Patents

Literature

73results about How to "Suppress spontaneous combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

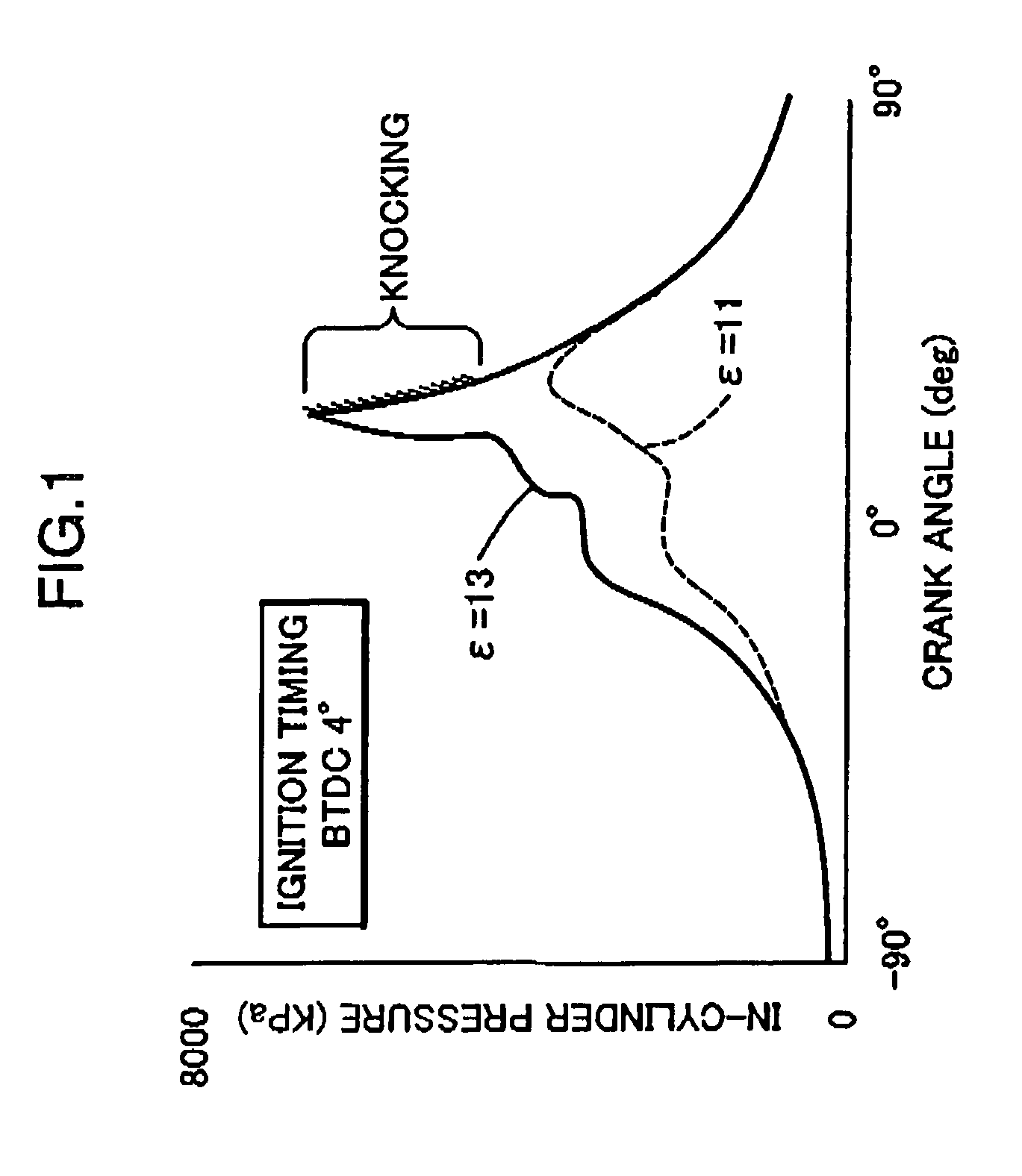

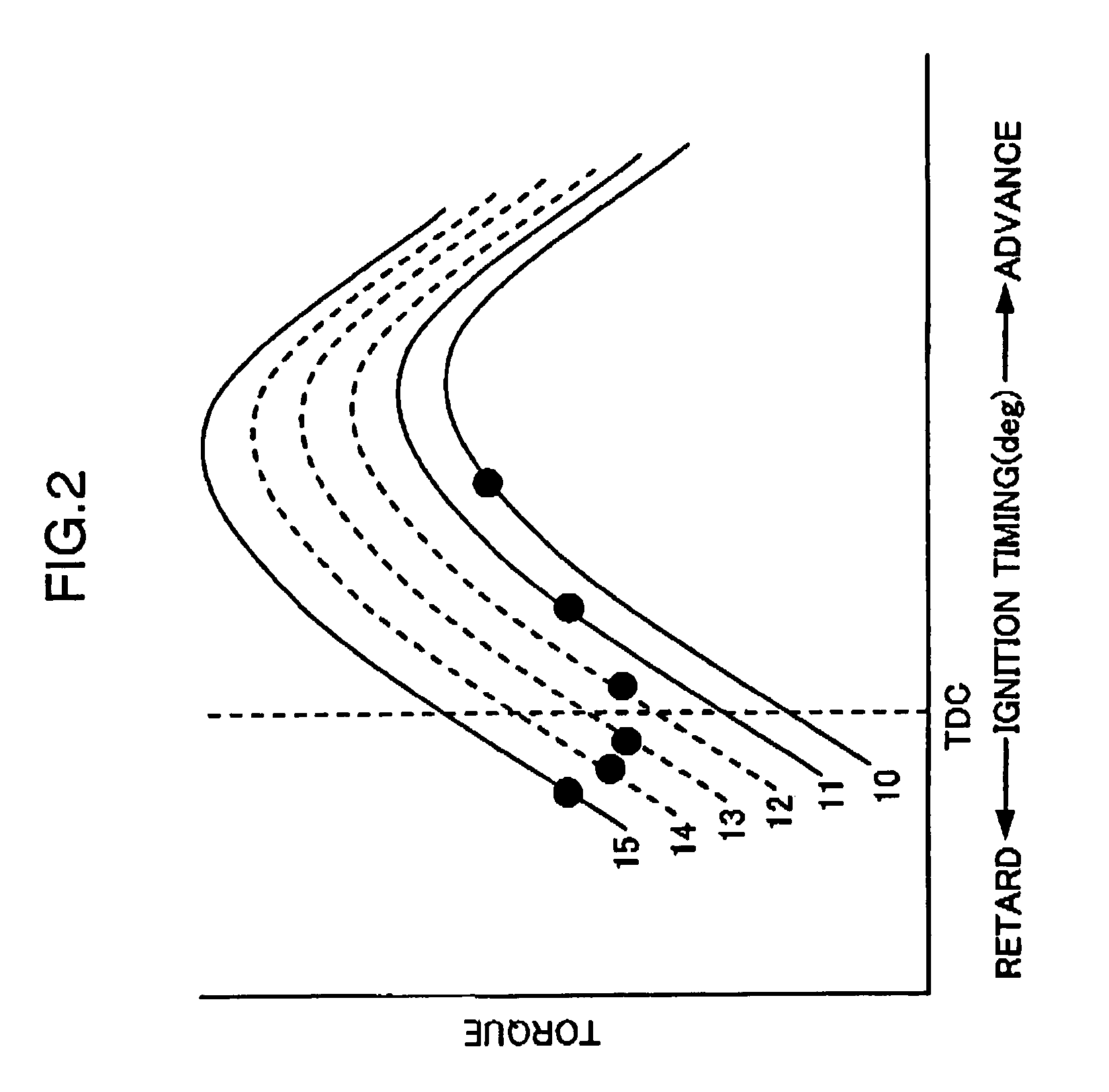

Spark-ignition gasoline engine

ActiveUS20090159045A1Quantity minimizationReduce consumptionElectrical controlAutomatic controlLow speedExhaust valve

