Patents

Literature

160results about How to "Produce more" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

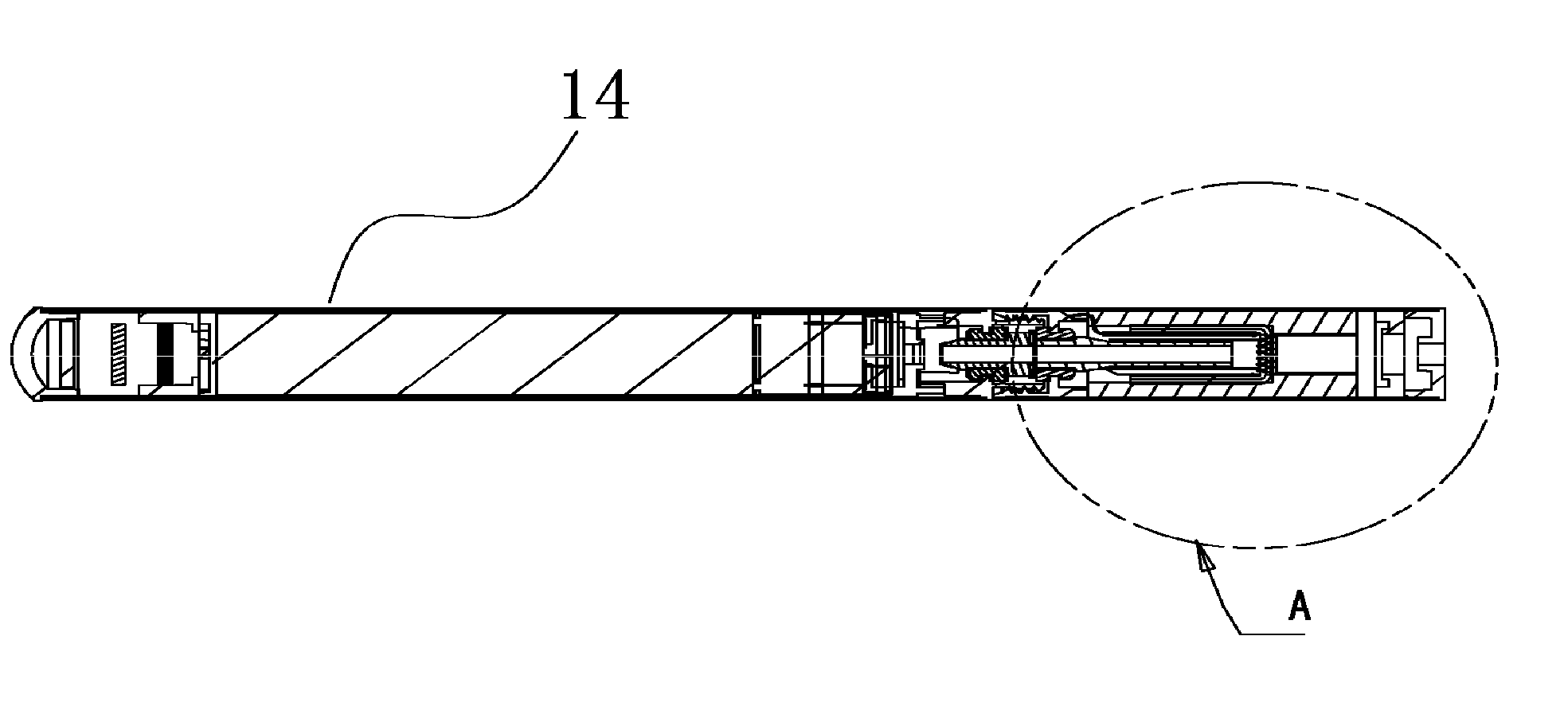

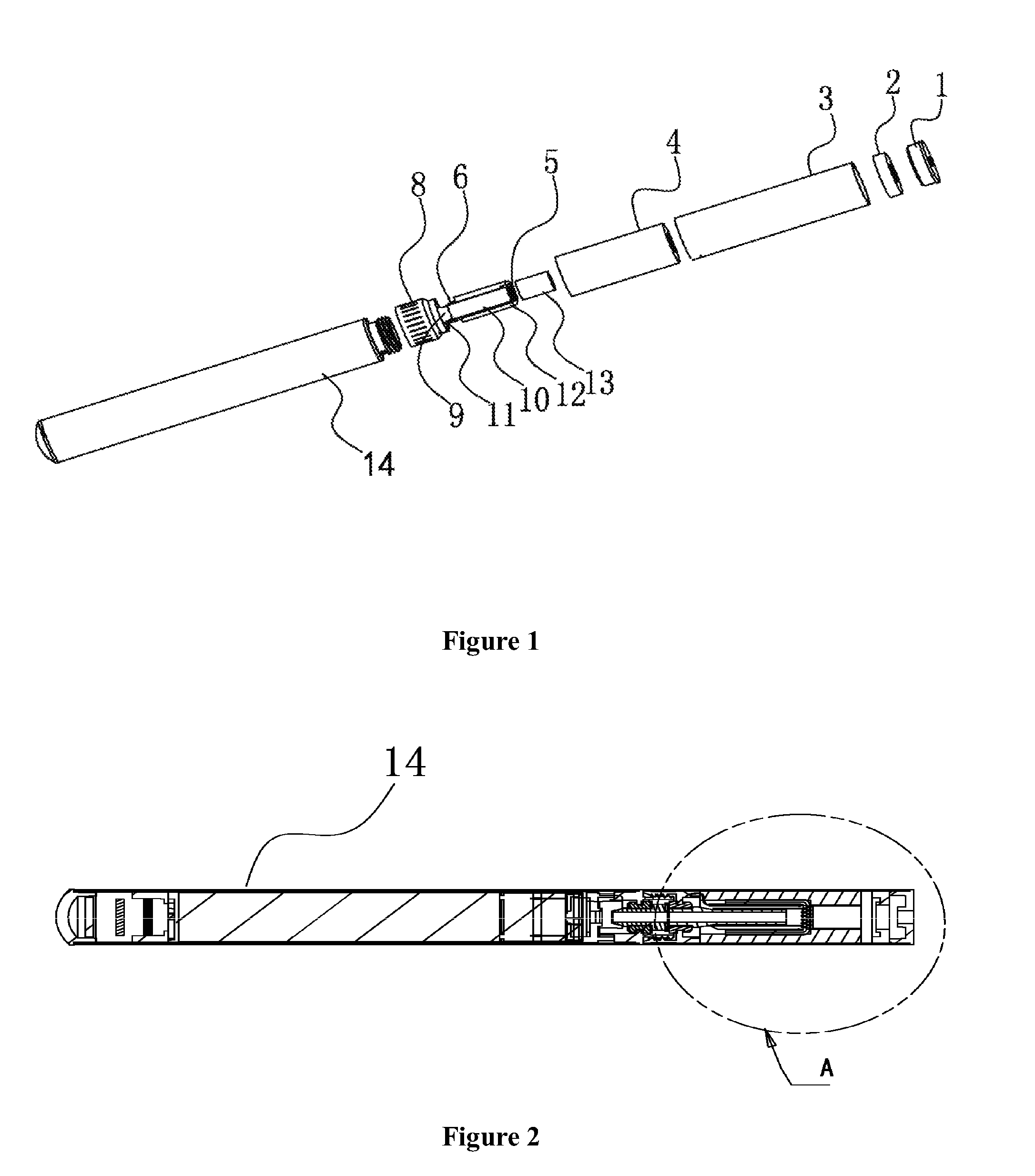

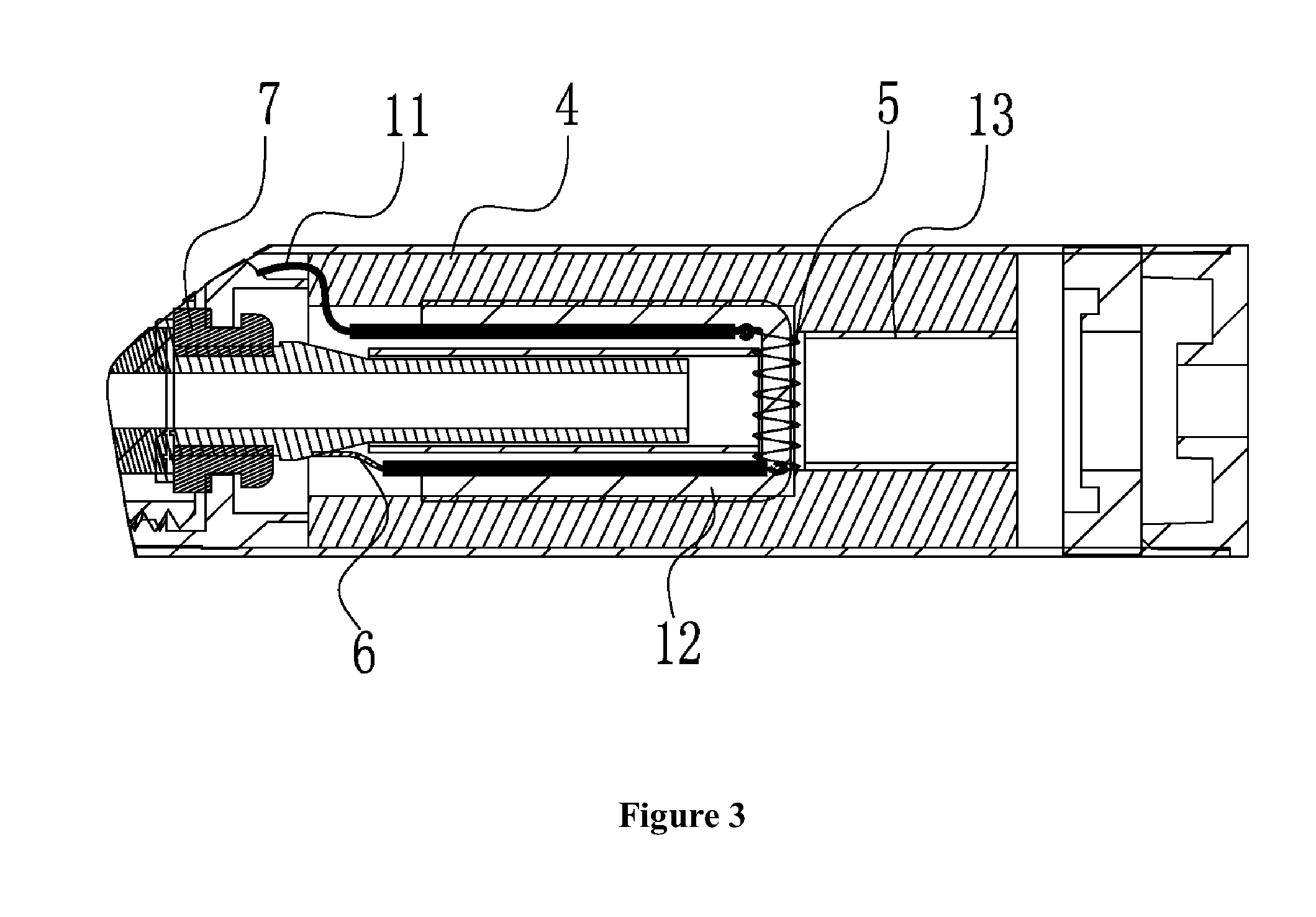

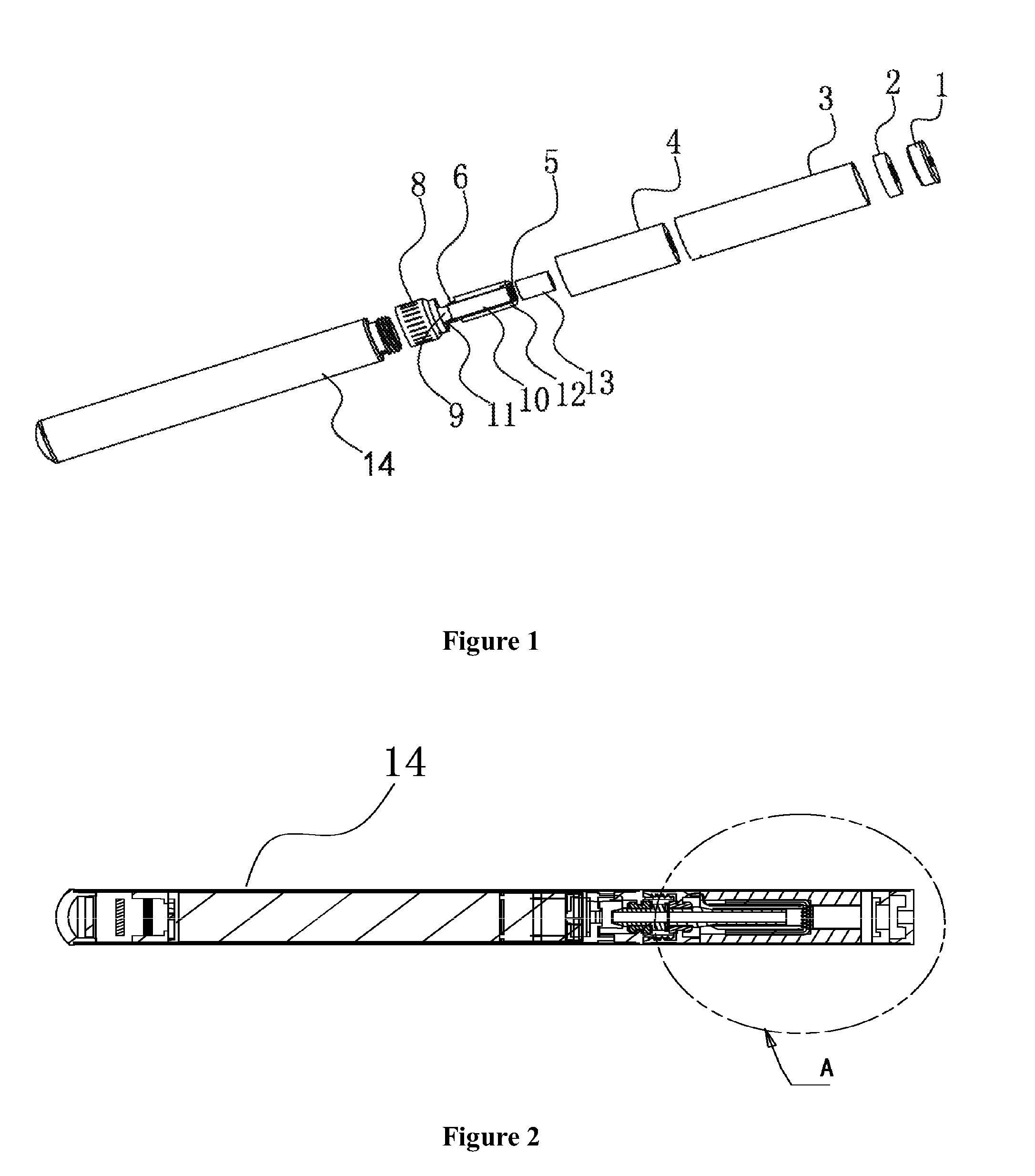

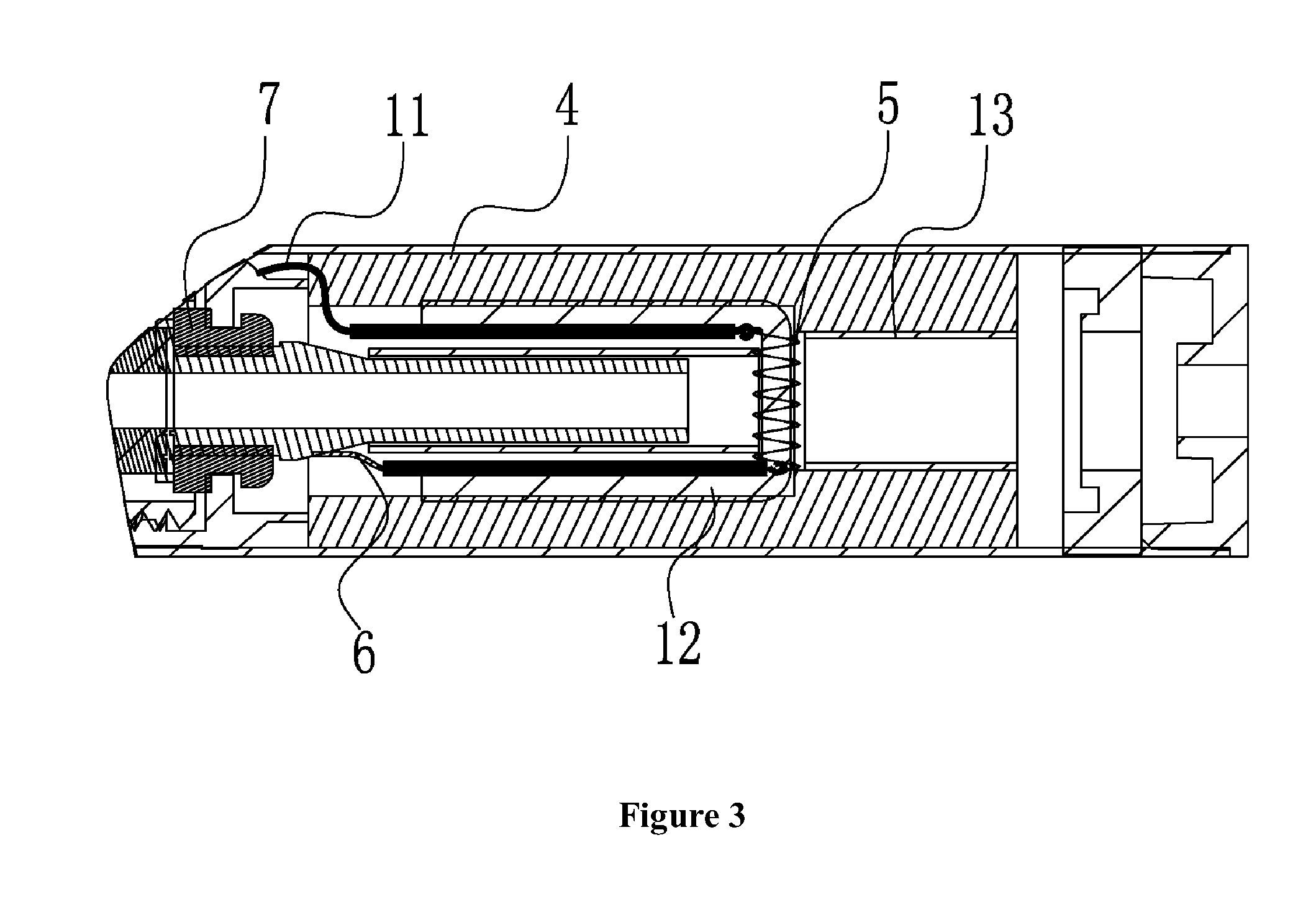

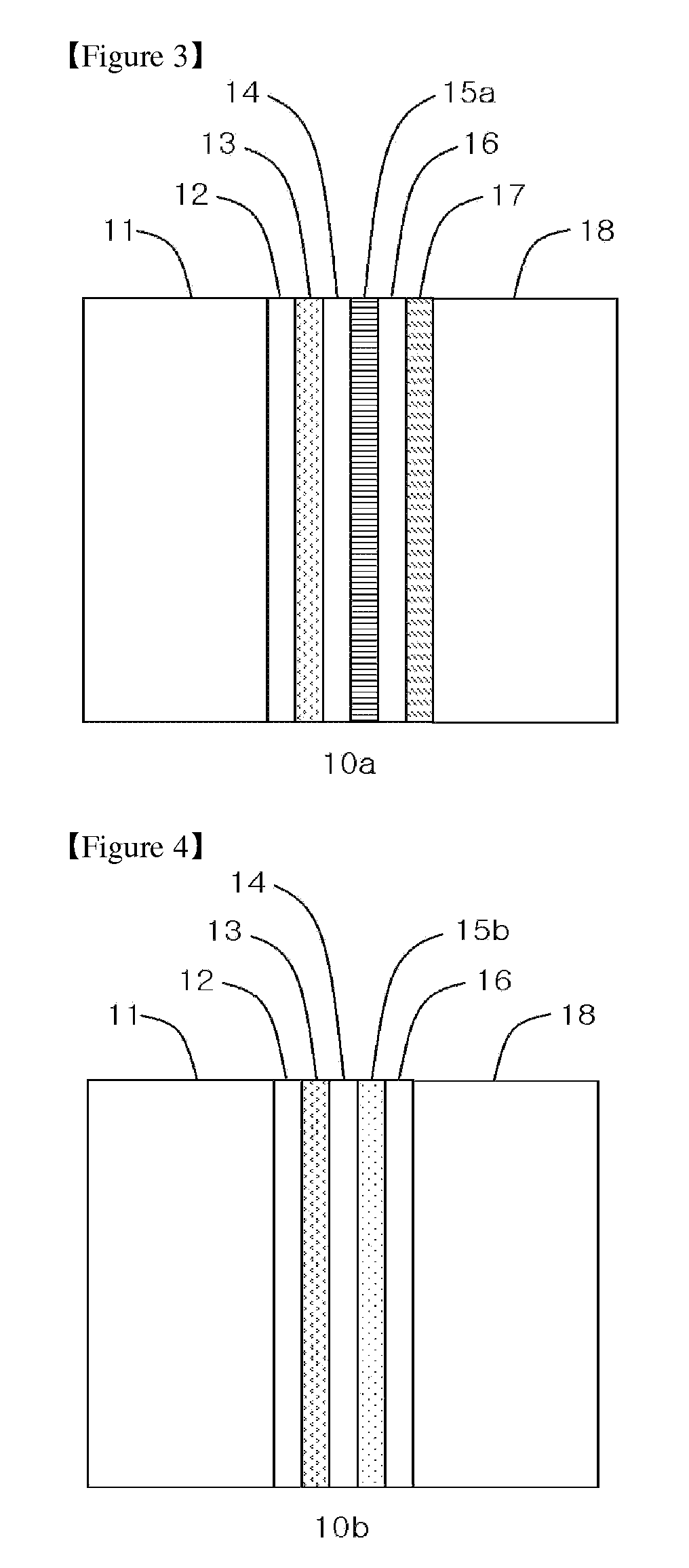

Disposable Atomizer of Electronic Cigarette

The invention discloses a disposable atomizer of an electronic cigarette, comprising a battery component and an atomizer, wherein the atomizer comprises an atomizer cover, a rubber sleeve, an atomizer sleeve, a tobacco tar cotton, two wires, a heating wire, a rubber pad, a threaded sleeve, a propping pin, a first fibre pipe, a tar guide rope and a second fibre pipe; the heating wire is connected with one ends of both wires, and each of the other ends of the wires is fixedly connected with the propping pin; the heating wire and the tar guide rope are wound around together; the first fibre pipe is arranged in the tar guide rope, the second fibre pipe and the first fibre pipe are coaxially arranged, and the second fibre pipe is positioned behind the first fibre pipe; both the tar guide rope and the second fibre pipe are arranged in the tobacco tar cotton, and both the tobacco tar cotton and the threaded sleeve are arranged in the atomizer sleeve; the atomizer cover is arranged at the tail end of the atomizer sleeve; and the rubber sleeve is arranged in the atomizer sleeve and positioned between the second fibre pipe and the atomizer cover. So that the disposable atomizer of an electronic cigarette has the advantages of simple production process, high production efficiency and low labor cost.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

