Patents

Literature

120results about How to "Safe mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

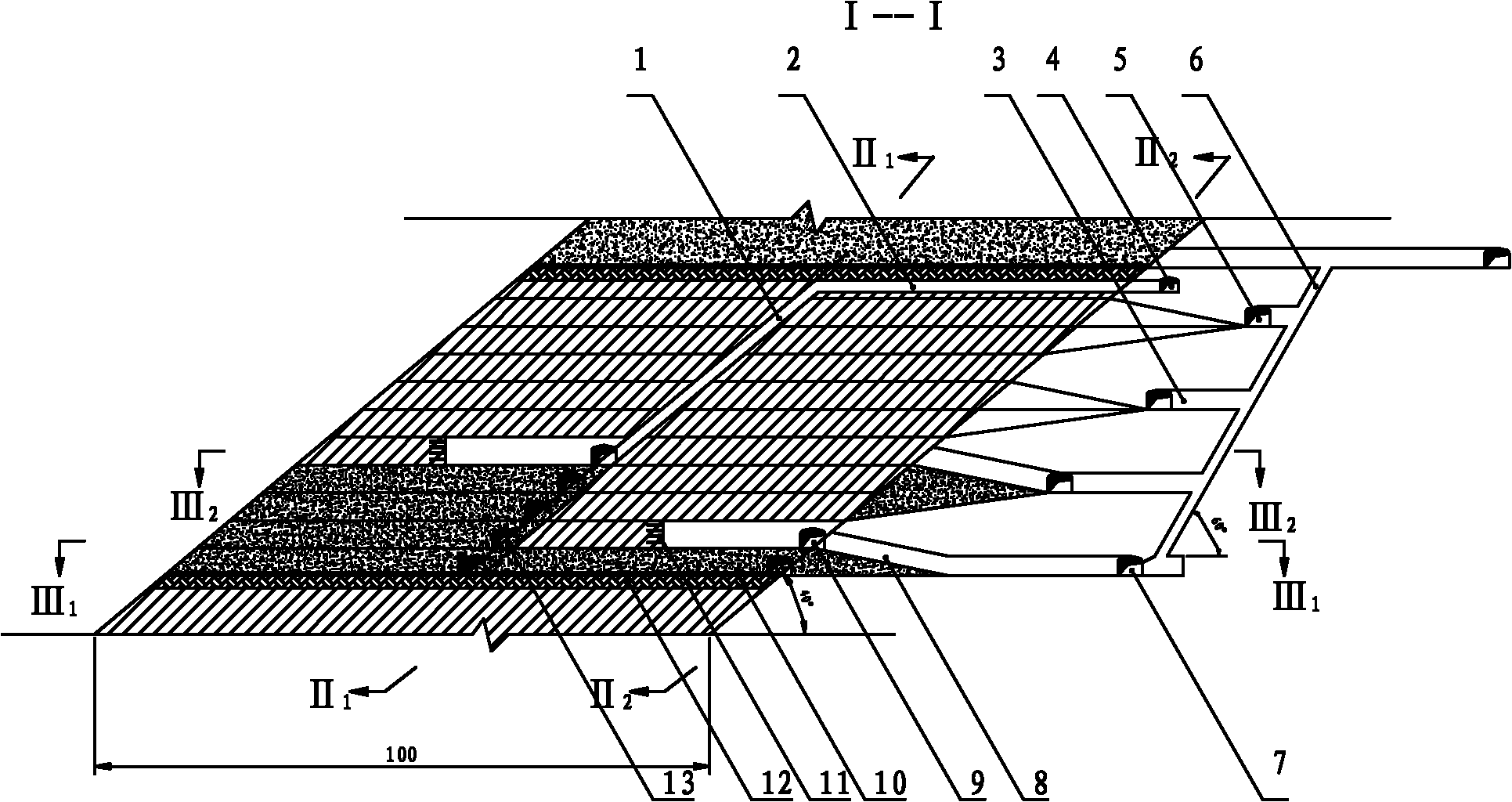

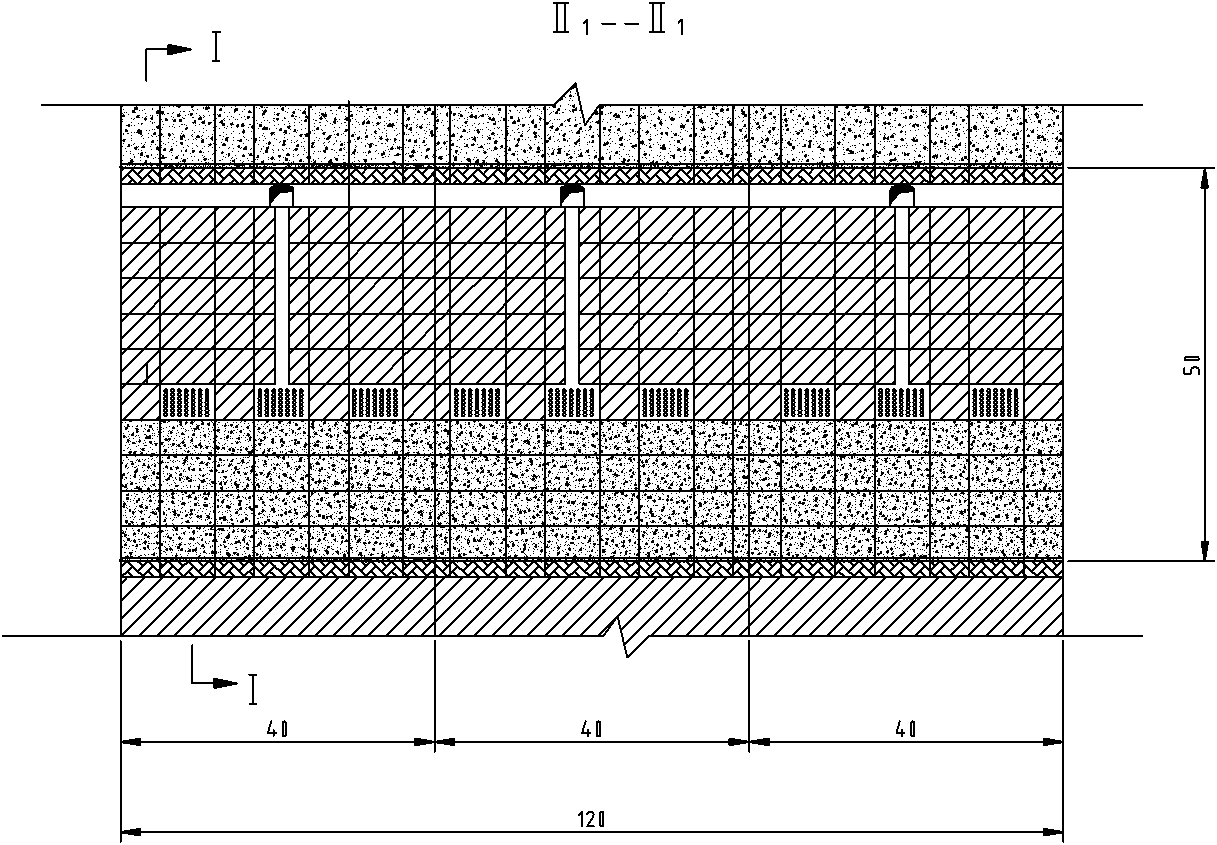

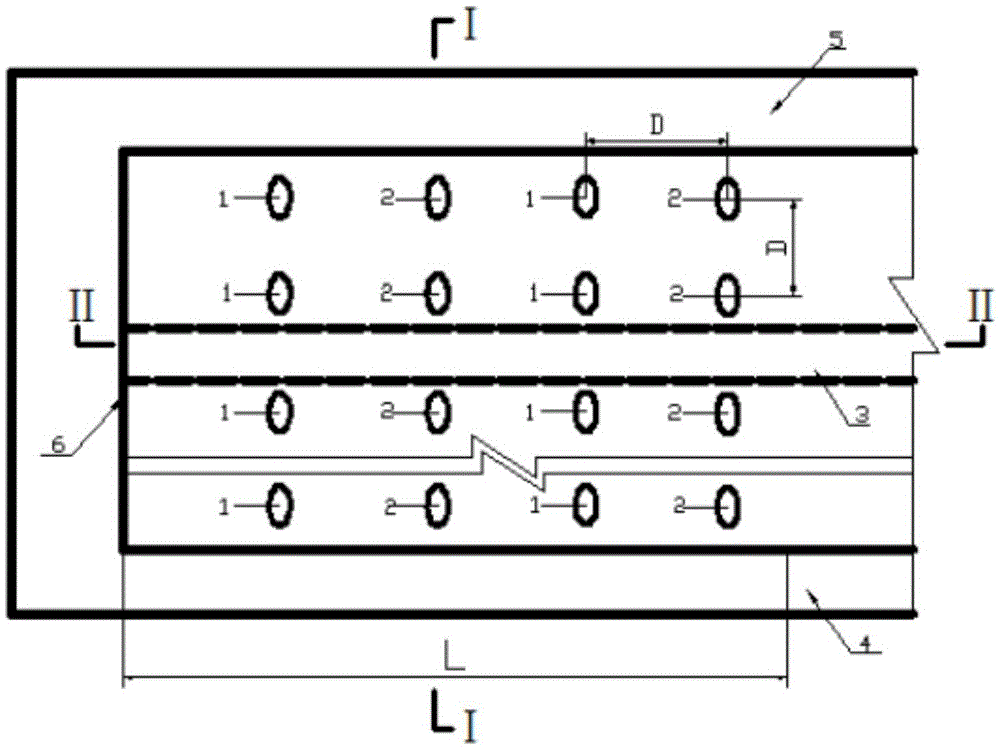

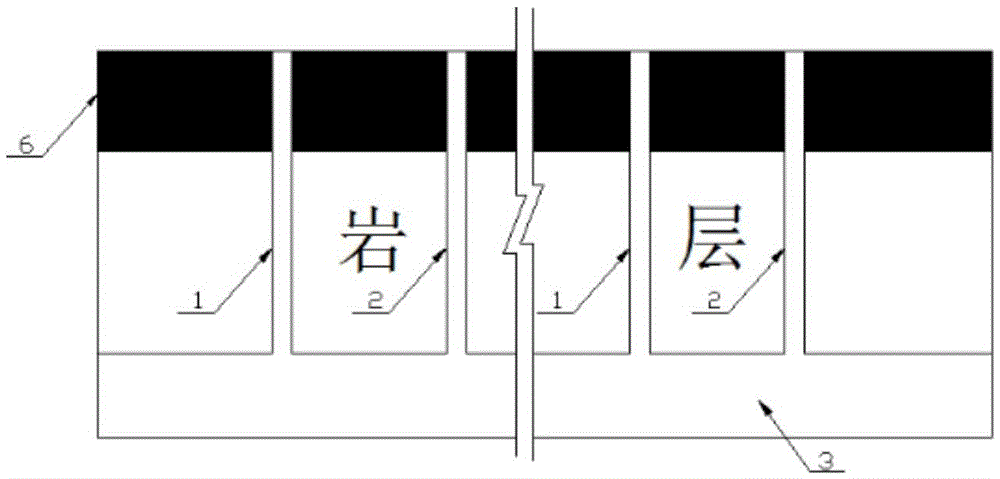

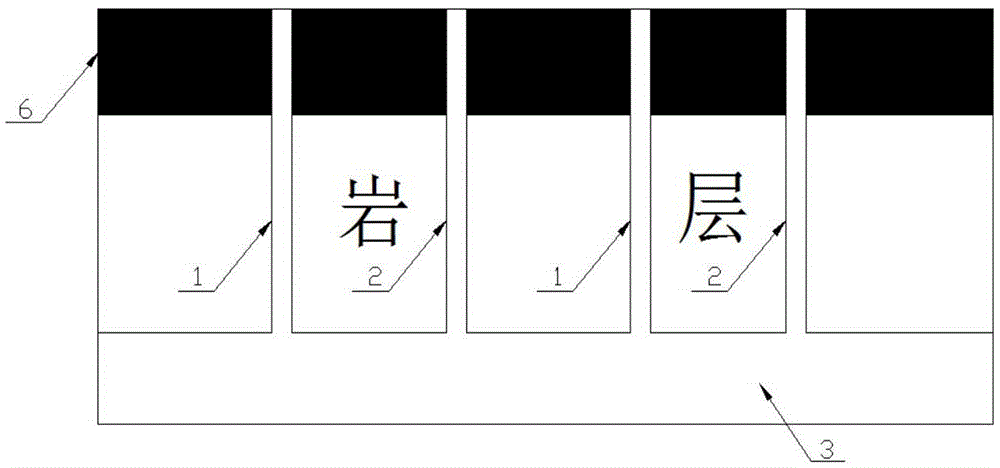

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

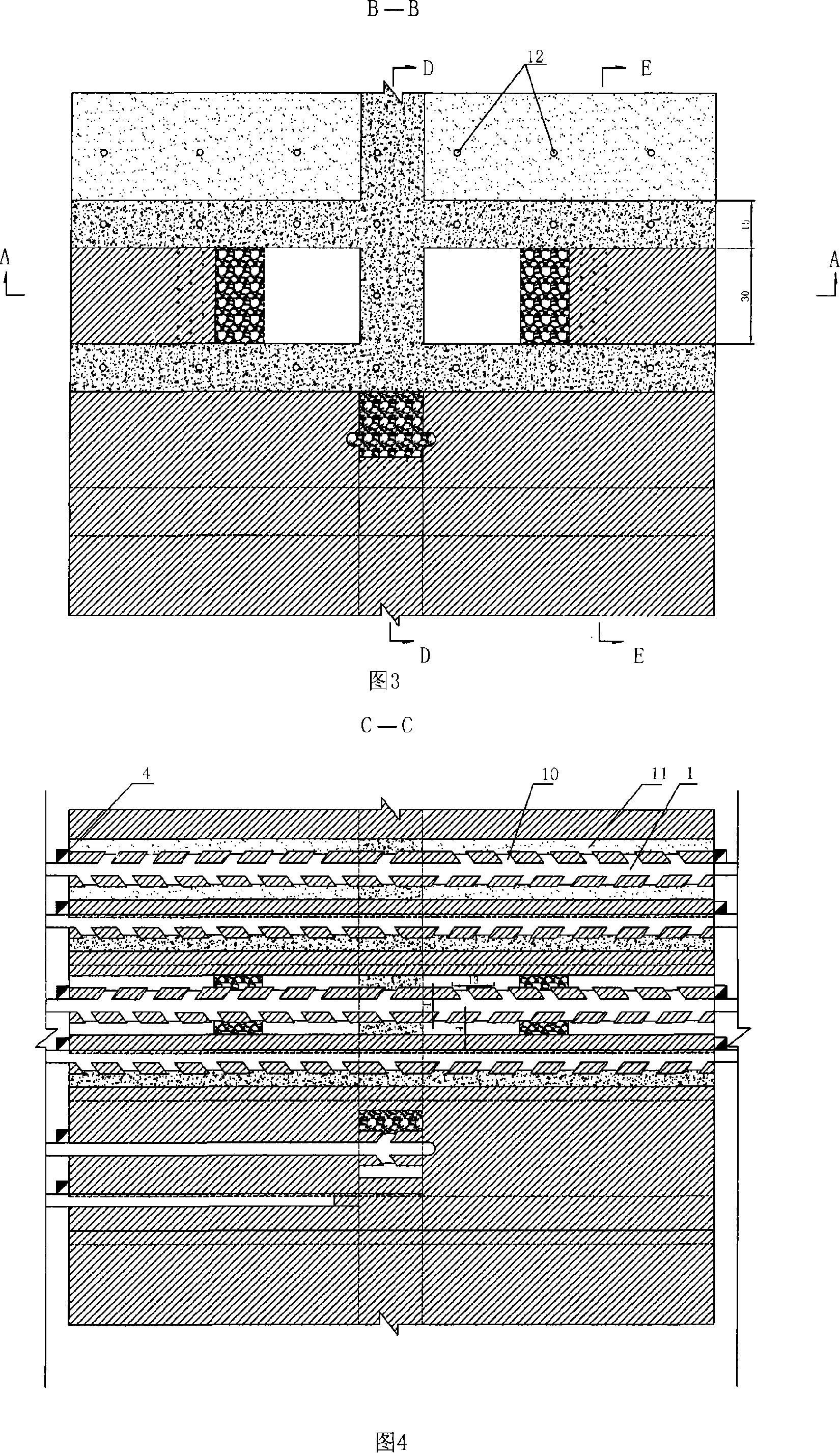

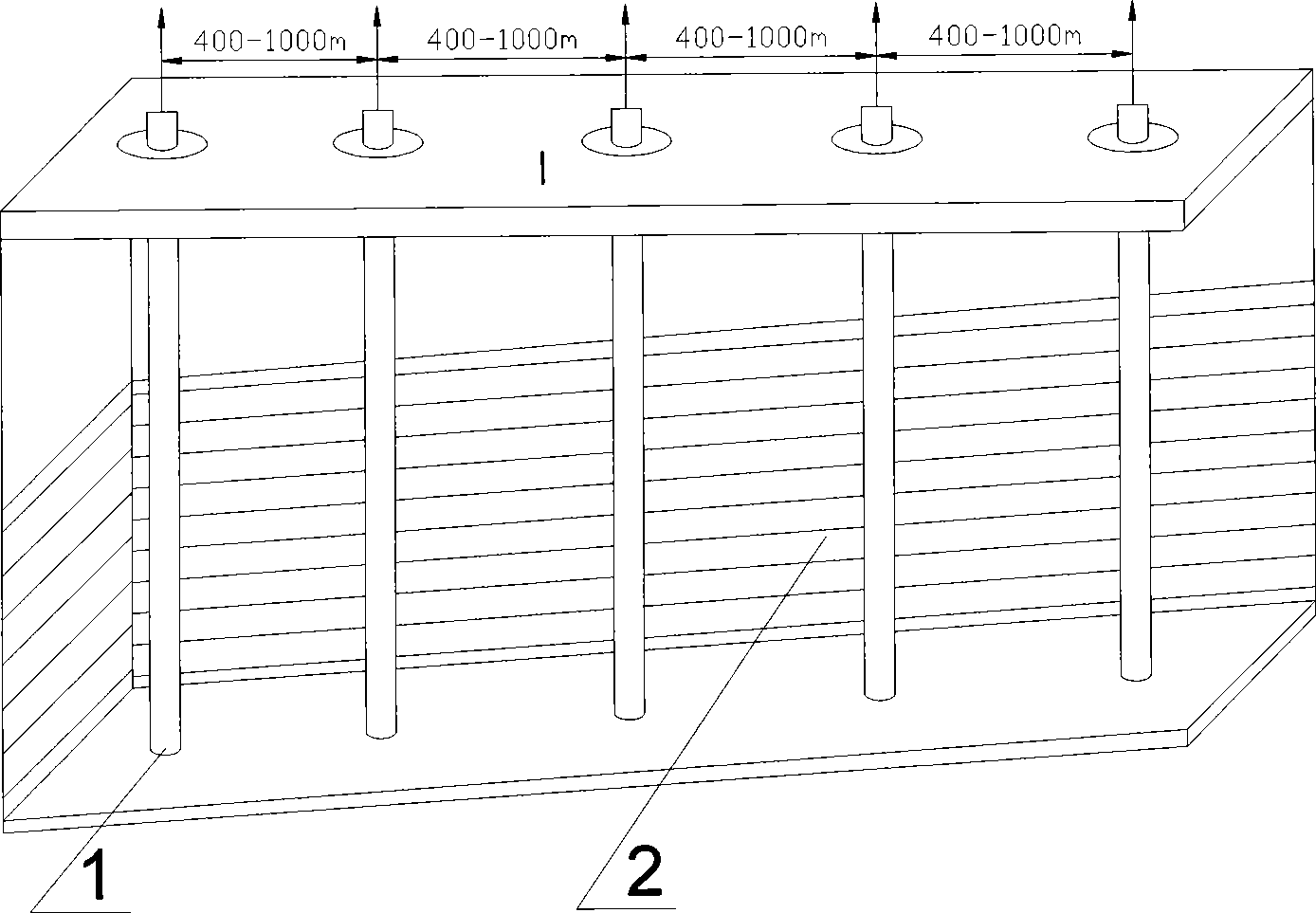

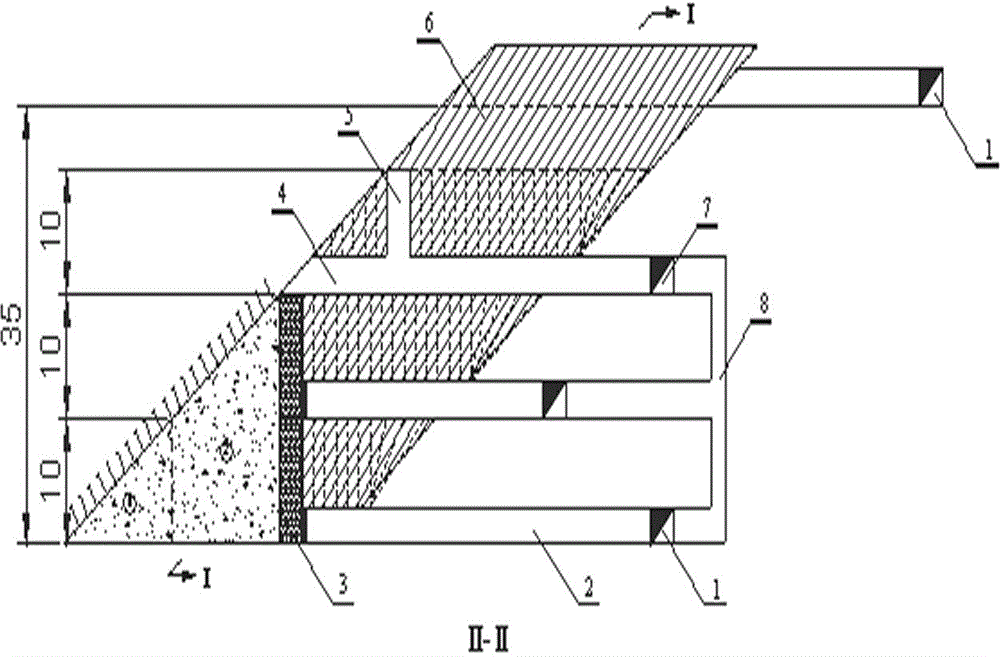

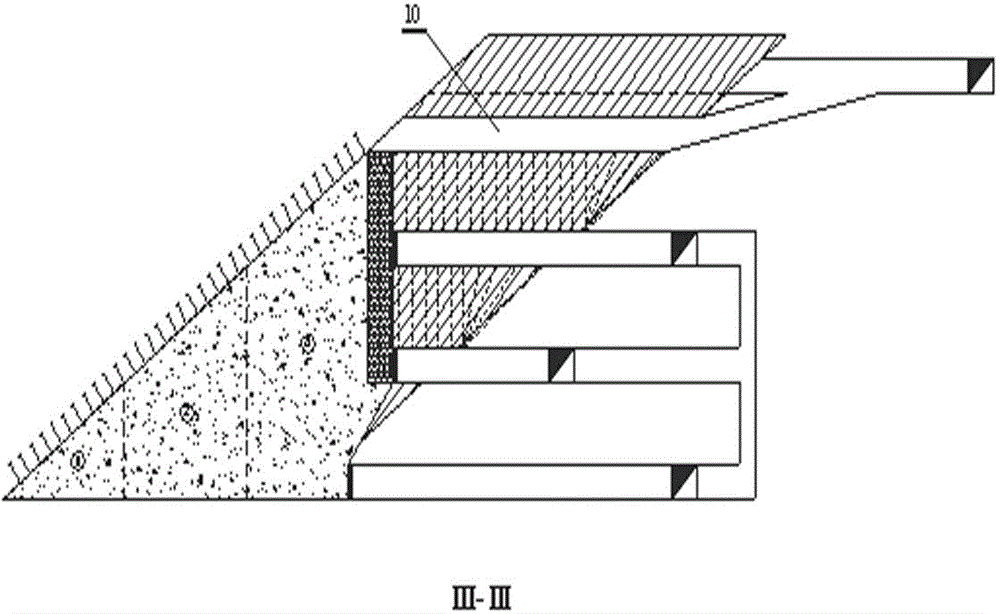

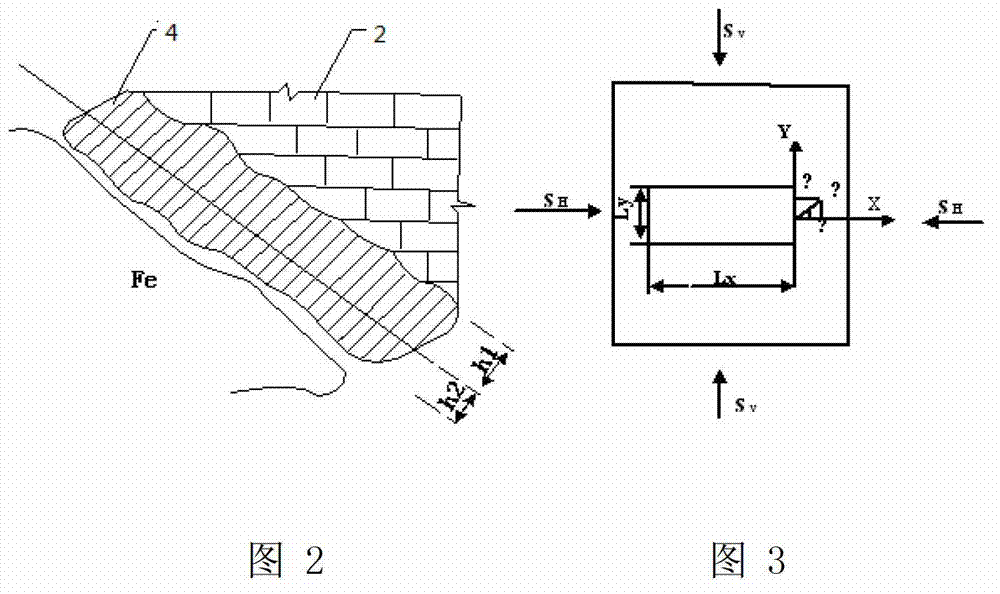

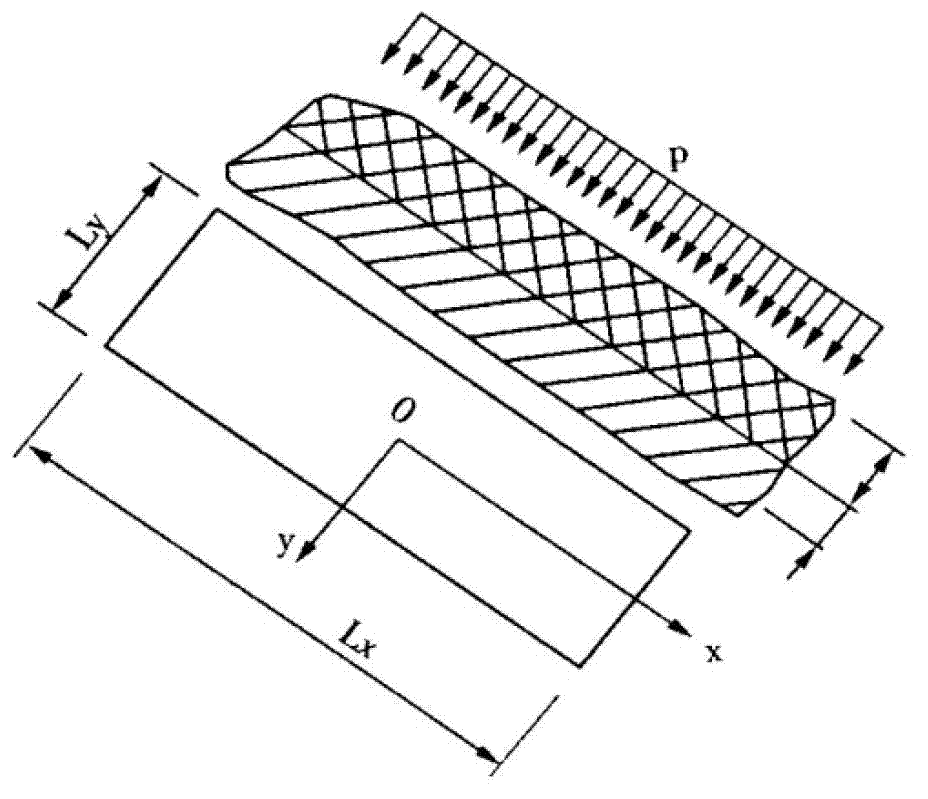

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

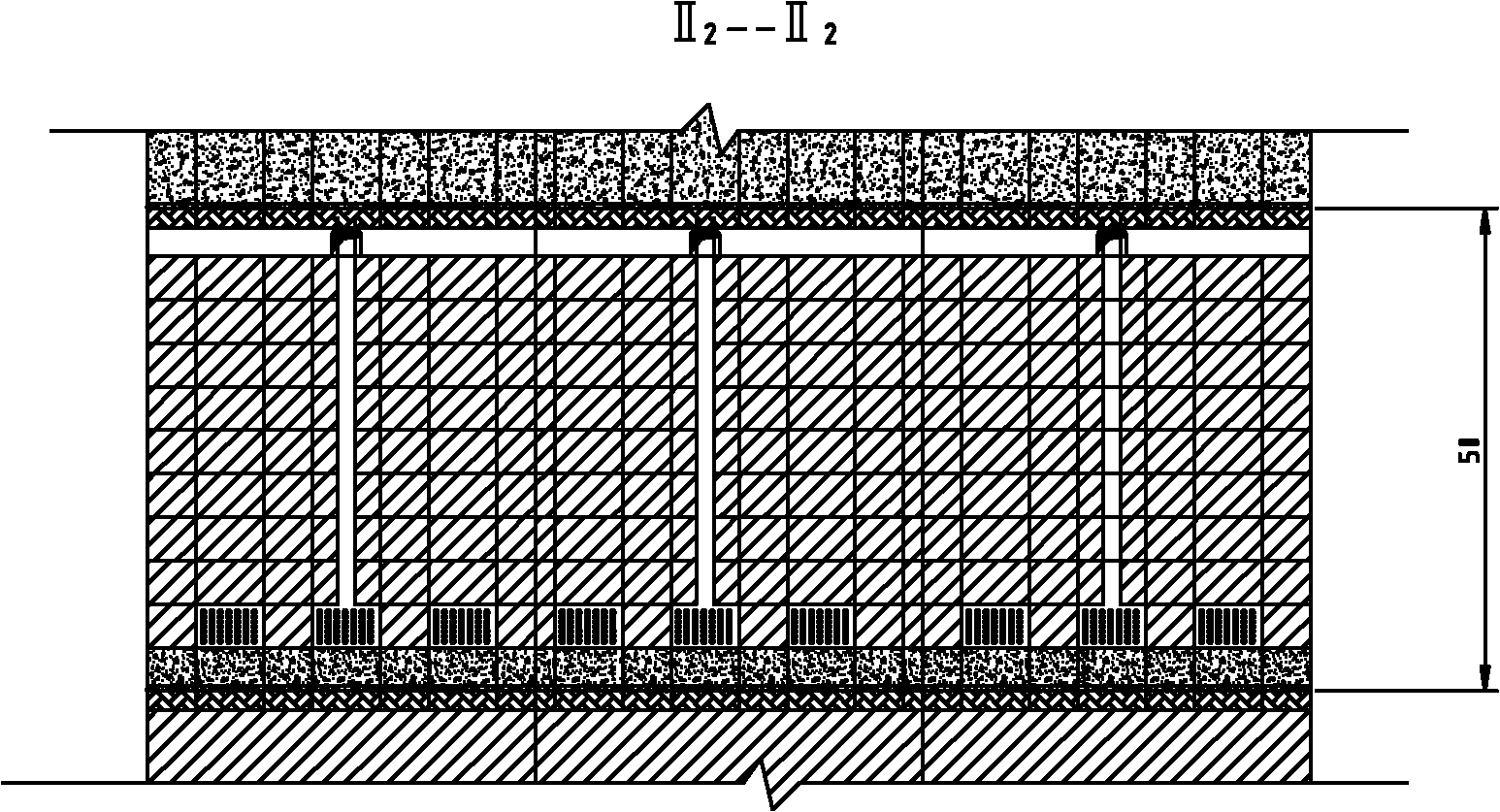

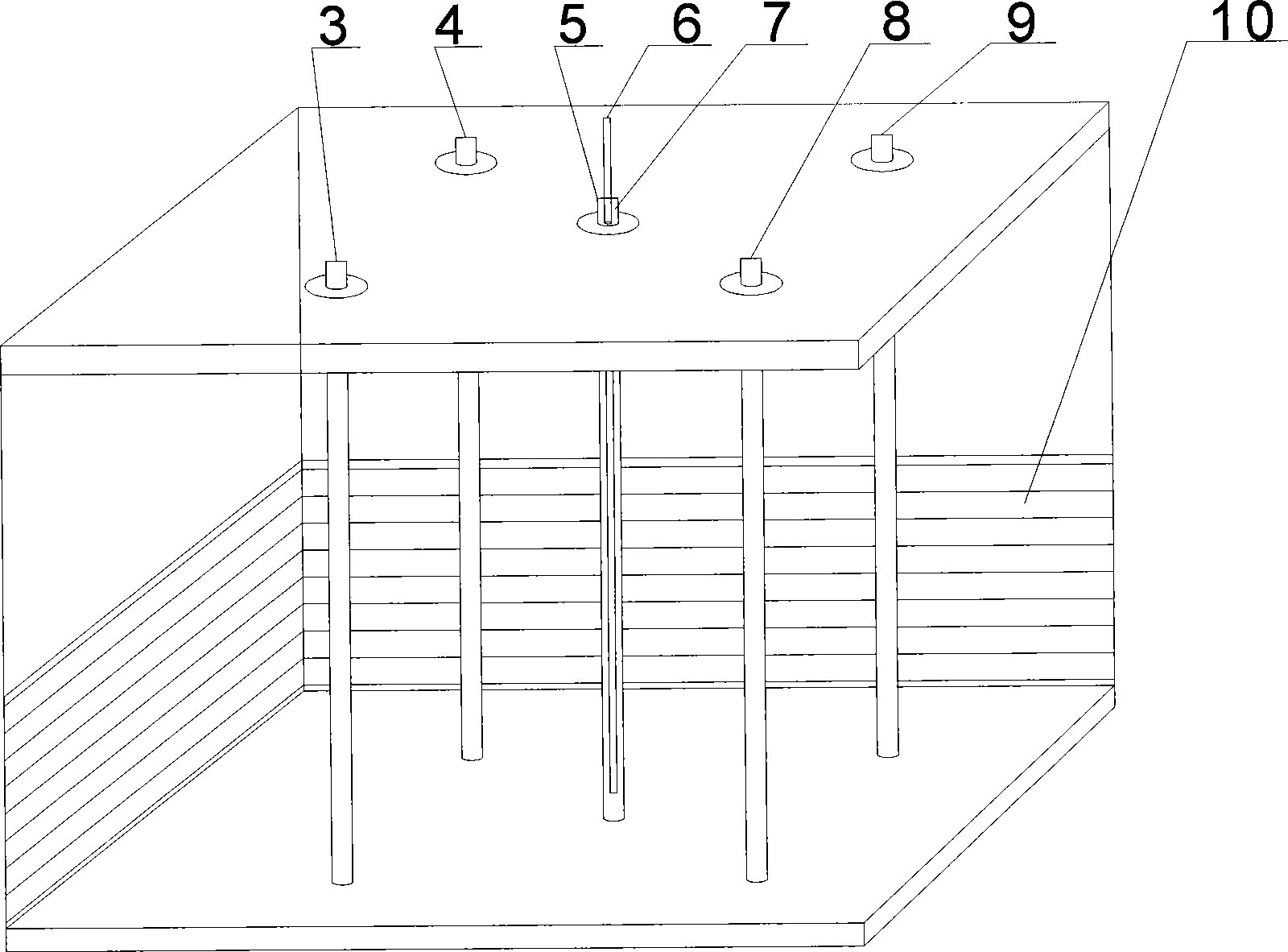

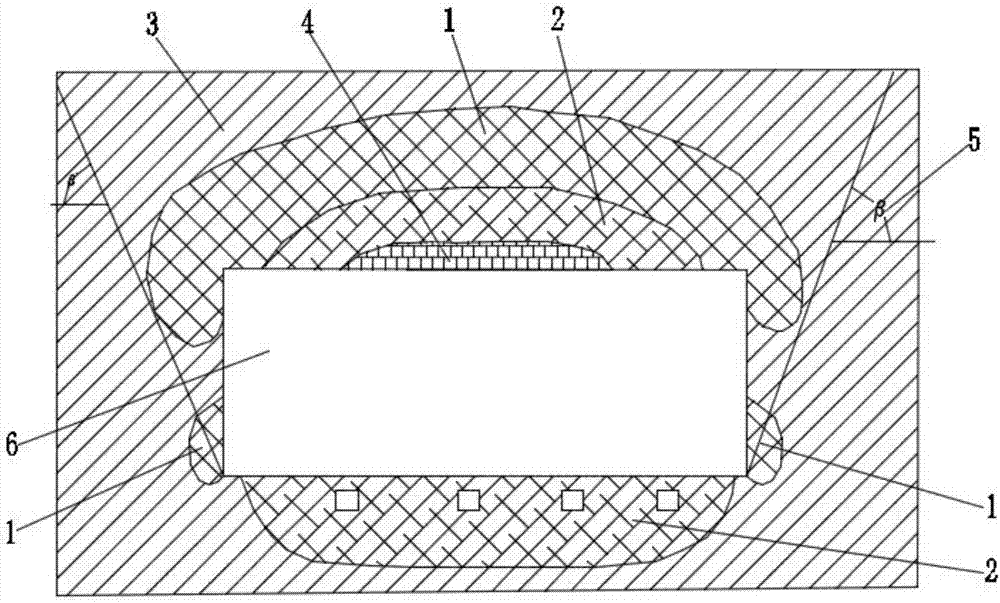

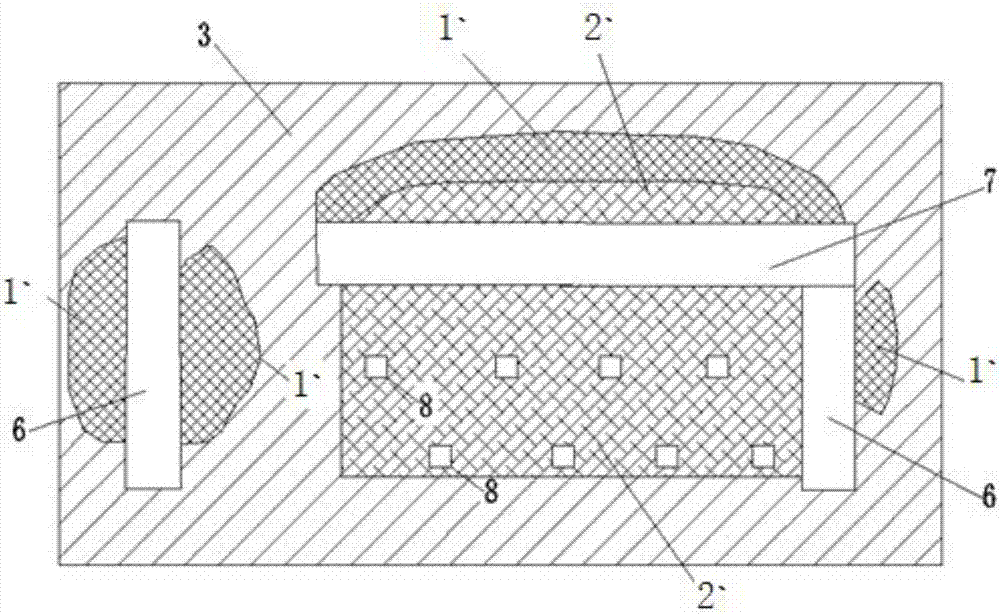

Mining environment reconstructed continuous mining afterwards filling mining method

InactiveCN101105129AHigh recovery rateImprove productivityUnderground miningSurface miningProduction rateMineralogy

The invention discloses a method of continuous mining followed by filling with mining environment reconstruction. The method comprises mining strip ore section in the middle part of the ore body, mining ore section with proper width extending towards two sides of the site that is perpendicular to and has proper distance far away the strip ore section followed by cementation filling to the mined-out area to form a continuous crisscross cementation filling top plate support frame structure. The frame structure meanwhile separates the ore body into several spaced and independent ore sections to reconstruct a new mining environment in the ore body. In such environment, performing spacedly or parallelly second mining with independent ore sections as second mining units followed by non-cementation filling to the mined-out area to realize continuous mining in the overall ore body, performing ore breaking in lateral direction with downward parallel and vertical deep holes, loading ore with double-trench or single-trench as bottom structure along ore blocks direction, landing down to the main gangway in the next stage through stage drop shaft, and transporting out of the mine by downhole locomotive. The invention has the advantages of safe and reliable mining environment, remarkably improved ore recovery rate and productivity, effectively controlled loss, and remarkably reduced production cost.