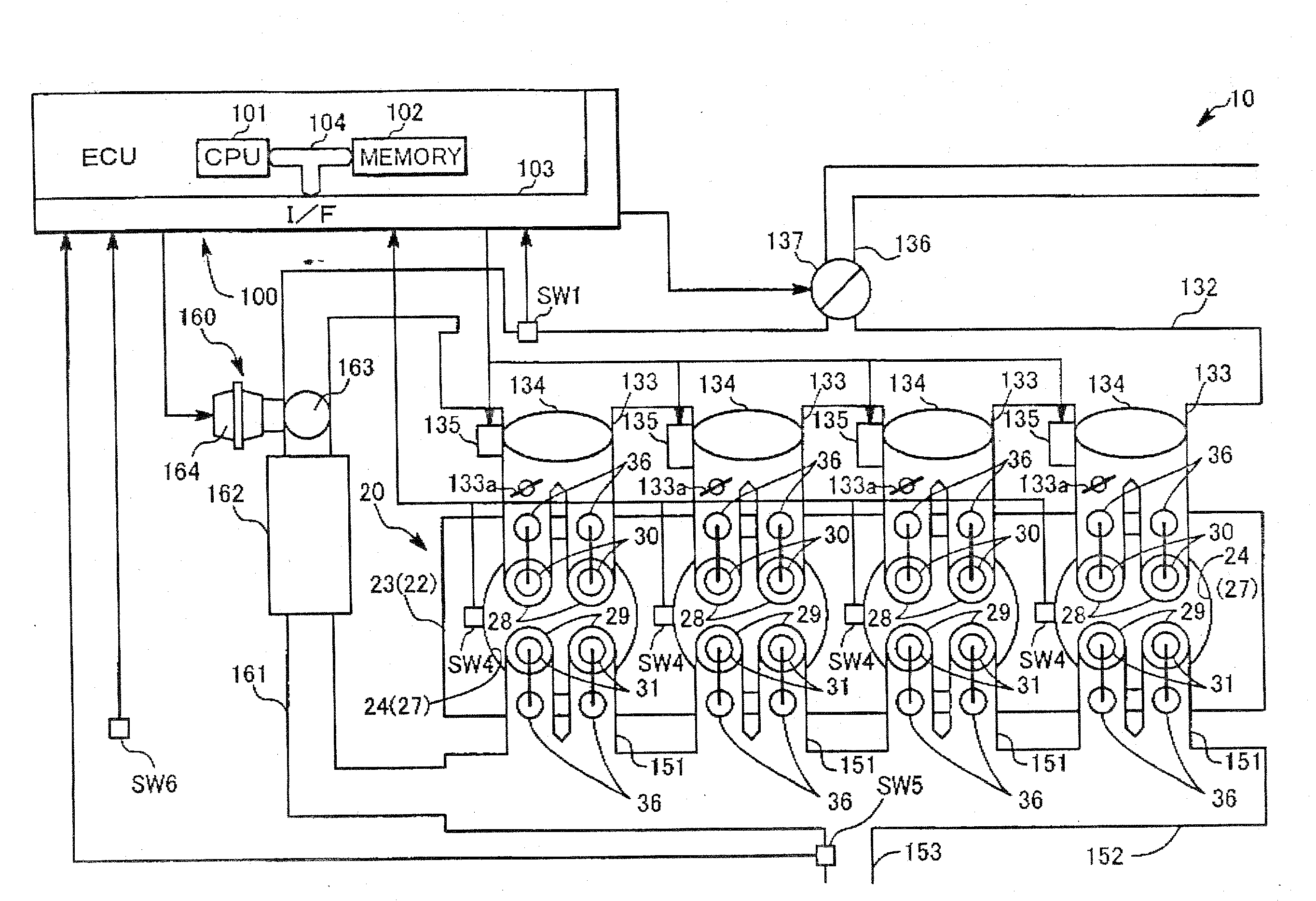

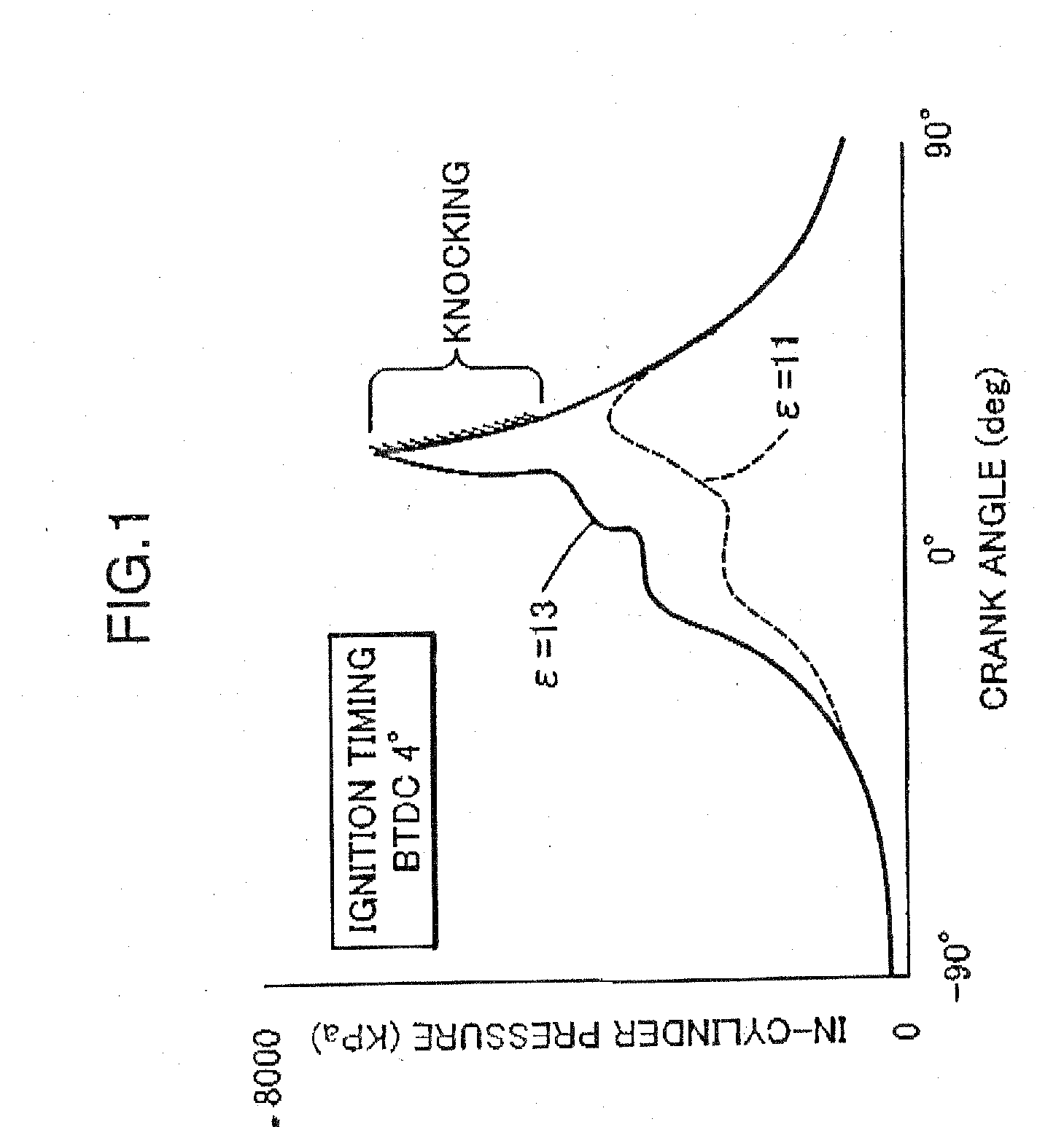

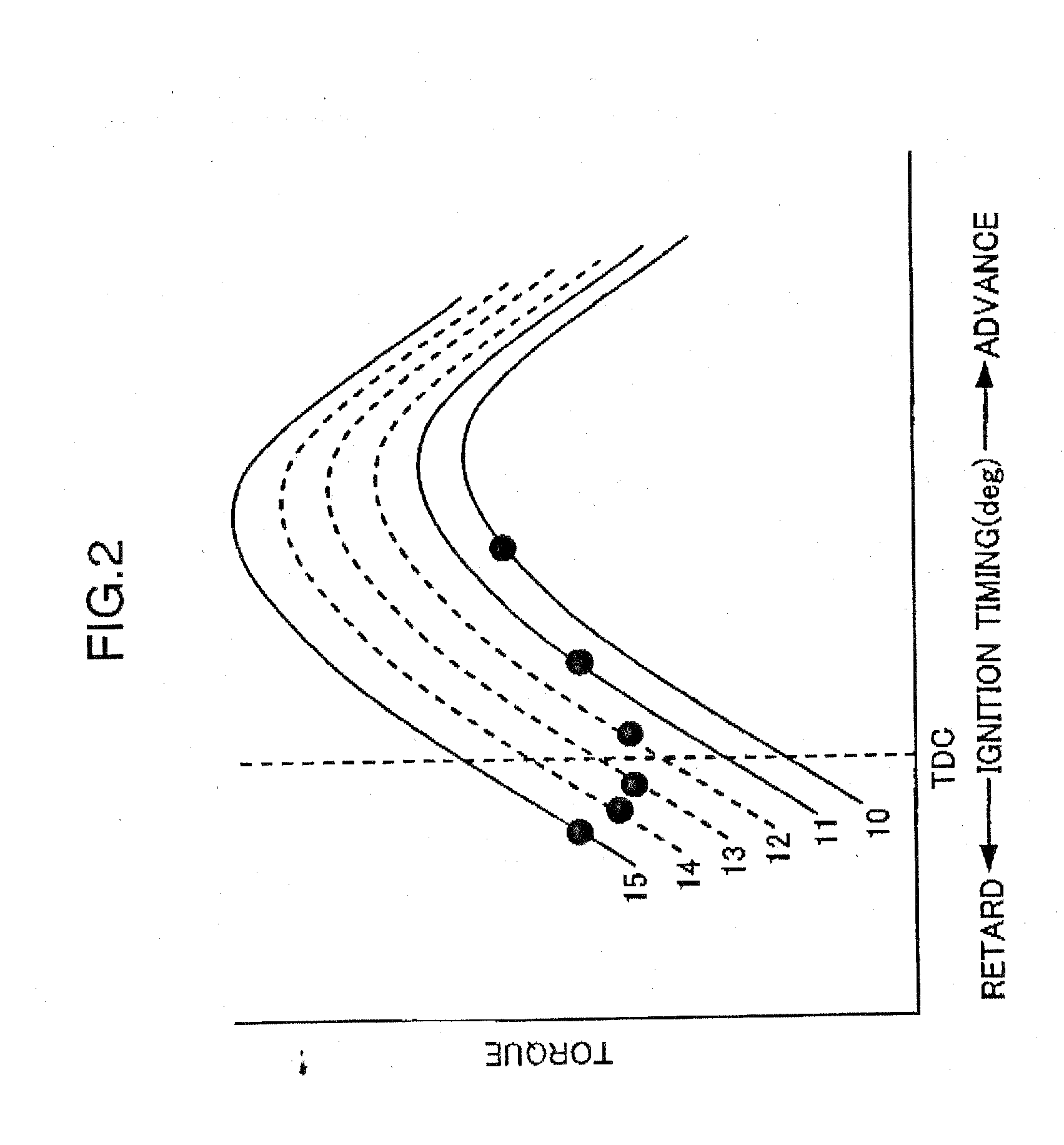

A spark-ignition gasoline engine having at least a spark plug, the engine including an engine body having a geometrical compression ratio set at 14 or more, and an intake valve and an exhaust valve provided, respectively, in intake and exhaust ports connected to each of a plurality of cylinders of the engine body. The intake and exhaust valves are adapted to open and close corresponding respective ones of the intake and exhaust ports. The engine further includes an operation-state detector adapted to detect an operation state of the engine body and a control system adapted, based on detection of the operation-state detector, to perform at least an adjustment control of an ignition timing of the spark plug, the control system being operable, when an engine operation zone is a high-load operation zone including a wide open throttle region within at least a low speed range, to retard the ignition timing to a point within a predetermined stroke range just after a top dead center of a compression stroke.

Owner:MAZDA MOTOR CORP

Inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in goaf of coal mine

InactiveCN101766877AAvoid contactStop spontaneous combustionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention discloses an inorganic salt type inhibitor for preventing and controlling spontaneous combustion of residual coal in a goaf of a coal mine, which belongs to the field of fire prevention and extinguishment in the goaf of the coal mine. The inorganic salt type inhibitor consists of sodium bicarbonate, calcium bicarbonate, calcium chloride, magnesium chloride, sodium chloride and zinc chloride according to a certain proportion by weight. The average inhibiting rate of the inorganic salt type inhibitor can achieve 85%, and the inhibiting effect is ideal. When in use, the inhibitor is covered on the surface of the residual coal in the goaf, thereby achieving the effects of preventing and controlling the spontaneous combustion of a coal layer in the region for a long time. The dusting method of the inorganic salt type inhibitor for fire prevention and extinguishment is safe and stable, the process flow is simple, the operation is convenient, the initial investment is low, and the using cost is relatively low. The fire prevention and extinguishment technology of the inorganic salt type inhibitor which has thermal instability and can release inert gas carbon dioxide has broad application prospects in the work of preventing and controlling the spontaneous combustion fire disasters of the coal layers. The inorganic salt type inhibitor is applicable to the fire prevention and extinguishment in the goaf of the coal mine.