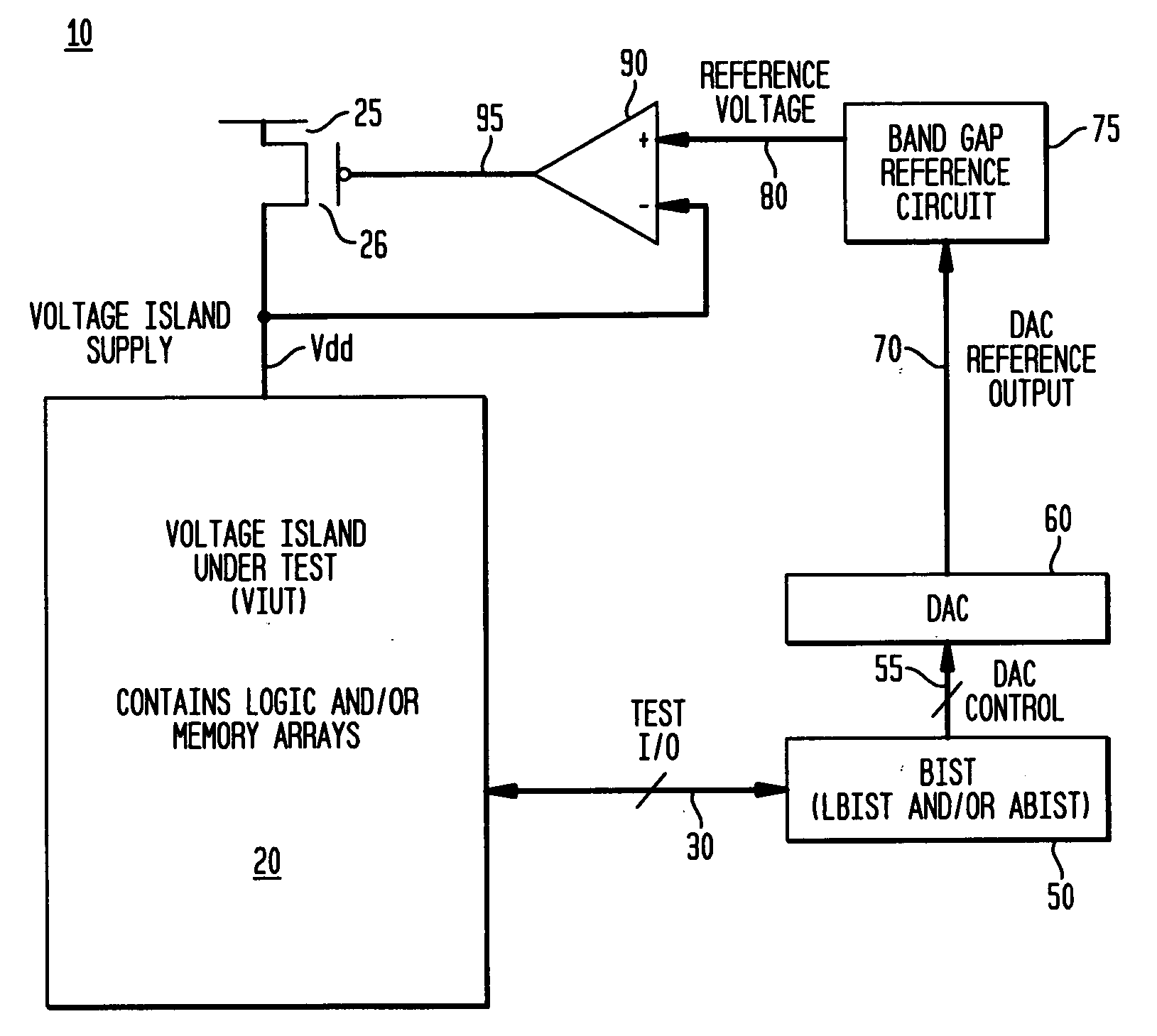

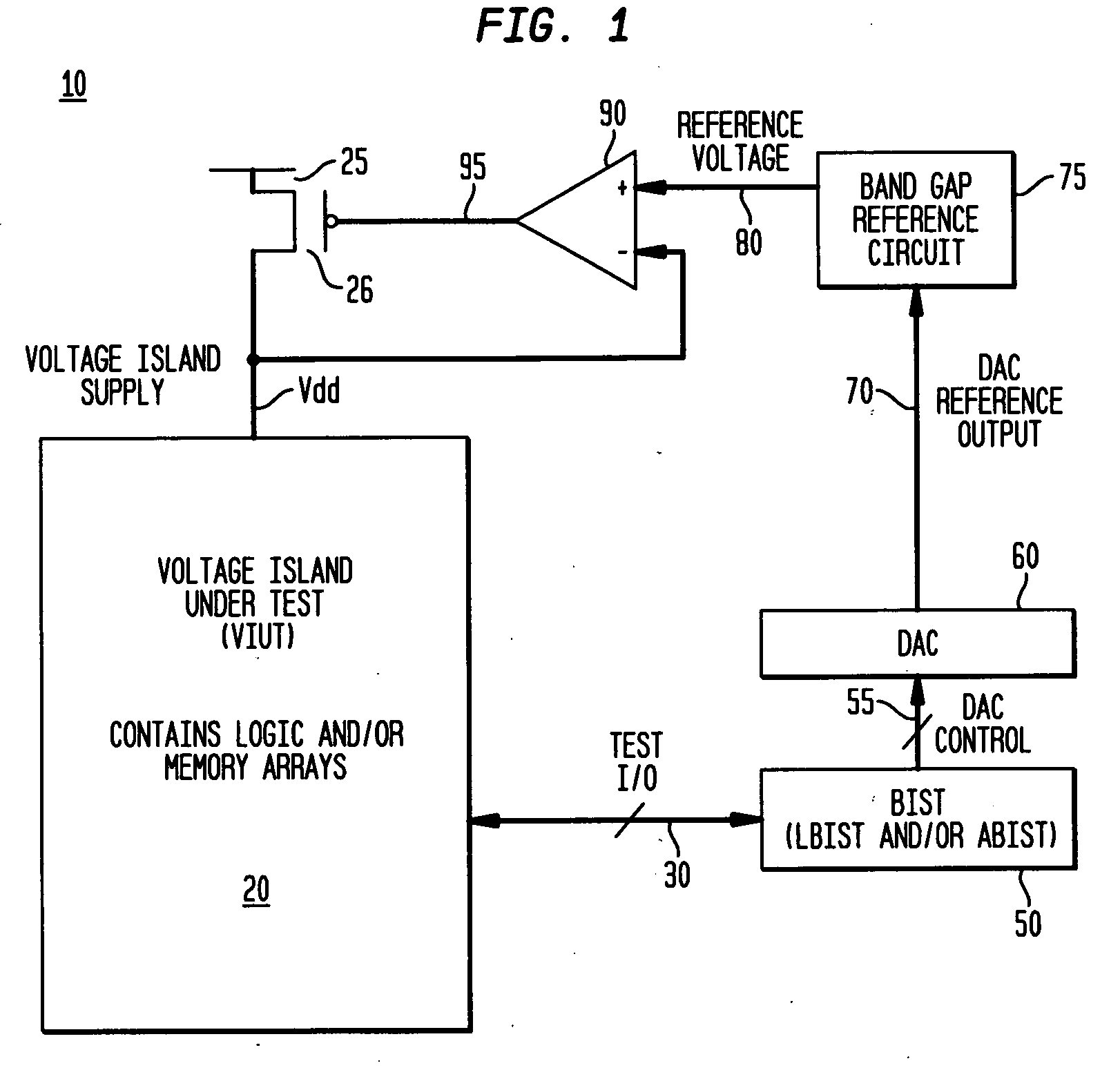

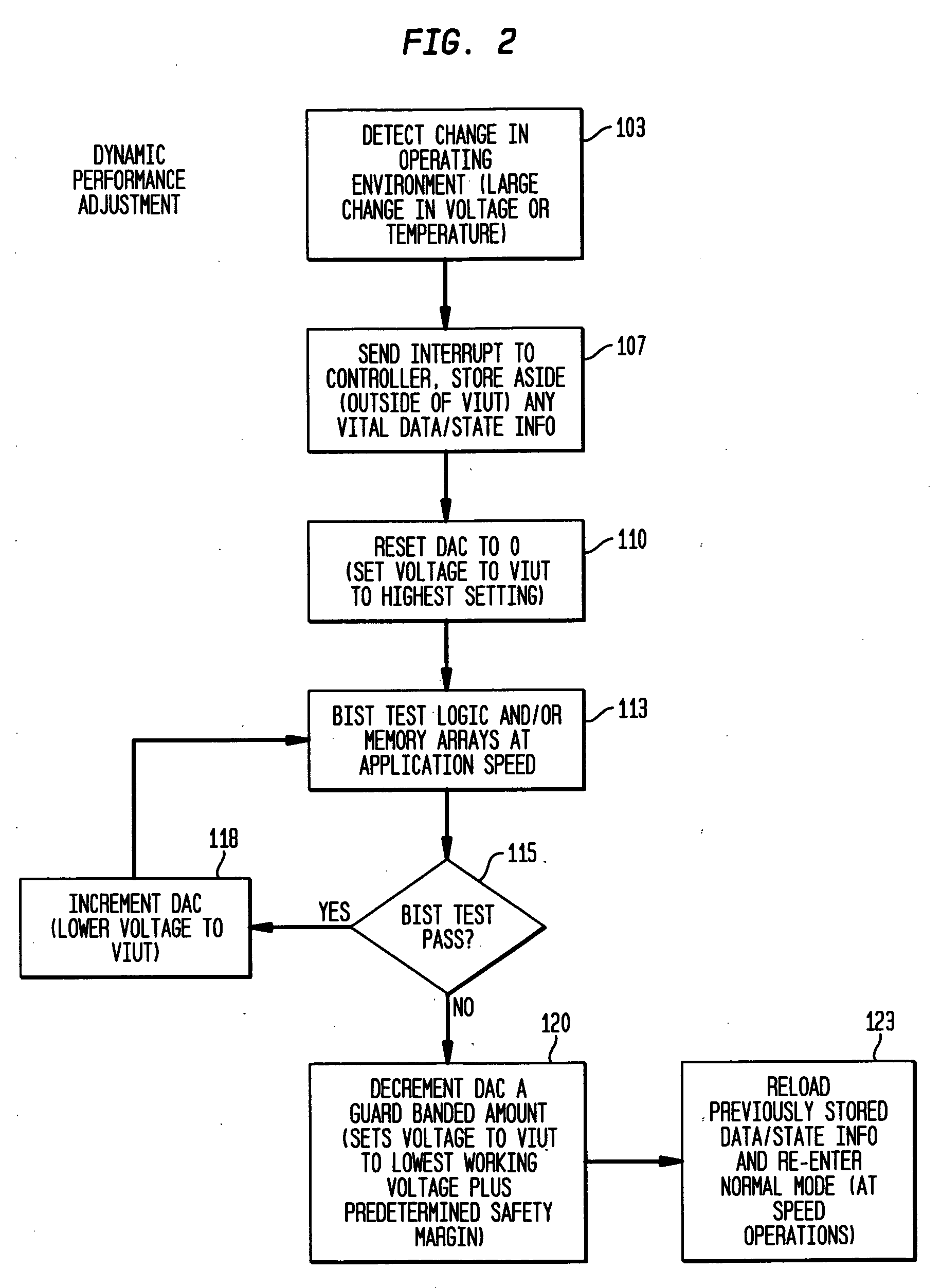

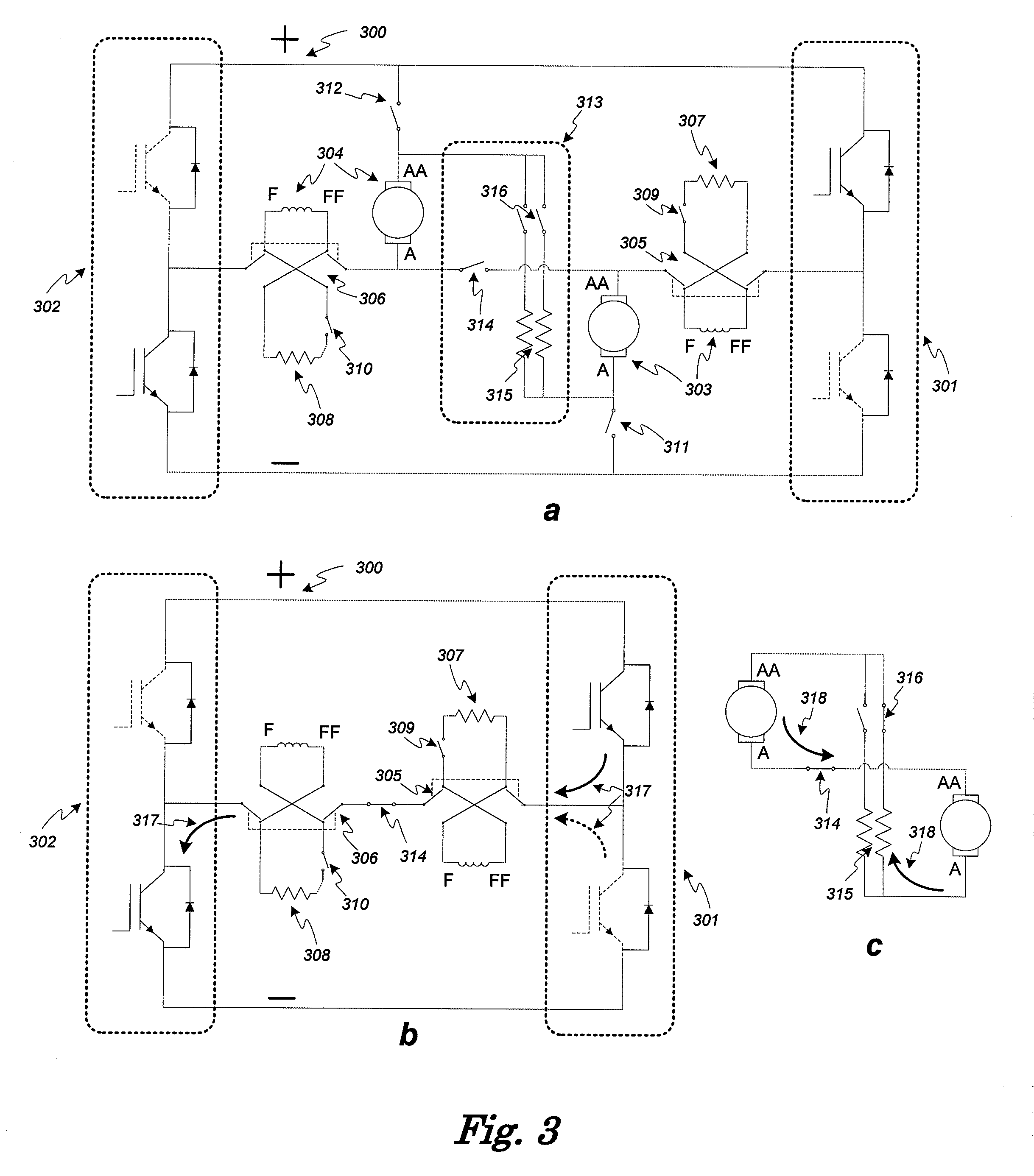

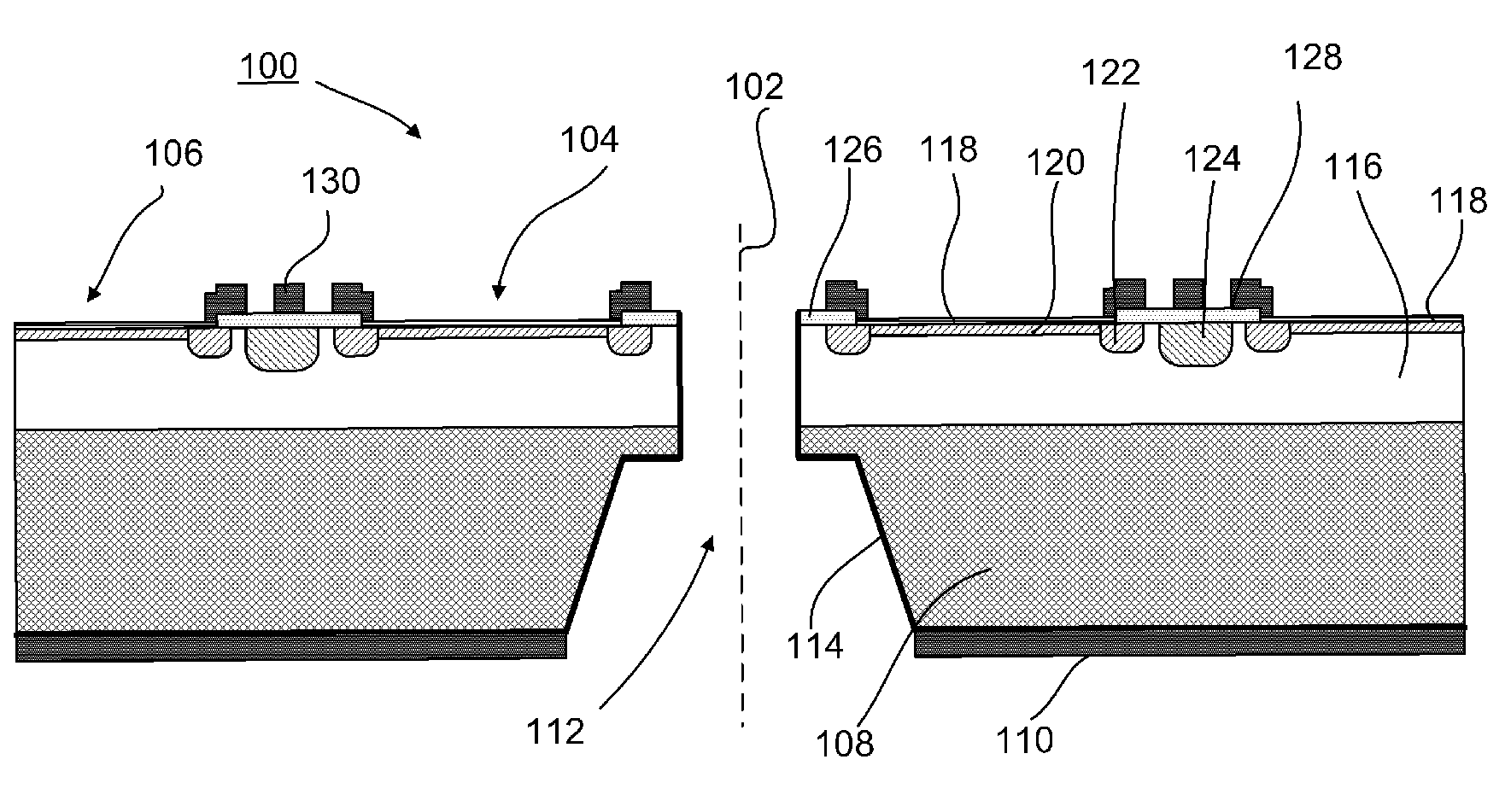

Self-test circuitry to determine minimum operating voltage

InactiveUS20060259840A1Reduce power consumptionMaintaining at-application speed performanceMarginal circuit testingTest flowVoltage source

A solution for determining minimum operating voltages due to performance / power requirements would be valid for a wide range of actual uses. The solution includes a test flow methodology for dynamically reducing power consumption under applied conditions while maintaining application performance via a BIST circuit. There is additionally provided a test flow method for dynamically reducing power consumption to the lowest possible stand-by / very low power level under applied conditions that will still be sufficient to maintain data / state information. One possible application would be for controlling the voltage supply to a group of particular circuits on an ASIC (Application Specific Integrated Circuit). These circuits are grouped together in a voltage island where they would receive a voltage supply that can be different from the voltage supply other circuits on the same chip are receiving. The same solution could be applied to a portion of a microprocessor (the cache logic control, for example).

Owner:IBM CORP

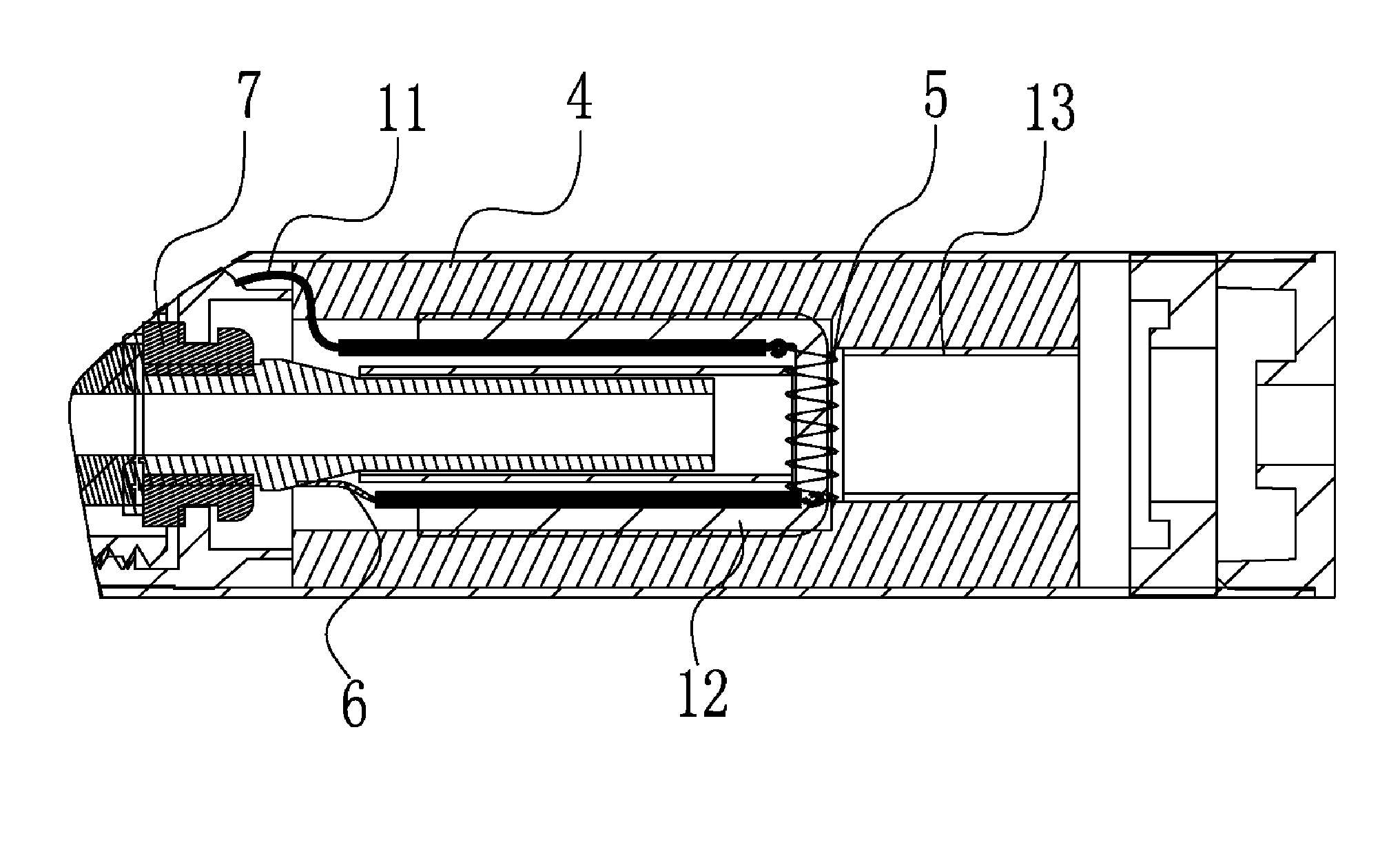

Disposable atomizer of electronic cigarette

The invention discloses a disposable atomizer of an electronic cigarette, comprising a battery component and an atomizer, wherein the atomizer comprises an atomizer cover, a rubber sleeve, an atomizer sleeve, a tobacco tar cotton, two wires, a heating wire, a rubber pad, a threaded sleeve, a propping pin, a first fiber pipe, a tar guide rope and a second fiber pipe; the heating wire is connected with one ends of both wires, and each of the other ends of the wires is fixedly connected with the propping pin; the heating wire and the tar guide rope are wound around together; the first fiber pipe is arranged in the tar guide rope, the second fiber pipe and the first fiber pipe are coaxially arranged, and the second fiber pipe is positioned behind the first fiber pipe; both the tar guide rope and the second fiber pipe are arranged in the tobacco tar cotton, and both the tobacco tar cotton and the threaded sleeve are arranged in the atomizer sleeve; the atomizer cover is arranged at the tail end of the atomizer sleeve; and the rubber sleeve is arranged in the atomizer sleeve and positioned between the second fiber pipe and the atomizer cover. So that the disposable atomizer of an electronic cigarette has the advantages of simple production process, high production efficiency and low labor cost.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

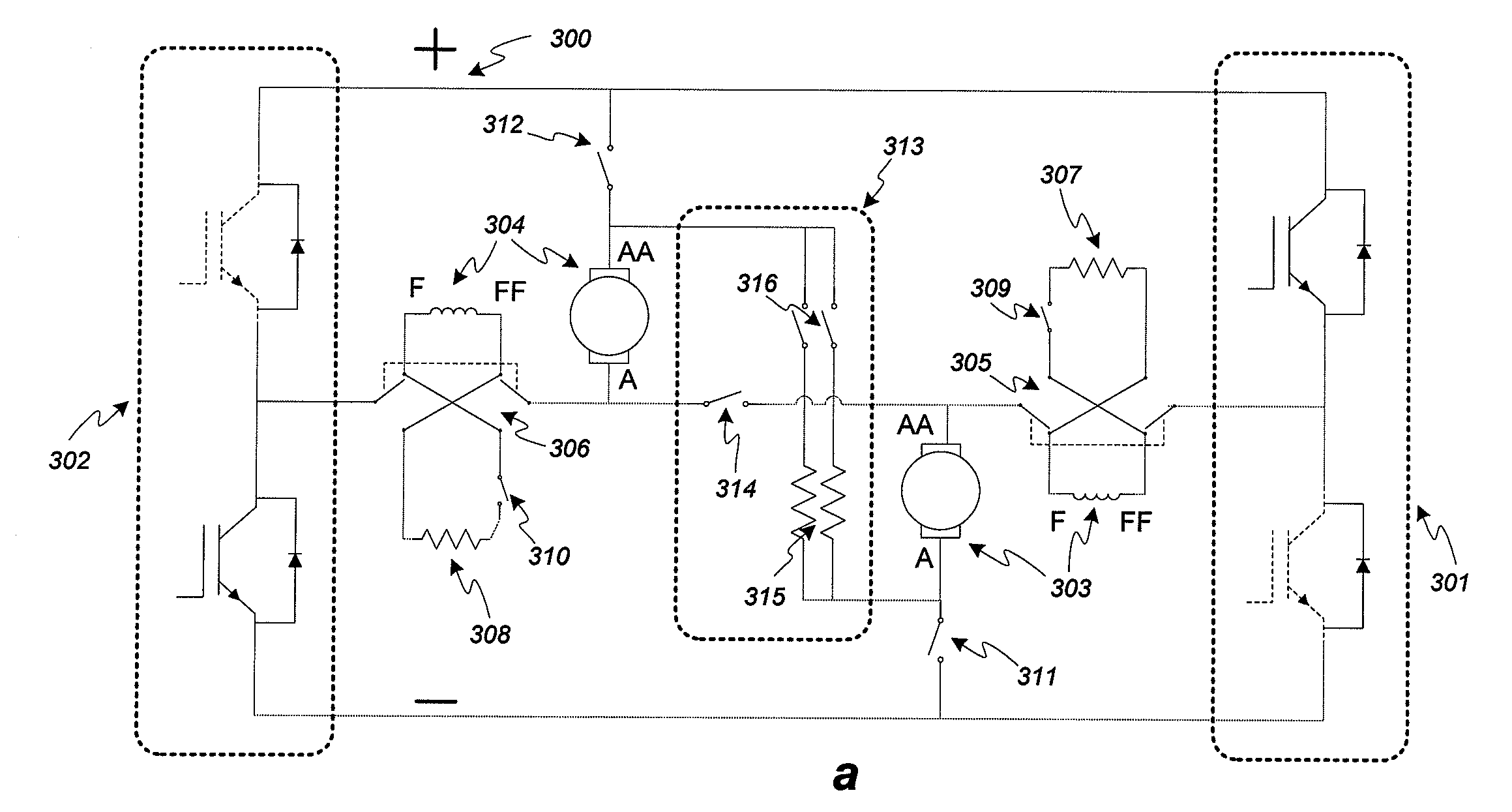

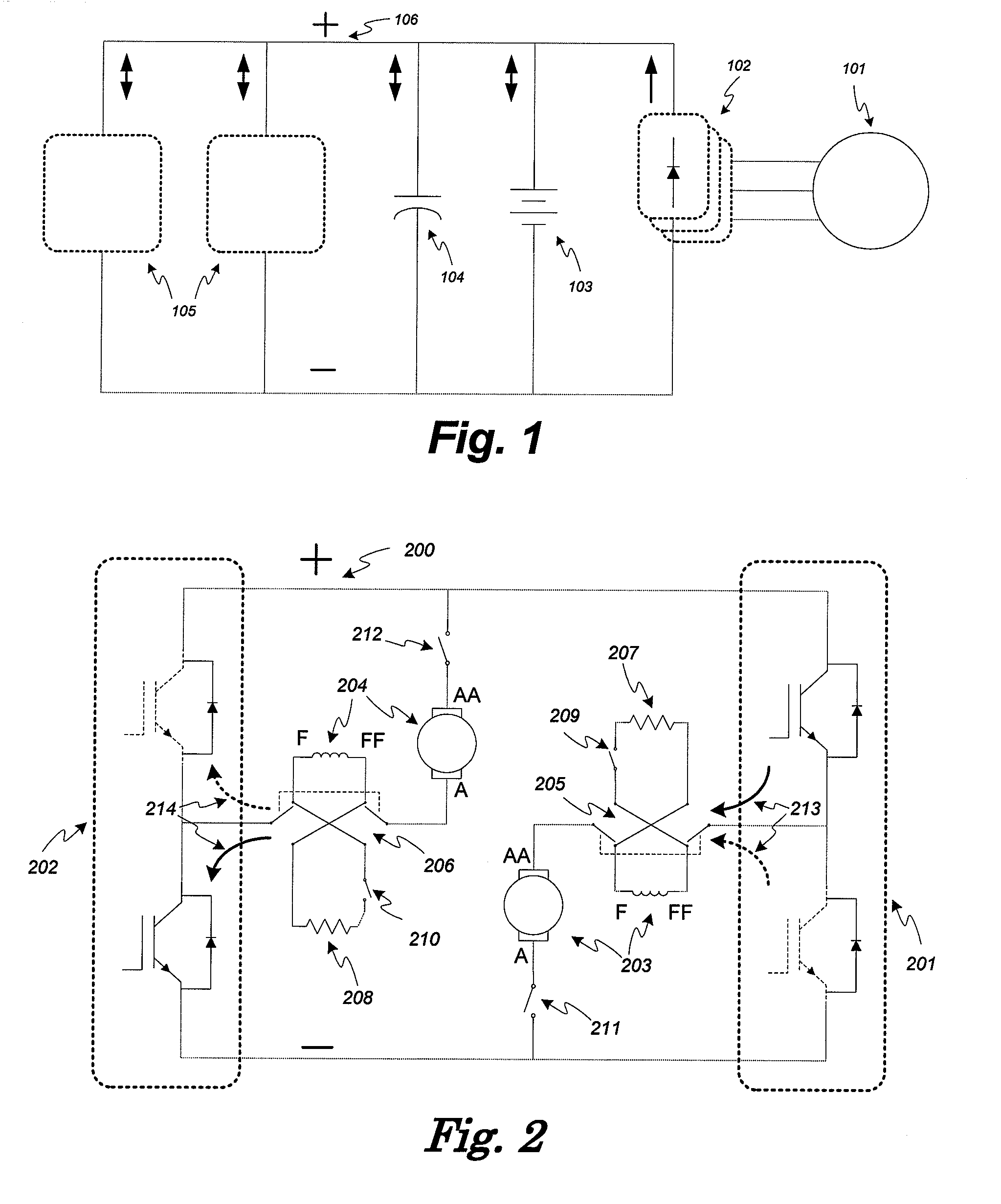

Power architecture and braking circuits for DC motor-propelled vehicle

InactiveUS20080290825A1Fast tractionAvoid developmentElectric devicesElectrodynamic brake systemsLow speedExcitation current

A dynamic braking circuit that can be operated with stability over both high and low speed regimes. This circuit has the advantage of using fewer components than previous circuits. In addition, when in braking mode, the armature and field currents tend to oppose each other across the main braking switch hence reducing electromechanical stresses when in high current regime. According to a second embodiment, a dynamic braking circuit implements a “soft” extended braking function with the capability of providing a smoother braking action at high braking effort at little extra cost resulting from the replacement of a contactor by a reverser. The main advantages of this preferred embodiment are that the current generated by the armatures during braking can be controlled independently from the excitation of the field windings at low speeds and that it enables simultaneous self supply, regeneration and dynamic braking.