Owner:CENT SOUTH UNIV

Novel coalbed gas thermal recovery process

The invention relates to a new coalbed gas thermal production process which is characterized in that full hot coke is arranged on the lower part of a coalbed gas production well or a gasification well, a gasification agent is pressed in so as to ignite a hole bottom coalbed; and the heat released from the combustion of part of the coalbed can heat up the adjacent coalbed, and improve the analysis capability, permeability coefficient and osmotic pressure of the coalbed, thereby improving the gas yield of the coalbed.

Owner:ENN SCI & TECH DEV

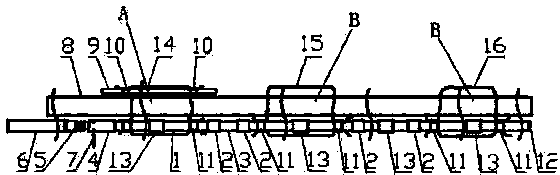

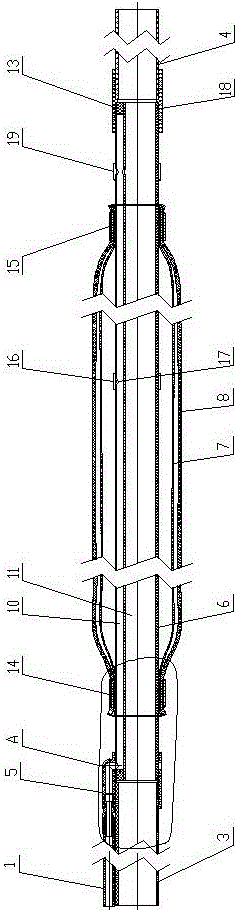

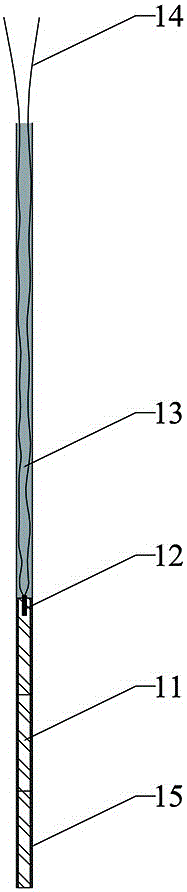

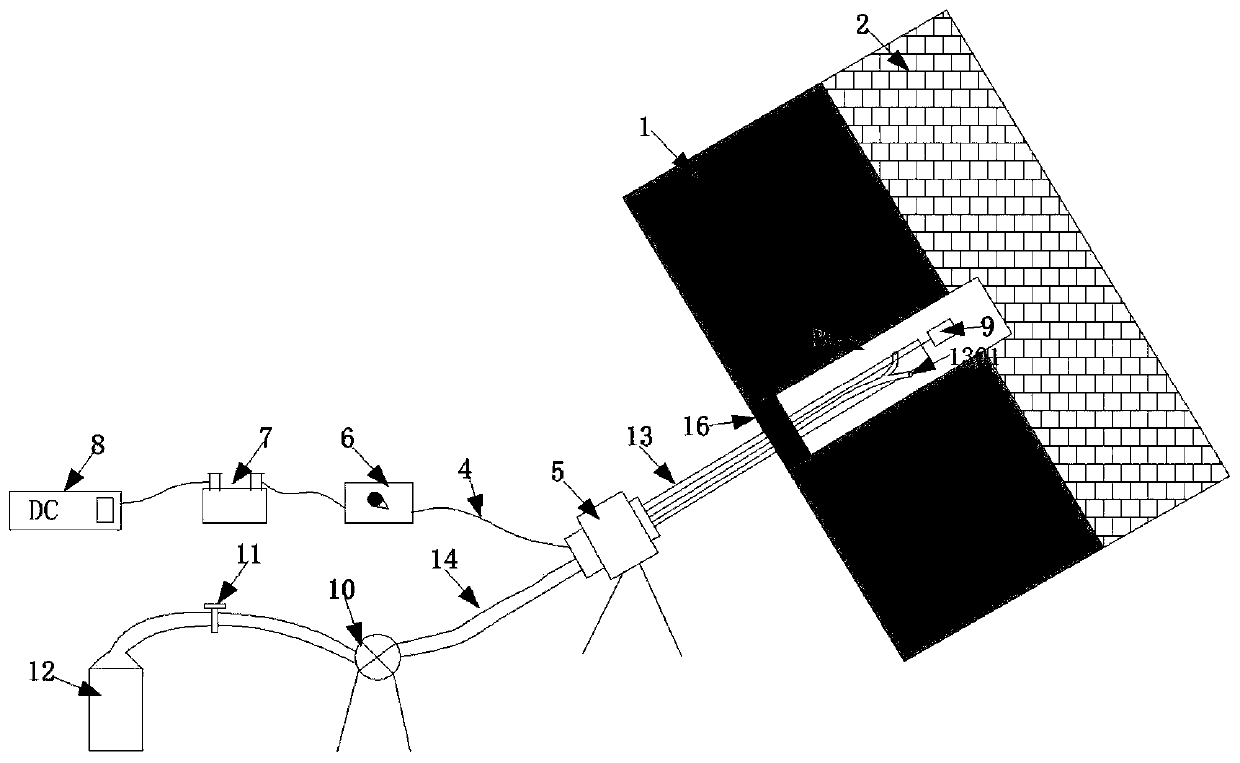

Gas pumping fixing occluder and use method thereof

ActiveCN103452525AEffective blocking purposeAvoid it happening againGas removalSealing/packingGas leakPipe

The invention discloses a gas pumping fixing occluder and a use method thereof. A three-hole pipe penetrates through three bags, a recyclable grouting pipe is communicated with a grouting channel of the three-hole pipe by a drainage device; a gas leaking handling pipe is communicated with a gas leaking handling channel of the three-hole pipe by a drainage device; a grouting hole of the drainage device and a grouting communicating small hole of the three-hole pipe are coaxial by a grouting small hole; a gas leaking handling hole of the drainage device and a gas leaking handling communicating small hole of the three-hole pipe are coaxial by a gas leaking handling small hole; check valves are arranged at the grouting channel in the three bags; a pressure check valve is mounted on the grouting channel between the No.2 bag and the No.3 bag. According to the gas pumping fixing occluder and the use method thereof, more effective grouting sealing can be realized on drill holes of a hole sealing section, generation of coal wall seams around drill holes at the hole sealing section can be more effectively avoided, and the occluder can also fill extremely small coal seams, so the hole sealing effect is optimal.

