Admixture master batch intelligent preparing system and control method thereof

A technology of intelligent batching and admixtures, applied in chemical instruments and methods, mixer accessories, dissolution, etc., can solve problems such as low production efficiency, affecting concrete quality, and reduced efficacy of admixtures, and achieve the effect of simple production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

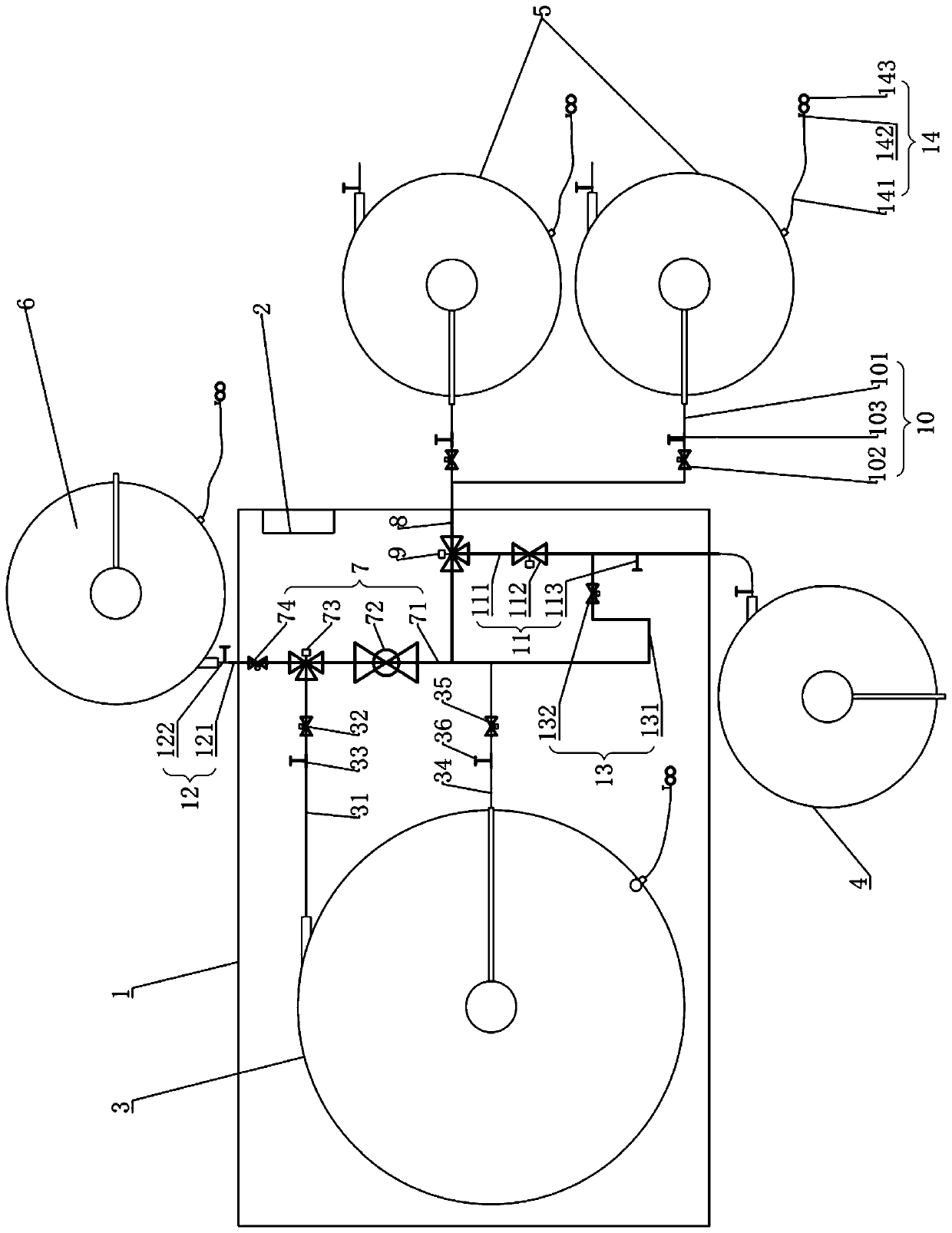

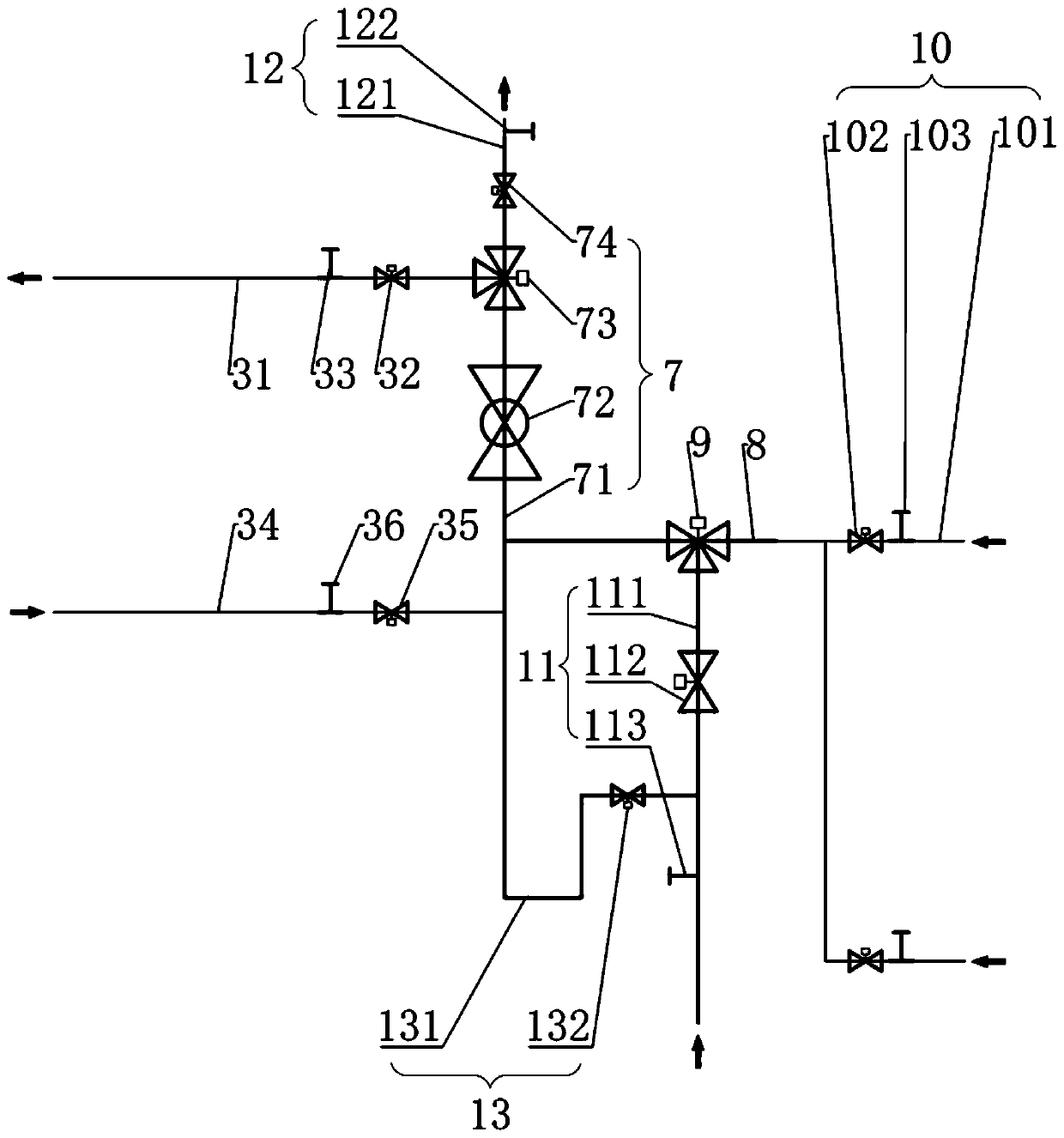

[0028] refer to Figure 1 to Figure 2 As shown, an intelligent batching system for admixture masterbatch includes a storage tank container 1 and a controller 2; a storage tank 3 with a built-in liquid level transmitter is provided in the storage tank container 1, and a storage tank 3 is installed in the storage tank The container 1 is provided with a water storage tank 4, a raw material tank 5 and a finished product tank 6; the storage tank 3 is connected to a batching pipeline 7 through a compounding pipe 31 and a batching discharge pipe 34, and the compounding pipe 31 is An electric valve for feeding material 32 and a manual valve for feeding material 33 are provided, an electric valve for discharging material 35 and a manual valve for discharging material 36 are arranged on the batching discharge pipe 34, and the batching pipeline 7 passes through a raw material feeding pipe 8 and A raw material delivery pipeline 10 is connected with the raw material tank 5, and the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com