Owner:RAILPOWER LLC

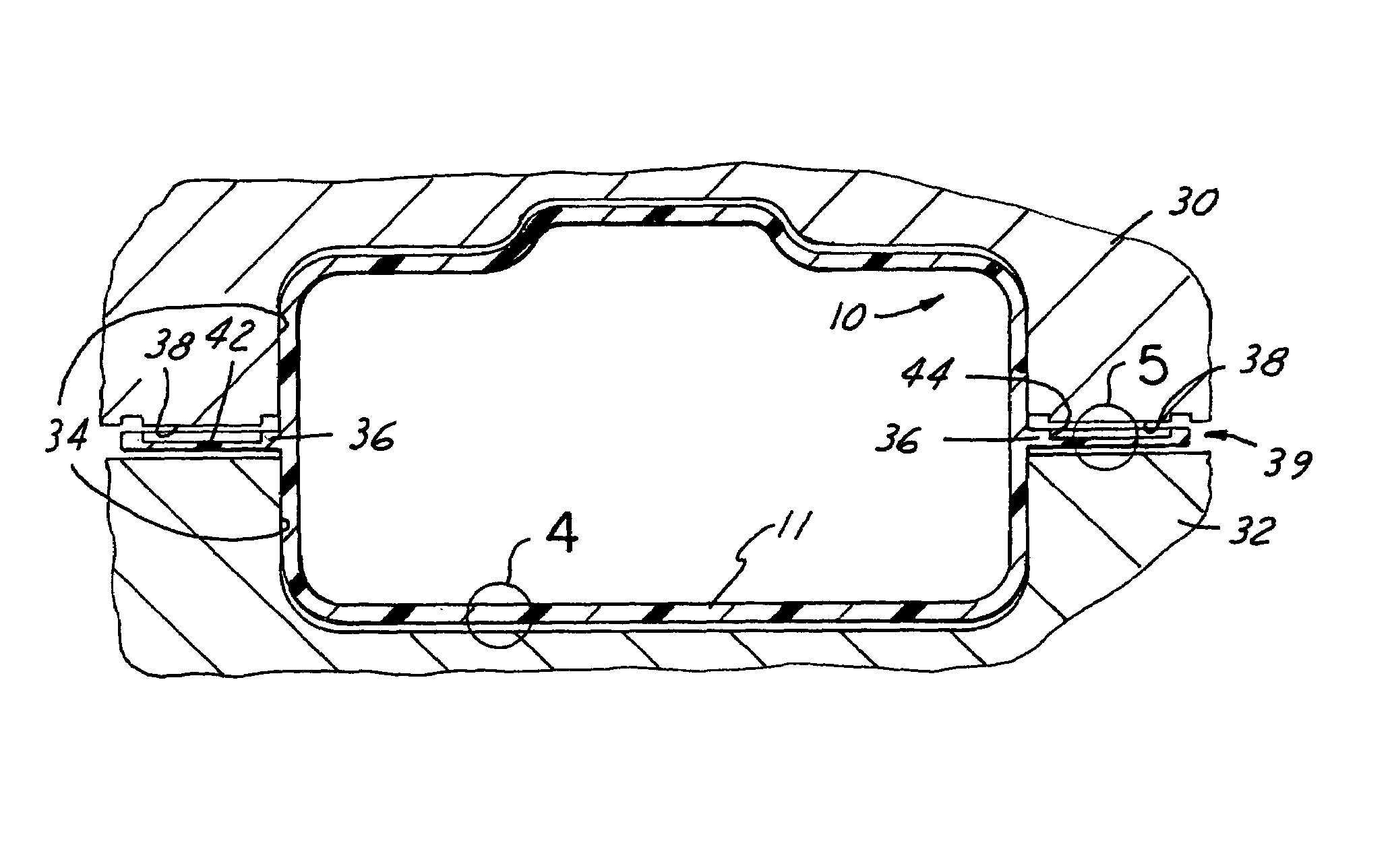

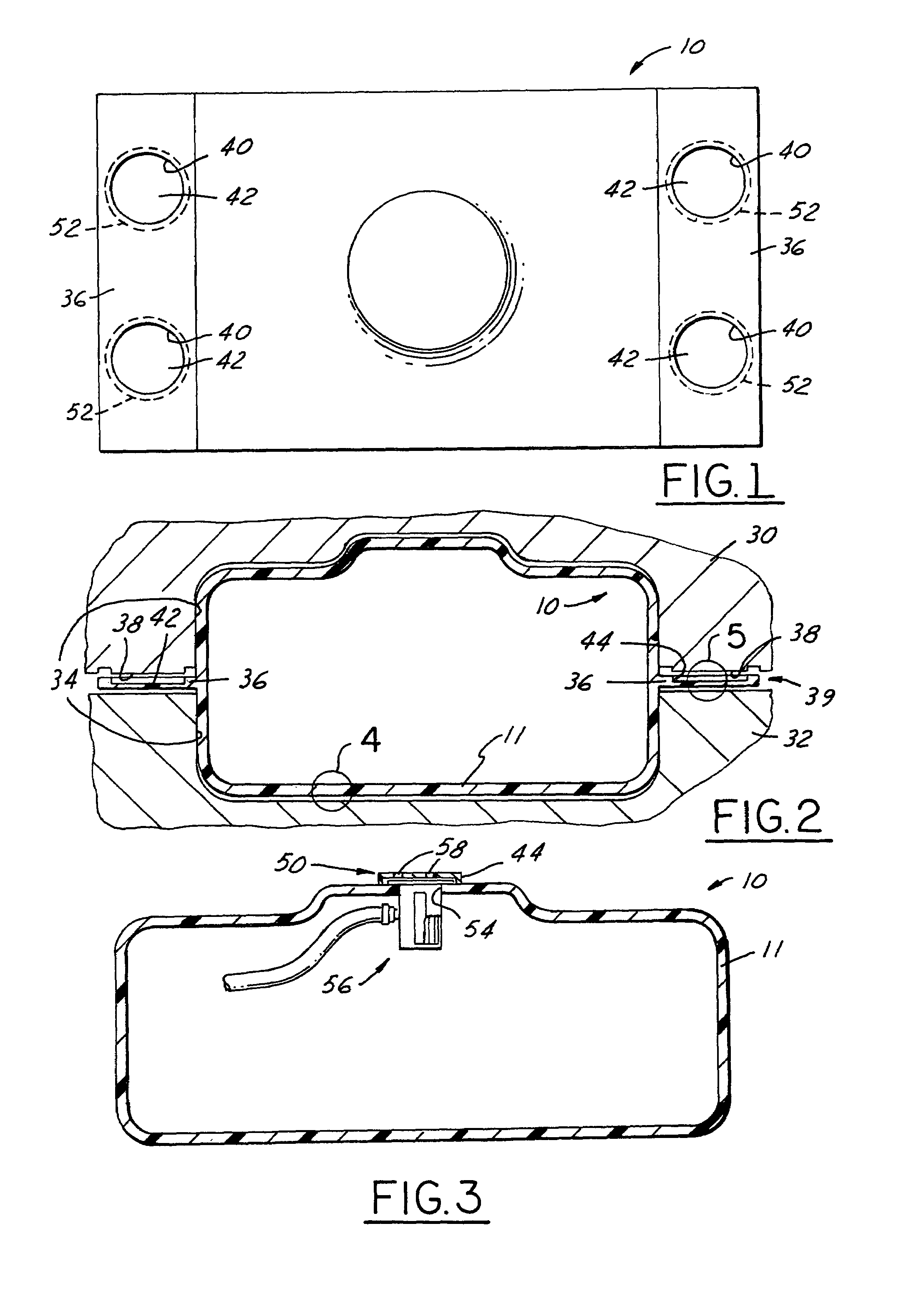

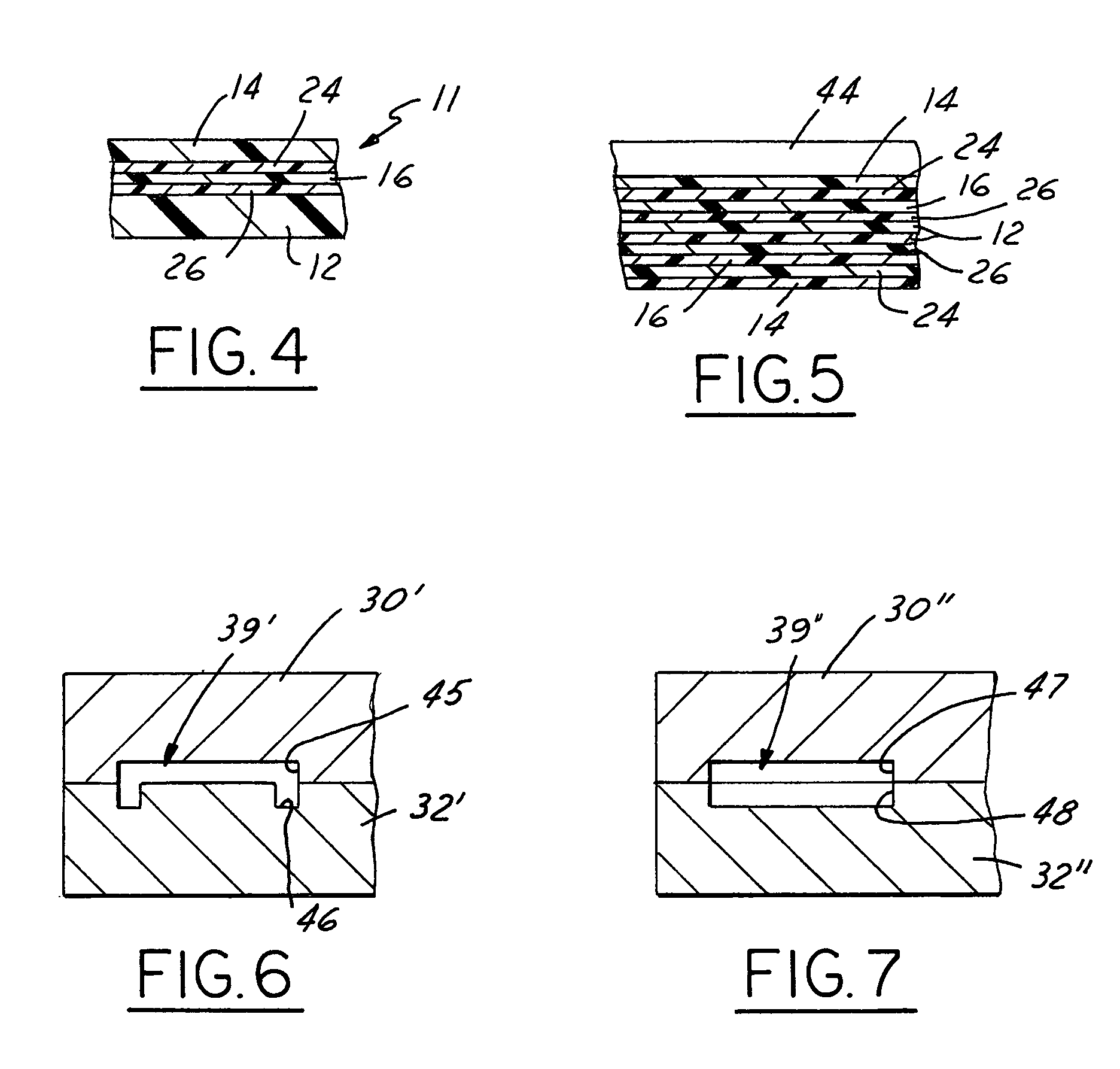

Multiple layer polymeric cap and method of making the same

A cap is formed within the flash of a molded polymeric article. Desirably, the material of the flash, and hence the cap, has the same properties as the molded article. In one embodiment, the molded article is a multi-layer plastic fuel tank having a vapor barrier layer sandwiched between structural and / or adhesive layers and the cap has the same general construction and may be fixed or welded to the fuel tank over an opening through the tank. Advantageously, the cap is formed in the same process used to form the molded article and reduces the scrap or waste material by utilizing a portion of the flash which is removed from the molded article after it is formed. Therefore, the cost and time to produce a molded article and one or more caps is greatly reduced.

Owner:TI GRP AUTOMOTIVE SYST LLC

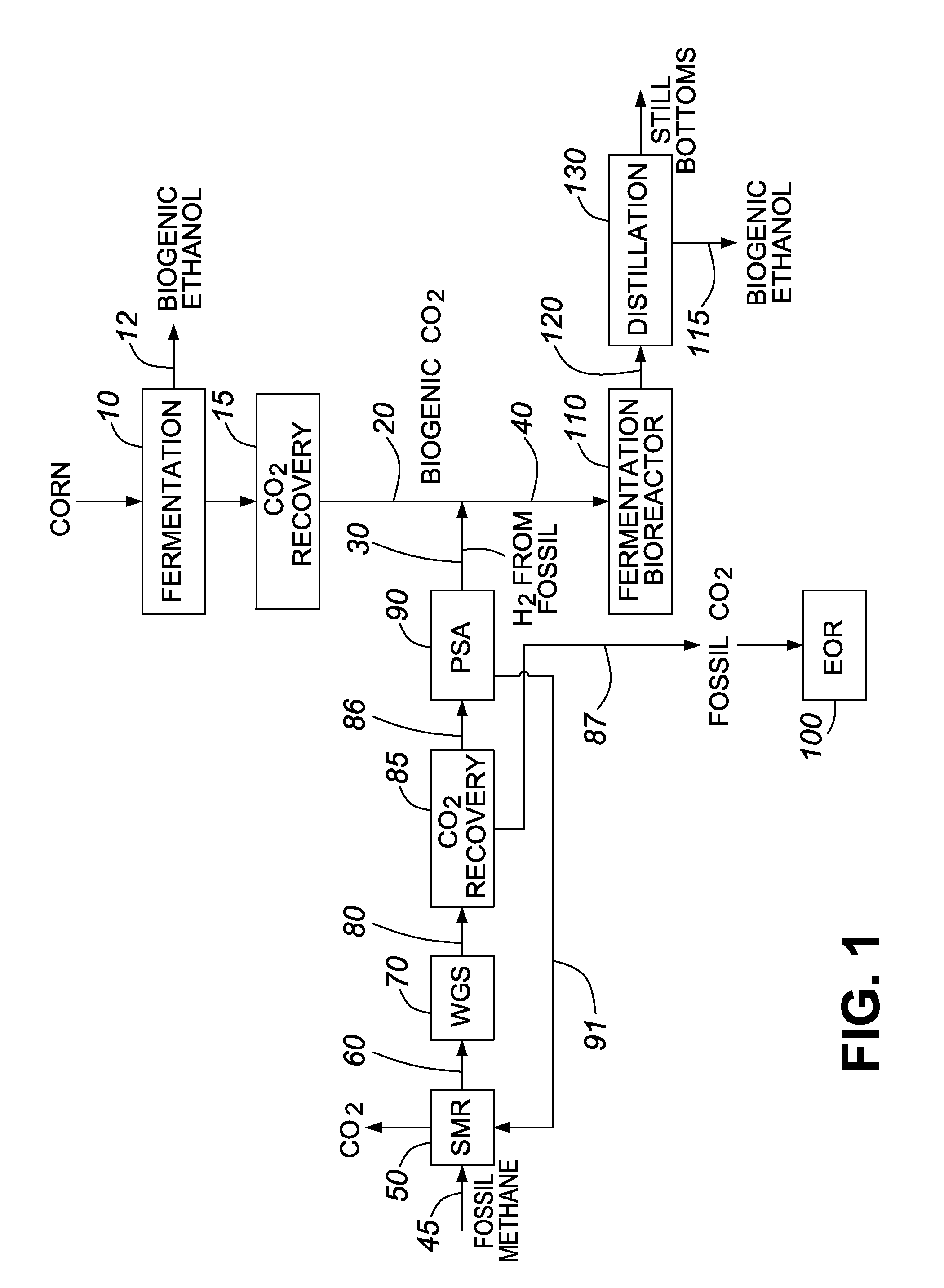

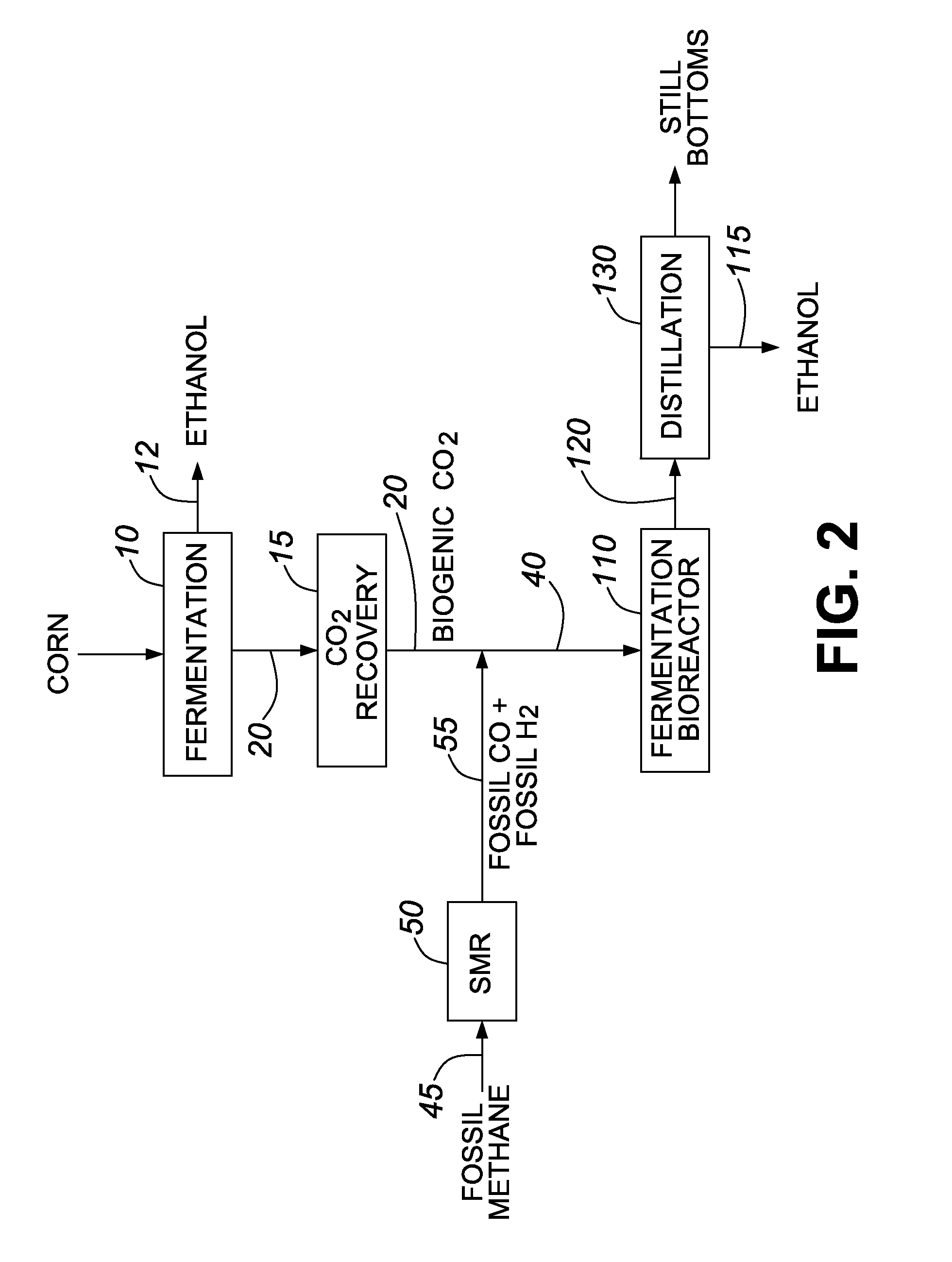

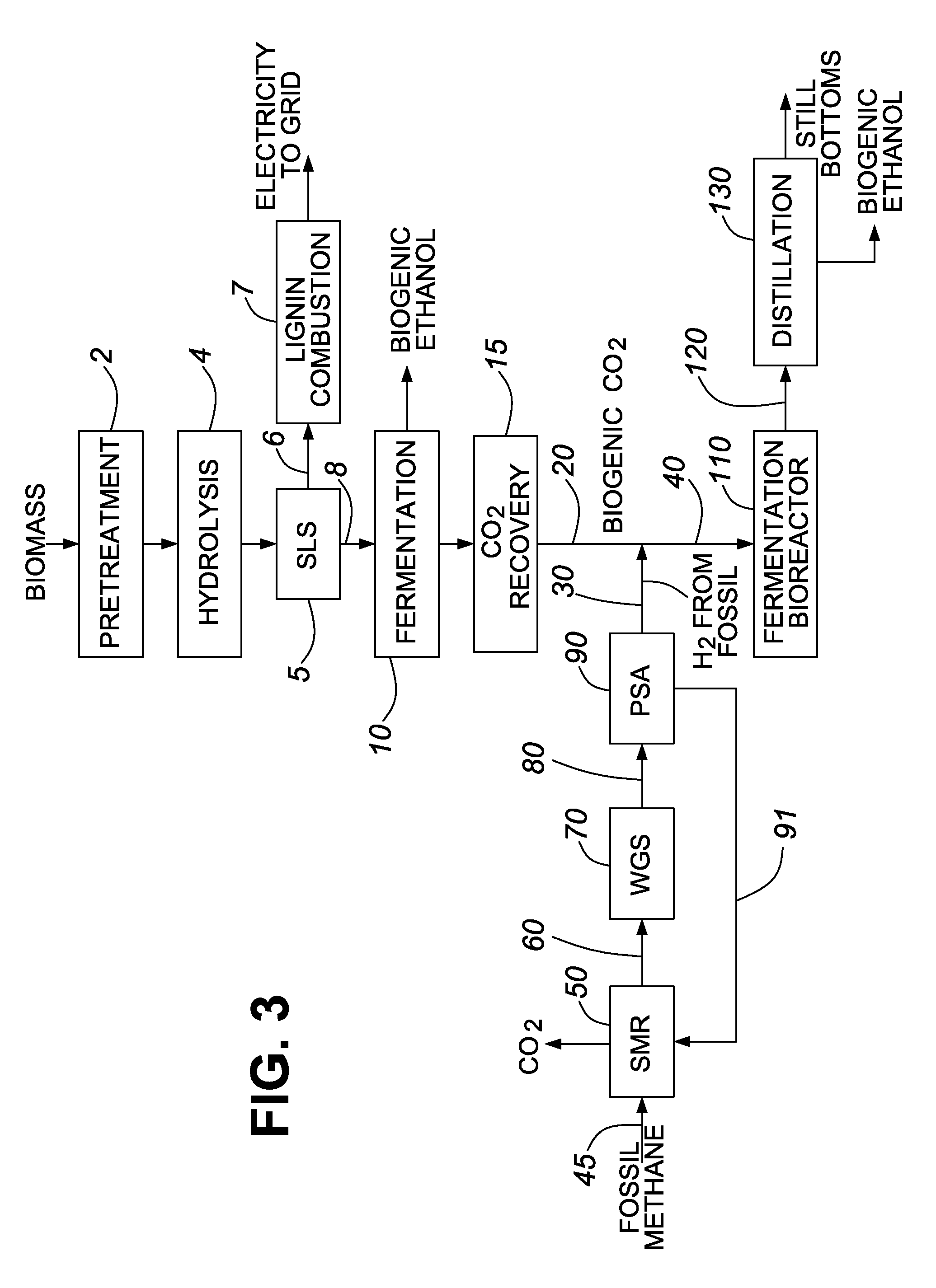

Process for using biogenic carbon dioxide derived from non-fossil organic material

ActiveUS9108894B1Improve production yieldProduce moreCarbon compoundsBiofuelsEnergy productsHydrogen

The present disclosure provides a process for forming a biogenic carbon-based fuel or a fuel intermediate from biogenic carbon dioxide and hydrogen. The hydrogen is sourced from a process that produces hydrogen and fossil carbon dioxide from a fossil-fuel hydrocarbon and separates the fossil carbon dioxide from the hydrogen. The process may further comprise carrying out or arranging for one or more parties to carry out at least one step that contributes to a reduction in the GHG emissions of the biogenic carbon-based fuel, or a fuel made from the fuel intermediate, of at least 20% relative to a gasoline baseline. In various embodiments this includes (a) introducing the fossil carbon dioxide underground, and / or (b) using a biogenic carbon-based product selected from a chemical and energy product produced from the non-fossil organic material to displace the use or production of a corresponding fossil-based product. Methods of using the present invention to enable fuel credit generation are also described.

Owner:IOGEN CORPORATION

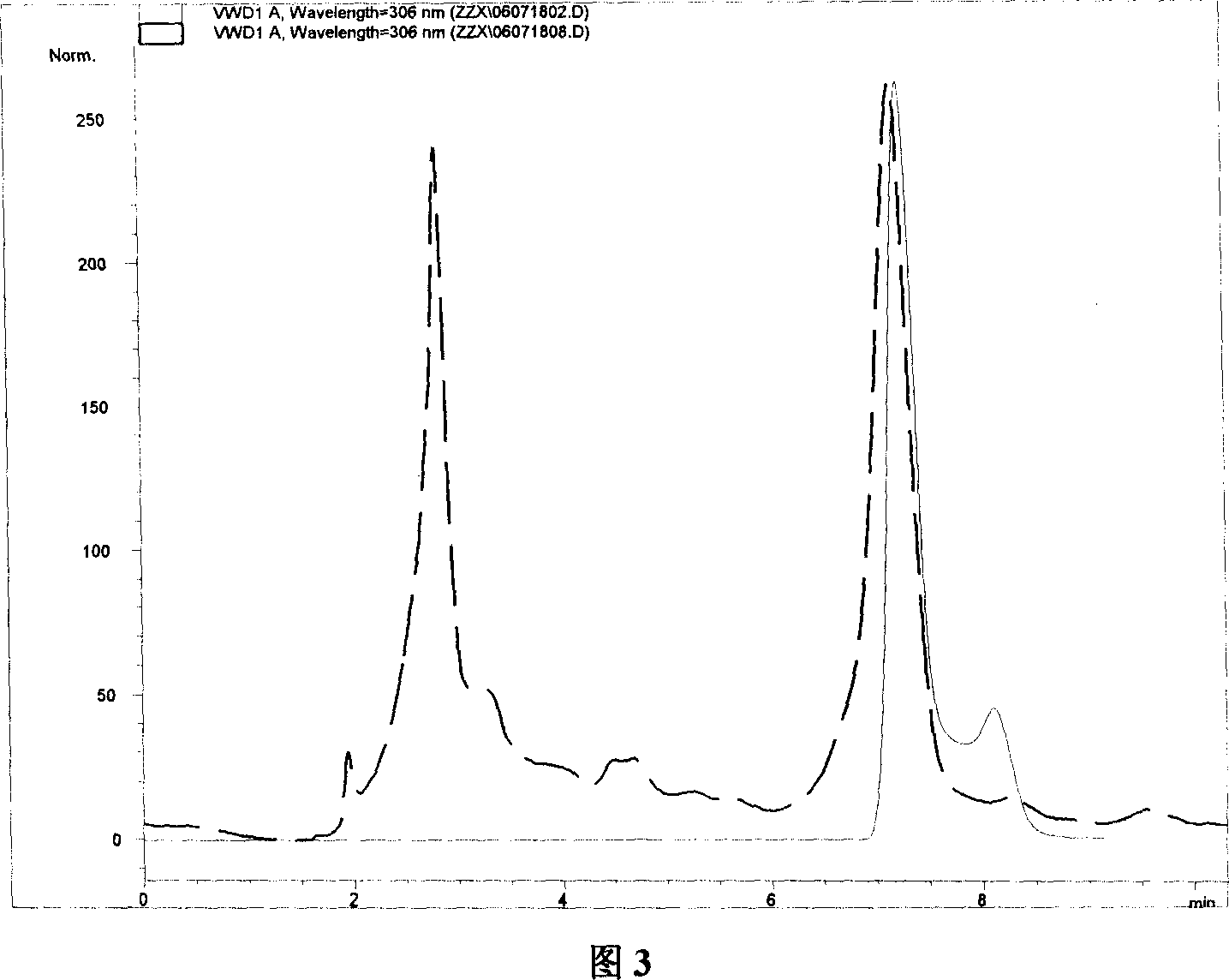

Cladosporium endogenic fungus capable of producing veralkol

This invention has clone Stilbene synthase gene (sts) from Parthenocissi Tricuspidatae endogeny eumycete, the coding sequence similarity between Stilbene synthase gene and Parthenocissi Tricuspidatae is 95.25%,this eumycete belongs to Cladosporium sp by 18SrDNA series assessment. High performance liquid chromatogram and mass chromatographic analysis indicate that this eumycete can also composite resveratrol by culture in vitro. The analysis about non- coding part of endogeny eumycete sts gene indicates that: it is very different from regulatory element of sts gene which is in plants. Importing exogenous gene(such as VHb,ipt and iaaM and so on ) in endogeny eumycete can promote endogeny eumycete growing.

Owner:林忠平

Alkali-free chloride-free liquid concrete enhancer and preparation method thereof

The invention relates to an alkali-free chloride-free liquid concrete enhancer and a preparation method thereof, wherein the enhancer mainly comprises the following materials according to weight percentages: 20-80% of anhydrous aluminum sulfate, 5-20% of triethanolamine, 0-0.2% of stabilizer, and 15-60% of water. The concrete enhancer is lower in cost, the preparation process is simple, the production of the ettringite in the early stage is increased when the concrete enhancer is added into a concrete mixture, so that more chemical bonds with stronger binding forces are produced among cement hydration particles, the Van der Waals' force is replaced the binding force of a cementing material is increased, the strength of the cement and concrete is reached, the quality and the property of the concrete material are improved, and the amount of consumed concrete cement is reduced.

