Bolster and side frame integral core producing method

A production method and integral core technology, applied in the direction of mold cores, casting molding equipment, metal processing equipment, etc., can solve the problems of large volume, difficult operation, low efficiency of production process, etc., and achieve high-quality products, efficient production operations, good The effect of the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

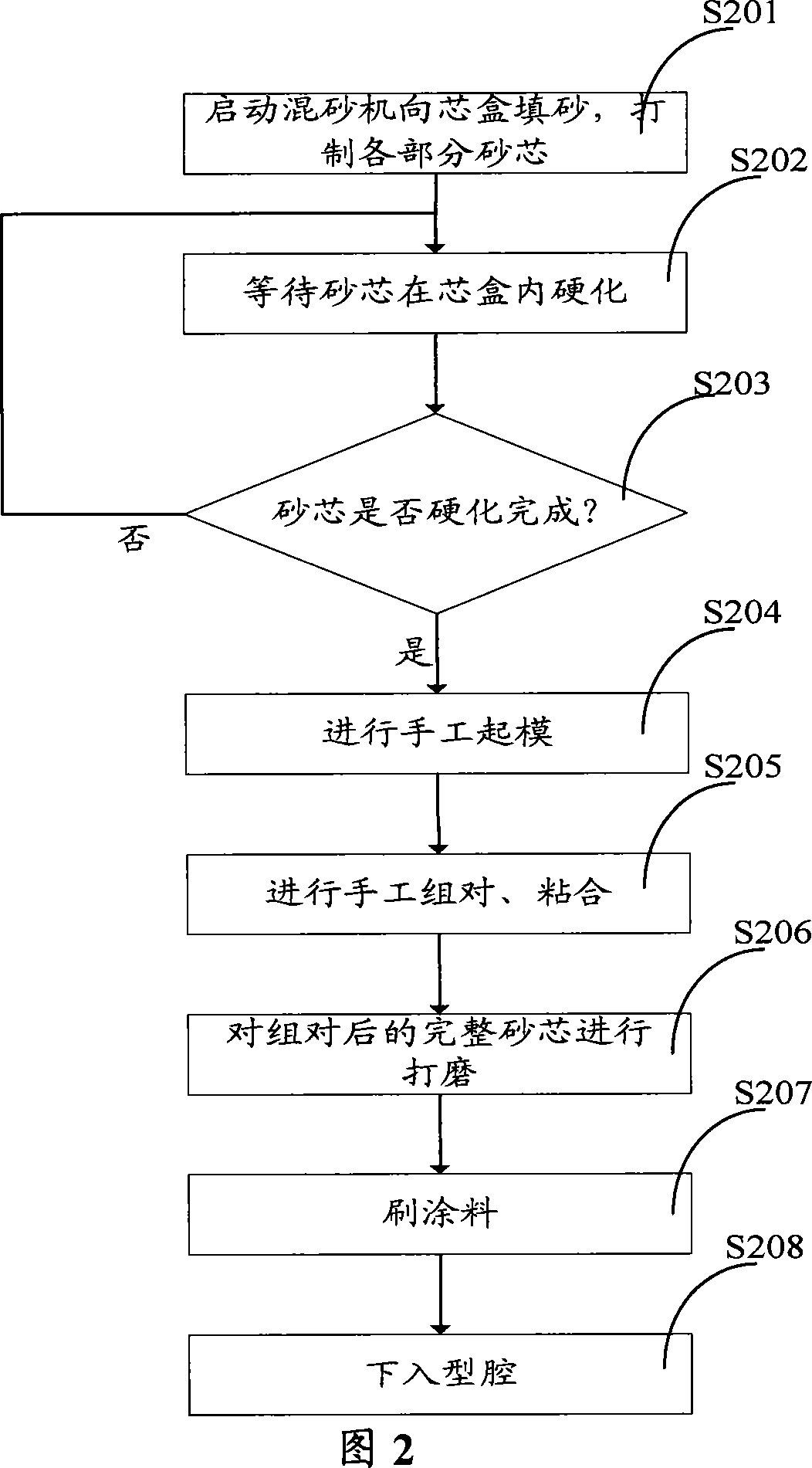

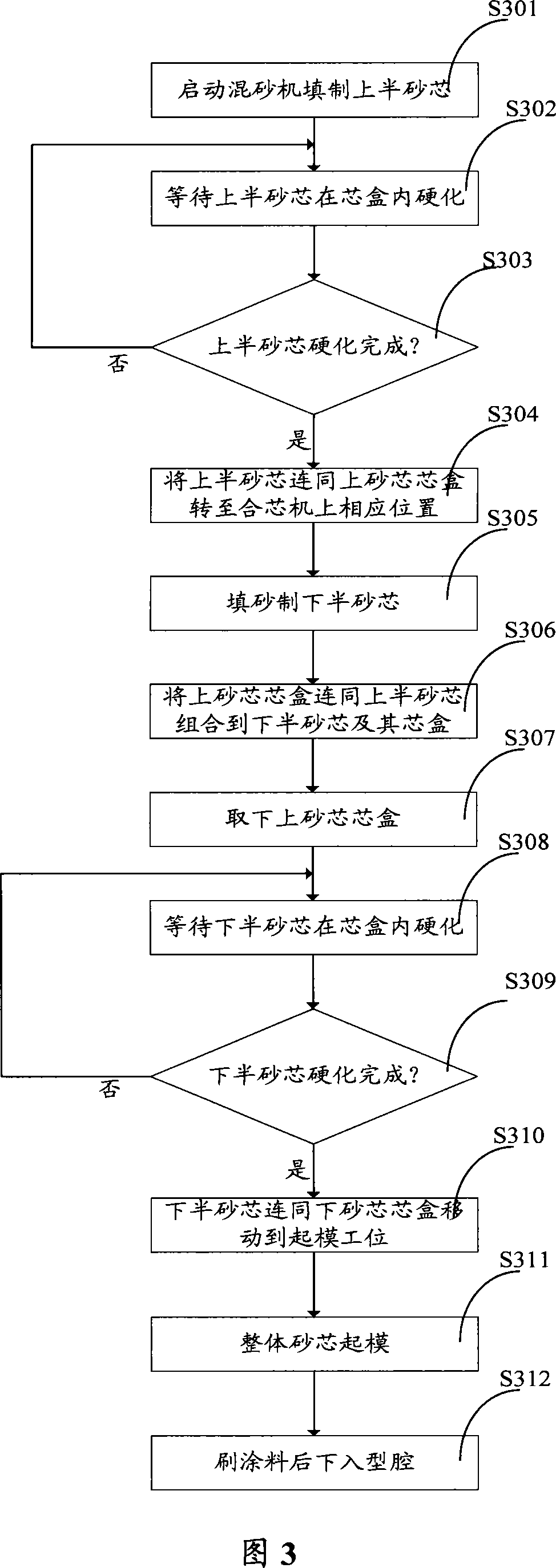

[0045] Please refer to FIG. 3, which shows a flowchart of the first embodiment of the present invention.

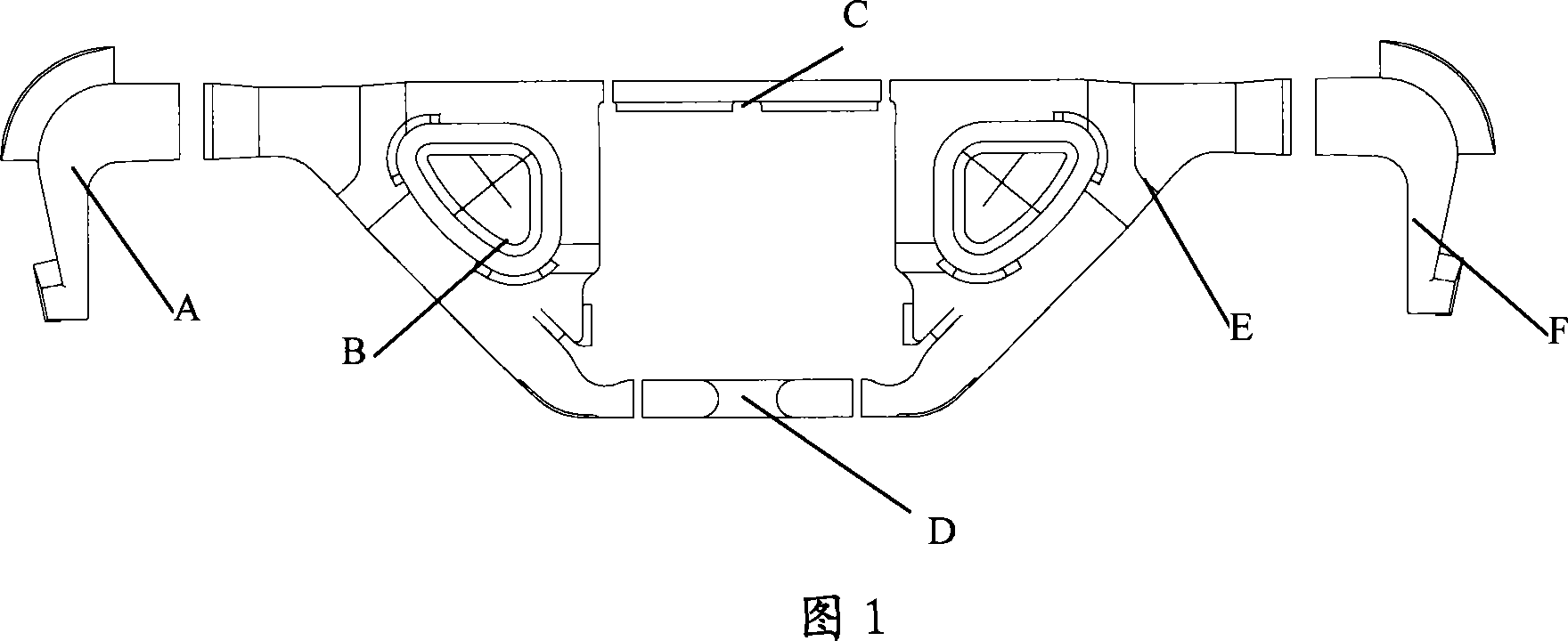

[0046] This embodiment is aimed at the integral core process of bolsters and side frames. The integral core process specifically designs the bolster and the inner cavity of the side frame as an integral core that is divided into upper and lower pieces and then assembled together. The bolster and side frame sand cores are all made of existing mature organic ester sodium silicate self-hardening sand.

[0047] Please refer to Fig. 4, which shows the integral core of the side frame adopted in the first embodiment of the present invention. piece.

[0048] Please refer to Fig. 5, which shows the upper half sand core of the integral core of the bolster adopted in the first embodiment of the present invention. Fig. 6 shows the lower half sand core of the integral core of the bolster adopted in this embodiment. The upper and lower sand cores are segmented at the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com