Anthracite carbon casting formed coke

A technology of anthracite and carbon, which is applied in coking ovens, special forms of dry distillation, and the petroleum industry, can solve problems such as slow heating of molten iron, blocked air flow, and slow combustion speed, and achieve high-quality products, high calorific value, moderately responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

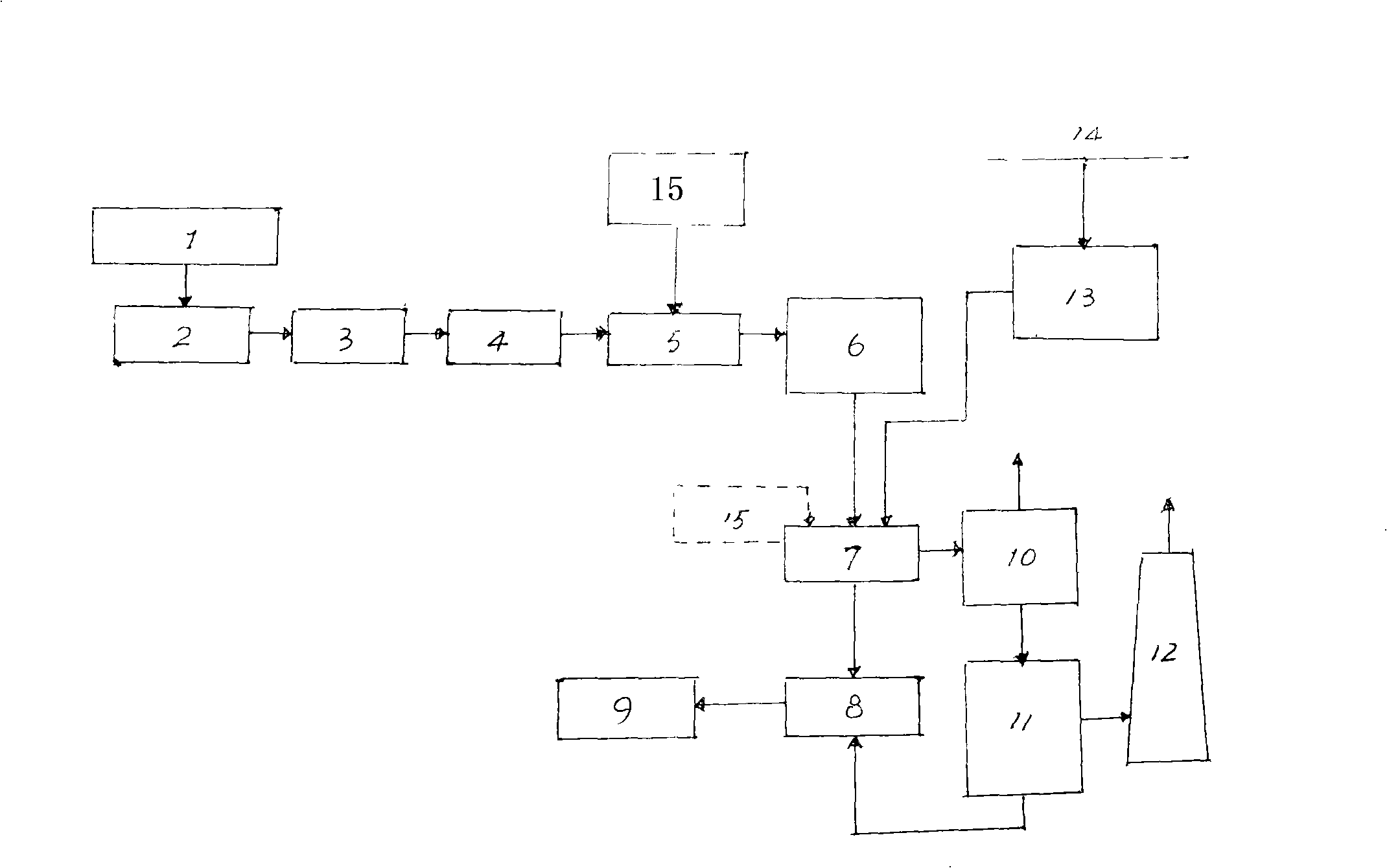

[0016] 1- raw coal stacking site; 2- coal loading hopper to send coal to the crusher; 3- crusher to crush raw coal; 4- pulverizer to grind coal powder into fine powder below 1mm; 5- cold and hot mixer to Raw coal powder and binder are added for uniform mixing and stirring; the heating of hot stirring is heated by the waste heat of high-temperature exhaust gas; 6-forming press sends the stirred coal into the mold for extrusion molding; 7-carbonization and carbonization chamber converts the mold The coke billet is loaded into the chamber, and the gas is sent from the gas generator to ignite and the combustion temperature is raised by 1050°C. When the volatile content in the coke billet is evaporated to about 1.5% in the state of air isolation, it can be released from the furnace; The molded coke is sent to the open high-pressure water nozzle to cool the hot molded coke to normal temperature; 9-The finished product warehouse is extinguished and the cooled molded coke is placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com