Owner:HENAN POLYTECHNIC UNIV

Fully-mechanized caving mining process technology with large mining height in super-high seam (14-20m)

ActiveCN101967975AIncrease coal breaking effectIncrease coal discharge spaceUnderground miningSurface miningControl measureCoal mining

The invention provides a coal mining method of fully-mechanized caving mining with large mining height in a super-high seam, a coal caving process, reasonable type of a support, production capacity of equipment, comprehensive control measures of coal wall spalling of working face, a technical route for improving the recovery rate of the fully-mechanized caving face with the large mining height, and feasibility evaluation indexes (thickness of the seam, top coal cavability, coal wall stability and roof pressure strength) of the fully-mechanized caving mining with the large mining height, and further forms a whole set of fully-mechanized caving mining process technology with the large mining height. The coal mining method is that the coal cutting height is 4.2-4.8m; the length of the working face is 200-280m; and the web of a coal mining machine is 0.8-1m. The process technology can increase the coal cutting quantity by 43%, shorten the coal caving time by 9%, relatively reduce the coal caving quantity by 9%, improve the resource recovery rate by 5% and reduce the mining-caving ratio to below 1:3 by increasing the coal cutting height, and can further realize the relatively balanced production of mining and caving of the working face.

Owner:DATONG COAL MINE GRP

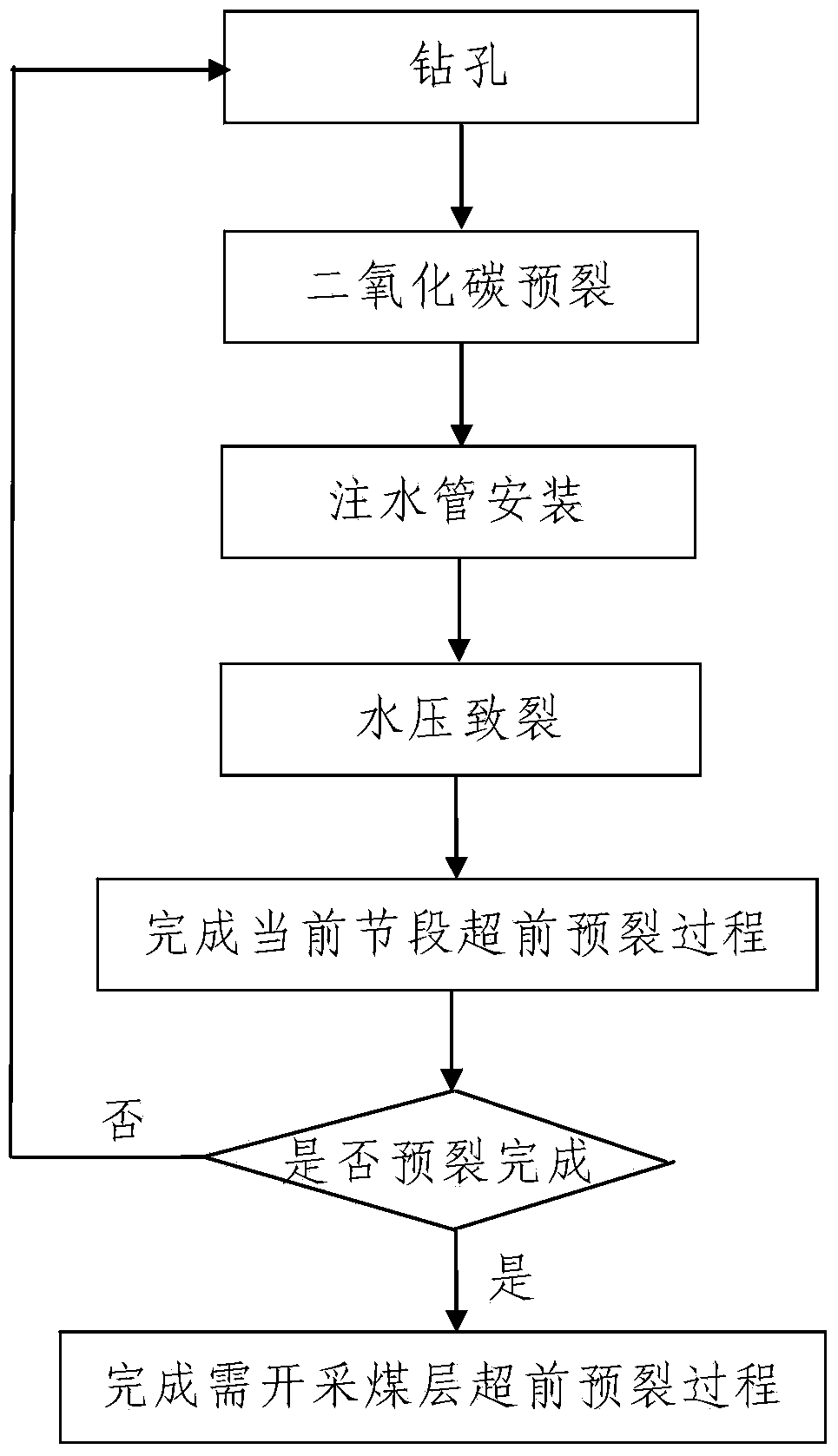

Advanced pre-splitting method for lump coal mining

ActiveCN103924956AThe method steps are simpleReasonable design and simple operationUnderground miningFluid removalHydraulic fracturingHigh pressure water

The invention discloses an advanced pre-splitting method for lump coal mining. The method with carbon dioxide pre-splitting and hydraulic fracturing combined is adopted, advanced pre-splitting of a working face is carried out on a coal layer needing mining in a multi-segmental mode from near to far in the advancing direction of the coal layer working face. The advanced pre-splitting method for every segment comprises the first step of hole drilling, wherein pre-splitting drill holes are drilled in the current pre-split segment; the second step of carbon dioxide pre-splitting, wherein a carbon dioxide pre-splitting device is installed in each drilled pre-splitting drill hole, the drill holes are sealed, and then pre-splitting is initiated; the third step of installation water injection pipes, wherein each pre-splitting drill hole is internally provided with one high pressure water injection pipe, and the holes are sealed; the fourth step of hydraulic fracturing, wherein water is injected into the pre-splitting drill holes through the high pressure water injection pipes to carry out hydraulic fracturing. According to the method, steps are simple, design is reasonable, the method is easy to implement and good in use effect, the problems that an existing deep hole blasting pre-splitting method is not safe, serious in pollution, high in investment cost, poor in use effect and the like are effectively solved, and the lump coal rate of a fully mechanized coal mining face is improved effectively.

Owner:XIAN UNIV OF SCI & TECH

End slope coal bed remote control excavating mining method

InactiveCN104074521AImprove the recovery rate of coal resourcesSimple production processUnderground miningSlitting machinesMining engineeringMan machine

The invention provides an end slope coal bed remote control excavating mining method, which belongs to an end slope residue coal resource extraction method and is used for open pit coal mine end slope and hillside outcrop and shallow surface coal bed mining. A coal mining system adopts a remote control excavating machine system, which comprises an excavating machine and a remote operating and control room, wherein operating and control equipment consists of three parts including a mining flameproof excavating machine electric control box, an excavating machine electric control box and an operating table; the operation function of long-distance wired control is realized; the man-machine separation is realized; and during the coal mining, people operate in a safe operation room. The main mining flow process comprises the steps of cleaning preparation, initial stage mining roadway pit selection, excavating and coal cutting by the excavating machine, coal loading by the excavating machine, belt extending, outward coal conveying by a belt, pile pouring by a loading machine, laneway exiting after coal excavating to a preset position, equipment withdrawing, overhauling, and preparation again for next roadway pit extraction. The end slope coal bed remote control excavating mining method has the characteristics that the coal resource extraction rate improved; the production process is simple, safe and efficient; and the production cost is low, and the like. The safe and efficient mining of open pit coal mine end slope remained coal resources is favorably realized.

Owner:CHINA UNIV OF MINING & TECH

Detection method for coal mine rock burst

The invention relates to a detection method for the coal mine rock burst. The detection method specifically comprises the steps of coal mine rock burst early warning detection, coal mine rock burst danger area classification and coal mine rock burst division. A mine vibration detector and a micro-earthquake detection system are installed in a mine in advance to carry out early warning detection on the rock burst in the coal mine; then through coal mine rock burst danger area classification, danger areas can be accurately detected; finally coal mine rock burst division is carried out, and therefore energy-gathered rock stratums in mining areas can be cut, energy can be fully released in the explosion process, and the mining safety can be improved. According to the invention, early warning, detection and division and danger treatment are carried out on the coal mine rock burst, and therefore coal mining is more accurate and safer.

Owner:LIAONING TECHNICAL UNIVERSITY

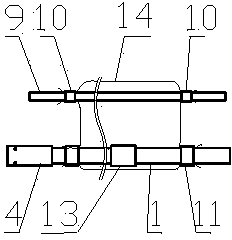

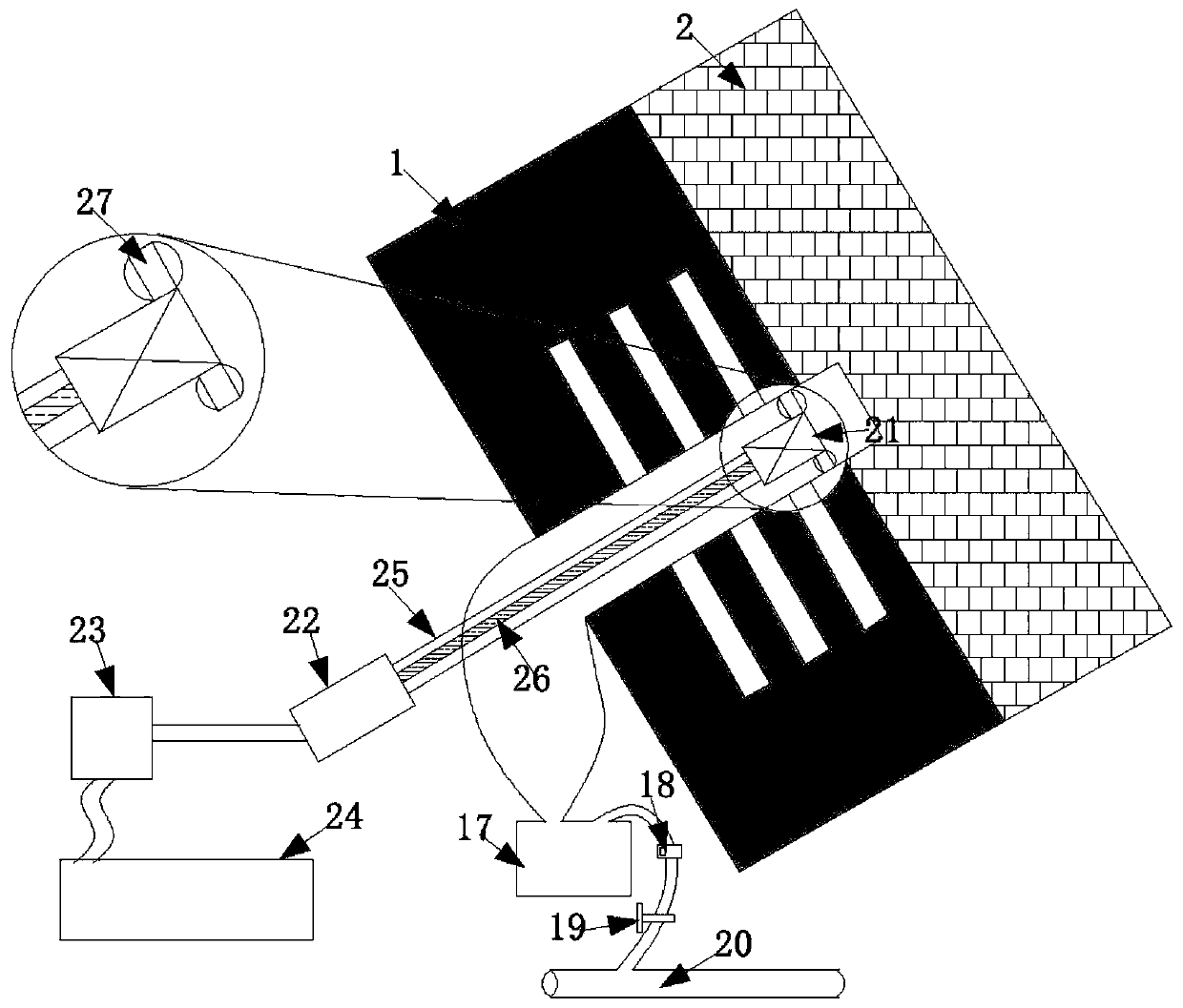

Gas pumping sleeve-penetrating occluder and use method thereof

ActiveCN103452522AFissure pluggingAvoid it happening againGas removalSealing/packingGas leakEngineering

The invention discloses a gas pumping sleeve-penetrating occluder and a use method thereof. The occluder is mainly formed by jointing a bag A combination and at least one bag B combination; the bag A combination comprises a No.1 bag (14),a grouting pipe (1), a gas leaking handling pipe and a transition part; the grouting pipe and the gas leaking handling pipe respectively penetrate through the No.1 bag; a check valve is arranged on the grouting pipe in the No.1 bag; the bag B combination comprises a No.2 bag and a grouting pipe penetrating through the No.2 bag; a check valve is arranged at the grouting pipe in the No.2 bag; short grouting pipes between the bag A combination and the bag B combination are jointed by a straight joint; a pumping pipe penetrates through the No.1 bag and the No.2 bag. According to the gas pumping sleeve-penetrating occluder and the use method thereof, one bag A combination and multiple bag B combinations can be serially connected, more effective grouting hole sealing can be realized on drill holes of a hole sealing section, generation and expansion of coal wall seams around the drill holes at the hole sealing section can be more effectively avoided, and the occluder can also fill extremely small coal seams, so the hole sealing effect is optimal.

Owner:HENAN POLYTECHNIC UNIV

Coal mine downhole country rock slight shock detection method

InactiveCN102506993ARealize real-time monitoringSolve the rock burst problemSubsonic/sonic/ultrasonic wave measurementEquipment useRock burst

The invention particularly provides a coal mine downhole country rock slight shock detection method, and solves the problem that no method for monitoring slight shock under the geological conditions of a hard top bottom plate and a hard coal bed exists. The coal mine downhole country rock slight shock detection method includes steps as follows: erecting equipment used for monitoring, collecting data, summarizing, analyzing and monitoring in real time, analyzing abnormal parameter conditions, and early warning possible rock burst times and positions. The method not only can solve the difficulty in rock bursts during coal mining and ensure the success and safe process of mining, but also has positive and effective directive function in the rock burst prevention work during the mining process in future.

Owner:DATONG COAL MINE GRP

Application of non-coal-pillar coal mining method in under-protected stratum exploitation

ActiveCN103266893ARealize continuous recoveryAchieve economical miningUnderground miningSurface miningFracture zoneEngineering

The invention relates to an application of a non-coal pillar roadway layout in the under-protected stratum exploitation. The non-coal pillar roadway layout comprises a stagger arrangement or gob-side entry driving roadway layout, the non-coal pillar roadway layout is adopted in the under-protected stratum exploitation of a dynamic disaster coal stratum, and a coal pillar supporting overlying strata between adjacent work surfaces is removed, so the inclined continuous recovery of a stope is realized; and a fracture zone above the stope ascends and the arrangement of the protected coal stratum in the fracture zone descends with the increase of the exploitation range, so the application range of the under-protected stratum exploitation is widened, the mining is full, the destressing effect is obvious, and the protected stratum is not influenced by the installation of the coal pillar in the protected stratum, thereby the safe and economic exploitation of the protected stratum is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