Owner:LUOYANG INST OF SCI & TECH

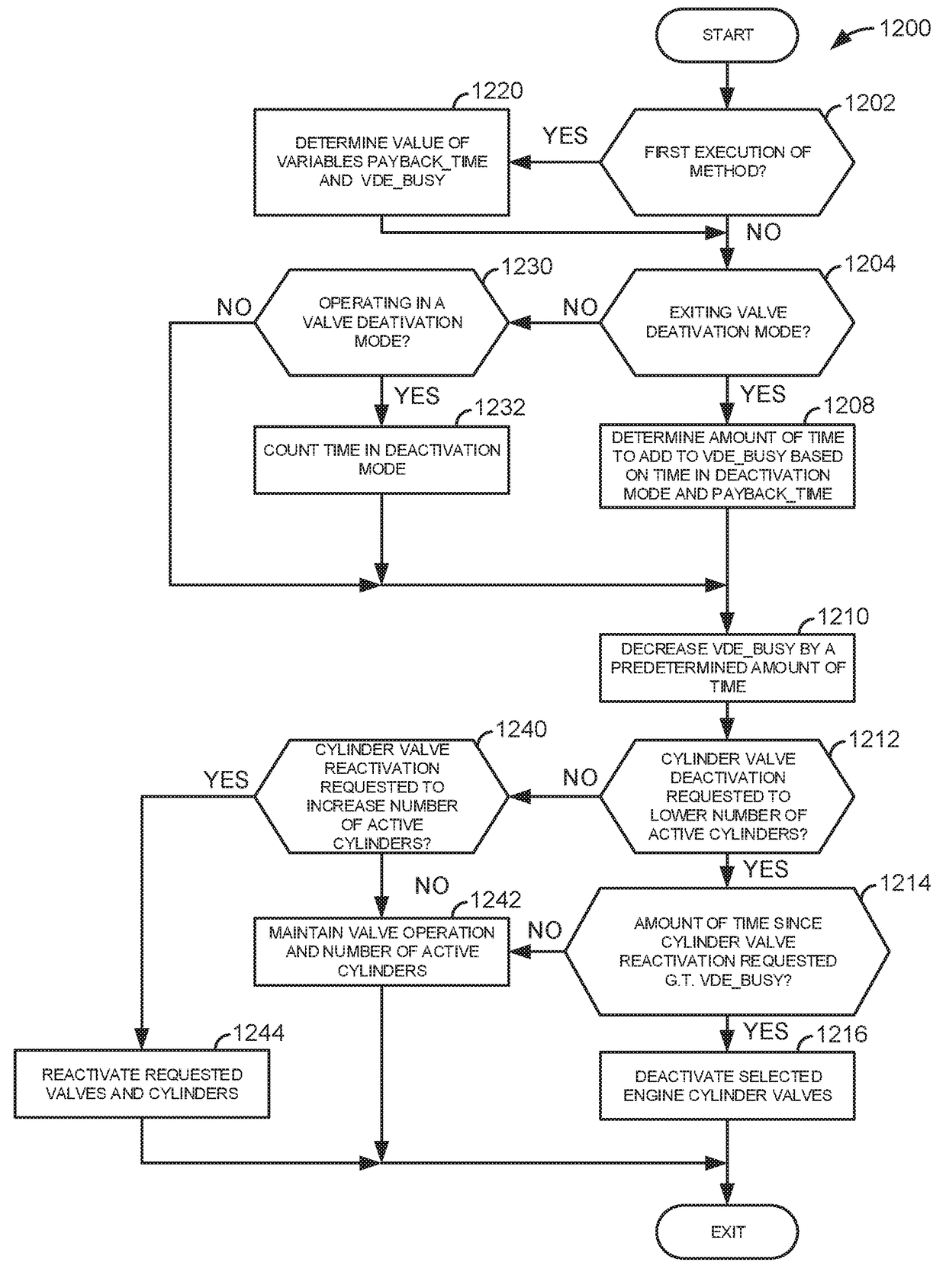

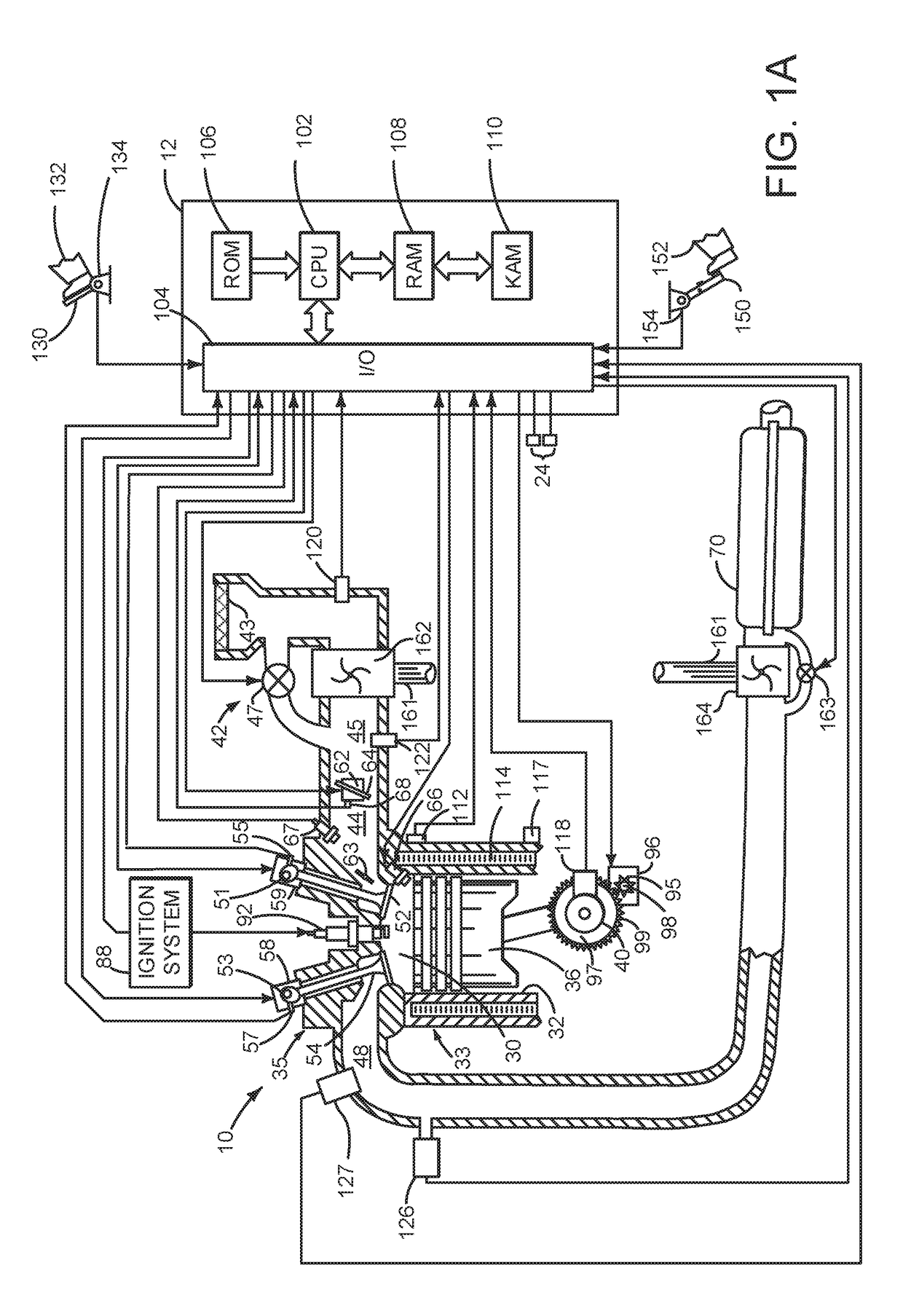

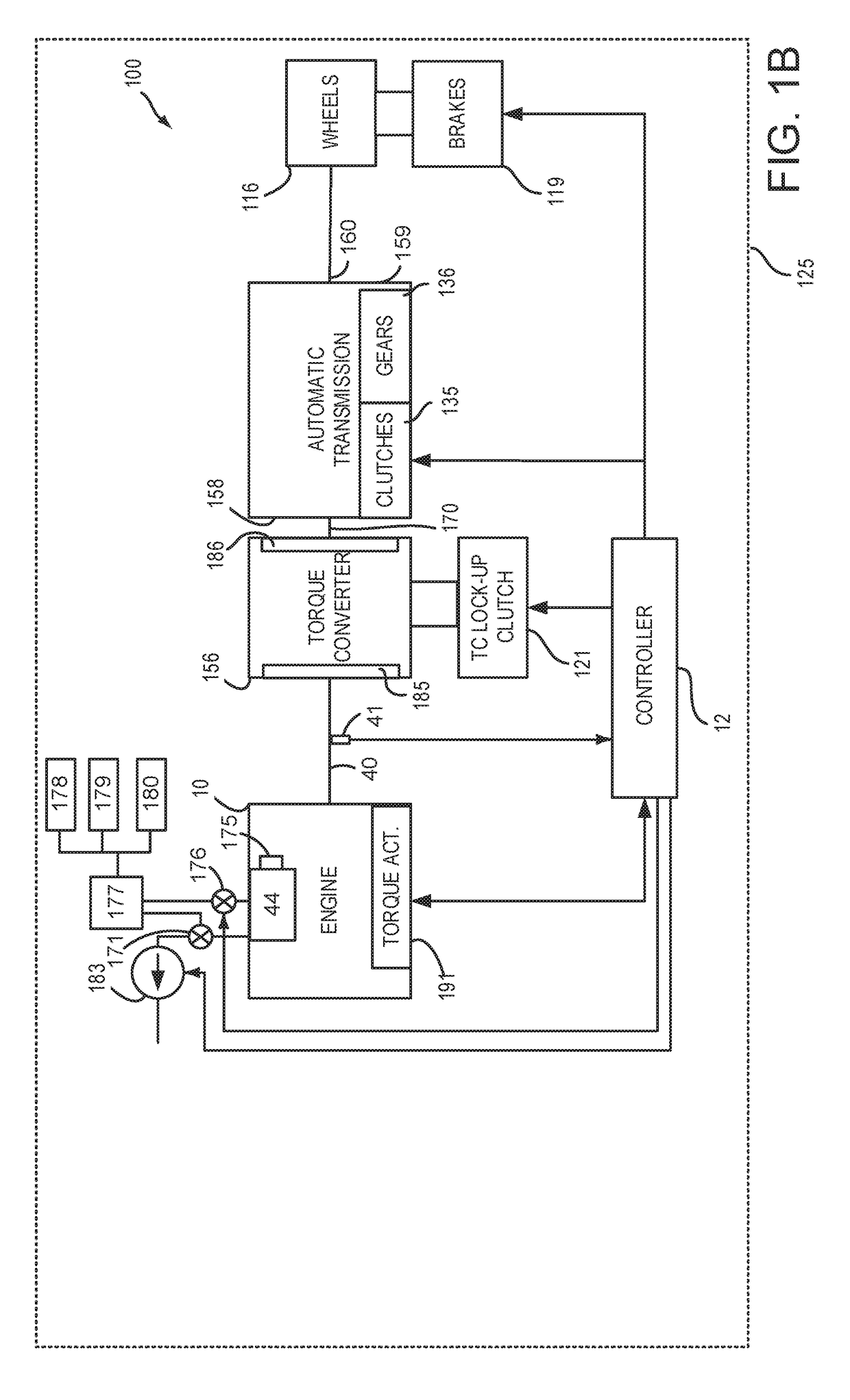

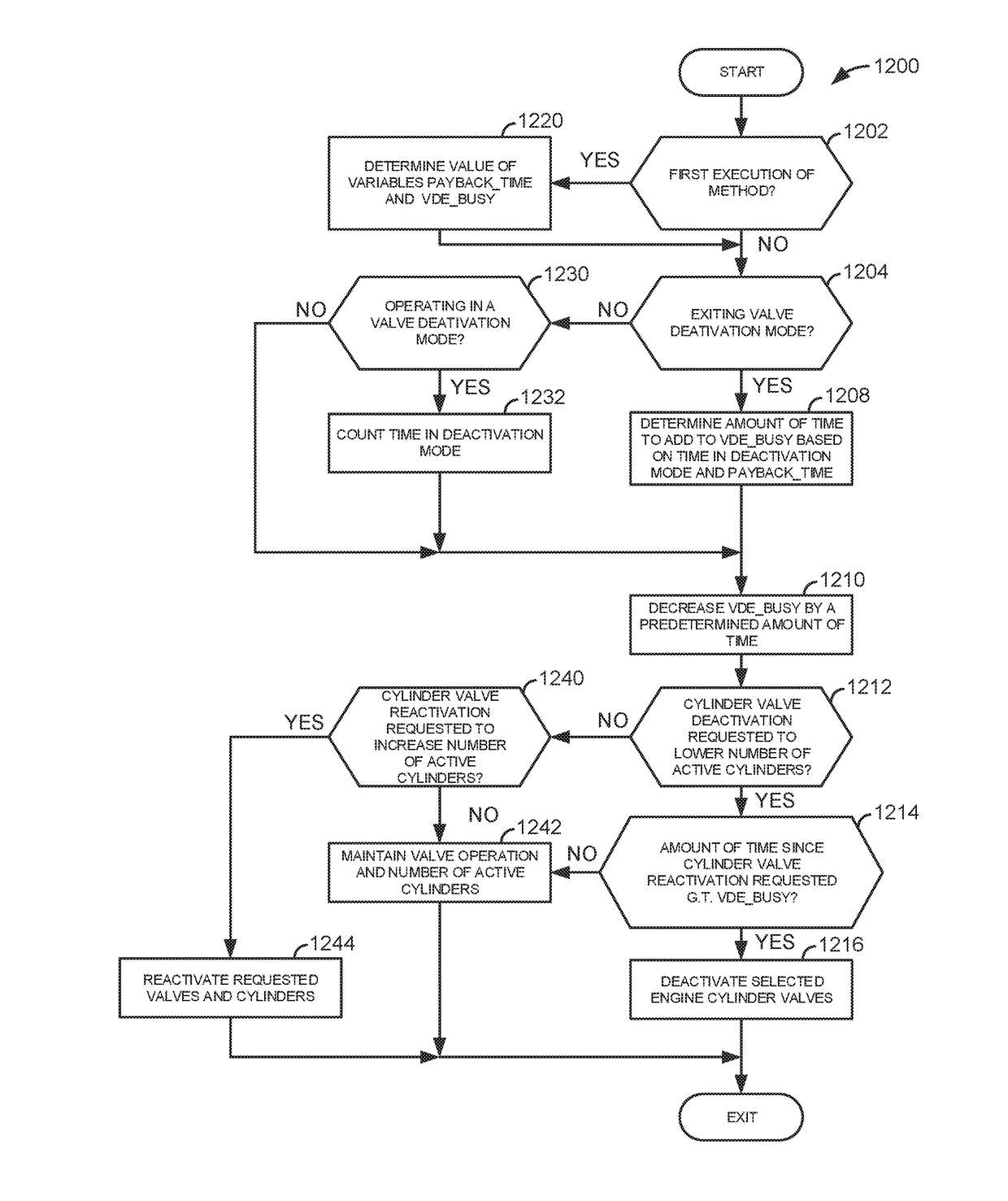

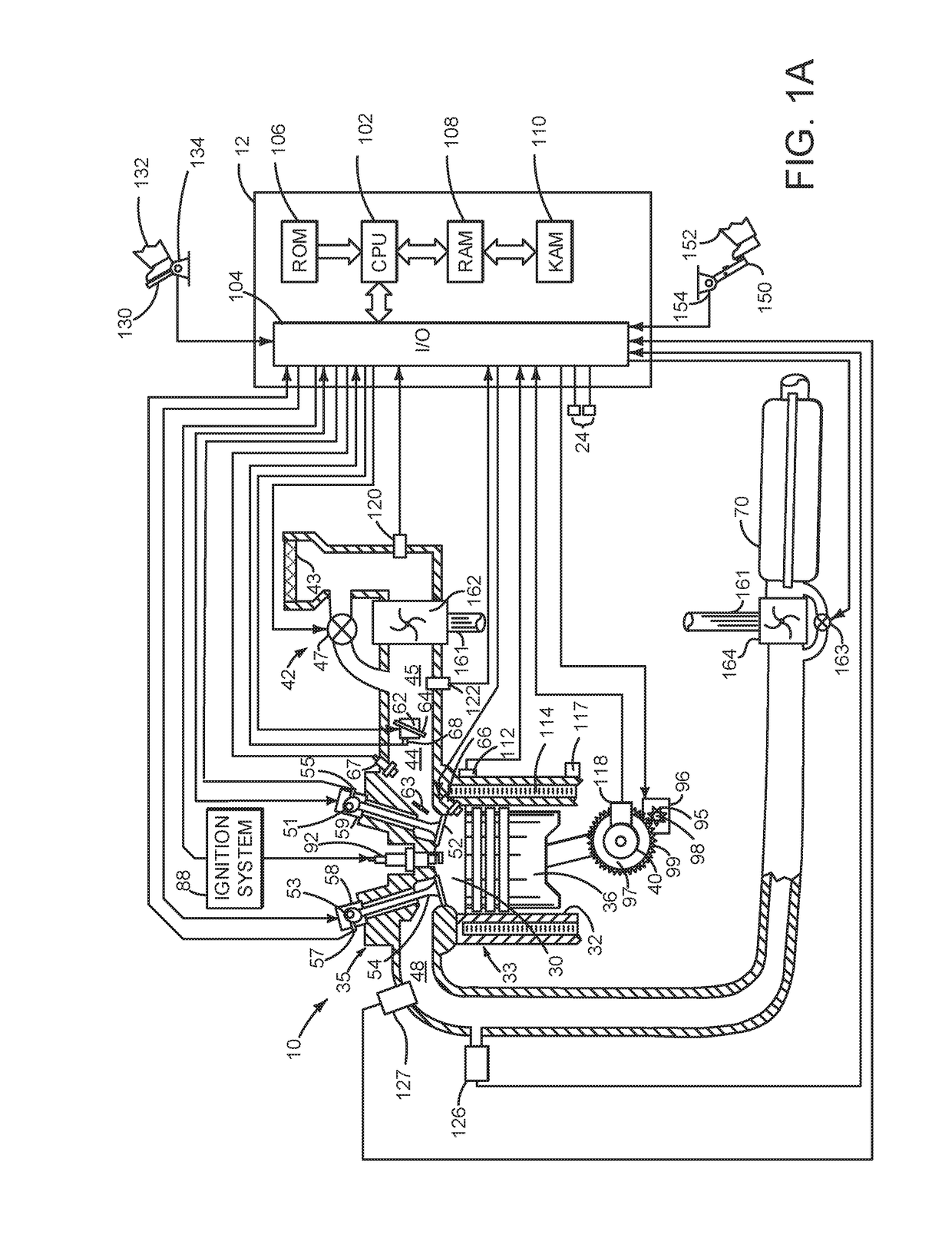

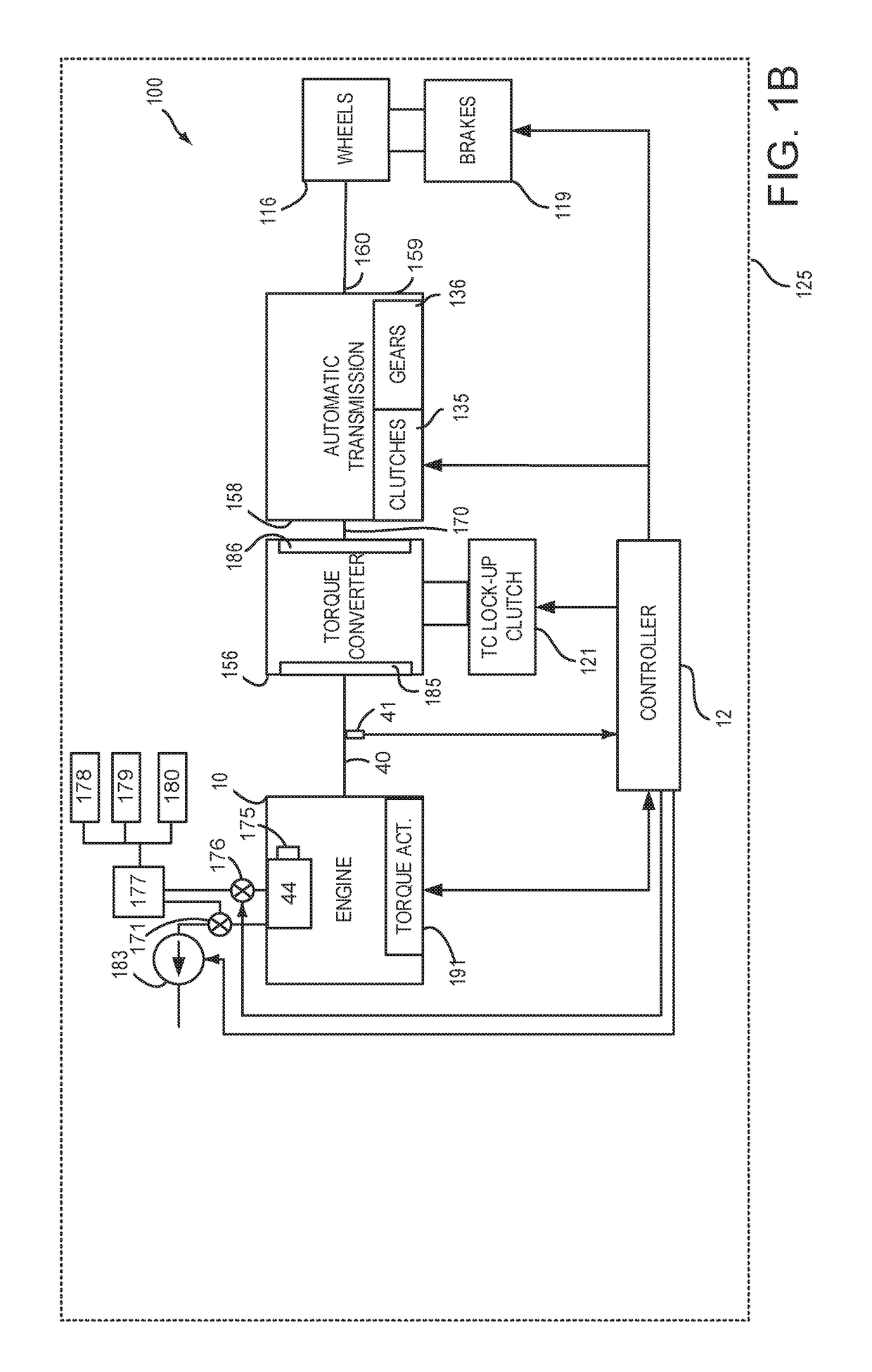

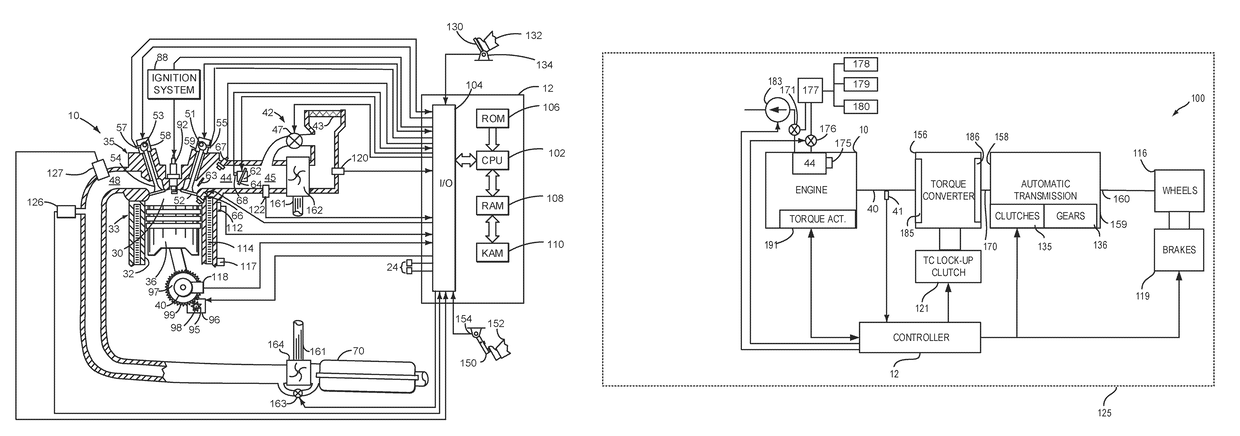

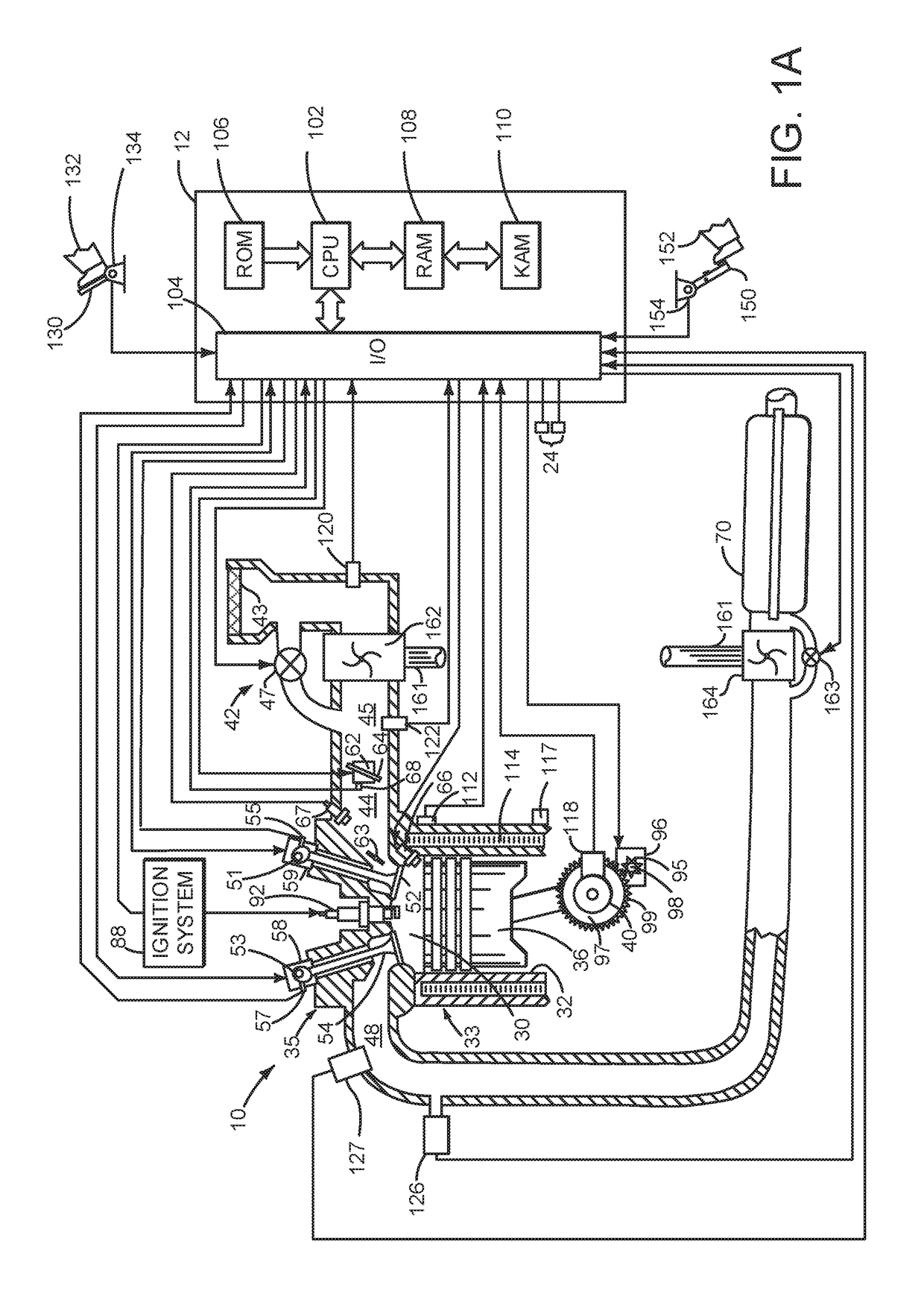

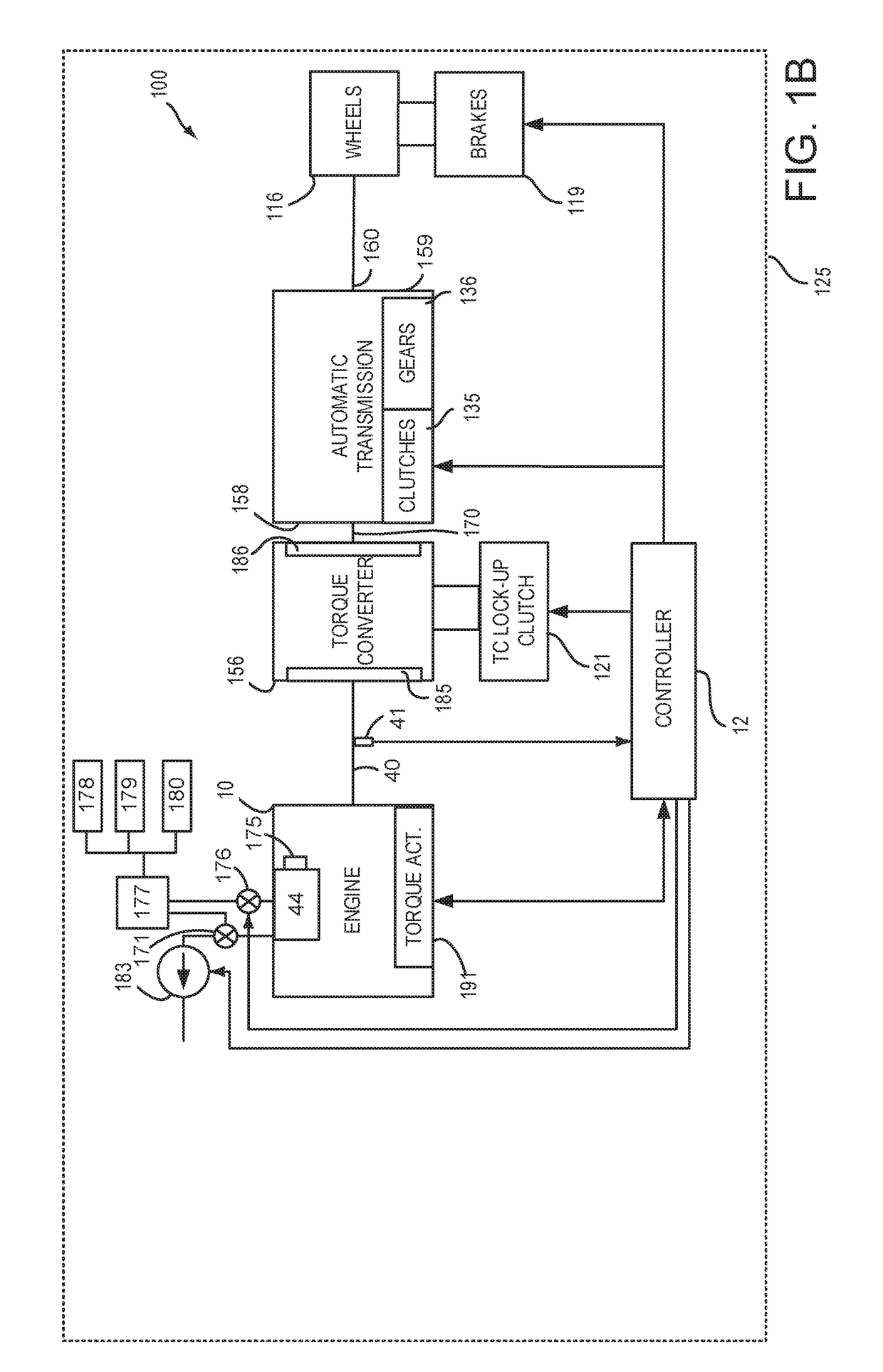

System and method for intake manifold pressure control

ActiveUS20170356372A1Reduce engine 's responseProduce moreElectrical controlInternal combustion piston enginesEngineeringActuator

Systems and methods for operating an engine with deactivating and non-deactivating valves are presented. In one example, engine volumetric efficiency actuators are adjusted in response to a request to activate engine cylinders so that engine intake manifold pressure is drawn down quickly toward its normal state at the engine's present speed and torque.

Owner:FORD GLOBAL TECH LLC

Catalyst for producing propenal with direct oxidation of propylene and method of producing the same

InactiveCN101402044AProduce moreHigh selectivityOrganic compound preparationCarbonyl compound preparationPotassiumAcrolein

The invention relates to a catalyst for producing acrolein through direct oxidation of propylene, which is obtained by kneading, molding, drying and baking a cesium-containing catalyst (I) and a potassium-containing catalyst (II) which are mixed according to the mass percentages of between 10 and 50 percent of the catalyst (I) and to between 50 and 90 percent respectively. The catalysts (I) and (II) are as follows: the catalyst (I) comprises Moa, Wb, Bic, Fed, (Co and / or Ni)e, Sif, Csg, an Ox, while the catalyst (II) comprises Moa, Wb, Bic, Fed, (Co or / and Ni)e, Sif, Kg, and Ox, wherein the subscripts a, b, c, d, e, f, g, and x are atomic numbers of corresponding elements, and a is between 10 and 12, b is between 0 and 2, a plus b is equal to 12, c is between 0.5 and 2, d is between 0.5 and 2, e is between 3 and 6, f is between 1 and 3, g is between 0.01 and 0.3, and x is the summation of oxygen atomic numbers of oxides of the corresponding elements. The one-way conversion rate of the propylene for the catalyst for the propylene is more than or equal to 97 percent, and the one-way yield of the acrolein is more than or equal to 85 percent.

