Porous ceramic material and preparation method thereof

A technology of porous ceramics and ceramic materials, applied in the field of ceramic materials, can solve the problems of many cracks, uneven pore size distribution, poor bonding force, etc., and achieve the effects of uniform and controllable production process, avoiding material defects, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

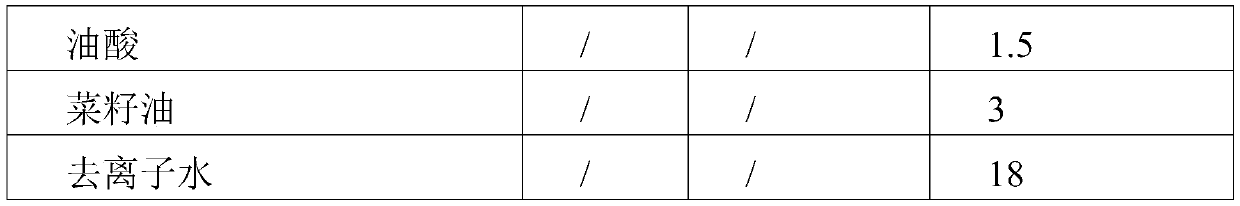

[0030] Table 1

[0031] raw material name Fineness μm Viscosity mpa.s parts by weight α-alumina 5 / 60 Suzhou kaolin 3 / 5 Tetrahydroxy aluminum oxalate particles 0.04-0.1 / 15 Zinc borate 1 / 1 Hydroxypropylmethylcellulose / 6000 3 Oleic acid / / 0.5 canola oil / / 1 Deionized water / / 15

[0032] Put tetrahydroxy aluminum oxalate particles and Suzhou kaolin into the mixer in turn and stir and mix, then add α-alumina and stir and mix again, then add zinc borate powder and stir and mix, and finally add hydroxypropyl methylcellulose, Obtain the premix; simultaneously oleic acid, rapeseed oil and water were pre-stirred and mixed for 5 minutes to obtain a mixed solution, and the gained premix was added to a kneader, and the mixed solution was added while kneading and kneaded for 20 minutes to obtain a kneaded sludge. Knead the mud for two times in vacuum, stale for 24 hours, extrude, microwave dry...

Embodiment 2

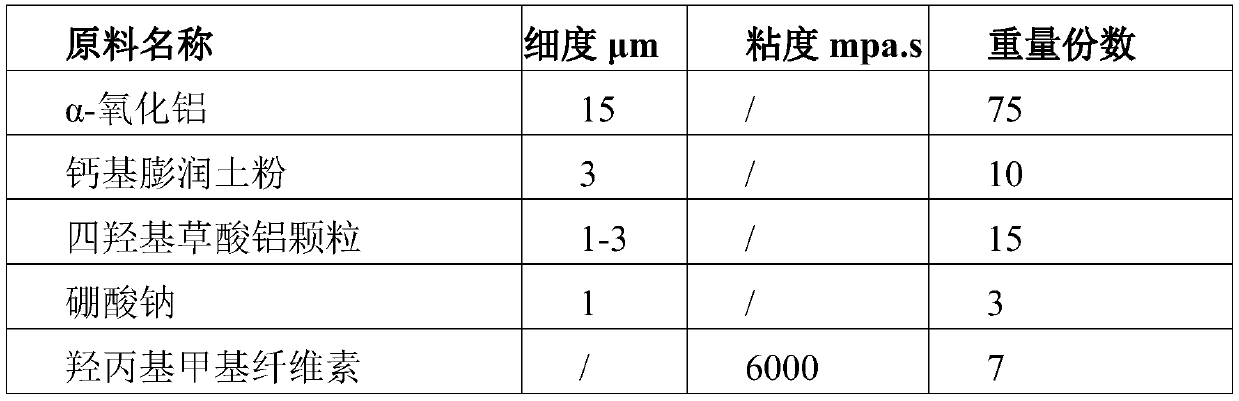

[0035] Table 2

[0036]

[0037]

[0038] Put tetrahydroxy aluminum oxalate particles and calcium-based bentonite powder into the mixer in turn and stir and mix, then add α-alumina and stir and mix again, then add sodium borate and stir and mix, finally add hydroxypropyl methylcellulose , to obtain a premix; at the same time, oleic acid, rapeseed oil and deionized water were mixed in advance for 8 minutes to obtain a mixed solution, and the resulting premix was added to a kneader, and the mixed solution was added while kneading and kneaded for 20 minutes to obtain a kneaded mud The kneaded mud material is vacuum smelted twice, aged for 30 hours, extruded, dried in microwave, fired in a tunnel kiln, from room temperature to 400 °C at a rate of 60 °C / h; then raised to 120 °C / h 1300°C, keep warm for 4 hours.

[0039] The product prepared according to the above process has a porosity of 42%, an average pore diameter of 2.1 microns, a maximum pore size of 2.89 microns, a fle...

Embodiment 3

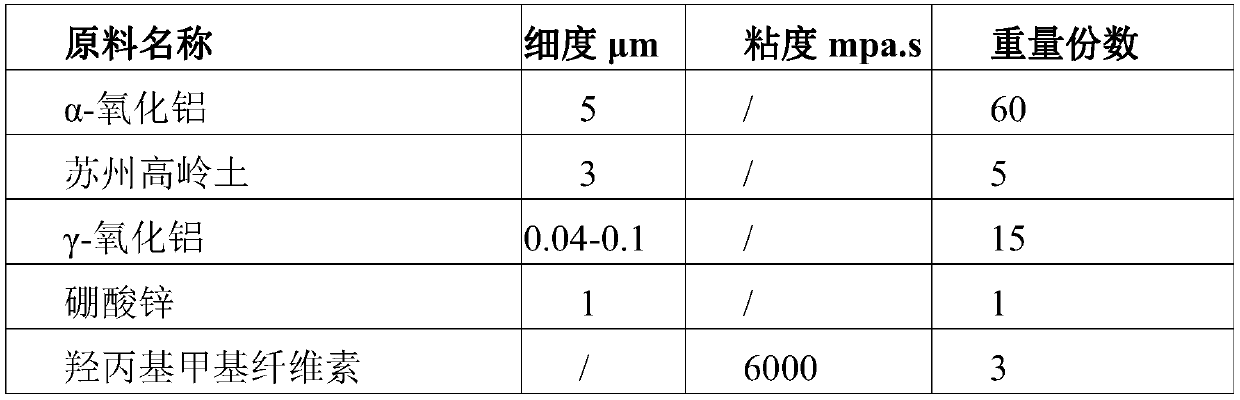

[0041] table 3

[0042] raw material name Fineness μm Viscosity mpa.s parts by weight Mullite powder 8 / 65 andalusite 5 / 10 Tetrahydroxy aluminum oxalate particles 0.1-1 / 12 boric acid 1 / 1.5 Starch ether / 4000 5 sodium stearate / / 1 Olefin oil / / 1 Deionized water / / 16

[0043]Put tetrahydroxy aluminum oxalate particles and andalusite into the mixer in turn and stir and mix, then add mullite powder and stir and mix again, then add boric acid and stir and mix, finally add starch ether to obtain a premix; Oil, sodium stearate and deionized water were stirred and mixed in advance for 10 minutes to obtain a mixed solution, and the obtained premix was added to a kneader, and the mixed solution was added while kneading and kneaded for 20 minutes to obtain a kneaded mud, and the kneaded mud was vacuum kneaded Clay twice, aged for 40 hours, extruded, microwave dried, fired in a tunnel kiln, fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com