Patents

Literature

83results about How to "High quality product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine-made sand processing process

ActiveCN102806133ALow stone dust contentReduce soil contentGrain treatmentsCrushed stoneProcess engineering

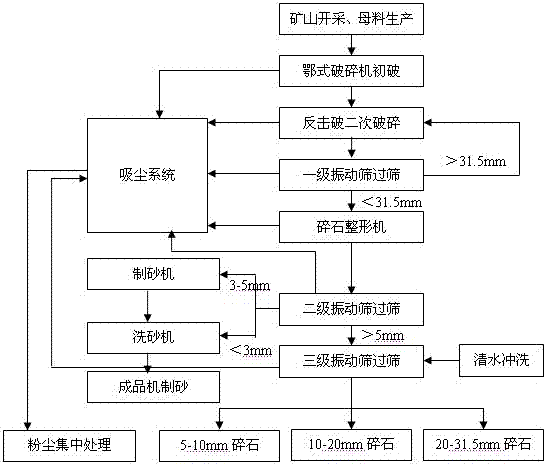

The invention discloses a machine-made sand processing process, which comprises the following processes that stone materials enter a jaw crusher to be decomposed into stone blocks not greater than 350mm, and then, the stone blocks enter a reverse smashing machine; the stone blocks are crushed into crush stones by the reverse smashing machine, the crushed stone enters a primary vibration sieve to be screened, the crushed stones smaller than 31.5mm enter an impact type crusher, and the crushed stones greater than 31.5mm return the reverse smashing machine to be crushed; after entering the impact type crusher to be crushed, the crushed stones enter a two-grade vibration sieve to be screened, and sand smaller than 3mm enters a sand washing machine; sand greater than 3 to 5mm enters an efficient fine crushing machine to be made into sand smaller than 3mm, and the sand smaller 3mm enters the sand washing machine after entering two-grade vibration sieve to be screened; the crushed stones greater than 5mm enter a three-grade vibration sieve; the crushed stones are screened into the crushed stones in three grades by the three-grade vibration sieve, and the crushed stones are used for material discharge in the vibration sieve after being flushed by water. The machine-made sand produced by the process provided by the invention has the advantages that each index can respectively meet the technical index of high-performance on machine-made sand, and the product quality is high, and stability and reliability are realized.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Intelligent screening system based on numerical control processing technology for difficult-to-machine metal

InactiveCN101930223AQuality improvementLow costBiological neural network modelsSpecial data processing applicationsNumerical controlOperational system

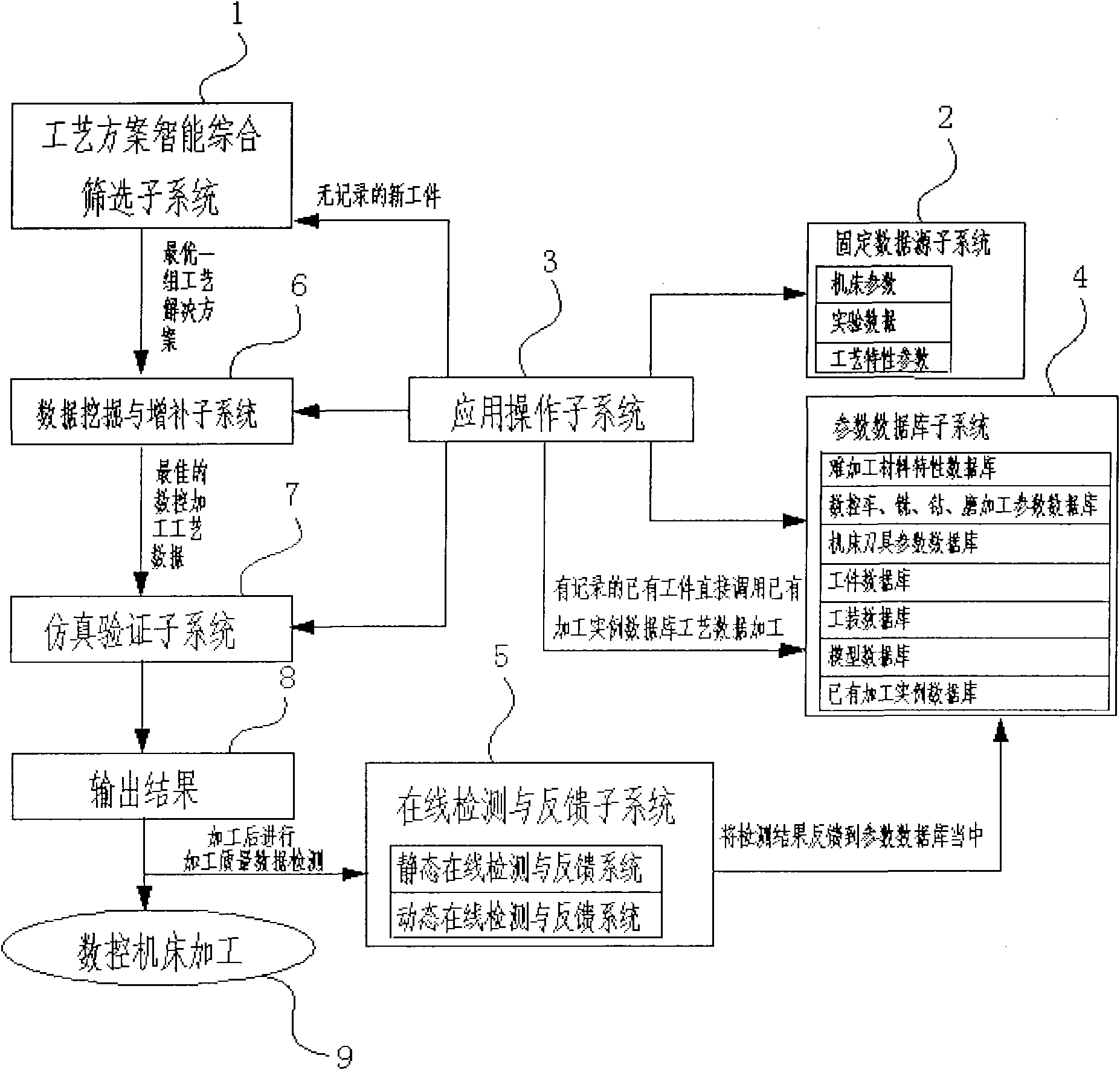

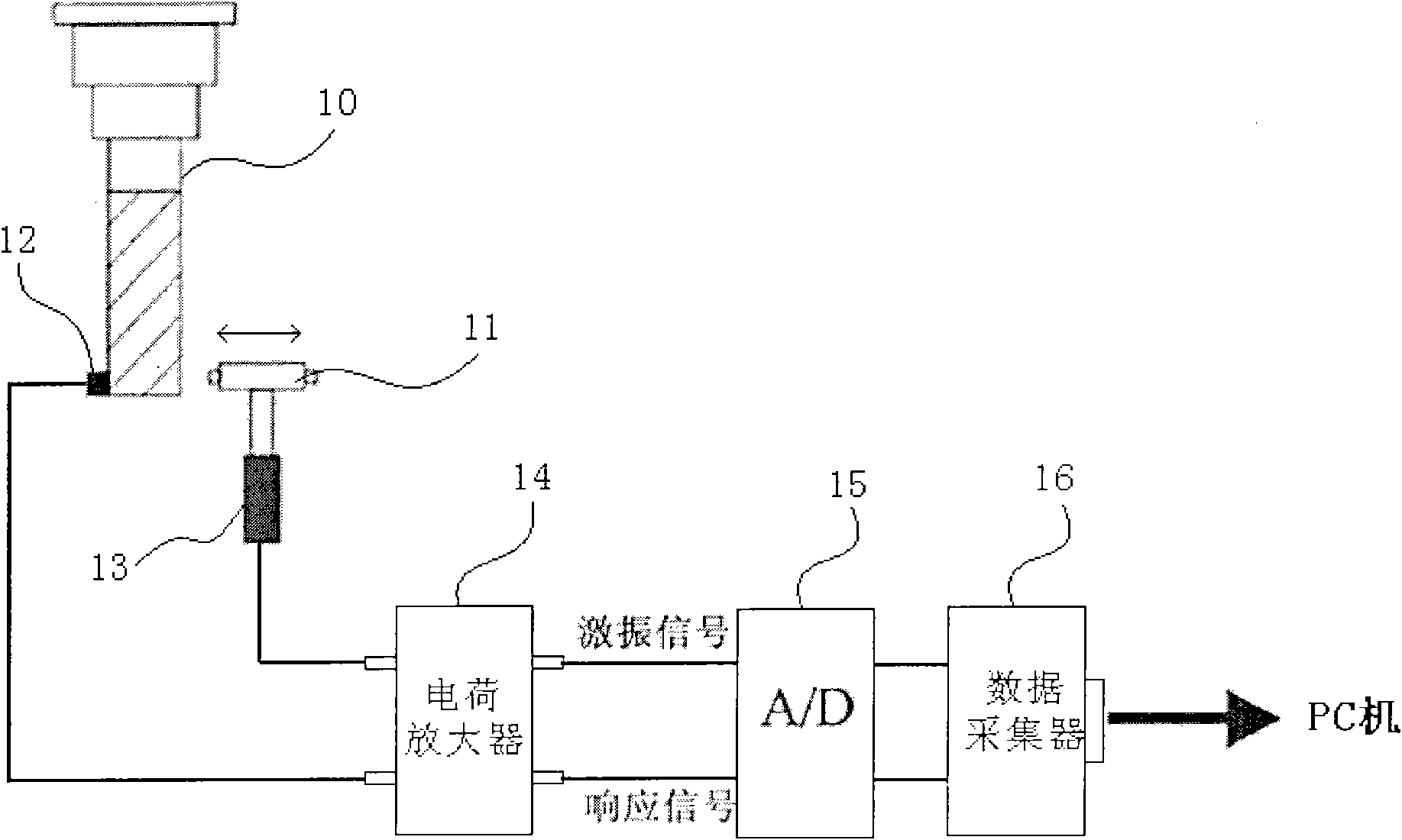

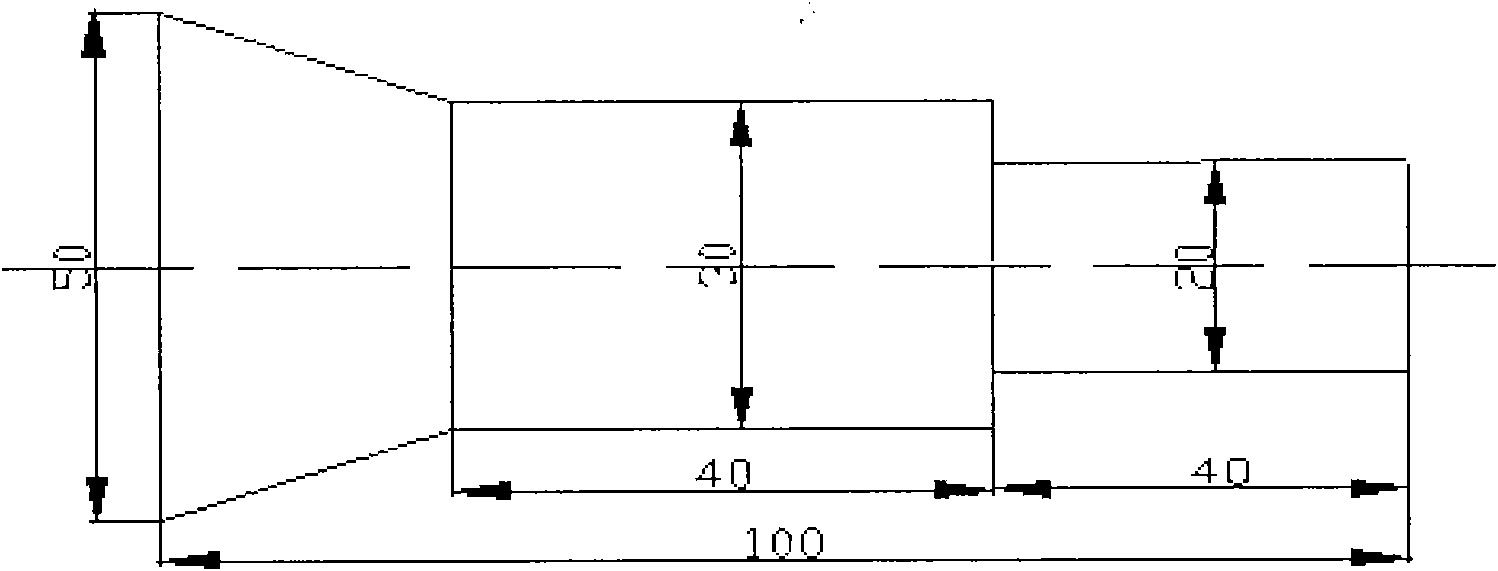

The invention discloses an intelligent screening system based on the numerical control processing technology for difficult-to-machine metal, which comprises the following subsystems: a parameter database subsystem, a fixed data source subsystem, an online detection and feedback subsystem, a technology intelligent comprehensive screening optimized scheme system, a data mining and supplementing subsystem, a simulation verification subsystem and an application operating system. The system has the characteristic of recognizing the reasonableness, the advancement and the high efficiency property of each technology scheme in the database, and is used for collecting the processing information of difficult-to-machine metal materials, the machine tool and cutter selection experience and cutting technological parameters accumulated in production practices and experiments. The roughness test data of the optimized cutting technological parameters is selected for processing, so that a reasonable and mature technological scheme is recommended for manufacturing enterprises, and the numerical control processing precision of the difficult-to-machine metal materials is controlled. The purposes of increasing the processing efficiency of the difficult-to-machine materials, reducing processing cost and acquiring high quality products are achieved.

Owner:曾谊晖

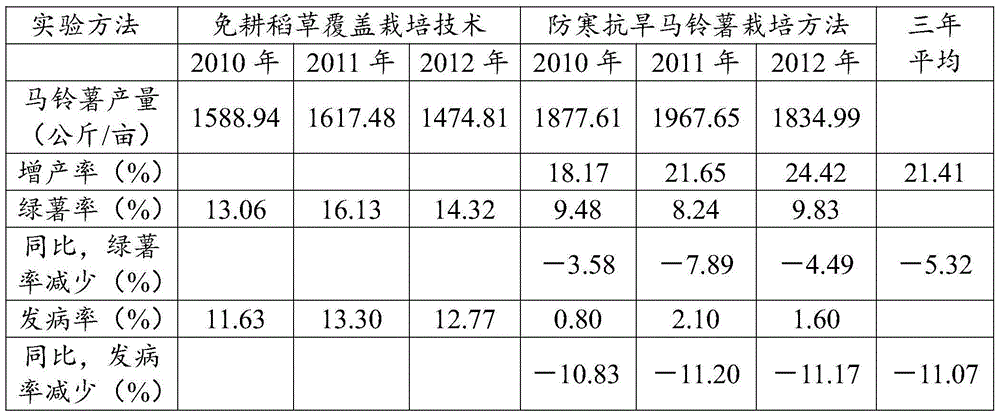

Cold-proof drought-resistant cultivation method for potatoes

InactiveCN104663226AAvoid infectionImprove germination ratePlant cultivationCultivating equipmentsEconomic benefitsInsect pest

The invention discloses a cold-proof drought-resistant cultivation method for potatoes, and relates to the technical field of potato cultivation. The cultivation method comprises the following steps: selecting varieties, processing potato seeds, preparing soil and ridging, sowing and applying a fertilizer, laying a trickle irrigation pipeline and watering, laminating a film and covering soil, taking cold-proof measures, preventing and controlling plant diseases and insect pests, harvesting and grading. Compared with a normal no-tillage cultivation and straw covering cultivation technology, the cold-proof drought-resistant cultivation method for potatoes disclosed by the invention does not need to use straws for planting the potatoes, so that the production raw materials and the artificial operation cost are reduced, the cold-proof drought-resistant effects are good, and high-quality products are produced. Moreover, a green potato rate and morbidity are obviously reduced, the goods potato rate of the potatoes and the yield are increased, so that the economic benefits are remarkable.

Owner:广西壮族自治区农业科学院经济作物研究所

Method for recovery plus-negative plate material from waste and old electrode plate

InactiveCN1758478AImprove adhesionImprove ductilityReclaiming serviceable partsWaste accumulators reclaimingMaterials scienceNickel–metal hydride battery

This invention relates to a method for recovering positive and negative materials from waste pole plates including a high temperature method and a specific gravity method, in which, the high temperature method includes putting the waste positive and negative pole plates under high temperature to dissolve the PVDF and break the positive and negative materials from the matrix and separate them from the conduction agent, then separating the PVDF with water, which applies a physical method to recover the materials and does not change the physical and chemical targets of the materials.