Owner:UNIV OF SCI & TECH BEIJING

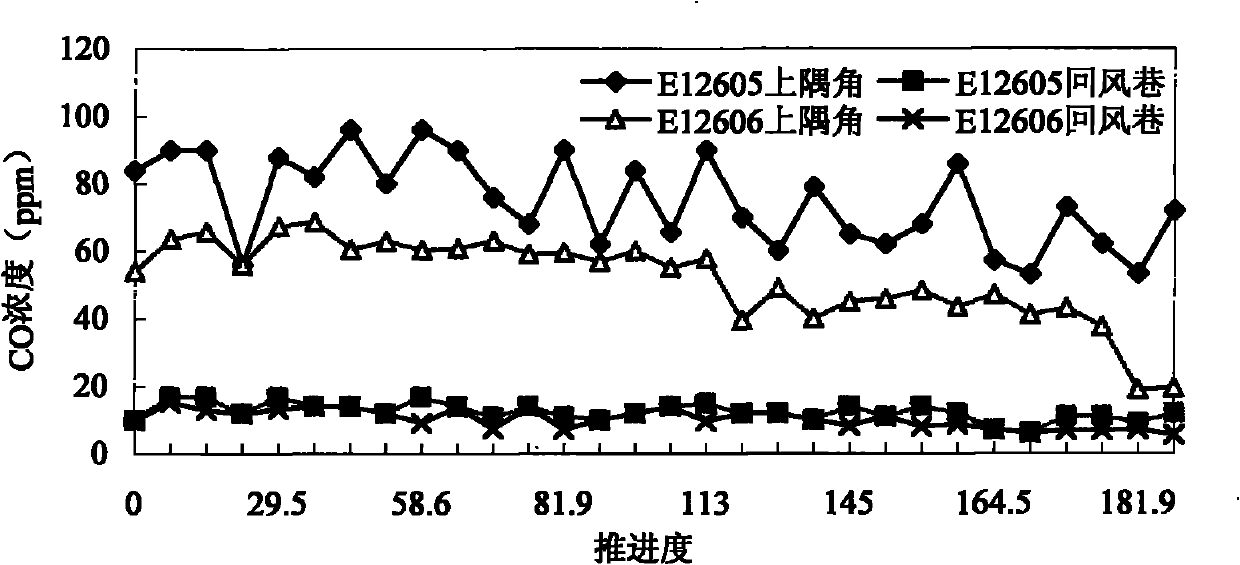

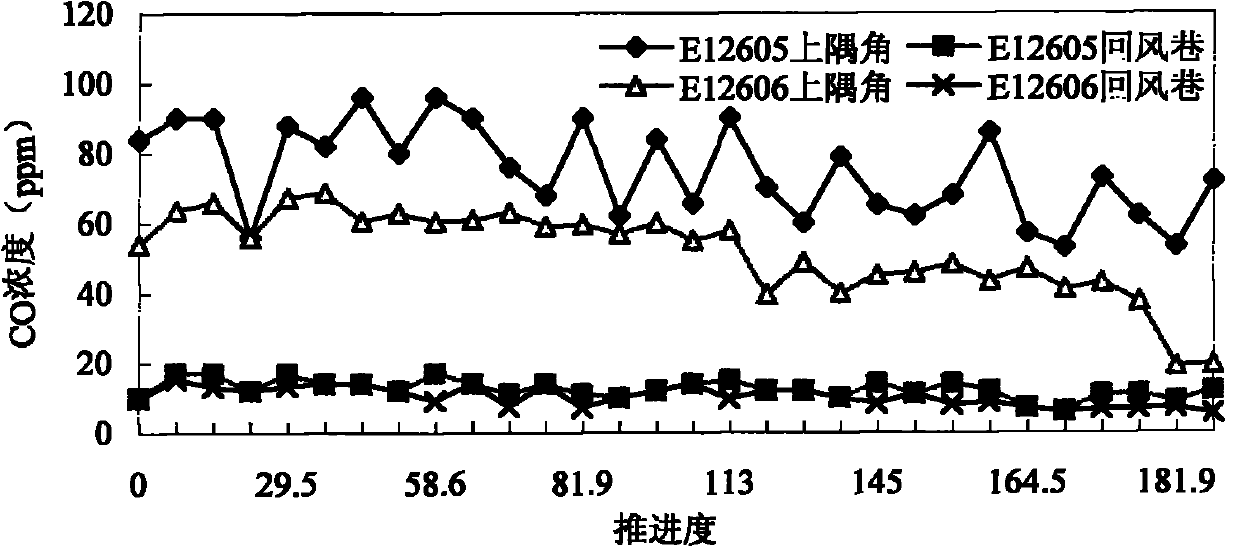

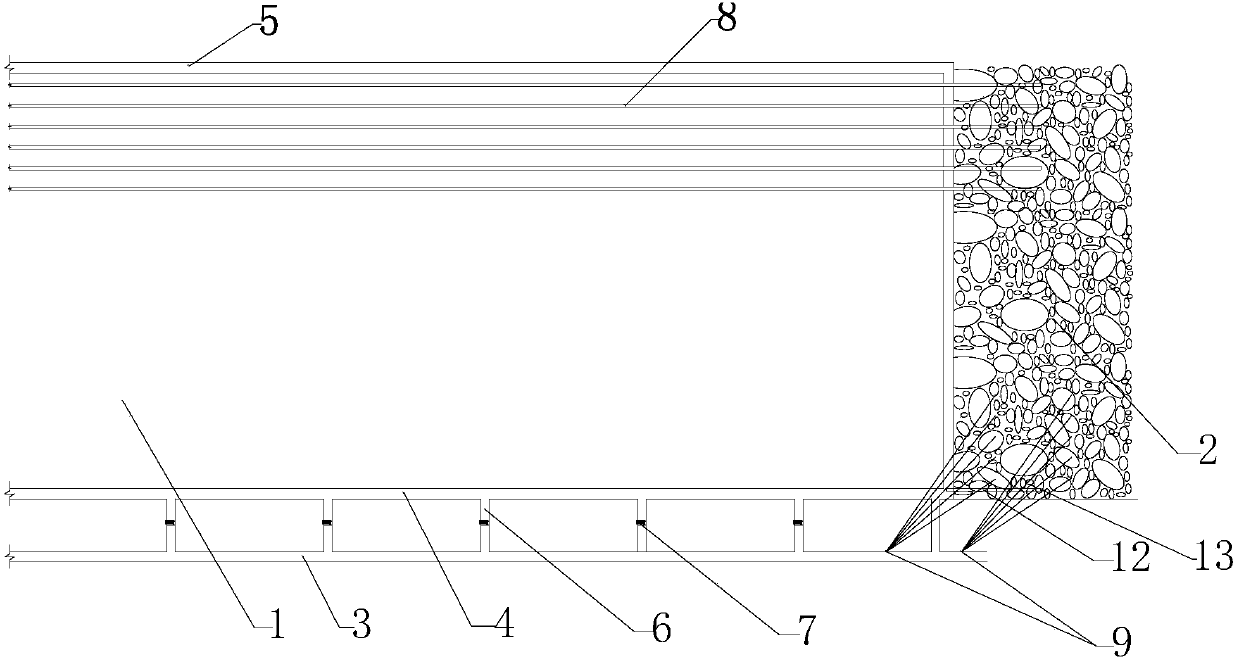

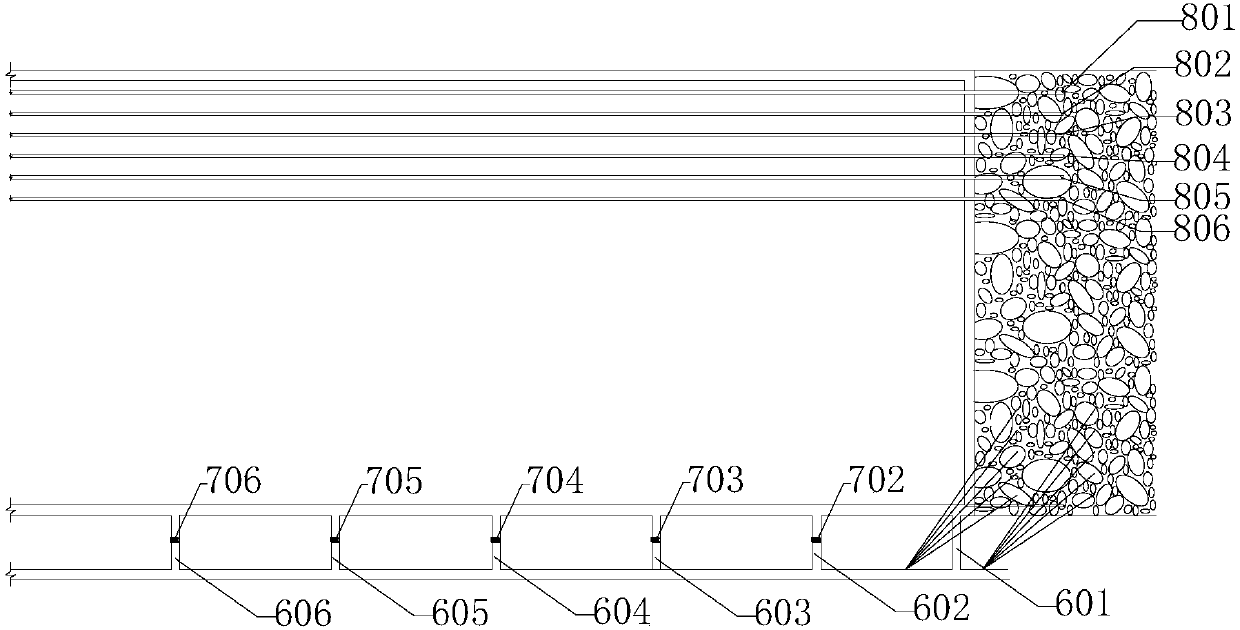

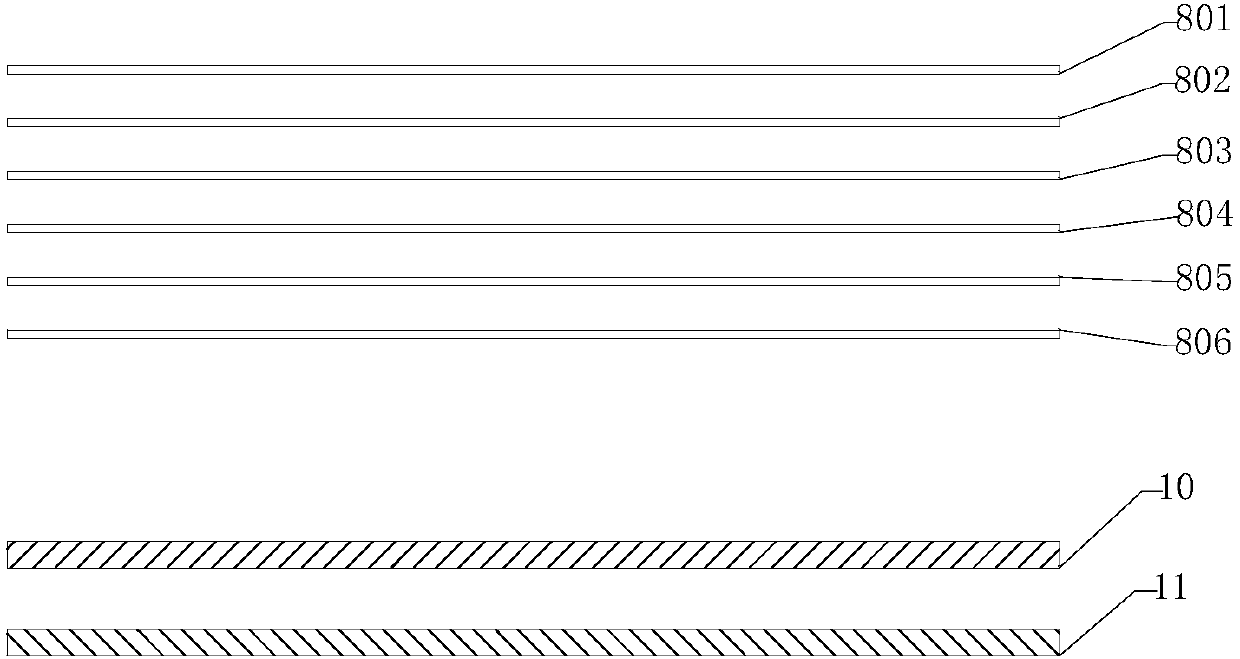

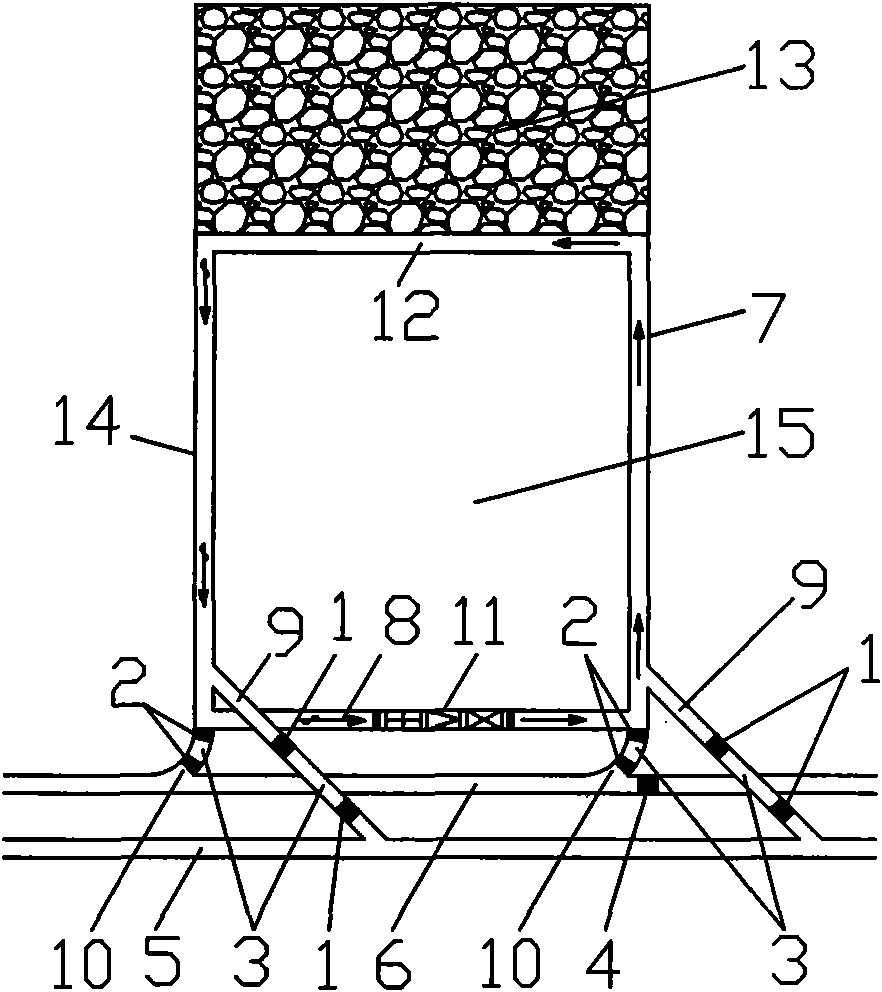

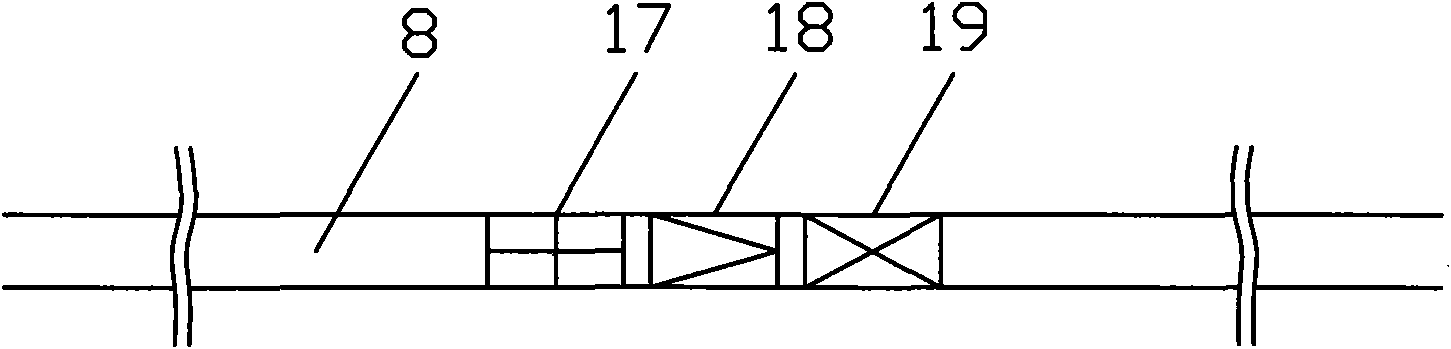

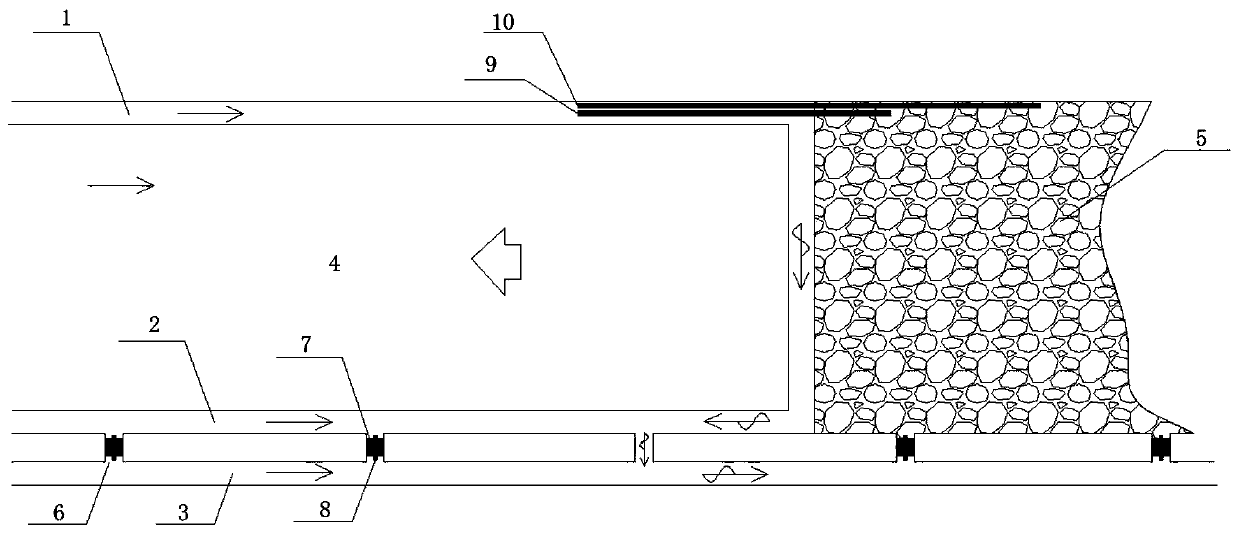

Joint treatment method for gas and coal spontaneous combustion in night distance seam mining

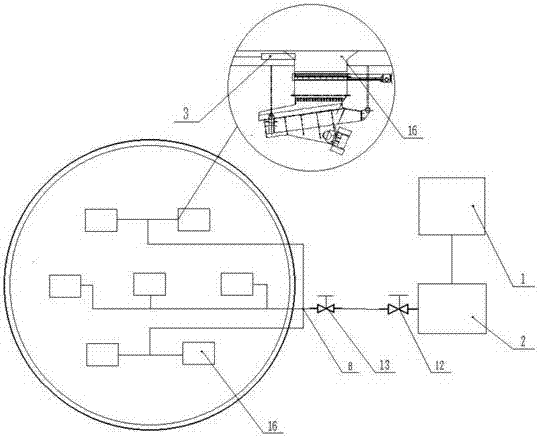

InactiveCN107859530APrevent overrunningLow costDust removalFire preventionCoal spontaneous combustionControl system

The invention discloses a joint treatment method for gas and coal spontaneous combustion in night distance seam mining. Gas gushing out of a stope working face is treated through a 'two intakes and one return' working face ventilation system, long drill holes in the trend of a fissure zone are utilized to replace a high pumping lane to extract gas gushing out of residual coal of night distance seams and a coal seam, thus corner gas overflow on the stope working face is avoided, and the gas extraction project cost is reduced. Gas injecting pipelines are arranged on a belt gate roadway of the stope working face to continuously inject liquid carbon dioxide into a goaf to restrain spontaneous combustion of the residual coal of the coal seam, low-position drill holes are formed in a track gateroadway of the stope working face to inject nitrogen to prevent spontaneous combustion of the coal of the night distance seams after extraction collapse, thus a coal spontaneous combustion three-dimensional preventing and control system of the goaf is formed, float coal spontaneous combustion in the goaf is accurately prevented and treated, finally, the purpose of joint treatment for gas and coalspontaneous combustion in night distance seam mining is achieved, the coal recovery rate of coal and the working face stoping continuous speed are increased, and safe production of the tope working face is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

