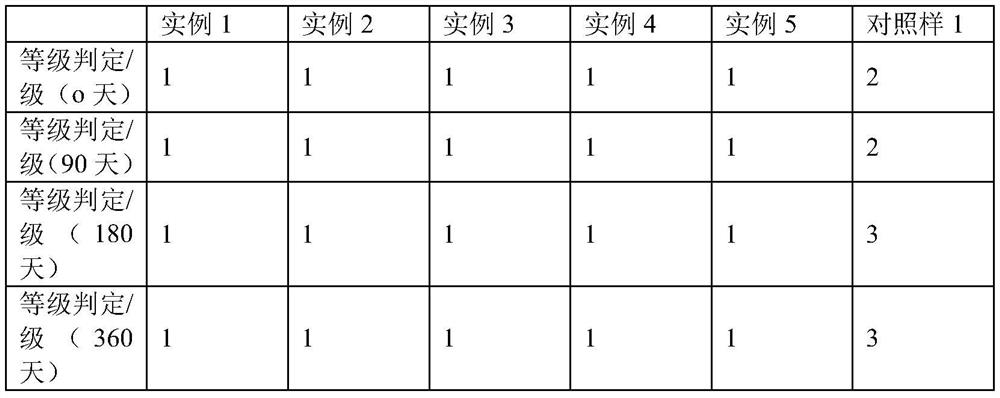

Porous ceramic material and preparation method thereof

The invention provides a porous ceramic material and a preparation method thereof, and belongs to the field of ceramic materials. The ceramic material is prepared from the following raw materials in parts by weight: 60 to 75 parts of aggregate; 5 to 10 parts of kaolin; 8 to 15 parts of tetrahydroxy aluminum oxalate; 1 to 3 parts of a fluxing agent; 3 to 7 parts of an adhesive; 0.5 to 2 parts of adispersing agent; 1 to 3 parts of a lubricating agent; and 15 to 18 parts of water. The tetrahydroxy aluminum oxalate releases gas in the firing process of ceramic mud, so that pore forming of the ceramic material is completed; superfine aluminum oxide obtained by decomposition is used as a ceramic component to be combined into a ceramic phase in situ; due to the addition of the fluxing agent, a temperature window generated by the decomposing and gas release of the tetrahydroxy aluminum oxalate in the firing process of the ceramic mud is matched with a temperature window generated by the low-melting ceramic phase, so that the problem that the ceramic does not generate a molten phase when a common pore-forming agent decomposes and releases gas is avoided, and the problem that the common pore-forming agent decomposes and discharges polluting gas is solved. The porous ceramic obtained by the method is uniform and through in pore channels, controllable in porosity and good in stability.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

A phase change heat storage material

ActiveCN109628068BHigh heat storage densityImprove thermal conductivityHeat-exchange elementsSilicon alloyCopper oxide

The invention relates to a phase change thermal storage material, and belongs to the technical field of ceramic materials. The material is prepared from the following steps that 1, quartz sand powder,corundum powder, copper oxide and zinc oxide are mixed to be uniform in proportion, compression moulding is conducted, then thermal treatment is conducted to obtain a screening material A; 2, the screening material A, carbon black and aluminum oxalate hydrate are mixed to be uniform in proportion, thermal treatment is conducted, and then an abrasive material B is obtained; 3, corundum particles,the corundum powder, the abrasive material B, an aluminium-silicon alloy and thermosetting phenolic resin are mixed to be uniform in proportion, compression moulding and thermal treatment are conducted, and a finished product is obtained. The phase change thermal storage material has the advantages of being large in thermal storage density, large in coefficient of thermal conductivity, high in compressive strength, high in thermal shock resistance, low in production cost, simple in process and the like.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

A high temperature phase change heat storage material

ActiveCN109609099BHigh heat storage densityImprove thermal conductivityTransportation and packagingMetal-working apparatusCopper oxideAlloy

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

High-strength potassium hexatitanate whisker porous ceramics and preparation method thereof

The invention relates to high-strength potassium hexatitanate whisker porous ceramics and a preparation method thereof. According to the technical scheme, the preparation method comprises uniformly mixing, by weight percentage, 50-70% of titanium dioxide, 20-40% of anhydrous potassium carbonate and 1-10% of thermosetting resin, performing compression molding, thermal treatment at 600-800 DEG C, crushing, grinding and screening to obtain a screened material A with a granularity of 0.088-0.25 mm and a screened material B with a granularity of 0.088 mm; uniformly mixing, by weight percentage, 40-60% of aluminum hydroxide, 10-20% of aluminum oxalate and 20-40% of triethanolamine boric acid, performing thermal treatment and grinding at 400-600 DEG C to obtain a ground materials with a granularity smaller than 0.088 mm; uniformly mixing, by weight percentage, 30-50% of the screened material A, 40-60% of the screened material B, 1-10% of the ground material and 1-10% of thermosetting resin, performing compression molding and thermal treatment at 800-1100 DEG C to prepare the high-strength potassium hexatitanate whisker porous ceramics. The prepared high-strength potassium hexatitanate whisker porous ceramics is uniform in size and high in porosity and compression strength.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of lithium difluoro bis (oxalato) phosphate

ActiveCN113753875AHigh selectivitySimple processSecondary cellsPhosphorus compoundsPhosphatePhysical chemistry