Owner:朱明明

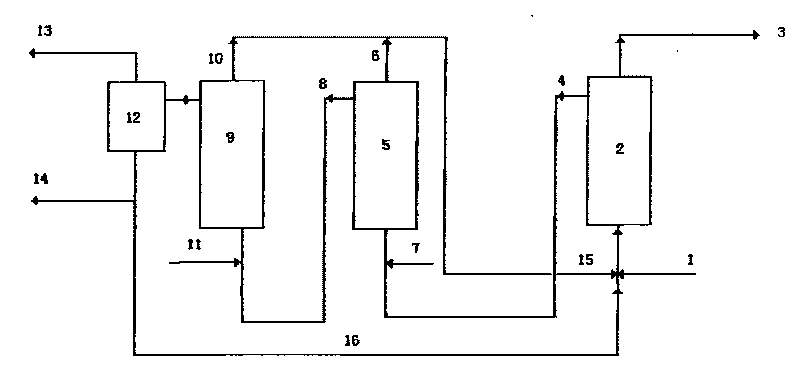

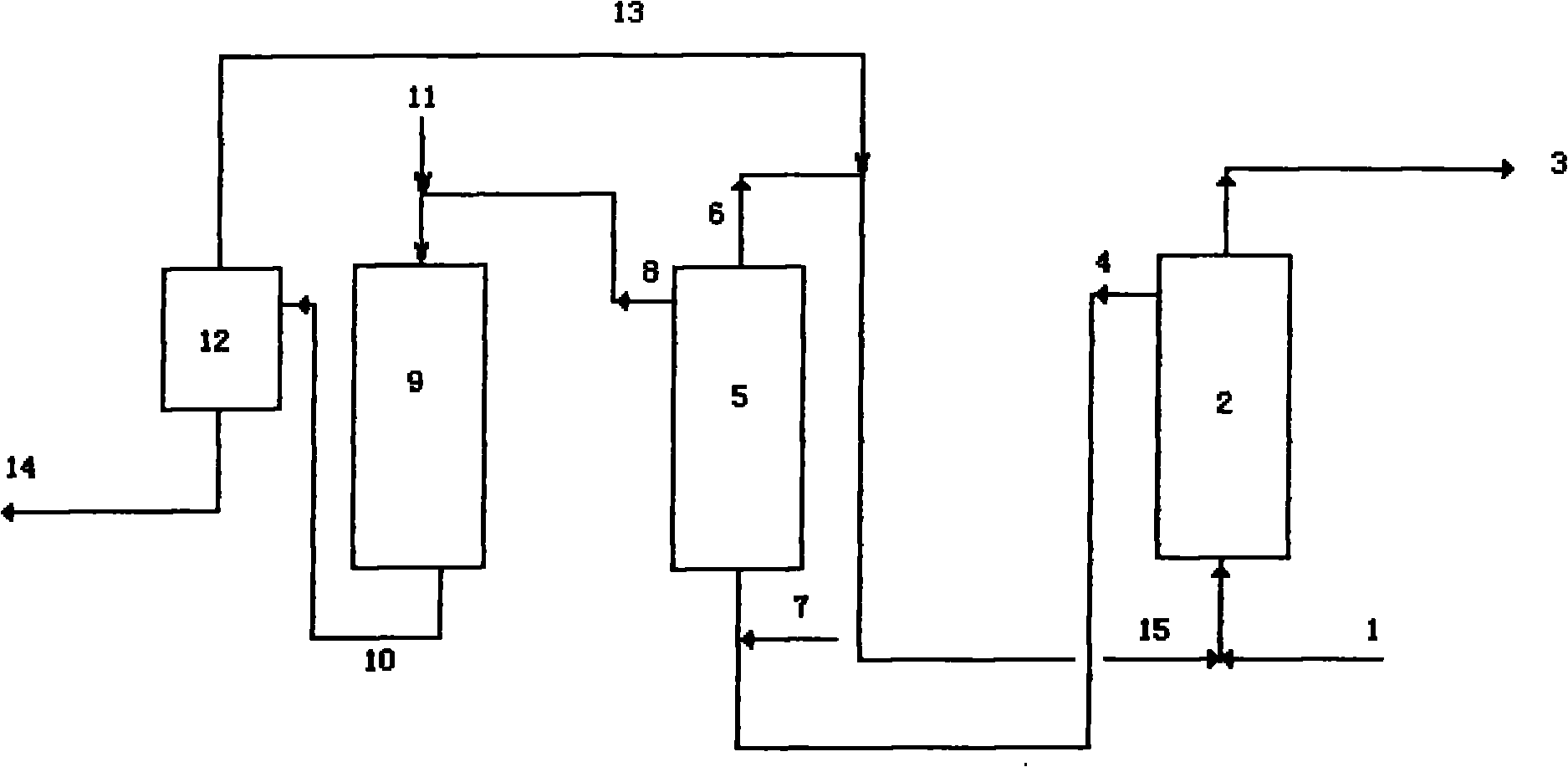

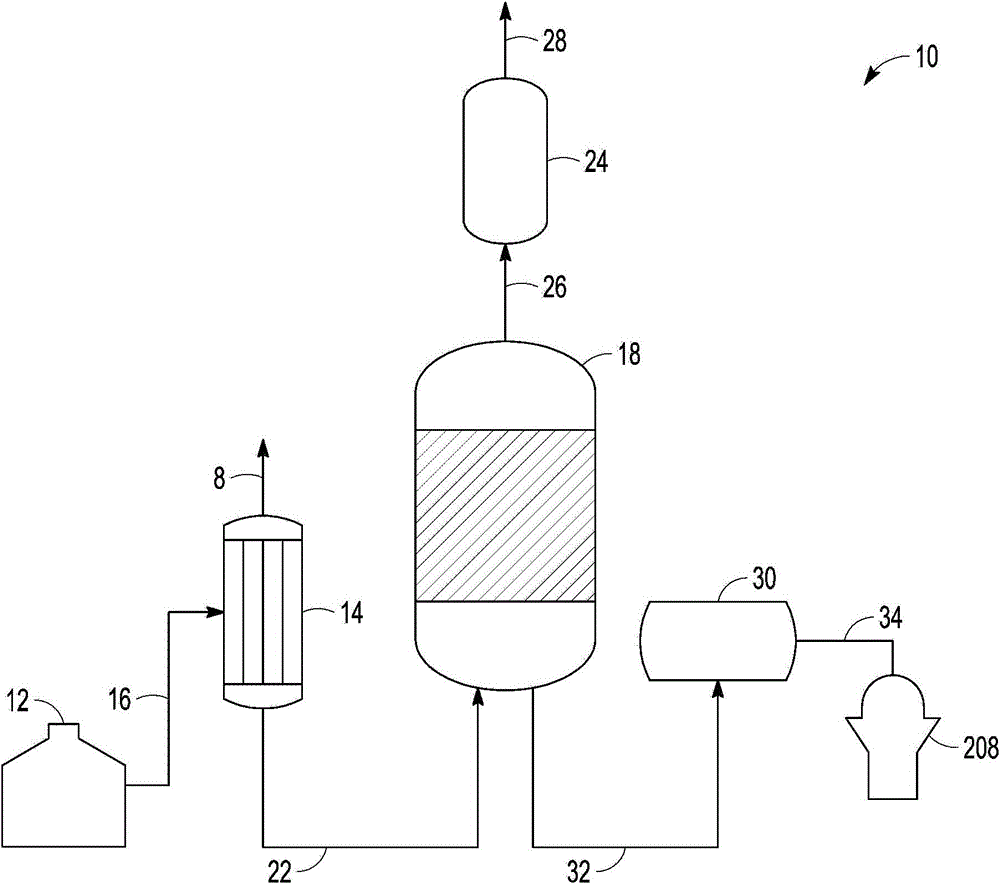

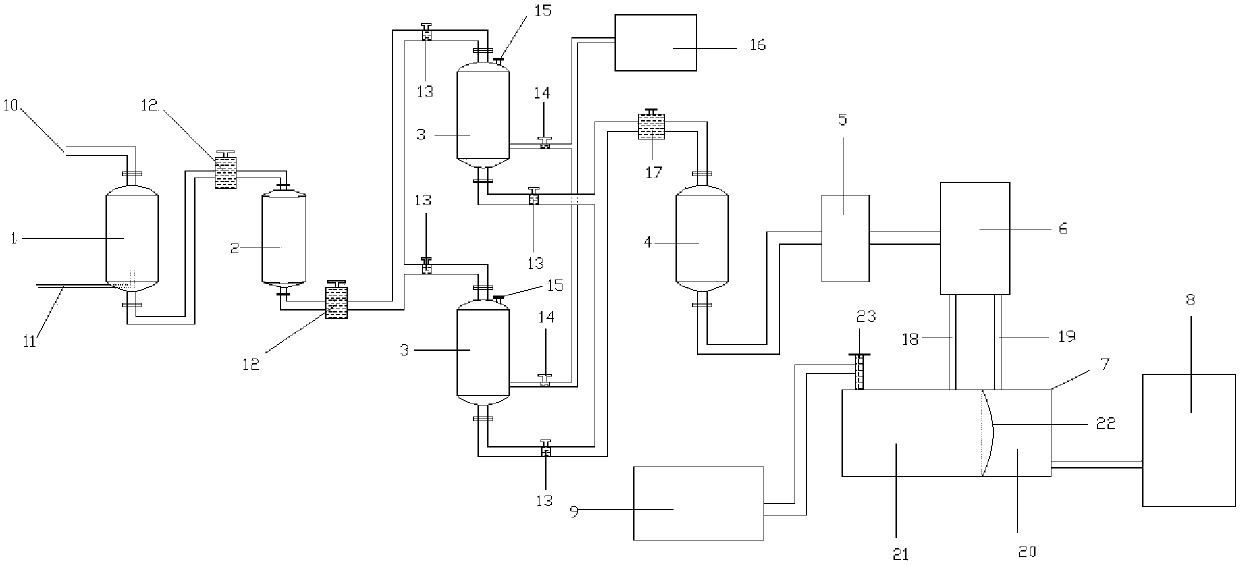

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

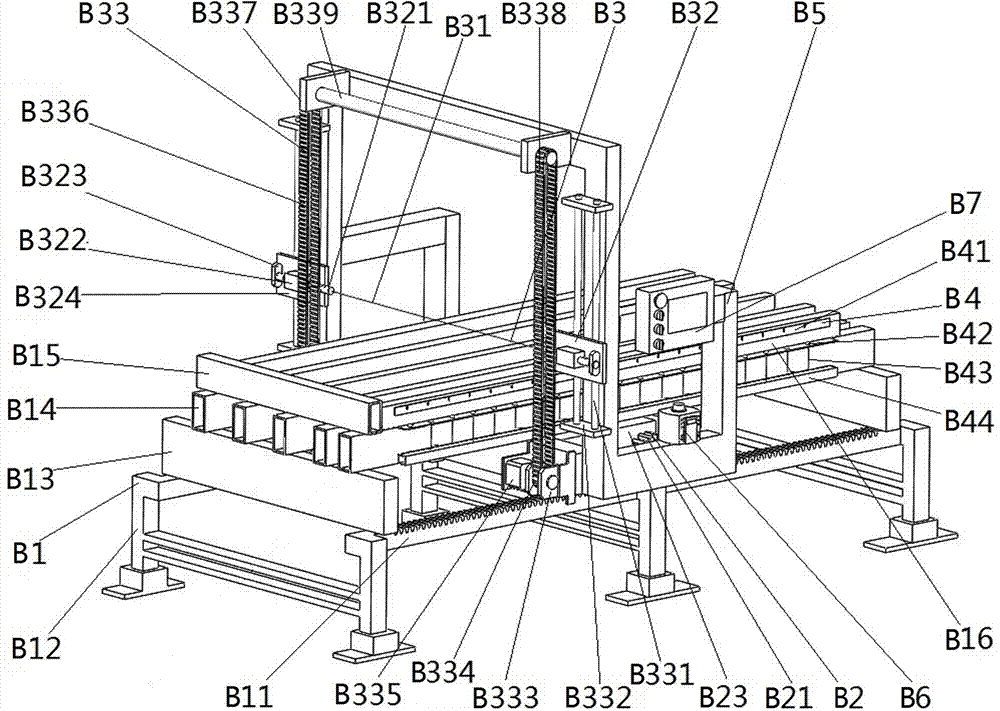

Automatic welding production line of lighter

InactiveCN102152031AAvoid randomnessIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses an automatic welding production line of a lighter, comprising a rack and a control device, The rack is provided with a transmission line; a fed-material feeding conveying station, a case flattening station, an inner machine head flattening station, an inner machine head directional assembling station, a welding station, a dust removing station, an inner machine head positioning station and a discharged-material conveying station. The automatic welding production line can weld a plurality of lighters simultaneously, therefore the production efficiency is greatly improved, and the product quality is more stable.

Owner:阮俊康

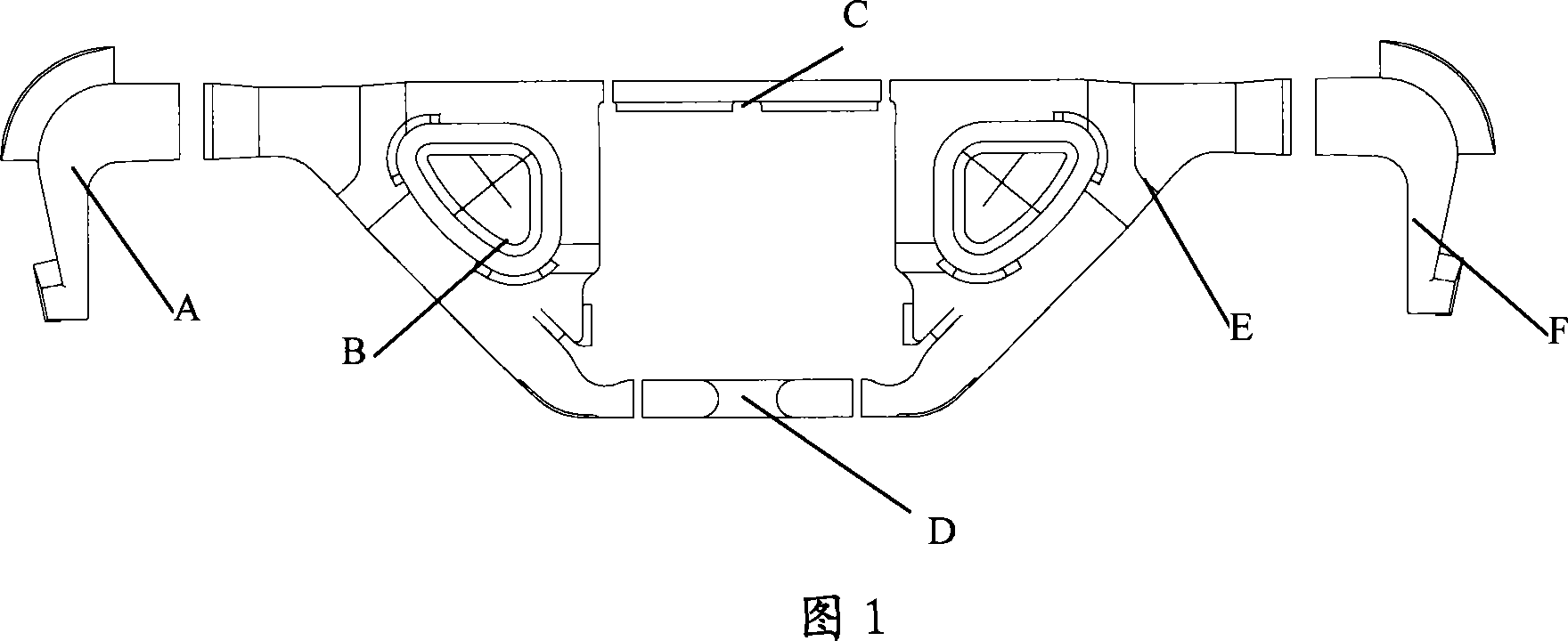

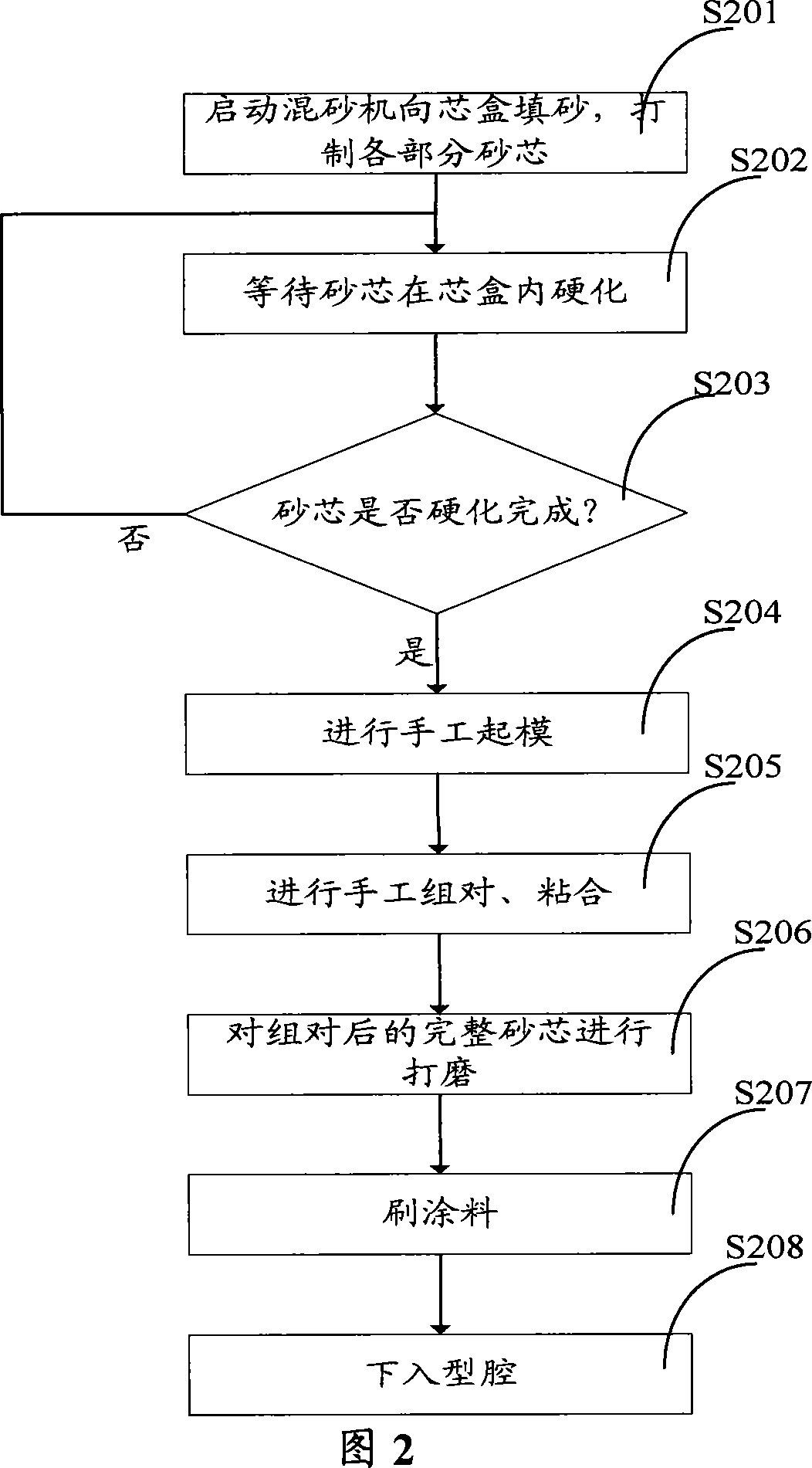

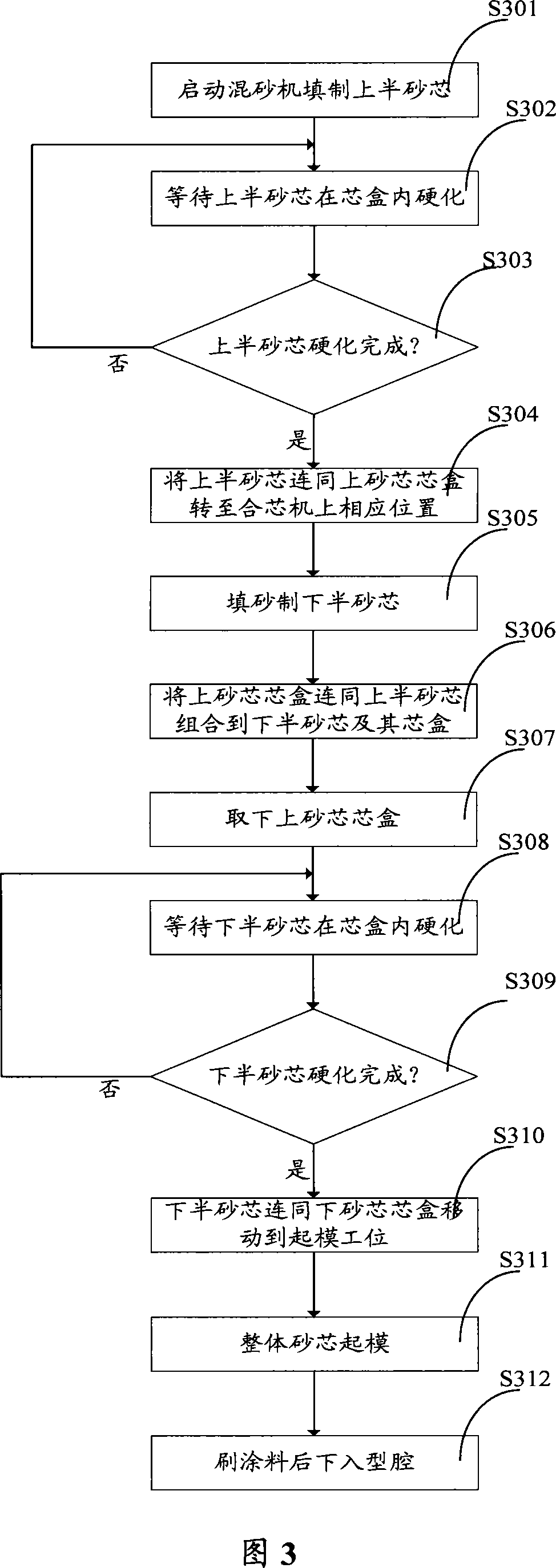

Bolster and side frame integral core producing method

ActiveCN101053891AEfficient production operationsImprove adhesionFoundry mouldsFoundry coresAdhesiveMaterials science

The invention discloses a production method of an integrated core for a bolster and a side frame. The method is used to a process of the integrated core of a cavity in the bolster and the side frame, which is designed as an upper and a lower sand cores, comprising: starting a sand mixing machine to produce a first slice of sand core by sand filling, and hardening the first slice of sand core in a corresponding sand core box; starting the sand mixing machine to produce a second slice of sand core by sand filling, in a state that the second slice of sand core is not hardened, combining the second slice of sand core and the core box thereof with the first slice of sand core and the sand core box thereof to hardening second slice of sand core; drawing of patterns of the integrated core. The integrated core production method of the bolster and the side frame provided in the invention omits operation process such as manual assembly, grinding and the like, adopted by the prior technology, due to the integrated core process, meanwhile, according to the production method, the upper and lower sand cores use a selfbonded manner, without bonding by an adhesive, thus a better bonding effect is achieved.

Owner:CRRC QIQIHAR ROLLING CO LTD

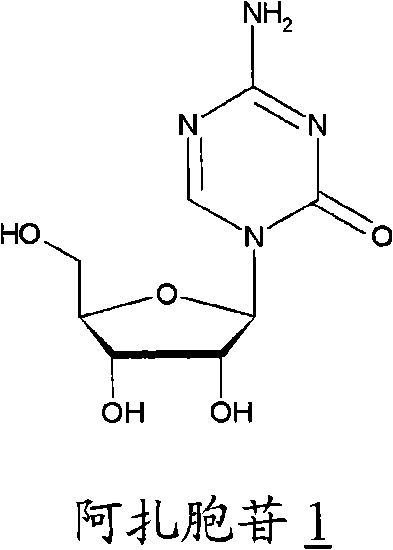

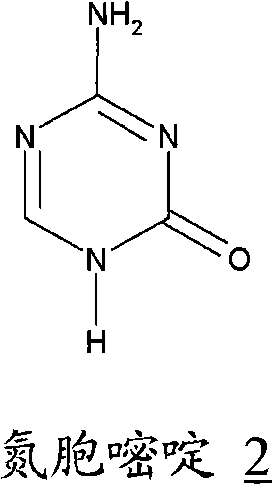

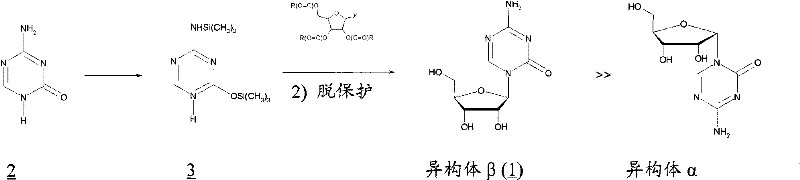

Process for the synthesis of azacitidine and decitabine

ActiveCN102206240AHigh yieldAvoid processing powerGroup 4/14 element organic compoundsSugar derivativesOrganic solventTrimethylsilyl

Described herein is a process for the synthesis of azacitidine or decitabine, comprising the silylation of azacytosine in the presence of N,O-bis-trimethylsilyl)-trifluoroacetamide. Such reaction is performed in an organic solvent, preferably aprotic, even more preferably selected from among dichloromethane, dichloroethane and / or acetonitrile. According to a further aspect of the process, 2 to 3 moles of N,O-bis-trimethylsilyl-trifluoroacetamide are used per mole of azacytosine, preferably from 2.2 to 2.5.

Owner:CHEMI SPA

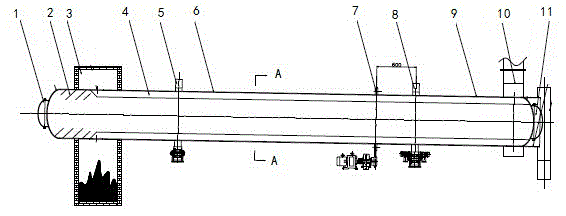

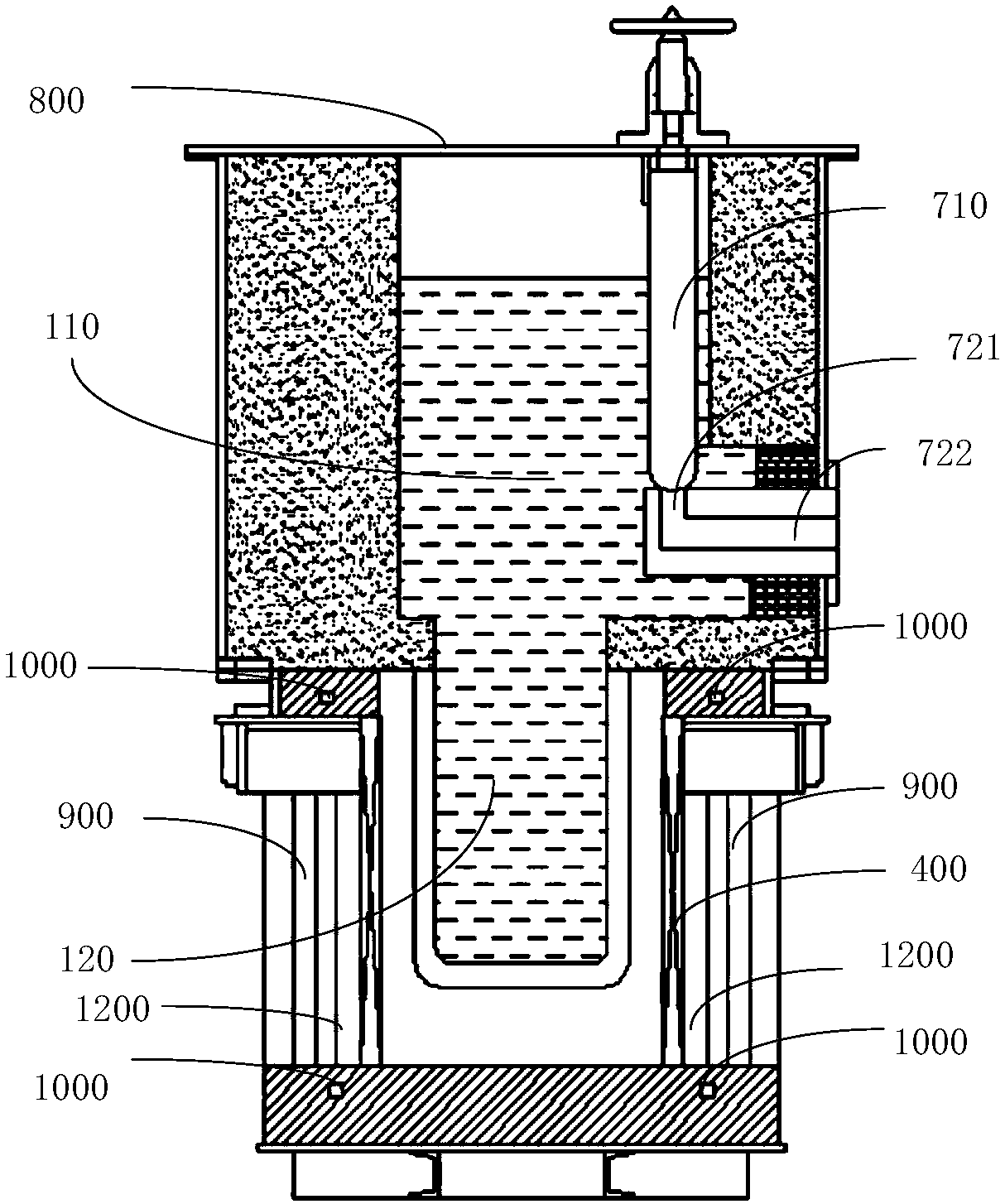

Rotary crystallization kiln for alpha gypsum powder

The invention discloses a rotary crystallization kiln for alpha gypsum powder. The rotary crystallization kiln for alpha gypsum powder comprises a rack, a kiln body, a feeding end, a discharging end, a tail gas collector, a heat supply chamber, a heat exchanging pipe, an inlet end socket, an outlet end socket and a power transmission device, wherein the kiln body and the power transmission device are mounted on the rack; the power transmission device is used for driving the kiln body to rotate on the rack, and when the inlet end socket and the outlet end socket are closed, the kiln becomes an airtight space; and a circle of heat exchanging pipe communicated with the heat supply chamber and having the function of a lifting board is fixed on the inner wall of the kiln body. The rotary crystallization kiln is in a dynamic mode rather than a static mode; the heat exchanging area is increased due to the arrangement of the heat exchanging pipe; heat energy is fully used through multiple technical methods, and therefore, energy consumption is lowered; the functions of pre-drying, autoclaving crystallization and product drying are integrated, the process steps are reduced, the quantity of equipment is lowered, the production time is shortened, and the production cost is lowered; and no external high-temperature steam or aqueous solution participates in heat exchange and reaction, and hemihydrate gypsum is prevented from being hydrated again into dihydrate gypsum, so that the product quality is more stable.