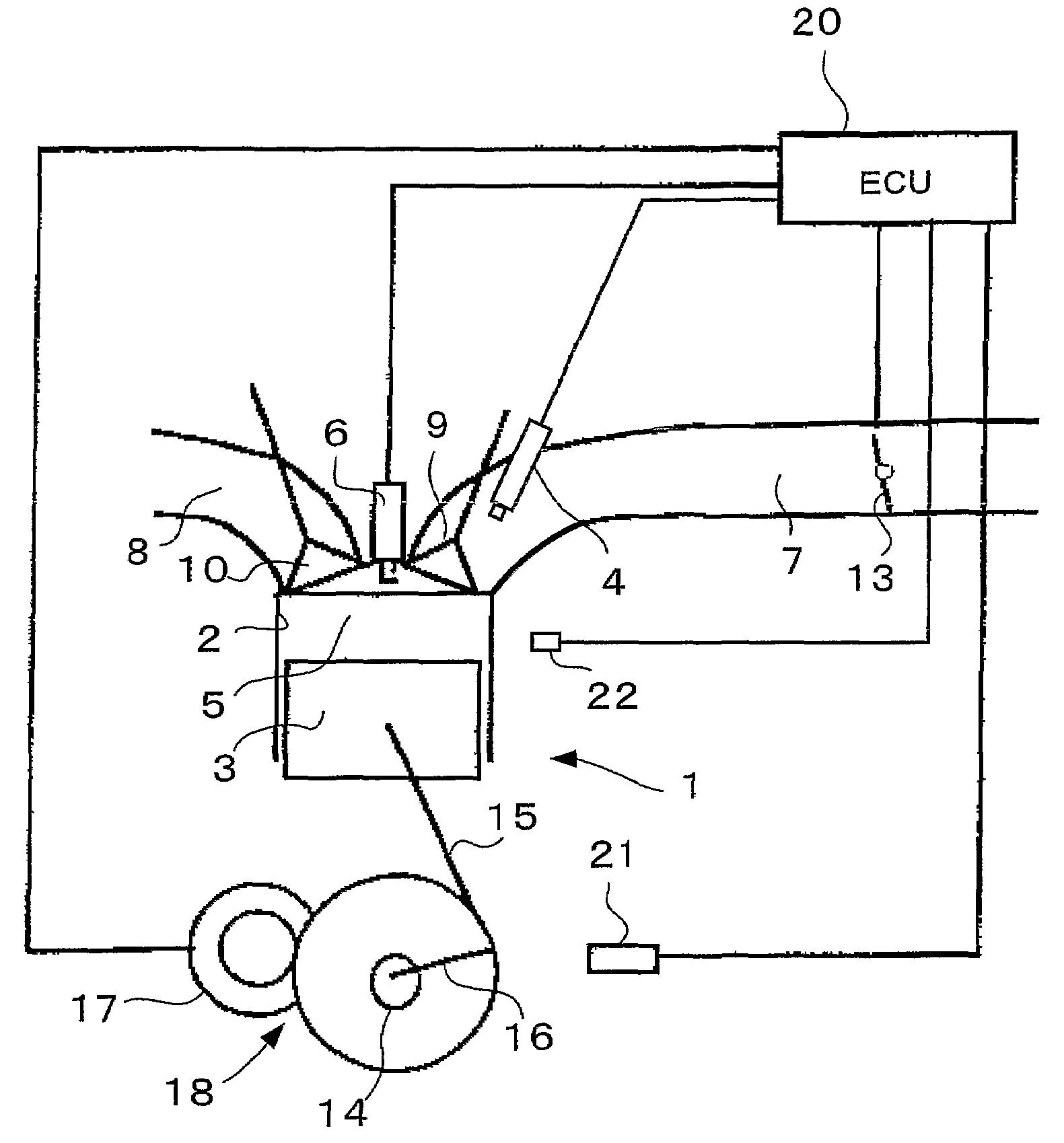

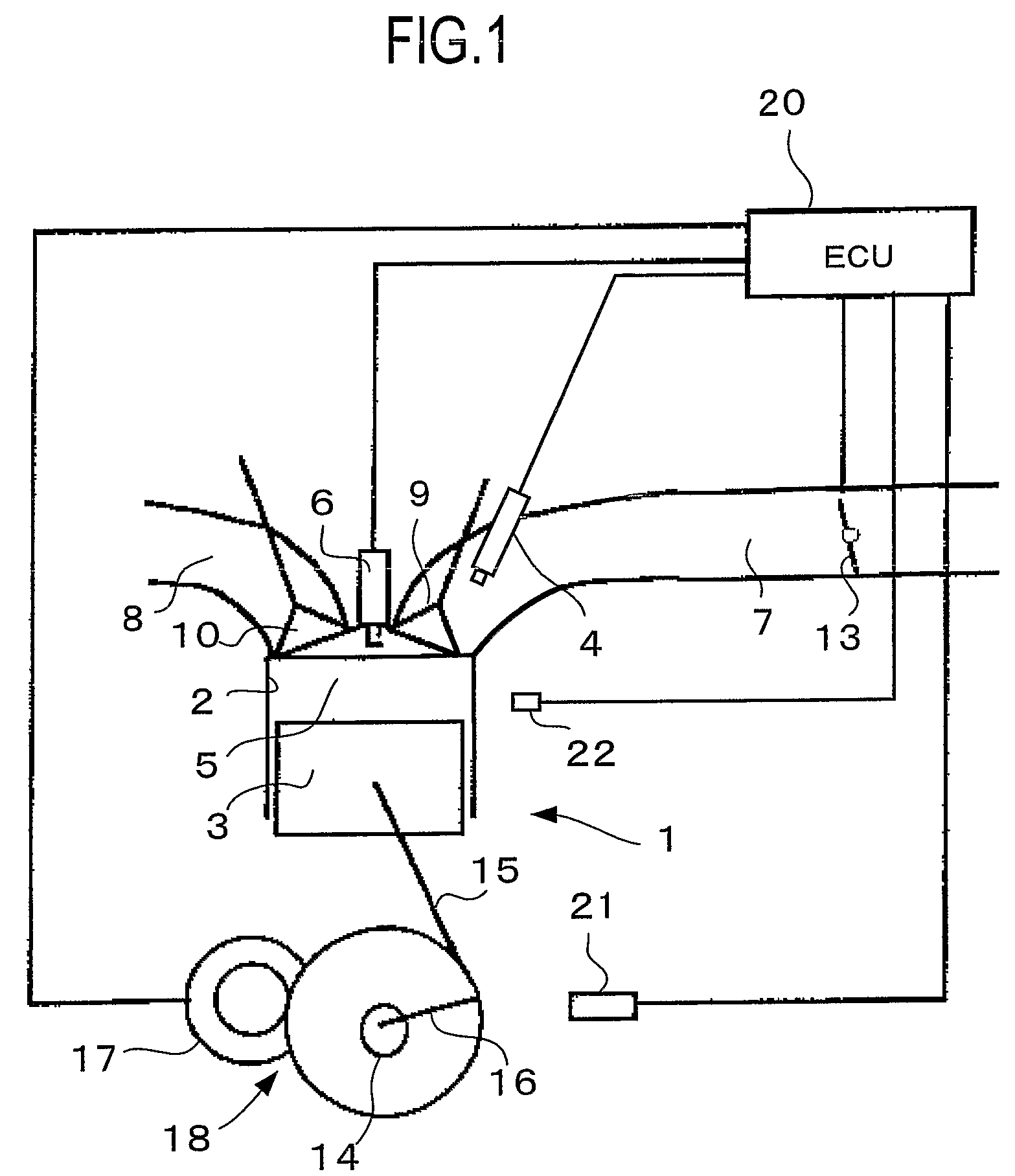

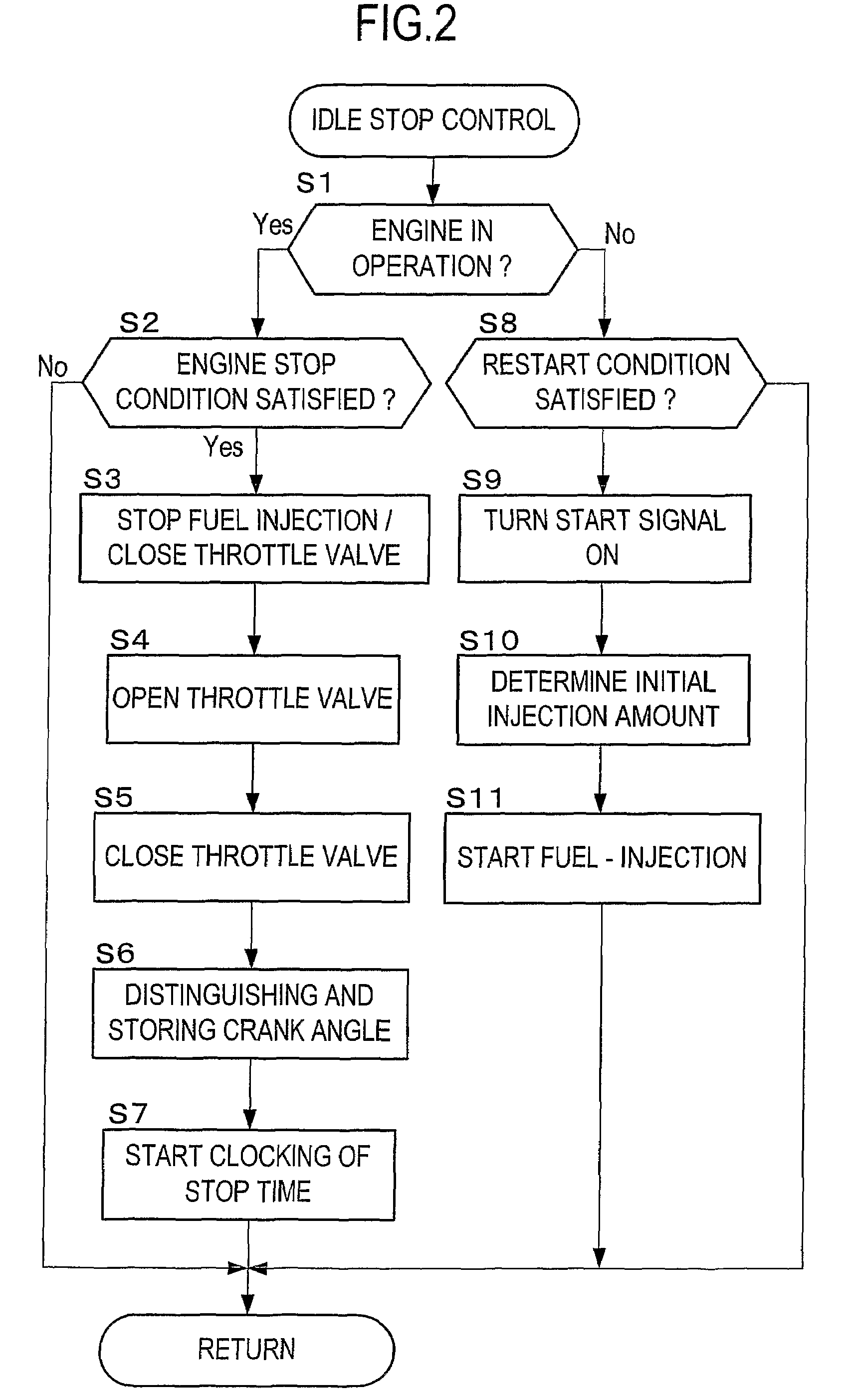

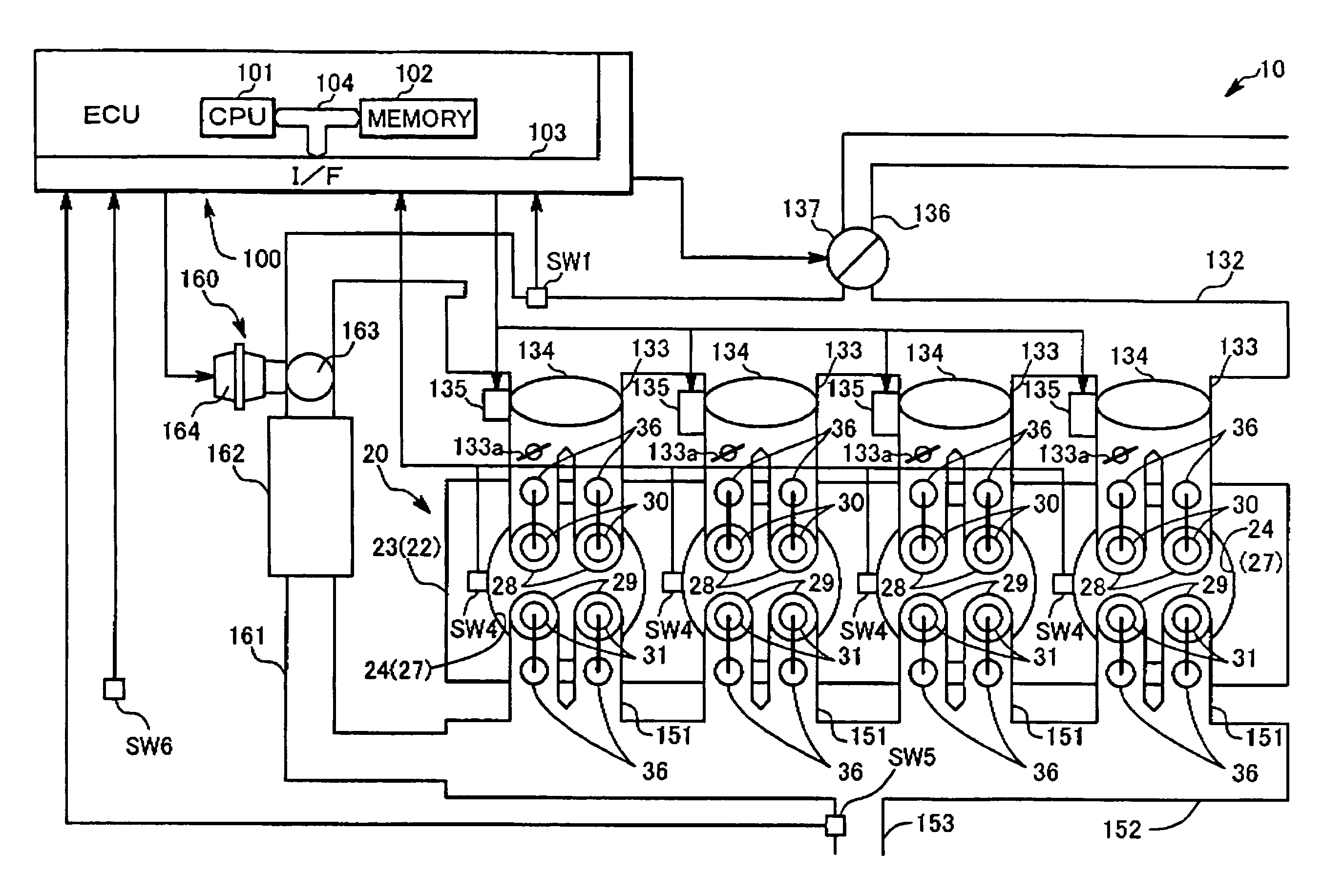

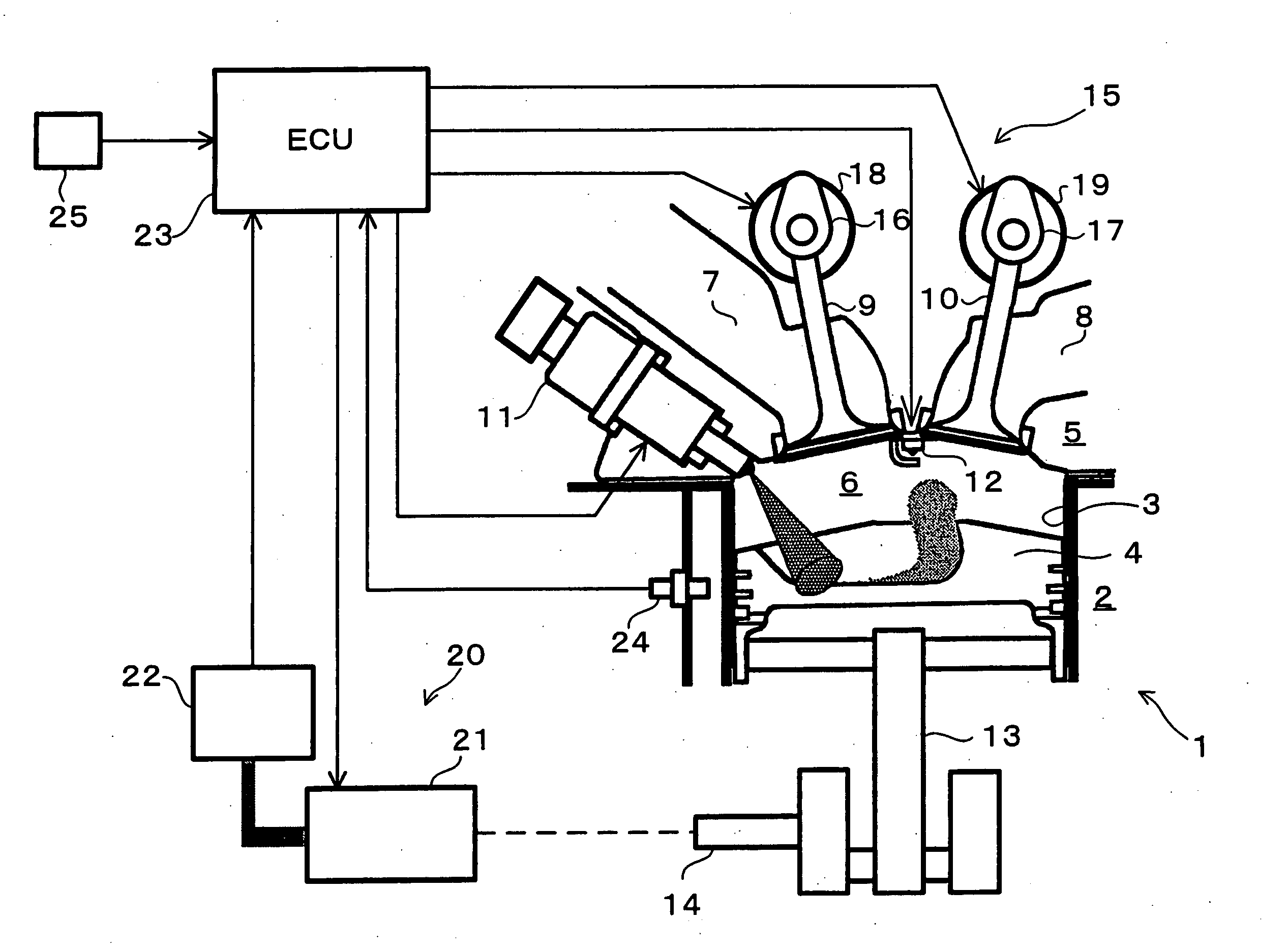

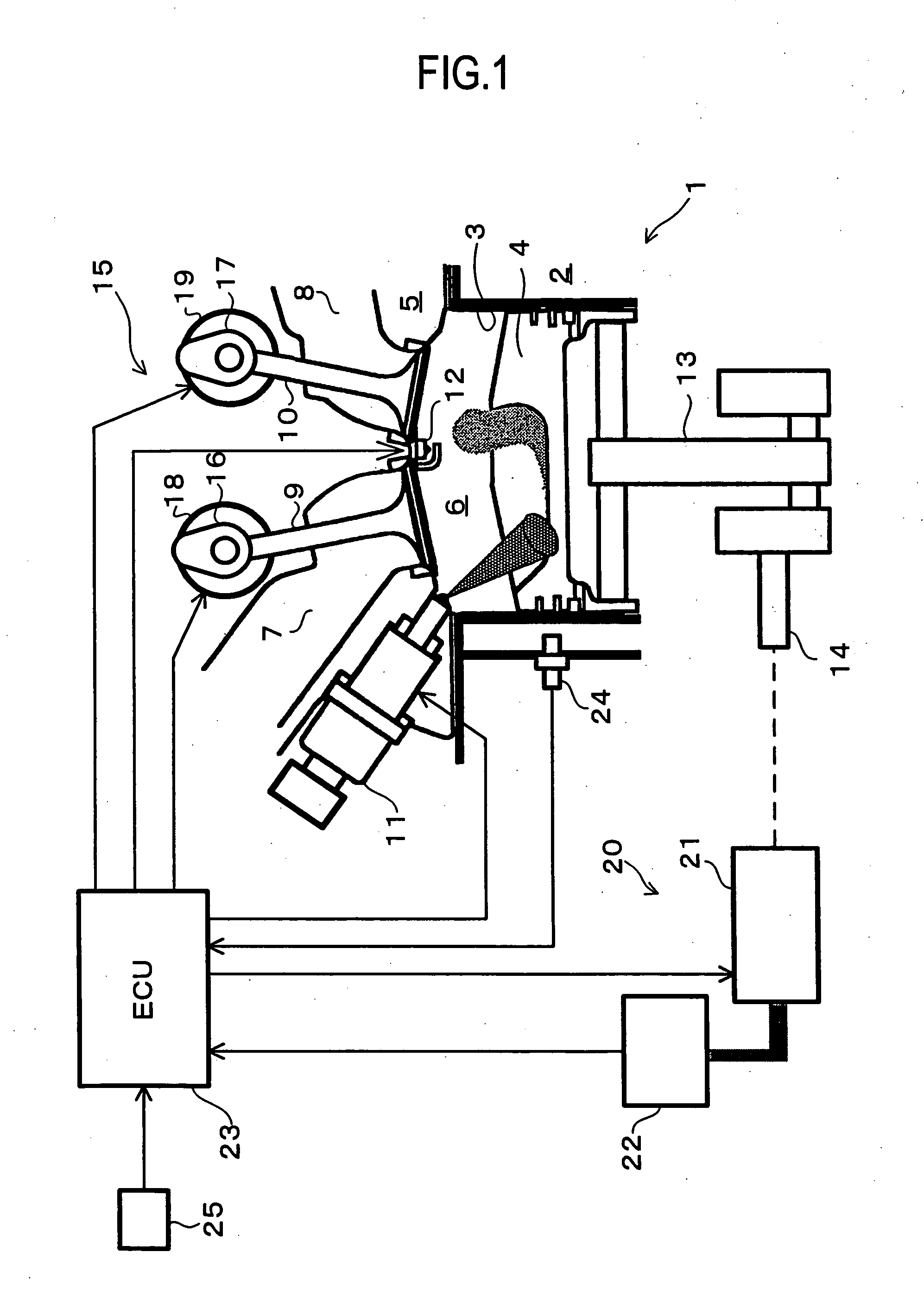

Start control apparatus for internal combustion engine

InactiveUS7472016B2Suppress spontaneous combustionAvoid it happening againAnalogue computers for vehiclesElectrical controlExternal combustion engineInternal combustion engine

There is provided a start control apparatus for an internal combustion engine (1) which starts the engine with injecting fuel to each cylinder (2) of the internal combustion engine in an intake stroke. The apparatus comprises a stop position distinction device (20) which distinguishes a piston position at a time of a stop of the internal combustion engine, and a fuel injection amount control device (20) which specifies a cylinder in which a piston stops in the intake stroke based on a distinction result of the stop position distinction device and which increases a fuel injection amount at starting for the specified cylinder more than a fuel injection amount for other cylinders.