Owner:重庆紫光海力催化剂有限公司

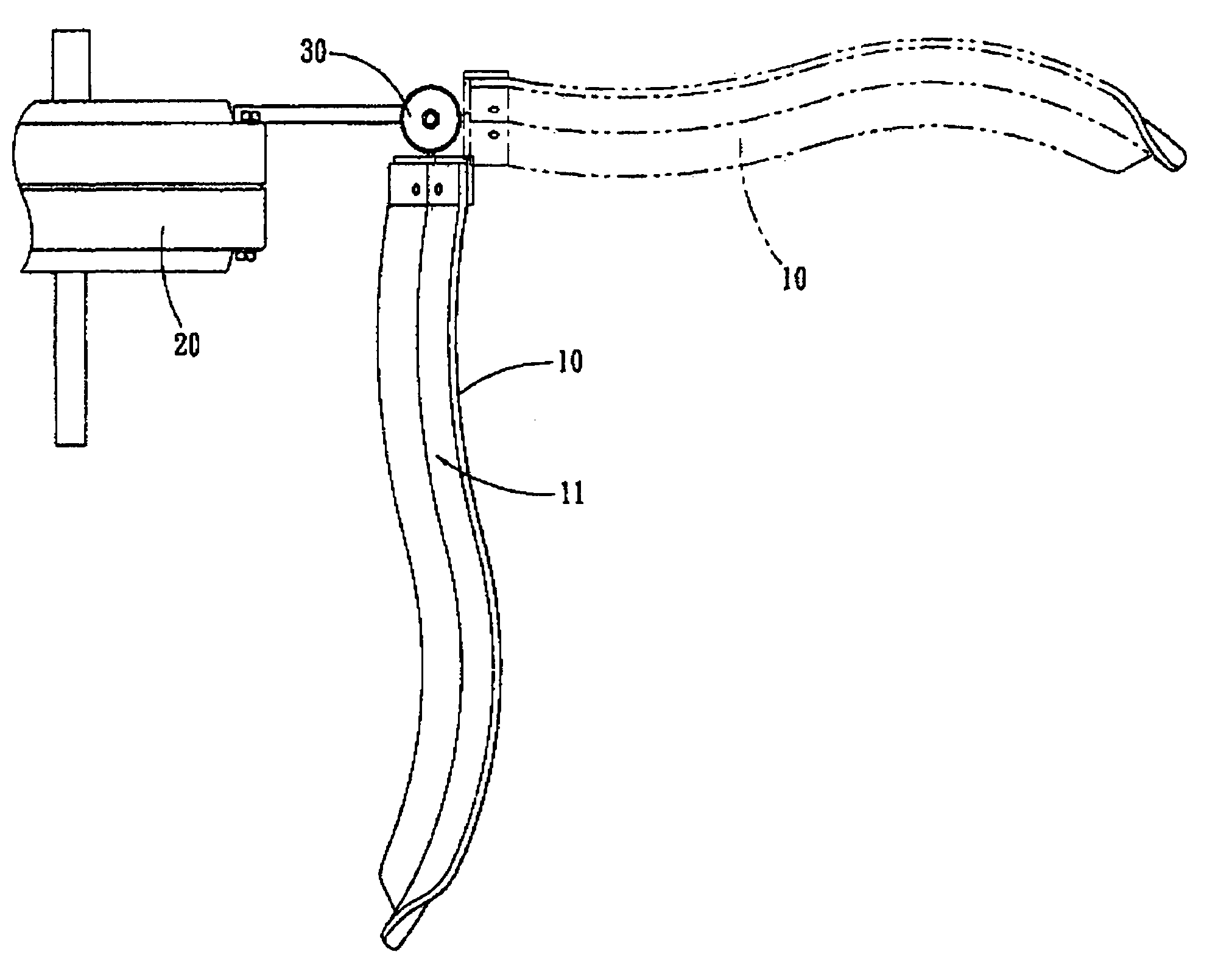

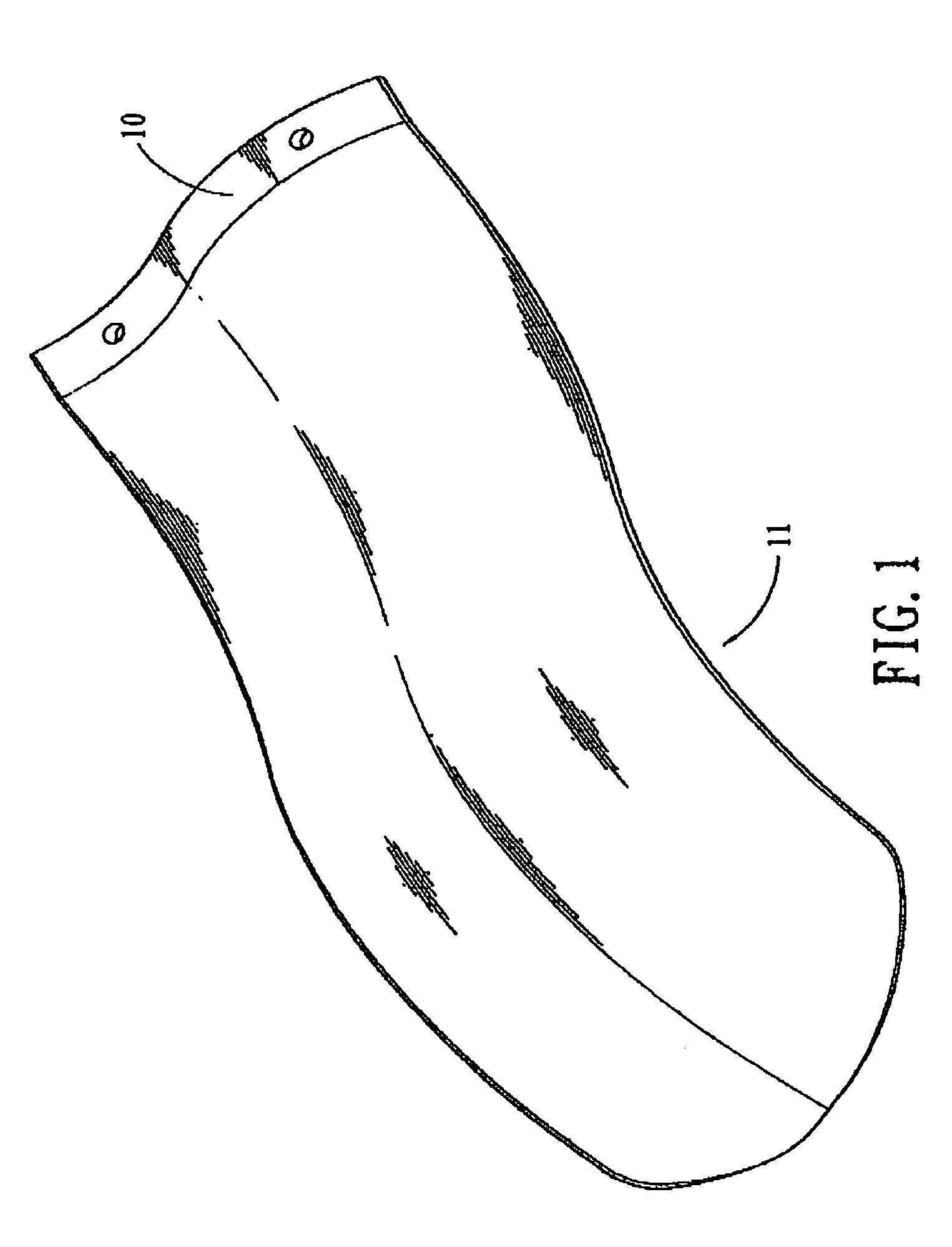

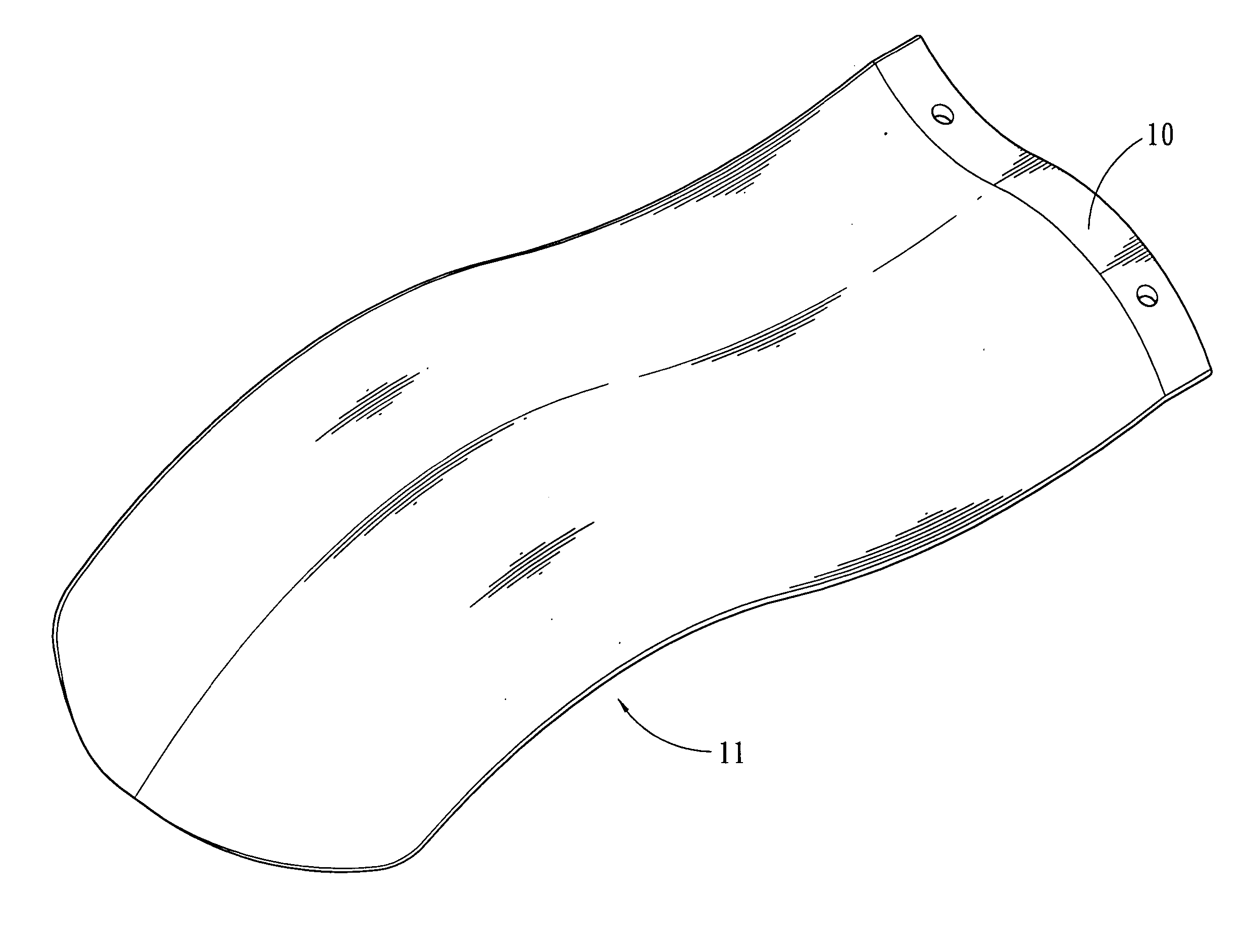

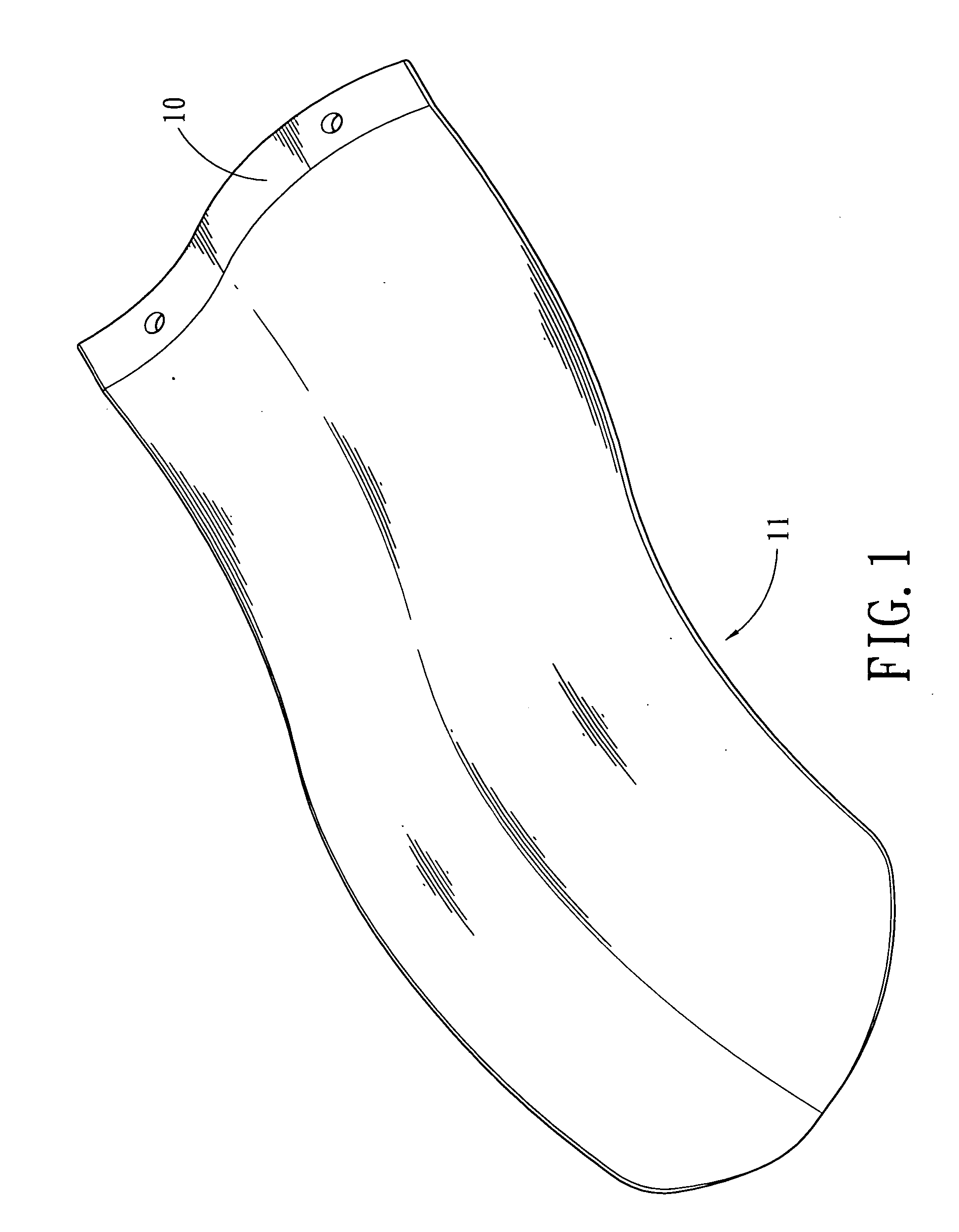

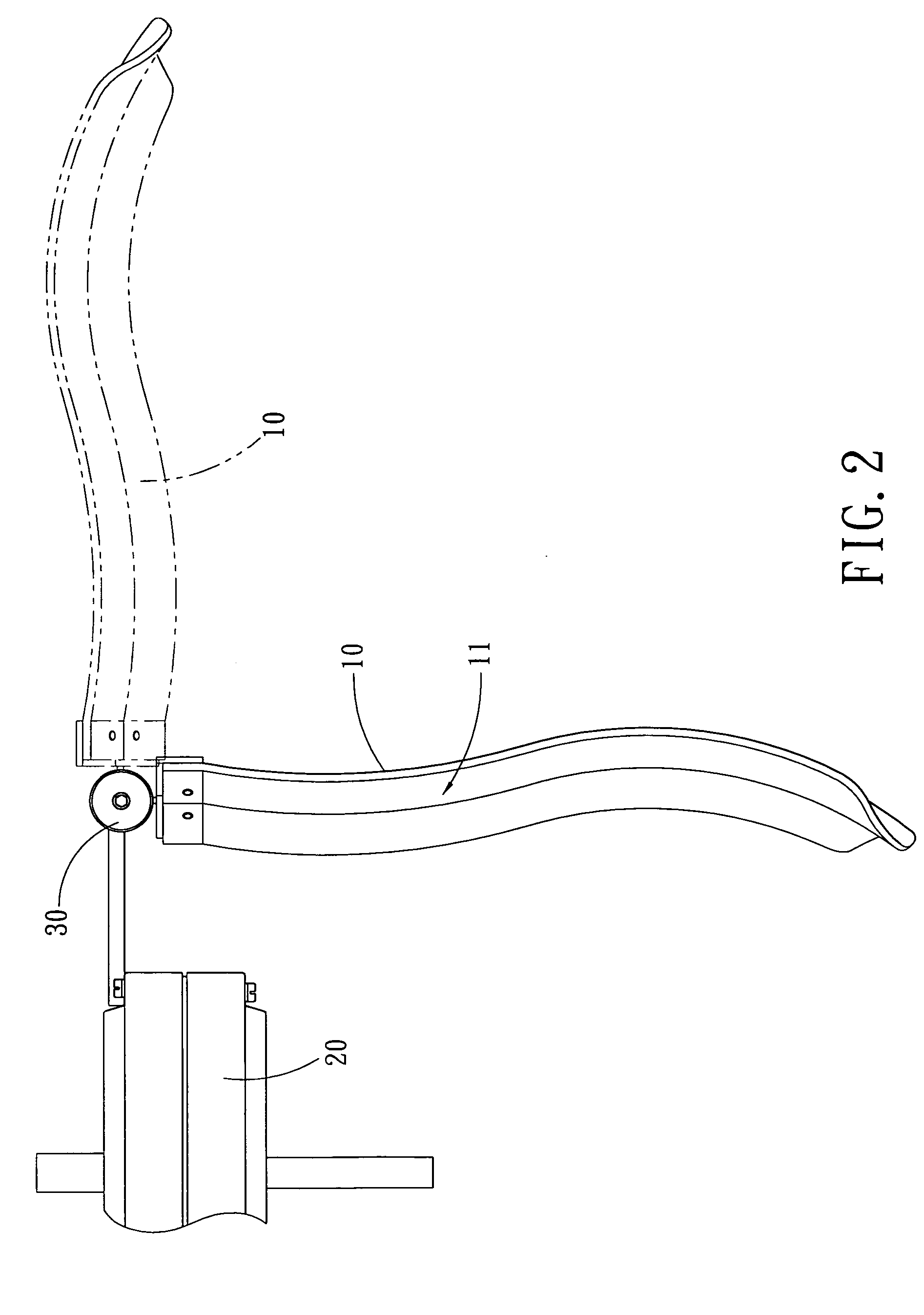

Ceiling fan blade

ActiveUS6991431B2Wind pressure and much windIncrease wind pressurePropellersRotary propellersCeiling fanEngineering

The present invention relates to a ceiling fan blade capable of producing full wind pressure and much wind. The solution of the present invention is to form a front and a rear wind receiving surfaces on the ceiling fan blade. A tangent angle of the rear wind-receiving surface is bigger than that of the front wind-receiving surface. A wavy wind guide surface is formed between the two wind receiving surfaces. The wavy wind guide surface and the two wind receiving surfaces can effectively increase the wind pressure and the wind; in addition, sinuous flow is substantially reduced when the blade is rotating.

Owner:PAN AIR ELECTRIC

System and method for adjusting intake manifold pressure

ActiveUS20170356358A1Improve fuel economyProduce moreElectrical controlInternal combustion piston enginesPressure systemControl theory

Systems and methods for operating an engine with deactivating and non-deactivating valves are presented. In one example, a position of an engine air intake throttle is adjusted during cylinder deactivation to control intake manifold pressure for cylinder reactivation. Closing of the throttle may be timed based on an actual total number of cylinder induction events expected to provide a desired engine intake manifold pressure.

Owner:FORD GLOBAL TECH LLC

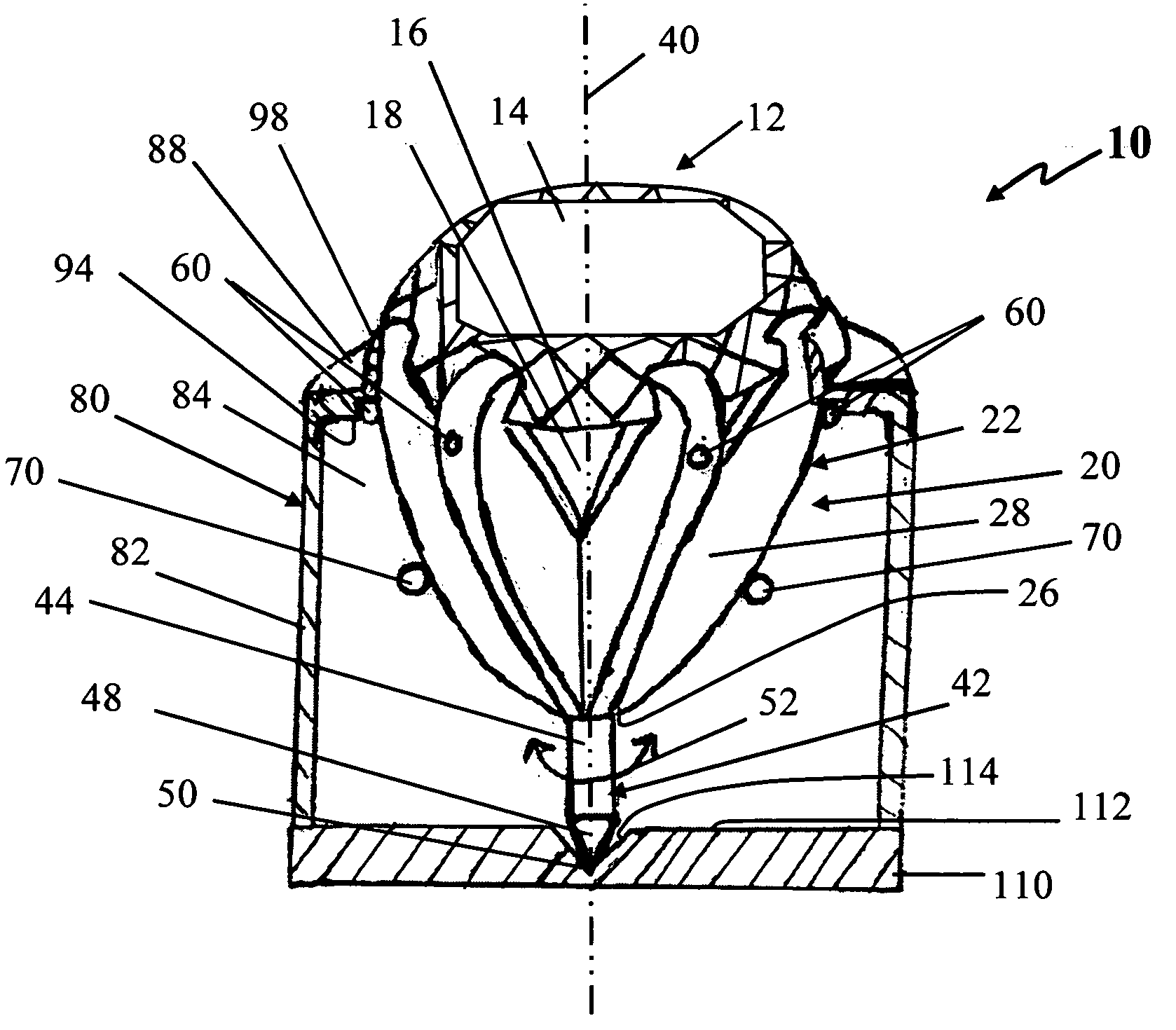

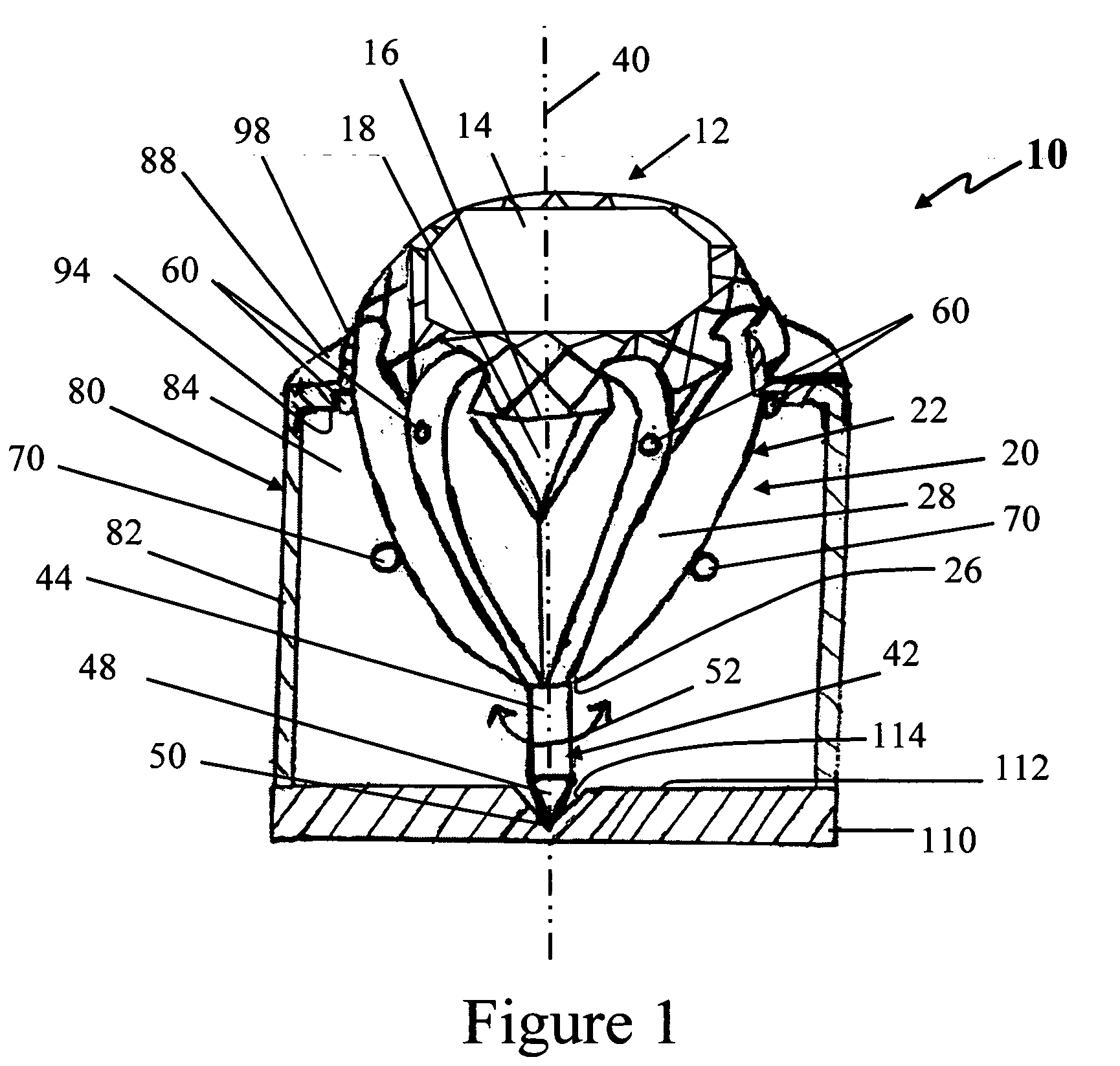

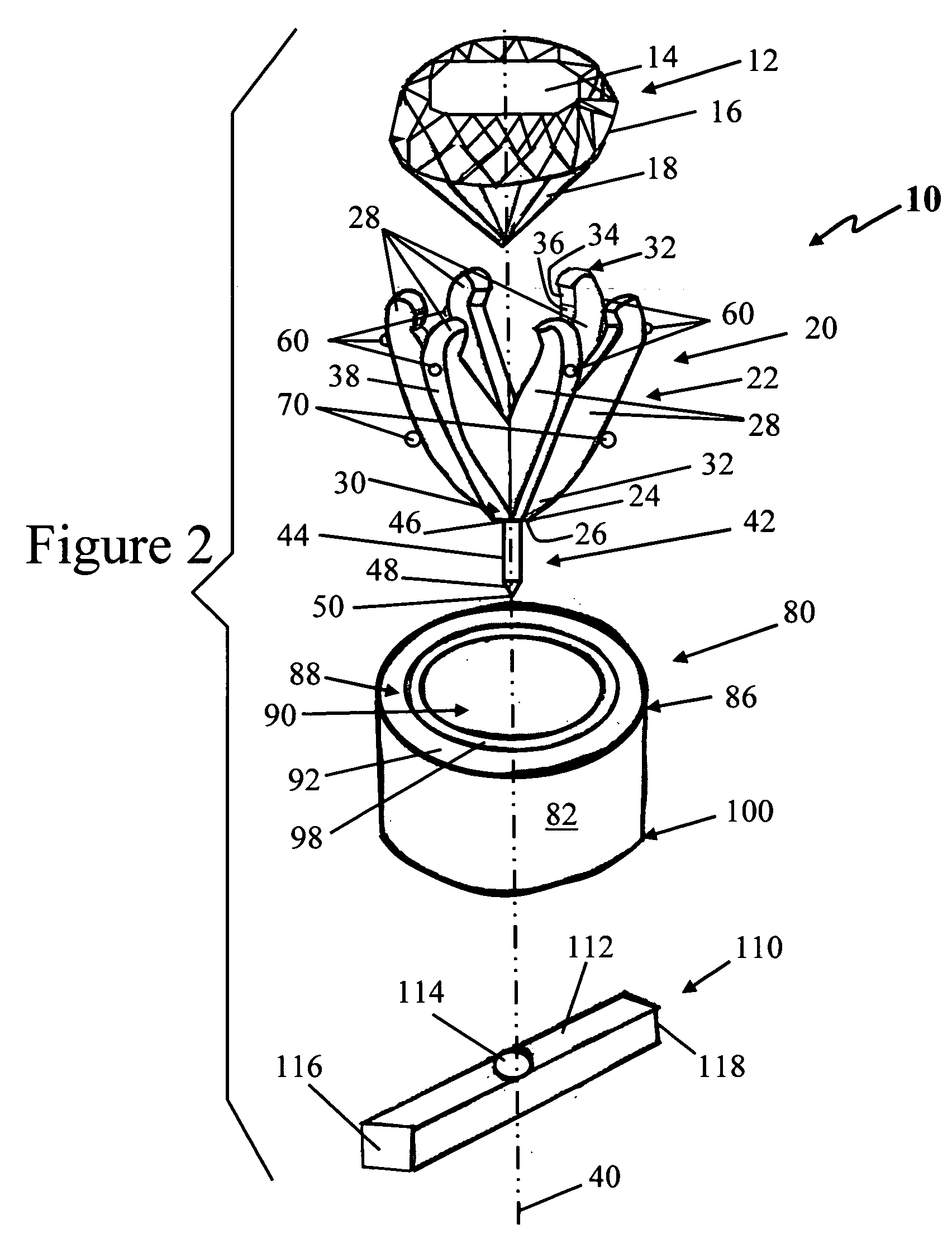

Rotatable setting device for jewelry articles

Rotatable setting device comprising a rotatable gem retaining element having an upper portion retaining a gem and including protrusions rotatably biased against an underside of a casing and a lower portion comprised of a member extending from the upper portion and terminating into a end rotateably received within a bottom coupled across a bottom end of the casing and further including at least one weighted element operatively coupled to the gem retaining element such that the rotatable setting device transforms forces including gravitational forces acting on at least the one weighted element and movement of a jewelry article comprised of the rotatable setting device into rotation of the gem that is viewable through a top opening in the casing thereby causing the gem to produce more fire and scintillation than its still set predecessors and increasing its aesthetic enjoyment, desirability, and value.

