Program control smoking and roasting betelnut production line

A production line, smoking and roasting technology, which is applied in food preservation, fruit and vegetable preservation, food processing, etc., can solve the problems of uneven quality of processed products, non-compliance of governance, and poor economic benefits, so as to improve the pass rate and economic benefits, The effect of reducing labor intensity and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

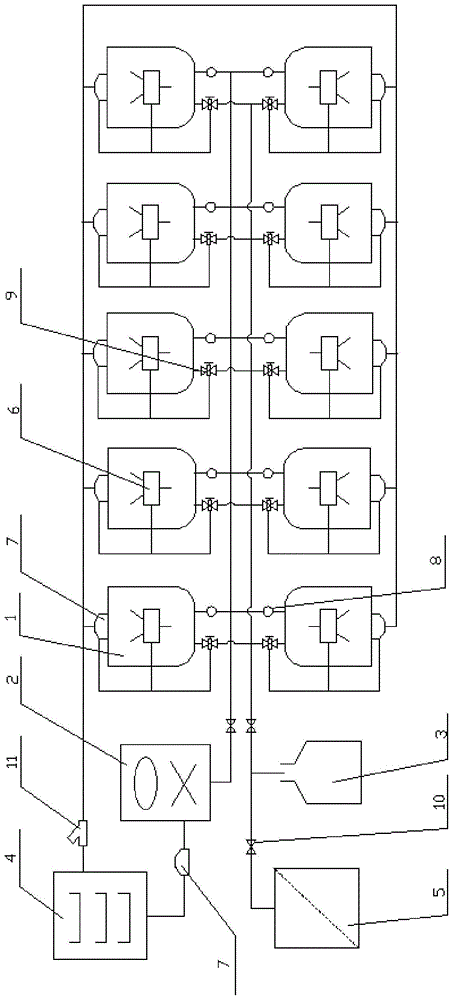

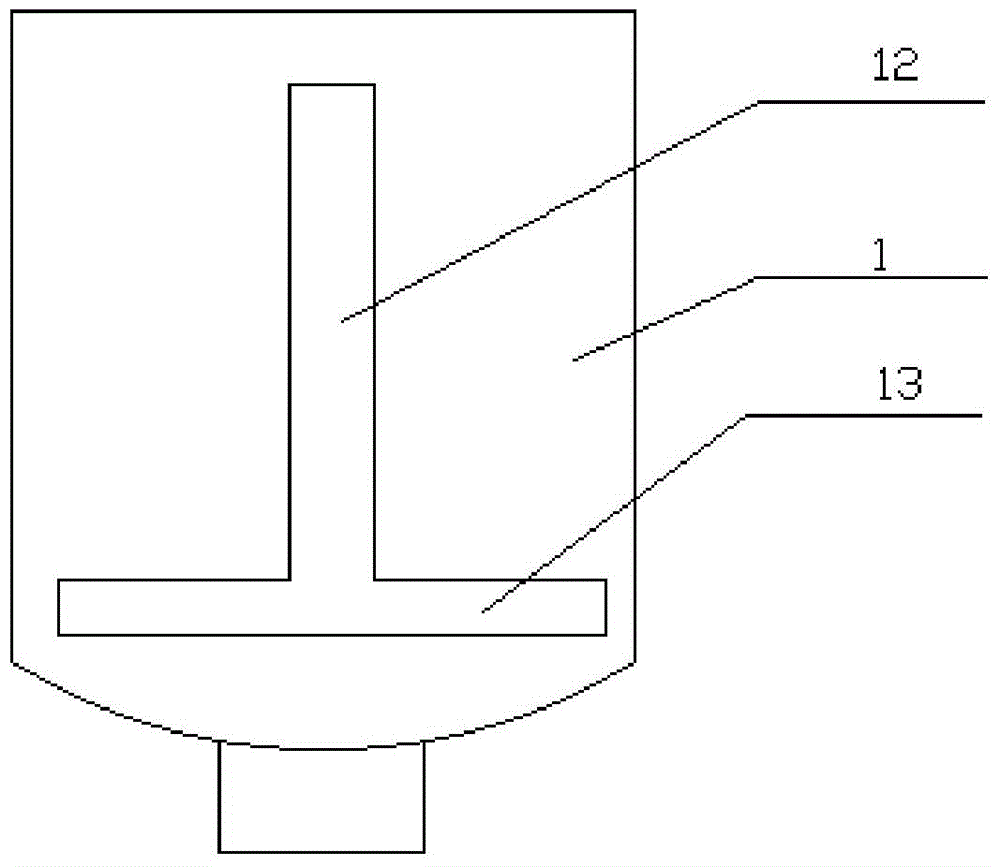

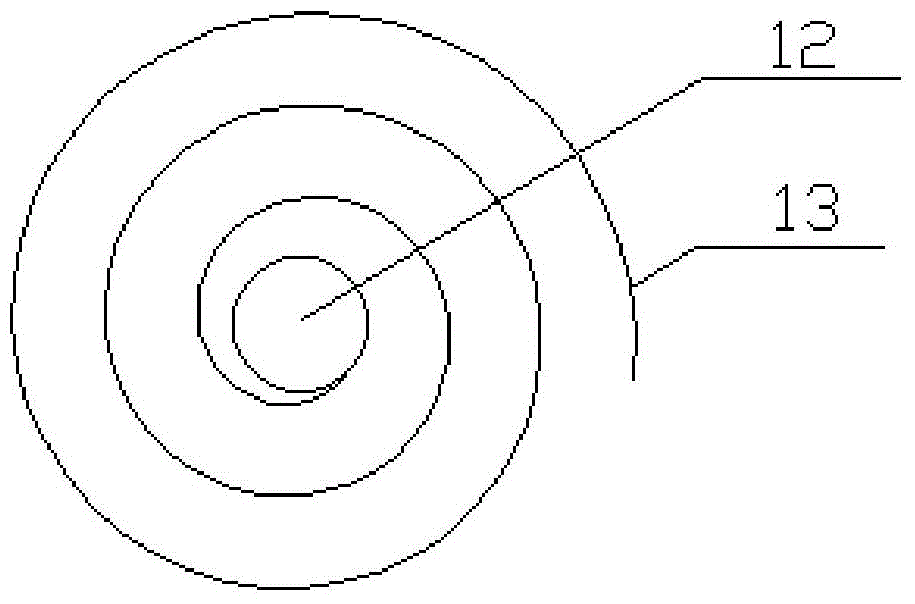

[0026] Such as Figure 1~4 As shown, the program-controlled smoking and roasting betel nut production line includes smoking oven 1, smoke generator 2, heat transfer oil boiler 3, dryer 4, fruit ripening machine 5, bucket elevator and conveyor. 1 are connected through an oil circuit and a flue, and the smoker 1 is provided with a sensor 6, a smoker pipe and a first heating oil pipe, and an exhaust fan 7 and a blower 8 are arranged on the flue near the smoker 1, and the blower 8 is set At the smoke inlet of the smoker oven 1, the exhaust fan 7 is arranged at the smoke outlet of the smoker oven 1, and the smoker pipe is connected to the smoke generator 2 through the flue.

[0027] Among them, the sensor 6 includes a temperature sensor, a smoke sensor and a humidity sensor. The temperature sensor is connected to the special control valve 9 to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com