Owner:TOYOTA JIDOSHA KK +1

Coal mining method for co-mining gas in mine

ActiveCN102061918ALower oxygen levelsSuppress spontaneous combustionUnderground miningSurface miningHigh concentrationHigh pressure

The invention relates to a coal mining method for co-mining gas in a mine. A method for injecting nitrogen in a sealed manner is adopted to close an upper drift and a lower drift of a stope face to ensure that the concentration of gas in a closed space is over 20%, the concentration of oxygen is lower than 12%, so that the explosive hazard of the gas is eliminated, and high-concentration gas in a roadway is drained so as to be utilized. A safety pressure-relief roadway needs to be remained in the mine with dangers of coal and gas outburst, and is used for releasing high-pressure gas generated by coal and gas outburst, and improving disaster resistant capability of the mine. An air regulating system is arranged in the closed space for regulating air, and a worker operates in the closed space under the condition that the safety protection is well done. Due to adoption of the method, the problem of gas explosion is solved fundamentally, the utilization ratio of gas is improved, fire disasters of the coal mine are eliminated fundamentally, the oxidation corrosion of various metal equipments is reduced, and simultaneously the equipment does not have anti-explosion requirements. As workers breathe air carried per se, the occurrence of respiratory occupational diseases is avoided. Therefore, the coal mining method for co-mining gas has extremely large popularization value.

Owner:CHINA UNIV OF MINING & TECH

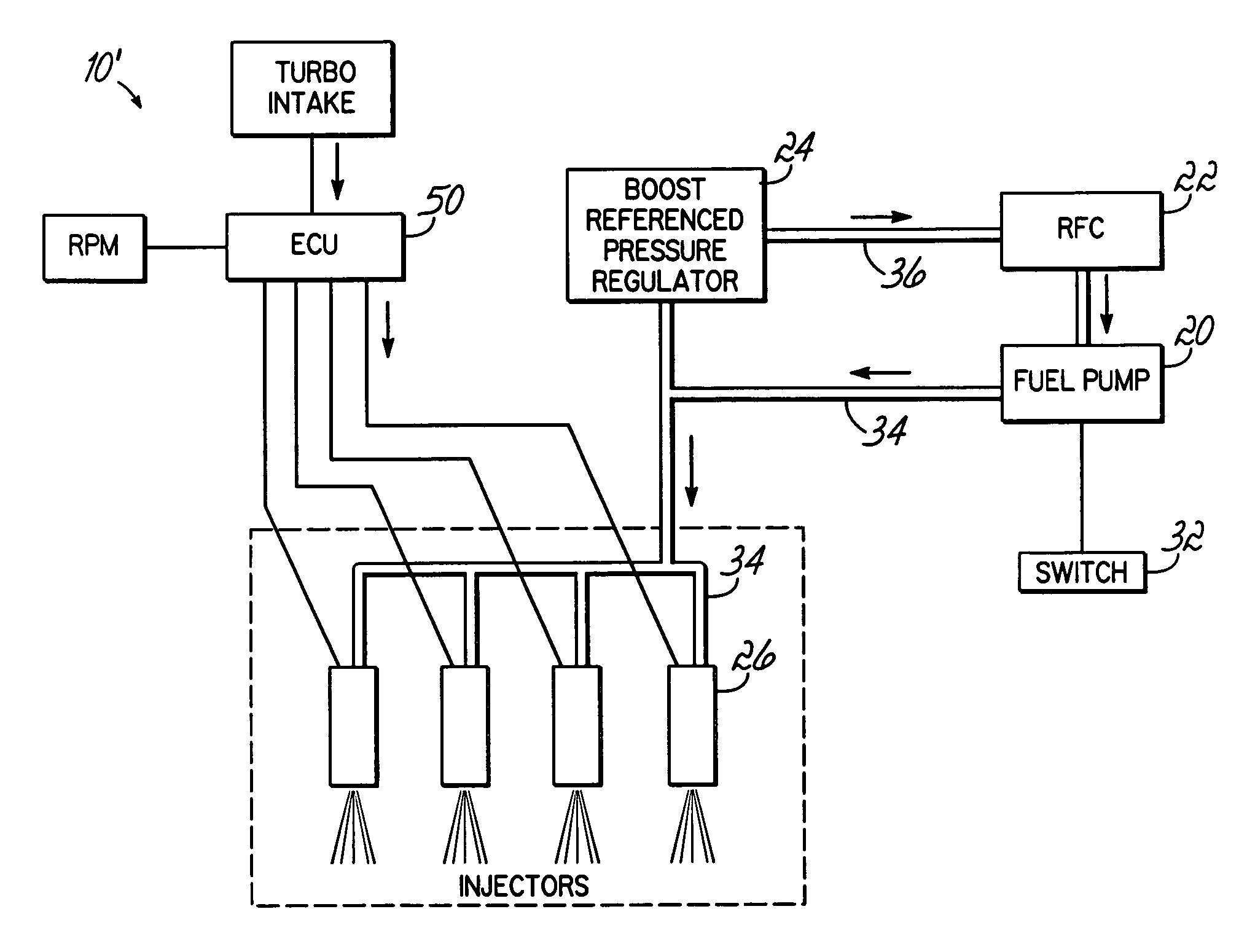

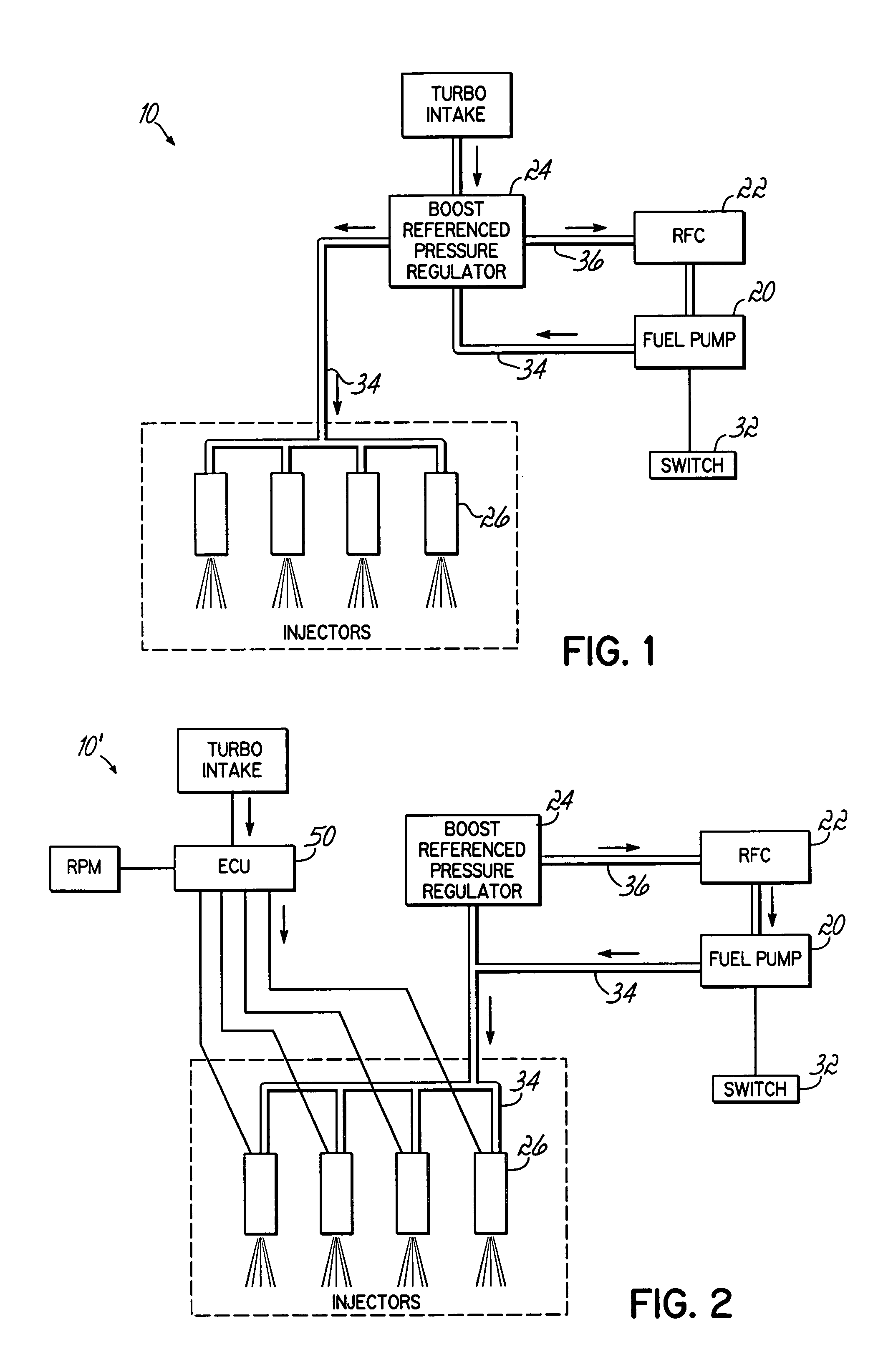

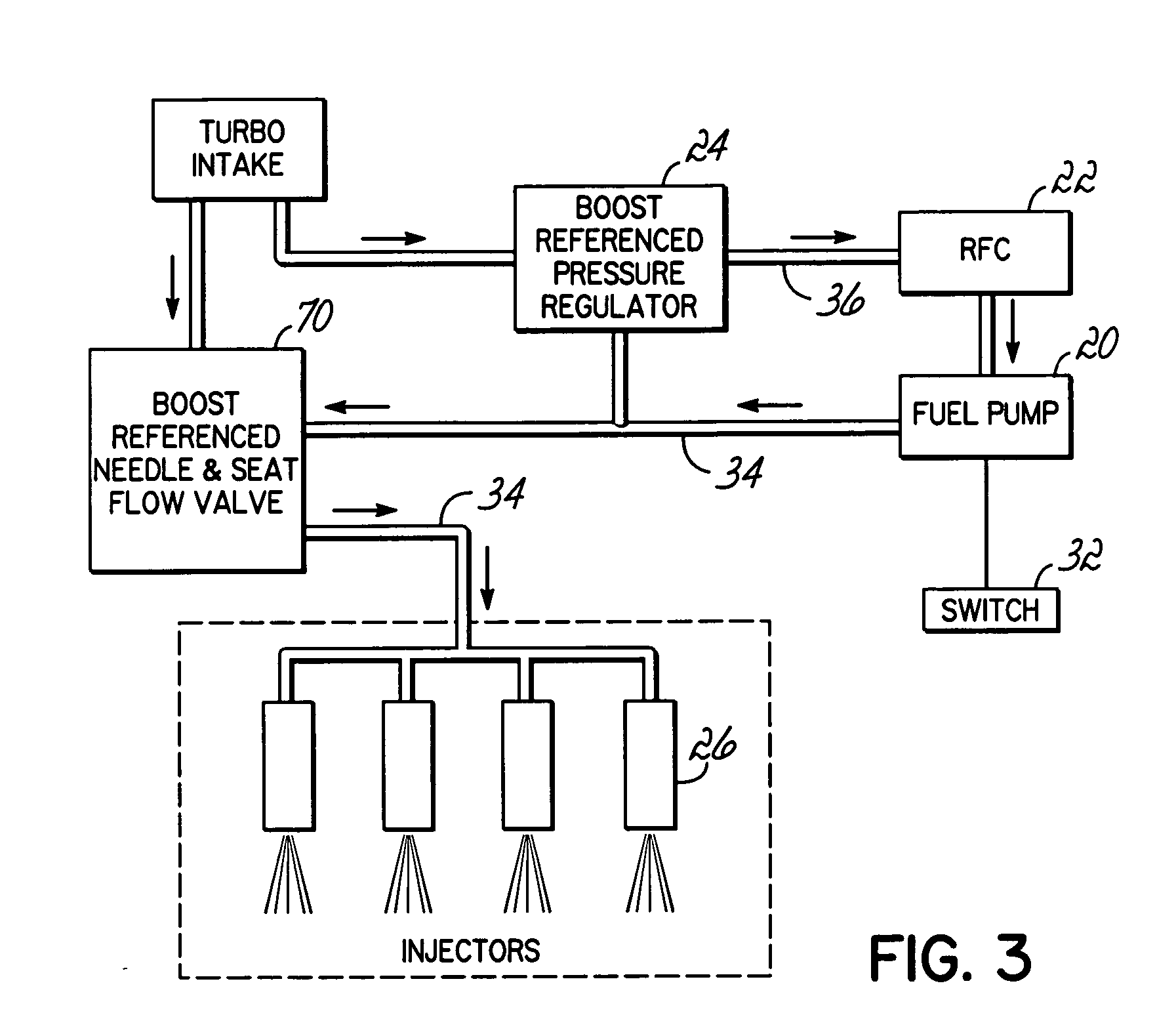

System and method for operating an internal combustion engine

InactiveUS20070119390A1Reduce waste costsSuppress spontaneous combustionElectrical controlNon-fuel substance addition to fuelEngineeringPetroleum

A method of operating an internal combustion engine generally comprises supplying a primary fuel having a first octane rating at to an intake manifold of the engine, supplying an amount of racing fuel concentrate to the intake manifold in response to a signal associated with engine load, and varying the amount of the racing fuel concentrate supplied to the intake manifold in response to variance of the signal. The racing fuel concentrate is a petroleum distillate racing fuel, such as Torco® Mach Series Accelerator Race Fuel Concentrate, that significantly increases the octane rating of the primary fuel when the concentrate is supplied to the manifold.

Owner:HERRMANN MARK L +1

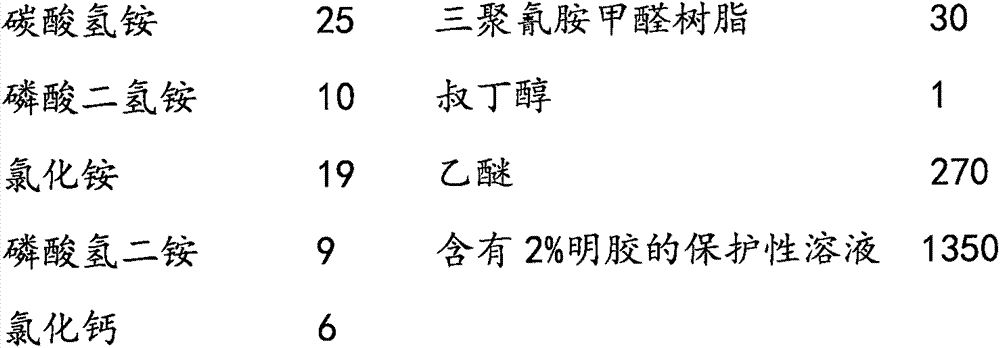

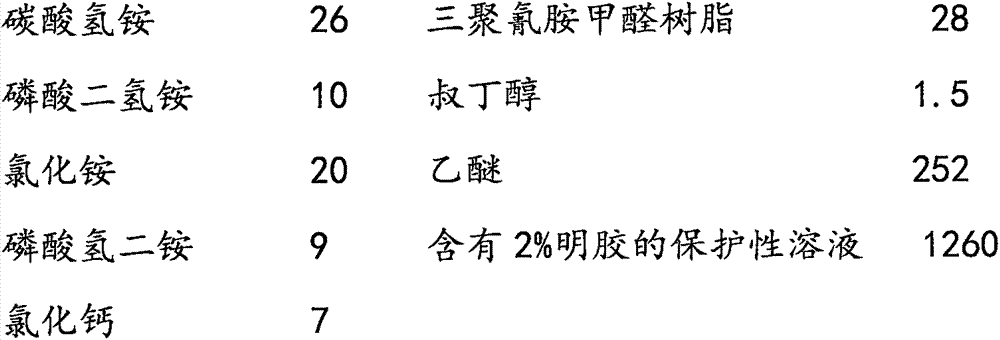

Capsule fire preventing and extinguishing material for coal bed fire and preparation method thereof

InactiveCN106913987ASmall water absorptionEasy to storeFire extinguisherWater bathsMelamine formaldehyde resin

The invention discloses a capsule fire preventing and extinguishing material for a coal bed fire and a preparation method of the capsule fire preventing and extinguishing material. The fire preventing and extinguishing material comprises a core material and a coating layer with which the outer side of the core material is coated. The core material is prepared from a powder stopping agent which is the mixed powder stopping agent comprising ammonium carbonate, ammonium dihydrogen phosphate, ammonium chloride, diammonium hydrogen phosphate and calcium chloride. The coating layer is prepared from an organic polymer which is melamine formaldehyde resin. The core material is coated with the coating layer through a water bath drying method. The mass fraction ratio of ammonium bicarbonate to ammonium dihydrogen phosphate to ammonium chloride to diammonium hydrogen phosphate to calcium chloride to melamine formaldehyde resin is 24-27:10-11:18-20:9-10:6-7:25-33:0.5. The capsule fire preventing and extinguishing material has the advantages of being nontoxic, free of pollution, convenient to store, capable of evenly covering a fire area, short in fire extinguishing period and good in effect, having the leakage stoppage, oxygen isolation, cooling and inhibition effects, being convenient to use and convenient and fast to operate and the like.