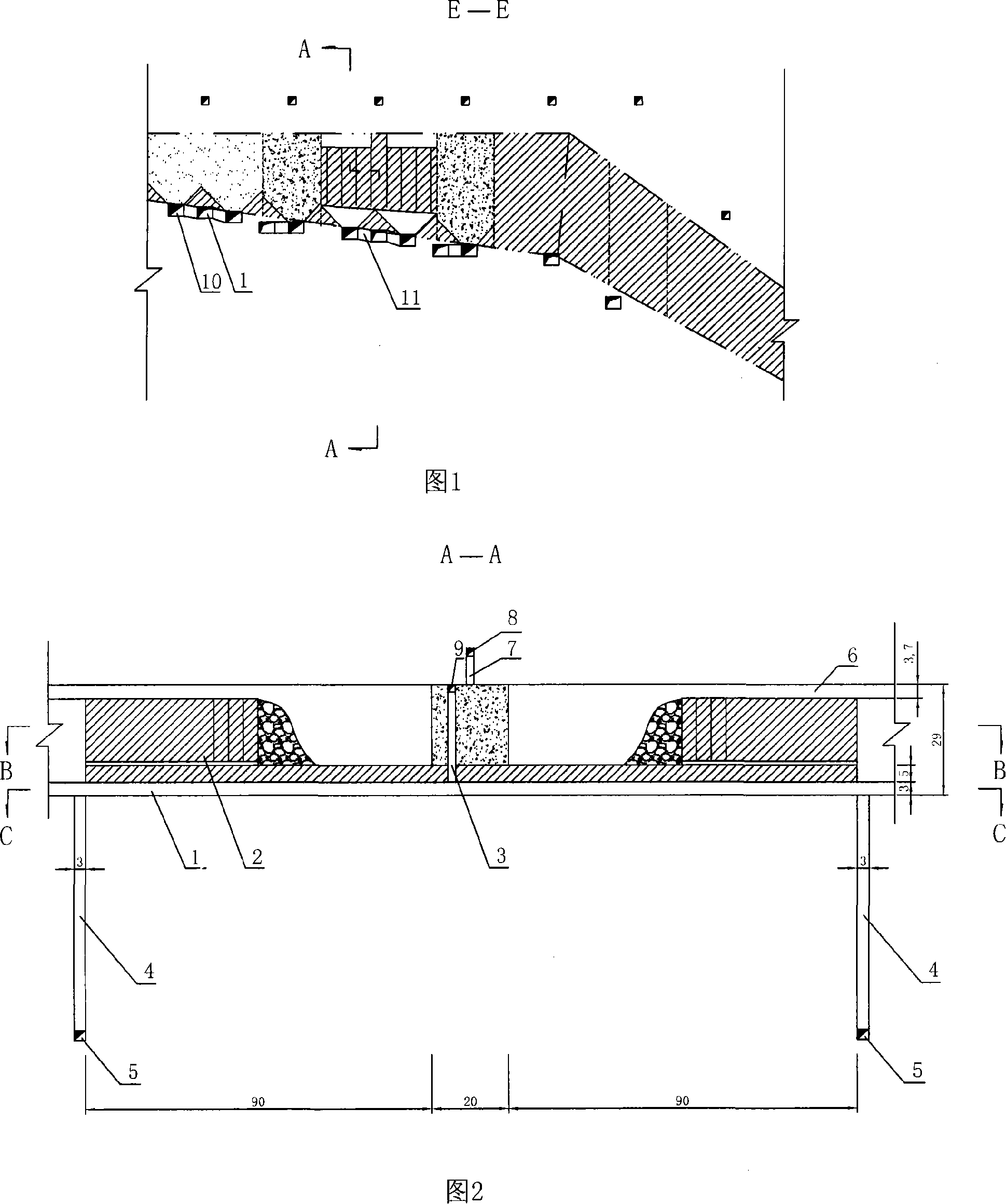

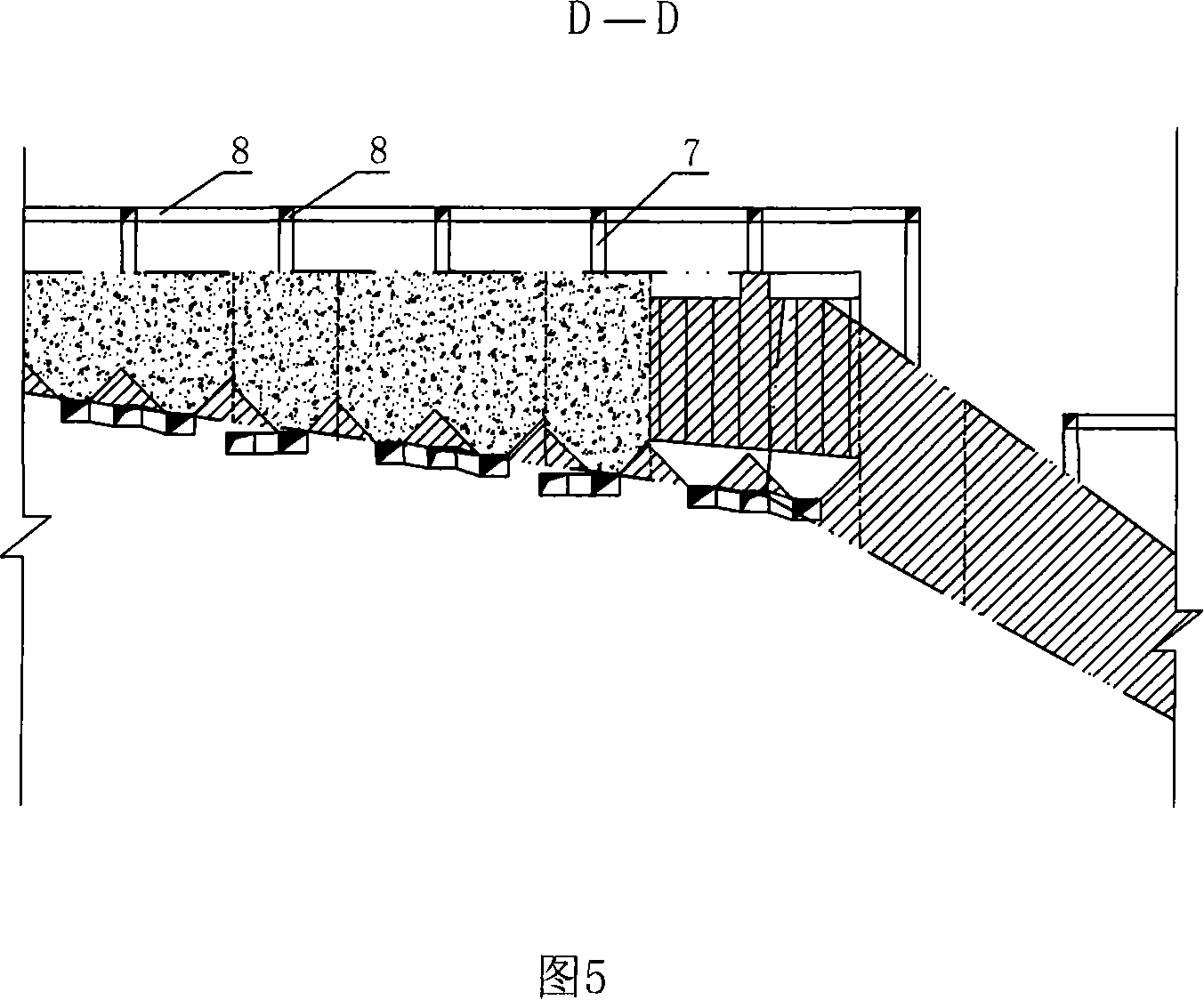

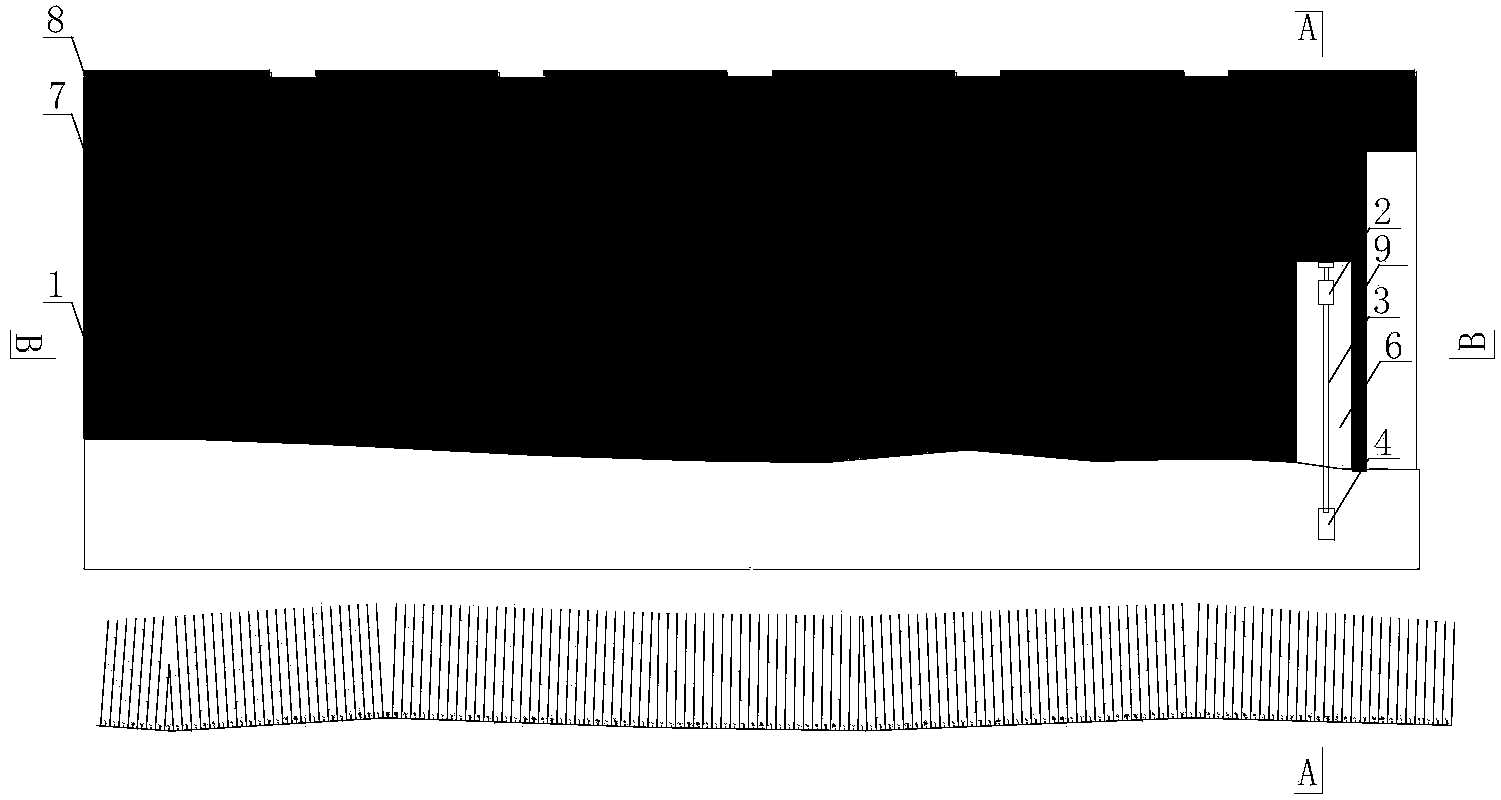

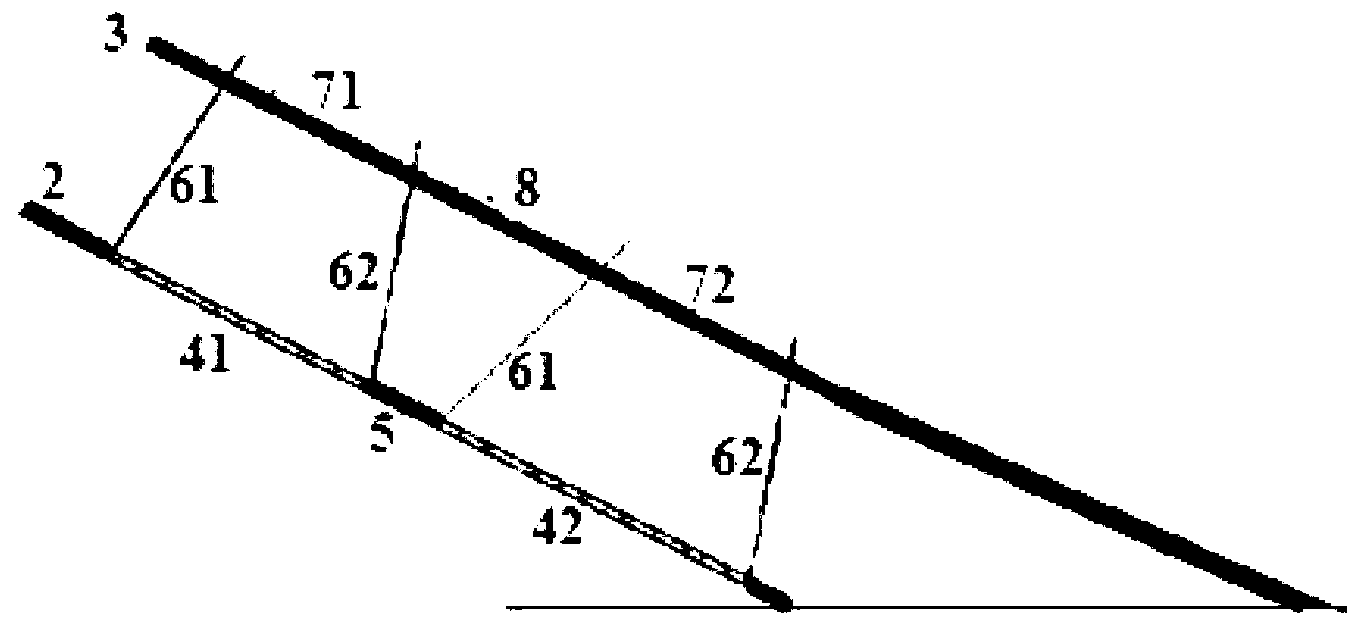

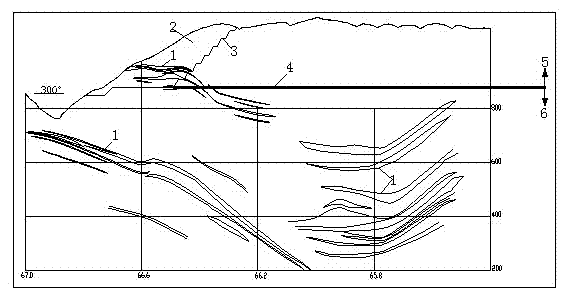

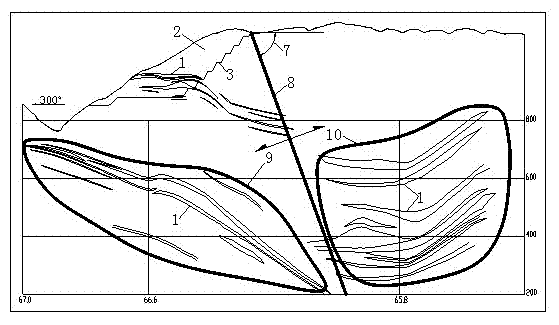

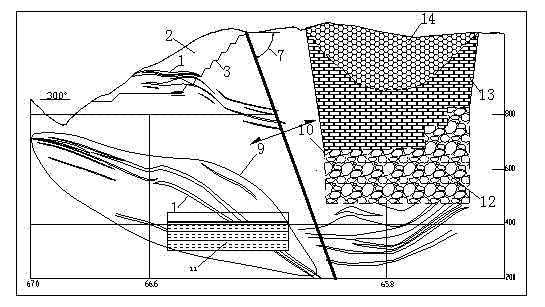

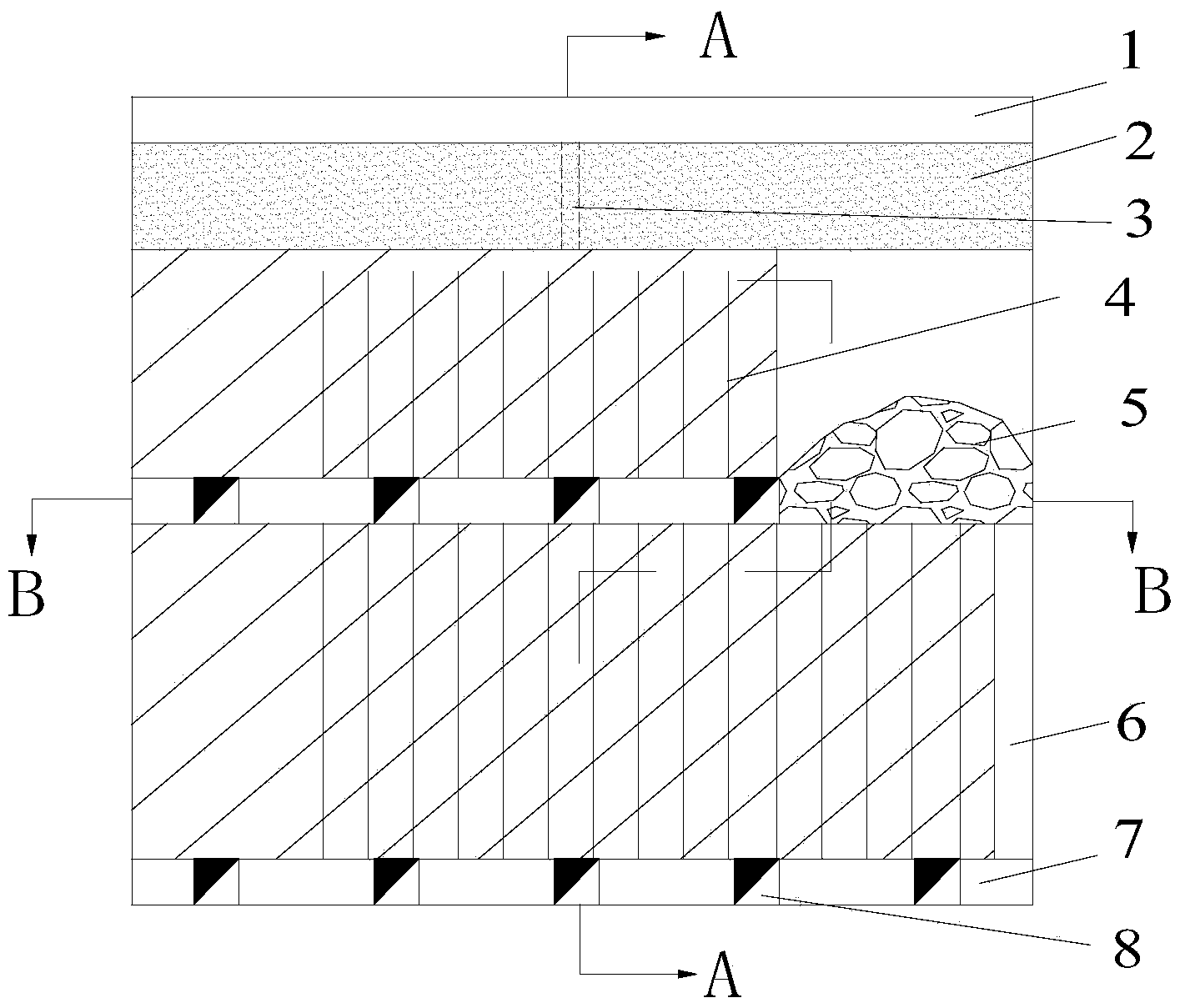

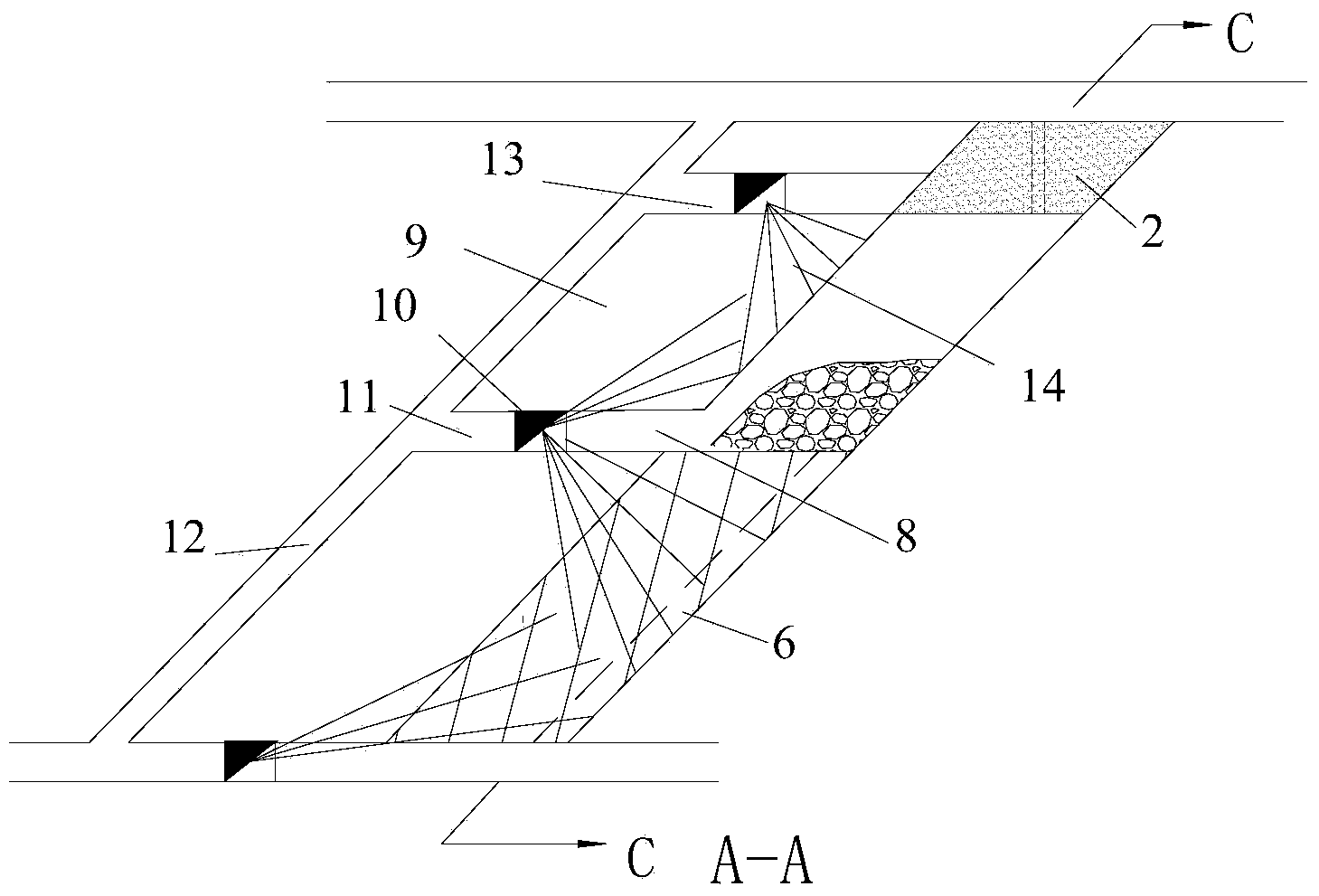

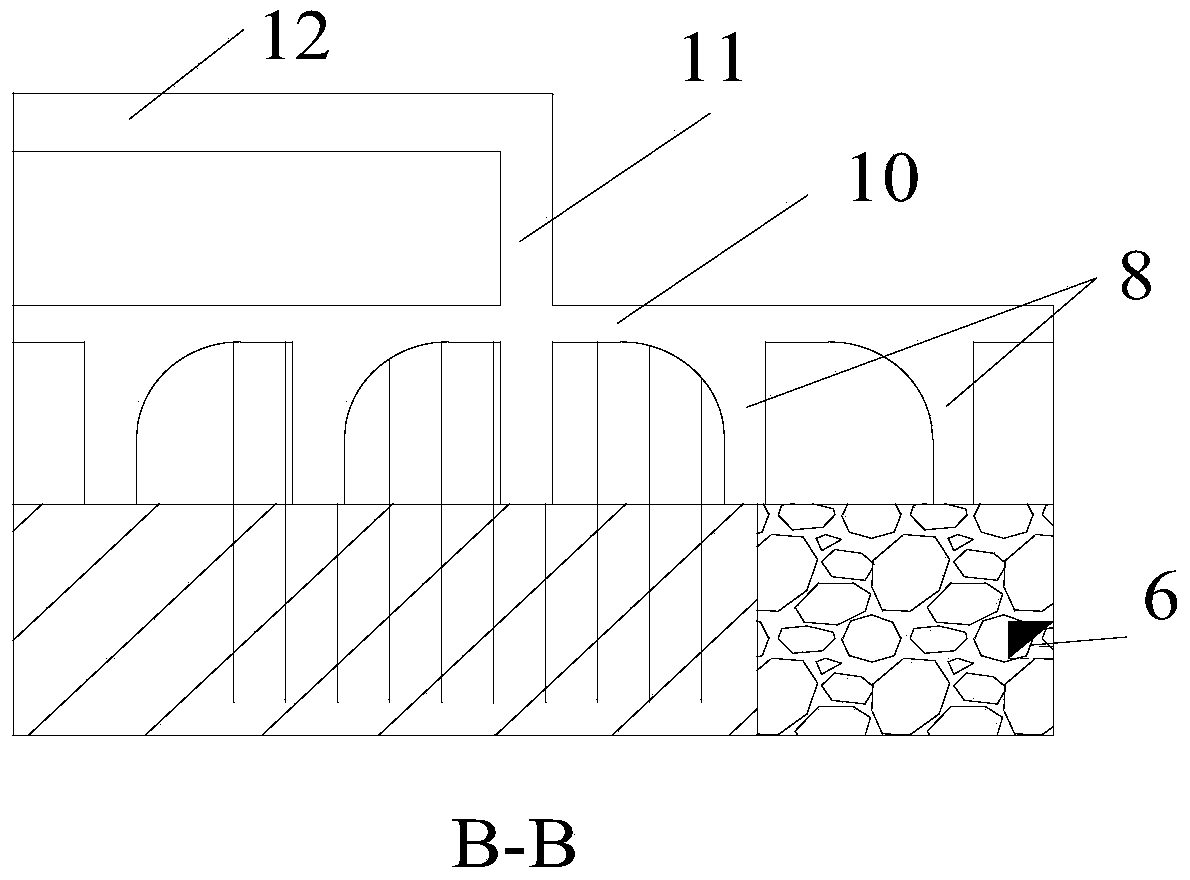

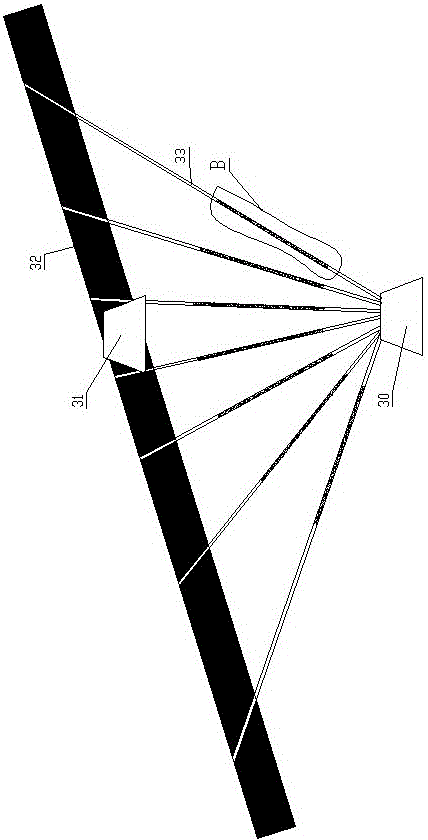

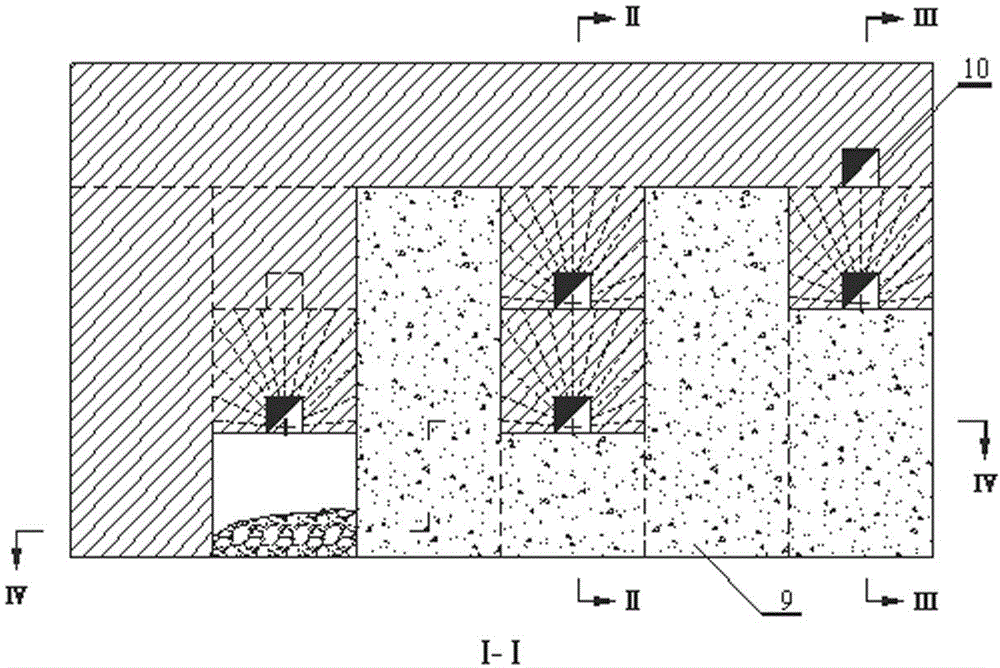

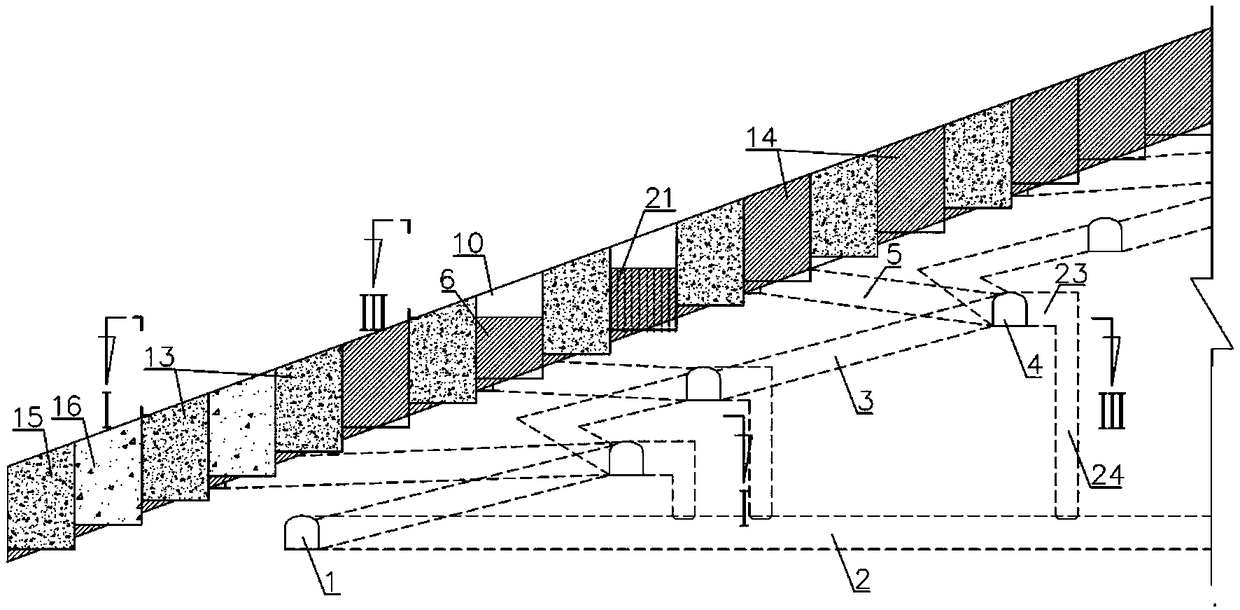

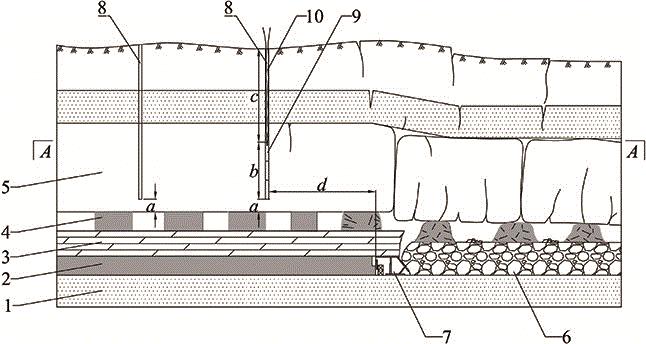

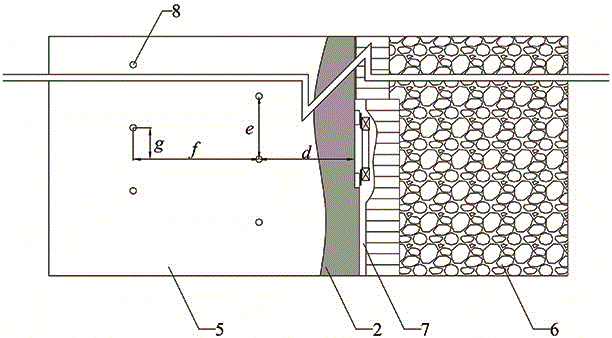

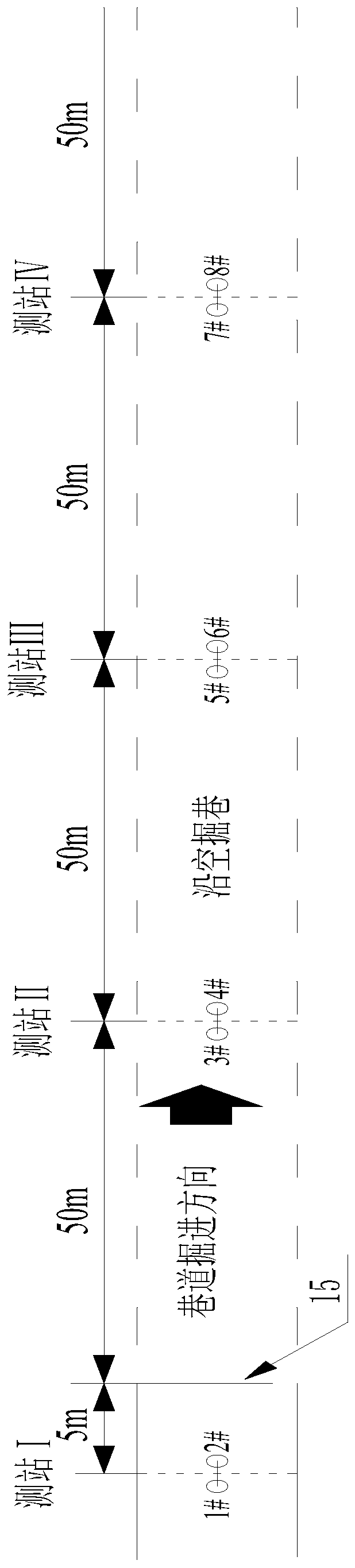

Open pit and underground space-time synchronous mining method for multiple-ore body

ActiveCN103590830ASafe miningGuaranteed thicknessUnderground miningSurface miningOpen-pit miningTime space

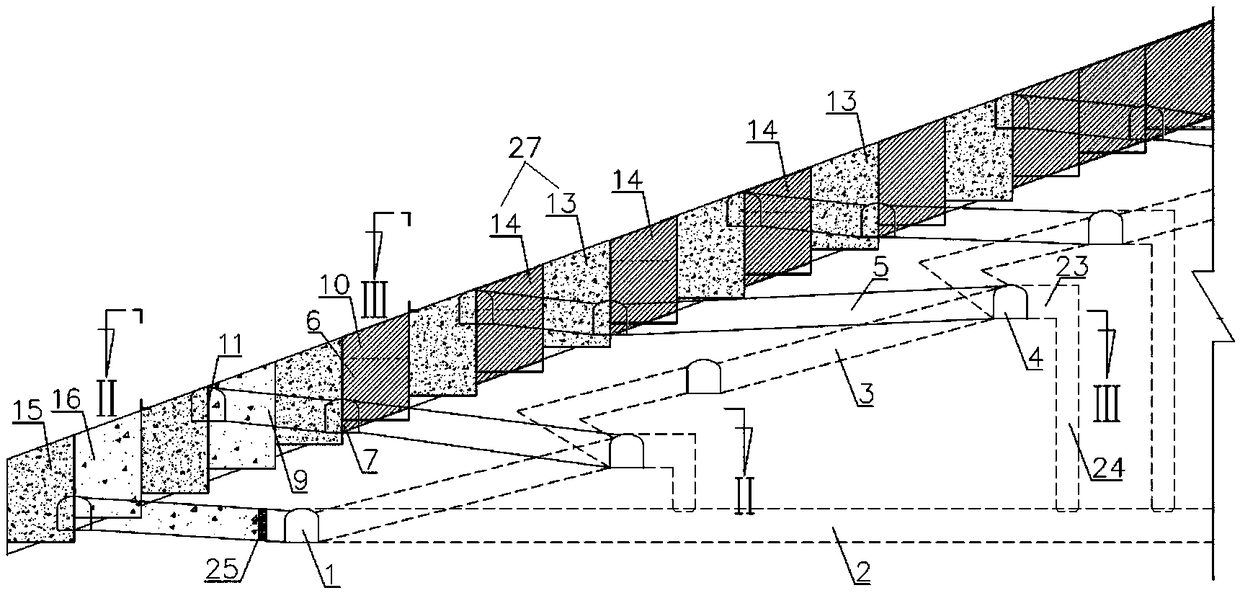

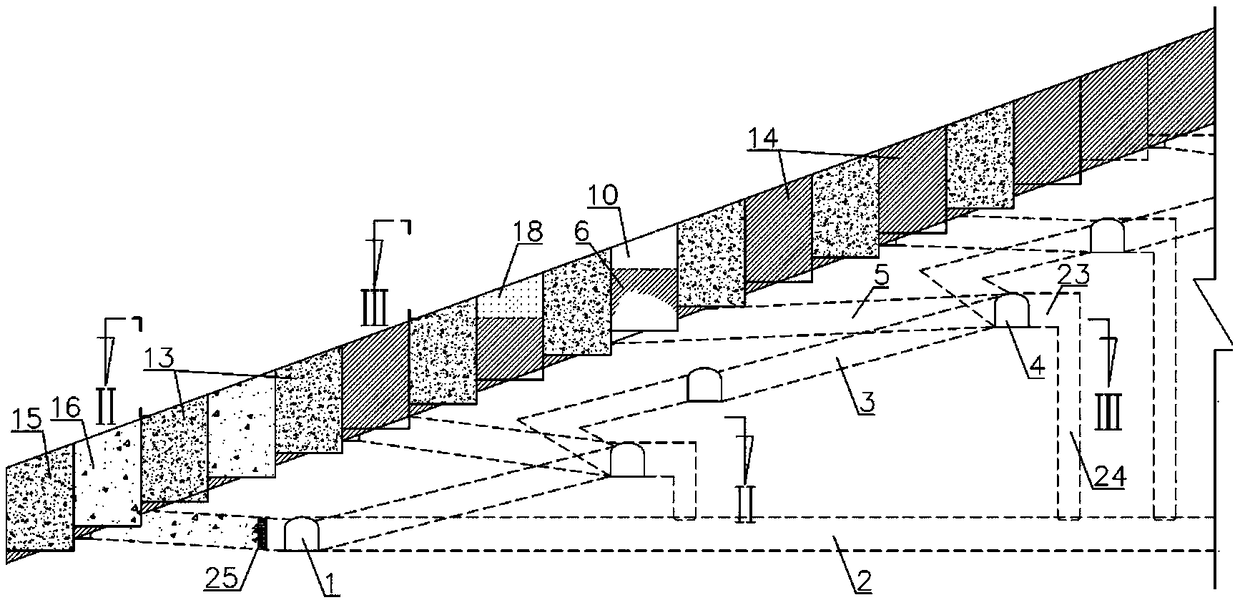

The invention discloses an open pit and underground space-time synchronous mining method for a multiple-ore body. According to the technical scheme, the method comprises the following steps: marking the demarcation line of the ore bodies at the shallow and deep positions so as to divide the multiple-ore body into a shallow-position ore body and a deep-position ore body according to an economical and reasonable stripping ratio; delineating the demarcation line of an open-pit mining protection zone according to a moveable angle (7) determined by underground mining by taking the largest demarcation ring of the open-pit mining as a protection line, wherein the deep-position ore body in the protection zone is a filling-process mining zone section (9) and the deep-position ore body outside the protection zone is a caving-process mining zone section (10); filling the waste stone stripped in open pit back to a waste stone back filled region (14) in a rubber belt conveying manner and carrying out cemented filling on the dead zone of the filling-process mining zone section (9) with tailings so as to form a tailings cemented filling region (11). According to the method, the technological characteristics of different mining manners such as open-pit mining, filling-process milling and caving-process mining are organically combined, so that the open-pit, underground space-time synchronous, environment-friendly and efficient mining of the multiple-ore body can be realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