Owner:湖南昌迅科技环保股份有限公司

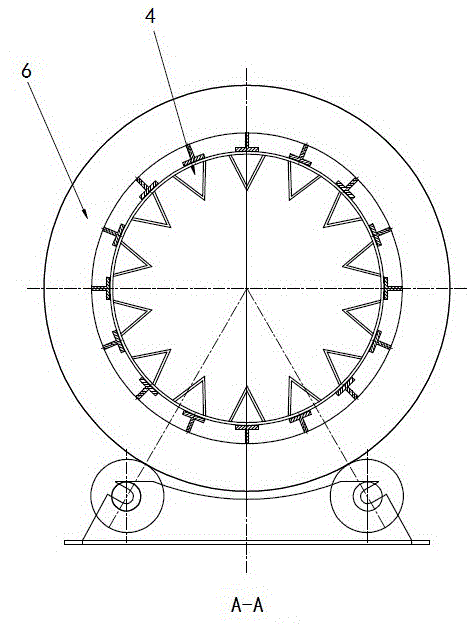

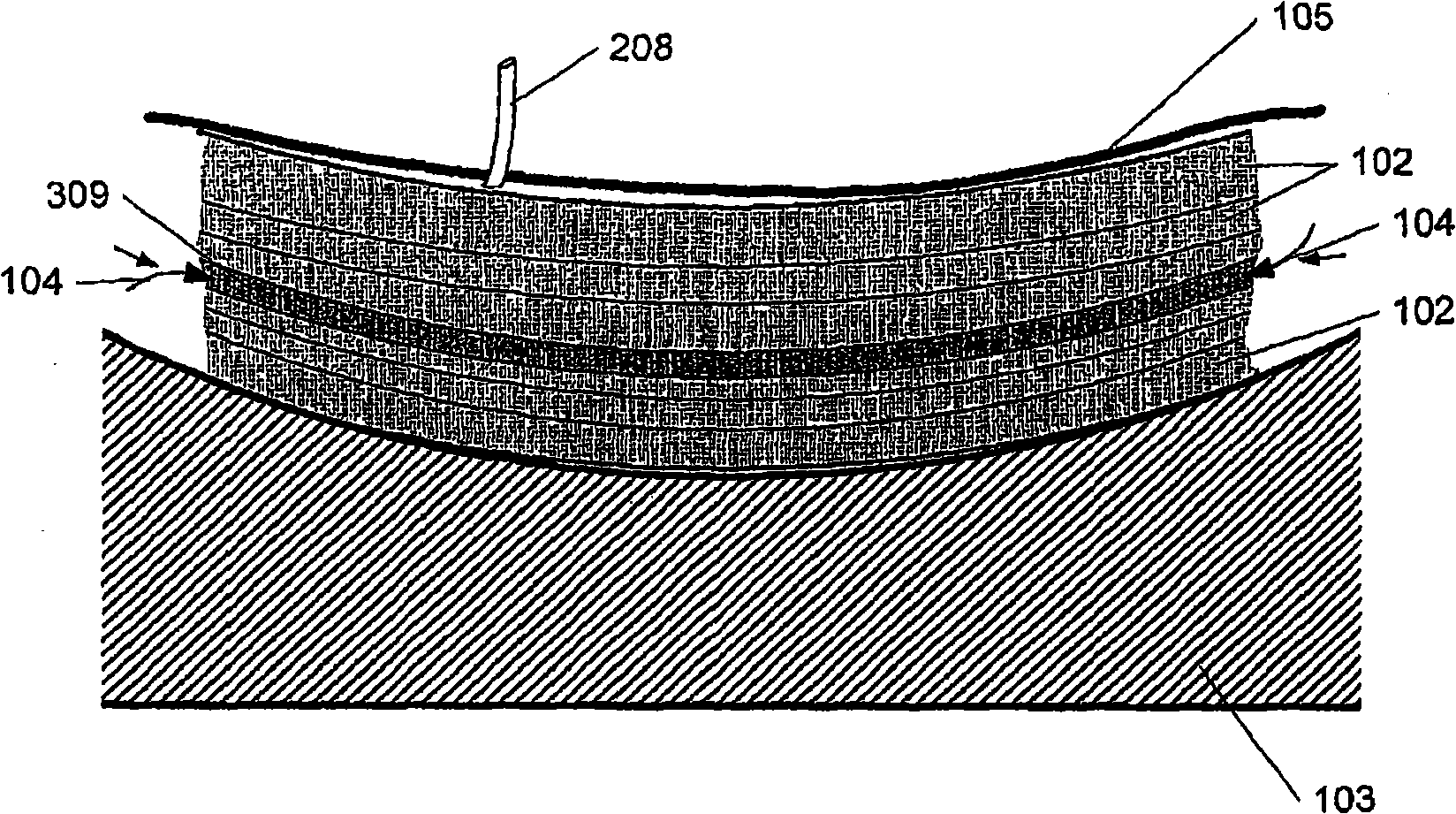

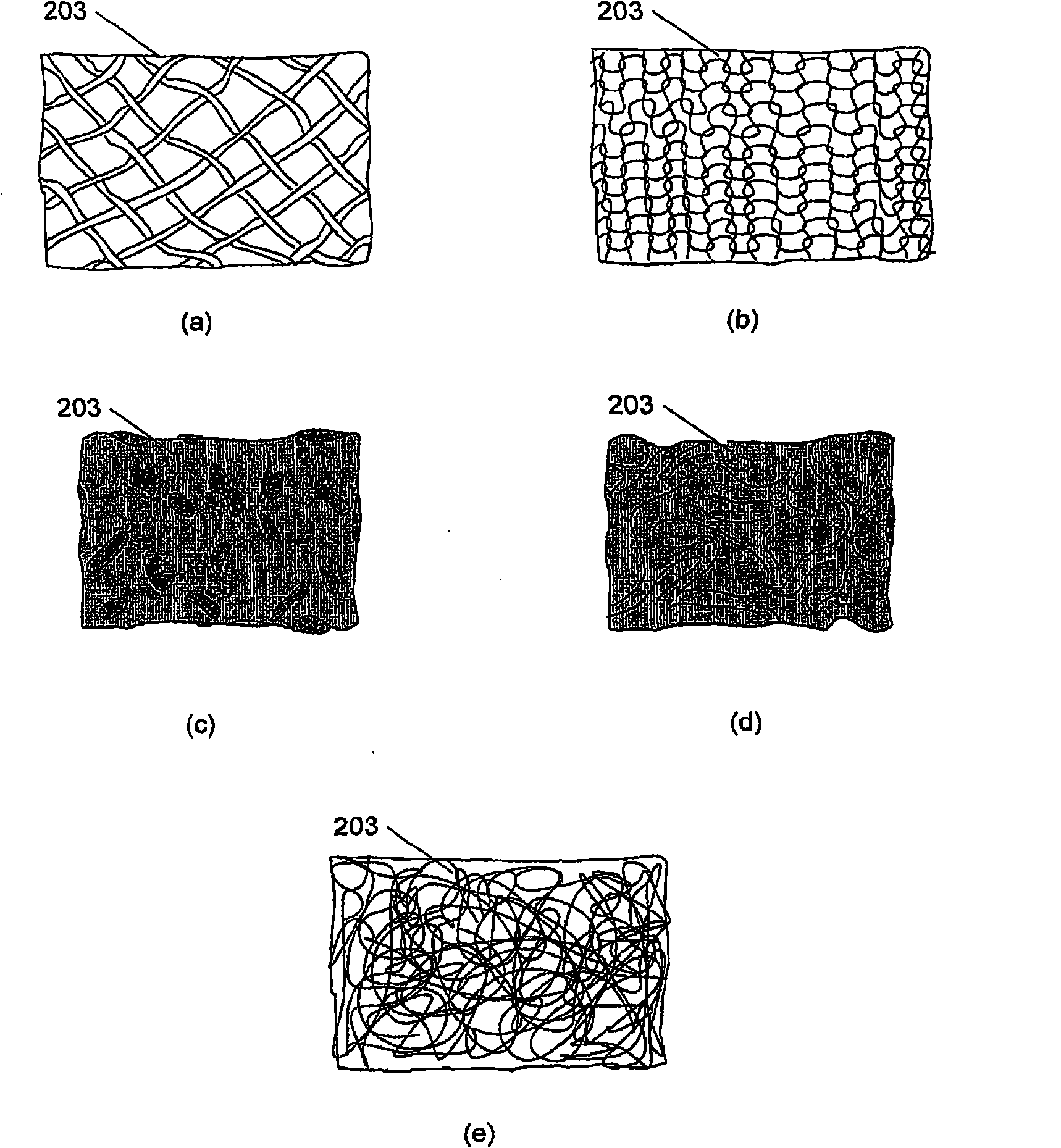

A method for producing a fibre-reinforced product

The present invention relates to a RTM method of producing a fibre-reinforced product which method comprises the steps of: a) placing at least one porous member (104) in a mould (103); b) placing one or more layer(s) of reinforcing fibres (102) in the mould; c) introducing resin for distribution through the porous member to the fibre layers, - and d) allowing the resin to cure and the distribution member to coalesce to form a continuous layer, as well as the produced fibre-reinforced composites. The invention furthermore relates to the use of a porous member of a material which is capable of coalescing to form a continuous layer in the finished fibre-reinforced product. The invention overcomes problems related to the use of conventional gelcoat materials and forms a surface layer of the final product having the same or similar characteristics as traditional gelcoat materials.

Owner:LM GLASSFIBER

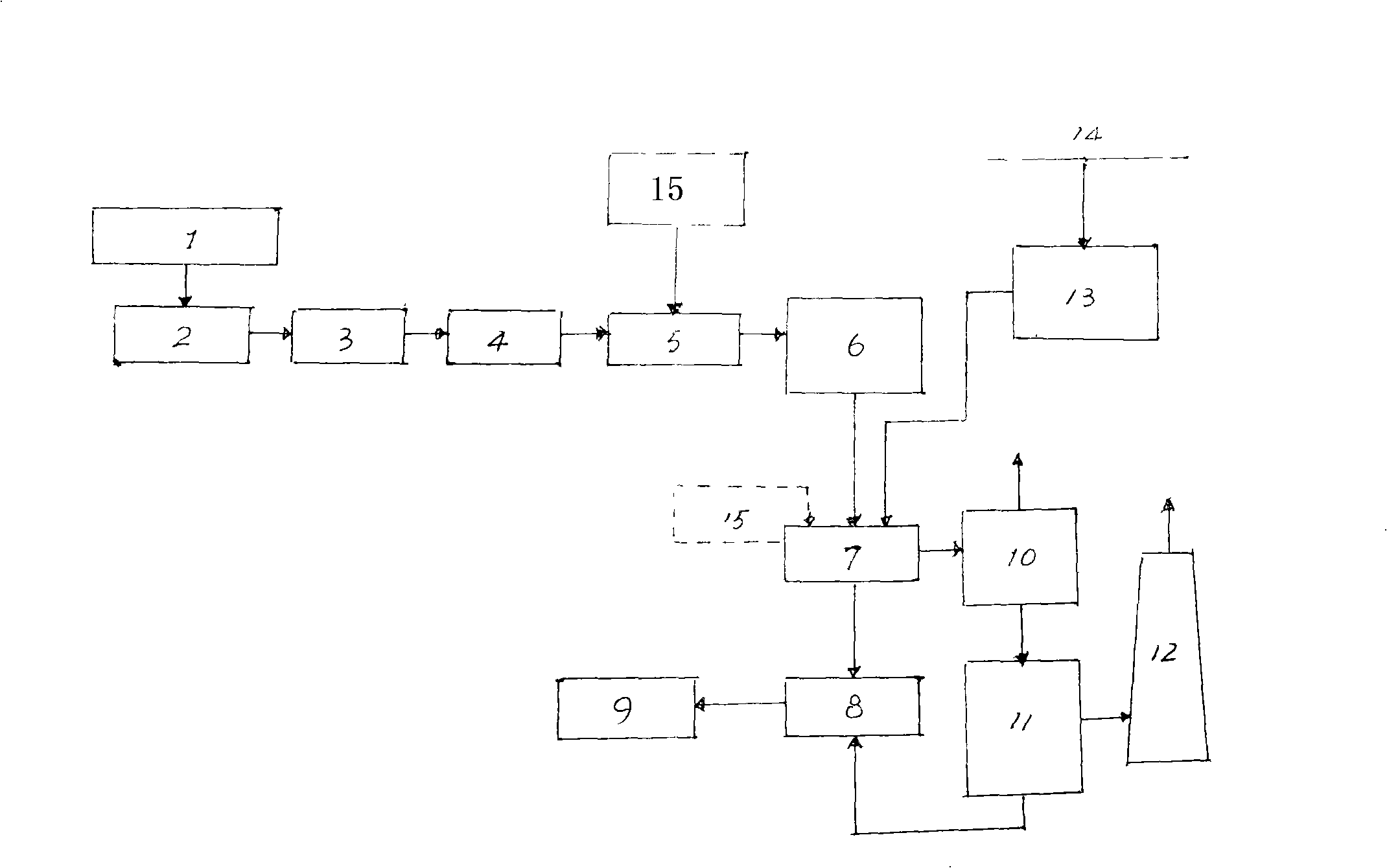

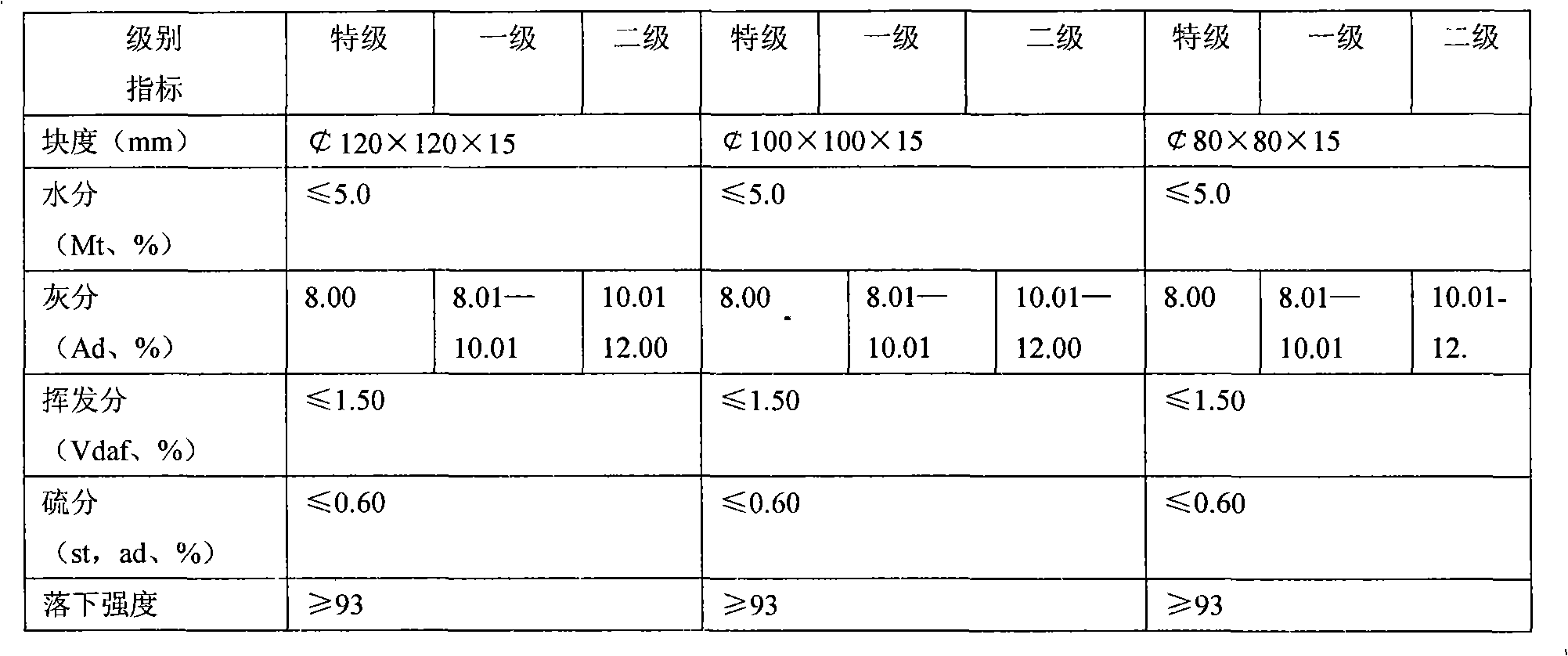

Anthracite carbon casting formed coke

InactiveCN101280203ARealize protection and meet emission standardsHigh carbon contentSpecial form destructive distillationFoundryHigh carbon

Disclosed is anthracite carbon foundry formed coke which solves the disadvantages of uneven granularity, insufficient oxygen-adding, high broken rate and environment pollution found in the formed coke in the prior art; the anthracite carbon foundry formed coke is characterized in that the anthracite or non-coking coal is used to produce the anthracite carbon foundry formed coke; the steps include that the raw coal is conveyed to the factory, crushed and grinded to powder; the binder is added to the grinded powder and the mixture is stirred under the cooling condition, and then stirred evenly after being heated; the mixture is conveyed to the pressing machine for the extruding formation; the formed material is conveyed to the carbonization chamber and then is processed with dry distillation and carbonization under the conditions of air-isolation and the temperature ranging from 950 DEG C-1050 DEG C; finally, the formed material is cooled and the finished product is outputted to be stored in the storehouse for sale; the process of comprehensive utilization of the coke-oven gas generated in the carbonization chamber is set for the lime joint production; the process of dust removal and desulfurization is set for the flue gas and SO2 in the exhausted gas; based on the special binder formula and the special product structure and compared with the traditional coking method, the anthracite carbon foundry formed coke has the advantages of high carbon content, high calorific value, low ash content and sulfur content, crush resistance, abrasion resistance, good intensity, moderate reactivity, high intensity after reaction, good cold and heat intensity, reasonable and simple structure, small investment, low expense and specially being applicable to the coking and the mechanical casting industries.