Owner:XIAN UNIV OF SCI & TECH

Spark-ignition gasoline engine

ActiveUS7484498B2Quantity minimizationReduce consumptionValve arrangementsElectrical controlLow speedTop dead center

Owner:MAZDA MOTOR CORP

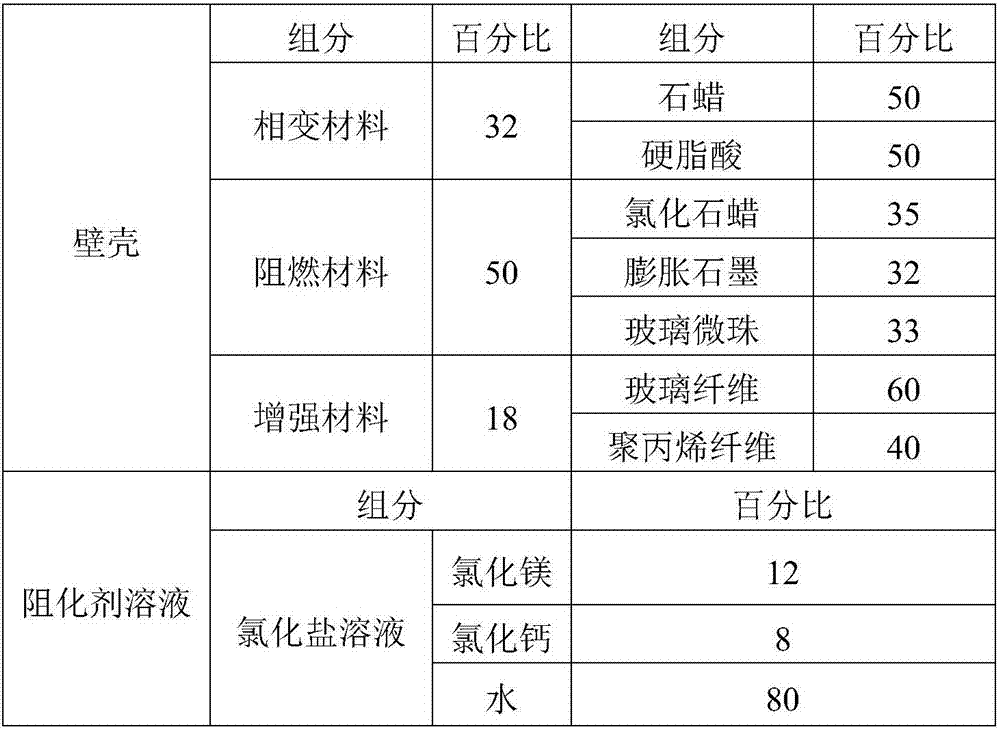

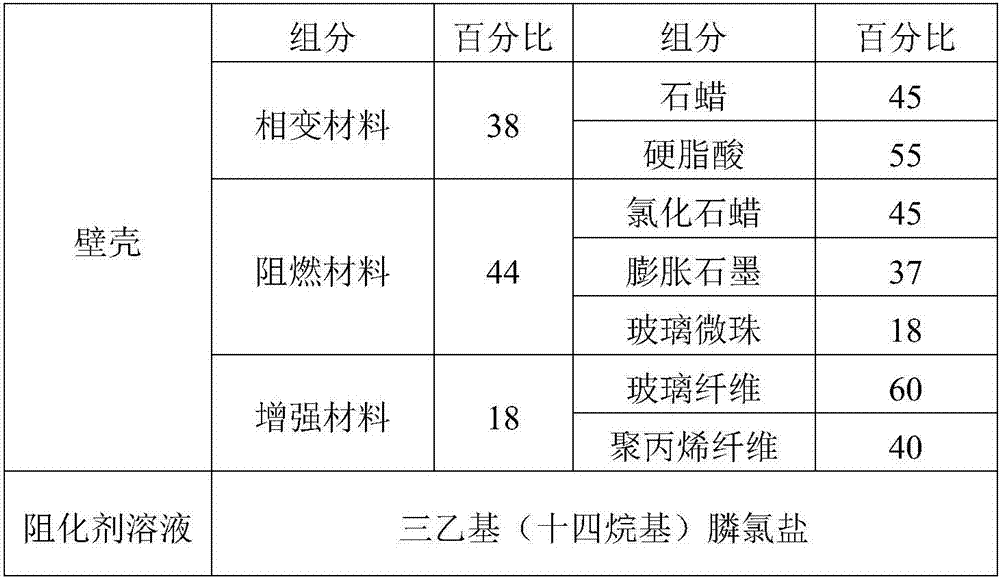

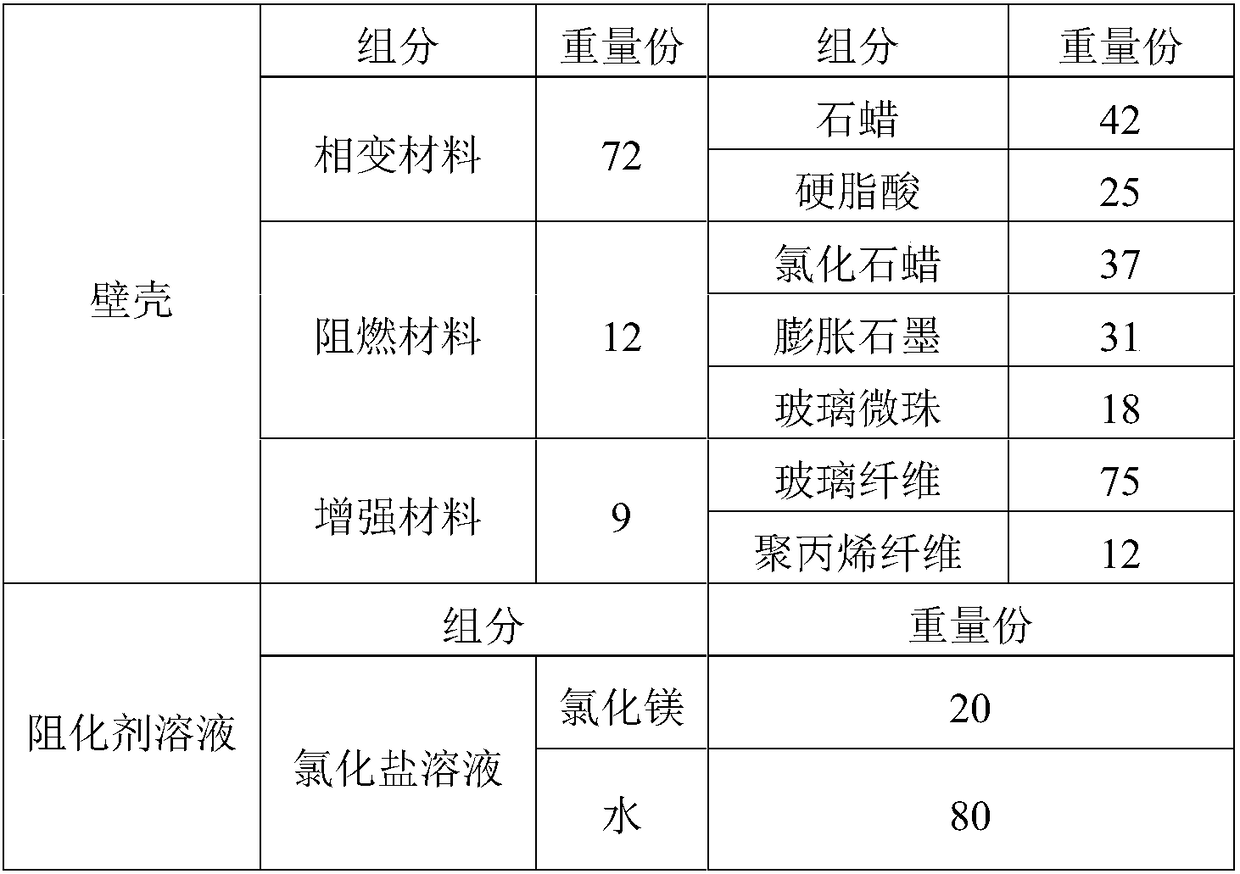

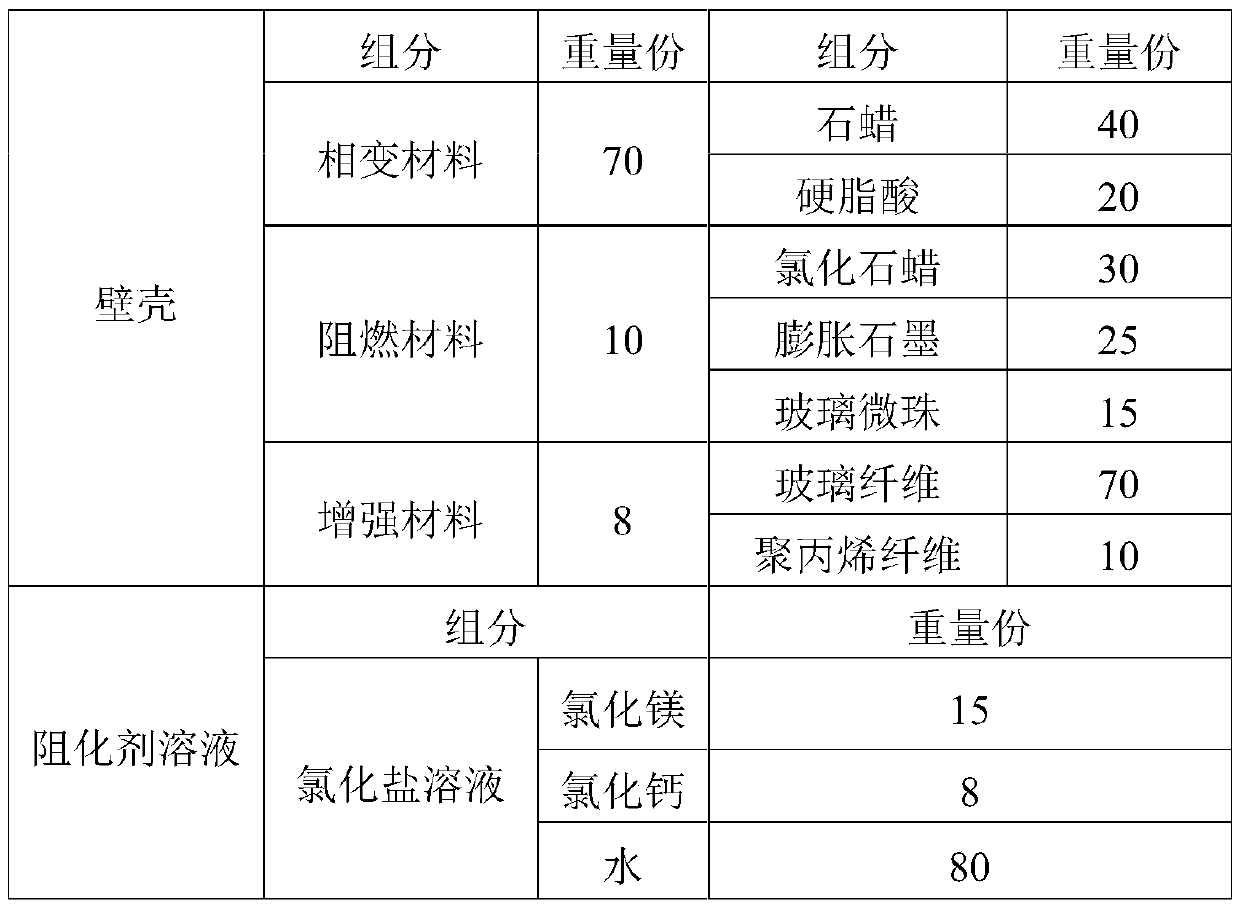

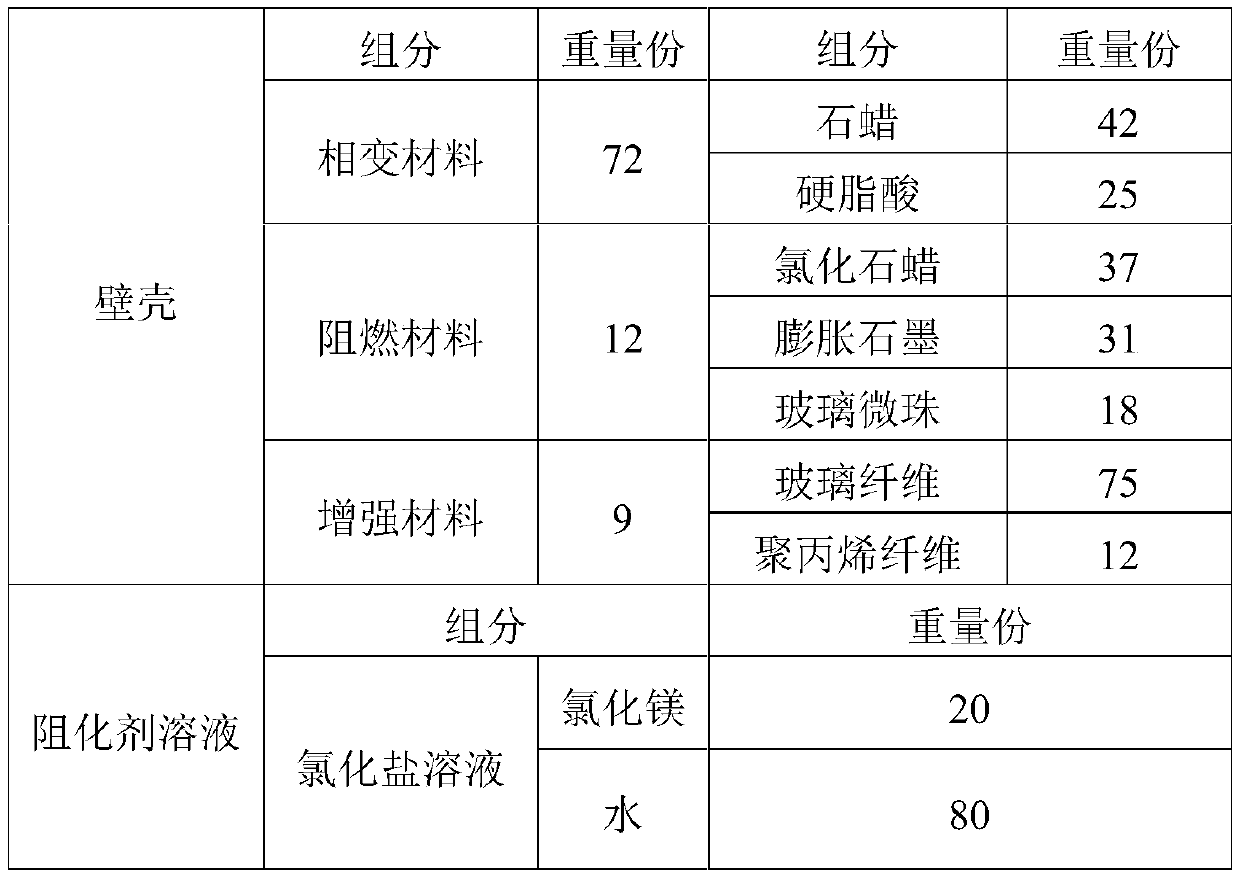

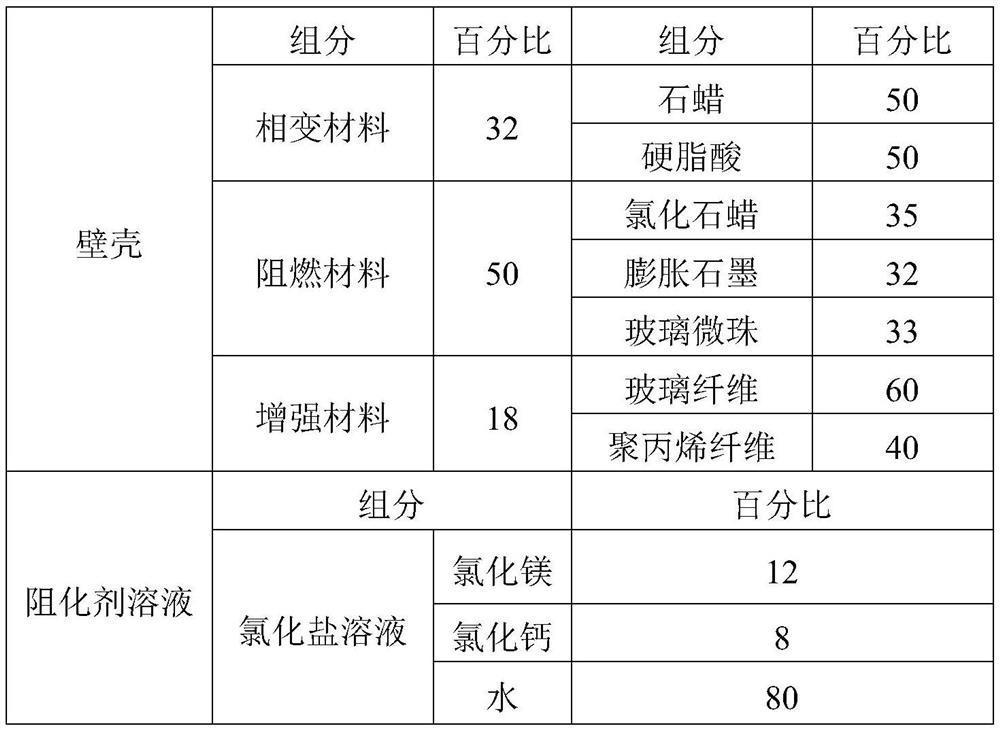

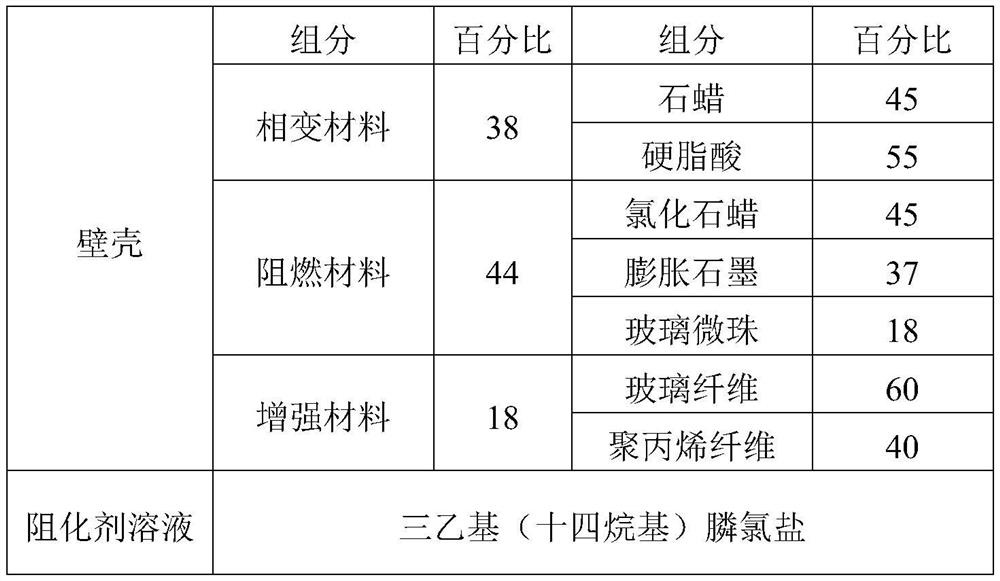

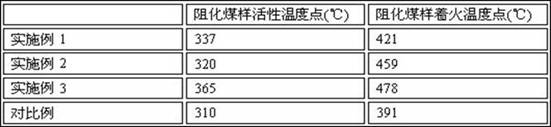

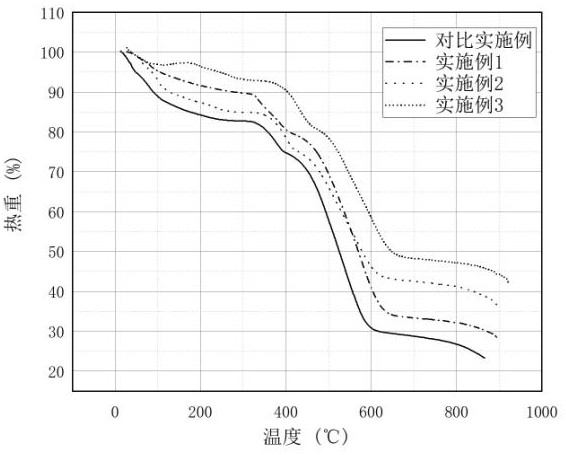

Phase change material temperature-sensitive coating as well as composite retarder and preparation method thereof

ActiveCN107955632AGood effectOvercome the disadvantages of easy failureDust removalFire preventionCoal briquetteHigh water content

The invention discloses phase change material temperature-sensitive coating as well as a composite retarder and a preparation method thereof. A temperature-sensitive phase change material is used as acoating shell, the composite retarder with high water content is directly and externally coated with a composite phase change material, and the composite material takes phase change materials such asparaffin and stearic acid as matrix, uses glass fibers, polypropylene fibers and the like as aggregates and is prepared from flame retardant materials such as magnesium hydroxide, chlorinated paraffin, expanded graphite and glass beads. The phase change material temperature-sensitive coating improves the hardness and ignition point of the phase change material, enables coal briquettes not easy tobreak when falling down, and not only overcomes the defect that the traditional fire preventing and extinguishing