Owner:HINTZE KARAN MARI

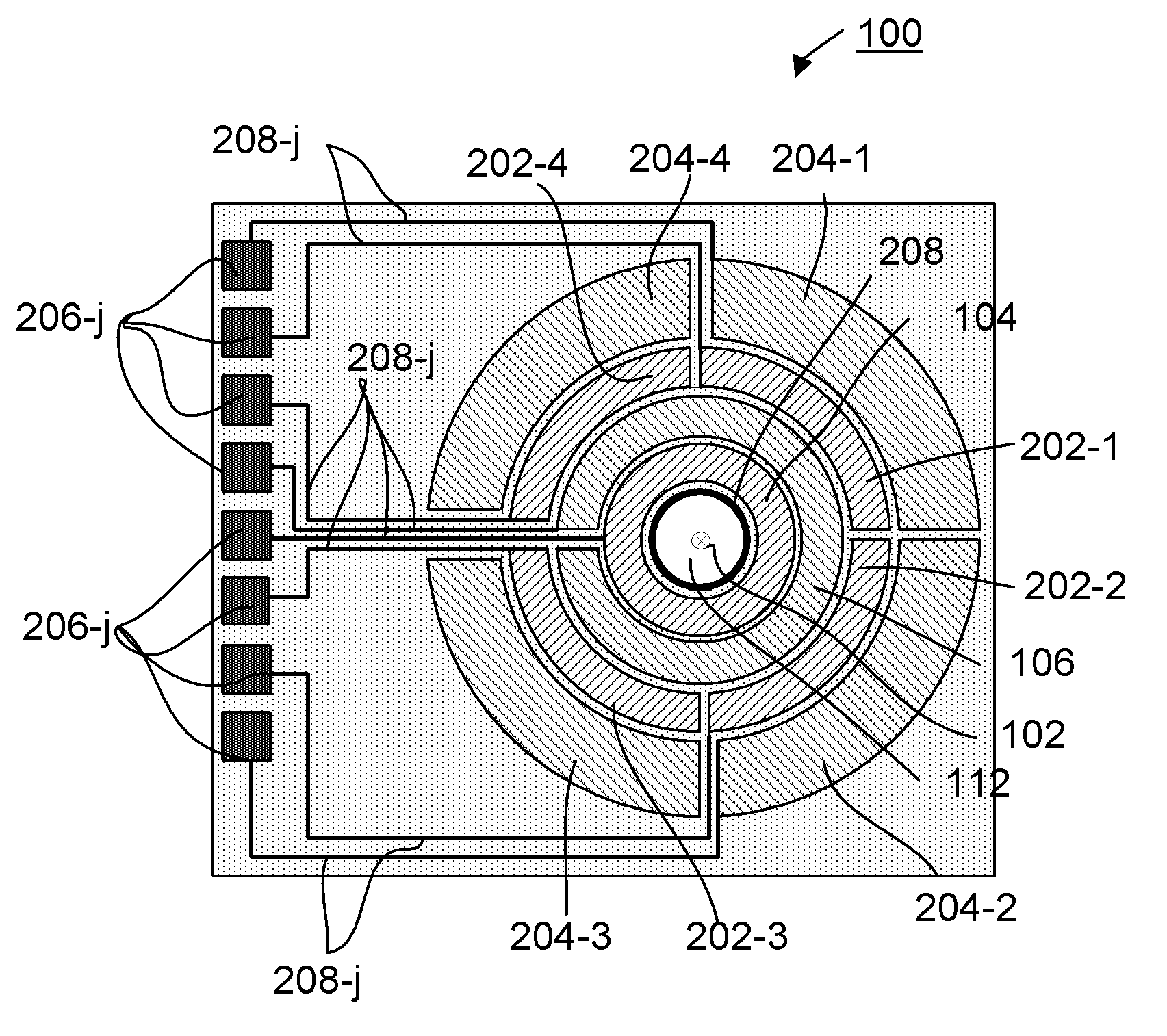

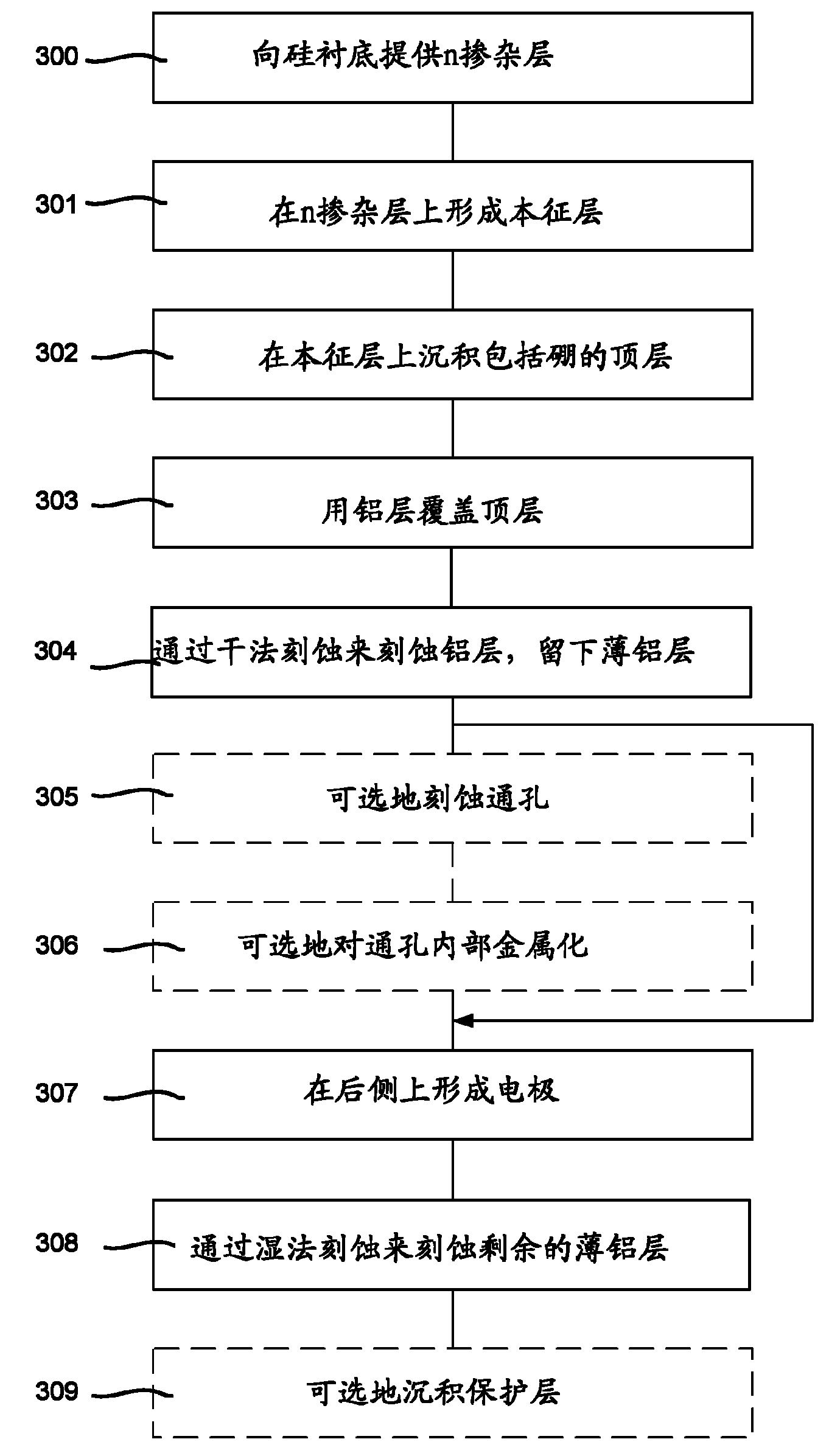

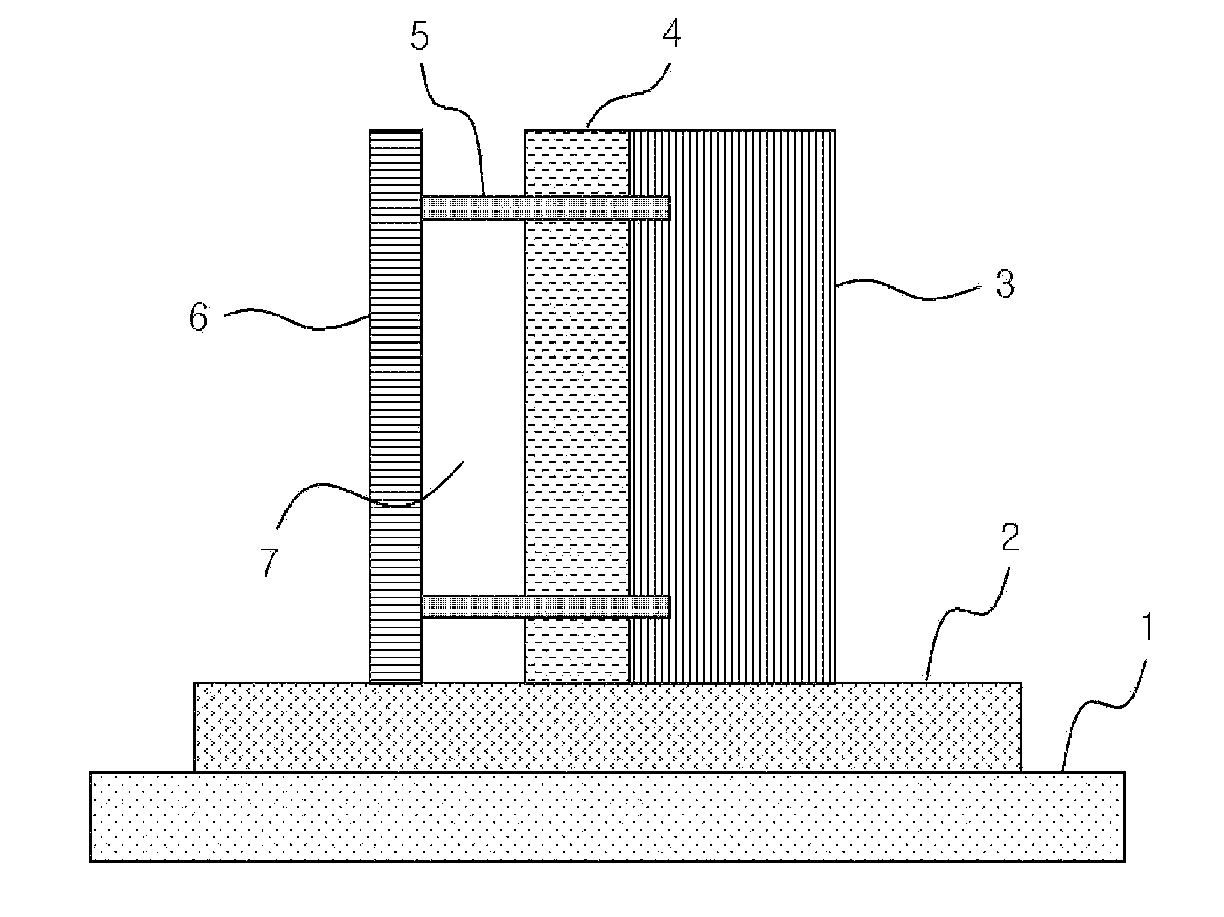

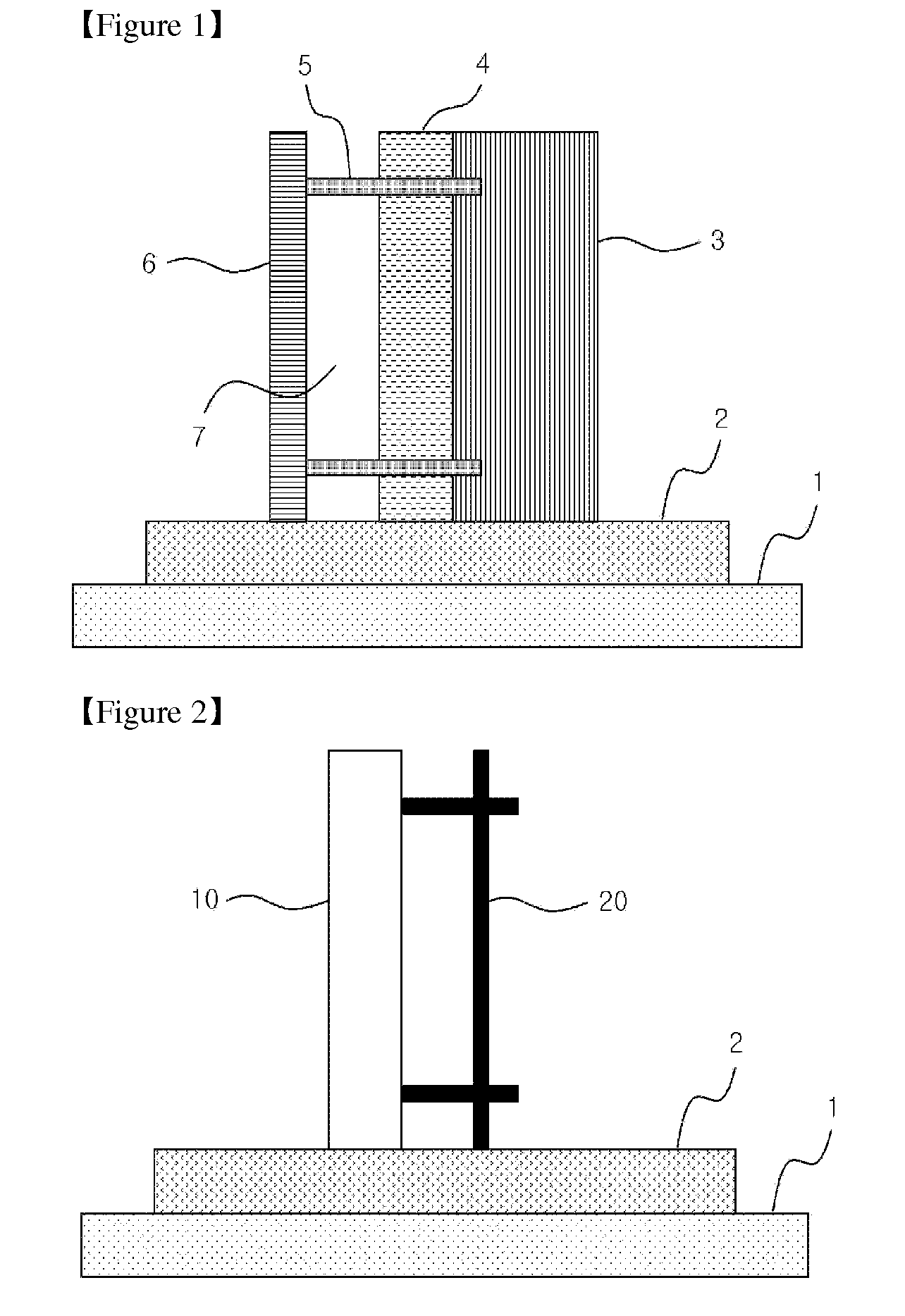

Radiation detector

ActiveCN102130218AReduce leakageProduce moreElectric discharge tubesRadiation controlled devicesScanning electron microscopeElectron microscope

The invention discloses a process for manufacturing a radiation detector for detecting e.g. 200 eV electrons. This makes the detector suited for e.g. use in an Scanning Electron Microscope. The detector is a PIN photodiode with a thin layer of pure boron connected to the p+-diffusion layer. The boron layer is connected to an electrode with an aluminium grid to form a path of low electrical resistance between each given point of the boron layer and the electrode. The invention addresses forming the aluminium grid on the boron layer without damaging the boron layer. To that end the grid of aluminium is formed by covering the boron layer completely with a layer of aluminium and then removing part of the layer of aluminium by etching, the etching comprising a first step (304) of dry etching, the step of dry etching defining the grid but leaving a thin layer of aluminium on the part of the boron layer to be exposed, followed by a second step (308) of wet etching, the step of wet etching completely removing the aluminium from the part of the boron layer to be exposed.

Owner:FEI CO

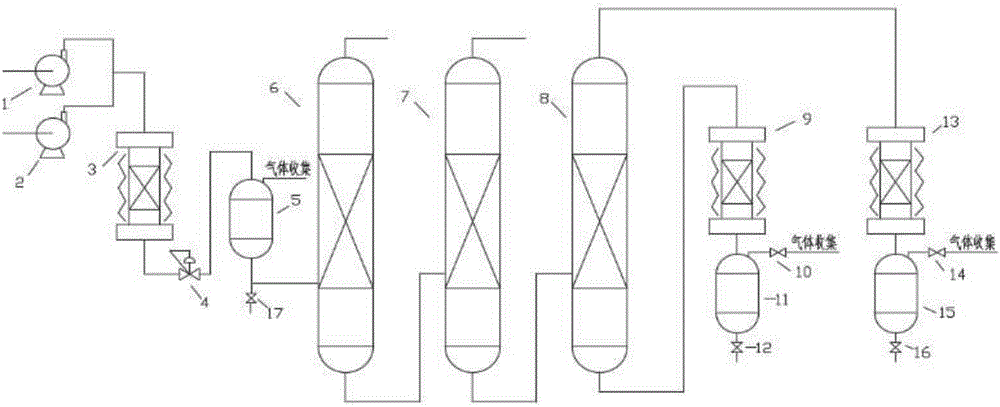

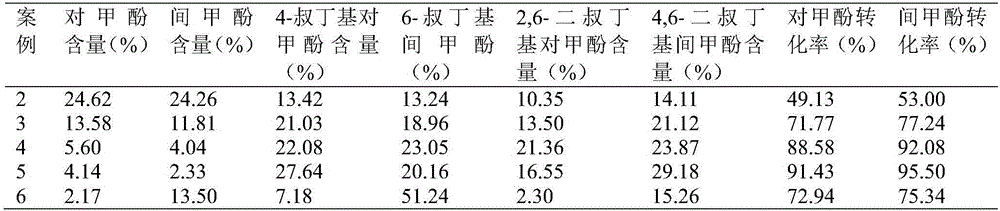

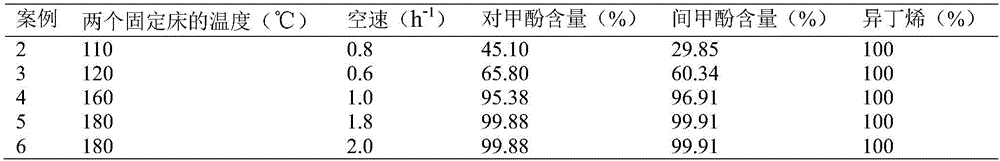

Method for separating m-cresol and p-cresol mixture by liquid-phase alkylation method

InactiveCN106810422AImprove conversion rateIncrease profitOrganic chemistryOrganic compound preparationCresolMetacresol

The invention discloses a method for separating an m-cresol and p-cresol mixture by a liquid-phase alkylation method. According to the method, alkylation reaction between isobutene mixed gas and the m-cresol and p-cresol mixture are performed through a fixed-bed reactor under the liquid phase state, the reacted mixture is separated to obtain metacresol and paracresol, the isobutene mixed gas serves as an alkylating agent, the m-cresol and p-cresol mixture serves as a raw material, the alkylation reaction is performed for the alkylating agent and the m-cresol and p-cresol mixture, and the treated mixture is separated to obtain pure metacresol and pure paracresol. The method overcomes the shortcomings of low utilization rate and serious environmental pollution of alkylating agents in gas-phase alkylation reaction in the prior art and solves the problems that production cost is high as high-purity isobutene serves as the alkylating agent in the gas-phase alkylation reaction.

Owner:HEBEI UNIV OF TECH +1

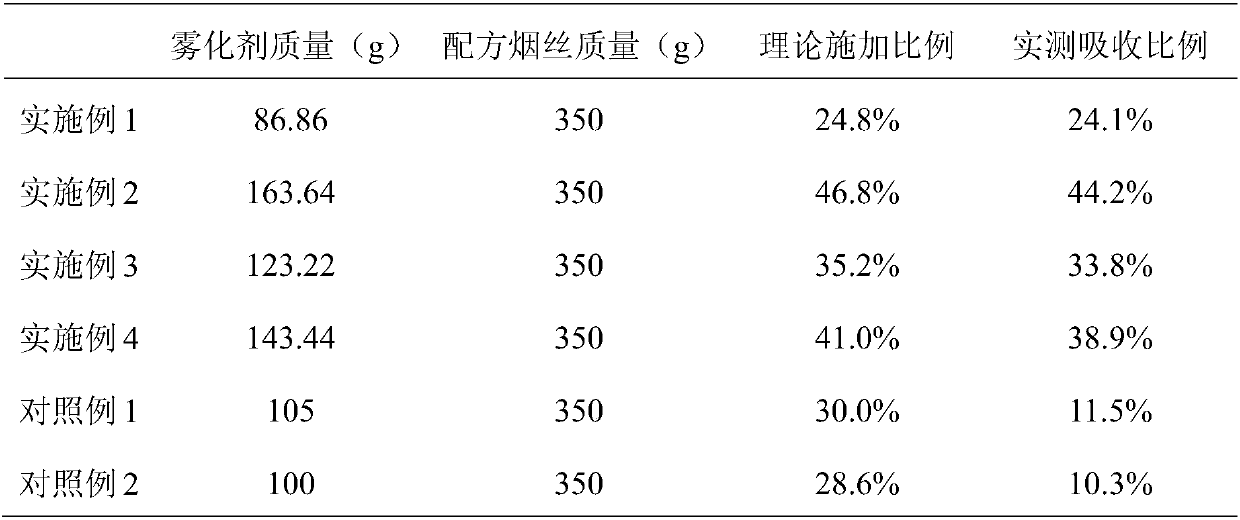

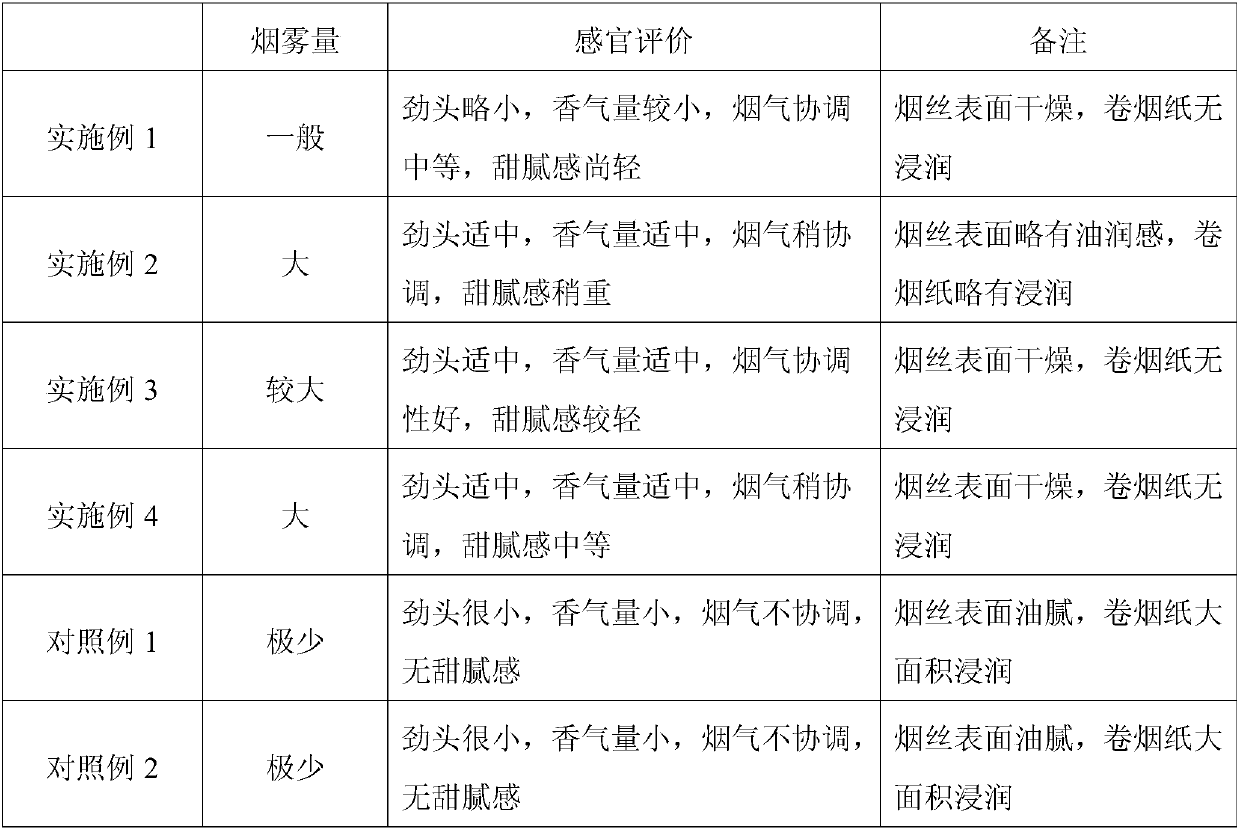

Chinese style efficient flue-cured tobacco atomizing agent and application method thereof

The invention discloses a Chinese style efficient flue-cured tobacco atomizing agent and an application method thereof. The atomizing agent is prepared from, by weight, 1 part of glycerinum, 10-20 parts of propylene glycol, 30-50 parts of dipropylene glycol, 2-10 parts of sorbitol and 0.43-0.82 part of geraniol. The prepared atomizing agent is put into a pressure relief groove of an improved vacuum freeze dryer, after vacuum freeze drying treatment is conducted on flue-cured tobacco ingredient cut tobaccos, when pressure of the atomizing agent is relieved in the freeze dryer, the atomizing agent is fast sprayed to the surface of the ingredient cut tobaccos, and the cut tobaccos which return the temperature fast and are in a structural expansion state fully absorb the atomizing agent. According to the flue-cured tobacco ingredient cut tobaccos treated through the atomizing agent, the problem that the glycerinum atomizing agent is difficult for the cut tobaccos to absorb under conventional conditions, and the defect that traditional Chinese style flue-cured tobaccos cannot generate smoke when applied to a smoking set having the function of heating without combustion is overcome. TheChinese style flue-cured tobaccos can generate a great deal of smoke when applied to the smoking set having the function of heating without combustion and volatilize tobacco fragrance, and good sensual pleasures are brought to a user.