Owner:YANGQUAN YANGMEI FORMED COKE TECH DEV CENT

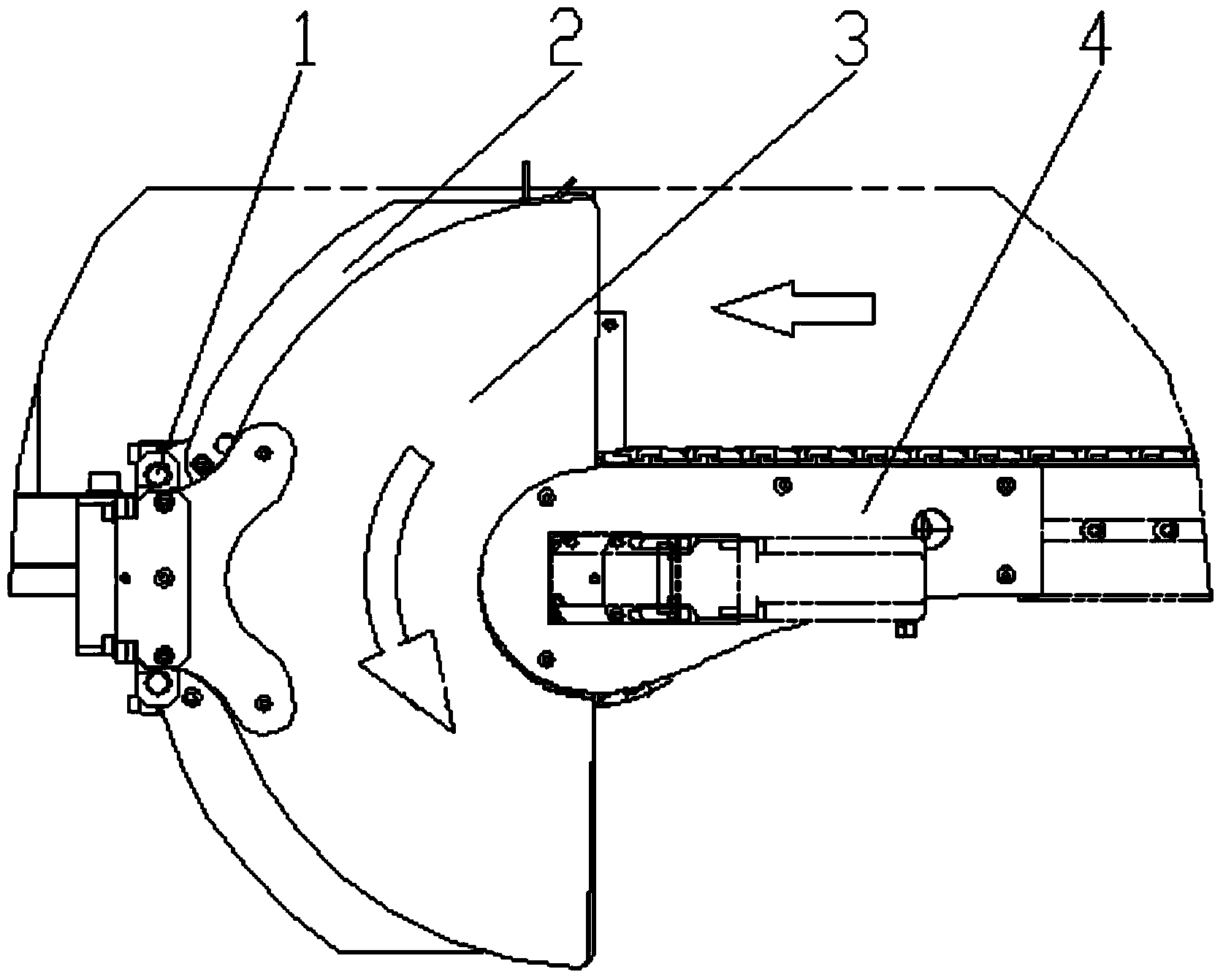

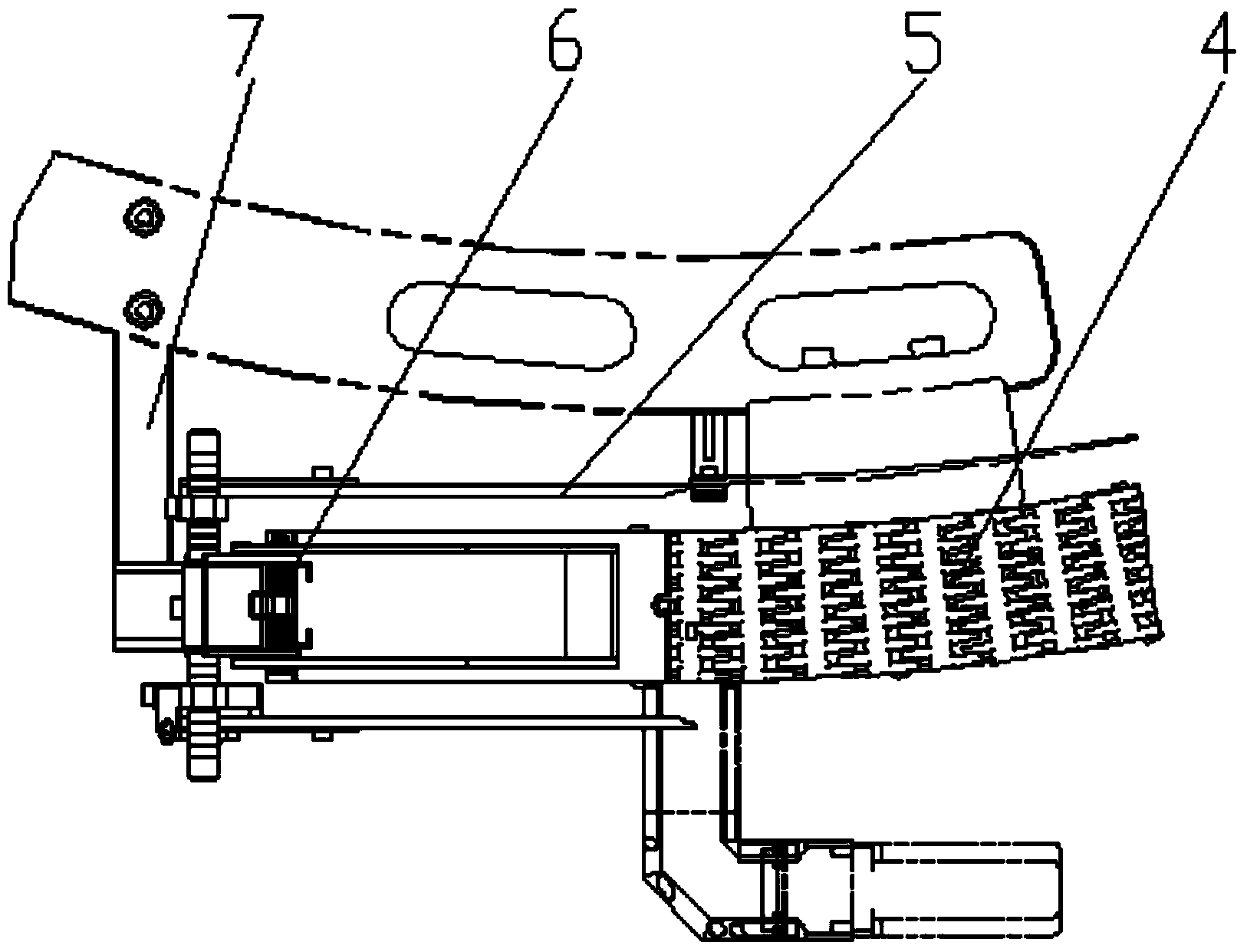

Flexible steering device for conveying rod-shaped materials

The invention relates to the field of rod-shaped material storing and conveying, in particular to a flexible steering device for conveying rod-shaped materials. The flexible steering device for conveying the rod-shaped materials comprises a circular disc storing-conveying device. A semicircular outer blocking plate and an inner side blocking plate are arranged at the steering portion of the circular disc storing-conveying device. A swinging arc flow guiding plate which is connected through a hinged shaft is arranged at a material inlet portion between the outer blocking plate and the inner side blocking plate. The swinging arc flow guiding plate is connected with a supporting block through the hinged shaft. The two ends of the supporting block are arranged in the middle of the outer blocking plate and the inner side blocking plate through an upper supporting rod and a lower supporting rod. A fixed arc flow guiding plate is arranged at a material output part between the outer blocking plate and the inner side blocking plate. An elastic device is arranged on the swinging arc flow guiding plate, and the position of the elastic device is adjusted according to a preset range. The problems that the conveyed rod-shaped materials are squeezed during steering, and gaps are generated during steering can be avoided, even output of the rod-shaped materials and material quality are guaranteed, and high-quality products are obtained.