retarder is easy to fail, but also well maintains the properties of the retarder; furthermore, the phase change material is more sensitive to temperature rise and can be melted before the critical temperature of coal spontaneous combustion, so that the retarder in the coating can be fully released so as to inhibit the coal spontaneous combustion. The preparation system adopts a modular design, is simple in structure and easy to operate, and can be used for efficiently producing and processing the retarder for the coating.

Owner:CHINA UNIV OF MINING & TECH

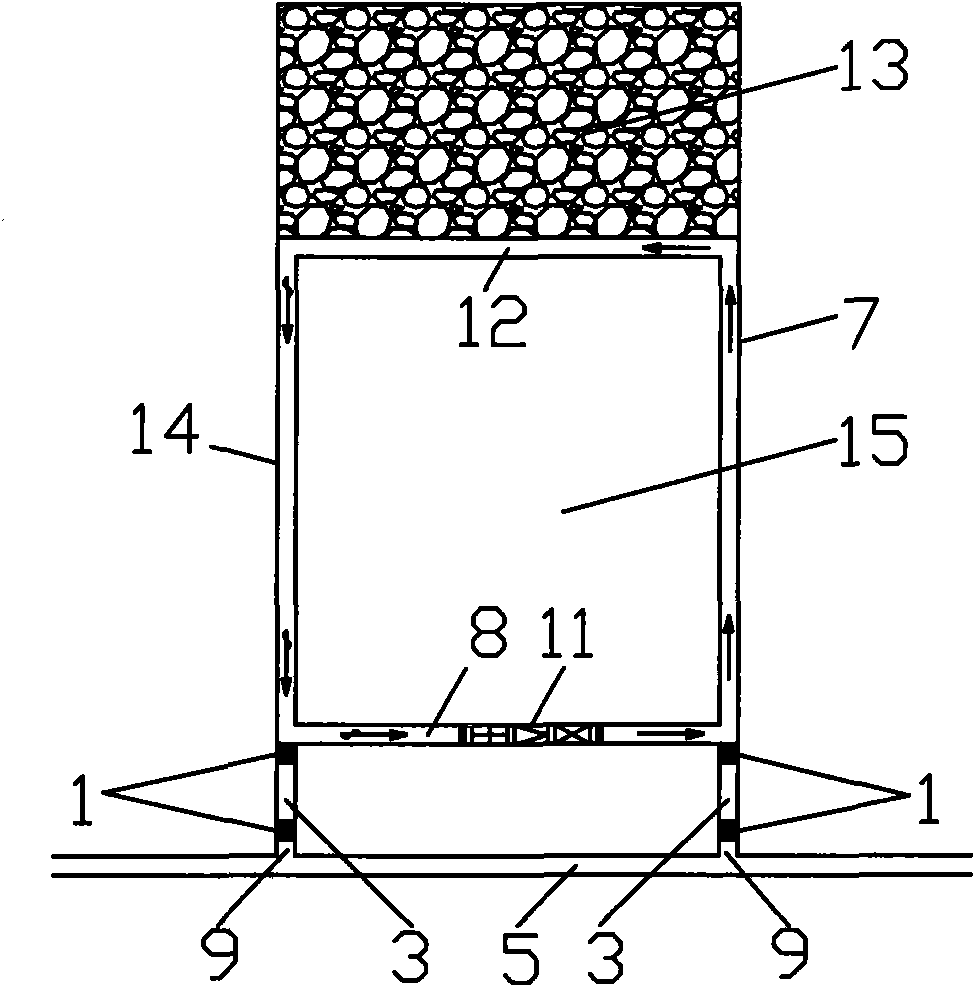

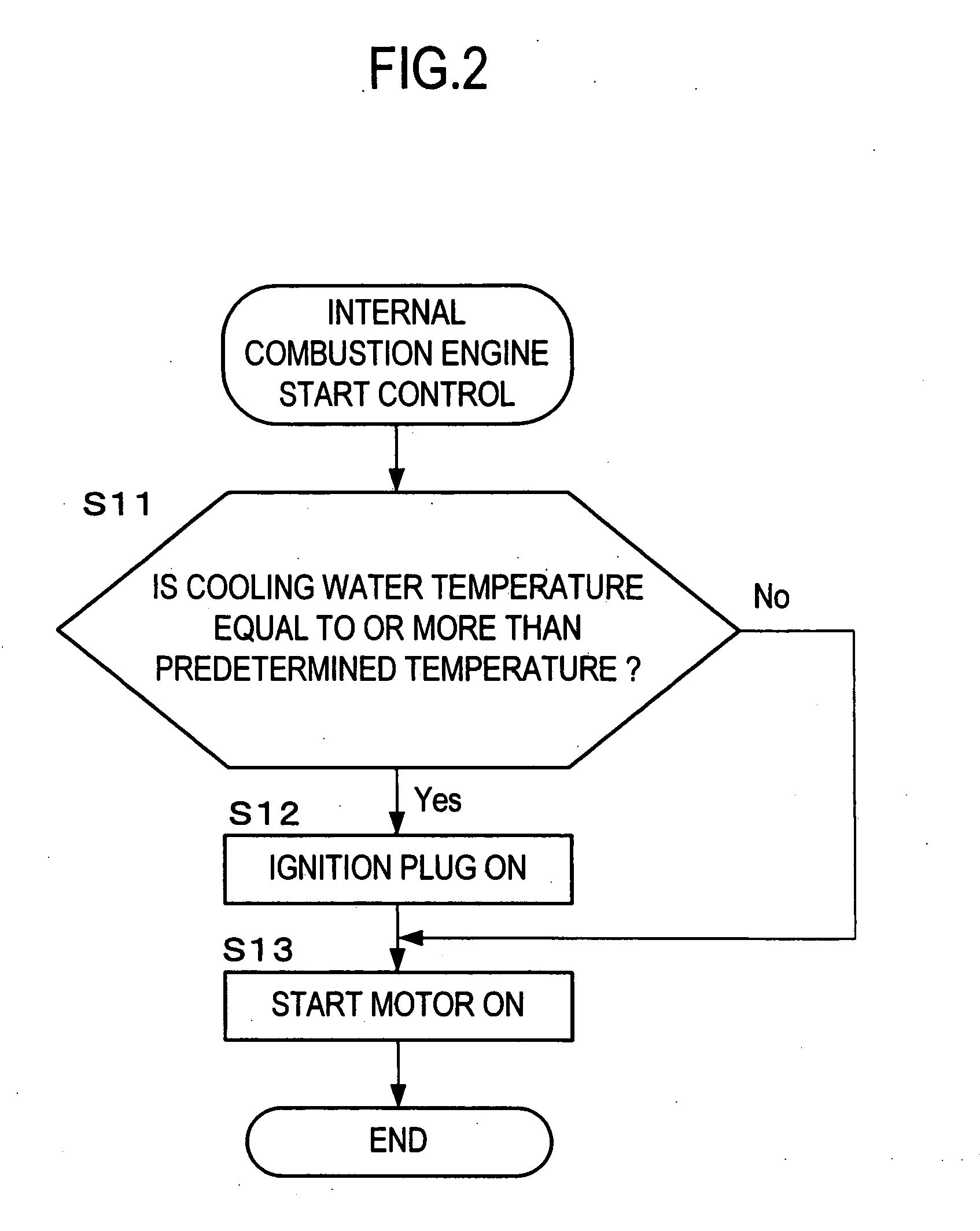

Start control apparatus of internal combustion engine

ActiveUS20060096565A1Suppress spontaneous combustionValve arrangementsElectrical controlCombustion chamberEngineering

A start control apparatus of an internal combustion engine comprises an ignition device for igniting an air-fuel mixture in a combustion chamber of the internal combustion engine, a start demanding device for demanding a start of the internal combustion engine, a starting device for starting the internal combustion engine, a determining device for determining a possibility of a self-ignition of the internal combustion engine at a time when a start demand is issued from the start demanding device, and a start procedure control device for igniting the air-fuel mixture in the combustion chamber by the ignition device after the start demand from the start demanding device in the case where the determining device determines that the possibility of the self-ignition of the internal combustion engine is higher than a predetermined level, thereafter starting the internal combustion engine by the starting device.

