Open pit and underground space-time synchronous mining method for multiple-ore body

A mining method and open-pit mining technology, applied in the directions of underground mining, surface mining, mining equipment, etc., can solve the problems of small production scale, lack of pertinence and adaptability, and large environmental damage, so as to solve the problem of tailing waste storage. The effect of soil and polluted environment, controlling the range of rock movement, and ensuring the thickness of the overburden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a further detailed description of the multi-ore body open-pit underground space-time synchronous mining method of the present invention in conjunction with the accompanying drawings and embodiments.

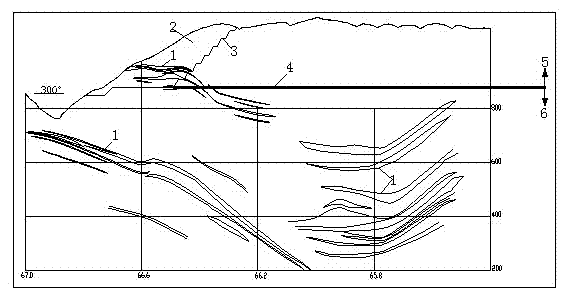

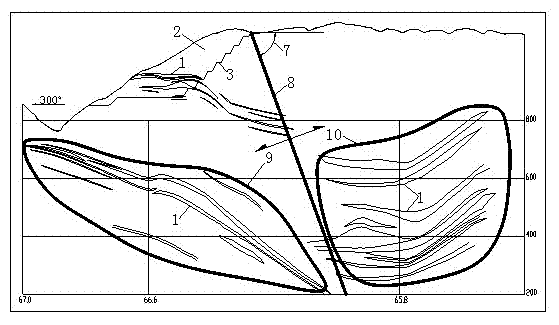

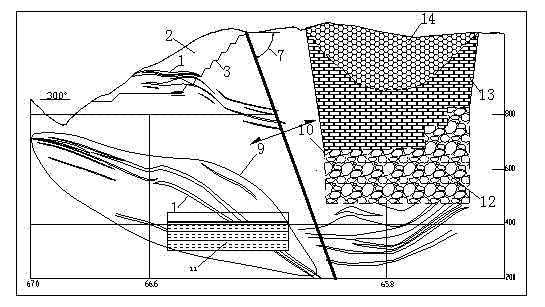

[0034] In this embodiment, the multi-ore body open-pit underground space-time synchronous mining method was carried out on-site industrial test in Dahongshan Iron Mine of Kunming Iron and Steel Co., Ltd. Depend on figure 1 The shown schematic diagram of the method of the present invention dividing the deep ore body and the shallow ore body can be seen, the multi-ore body open-pit underground space-time synchronous mining method of the present invention, at first delimits the shallow and deep ore body divisions according to the economical rational stripping ratio Boundary line 4, the multiple ore body 1 is divided into shallow ore body 5 and deep ore body 6 by the boundary line 4 between shallow and deep ore bodies. The end of the borderline 3.

[0035] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com