Owner:河南施普盈科技有限公司

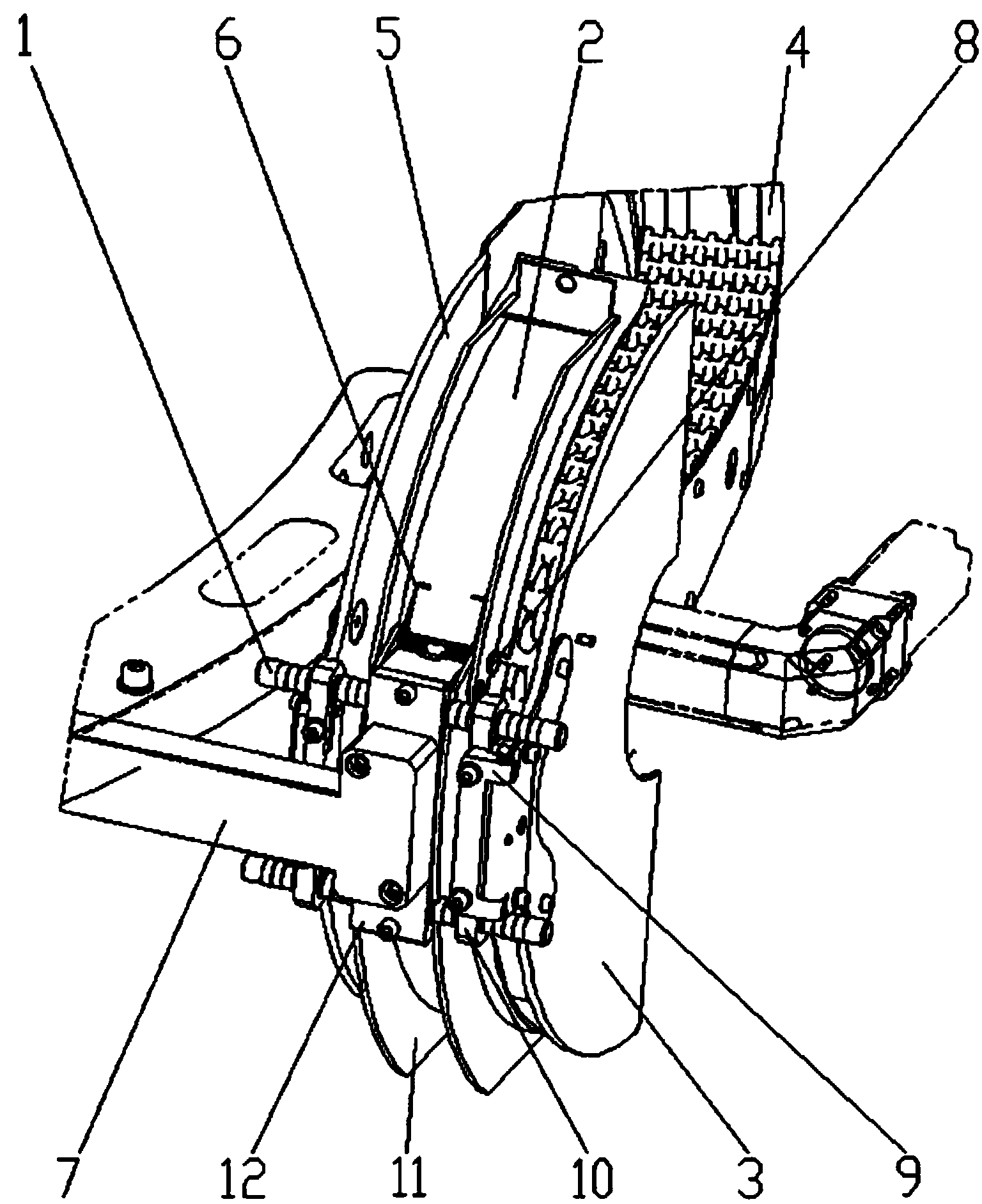

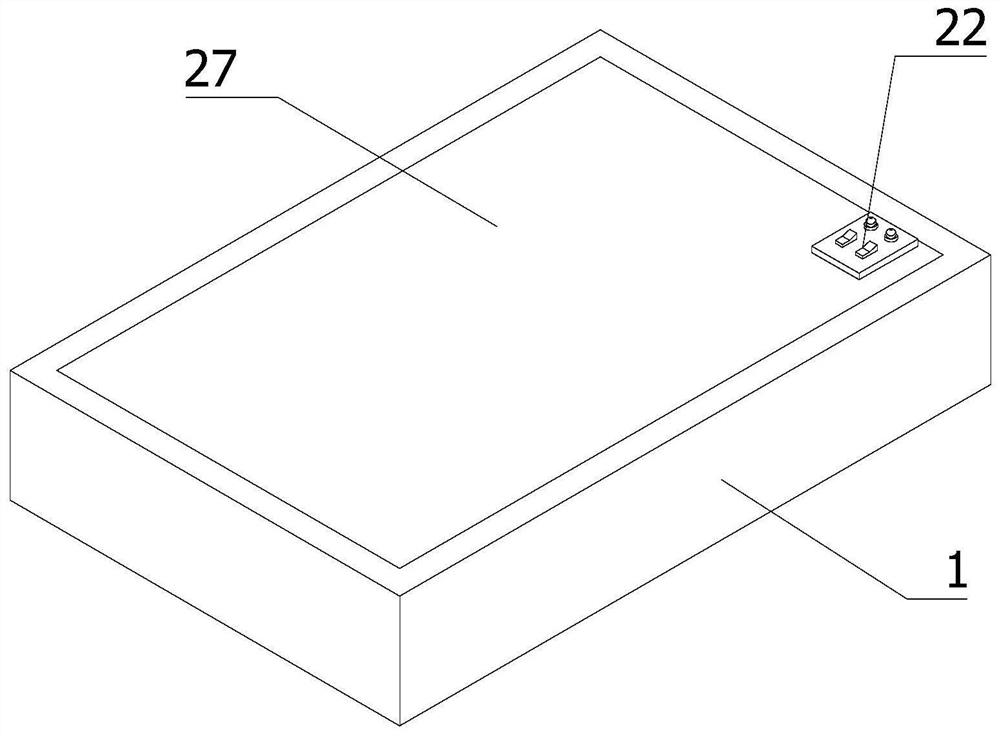

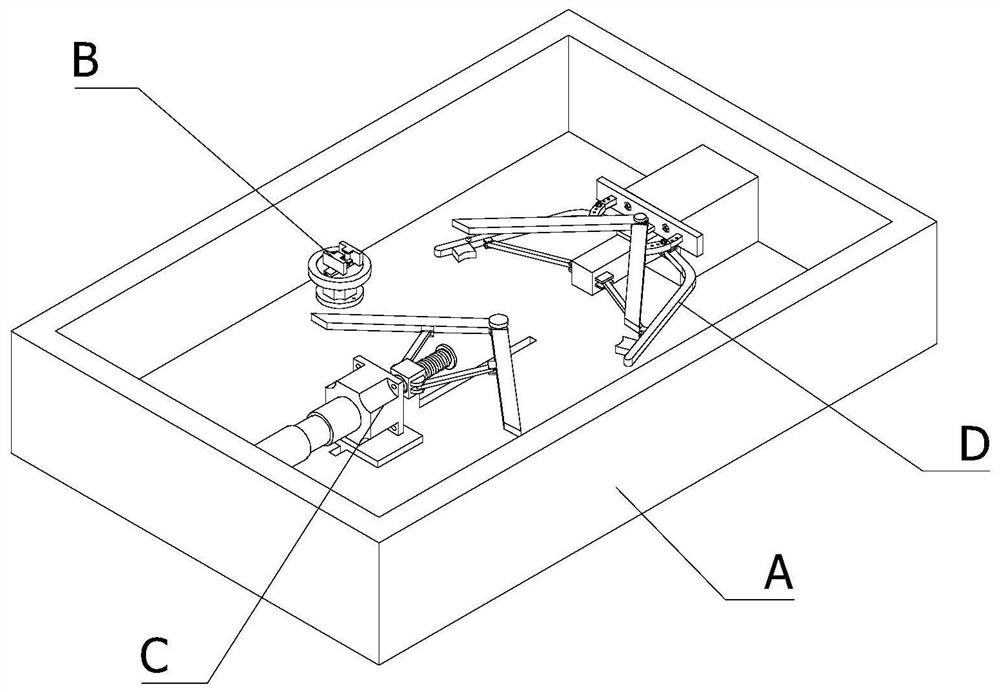

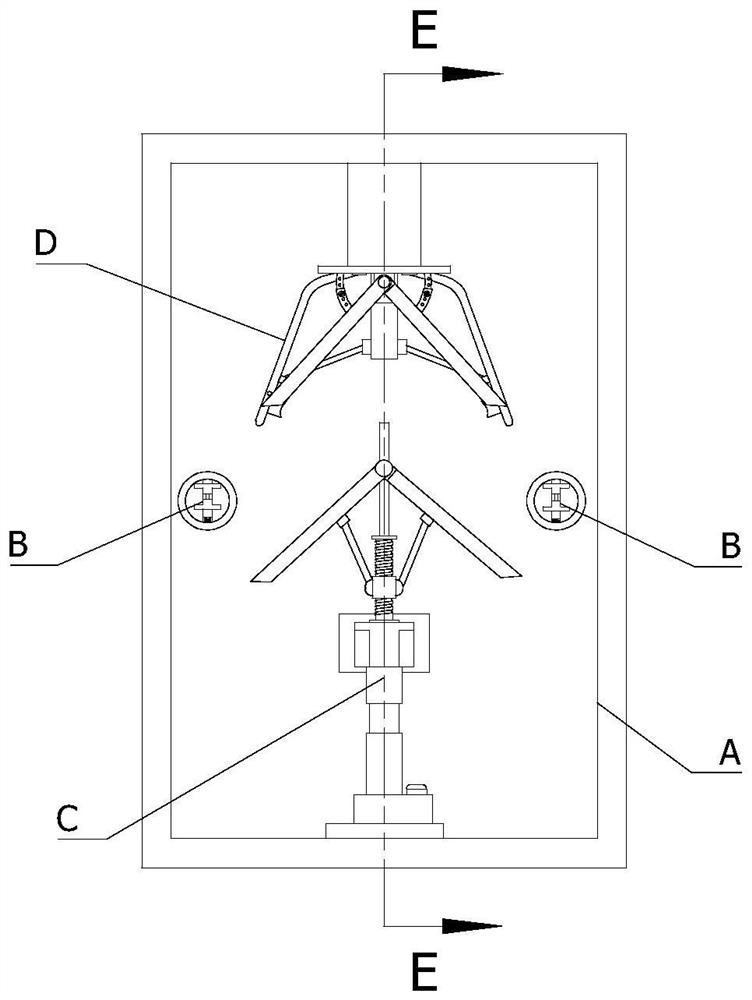

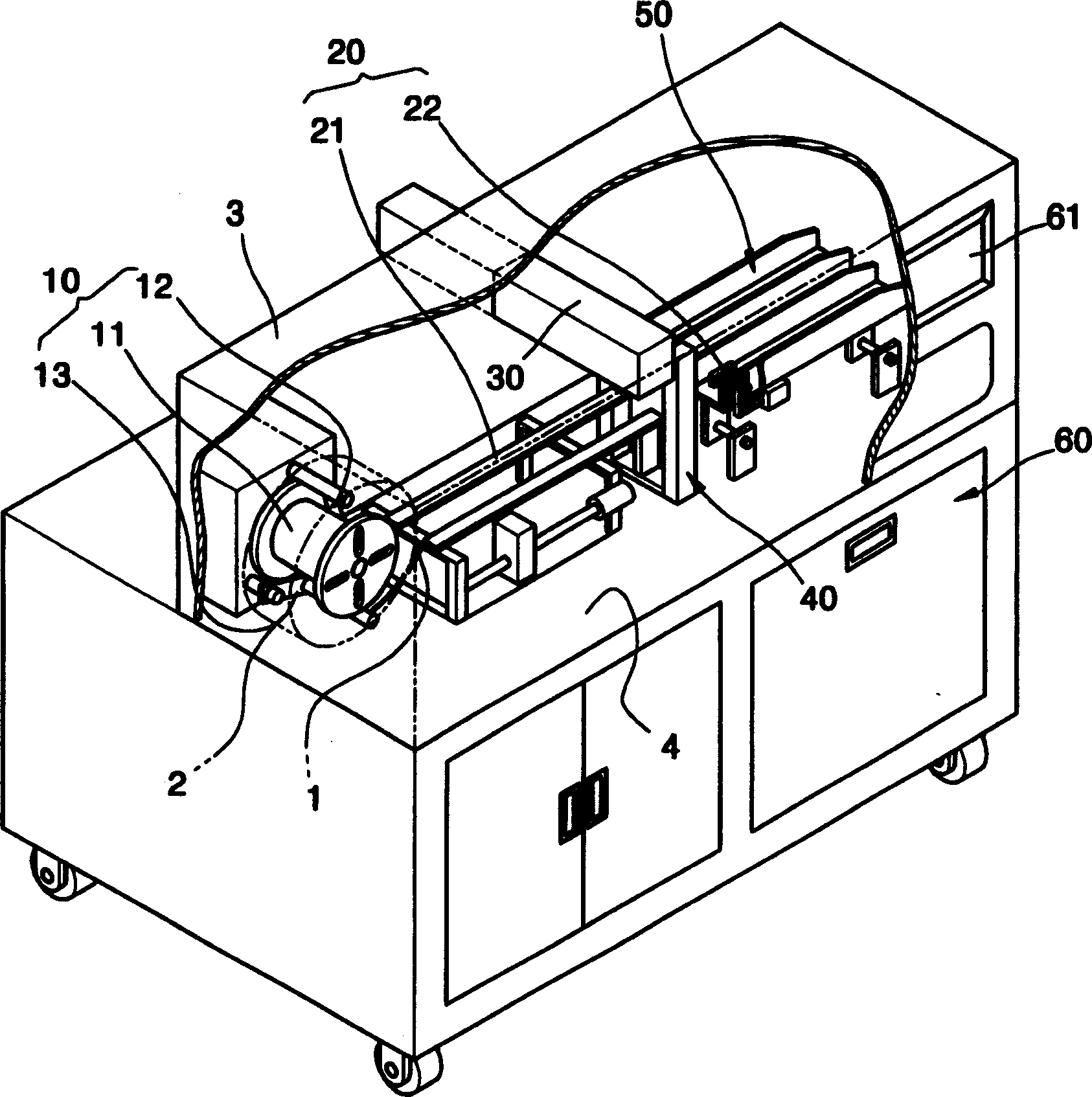

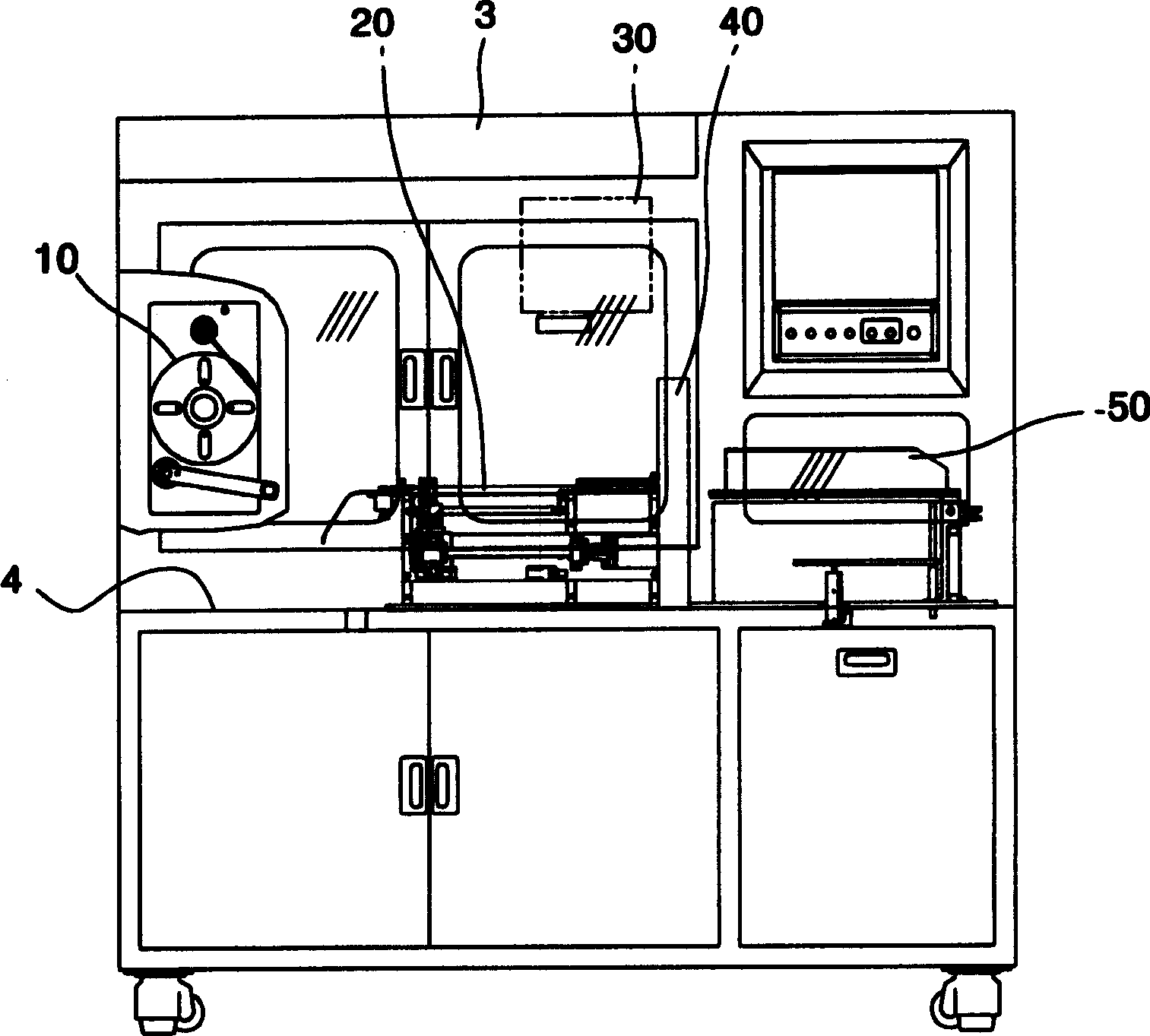

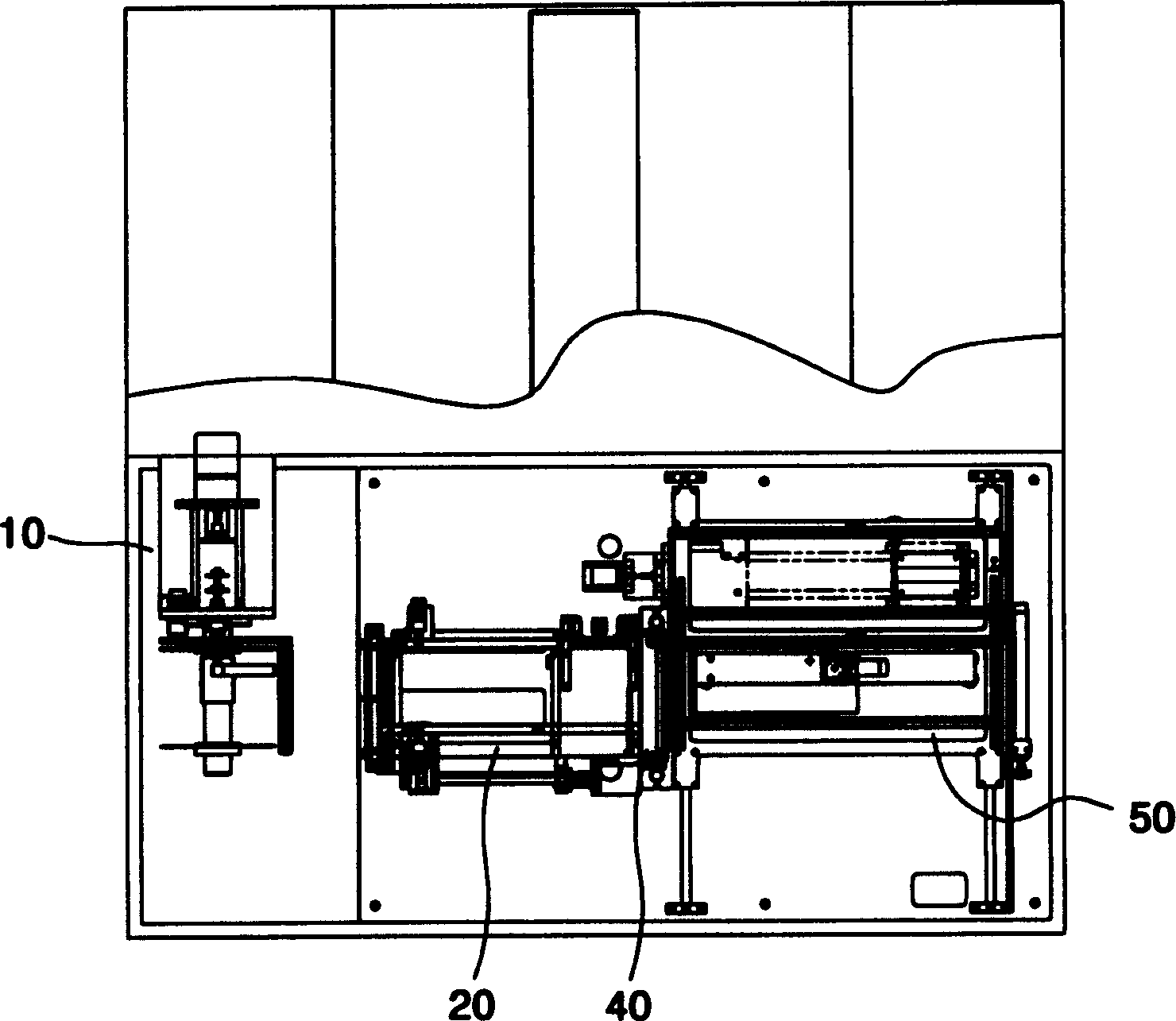

Corner combining machine for curtain wall door and window machining

ActiveCN111659776AEasy to processEasy to useMetal-working feeding devicesPositioning devicesElectrical connectionMachine

The invention relates to the field of corner combining machines, in particular to a corner combining machine for curtain wall door and window machining. The corner combining machine comprises a closedworking bin, fixers, a bending mechanism, a shape correcting mechanism and a controller, wherein the fixers, the bending mechanism and the shape correcting mechanism are all installed in the closed working bin, the two fixers are arranged on the two sides of the closed working bin in the width direction, the bending mechanism is provided with a first working end and a second working end which arematched with each other, the first working end and the second working end are arranged on the two sides in the length direction of the closed working bin correspondingly and are oppositely arranged,the shape correcting mechanism is arranged under the second working end, and the controller is electrically connected with the bending mechanism and the shape correcting mechanism. According to the corner combining machine, the bending angle can be adjusted, bent clamping rods can be limited, errors are prevented, and aluminum alloy needing to be treated can be clamped.

Owner:诸暨市鑫海纺织服饰有限公司

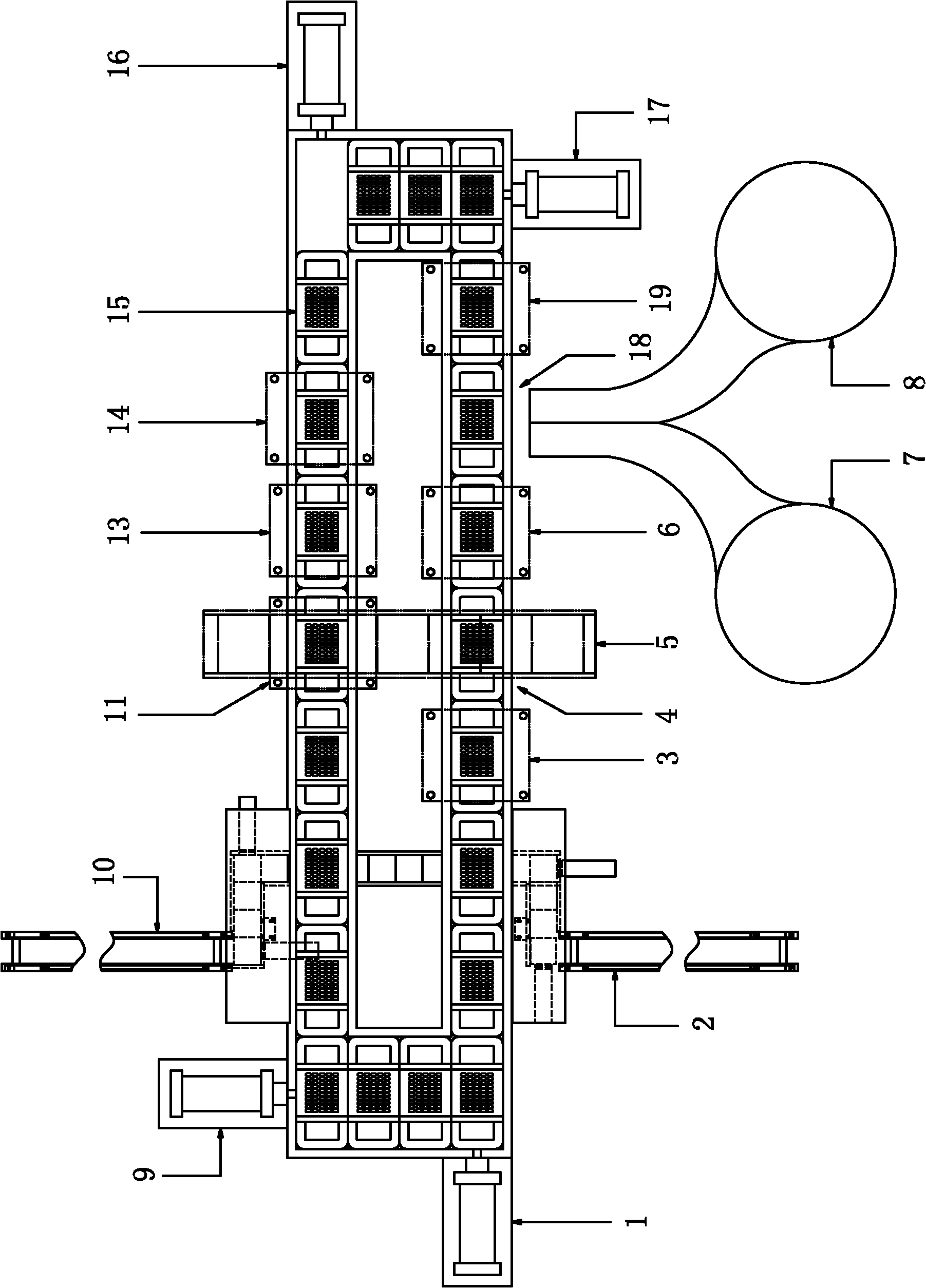

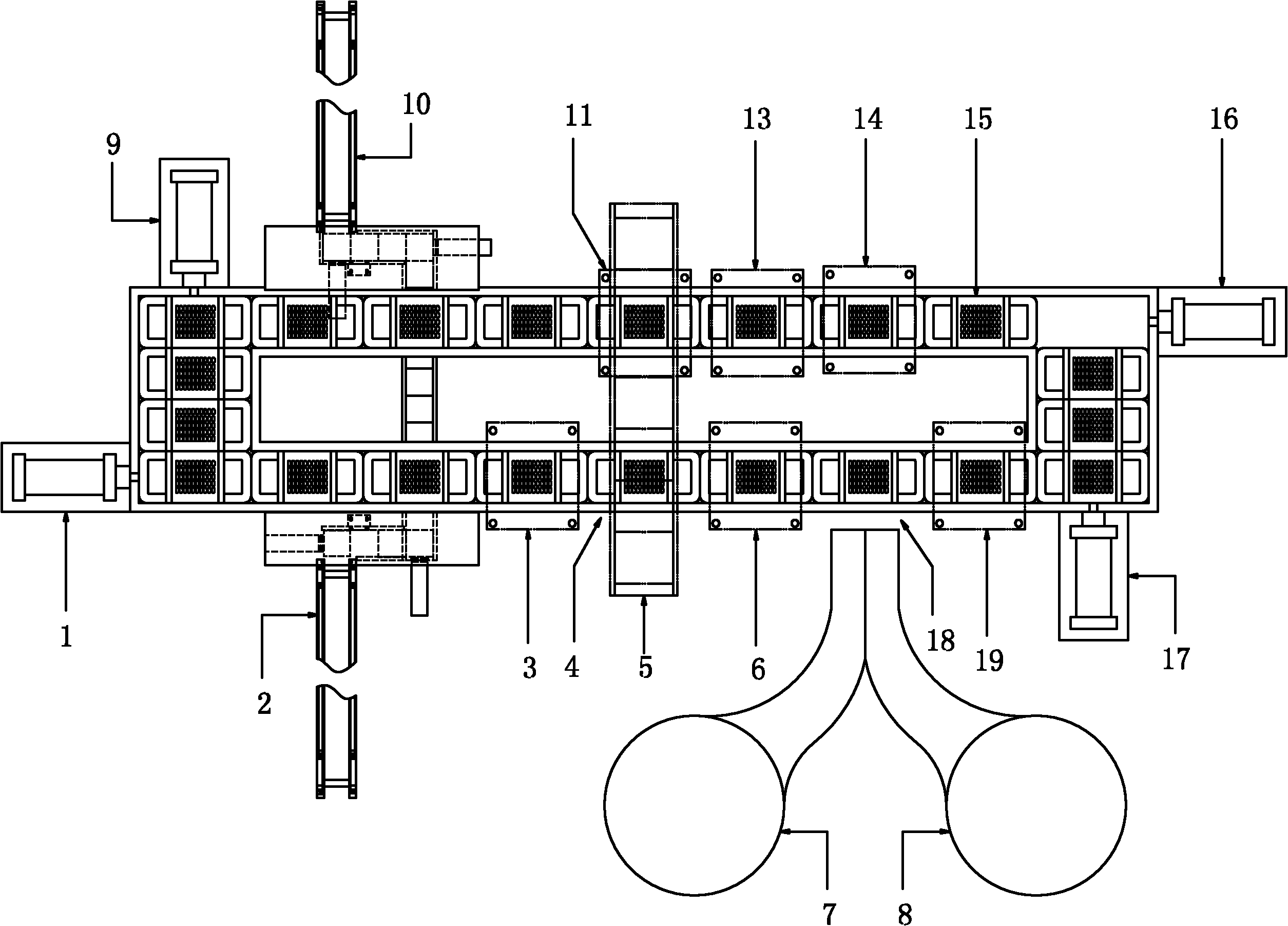

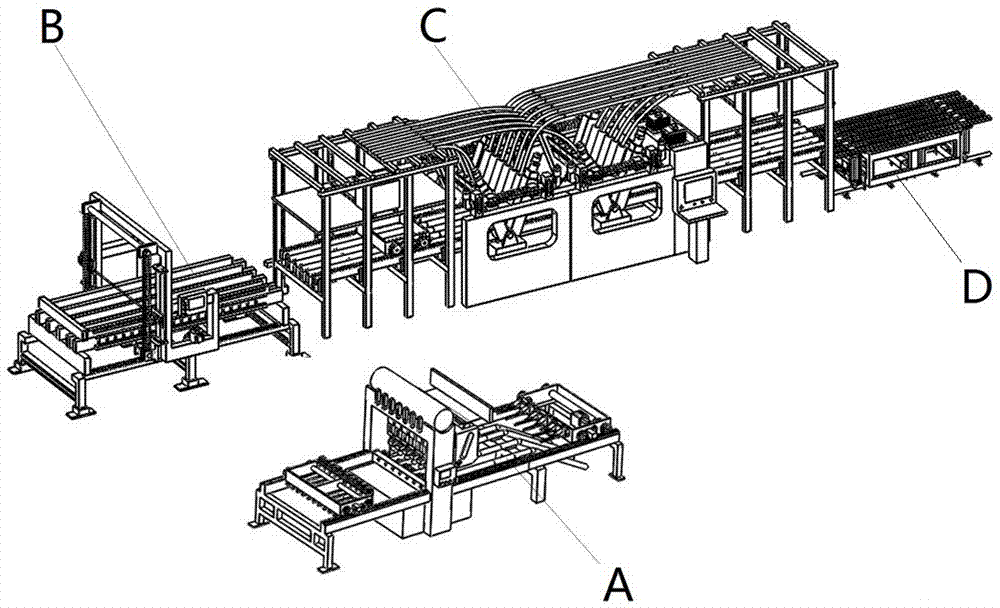

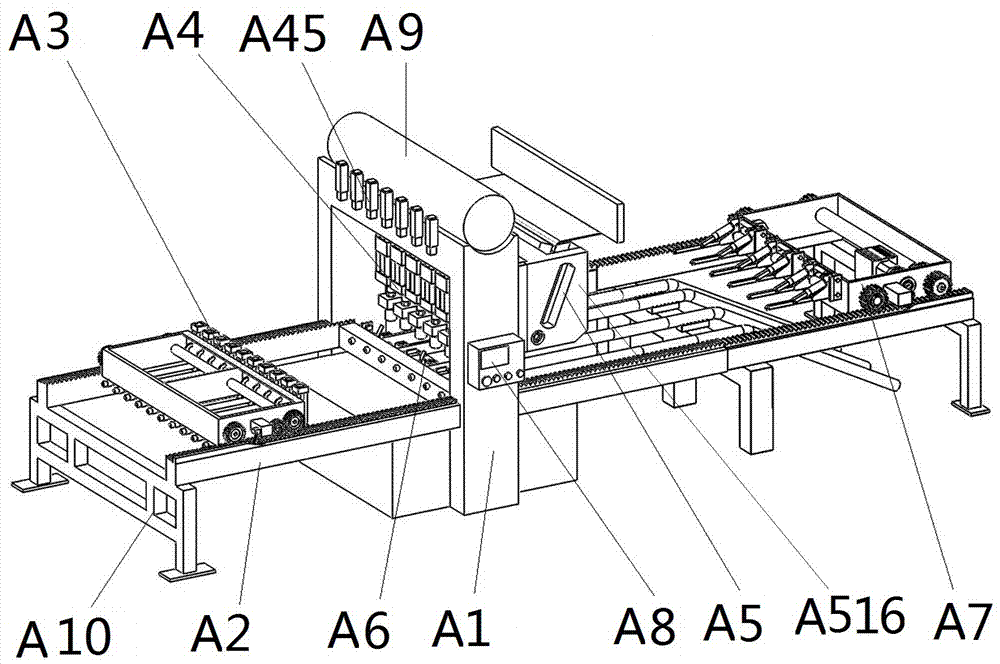

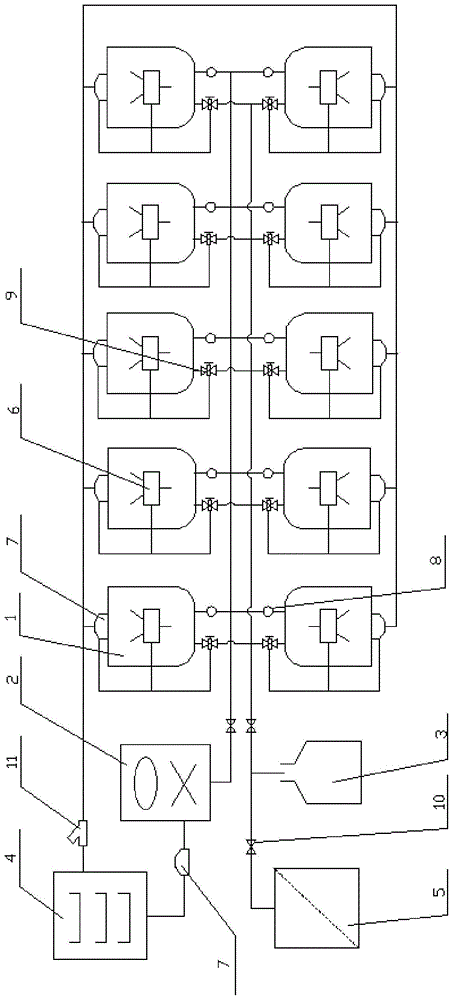

Net rack production line for producing heat insulation board wall

PendingCN107537959AEfficient productionMeeting urgent needsWire networkMetal working apparatusProduction lineEngineering

The invention discloses a net rack production line for producing a heat insulation board wall. The net rack production line comprises a flat net welding machine for welding already straightened longitudinal bars and transverse bars into flat net layers, a heat insulation board cutting machine for carrying out heat insulation board cutting in the thickness, length and width directions of an heat insulation board and forming the heat insulation boards meeting the specification requirements by cutting, an oblique inserting rib welding machine for inserting oblique inserting ribs into the heat insulation board and welding the oblique inserting ribs to the two flat net layers up and down, and a net rack heat insulation board conveyer for conveying an already produced net rack heat insulation board; the feed end of the oblique inserting rib welding machine corresponds to the discharge end of the flat net welding machine and the discharge end of the heat insulation board cutting machine; thedischarge end of the oblique inserting rib welding machine corresponds to the feed end of the net rack heat insulation board conveyer; and the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer are each provided with control equipment for controlling various mechanisms in the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer to carry out coordinative operation. Welding productionof the flat nets, efficient cutting of the heat insulation board, accurate insertion and welding of the oblique inserting ribs, conveying and transportation of the net rack heat insulation board are integrated in the net rack production line, so that the effect of efficiently producing the net rack heat insulation board throughout is realized.

Owner:河北森阳建筑设备科技有限公司

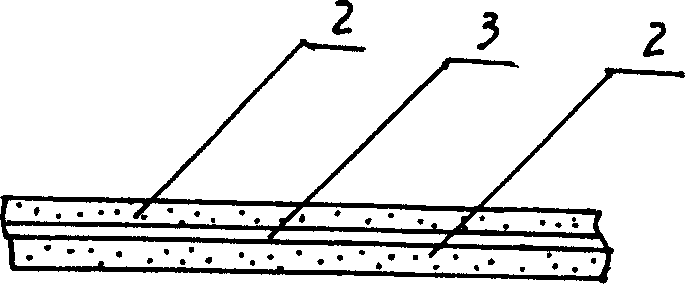

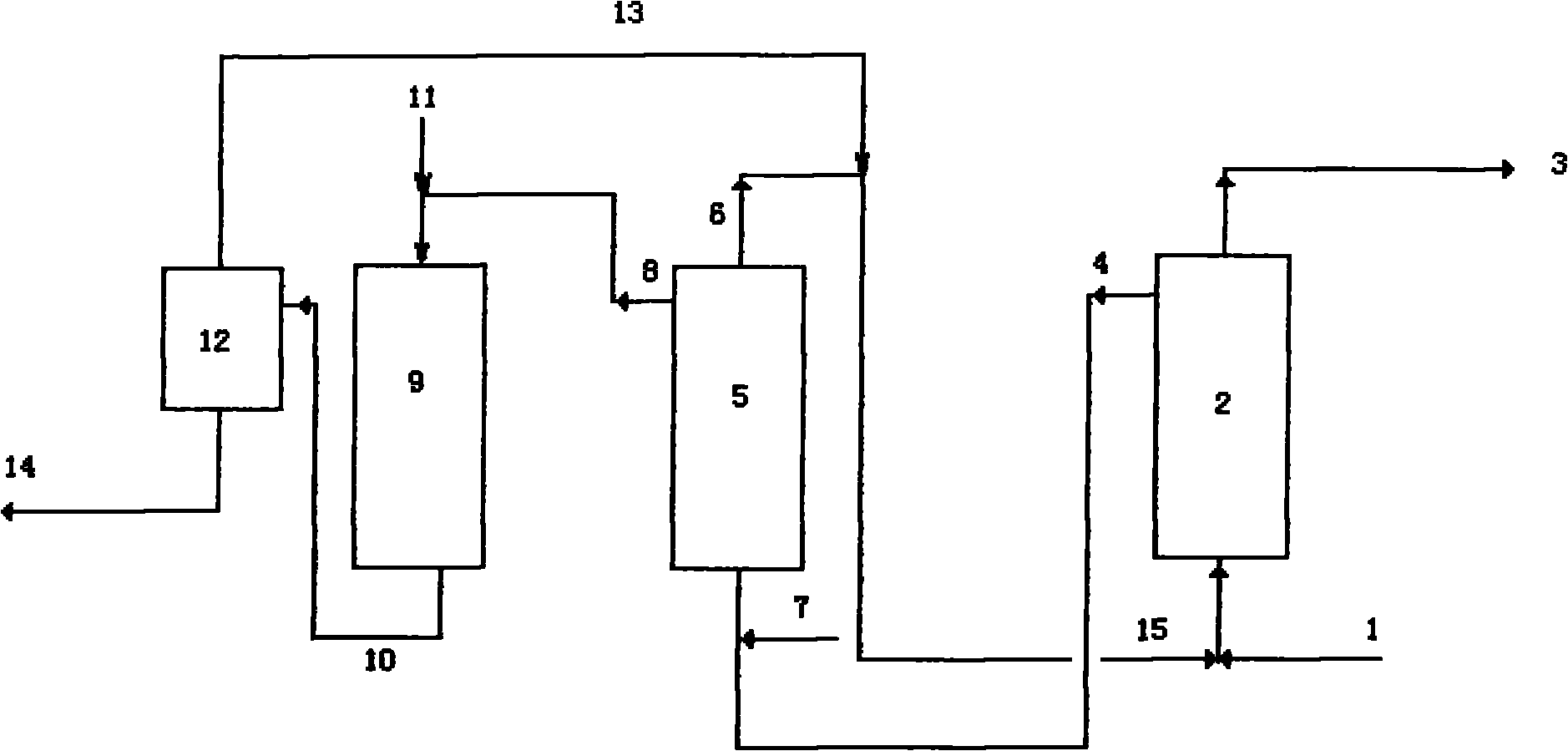

Multistage hydrogenation method for heavy hydrocarbon

ActiveCN102071059AWide applicability of raw materialsImprove product qualityTreatment with hydrotreatment processesHydrogenation reactionGas phase