Owner:CHINA TOBACCO JIANGSU INDAL

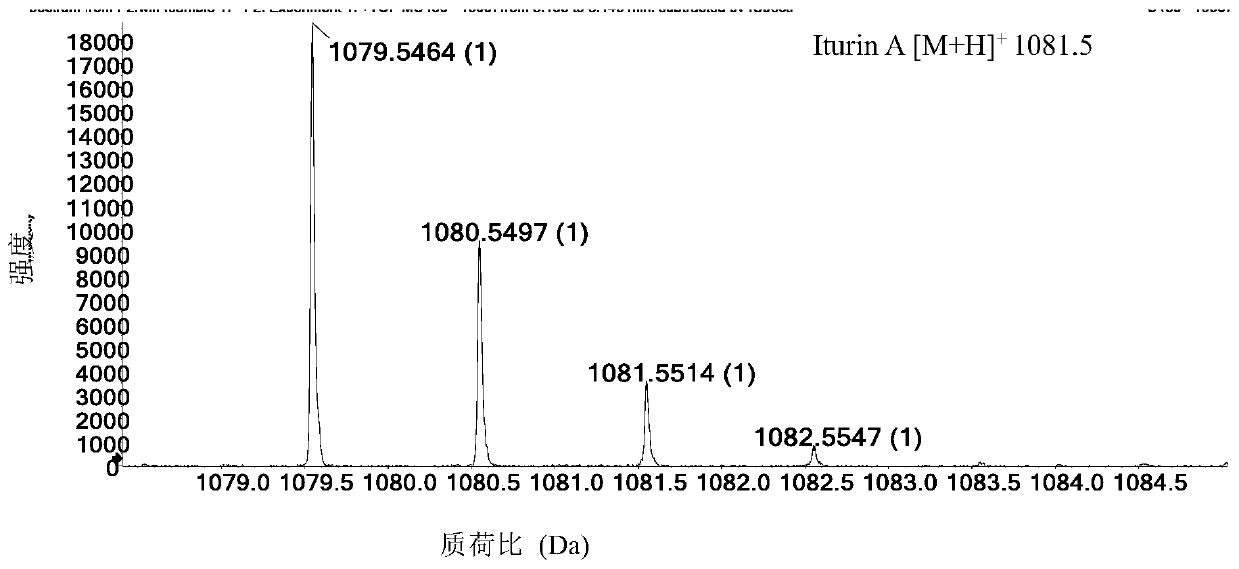

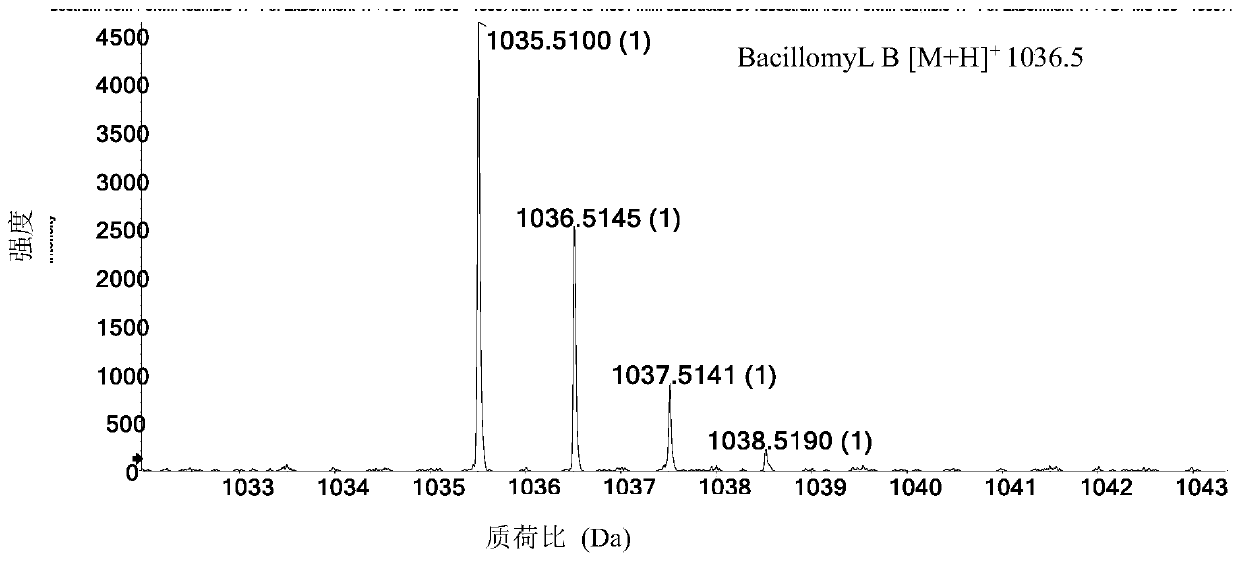

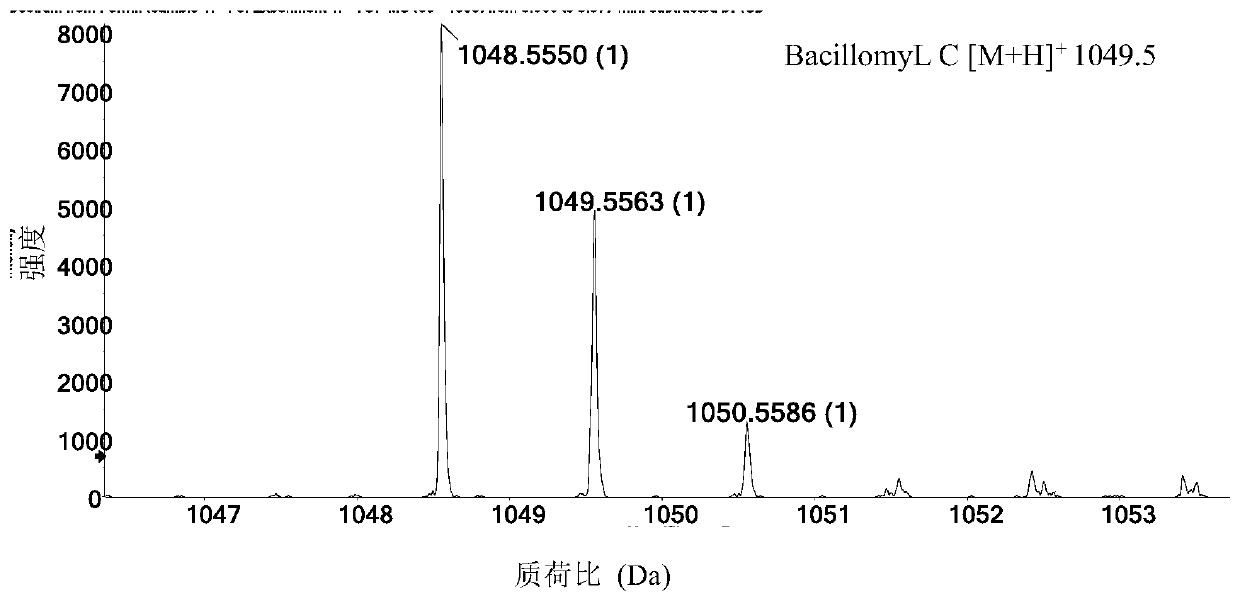

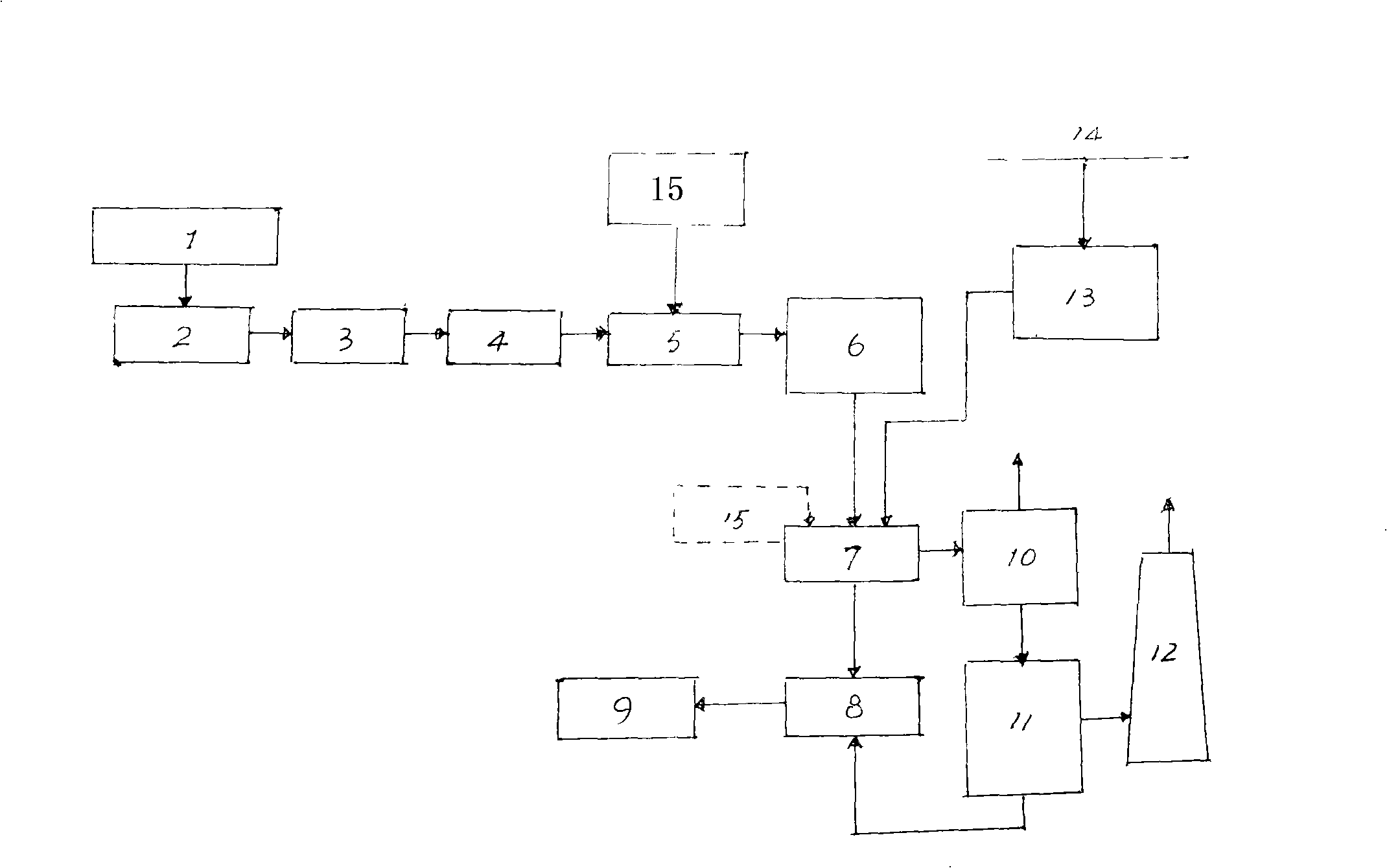

Bacillus subtilis strain and application thereof

The embodiment of the invention discloses a bacillus subtilis strain and application thereof. The bacillus subtilis strain is preserved in the China General Microbiological Culture Collection Center on October 10th, 2018, and the preservation number is CGMCC NO.16568. The bacillus subtilis strain can effectively inhibit escherichia coli, salmonella typhimurium, staphylococcus aureus and aspergillus niger, and more antibacterial substances are generated; bacillus subtilis high-density fermentation liquor containing bacillus subtilis strain metabolite has broad-spectrum antibacterial capability, contains high-content cyclic lipopeptide, and has wide application prospects. The bacillus subtilis high-density fermentation liquor also has good effects in inhibiting escherichia coli, salmonella typhimurium, staphylococcus aureus and aspergillus niger.

Owner:BEIJING FORESTRY UNIVERSITY

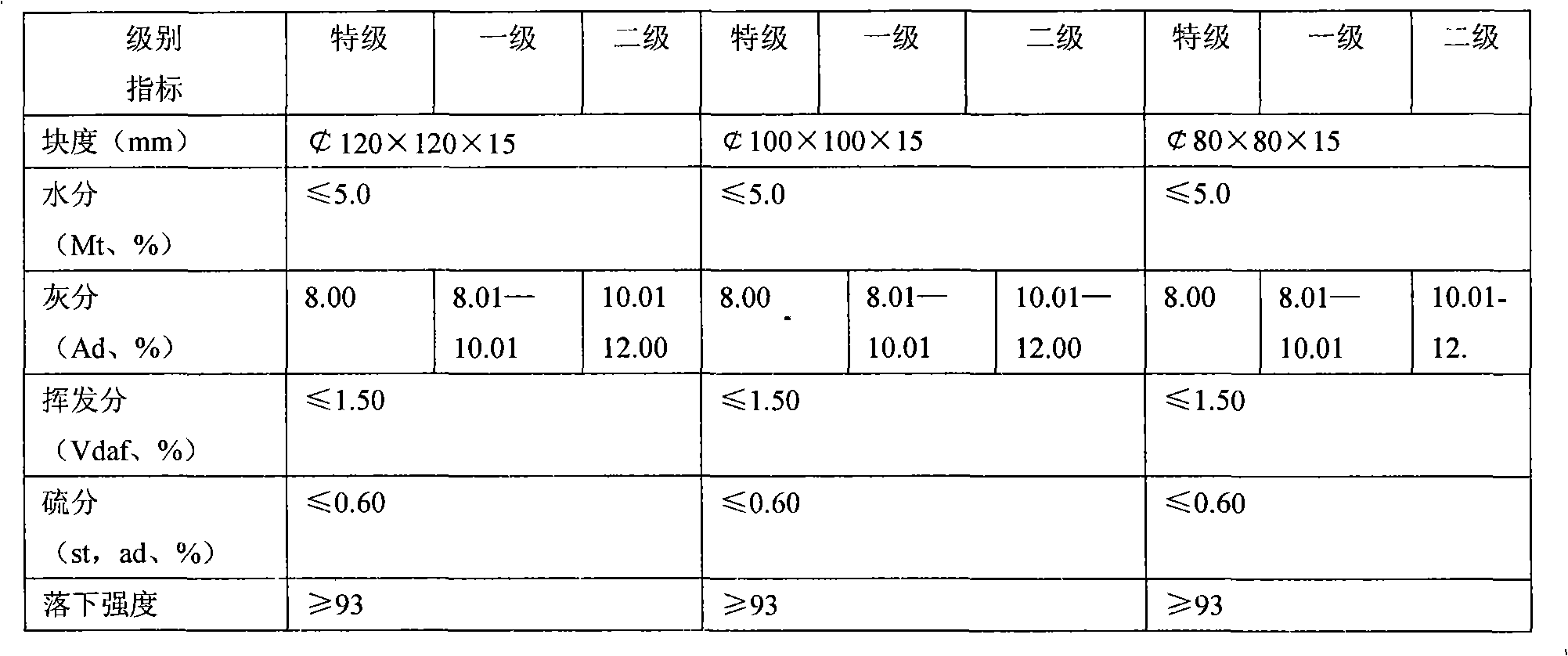

Anthracite carbon casting formed coke

InactiveCN101280203ARealize protection and meet emission standardsHigh carbon contentSpecial form destructive distillationFoundryHigh carbon

Disclosed is anthracite carbon foundry formed coke which solves the disadvantages of uneven granularity, insufficient oxygen-adding, high broken rate and environment pollution found in the formed coke in the prior art; the anthracite carbon foundry formed coke is characterized in that the anthracite or non-coking coal is used to produce the anthracite carbon foundry formed coke; the steps include that the raw coal is conveyed to the factory, crushed and grinded to powder; the binder is added to the grinded powder and the mixture is stirred under the cooling condition, and then stirred evenly after being heated; the mixture is conveyed to the pressing machine for the extruding formation; the formed material is conveyed to the carbonization chamber and then is processed with dry distillation and carbonization under the conditions of air-isolation and the temperature ranging from 950 DEG C-1050 DEG C; finally, the formed material is cooled and the finished product is outputted to be stored in the storehouse for sale; the process of comprehensive utilization of the coke-oven gas generated in the carbonization chamber is set for the lime joint production; the process of dust removal and desulfurization is set for the flue gas and SO2 in the exhausted gas; based on the special binder formula and the special product structure and compared with the traditional coking method, the anthracite carbon foundry formed coke has the advantages of high carbon content, high calorific value, low ash content and sulfur content, crush resistance, abrasion resistance, good intensity, moderate reactivity, high intensity after reaction, good cold and heat intensity, reasonable and simple structure, small investment, low expense and specially being applicable to the coking and the mechanical casting industries.

Owner:YANGQUAN YANGMEI FORMED COKE TECH DEV CENT

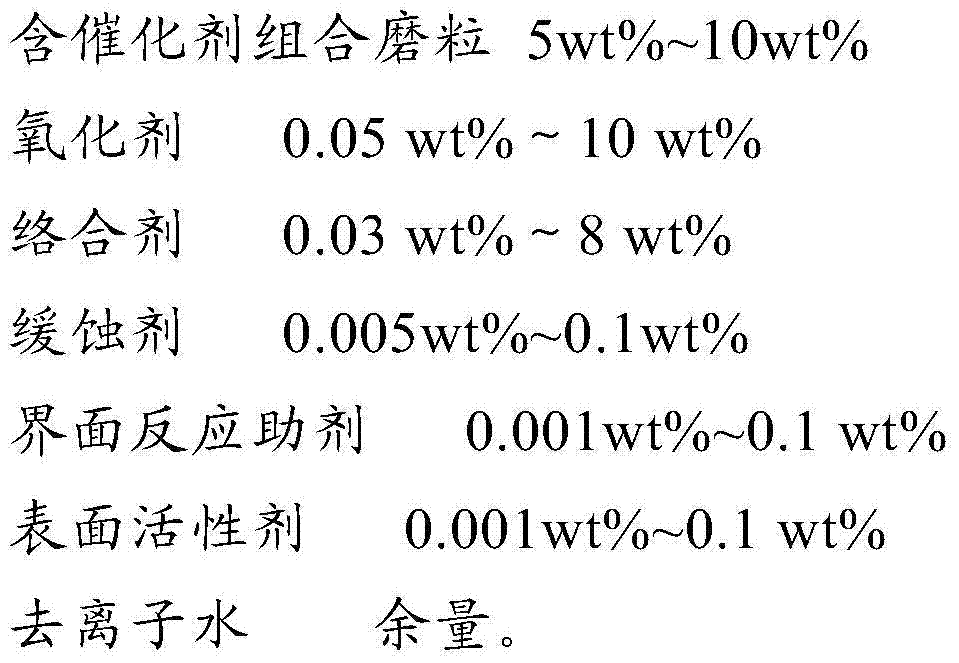

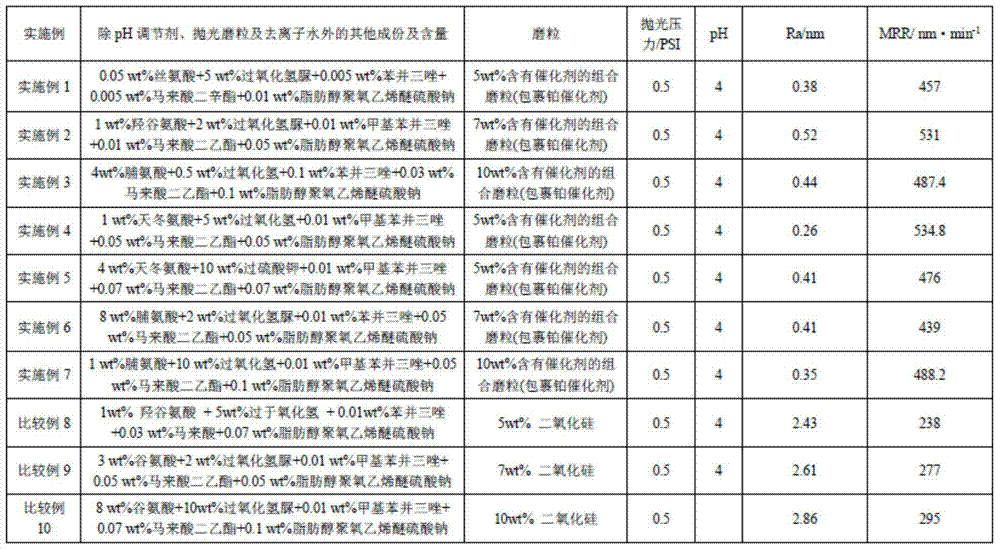

Integrated circuit copper CMP composition and preparation method thereof

InactiveCN104513627AProduce moreSolve the problem of low removalPolishing compositions with abrasivesCatalytic oxidationSurface-active agents

The invention relates to an integrated circuit copper CMP composition and a preparation method thereof, belongs to the technical fields of micro-electronics auxiliary materials and ultra-precision machining technology, and particularly relates to a polishing composition with a catalytic action. The composition comprises deionized water, combined abrasive particles containing catalysts, an oxidizing agent, a complexing agent, a corrosion inhibitor, an interface reaction assistant, a pH conditioning agent and a surface active agent, and the pH value of a polishing liquid composition is 2.0-5.5. The polishing abrasive particles are combined with the catalysts, so that the polishing abrasive particles have catalytic activity while reaching a mechanical grinding action, have the capacity of catalytic oxidation, and also double as a mechanical action and a chemical action; the polishing surface quality can be kept, and a copper chemical mechanical polishing composition realizing quick removal can be realized.

Owner:SHENZHEN LEAGUER MATERIAL +2

Ceiling fan blade

ActiveUS20050129523A1Wind pressure and much windIncrease wind pressurePropellersPump componentsCeiling fanAir volume

The present invention relates to a ceiling fan blade capable of producing full wind pressure and much wind. The solution of the present invention is to form a front and a rear wind receiving surfaces on the ceiling fan blade. A tangent angle of the rear wind-receiving surface is bigger than that of the front wind-receiving surface. A wavy wind guide surface is formed between the two wind receiving surfaces. The wavy wind guide surface and the two wind receiving surfaces can effectively increase the wind pressure and the wind; in addition, sinuous flow is substantially reduced when the blade is rotating.

Owner:PAN AIR ELECTRIC

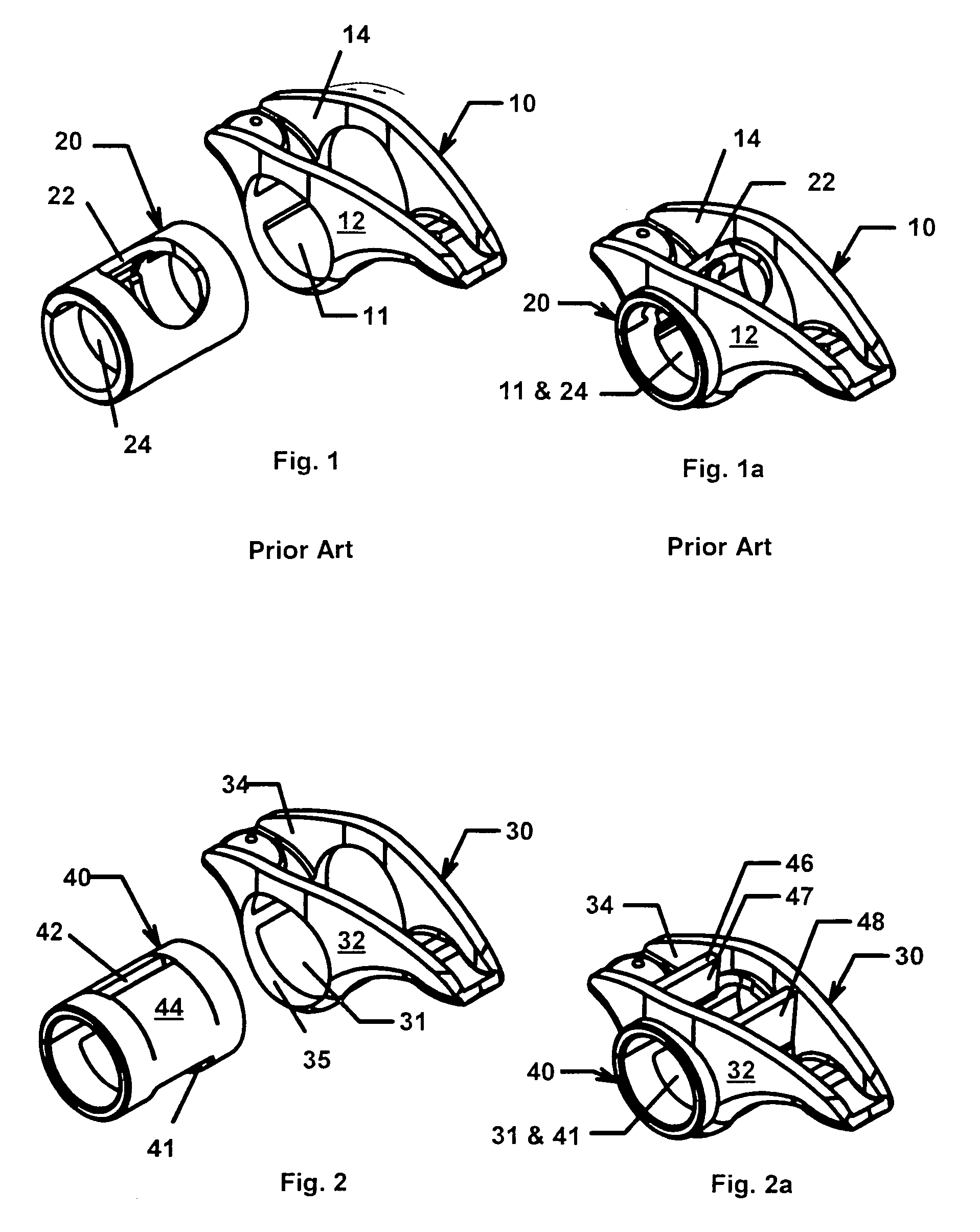

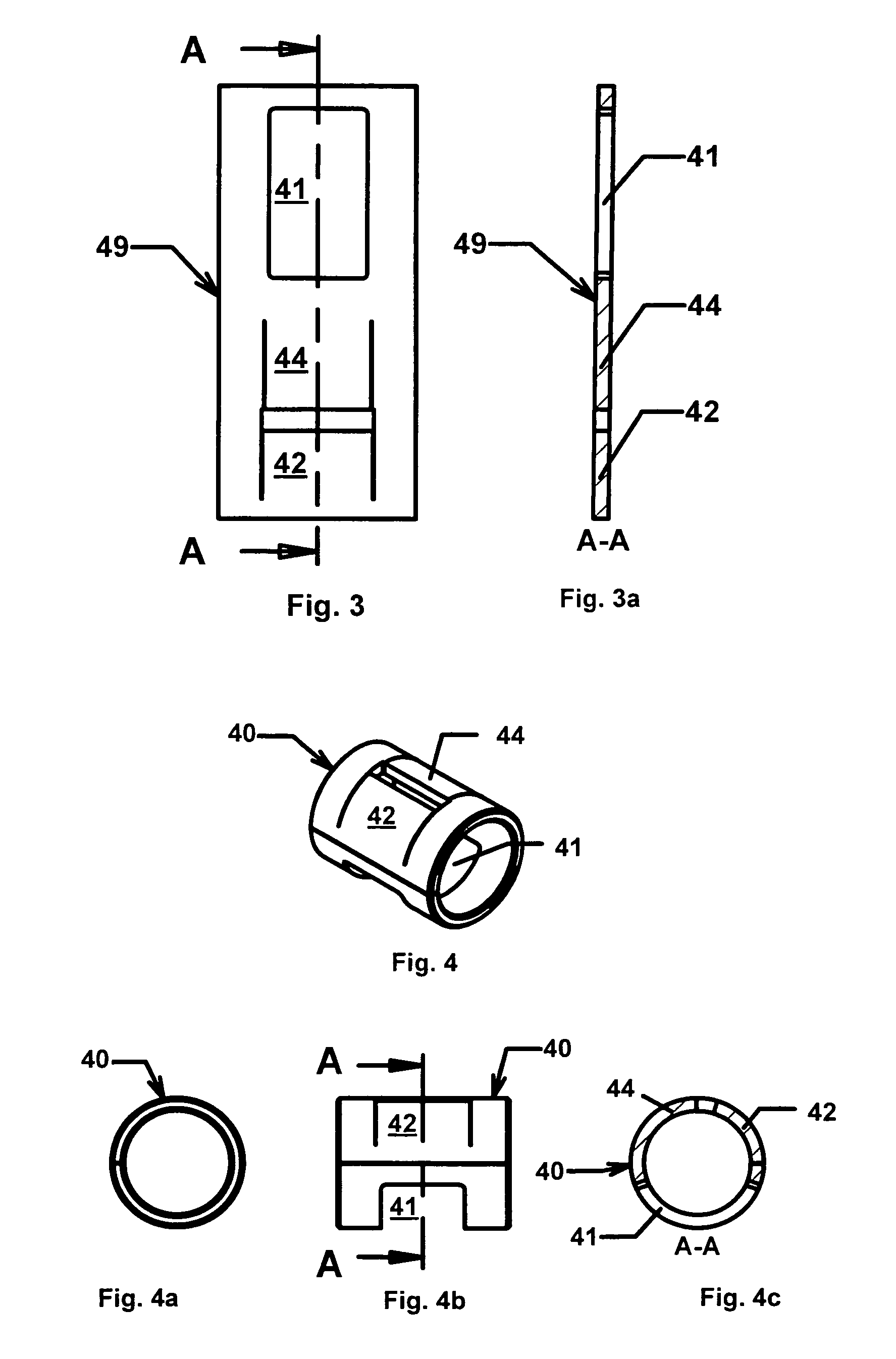

Sheet metal rocker arm with integrally formed cross member

InactiveUS7185618B1Increase stiffnessProduce moreControlling membersValve arrangementsEngineeringRocker arm

A sheet metal rocker arm of the welded and brazed tube and “boat type” rocker arm formed from sheet metal and characterized by having a reinforcing cross member which is integrally formed from a tab created by slitting the tube insert and which yields a unitary structure that introduces substantially greater stiffness to the rocker arm. The tube may be optionally rolled from sheet metal or by using seamless tubing. The method of creating integrally formed reinforcing cross-members by appropriate lancing slits in the sheet metal can be applied to any stamped rocker arm that has a U-channel architecture, e.g., including, for example, rocker arms for pushrod type valve trains as well as roller finger follower type rocker arms. Provision of the integrally formed cross member renders stiffness to the rocker arm that enables an engine to operate at a higher rpm and thereby to produce more horsepower.

Owner:GENTEK TECH MARKETING

Solar cell module with layers of design for integration into buildings

InactiveUS20120012163A1Maximize exterior effectIncrease valuePhotovoltaic supportsPV power plantsSteel frameEngineering

Disclosed is a solar cell module which incorporates layers of design is adapted for integration into construction as exterior walls incorporated into the steel frame of buildings, and comprises a double glass module having an external panel and an internal panel of tempered glass, with solar cells and layers of design between the external tempered glass panel and internal tempered glass panel.

Owner:LG HAUSYS LTD

System and method for intake manifold pressure control

ActiveUS10024256B2Demand torque is lowProduce moreElectrical controlInternal combustion piston enginesCurrent velocityActuator

Systems and methods for operating an engine with deactivating and non-deactivating valves are presented. In one example, engine volumetric efficiency actuators are adjusted in response to a request to activate engine cylinders so that engine intake manifold pressure is drawn down quickly toward its normal state at the engine's present speed and torque.

Owner:FORD GLOBAL TECH LLC

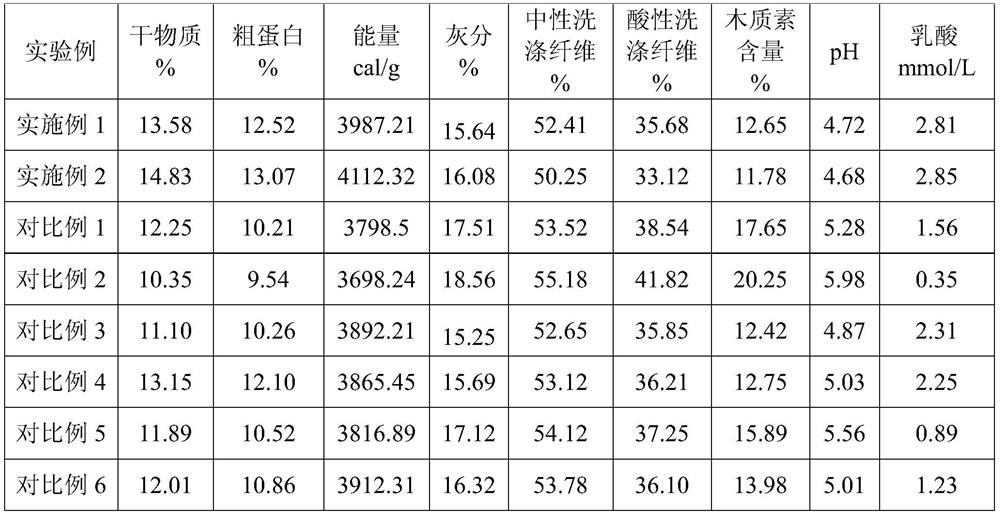

Processing method of ramie and pennisetum purpureum mixed silage

PendingCN112006157AMake up for the defect that silage is difficultIncrease dry matterFood processingAnimal feeding stuffBiotechnologyPennisetum purpureum

The invention provides a processing method of ramie and pennisetum purpureum mixed silage, and belongs to the field of feed additives. The processing method comprises the following specific steps: mixing 60%-80% of pennisetum purpureum and 20%-40% of ramie to obtain silage; then spraying fermentation liquor to the silage, spraying an additive at the same time, and then performing fermentation. Thefermentation liquor comprises compound bacteria, compound enzyme and water, and the compound bacteria comprise lactobacillus plantarum, lactobacillus buchneri, pediococcus pentosaceus and bacillus subtilis; the compound enzyme comprises cellulase, xylanase and laccase; and the additive comprises calcium propionate, molasses, urea, ethanol and water. According to the processing method of the silage, ramie and pennisetum purpureum mixed silage is adopted, nutrients are complemented, the fermentation liquid and the additive are combined for fermentation, the defect that ramie and pennisetum purpureum silage is difficult to silage is overcome, the dry matter and crude protein content and lactic acid bacteria of the silage are increased, and the crude ash content, the acid washing fiber content, the lignin content and the pH value are reduced.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION BUFFALO INST

Anti-skin allergy repair emulsion and preparation method thereof

InactiveCN107184522ACause irritation damageReduce sensitivityCosmetic preparationsToilet preparationsIrritationAdditive ingredient

The invention discloses an anti-skin allergy repair emulsion and a preparation method thereof. The anti-skin allergy repair emulsion is prepared from, by weight, 1-2 parts of extracts of pine bark from French coasts, 2-4 parts of mung bean fermentation broth, 1-2 parts of gentian extracts, 2-4 parts of squalane, 3-5 parts of pseudo-ginseng, 4-6 parts of glucan, 10-12 parts of purslane, 1-2 parts of prinsepia utilis royle, 4-6 parts of liquorice, 2-4 parts of fucoidan, 1 part of Chinese herbaceous peony, 1 part of peach kernel, 1 part of perilla leaf, 2-4 parts of chamomile, 15-20 parts of honey, 2-4 parts of ceramide and the balance deionized water. The anti-skin allergy repair emulsion has the advantages of relieving skin, repairing the defensive system of skin, invigorating the circulation of blood to clean channels of skin metabolism, decreasing skin sensitiveness, diminishing inflammation and clearing heat. Moreover, since the Chinese medicine components are adopted in the formula of the emulsion, the emulsion also has the advantages of being environmental-friendly, providing no irritation for skin, and meanwhile, not only achieving an anti-allergic effect in long-term use, but reappearing healthy gloss of skin in long-term use.