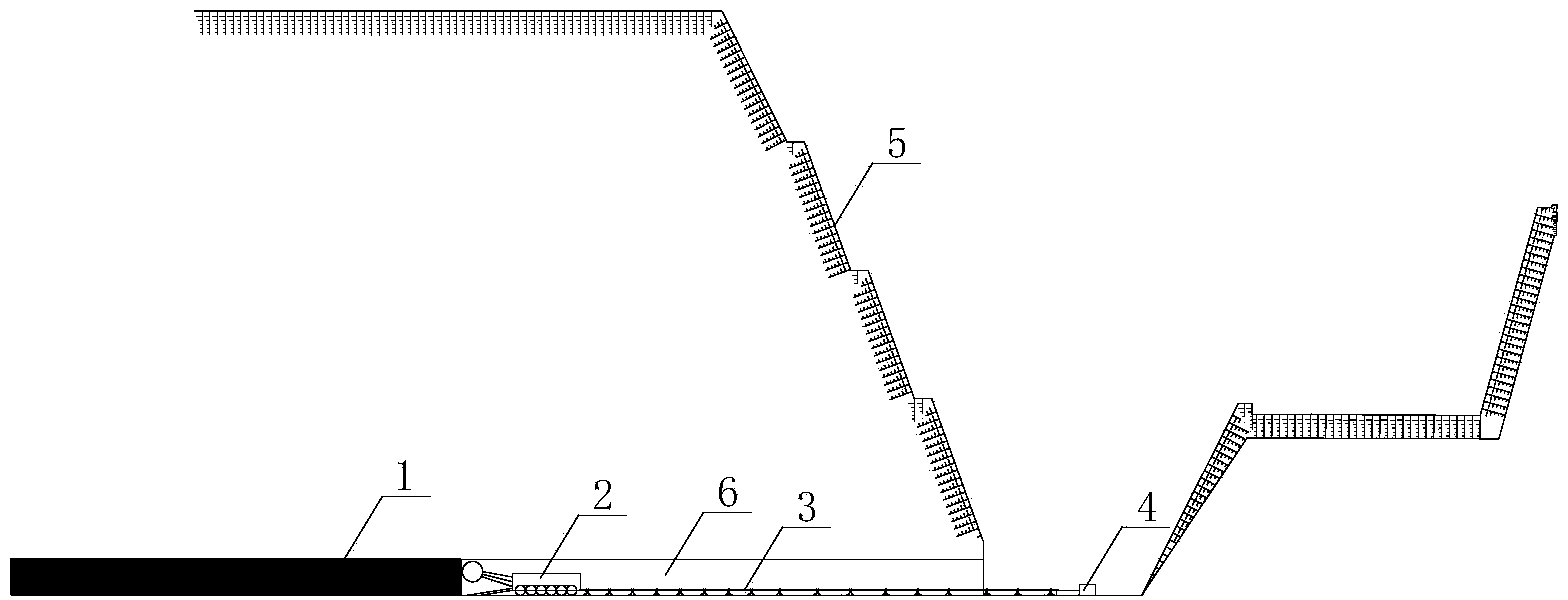

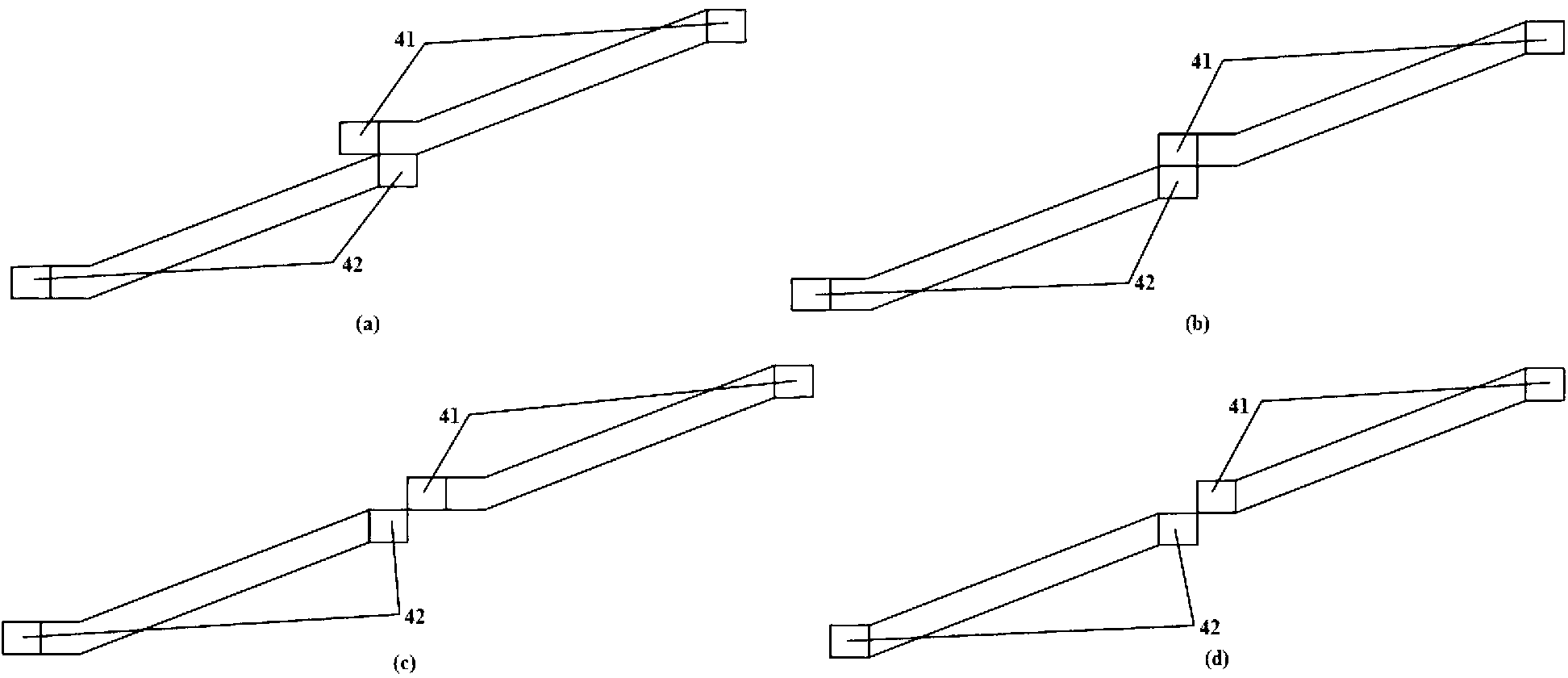

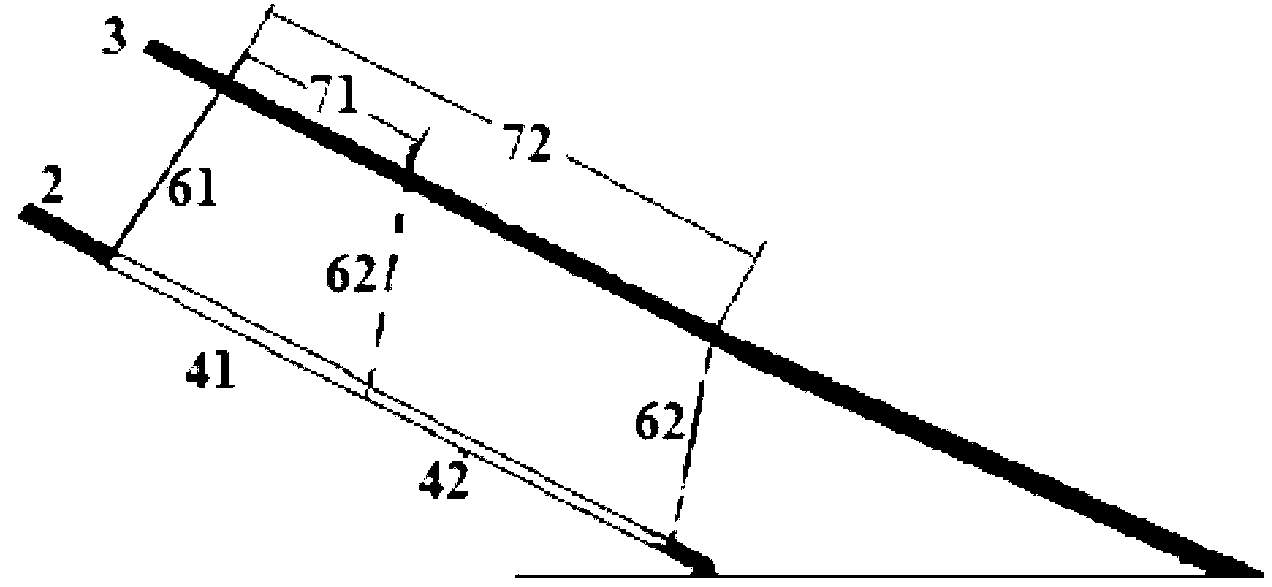

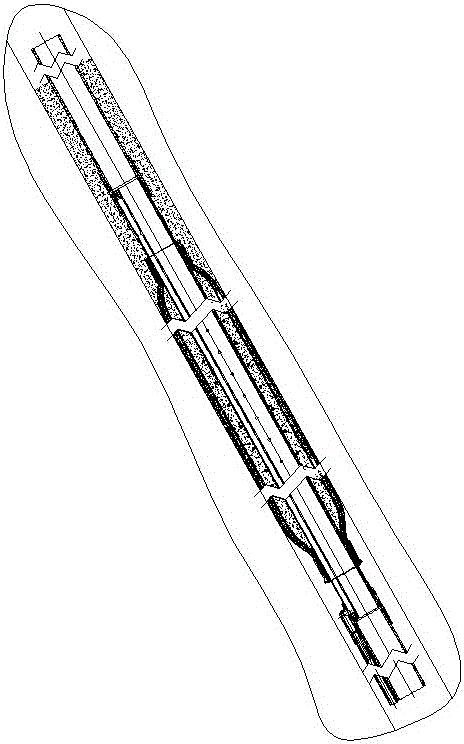

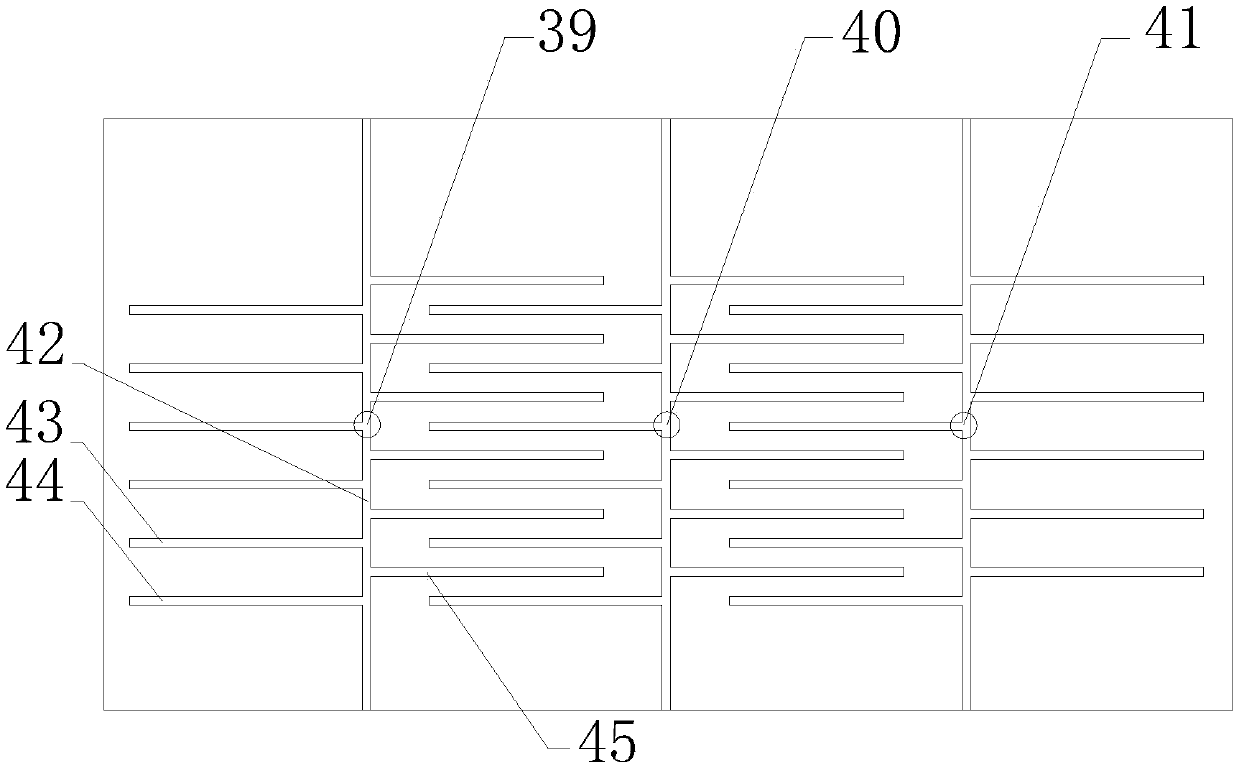

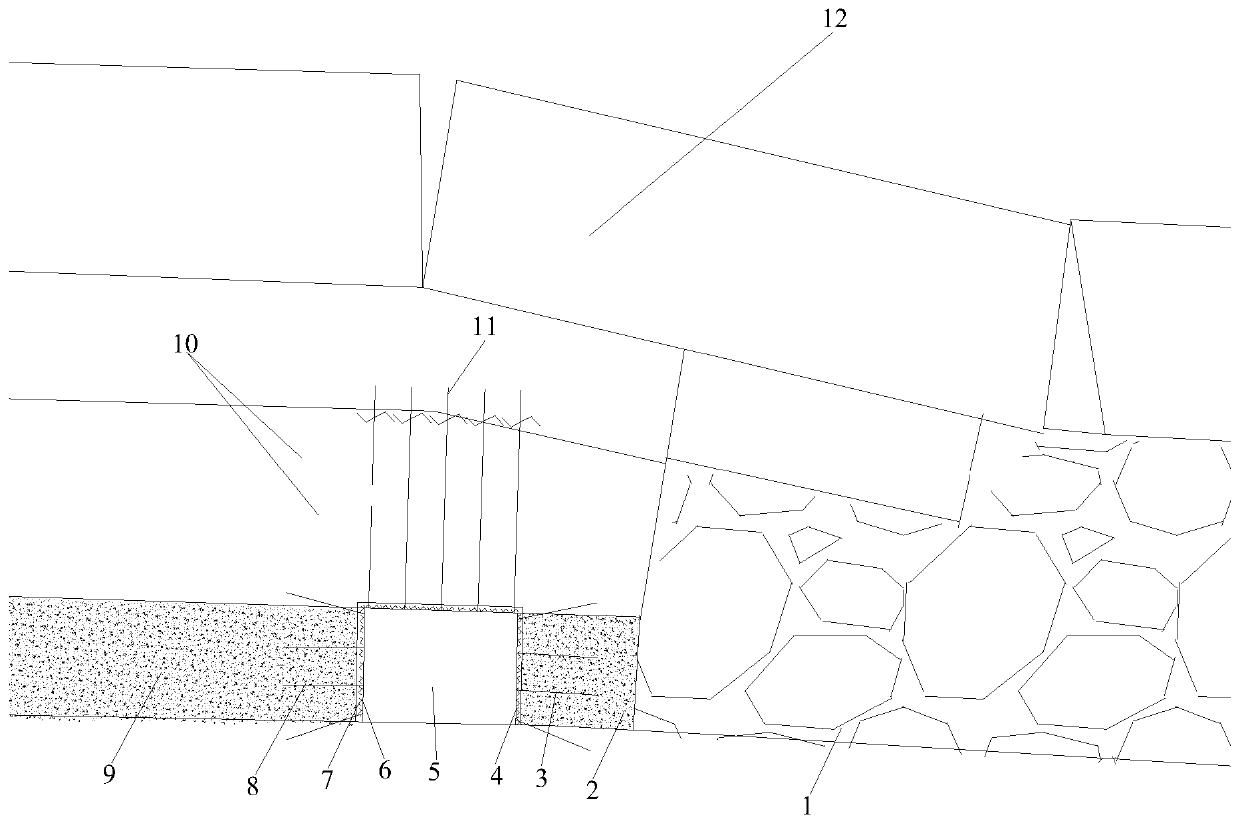

Medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of combined reconstructed structural body

ActiveCN103437769AGuarantee of technical problems in safe and efficient miningSafe and efficient miningUnderground miningSurface miningEngineeringStoping

The invention discloses a medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of a combined reconstructed structural body. The method adopts downward type sublevel stoping, and comprises the following steps: firstly, excavating a top cut heading way in a hanging wall surrounding rock; building an artificial roof (reserved with a fill raise) along the ore body striking direction by adopting smooth blasting after top cut is completed; excavating a multifunctional roadway integrating the functions of rock drilling, supporting and ore removal along the ore body striking direction in the hanging wall surrounding rock; and arranging fan-shaped blast holes by medium-length holes, and arranging a surrounding rock grouting reinforcement and anchor cable support hanging wall project by utilizing the medium-length holes at the same time to integrate surrounding rock grouting reinforcement, ore breaking by blasting and anchor cable support. By adopting retreat type stoping and ore removal by a scraper, the method realizes safe, efficient and large-scale stoping of ore bodies. The mining method is suitable for mining the inclined ore bodies with surrounding rocks which are evenly and stably distributed, and has the characteristics of being small in stope preparation work amount, safe and reliable to operate, high in stoping efficiency, etc.

Owner:CENT SOUTH UNIV

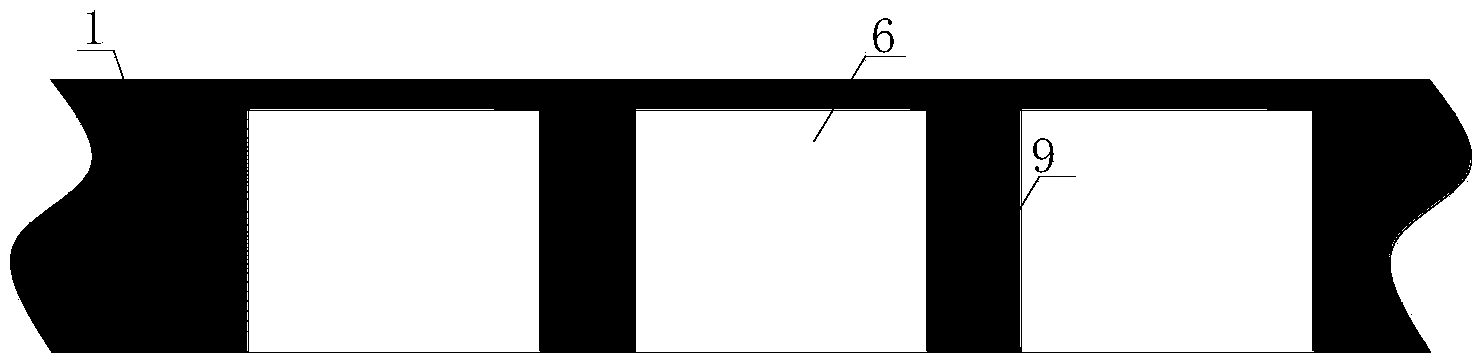

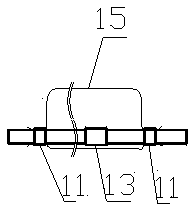

Single-bag grouting hole sealing device for upward crossing boreholes and hole sealing method adopting single-bag grouting hole sealing device

InactiveCN105840134ASimple structureEffective grouting pluggingGas removalSealing/packingEngineeringSlurry

A single-bag grouting hole sealing device for upward crossing boreholes comprises a recoverable grouting pipe, a grouting pipe joint, a front gas extraction pipe, a drainage device, a double-orifice pipe, an expansion bushing, an expansion bag, a pressure control valve and a rear gas extraction pipe, wherein the recoverable grouting pipe is communicated with a grouting channel of the double-orifice pipe through the drainage device, during use, the hole sealing device is arranged on the front gas extraction pipe in a sleeving manner through the drainage device, slurry is injected into the hole sealing device through the recoverable grouting device, and the expansion bushing and the expansion bag after filled with slurry expand to seal and plug the boreholes; grouting hole sealing of the inclined boreholes at different angles is realized by adjusting the position of the pressure control valve on the hole sealing device. More effective grouting hole sealing on the boreholes in the inclined borehole sealing section can be realized, and production and development of gas leakage cracks around the boreholes in the borehole sealing section are better prevented; according to a method, grouting under set pressure is performed by the pressure control valve on the hole sealing device, so that the grouting section is lengthened, and the hole sealing effect of the inclined boreholes is further enhanced.

Owner:HENAN POLYTECHNIC UNIV

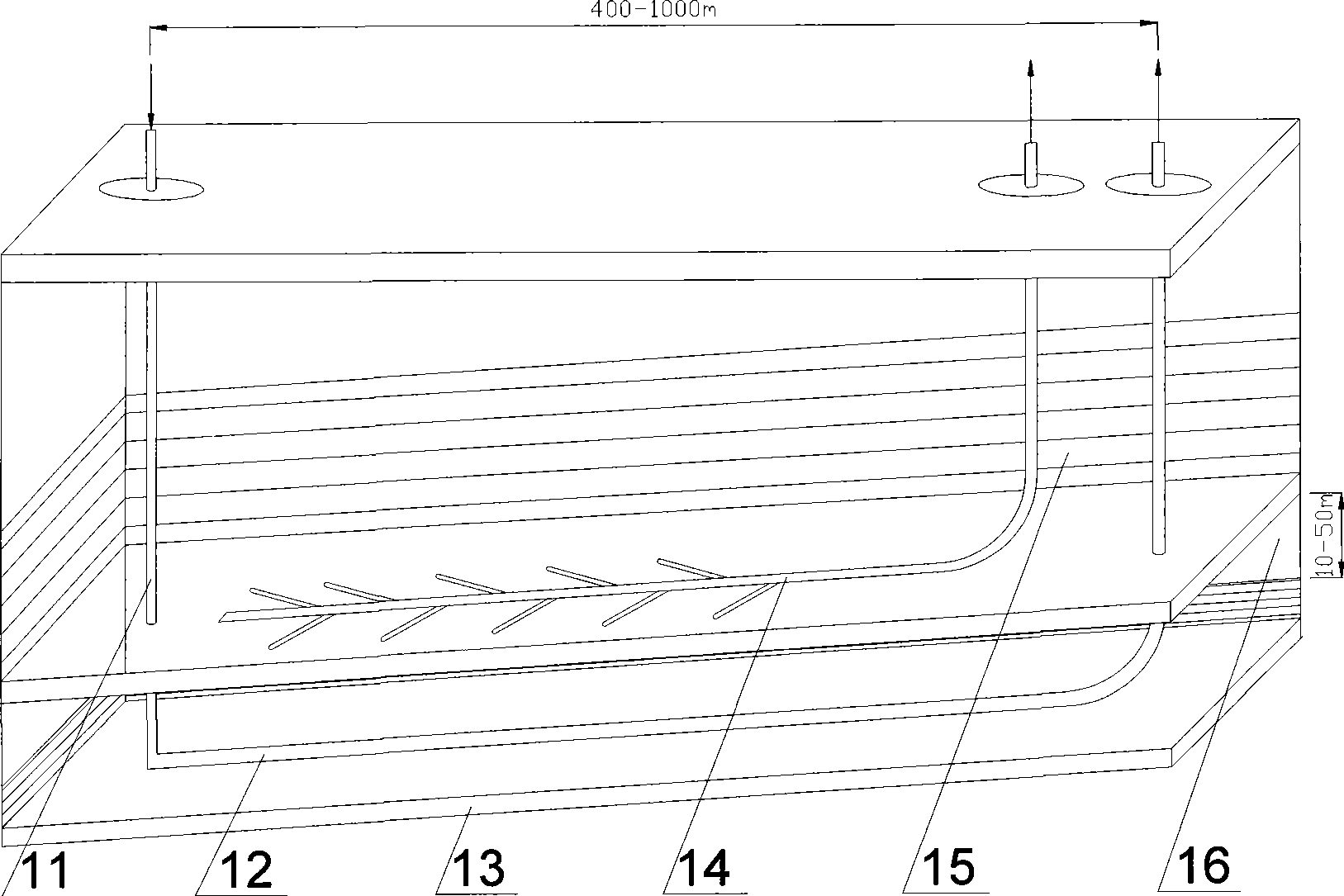

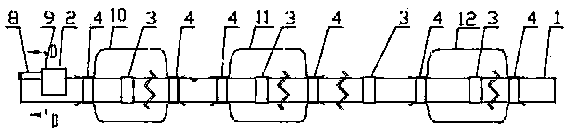

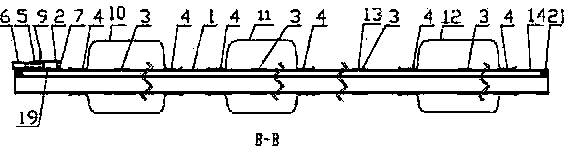

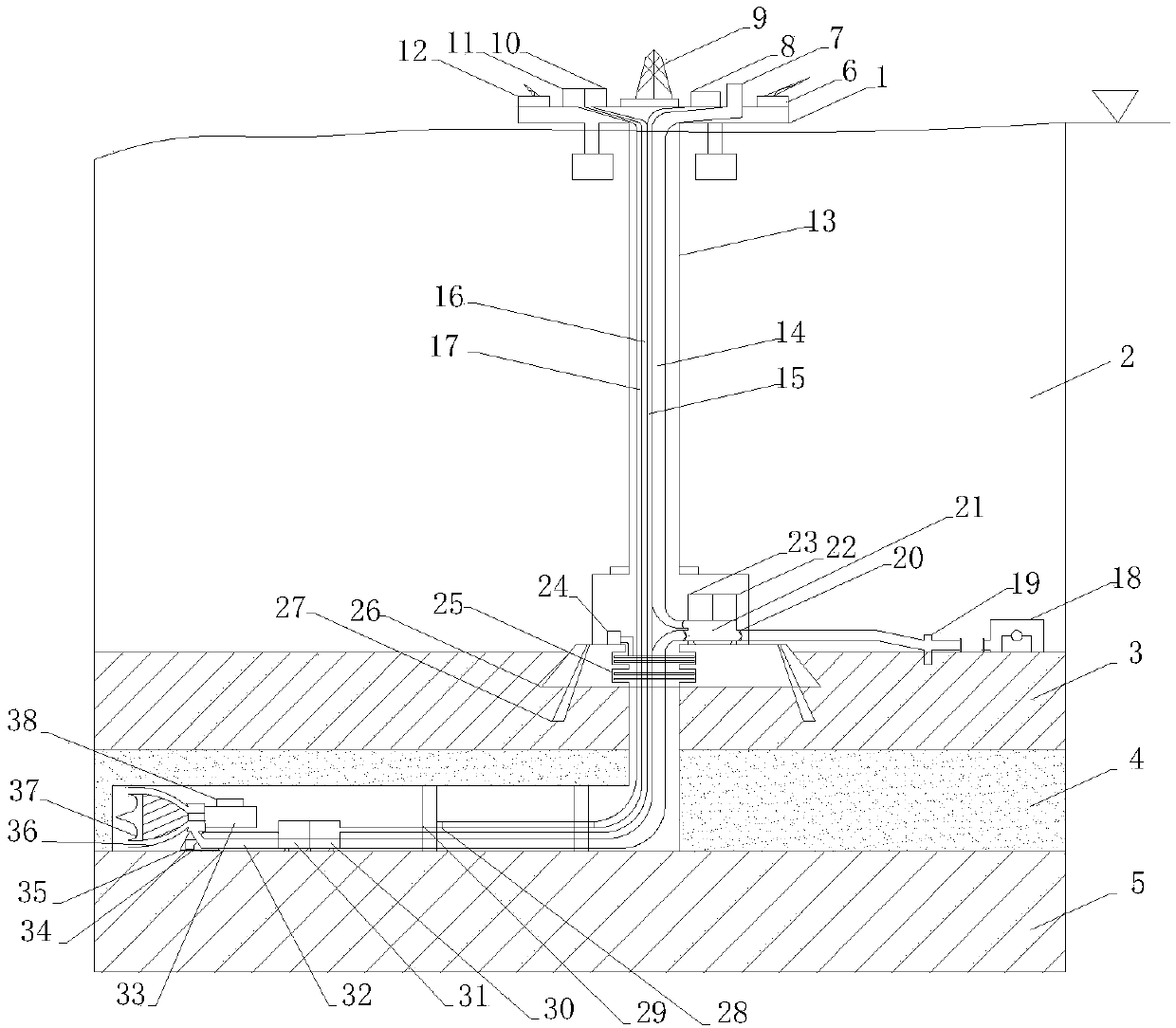

Air column well completion back coming subsequent filling mining method

ActiveCN104695960ASafe miningEfficient miningUnderground miningSurface miningStop timeUltimate tensile strength

The invention discloses an air column well completion back coming subsequent filling mining method of a thick and large metal ore bed under an ore rock unstable condition. Subsections are divided in a vertical level to carry out stope preparation; a stope is divided along the moving direction of a crushed body to be used as a back stoping unit; in each stope, back coming is carried out by a middle depth hole from an upper disc to a lower disc; the back stoping is carried out at the same time in the plurality of subsections; and the roof exposed area of the stope is controlled. When one section is exploited and ores are discharged, an air column is put down from an upper subsection rock drilling roadway and is distributed nearby an unexploded ore body; after filling and curing, 1-2 rows of cannon arrangement holes in the rear row are exploded for two times to form grooves. The stope width, the recovery length of each time, the filling material ratio, the strength of a filling body and the like are obtained by an ore rock mechanical parameter test, mechanical analysis and numerical value simulation analysis. The rock drilling, the explosion, the ore removal and the shoring are finished by trackless equipment; and the air column well completion back coming subsequent filling mining method has the characteristics of high exploiting safety, small resource loss, high mechanical degree, low labor intensity, great production capability, short back stoping time, and the like.

Owner:SHANDONG GOLD MINING LINGLONG

Double-layered and bidirectional horizontal stripping open-stope backfilling mining method

ActiveCN108708726AReduce the number of installationsReduce the proportionUnderground miningSurface miningComputer science

The invention relates to the technical field of mining, in particular to a double-layered and bidirectional horizontal stripping open-stope backfilling mining method. The double-layered and bidirectional horizontal stripping open-stope backfilling mining method comprises the following steps: S7, separately forming two lower slice slicing stope openings in two sides of the tail of a vein connectionroadway, separately arranging lower slice stope connection roadways towards an lower slice stope of a stope in step one and an lower slice stope of a stope in step two from every lower slice stope; S8, continuing tunneling and arranging upper and lower slice connection roadways in the extension direction of the vein connection roadway from the tail of the vein connection roadway, and enabling thetails of the higher and lower slice connection roadways to be positioned between the two higher slice stopes of an adjacent horizontal stope below a horizontal stope in step S6; and S9, separately forming two upper slice stope openings in the two sides of the openings of the upper and lower slice connection roadways, separately arranging upper slice stope connection roadways towards an upper slice stope of the stope in step one and an upper slice stope of the stope in step two from every upper slice stope opening, and enabling the opening of each upper slice stope connection roadway to be positioned in the center of the corresponding upper slice stope.

Owner:CENT SOUTH UNIV

Method for promoting gas extraction and working face dust fall by injecting water at intervals in drilling holes

InactiveCN105484790AReduce chance of overrunReduce coal dust contentDust removalFire preventionCoal dustEngineering

The invention discloses a method for promoting gas extraction and working face dust fall by injecting water at intervals in drilling holes. In an influence scope of advanced support pressure at a coal mining working face, high pressure water injection is performed, at intervals, on parts of the gas extraction drilling holes of a floor roadway. Intense extraction of advanced pressure relief gas is promoted in the gas extraction drilling holes adjacent to the water injection drilling holes by using a displacement role of the high pressure water to coal seam gas and a pressure relief and fluid increase effect of the coal seam gas at an advanced support pressure relief segment at the coal mining working face. The high pressure water fully permeates the coal body by using a character that coal body fractures are more developmental in the influence scope of the advanced support pressure at the coal mining working face. The flying capacity of original coal dust in the coal body is eliminated. The generation amount of the coal dust is reduced. The dust fall of the working face is promoted. A dilemma that the advanced pressure relief gas extraction at the high gas working face and the coal layer water injection and dust fall cannot be both considered is solved. The advanced pressure relief gas extraction is realized, and a target of effective dust fall at the working face is realized too.