The invention discloses a multistage hydrogenation method for heavy hydrocarbon. The method comprises the following technical steps of: mixing a condensed heavy hydrocarbon raw material and a gas phase material flow discharged from a hydrogenation desulfurization reactor and a hydrogenation denitrification reactor, and putting the mixture into a boiling bed hydrogenation demetalization reactor; cooling and purifying the reacted gas phase material flow and taking the cooled and purified reacted gas phase material flow as recycled hydrogen; mixing a liquid phase material flow subjected to the boiling bed demetalization reaction and the hydrogen, and putting the mixture into the hydrogenation desulfurization reactor; mixing the liquid phase material flow subjected to the desulfurization reaction with the hydrogen, and putting the mixture into the hydrogenation denitrification reactor, wherein at least one of the hydrogenation desulfurization reactor and the hydrogenation denitrification reactor is a fixed bed reactor. Compared with the prior art, the method provides a novel flexible, efficient and energy-saving operating mode for treating inferior heavy and residual oil raw materials; the property of the raw materials is organically combined with characteristics of the hydrogenation reactions, so the reaction released heat is fully used, the quality of the product is perfect and the operation process can be flexibly adjusted as required on the premise of guaranteeing the stable operation of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting L-isoleucine through whole membrane technology

ActiveCN106220521AIncrease incomeSimple processOrganic compound preparationMicroorganismsFlocculationFiltration membrane

The invention belongs to the technical field of base acid production, and discloses a method for extracting L-isoleucine through whole membrane technology. The method comprises the following steps: step 1) filtering through a micro-filtration membrane and removing impurities through flocculation; step 2) filtering through an ultra-filtration membrane, step 3) concentrating through a reverse osmosis membrane; step 4) concentrating and crystallizing. The membrane technology is combined with the flocculation agent to remove the impurities, the process is simple and feasible, and the yield and the purity of the product are greatly improved.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

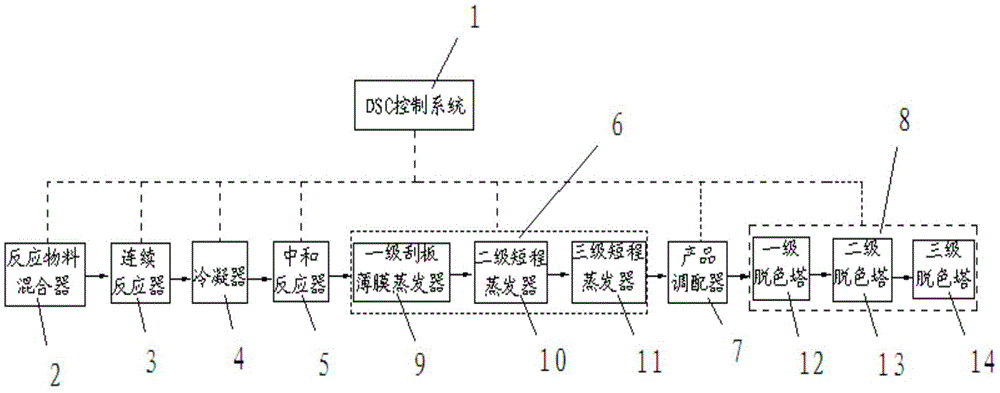

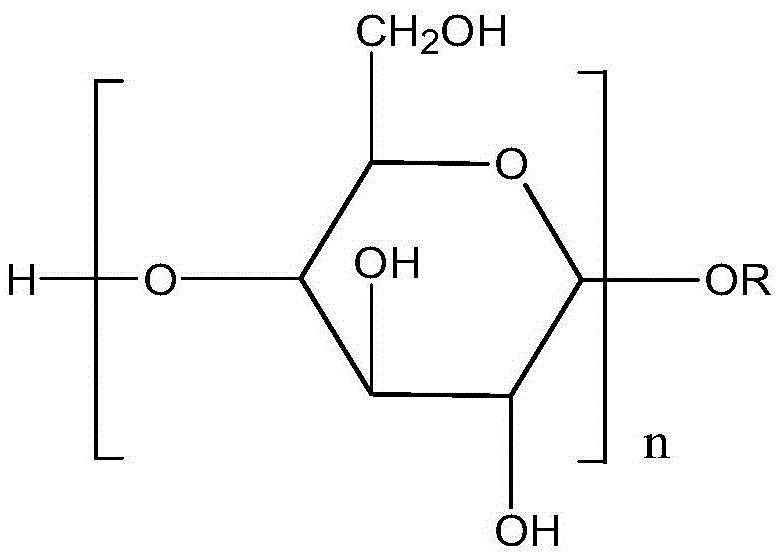

Method and production device for continuously producing alkyl glucoside

ActiveCN105418699AAvoid depositionReduce or even eliminate residual sugar contentSugar derivativesSugar derivatives preparationEcological safetyEvaporation

The invention relates to a method for continuously producing alkyl glucoside. According to the method, anhydrous glucose or glucose monohydrate and fatty alcohol carry out reactions continuously; then the reaction product is subjected to a continuous three grade vacuum distillation alcohol removing treatment, which comprises primary scraping plate evaporation, secondary short term evaporation, and tertiary short term evaporation, to remove fatty alcohol, and finally the reaction product is subjected to a continuous three-grade counter current discoloring treatment, which adopts ozone as the discoloring agent, so as to produce colorless, transparent, high purity and high quality alkyl glucoside. The obtained alkyl glucoside is colorless, transparent, and tasteless, and has the advantages of stable quality, high surface activity, good ecological safety, good intermiscibility, and low production cost. At the same time, the invention also relates to a production device capable of producing alkyl glucoside continuously, and has the advantages of high automation degree, short procedure, and suitability for large scale industrial production.

Owner:河北合佳医药科技集团股份有限公司

Method for consistent hole tray seedling cutting for photinia fraseri

InactiveCN103283448ARealize large-scale cutting plantingRealize large-scale cutting propagationHorticultureAxillary budScars

The intention discloses a method for consistent hole tray seedling cutting for photinia fraseri, and belongs to the field of seedling cultivation. The method includes that fresh and vigorous photinia fraseri branches are harvested and subjected to strict grading to guarantee the same to be consistent in size, cuts of seedlings are preferably 3-3.5cm in length, and each seedling reserves one leaf and one bud; an upper cut is located 2mm above an axillary bud of the reserved leaf to ensure vitality of the axillary bud, and a lower cut is selectively arranged 1mm below a leaf stalk or a stipule scar so as to facilitate rooting; roots of the seedlings are treated by being quickly dipped in hormone, and the seedlings are cut into a hole tray full of matrix according to 40cm X 35cm in space between rows, normal roots are watered sufficiently, and management is followed. By strict cutting control, high-quality consistent seedlings are harvested in large-scale cutting cultivation of the photinia fraseri. Special treatment is given to mother branch collecting, the cuts of the seedlings and biological hormone dipping, and the seedlings are subjected to the management after the seedling cutting, so that large-scale cutting propagation of the photinia fraseri is realized, and high-quality products are obtained.

Owner:JIANGSU MACRO AGRI SCI & TECHLIMITED

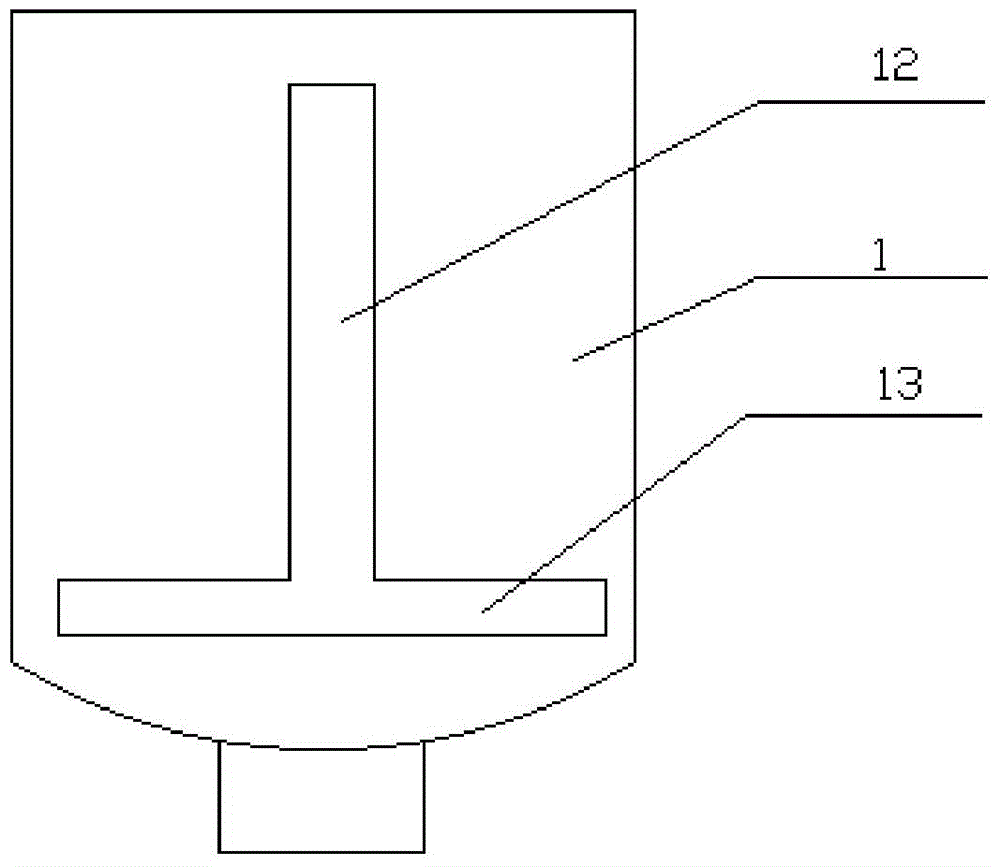

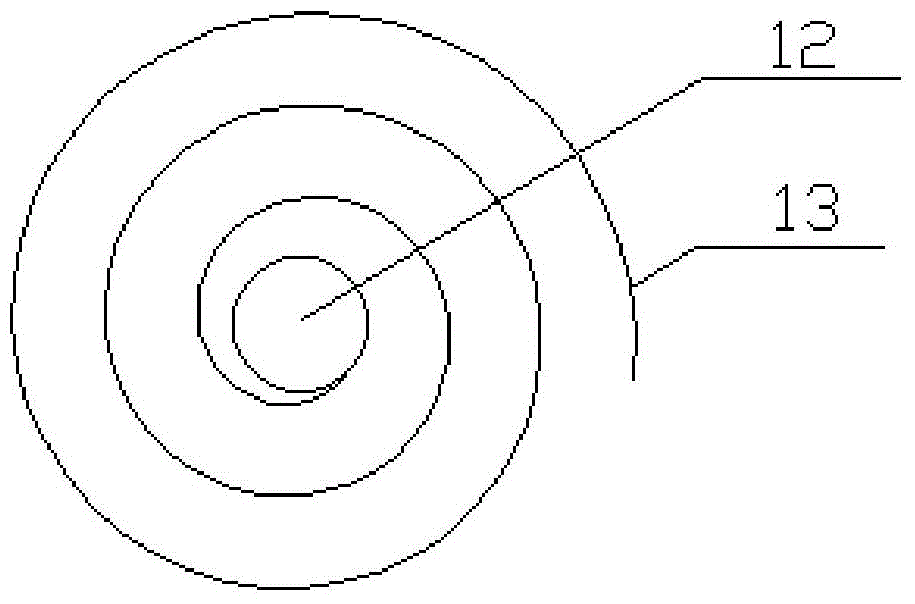

Induction furnace system and production process thereof

PendingCN108746520AProduct composition is stableProduct surface and internal quality are excellentFurnaces without endless coreMetalInduction furnace

The invention provides an induction furnace system and a production process thereof, and relates to the technical field of metal smelting. The induction furnace system comprises a smelting furnace, aheat preserving furnace, a crystallizer and a casting device, wherein in a flowing direction of melt, the smelting furnace, the heat preserving furnace, the crystallizer and the casting device are sequentially arranged; induction coils are separately arranged on the outer part of the smelting furnace and the outer part of the heat preserving furnace; the smelting furnace and the heat preserving furnace are coreless induction furnaces; and melt in the furnace is heated by the induction coils, so that the technical problem that the coreless induction furnaces in the prior art cannot continuouslycast is solved.

Owner:南京科砬世益新材料科技有限公司

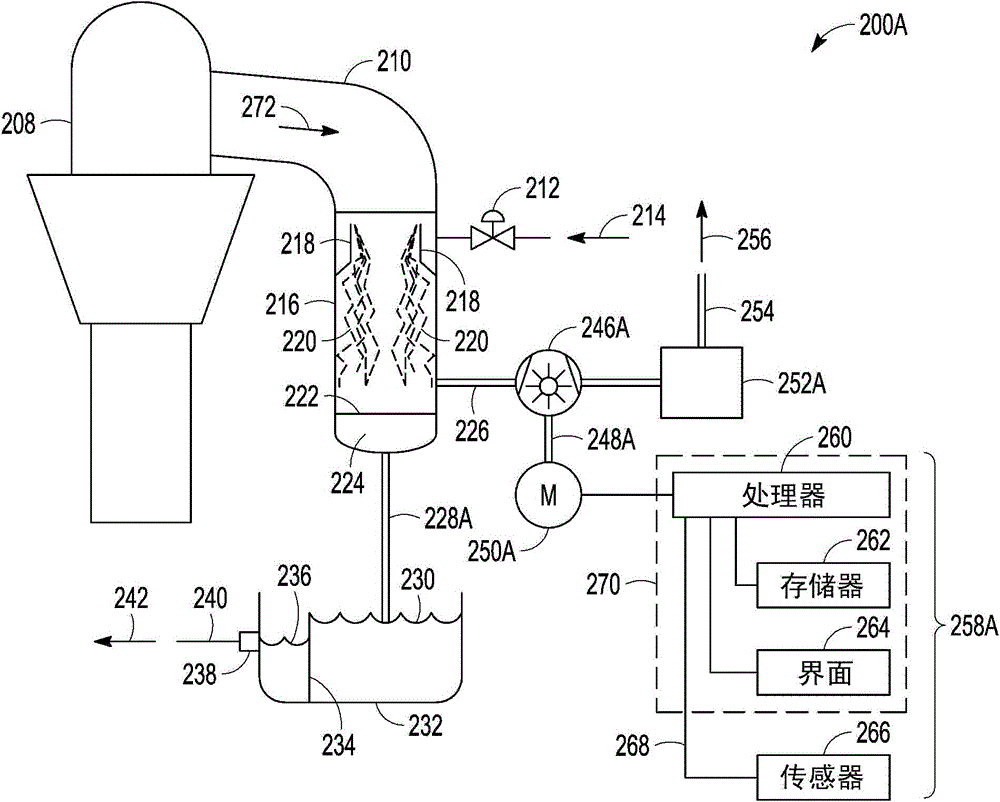

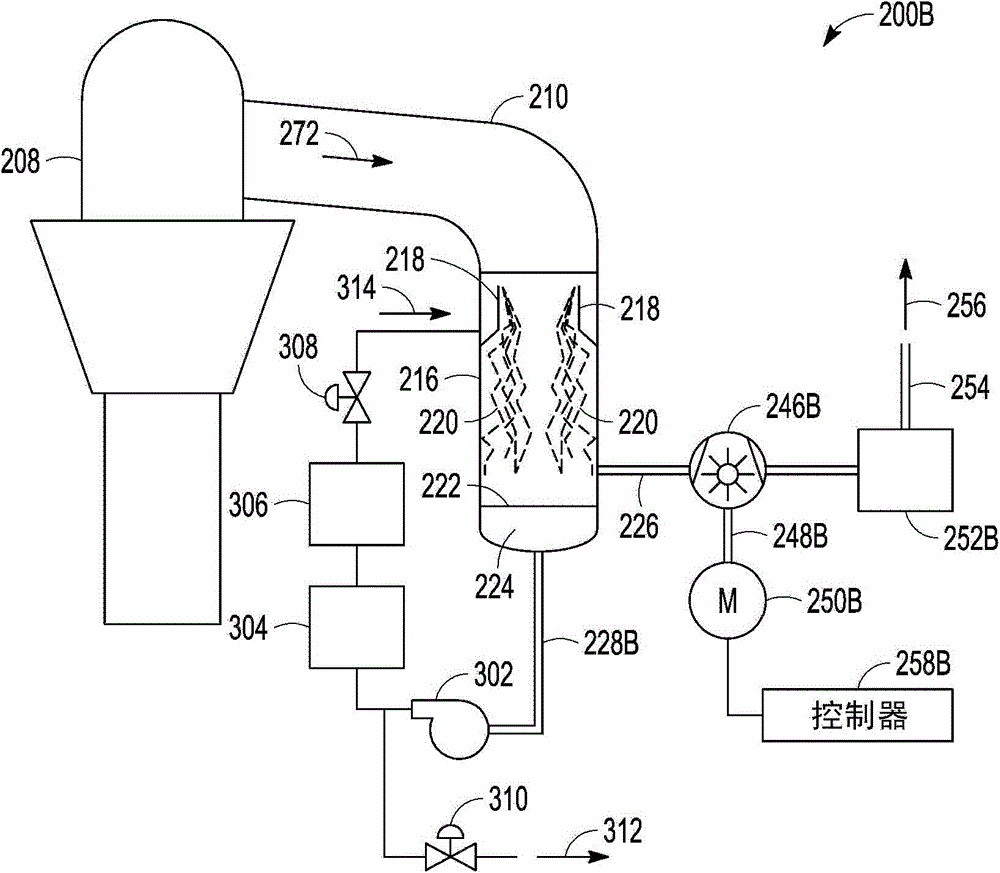

Process pressure control in nylon synthesis

A system is configured for continuous polyamide synthesis. The system includes a vent condenser and a vacuum pump. The vent condenser is coupled to a polymerization finisher. The vent condenser has a liquid reservoir and a vent discharge port above a level of the liquid reservoir. The vacuum pump is coupled to the vent discharge port by an intake line. The vacuum pump has an output port and a rotary shaft. A gaseous mixture proximate the vent discharge port is removed at a rate determined by a speed of the rotary shaft. The vacuum pump is configured to have a liquid ring seal.

Owner:INVISTA TEXTILES (U K) LTD

Program control smoking and roasting betelnut production line

InactiveCN104664568ASolve the pollution of the environmentSolve labor intensityFruit and vegetables preservationFood treatmentProduction lineHeating oil

The invention discloses a program control smoking and roasting betelnut production line, which comprises a smoking and roasting oven, a smoke generator, a heat conducting oil boiler, a drier, a fruit ripening machine, a bucket elevator and a conveyor, wherein a sensor, a smoking and roasting pipe and a first heating oil pipe are arranged in the smoking and roasting oven, an exhaust fan and a blast blower are arranged in positions, near the smoking and roasting box, on a flue, the smoking and roasting pipe is connected with the smoke generator through the flue, a second heating oil pipe is arranged in the fruit ripening machine, the first heating oil pipe and the second heating oil pipe are connected with the heat conducting oil boiler through an oil path, the sensor connects and controls a special control valve and the exhaust machine, a smoke inlet of the smoke generator is connected with the drier, and smoke exhausted by each exhaust fan is gathered in the drier. The program control smoking and roasting betelnut production line has the advantages and positive effects that the three-waste discharge of the production line conforms to national environment-protection discharge standards, the zero discharge is basically realized, the problems caused by the adoption of manual control on smoke degree, temperature, humidity and the like of the existing production equipment are solved, and the product quality qualification rate and the economic benefits are improved.

Owner:张锡来

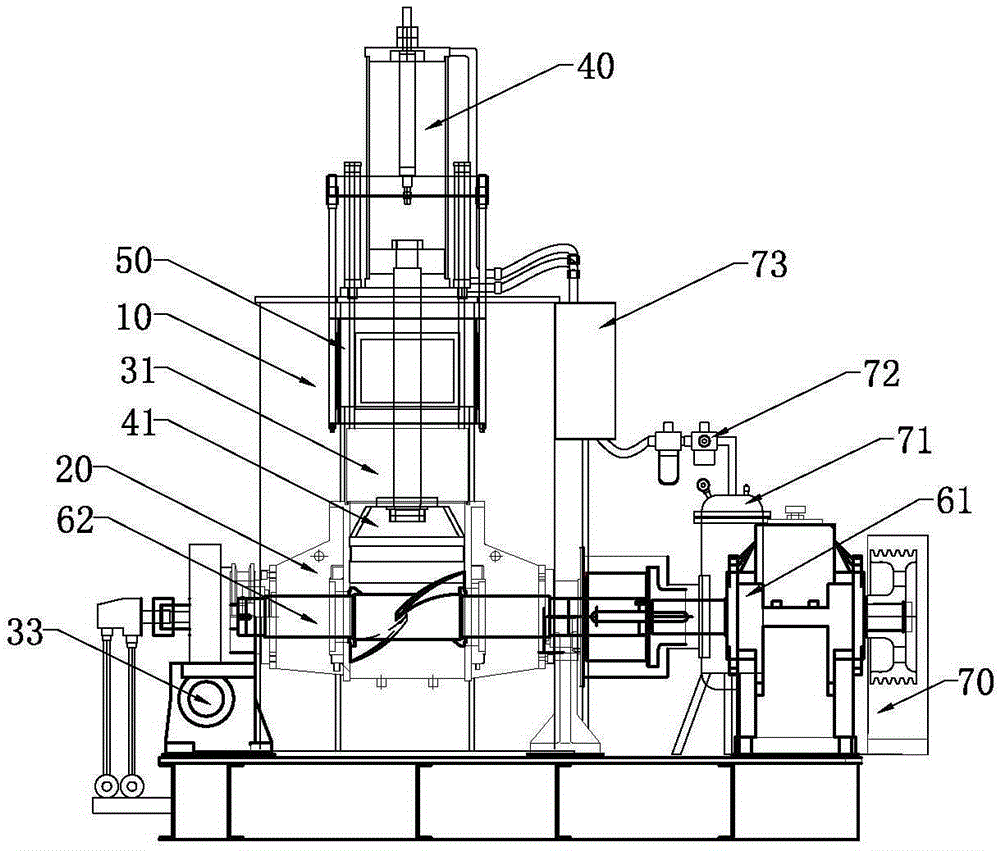

A vacuum mixer

ActiveCN103552167BPrevent oxidationRealize low-carbon developmentPlastics industryMechanical engineering

The invention relates to the technical field of chemical raw material internal mixing equipment, and in particular to a vacuum internal mixer, which includes a frame. The lower part of the frame is provided with an internal mixing chamber, and the upper part of the frame is provided with a pressing device. The internal mixing chamber is connected with a Internal mixing device, a vacuum device for vacuuming the internal mixing chamber is provided above the internal mixing chamber. The invention can automatically evacuate the mixing chamber during work, prevent harmful gases in the mixing chamber from being discharged to the outside world and cause pollution, prevent chemical raw materials in the mixing chamber from being oxidized by outside air, and ensure the production of high quality products. products; and is of great significance to the realization of low-carbon development of the rubber and plastics industry and the reduction of energy consumption; ensuring the production efficiency and product quality of rubber products is of great significance to building a modern, high-quality, efficient, energy-saving and emission-reducing enterprise and establishing an environment-friendly society. It is of extremely important strategic significance.