Owner:广州元基生物科技有限公司

Method for preparing high gamma-aminobutyric acid instant tea

ActiveCN103766531ASmall amount of boiling waterEmission reductionPre-extraction tea treatmentTea extractionFreeze-dryingReverse osmosis

The invention discloses a method for preparing high gamma-aminobutyric acid instant tea. The method comprises the following steps: soaking fresh tea leaves into a 0.25% to 2.5% glutamic acid aqueous solution, the weight of which is one to four times that of the fresh tea leaves; performing anaerobic treatment on the tea leaves for 0.5 to 30 hours under the vacuum degree being -0.05mpa to -0.1mpa; taking out the tea leaves and putting the tea leaves into boiling water, the weight of which is one to four times that of the tea leaves, for 10 to 30 seconds; combining the tea leaves with the glutamic acid aqueous solution after being used for soaking the fresh tea leaves; crushing and homogenizing for 1 to 5 minutes; filtering with a filter screen being 200 meshes; performing high-speed centrifugation on a filtrate at 5000rpm to 7000rpm (Revolutions Per Minute); performing reverse osmosis concentration until the concentration is greater than or equal to 100g / L; then performing reduced pressure evaporation concentration until the concentration is greater than or equal to 300g / L; and performing spray drying or freezing drying until the water content is less than or equal to 5%, thereby obtaining the high gamma-aminobutyric acid instant tea in a shape of green powder. The content of gamma-aminobutyric acid in gamma-aminobutyric acid is between 20.5mg / g and 35.5mg / g.

Owner:ZHEJIANG UNIV

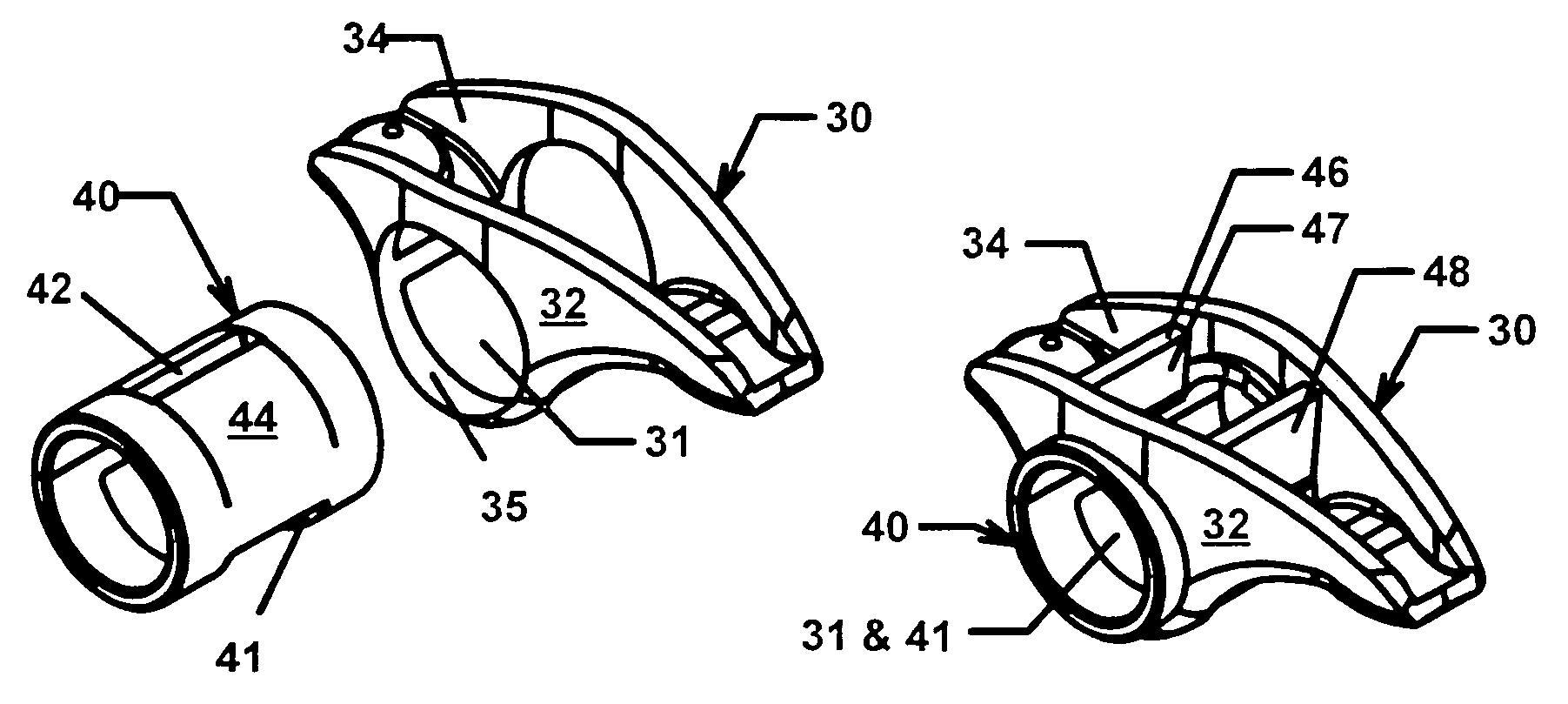

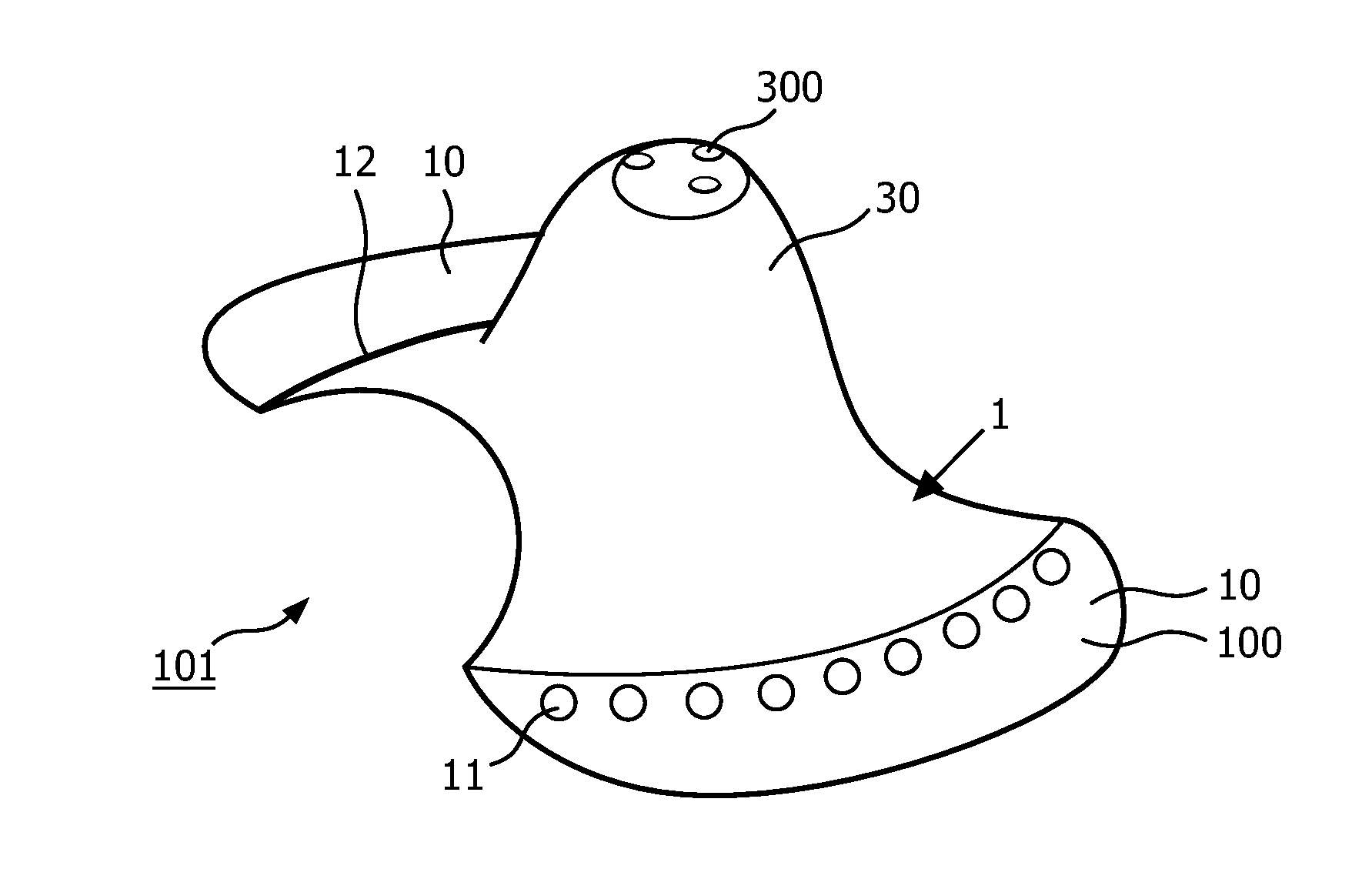

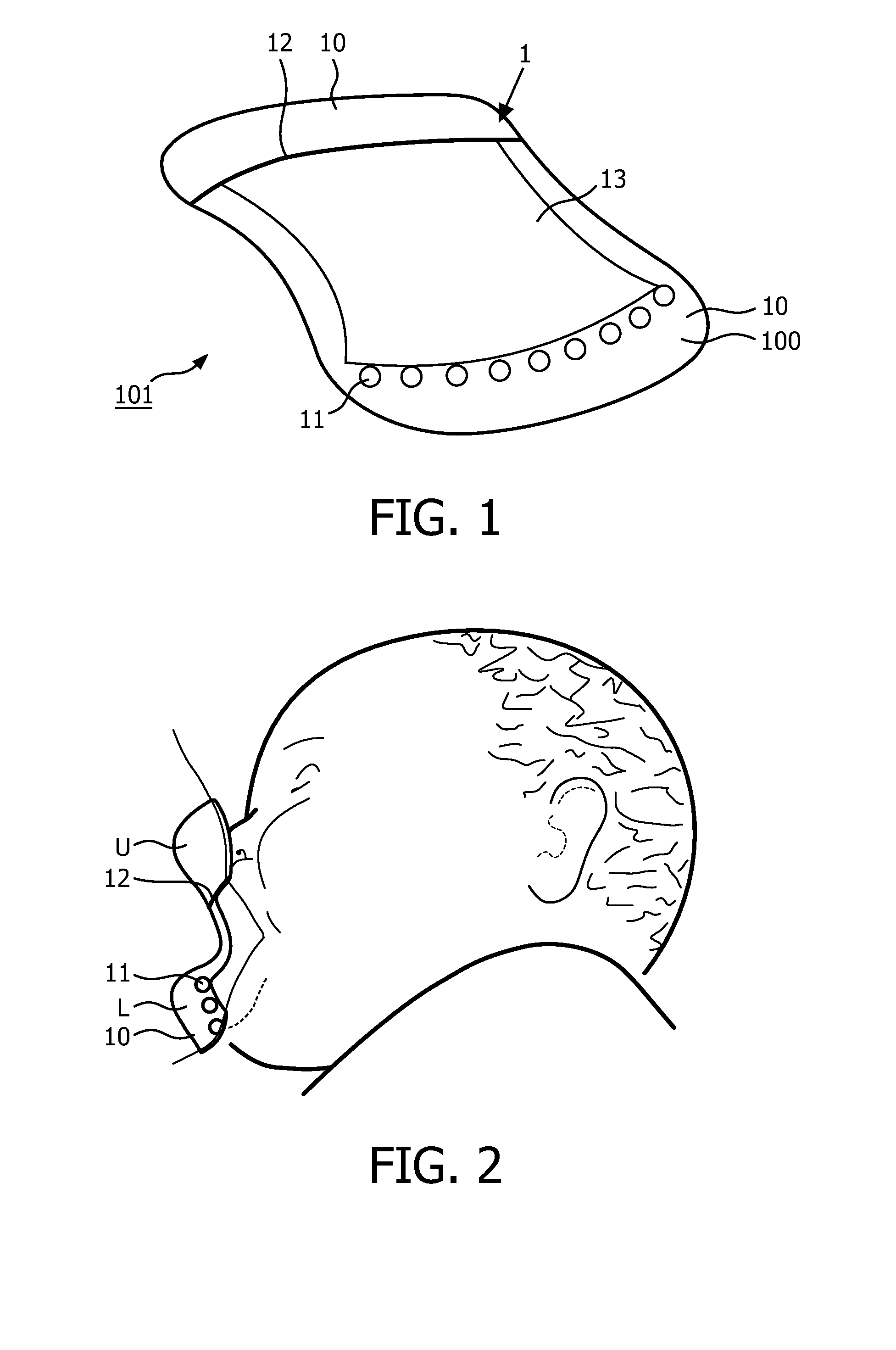

Device and method for guiding latch-on

The invention proposes a device (1) and a corresponding method, wherein the device (1) comprises: a first element (10) to be attached to a breast of a breastfeeding mother; and a first marker (11) located on the outer surface (100) of the first element (10), wherein the first marker (11) is used for indicating a position of a mother's breast that the baby's lip is expected to contact in order to correctly hold the mother's breast. With the device (1) attached to the mother's breast, the first marker (11) indicates a position that the baby's lip is expected to contact, and the breastfeeding mother can have a clear view of whether the baby correctly holds the mother's breast according to the distance between the first marker (11) and the baby's lip.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

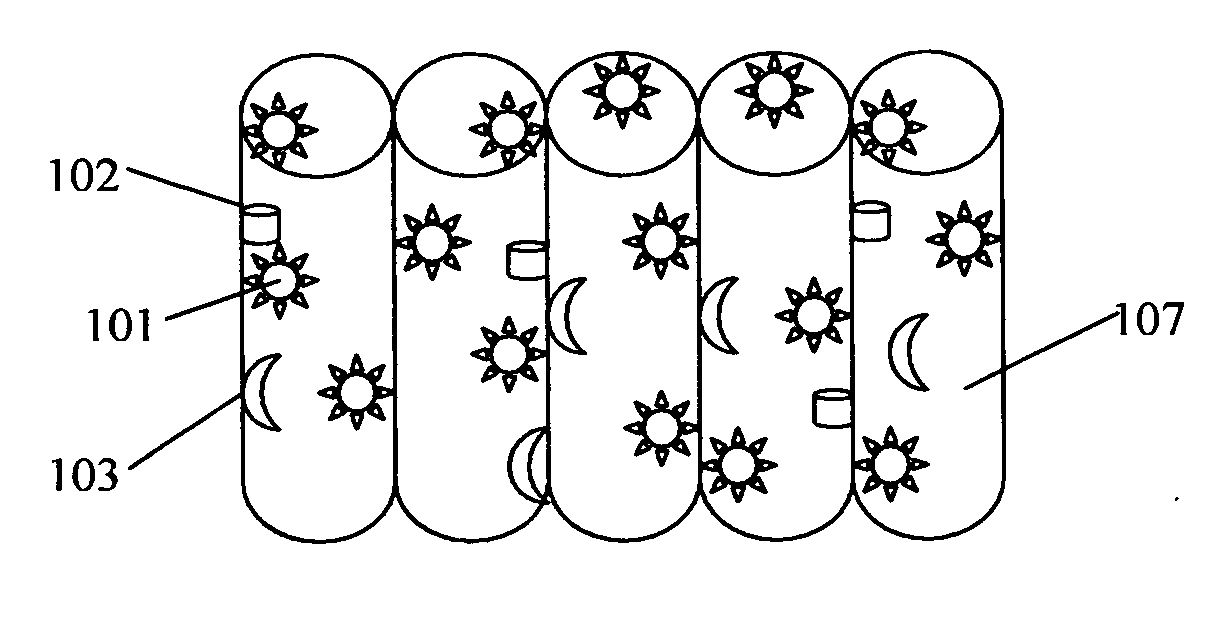

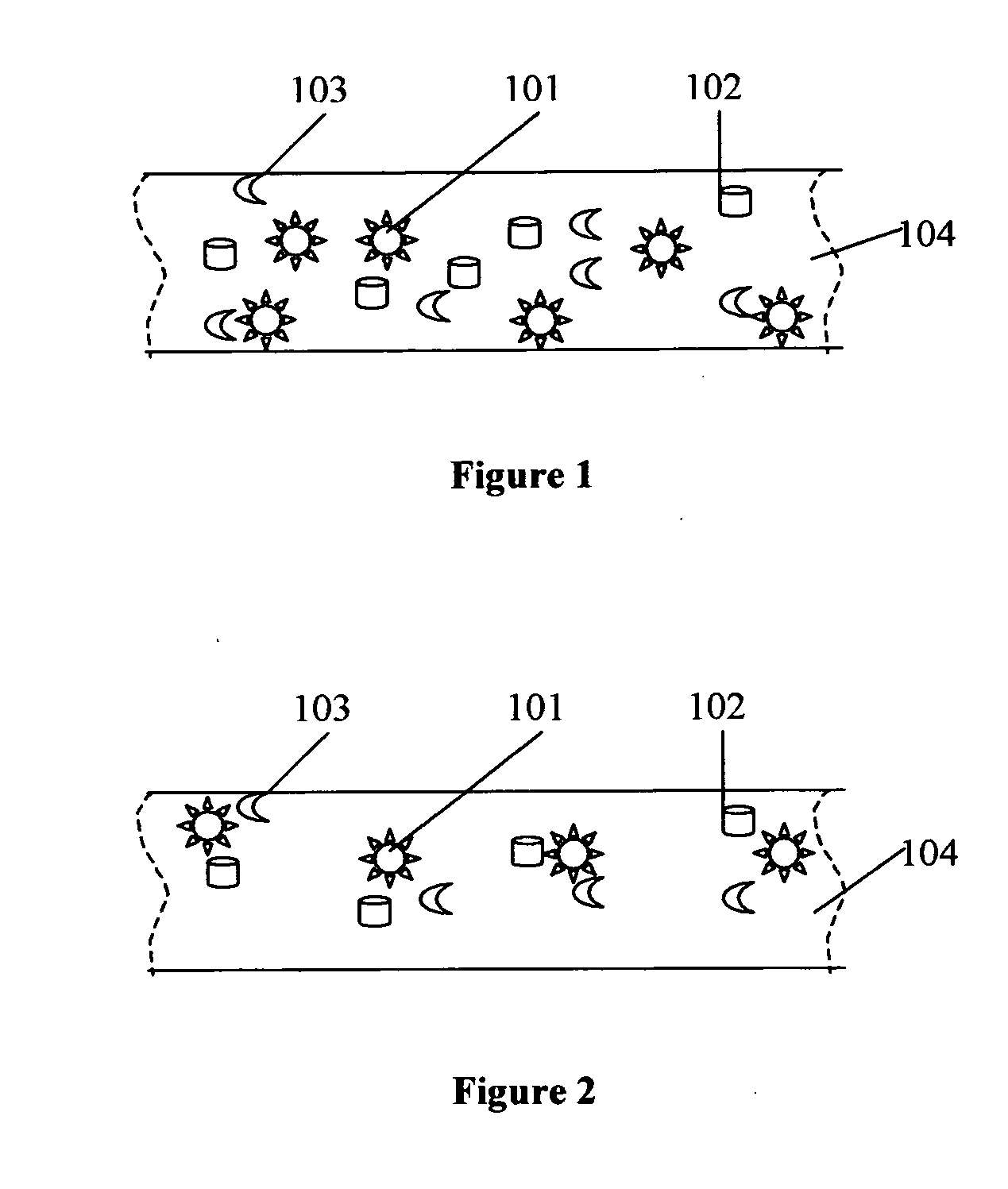

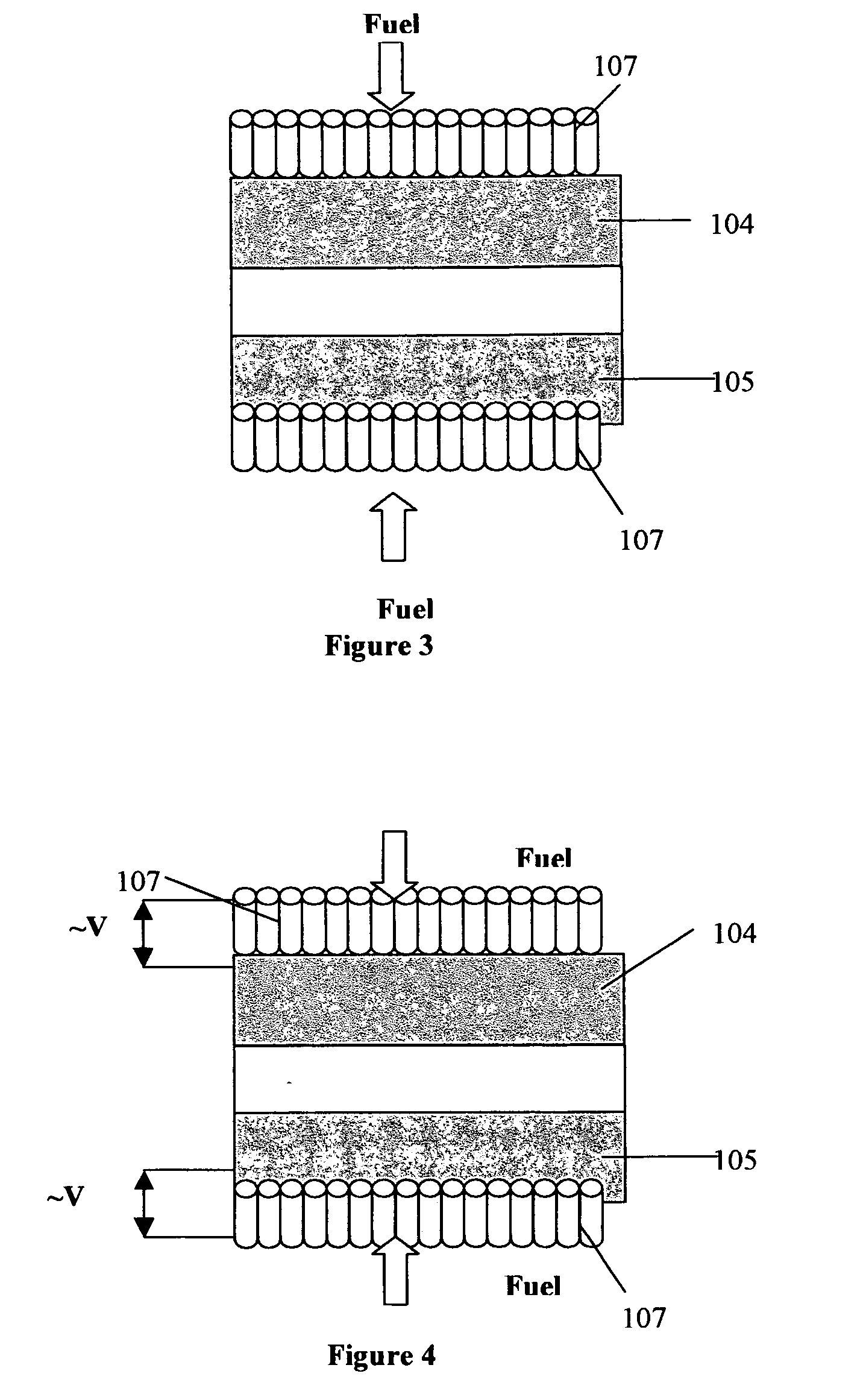

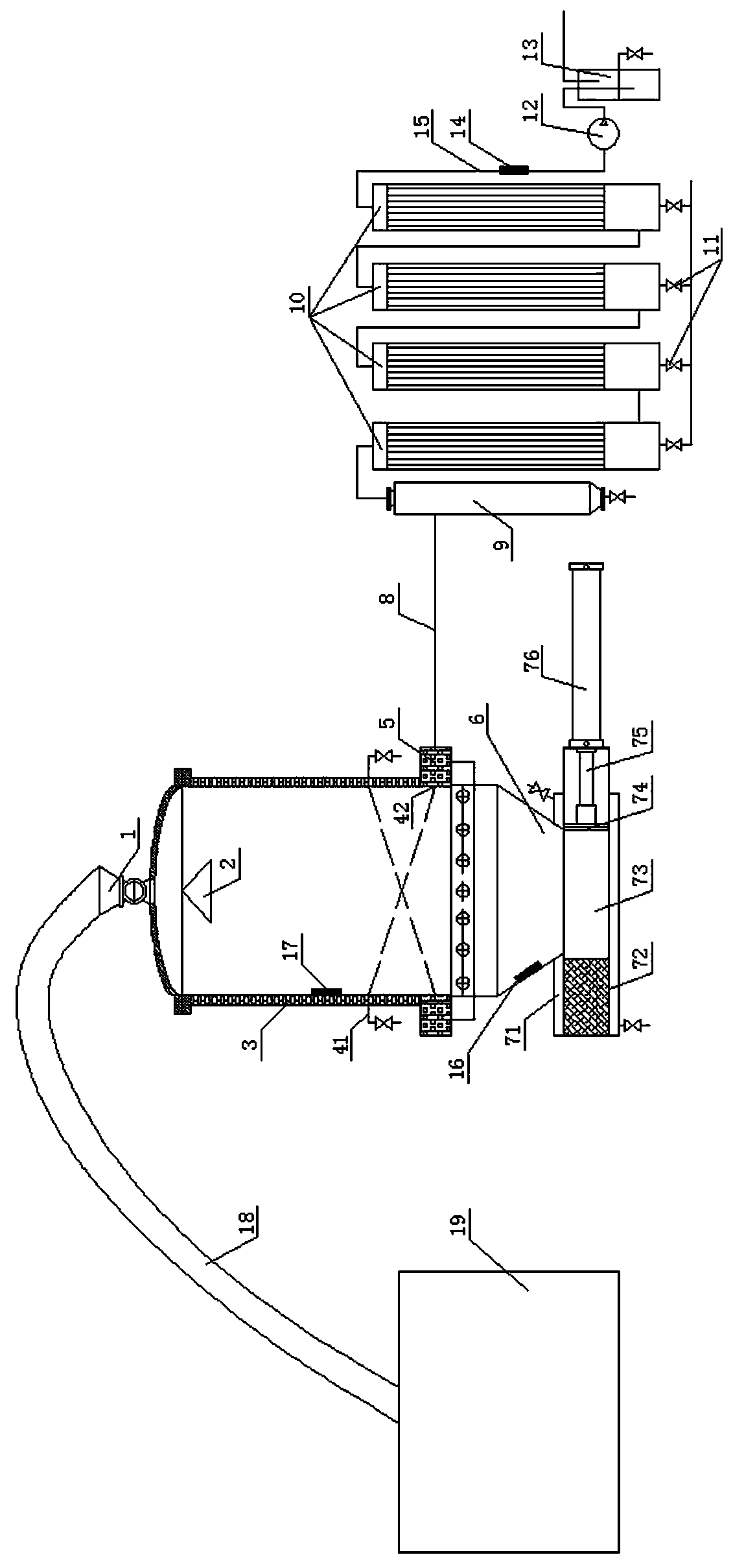

Plasmonic fuel cell

InactiveUS20070160896A1Effective electrochemical reactionGood generation/diffusionMaterial nanotechnologyReactant parameters controlElectrochemical responseElectricity

The invention discloses novel solutions in fuel cell technology that are based upon advances in nanotechnology. The solutions relate to the use of an embedded plurality of nanostructures in a fuel cell, to the nanostructures micro- to nano-positions with respect to each other, to tuned nanostructure properties to energy sources and nanotechnology effects. Such proposed solutions lead to more effective electrochemical reactions, to better generation / diffusion of ions, electrons, and reaction products at the reaction sites, to better “burning” of fuels, to reduced fuel cross-over effects, to more robust the fuel cell, to significant increased production of electricity in the proposed fuel cells, and to other beneficial effects.

Owner:AMERICAN ENVIRONMENTAL SYST

Sludge low temperature smoldering pyrolysis apparatus with automatic control and monitoring

ActiveCN110395865AReduce settingsReduce stirringSludge treatment by pyrolysisByproduct vaporizationAutomatic controlSlag

The invention discloses a sludge low temperature smoldering pyrolysis apparatus with automatic control and monitoring. The apparatus comprises control monitoring equipment, and one or more smolderingpyrolysis equipment, wherein the smoldering pyrolysis equipment comprises a pyrolysis furnace body and a sensing detection system, a closed feeder is arranged at the top of the pyrolysis furnace body,a slag discharge device is arranged at the bottom of the pyrolysis furnace body, and a carbon slag treatment device is equipped at a slag outlet of the slag discharge device; the bottom of the side wall of the pyrolysis furnace body is provided with a plurality of gas suction groups around the circumference, each gas suction group comprises a gas inlet and a gas outlet, the gas inlets are locatedabove the gas outlets, each gas inlet and the corresponding gas outlet are located at opposite side surfaces of the pyrolysis furnace body, an annular gas guiding pipe is arranged on the pyrolysis furnace body, each gas outlet communicates with the annular gas guiding pipe, and each gas inlet and each gas outlet are equipped with corresponding control valves; and a ventilation pipe is arranged onthe annular gas guiding pipe. According to the apparatus, the best smoldering effect is achieved, and monitoring of an operating state and a target position of each smoldering pyrolysis equipment isrealized by the control monitoring equipment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High-yield aquaculture method for river snails

ActiveCN106614162AGrowth adaptationPrevent escapeFodderSpecific water treatment objectivesWater sourcePaddy field

The invention relates to the technical field of river snail aquaculture, in particular to a high-yield aquaculture method for river snails. The aquaculture method uses mountain spring as a river snail aquaculture water source, the water source is natural and pollution-free, and a good growth environment is provided for the river snails; a rice field is further modified to ensure flowing water in the rice field, and an environment suitable for growth of the river snails is created; reinforced management is performed, a filtering medicine package is arranged in a water inlet, and leeches can be prevented from entering an aquaculture pool from the source; the method uses traditional Chinese medicine powder to perform disinfection, disinfection of the rice field can be achieved, and the immunity of the river snails can be enhanced; and scientific formula of bait and a basal material can effectively promote growth of the river snails, and disease control and a high-yield objective can be achieved.

Owner:贵港沃斯顿科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com