Owner:CHINA UNIV OF MINING & TECH

Design method for mining upper protective seam close to total rock for use in coal-bed mining

InactiveUS20190071967A1Economically efficient, safe and reliableWide applicabilityUnderground miningDesign optimisation/simulationDesign methodsPlastic property

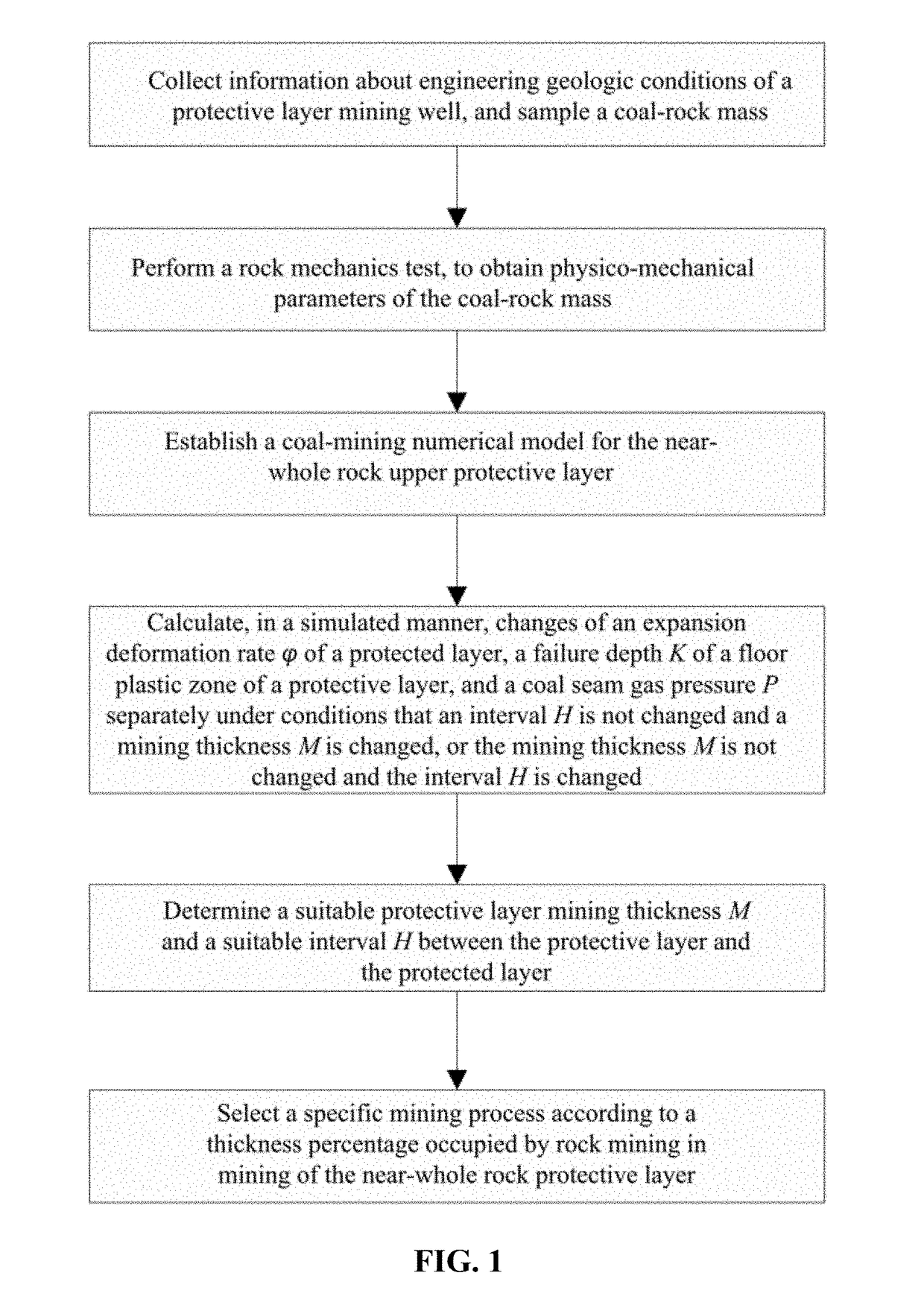

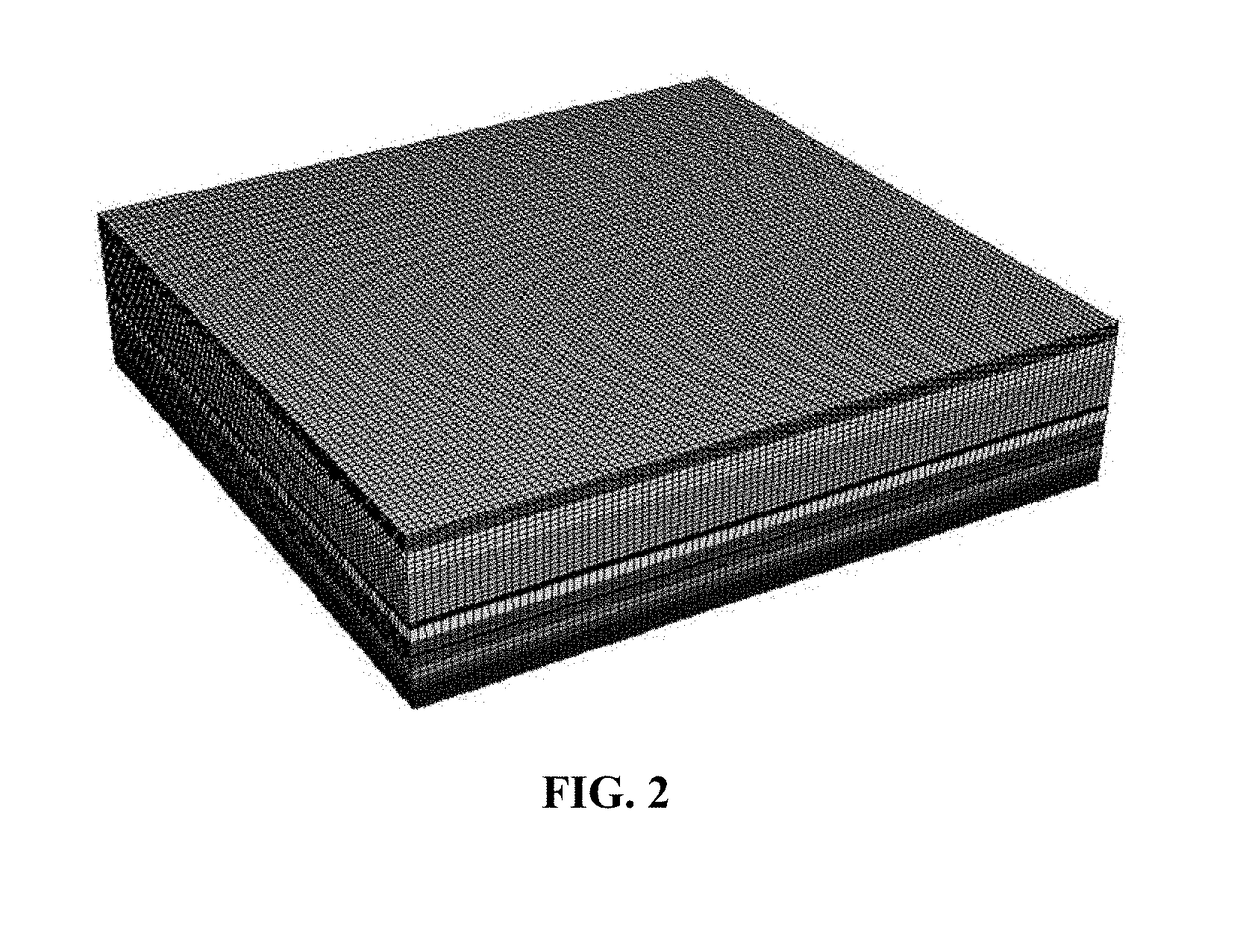

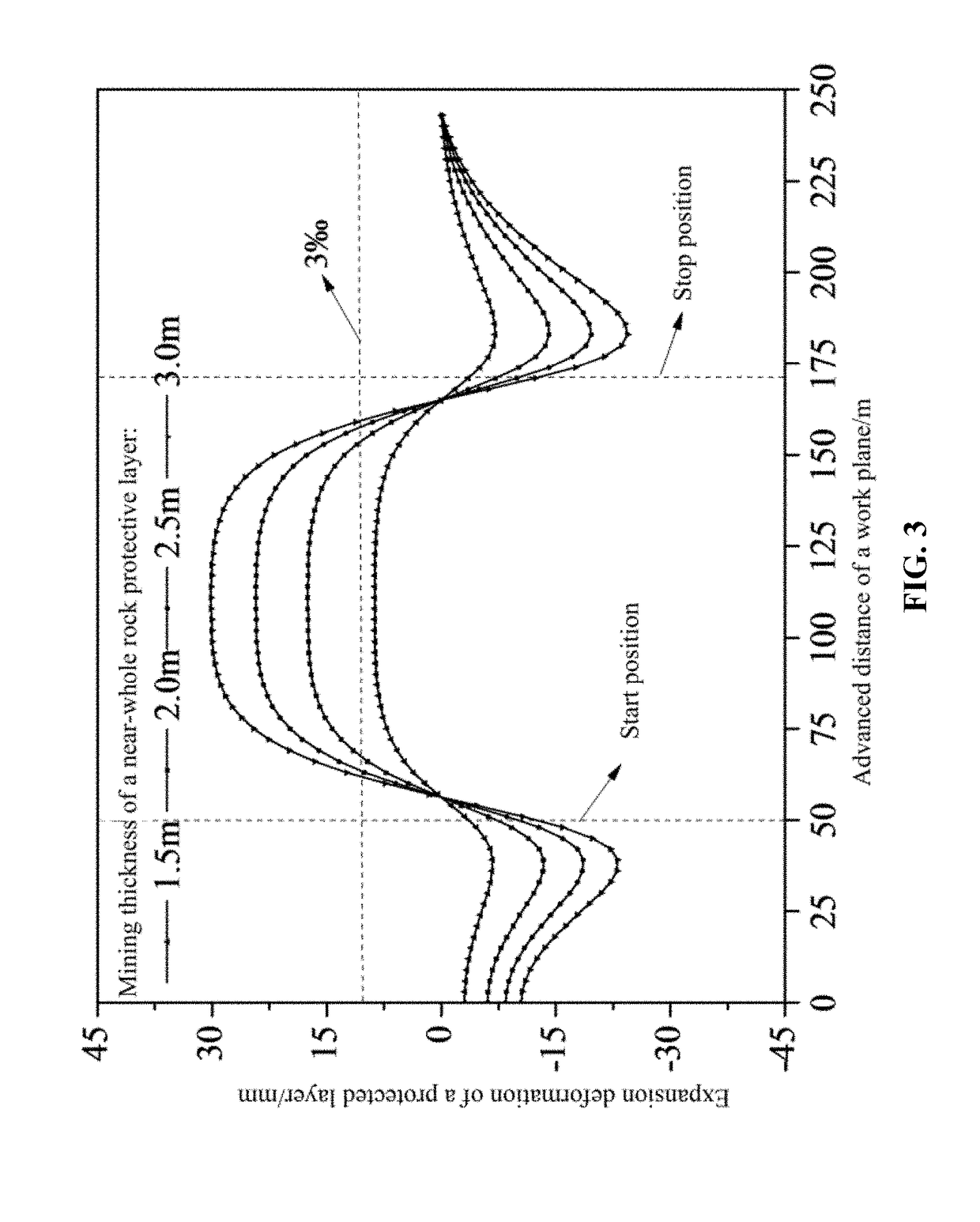

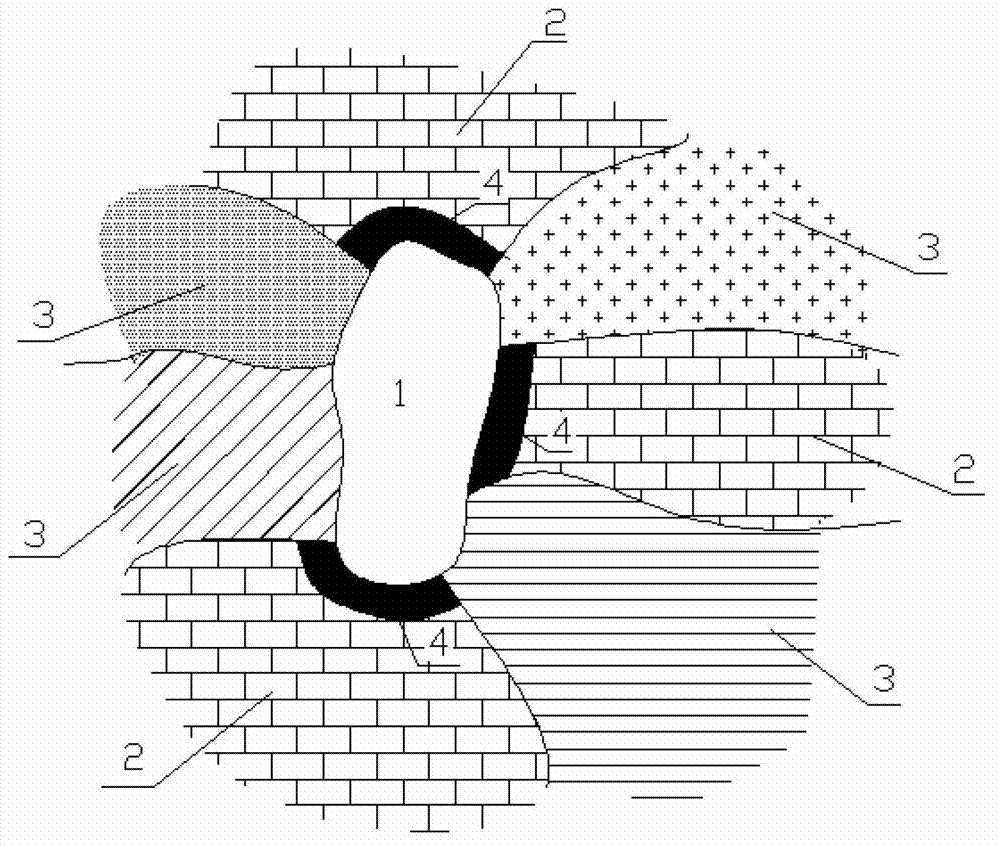

A mining design method for an upper protective layer in coal seam mining, and provides a mining design method for a near-whole rock upper protective layer. Based on information about engineering geologic conditions of a protective layer mining well and physico-mechanical parameters of a coal-rock mass sample, a protective layer mining thickness M and an interval H between the protective layer and the protected layer are determined by means of numerical analysis such that an expansion deformation rate φ of a protected layer, a failure depth K of a floor plastic zone of a protective layer, and a coal seam gas pressure P meet the Provision in Prevention and Control of Coal and Gas Outburst. Then, according to a mining thickness percentage accounted by rock in the near-whole rock upper protective layer, a mining process of the near-whole rock protective layer is determined from among a traditional fully-mechanized coal mining process, a traditional fully-mechanized coal mining process assisted by single-row hole pre-splitting blasting, and a traditional fully-mechanized coal mining process assisted by double-row twisted hole blasting. This method provides a theoretical basis for safe mining of a low-permeability gas-rich coal seam without a regular protective layer, and further enriches mining design methods with a protective layer. This method is economically efficient, safe and efficient, and has a wide applicability.

Owner:CHINA UNIV OF MINING & TECH

Reconstruction method for water-proof shell

InactiveCN103032083AReduce infiltrationReduce groundwater drainageUnderground chambersTunnel liningComputed tomographyKarst

The invention discloses a reconstruction method for a water-proof shell. The distribution condition of aquifers around an ore body is determined; reconstruction of the water-proof shell is performed in the aquifers; and a complete continuous water-proof key layer is formed around the ore body. The required thickness of a water-proof top plate is calculated in combination with an actual engineering condition and a mechanical principle. Whether damage occurs is judged by simulating water-proof shell stress, plastic zone and settlement distribution condition by utilizing Flac3d under an ore body mining condition. In engineering implementation, detection holes are firstly formed in the aquifers and positions of karst caves and fissures are determined by using a geological survey instrument, connection roadways are constructed in the aquifers around a middle section, and drilling and grouting underground chambers are constructed on parts of the roadway close to the fissures of the aquifers. Grouting holes are rationally arranged in the roadways and the underground chambers and encrypted grouting is performed, and finally, inter-hole CT (Computed Tomography) fluoroscopy is performed to check the grouting and water plugging effect. According to the method, a mine floor mining environment is reconstructed, so that mine floor mining is performed safely and efficiently, and geological disasters are effectively reduced.

Owner:CENT SOUTH UNIV

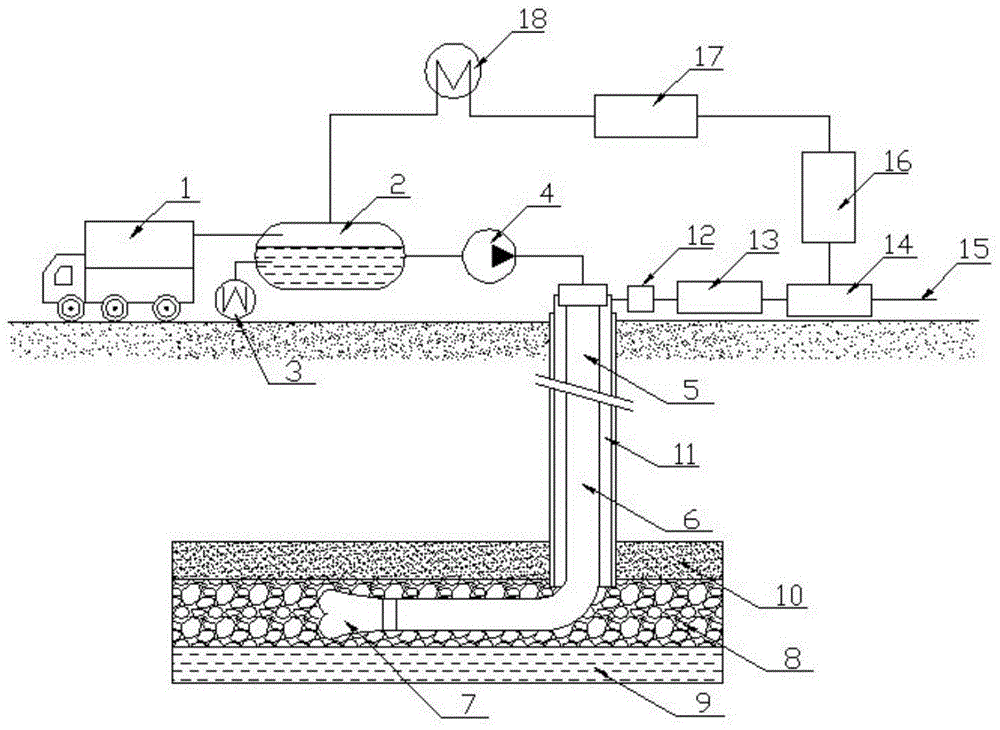

Supercritical carbon dioxide jet injection drilling exploitation hydrate device and method

InactiveCN104563974AEmission reductionMaintain integrityConstructionsLiquid/gas jet drillingJet injectionHigh pressure

The invention belongs to the technical field of hydrate drilling exploitation equipment and processes and relates to a supercritical carbon dioxide jet injection drilling exploitation hydrate device and method. The supercritical carbon dioxide jet injection drilling exploitation hydrate device is adopted to realize exploitation of hydrate, a carbon dioxide storage device is filled with carbon dioxide firstly, then the carbon dioxide is continuously cooled to the liquid state via a storage tank cooling device, the liquid carbon dioxide is pressurized by a high pressure pump prior to be pumped into a drilling tool for jet drilling by the aid of the prior art, after the drilling tool drills into a hydrate reservoir, the jet temperature of the high-pressure supercritical carbon dioxide injected by a drill bit is lowered, the hydrate brought out of a wellbore and a near wellbore formation moves upwards along an annular space; after reaching a wellhead throttling device, the hydrate sequentially passes through a three-phase separator and a gas separator to spate natural gas and carbon dioxide so as to complete exploitation of the hydrate. The used device is simple in structure, convenient to operate, low in maintenance cost, simple in exploitation method, scientific in principle and safe in exploitation process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

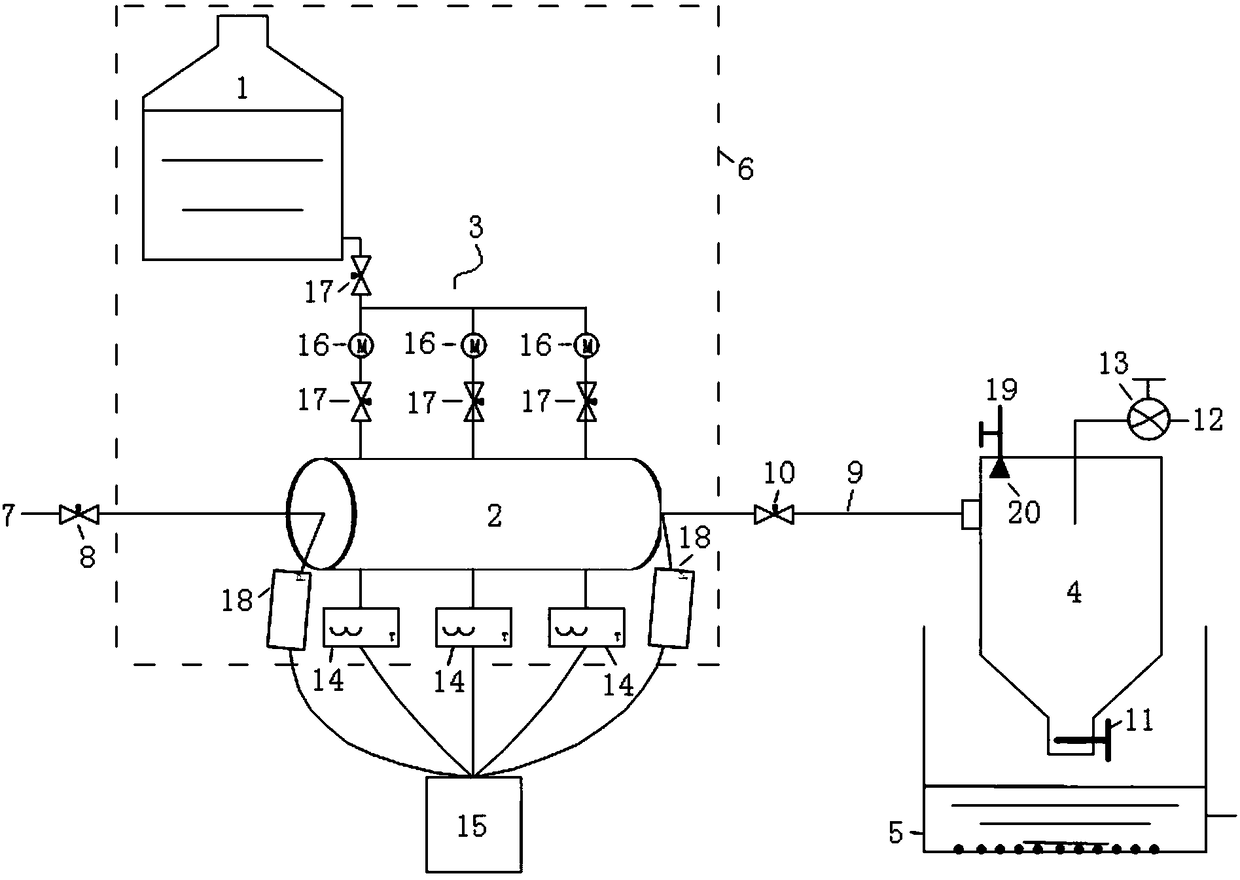

Sanding simulation measuring device and method for marine natural gas hydrate reservoir mining process

The invention relates to a sanding simulation measuring device and method for marine natural gas hydrate reservoir mining process. The sanding simulation measuring device comprises a seawater storagetank, a sand filling pipe, seawater intrusion simulation pipelines, a gas-water-sand separating device, a sand / water receiver and a high and low temperature test chamber. The seawater storage tank andthe sand filling pipe are placed in the high and low temperature test chamber, and a pipe cavity of the high pressure sand filling pipe is connected with the seawater storage tank through the seawater intrusion simulation pipelines. The inlet end of the high pressure sand filling pipe is connected with a high pressure gas source through a gas injection pipeline and a gas injection valve, and theoutlet end of the high pressure sand filling pipe is connected with the gas-water-sand separating device through a mining pipeline and a connecting valve. The gas-water-sand separating device is placed in atmosphere and is in a funnel shape, and a first on-off valve is arranged at the bottom outlet of the gas-water-sand separating device. A gas recovery pipeline is arranged on the top of the gas-water-sand separating device, the inlet end of the gas recovery pipeline extends into the gas-water-sand separating device, and a back pressure valve is arranged on the gas recovery pipeline. The sand / water receiver is arranged below the first on-off valve of the bottom of the gas-water-sand separating device.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Surface drilling pre-splitting blasting shallow burying method for room type goaf roof

ActiveCN106705773APrevent crushingSafe miningUnderground miningBlastingLongwall miningShortest distance

The invention discloses a surface drilling pre-splitting blasting shallow burying method for a room type goaf roof and belongs to a roof disaster preventing and controlling method for mining of a short distance coal bed below a shallowly-buried goaf. During long wall mining of the short distance coal bed below the shallowly-buried room type goaf, main roof large-area pressure coming happens easily, the yielding damage happens to a small-size coal column under the fracture load of a main roof, a large-size coal column has an elastic kernel and acts the concentrated stress on a lower coal bed work face hydraulic support, and collapse of a work face inner roof, pushing down of a support, hurricane impacting and other disasters are caused. According to the method, drilling pre-splitting blasting of the roof is performed on the ground, the problems that construction is difficult and the effective distance of drilling is short during forced caving of room penetrating type drilling pre-splitting blasting of the goaf are solved, roof large-area pressure coming, roof collapse, pushing down of the support and other disasters can be effectively prevented, and the method is also applicable tomining of lower coal beds of concentrated coal columns of a shallowly-buried long-wall goaf. The method is simple in implementation process, safe and efficient and has wide applicability.