Owner:GUANGDONG LINA IND CO LTD

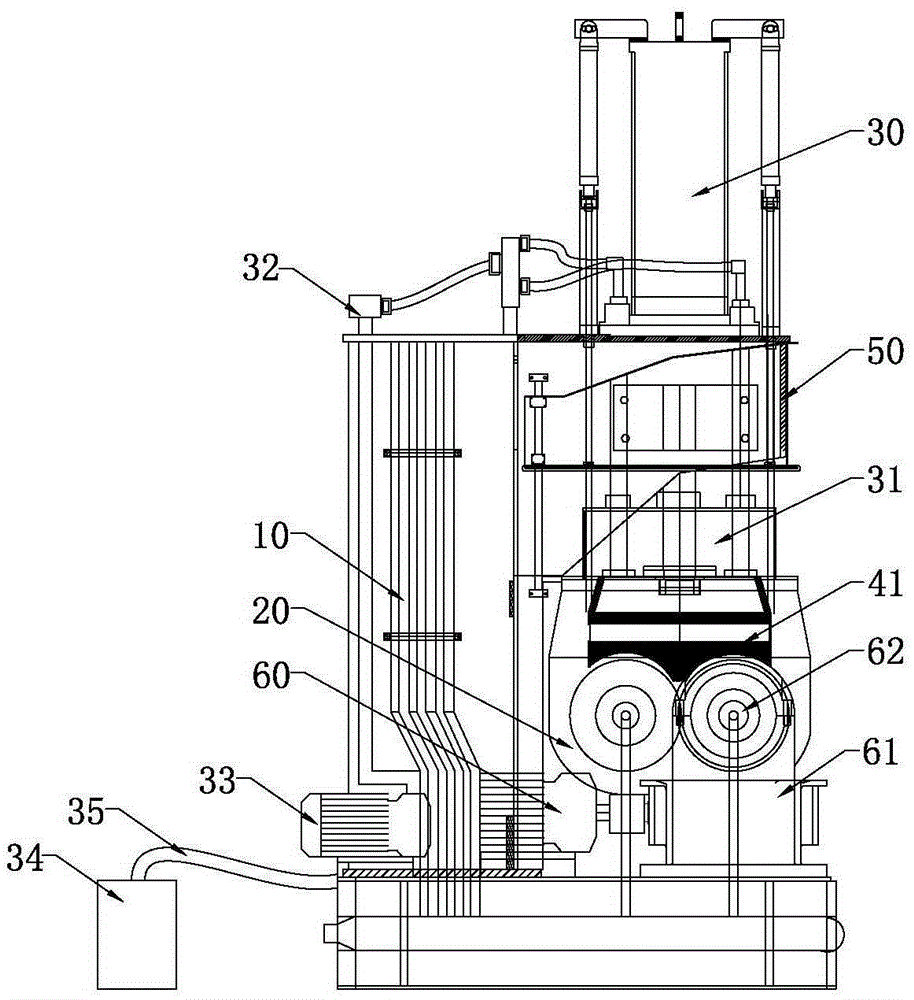

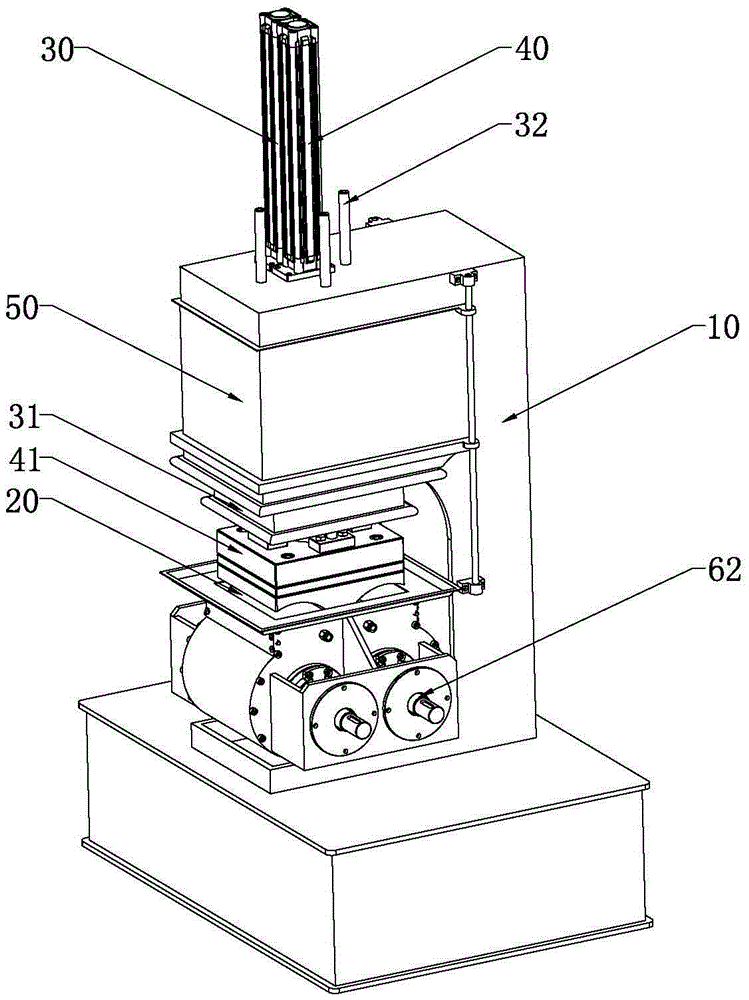

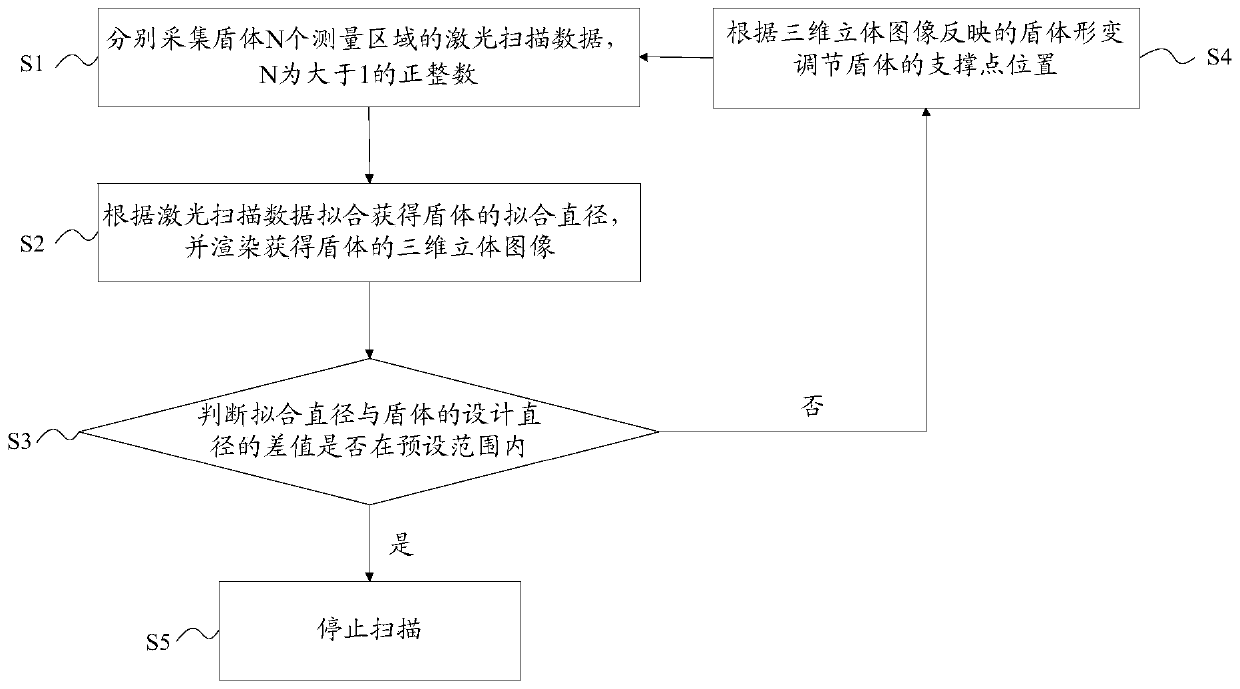

Shield tunneling machine upper shield deformation detection and online correction method

The invention discloses a shield tunneling machine upper shield deformation detection and online correction method. The method includes the steps that laser scanning data of N measuring areas of a shield are collected respectively, the fitting diameter of the shield is obtained according to the laser scanning data, and a three-dimensional image of the shield is obtained through rendering; whetherthe difference value of the fitting diameter and the design diameter of the shield is in the preset range or not is judged, and if the difference value of the fitting diameter and the design diameterof the shield is in the preset range, scanning is stopped; and if the difference value of the fitting diameter and the design diameter of the shield is not in the preset range, the position of a supporting point of the shield is adjusted according to the shield deformation reflected by the three-dimensional image, laser scanning data of all the measuring areas are collected again, subsequent stepsare executed, and scanning is stopped till the difference value of the fitting diameter and the design diameter of the shield is in the preset range. By means of the method, deformation of a workpiece can be accurately obtained, errors between the deformation of the workpiece and the theoretical mathematical model are obtained, and therefore proper correction can be conducted conveniently. In addition, the method is not limited by to-be-machined sizes, the measuring and detection size range is enlarged, an existing cumbersome measuring mode is changed, and the measuring efficiency and the measuring quality are improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Dyeing and finishing technology for wool and recycled polyester blended fabric

InactiveCN103643564AHigh quality productDry-cleaning apparatus for textilesBleaching apparatusPolyesterLead sulfate

The invention discloses a dyeing and finishing technology for a wool and recycled polyester blended fabric, comprising the following steps: 1) desizing: adding a 4-6 g / L chelated dispersing agent, a 1-2 g / L wax removal agent, an 8-9 g / L desizing enzyme and a 6-7 g / L refining agent; 2) bleaching: adding 3-4 g / L lead sulfate tribasic and 8-9 g / L hydrogen peroxide; 3) setting for 1 minute at 220 DEG C; 4) dyeing; 5) padding the dyed blended fabric in a treatment solution composed of a 30 g / l softening agent, an 80 g / L hairy feeling finishing agent and a 2-5 g / L fluffing agent; and 6) mechanical softening finishing, wherein wet pickup is 100%, and mechanical softening finishing time is 20 minutes. The dyeing and finishing technology for a wool and recycled polyester blended fabric provided by the invention can coordinate the dyeing conditions of wool and recycled polyester well so as to produce high-quality products.

Owner:常熟市华宇针织印染有限公司

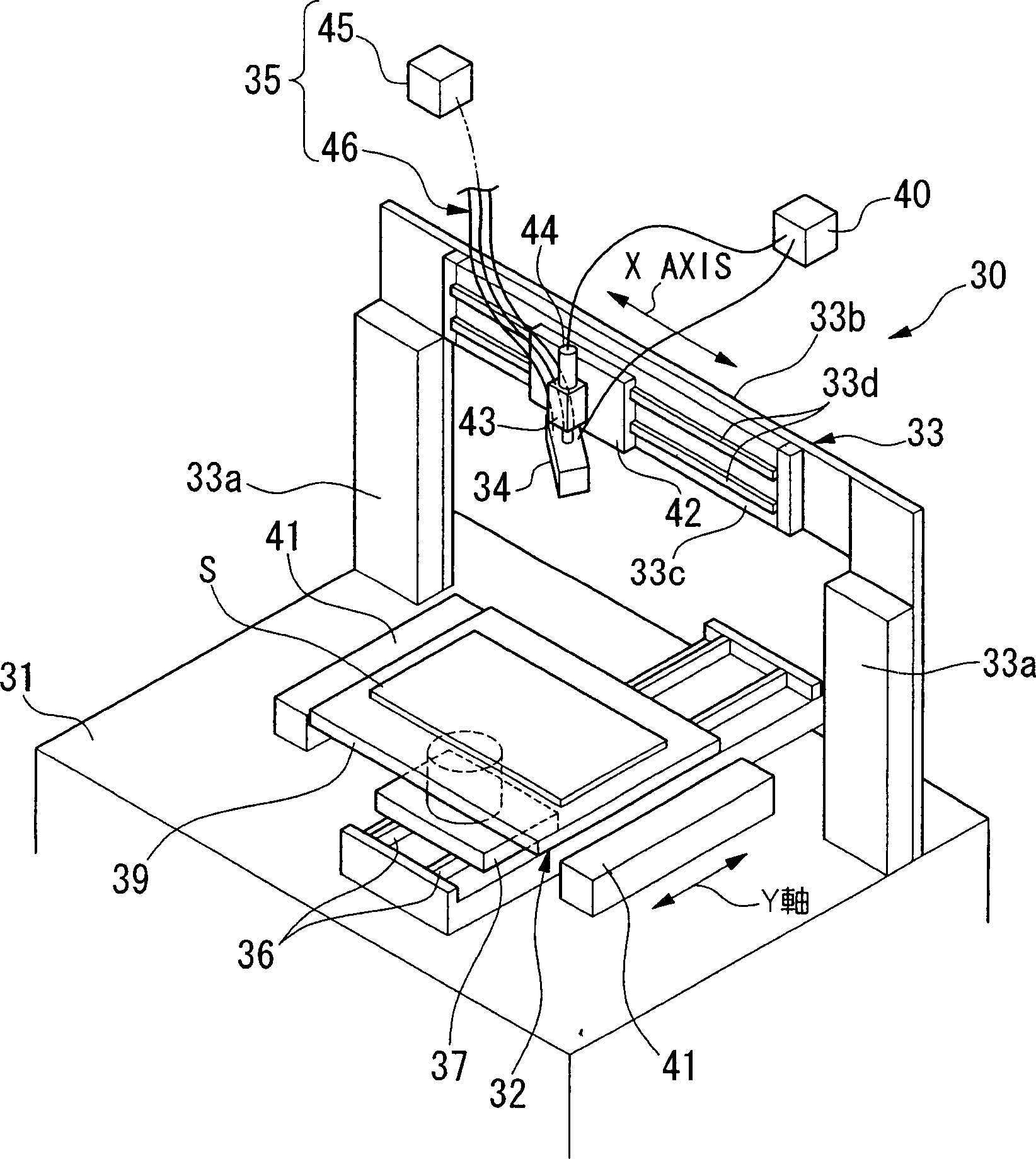

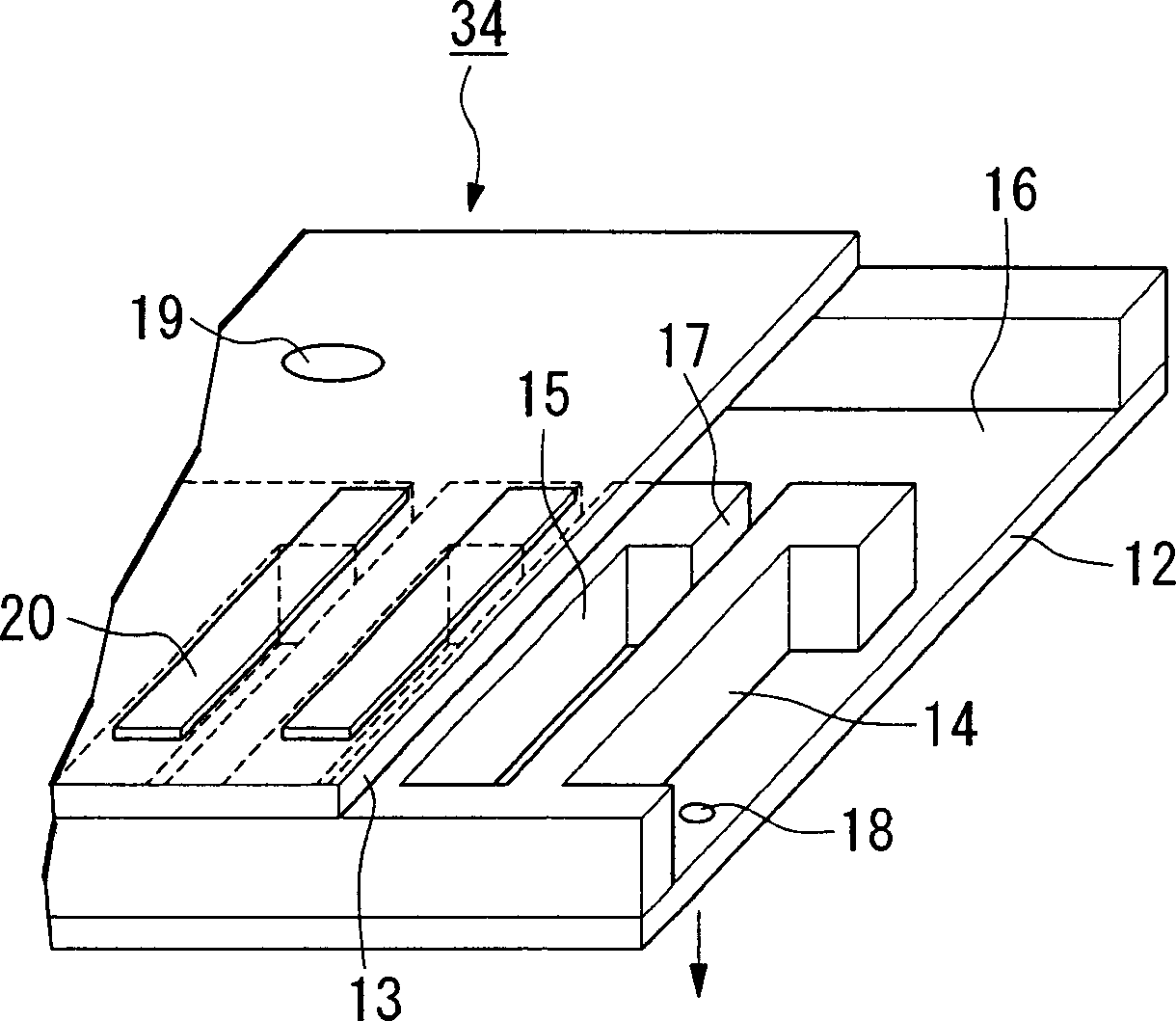

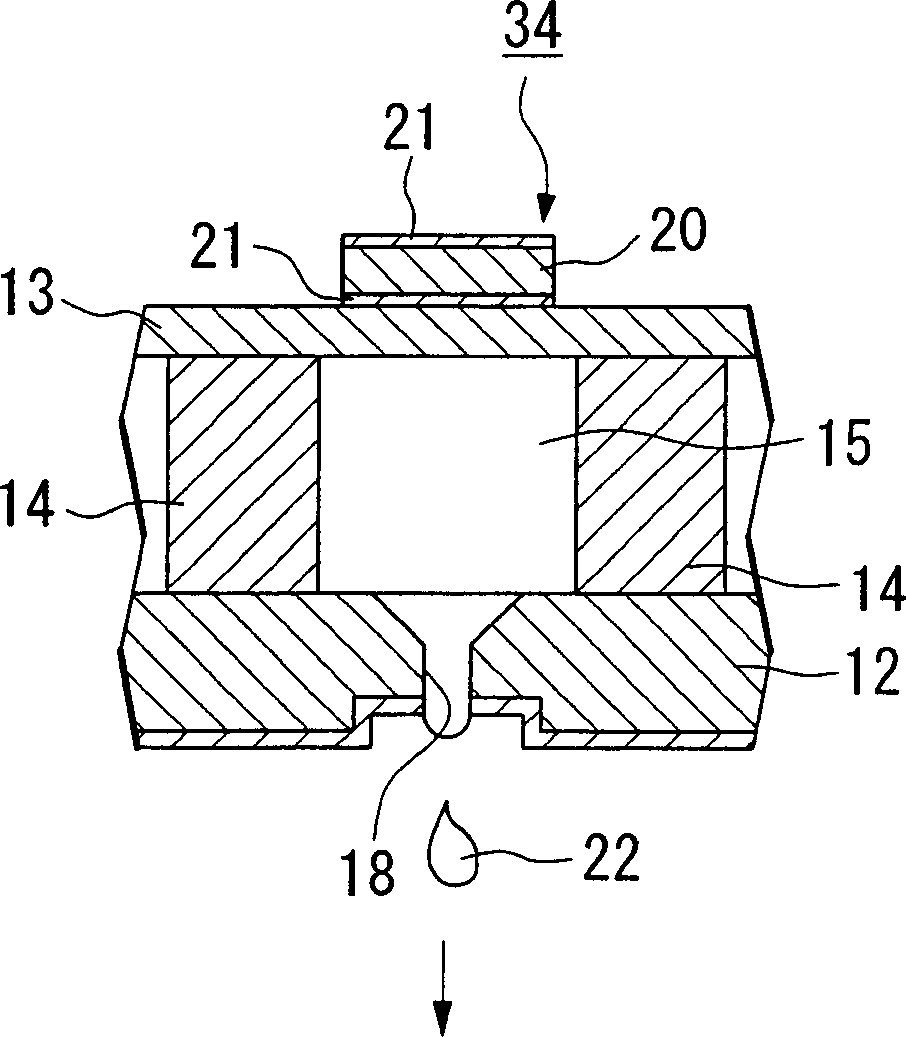

Coating forming method, apparatus and device, method for mfg. device and electronic apparatus

InactiveCN1452235AImprove continuityHigh quality productSemiconductor/solid-state device manufacturingTypewritersElectronMotherboard

A large number of unit areas (bits) B are provided on the motherboard (S). Droplets made of a certain liquid composition are ejected from the droplet ejection head (34) to the unit area B to form a coating layer on the mother substrate (S). A first group of nozzles Na consisting of N nozzles in the ejection head (34) forms a first pattern. The second group of nozzles Nb different from the first group of nozzles Na forms a second pattern. In doing so, when patterns having different characteristics are formed on the reference plate, it is possible to maintain a stable ejection operation and form patterns with better precision using this droplet ejection device.

