Gas pumping sleeve-penetrating occluder and use method thereof

A occluder and sleeve-through technology, which is applied in the direction of gas discharge, earthwork drilling, sealing/isolation, etc., can solve the problems of concentration attenuation, high processing cost, and large outer diameter of occluder in coal mine gas drainage. To achieve the effect of safe mining and reduce air permeability

Active Publication Date: 2013-12-18

HENAN POLYTECHNIC UNIV

View PDF6 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, as the extraction time goes by, the concentration of coal mine gas extraction gradually decays

Due to the release of the elastic potential of the coal body and the reduction of the gas pressure and gas content in the coal seam, the coal seam is displaced and deformed, and the voids around the drill hole are gradually developed and expanded. The hole is sealed tightly, and there is a phenomenon of air leakage

The applicant's invention of the "Gas Drainage Center Divided Grouting Sealing Device and Sealing Method" (ZL201110120920.3) cannot achieve the ideal sealing effect, and the processing cost is relatively high

However, when the side grouting type meets the size of the drainage channel, the overall outer diameter of the occluder is relatively large. When the borehole collapses, it is difficult to insert the occluder into the borehole smoothly.

In addition, the length of the occluder I invented before is relatively long, which is inconvenient to transport

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

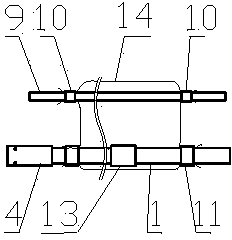

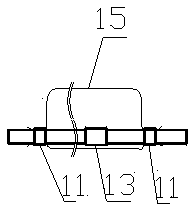

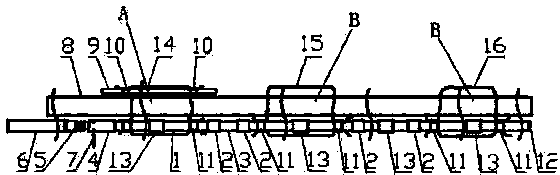

The invention discloses a gas pumping sleeve-penetrating occluder and a use method thereof. The occluder is mainly formed by jointing a bag A combination and at least one bag B combination; the bag A combination comprises a No.1 bag (14),a grouting pipe (1), a gas leaking handling pipe and a transition part; the grouting pipe and the gas leaking handling pipe respectively penetrate through the No.1 bag; a check valve is arranged on the grouting pipe in the No.1 bag; the bag B combination comprises a No.2 bag and a grouting pipe penetrating through the No.2 bag; a check valve is arranged at the grouting pipe in the No.2 bag; short grouting pipes between the bag A combination and the bag B combination are jointed by a straight joint; a pumping pipe penetrates through the No.1 bag and the No.2 bag. According to the gas pumping sleeve-penetrating occluder and the use method thereof, one bag A combination and multiple bag B combinations can be serially connected, more effective grouting hole sealing can be realized on drill holes of a hole sealing section, generation and expansion of coal wall seams around the drill holes at the hole sealing section can be more effectively avoided, and the occluder can also fill extremely small coal seams, so the hole sealing effect is optimal.

Description

technical field [0001] The invention relates to a plugging device for gas drainage boreholes in coal mines, and is especially suitable for permanent plugging of gas drainage in the coal seam of coal mines and gas leakage treatment in the later stage of gas drainage. Background technique There are many methods for underground gas drainage equipment in coal mines in my country, most of which are to carry out a section of hole sealing treatment at a certain distance from the borehole. Borehole sealing for underground gas drainage in coal mines is divided into permanent sealing and temporary sealing. At present, the known permanent sealing uses foamed polyurethane, foamed cement and other foaming materials as the sealing material. Temporary hole sealing for gas drainage is usually sealed by mechanical hole sealing device. Most of the current bladder occluders are in the form of central grouting and side grouting. The extracted gas concentration has been greatly improved. H...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B33/12E21F7/00

Inventor 孙玉宁马耕黄小明张国平周成龙杨坤丁立陪

Owner HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com