Owner:CHINA UNIV OF MINING & TECH

Method for exploiting of submarine natural gas hydrate through solid replacement and pressure maintaining

ActiveCN108049846AAvoid decompositionMining principle is simpleConstructionsFluid removalEcological environmentSlurry

The invention discloses a method for exploiting of submarine natural gas hydrate through solid replacement and pressure maintaining, and belongs to the field of energy and environments. The method comprises the steps that by arranging a stope at a hydrate layer, the stope temperature and pressure are monitored by using a temperature and pressure sensor and fed back to an offshore platform, existing conditions of the hydrate are maintained by adopting a sealing device according to a hydrate temperature and pressure curve, the hydrate is made to be not disintegrated, the solid form of the hydrate is maintained, solid-state mechanization mining, solid-liquid slurry conveying, gas separation and liquefaction transport are further conducted on the hydrate, a separated hydrate skeleton is brokenagain, and a cavity is filled after a rapid solidification material is added, thus destroy of submarine landslide, tsunami and a submarine ecological environment can be effectively prevented, and thepurpose of green exploiting is achieved. According to the method for exploiting of the submarine natural gas hydrate through solid replacement and pressure maintaining, the system is simple, and themethod is suitable for a hydrate pressure bearing layer with an upper impermeable cover layer and a lower impermeable cover layer, and has a good application prospect.

Owner:CHINA UNIV OF MINING & TECH

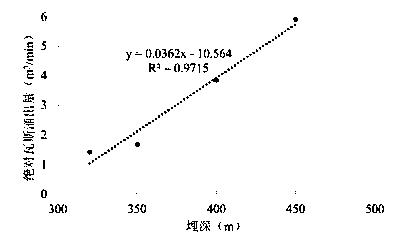

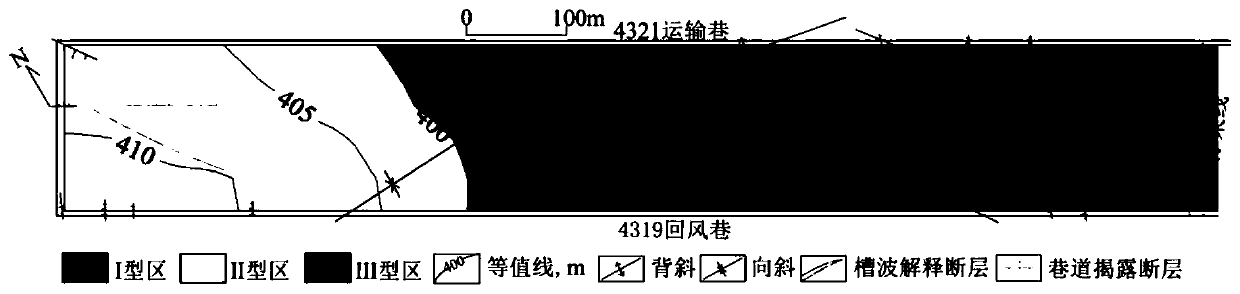

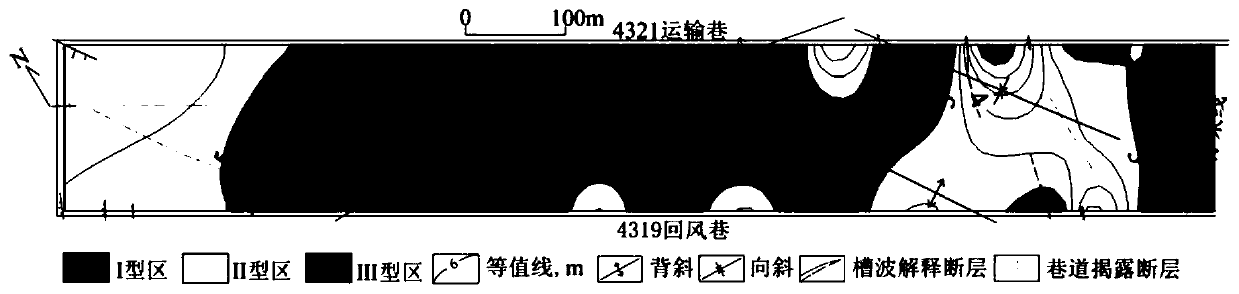

Coal mine working face gas geological risk evaluation method

ActiveCN110458367AIn line with the actual geological conditionsPrecision miningForecastingResourcesIndex systemRisk evaluation

The invention discloses a coal mine working face gas geological risk evaluation method. A working face gas geological evaluation index system comprising coal seam basic characteristics, coal seam structure characteristics, gas emission characteristics and gas outburst characteristics, and a grading standard are constructed, wherein the indexes specifically comprise secondary indexes such as coal seam burial depth, thickness, fault fractal dimension, structural curvature, absolute / relative gas emission amount, gas content, coal body structure and local outburst prediction indexes; a working face scale gas geology grading evaluation method system is determined, and the method specifically comprises the steps of evaluation parameter system establishment and grading, membership function and weight determination, multi-level fuzzy mathematical evaluation model construction, and geology mapping and zoning evaluation. The working face gas geology grading evaluation standard and method meet the actual geological conditions of the Korean mining area, the grading and zoning result is reliable, the potential of being popularized to other high-gas mines and tectonic coal development areas is achieved, and a basic basis can be provided for accurate, safe and efficient coal mining geology guarantee.

Owner:XIAN UNIV OF SCI & TECH +1

Method for backfilling land collapse pit of mine subjected to caving mining by utilizing tailings

ActiveCN107975044AEliminate geohazard problemsSave management feeEmbankmentsSingle pointMining engineering

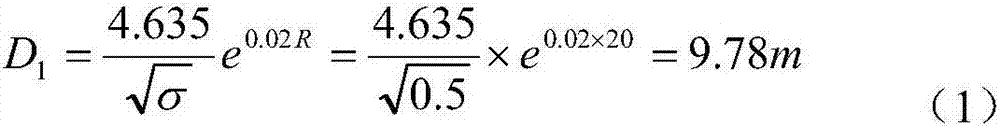

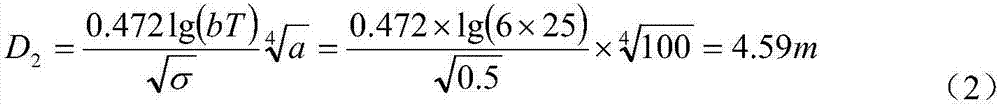

The invention provides a method for backfilling a land collapse pit of a mine subjected to caving mining by utilizing tailings. The method comprises the steps that (1) a collapse pit mill tailing backfill material is prepared, specifically, binding materials and mill tailings are mixed and stirred at the proportion of (1:6)-(1:8), and the concentration of backfill slurry can reach over 65%; (2) backfill zoning is conducted on the mine land collapse pit; (3) a solidified tailing slurry single-point piling and discharging flowing average expansion radius is determined, specifically, the solidified tailing slurry single-point piling and discharging flowing average expansion radius is determined to be 20 m; and (4) backfill material solidifying is conducted, specifically, tailing solidifying and backfilling units are arranged along the boundary arc length of a piled and discharged position of a semi-secure area at intervals of 20 m when on-site piling and discharging are conducted, the prepared backfill material is directly discharged into the designated backfilling units, the one-time piled and discharged thickness is (4.59-4.59 m)-9.78 m, the solidifying time lasts for 14 days, and circulation backfilling is conducted. According to the method, potential safety hazards of a tailing pond can be avoided, a lot of lands can be saved, meanwhile the problem of safety of a land collapsearea is solved, and the engineering amount and the cost of mine terminal-stage management of geological disasters are greatly reduced.

Owner:NANJING MEISHAN METALLURGY DEV

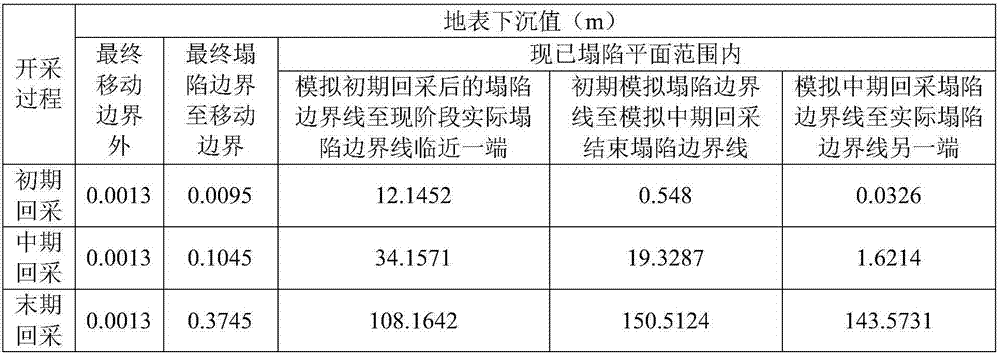

Underground rock mass engineering ground pressure management and control method

ActiveCN107145684AImprove stress distributionReduce peripheral stressData processing applicationsDesign optimisation/simulationStress concentrationHigh stress

The invention discloses an underground rock mass engineering ground pressure management and control method. The method comprises the following steps that firstly, a ground pressure displaying rule is researched (Study) and disclosed so as to obtain a stress rise area, a stress reducing area, a tensile stress area and a rock mass moving angle in an underground mine rock mass; secondly, mining area ground pressure transfer (Transter) is guided, and a horizontal cutting roadway and a vertical cutting groove mode are used in the underground mine rock mass to guide the stress in a mining area to be transferred; thirdly, by means of mining area high-stress collapse is used (Use), the impact potential hazard of stress concentration on a top plate of a goaf is eliminated, and meanwhile, a covering layer required by recovery is formed; fourthly, the ground pressure of an operation area is controlled (Control), a stoping roadway is supported by means of an internal reinforcement mode of an anchor rod or an anchor cable, passive control of the ground pressure is converted into active management, ground pressure display like collapse and wall caving is controlled, and the stoping safety is guaranteed.

Owner:CENT SOUTH UNIV +1

Electric knocking cracking and microwave collaborated heat driving gas extraction system and method

ActiveCN110578549AAchieve synergyImprove desorption efficiencyFluid removalGas removalElectricityMicrowave

The invention discloses an electric knocking cracking and microwave collaborated heat driving gas extraction system and a method. The system comprises an ultra-high pressure water jet generating system, an electric knocking cracking system, a microwave heat injection system and a gas extraction system. In work, a drilling machine clamps the tail end of an insulating sleeve, and the front end of the insulating sleeve stretches into a gas extraction hole. The input end of a rotating sealing device of the drilling machine is connected with an ultra-high pressure water pump through a nanometer fluid pipeline, and the output end is connected with the tail end of the insulating sleeve. The using method of the system comprises the steps of construction of the gas extraction hole, injecting of nanometer fluid suspension liquid, discharging, heating and the like. According to the system, electric cracking is combined with microwave heat injection, the coal layer cracking and heat driving gas collaborated effect is achieved, the gas desorption efficiency is remarkably improved, the purpose of preventing and treating gas disasters is achieved, and efficient and safe mining of coal resources is achieved.

Owner:NORTH CHINA INST OF SCI & TECH +1

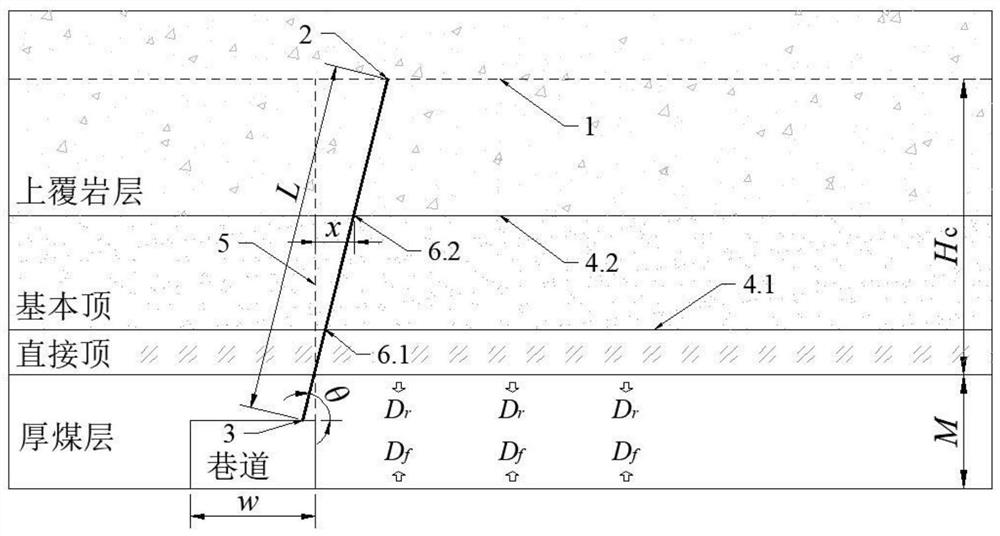

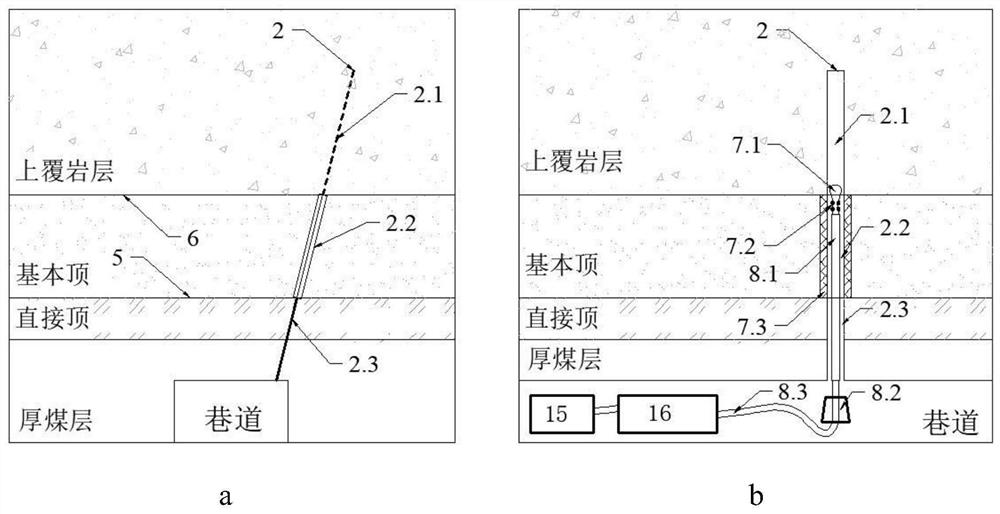

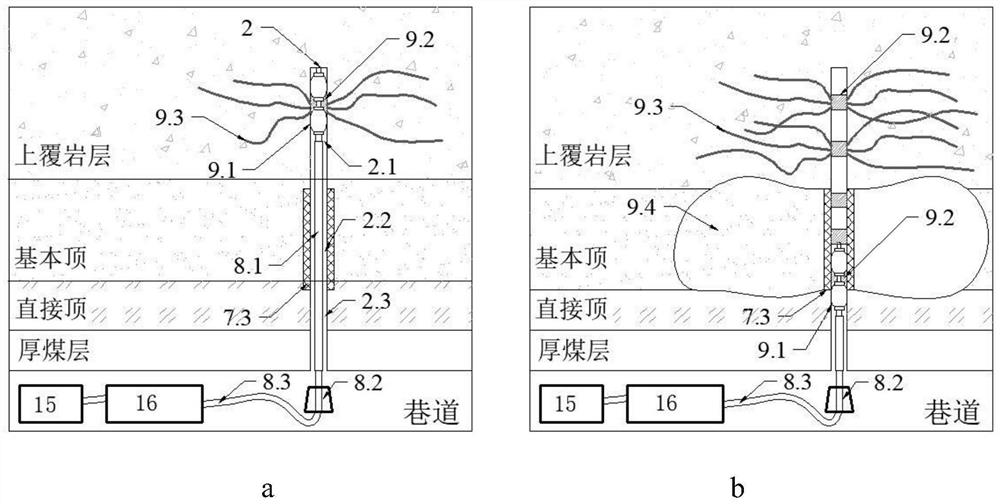

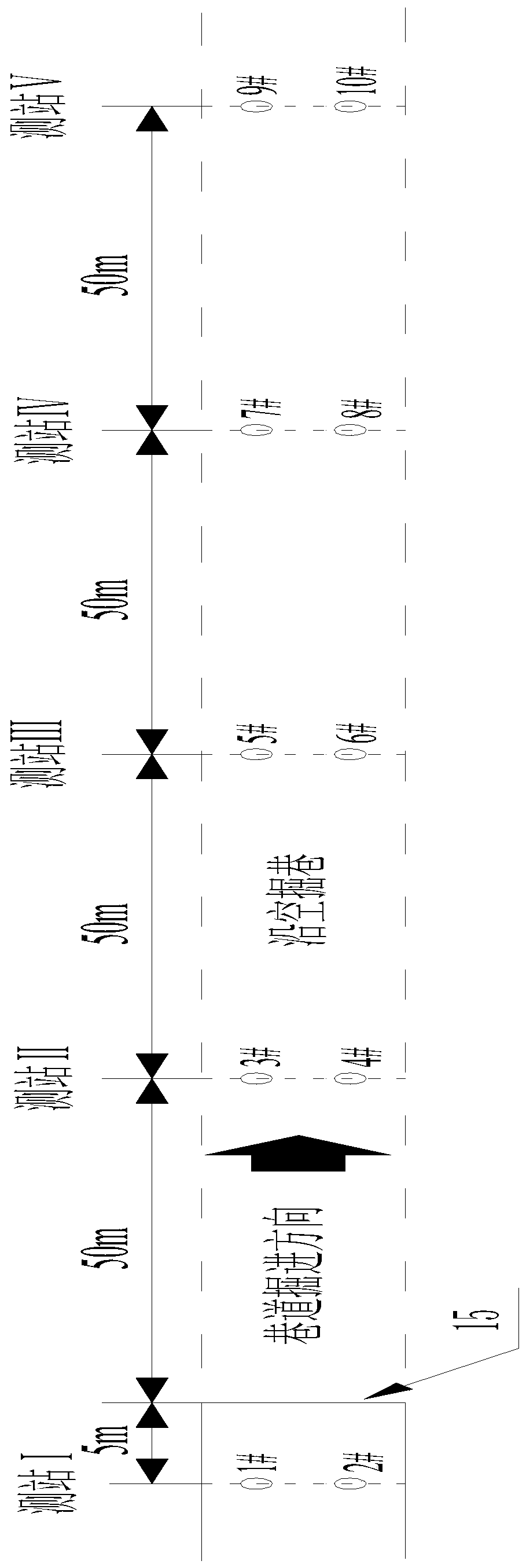

Hydraulic fracturing roof cutting gob-side entry retaining method for thick coal seam

ActiveCN112901166AReduce disturbanceMitigate overrunDisloding machinesStructural engineeringHydraulic fracturing

The invention discloses a hydraulic fracturing roof cutting gob-side entry retaining method for a thick coal seam. The method comprises the specific steps of calculating the roof cutting height of the thick coal seam, constructing fracturing drill holes, cutting hole walls through high-pressure jet flow, conducting single-hole multi-time hydraulic fracturing, sequentially fracturing multiple sets of fracturing drill holes, conducting roof cutting entry retaining and taking auxiliary measures. According to the method, the disturbance effect of the hydraulic fracturing technology on a roadway is small, the problems of gas accumulation and harmful gas overrun are relieved, fracturing construction mainly consumes underground industrial water and has little influence on the environment, hydraulic fracturing can be conducted on the multiple sets of fracturing drill holes simultaneously or alternately, the time cost is saved, the excavation and replacement efficiency is improved, and the method can replace the energy gathering blasting technology to achieve safe, efficient and rapid roof cutting entry retaining of thick coal seam mining.

Owner:CHINA UNIV OF MINING & TECH

Gob-side entry driving method based on complete period of roadway service and adopting grouting anchor cable

The invention relates to a gob-side entry driving method based on a complete period of roadway service and adopting a grouting anchor cable, belongs to the technical field of coal mining, and solves the problems of difficult supporting in an existing gob-side entry driving period, and complex advanced supporting operation and high labor intensity of workers in a later-period working face stoping period. The gob-side entry driving method comprises the following steps: driving along the edges of gobs in adjacent sections; laying metal meshes on the top plate and the two sides of a roadway; installing the hollow grouting anchor cable in a anchor cable hole in the top plate of the roadway, and installing a hollow grouting anchor rod and a high-strength anchor rod in anchor rod holes in the side of a coal pillar and the side of a working face separately; distributing observation equipment used for monitoring the fracture development of surrounding rock of the roadway on the surrounding rockof the roadway, and obtaining the fracture development degree of the surrounding rock of the roadway through the observation equipment; grouting to the hollow grouting anchor cable and the hollow grouting anchor rod on the basis of the fracture development degree of the surrounding rock of the roadway; and step S6, continuously cyclically repeating the steps S1-S5 until the gob-side entry drivingis completed. The gob-side entry driving method is easy to operate, and capable of greatly reducing the labor intensity of the workers, and the cost.

Owner:CHINA UNIV OF MINING & TECH

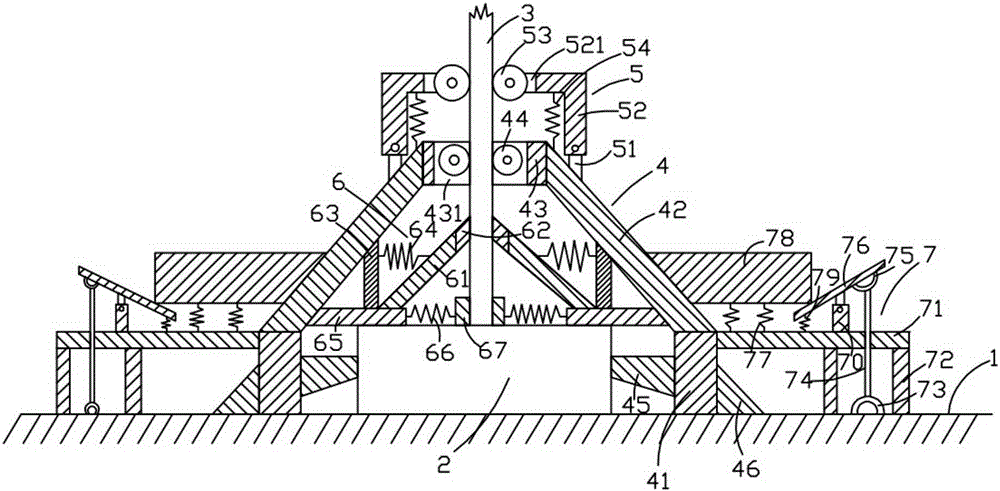

Cable fixing device for petroleum wellhead fishing operation

ActiveCN105186356ASafe miningEffectively fixedPipe supportsCable installation apparatusFishingPetroleum

The invention discloses a cable fixing device for a petroleum wellhead fishing operation. The cable fixing device comprises a first fixing device, a second fixing device, a third fixing device and a fastening device, wherein a first support rod, a first sway rod, a first cross rod, a first fixed wheel, a locating block and a triangular block are arranged on the first fixing device; a first fixed block, a first bracket, a second fixed wheel and a first spring are arranged on the second fixing device; a second sway rod, a first friction block, a first vertical rod, a second spring, a second cross rod, a third spring and a second friction block are arranged on the third fixing device; and a support plate, a second support rod, a first fixing ring, a connection rope, a second fixing ring, a rotating rod, a fourth spring, a lower pressure block, a fifth spring, a first fixing post and a second fixing post are arranged on the fastening device. According to the cable fixing device, the cable can be effectively fixed and is prevented from coming off; the safety is improved; the losses are reduced; safe and rapid exploitation of petroleum is ensured; and the work efficiency is improved.

Owner:浙江永明中策科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com