The invention discloses a preparation method of lithium difluoro bis (oxalato) phosphate, the preparation method comprises the following step: reacting lithium hexafluorophosphate with anhydrous aluminum oxalate in an aprotic solvent to obtain the lithium difluoro bis (oxalato) phosphate, wherein the water content of the anhydrous aluminum oxalate is less than 500ppm, and the anhydrous aluminum oxalate is obtained by removing crystal water through secondary vacuum drying of aluminum oxalate. The method has the advantages of simple process, high yield, high product purity, suitability for industrial production and the like.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

Temperature-resistant polyvinyl chloride material and preparation method thereof

InactiveCN107286521APromote decompositionImprove thermal conductivityPolyvinyl alcoholPolyvinyl chloride

The invention relates to a temperature-resistant polyvinyl chloride material which includes: polyvinyl chloride, modified graphite, modified paraffin, polymaleic acid, metal filled graphite, diisodecyl pentaerythritol diphosphite and magnesium stearate; wherein the modified graphite is prepared through a reaction to hydrofluoric acid, hydrosulfuric acid, graphite, isopropanol and silver powder; the modified paraffin is prepared through a reaction to ethanol, paraffin, dimethyl formamide and copper powder; the metal filled graphite is prepared through a reaction to aluminum powder coating silver powder, graphite, chlorosulfonic acid and dimethyl formamide; and the aluminum powder coating silver powder is prepared through a reaction to silver oxalate, aluminum oxalate, sodium oxalate, polyvinyl alcohol 1000 and water. The polyvinyl chloride material has excellent temperature resistance and mechanical strength.

Owner:周佳瑜

A kind of preparation method of germanium-coated lithium-ion battery ternary composite cathode material

The invention relates to a preparation method for a ternary composite cathode material for a germanium-coated lithium ion battery. The chemical formula of the cathode material is LiNi1-x-yAlxCoyO2-zFz, wherein x is 0.26 to 0.32, y is 0.18 to 0.22, and z is 0.005 to 0.01. The method comprises the following steps: (1) preparing nickel oxalate, aluminum oxalate and cobalt oxalate into a mixed solution, adding argon into the prepared metal ion solution, stirring, heating, instilling a KOH solution into a stirred reactor very slowly to produce (Ni1-x-yAlxCoy)(OH)2 sedimentation, filtering, washing, and drying so as to obtain a granulous (Ni1-x-yAlxCoy)(OH)2 precursor; (2) respectively weighing the precursor, lithium hydroxide and lithium fluoride, performing ball-milling, drying, and sintering so as to obtain the ternary composite cathode material LiNi1-x-yAlxCoyO2-zFz; (3) obtaining germanium oxide coated LiNi1-x-yAlxCoyO2-zFz through the adoption of germanium sol coating. According to the preparation method for the cathode material, a wet method is adopted to prepare the ternary material precursor so as to obtain higher energy density and material activity; a solid phase sintering method is adopted to dope F in the material to further improve the stability of the material, and finally the germanium coating is adopted to improve the overall performance of the material.

Owner:山东毅聪新能源有限公司

Scrap tire rubber powder modified bamboo fiber board for office furniture and preparing method of scrap tire rubber powder modified bamboo fiber board

InactiveCN105128115AImprove mechanical propertiesImprove flame retardant performanceFlat articlesDomestic articlesFiberMicrosphere

The invention relates to a scrap tire rubber powder modified bamboo fiber board. The scrap tire rubber powder modified bamboo fiber board comprises, by weight, 162-164 parts of bamboo fibers, an appropriate amount of a 0.2% sodium hydroxide solution, 16.2-16.7 parts of soy isolate protein, 1.5-1.6 parts of a corrosion remover, 6-6.5 parts of scrap tire rubber powder, 1.3-1.6 parts of nanometer hydroxyl aluminum oxalate, 0.8-1 part of vitreous carbon nanofibers, 0.5-0.8 part of microencapsulation red phosphorus and 0.8-1 part of ceramic microballoons. According to the scrap tire rubber powder modified bamboo fiber board, the scrap tire rubber powder is used for modifying, and the surface of the board has the good hydrophobicity; the nanometer hydroxyl aluminum oxalate, the vitreous carbon nanofibers, microencapsulation red phosphorus and the ceramic microballoons are used, so that the fire resistance, the mechanical property and the heat resistance of the board are greatly improved, and the scrap tire rubber powder modified bamboo fiber board is suitable for manufacturing office furniture, resistant to water and pressure and low in cost.

Owner:ANHUI BAIYI FURNITURE

A kind of preparation method and application of mildew-proof tanning protein filler

ActiveCN109022634BControl releaseEnhance binding strengthTanning treatmentLeather impregnationPolymer scienceCollagenan

The present invention relates to a preparation method and application of mildew-proof tanning protein filler. Take 42g of collagen powder, add the etherified amino resin and 60g of water obtained in the step into a three-necked flask, adjust the pH of the system to 8-9, and set the pH at 70 Stir and react at ~90°C for 1~2h, then add 1~5g of aluminum oxalate and 1.2~3.4g of substance A, stir and react at 60~80°C for 30min~75min, and vacuum dry to obtain mildew-resistant tanning protein filler. The anti-mildew tanning protein filler is used in the retanning filling process of leather, and the obtained leather has anti-mildew.

Owner:广东紫翼鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com