Owner:SEIKO EPSON CORP

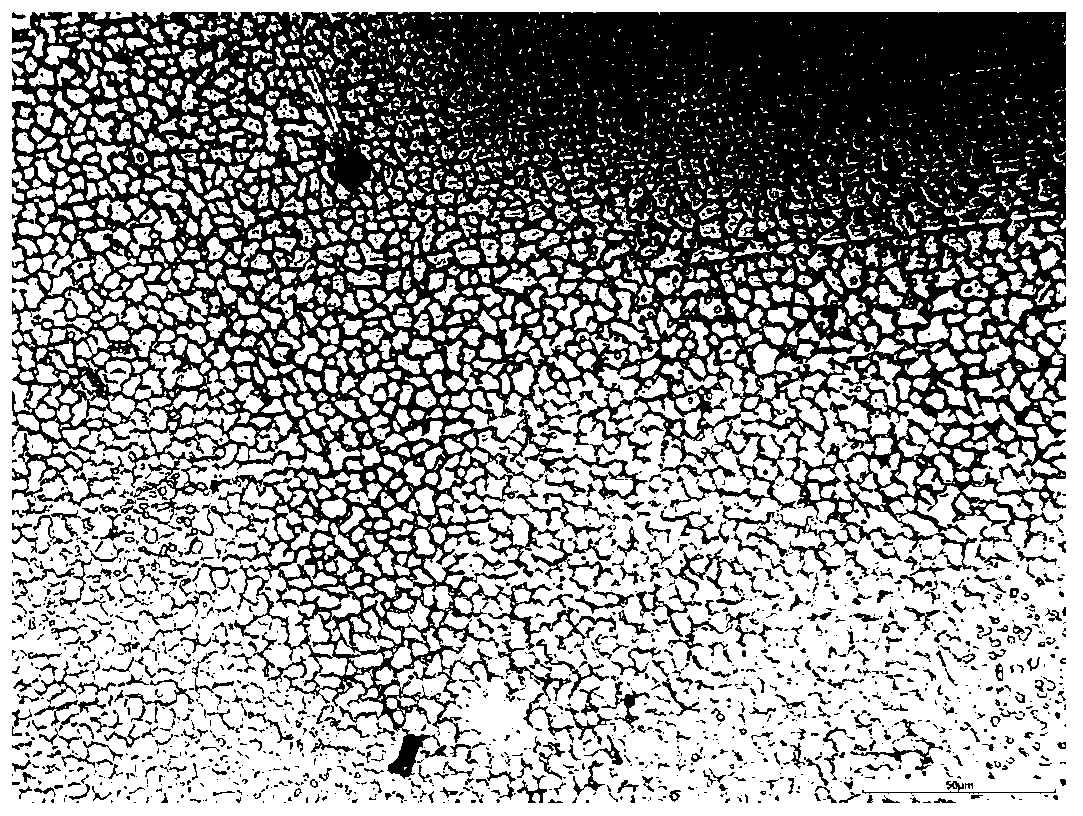

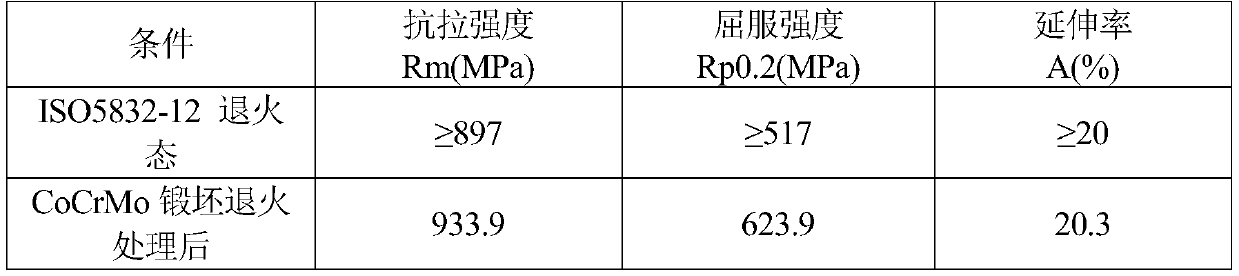

Production method of CoCrMo alloy for artificial joints

InactiveCN110129591AImprove production yieldHigh purityIncreasing energy efficiencyTissue regenerationArtificial jointsCobalt based alloy

The invention relates to the field of cobalt-base alloys, in particular to a production method of a CoCrMo alloy for artificial joints. According to the method, at first, a forged blank is obtained bymeans of vacuum induction furnace smelting and electroslag remelting; then the blank is heated to 1150 DEG C-1250 DEG C for heat preserving, and then forging is carried out; in the forging process, the temperature of the blank is strictly controlled within a certain temperature range, the temperature preserved for the final heating number is 1150 DEG C, the temperature for final forging of each heating number is no lower than 1000 DEG C, and thus it is guaranteed that the CoCrMo forged blank is always in a good plastic processing state; and after forging, diffusion annealing treatment is carried out, and the annealing temperature ranges from 1000 DEG C to 1050 DEG C. According to the production method, the qualified CoCrMo forged blank is obtained through the production method, qualifiedraw materials are provided for manufacturing the artificial joint parts, the most important link for obtaining the raw materials of the qualified CoCrMo artificial joint parts is forging, and strict control over the temperature for initial forging and final forging is the most key part for ensuring that the high-quality products are obtained and the production yield is increased.

Owner:KAILI UNIV

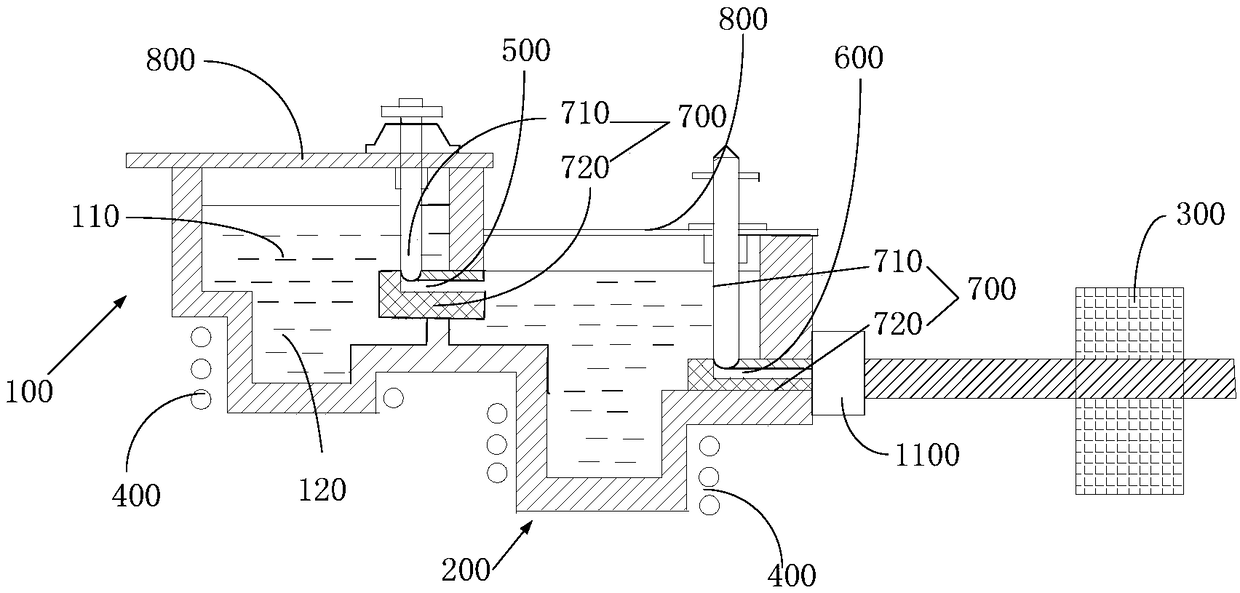

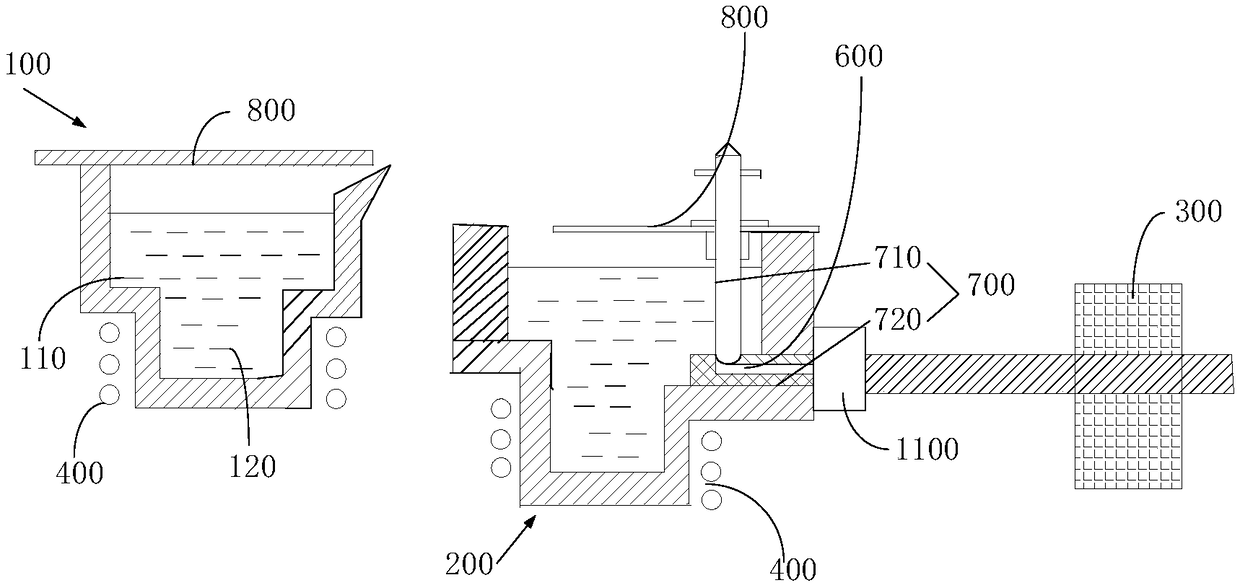

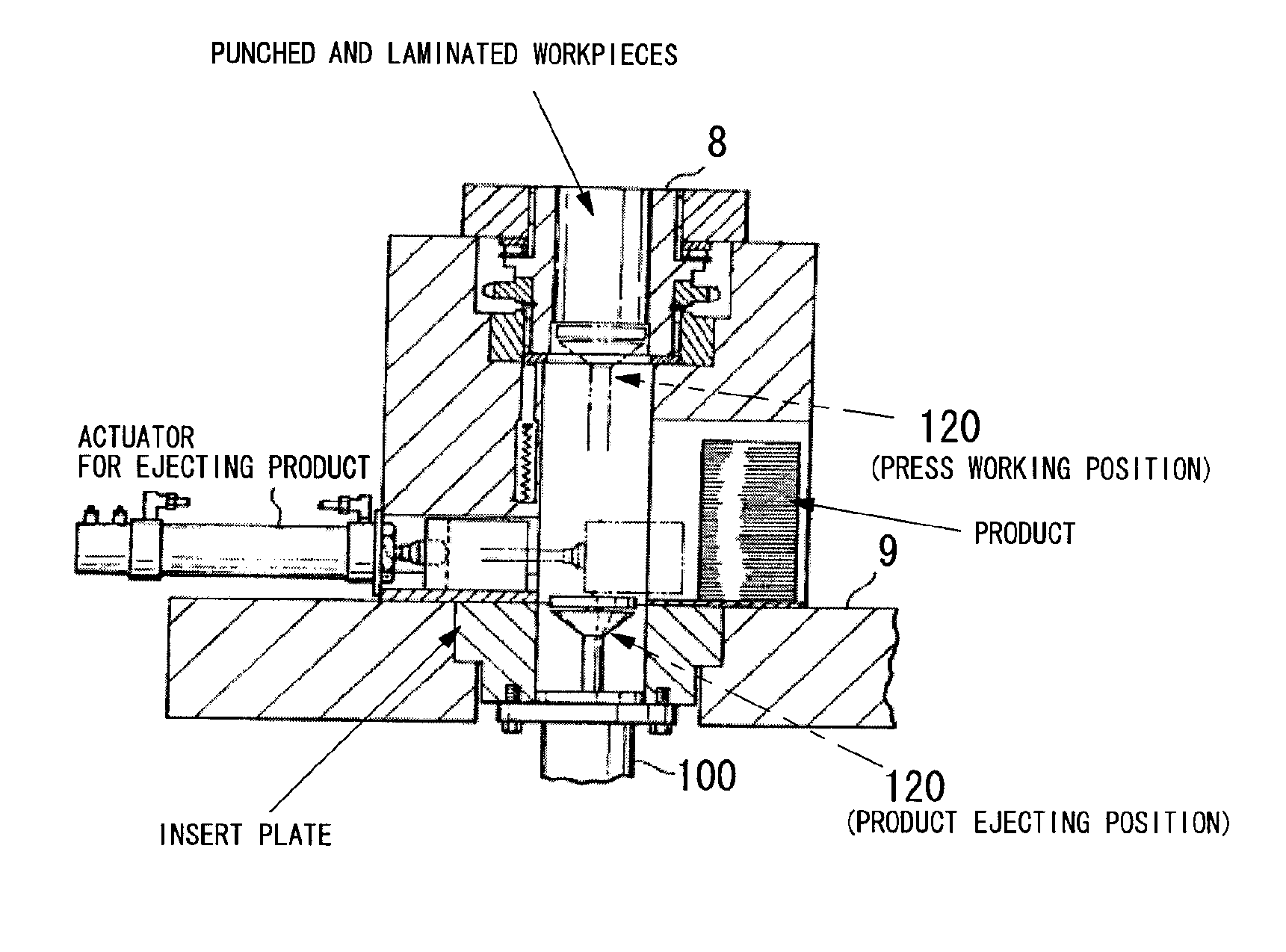

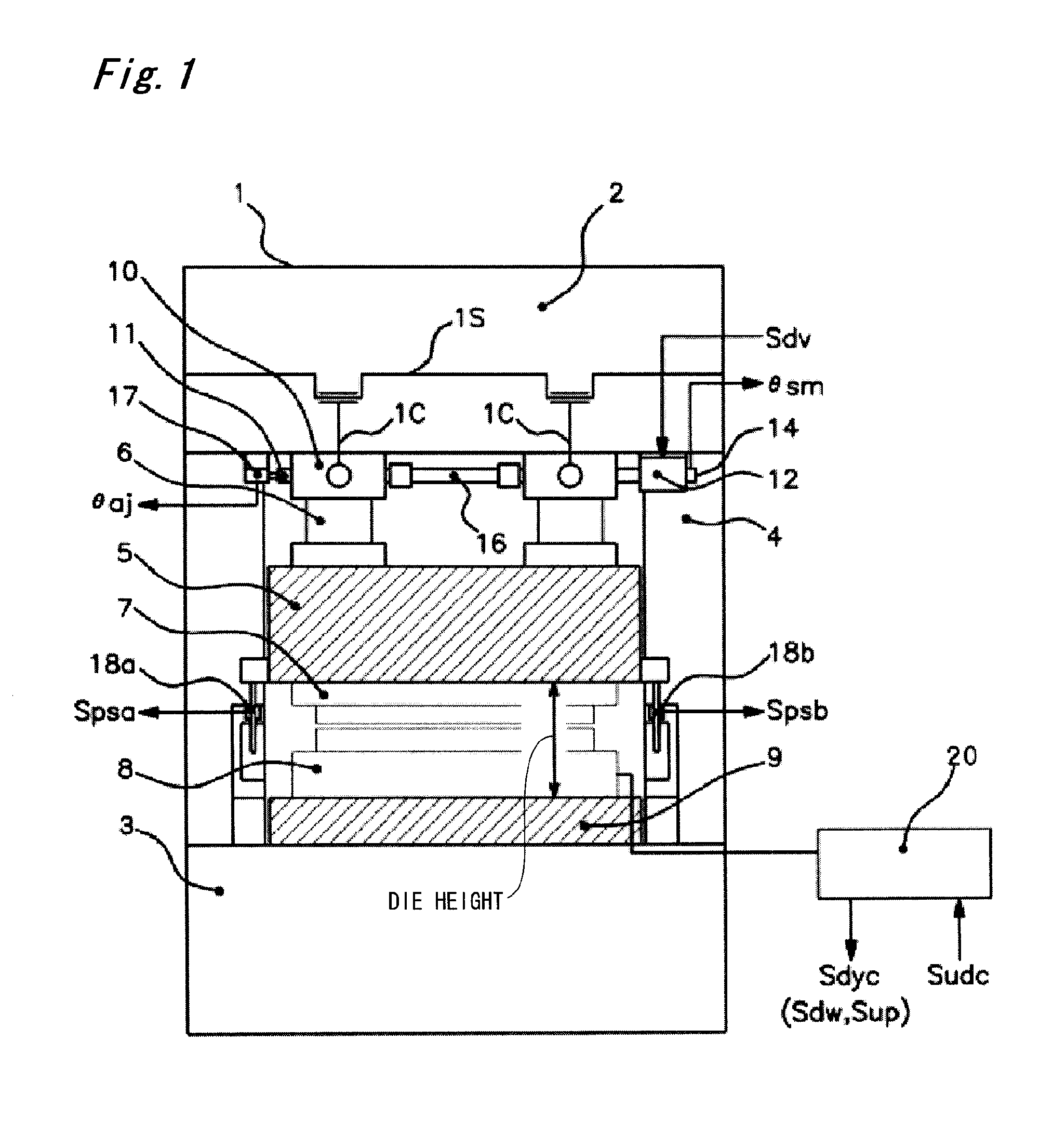

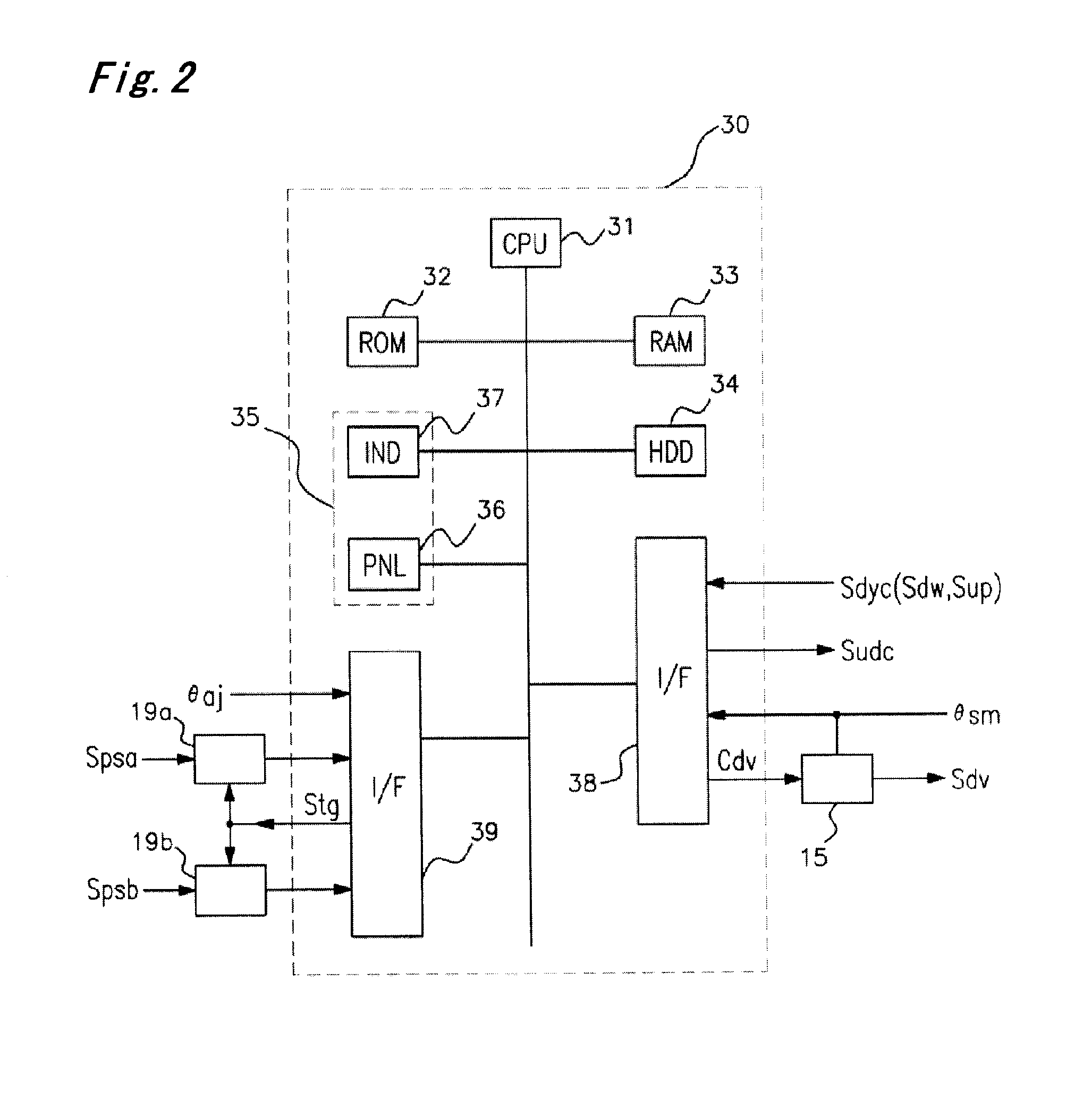

Press machine

ActiveUS20150007627A1High-quality productProduct qualityShaping safety devicesStripping-off devicesMachine pressEngineering

A press machine is provided with a bottom dead center position correction control section, a selected lower bottom dead center position setting section, and a bottom dead center position switching section. The bottom dead center position correction control section is configured to perform, based on the selected bottom dead center position after the switching and the detected bottom dead center position, positional correction so that the actual bottom dead center position of the slide is adjusted to the selected bottom dead center position.

Owner:AIDA ENG LTD

Pure water production system

ActiveCN107758921ASimple structureIngenious ideaTreatment involving filtrationWater/sewage treatment by ion-exchangeReverse osmosisWastewater

The invention relates to a pure water production system which comprises a quartz sand tank, a precise filter, an active carbon tank, a resin tank, a security membrane, a reverse osmosis device, a water storage barrel and canning equipment which are sequentially communicated through a water pipe, wherein the water storage barrel is composed of a wastewater room and a pure water room; a water inletof the wastewater room is connected with a wastewater pipe of the reverse osmosis device; a water inlet of the pure water room is connected with a pure water pipe of the reverse osmosis device; a water outlet of the pure water room is connected with the canning equipment; a flow making pipe is also arranged at the bottom of the quartz sand tank; a pipe orifice of the flow making pipe faces upwardand is opposite to a downward pipe orifice of a source water inlet pipe at the top of the quartz sand tank.

Owner:夏向东

Thin membrane marking system and controlling method thereof

InactiveCN1457029AReduce manufacturing costWork lessStampsElectrographic process apparatusControl signalThin membrane

The invention discloses film marker system that enables continuous mass-production by automating the manufacturing process and to provide the method of controlling the same. This film marker system comprises a loading device for supplying a film, a conveying device for conveying the supplied film to an irradiation position, a laser module for marking a desired character, numeral or symbol by irradiating a laser light to the film provided on the irradiation position, a cutting device for cutting the marked film in a predetermined length, a piling device for sequentially piling up the cut films on a detachable jig, and a control section for controlling the operations of the above devices and the laser module by applying the control signals thereto.

Owner:TECHNICS

Liquid repair film for indoor and outdoor ceramic tiles and preparation method of liquid repair film

The invention discloses a liquid repair film for indoor and outdoor ceramic tiles and a preparation method of the liquid repair film, and problems that when jelly like non smashing brick repairing liquid and transparent waterproof glue are used for indoor and outdoor repairing, the repairing effect is poor, water leakage is easy, and building beauty is affected are solved. The liquid repair film is prepared from the following raw materials in parts by weight: 15-26 parts of a curing agent, 17-30 parts of high-strength resin, 1-60 parts of a diluent and 0.01-5 parts of a surface modifier. According to the liquid repair film for the indoor and outdoor ceramic tiles and the preparation method of the liquid repair film, a novel material is adopted to make a product of high quality and prolongthe service life of the product at the same time, the product has the advantages of convenient construction, high ceramic texture, increased ceramic tile luster, high product strength, can be used outdoors, cannot be whitened and non-scale due to soaking in water for a long time, has high adhesion with the ceramic tiles, is easy to maintain and take good care of, and can be constructed on a wet base surface.

Owner:窦传勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com