Owner:TOYOTA JIDOSHA KK

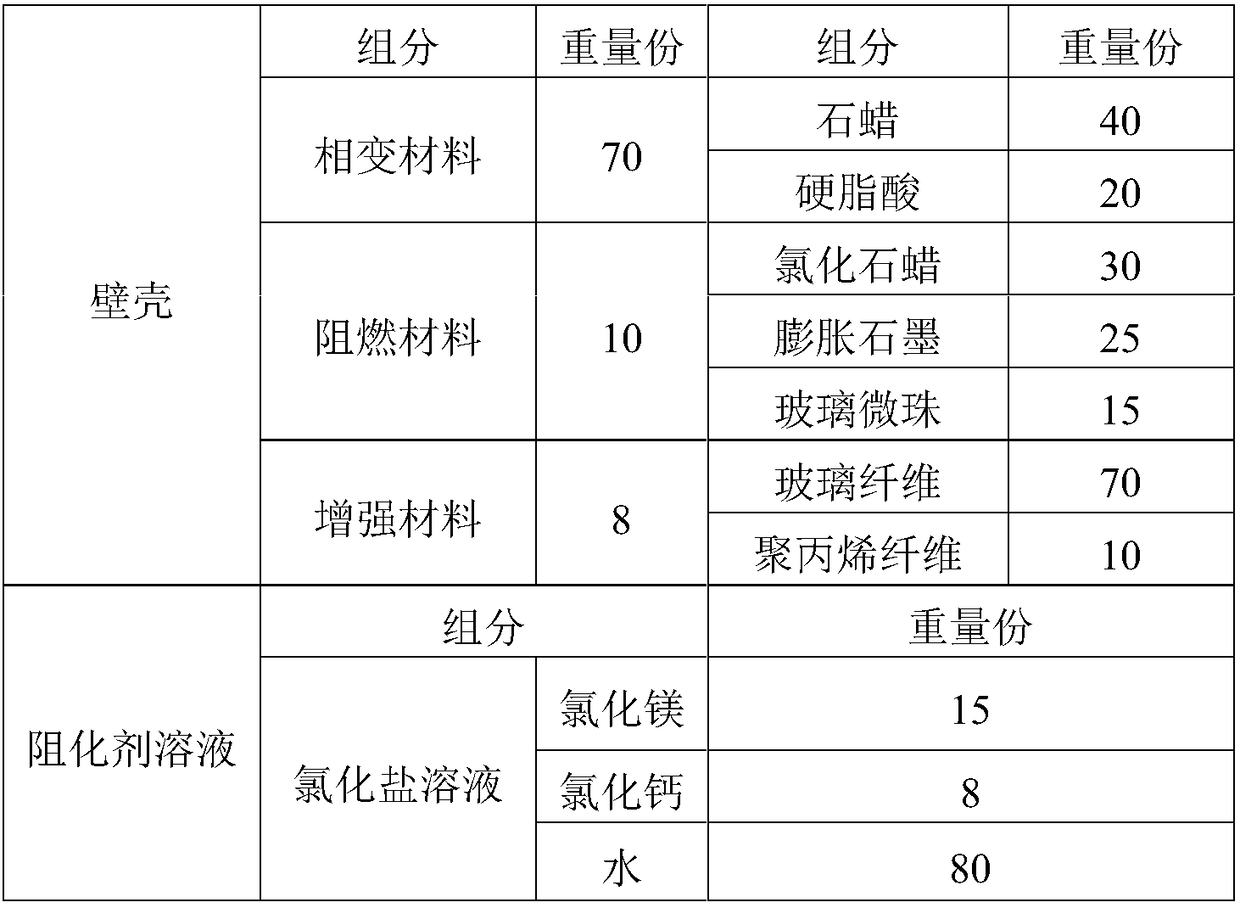

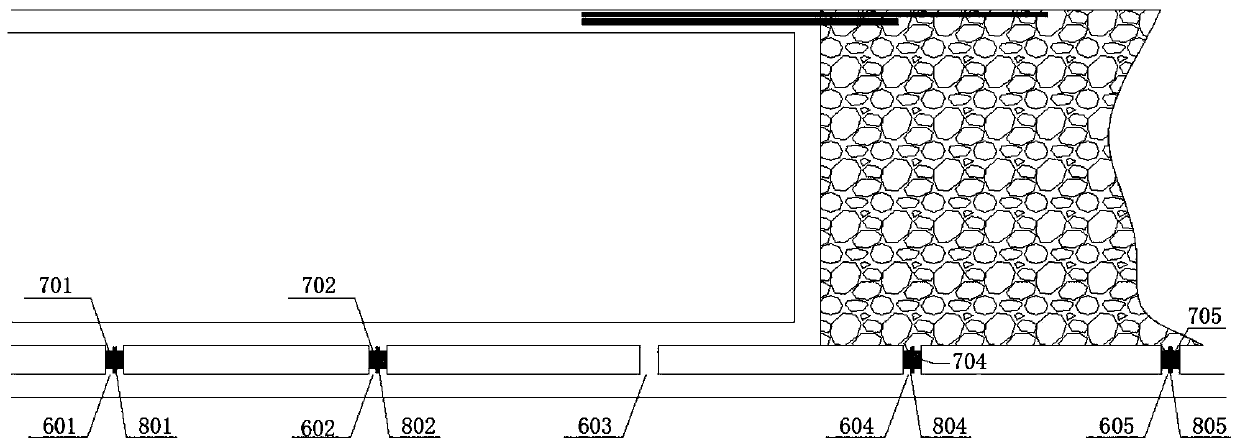

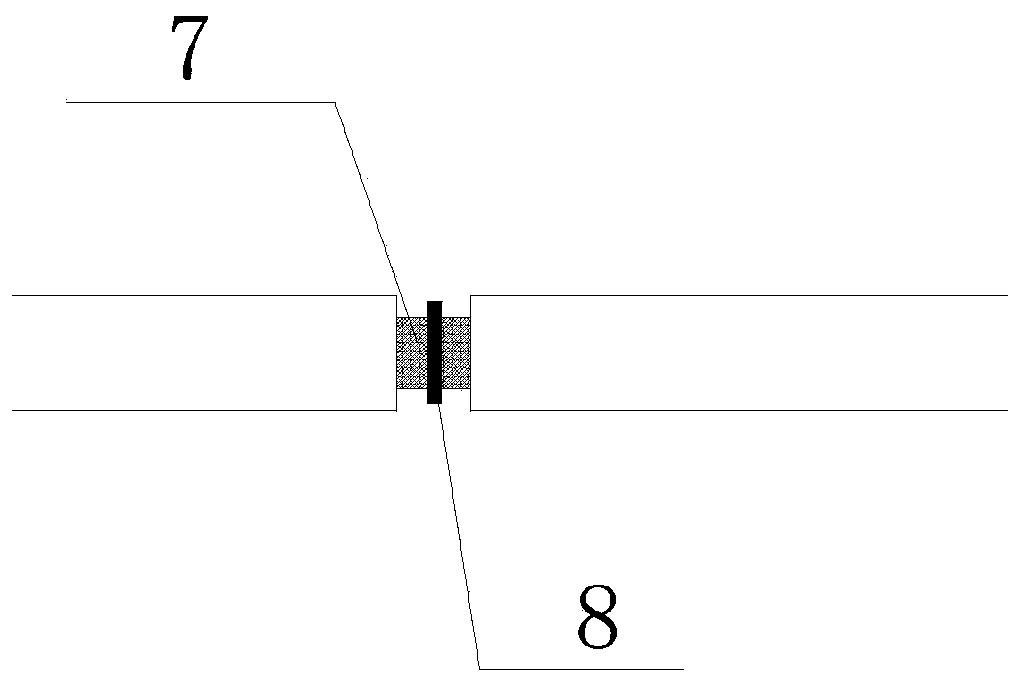

Composite microcapsule stopping agent for preventing coal spontaneous combustion and preparation method of composite microcapsule stopping agent

The invention relates to a composite microcapsule stopping agent for preventing coal spontaneous combustion and a preparation method of the composite microcapsule stopping agent. The stopping agent comprises a wall shell and a stopping agent solution sealed in the wall shell. The wall shell is mainly prepared from the following components of, by weight, 70-80 parts of phase-change materials, 10-20parts of flame-resistant materials and 8-12 parts of reinforcing materials. The stopping agent solution is ionic liquid or a chloride solution. The stopping agent solution is evenly composited to thecomposite phase-change materials to obtain a mixed emulsion, the mixed emulsion is sprayed into a dry porous medium in an emulsion-drop mode through a spraying device to enable mixed emulsion drops to be further atomized into mist drops with the particle diameter of 30-50 [mu]m, and after the mixed emulsion which is formed into the mist drops makes contact with cold air, the composite phase-change mixed materials are quickly solidified to wrap the stopping agent solution to form the composite microcapsule stopping agent. The stopping agent can be evenly distributed in coal seams, the coveragerange is wide, accumulation of heat is prevented, coal spontaneous combustion is resisted, and the preparation method can efficiently produce and process the composite microcapsule stopping agent.

Owner:CHINA UNIV OF MINING & TECH

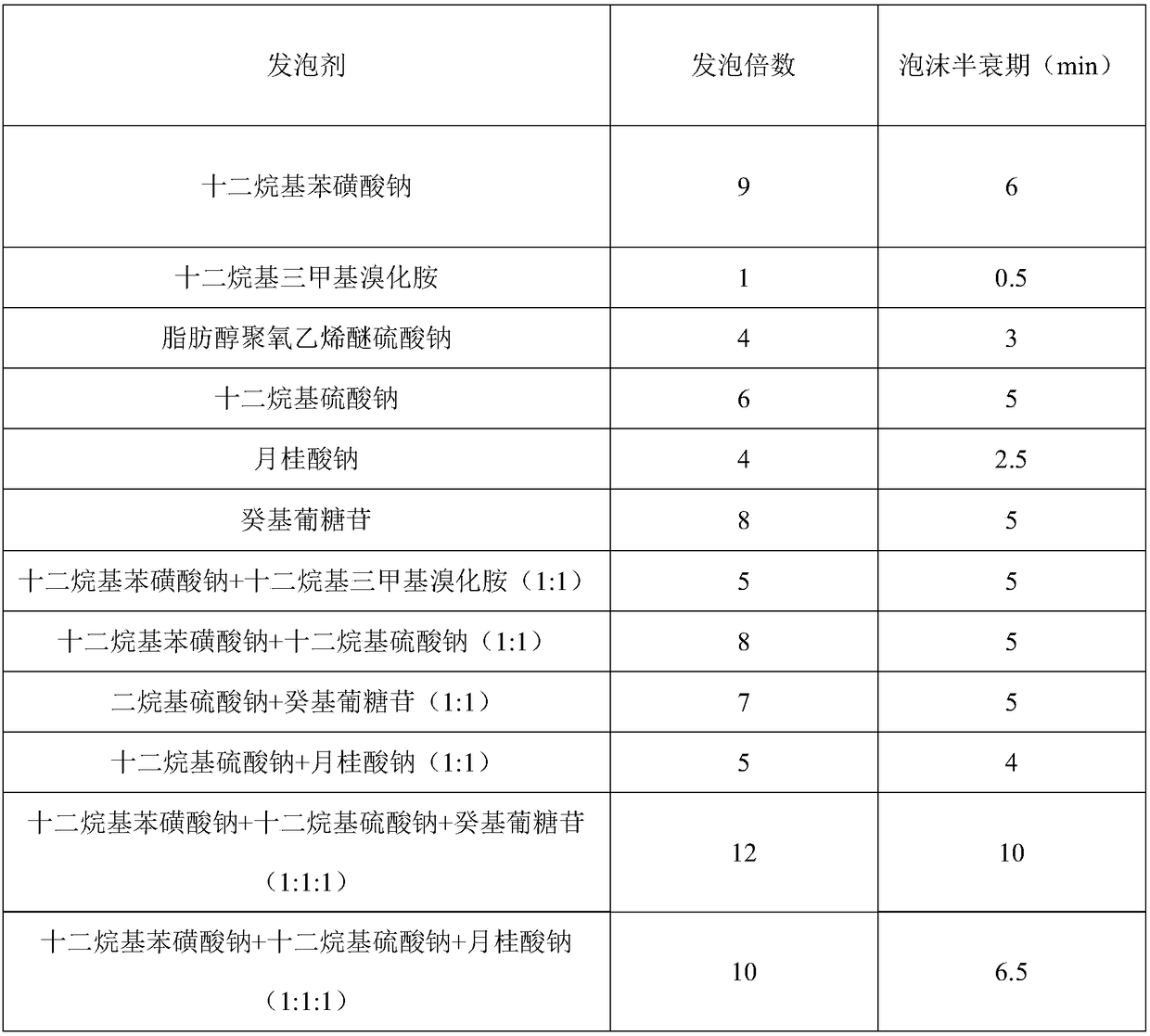

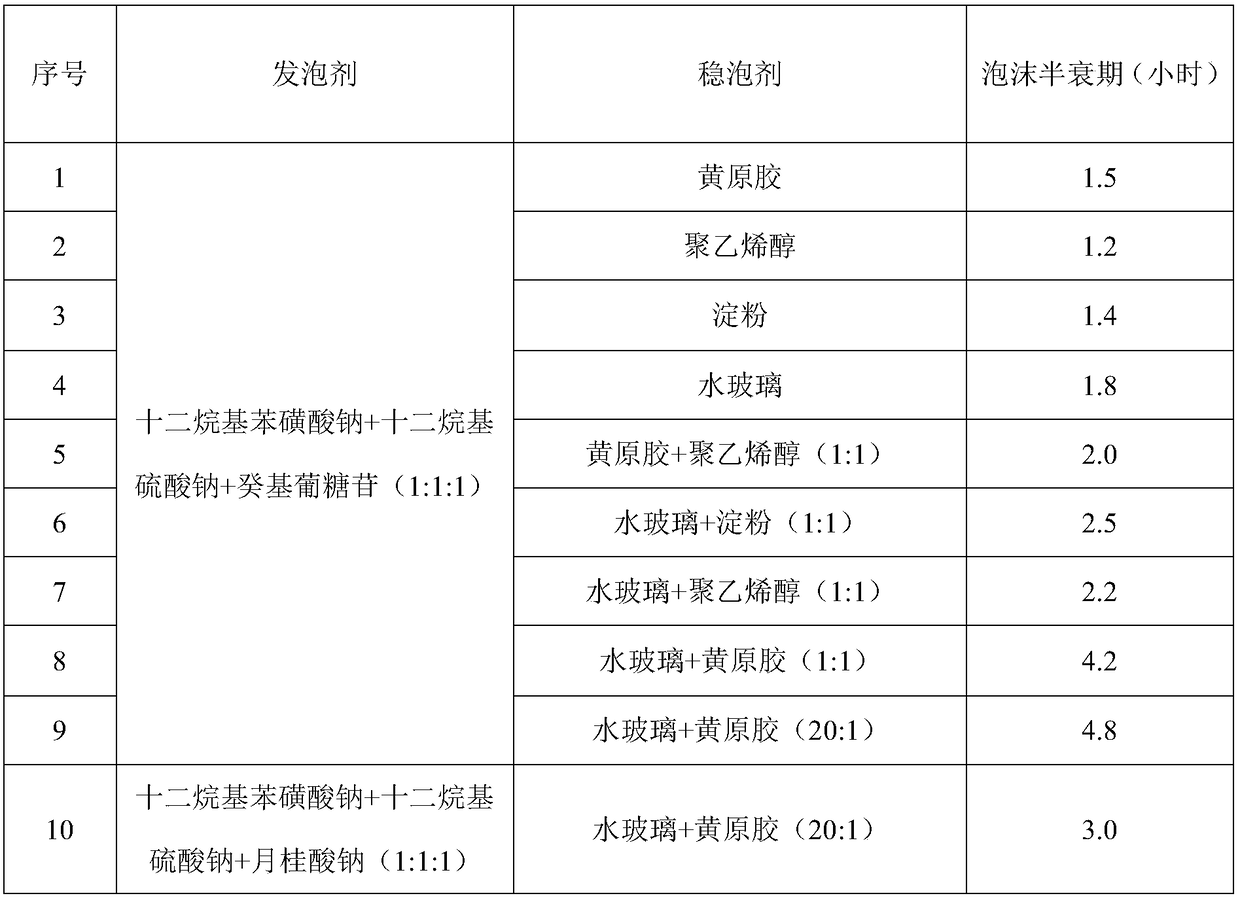

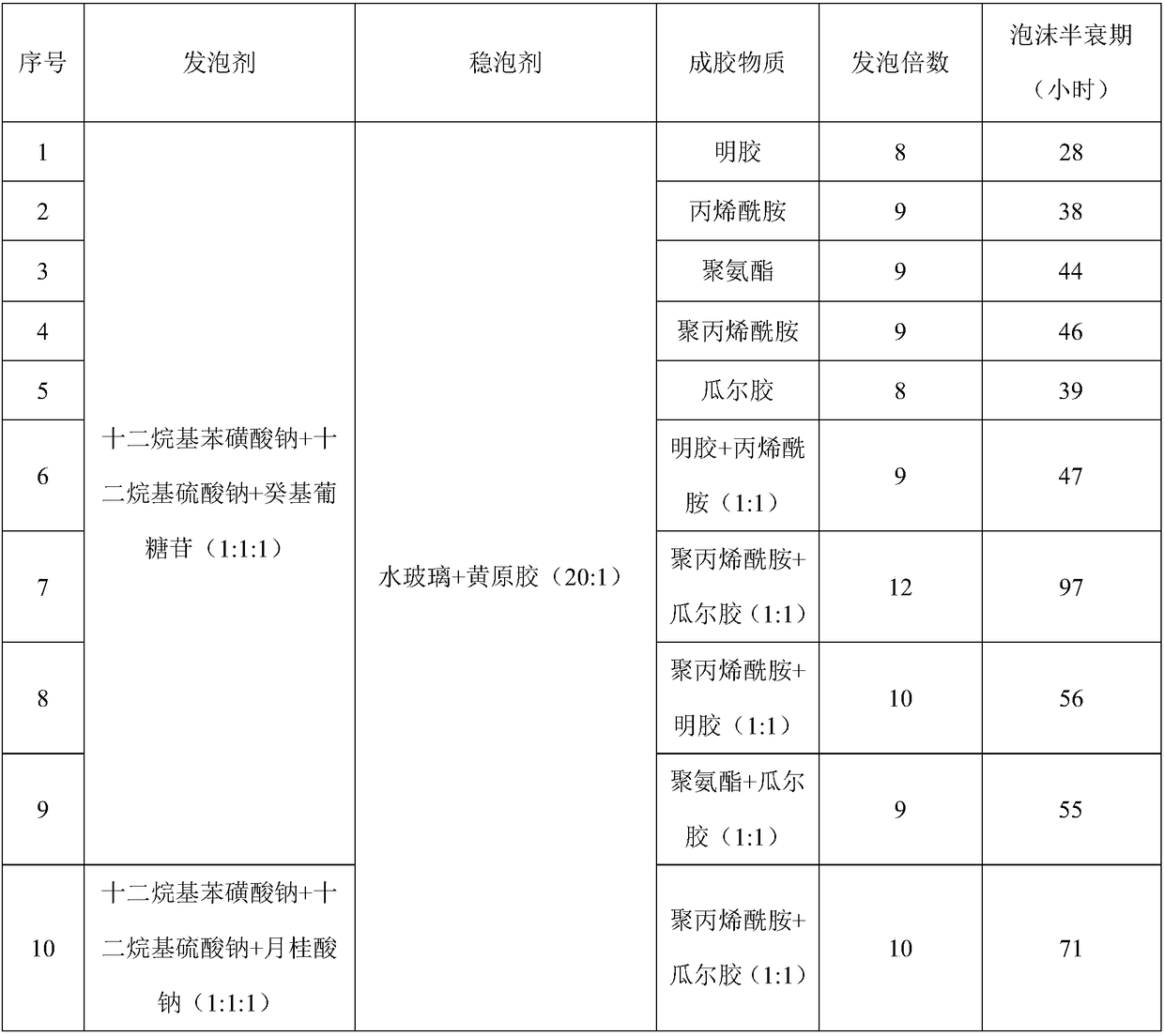

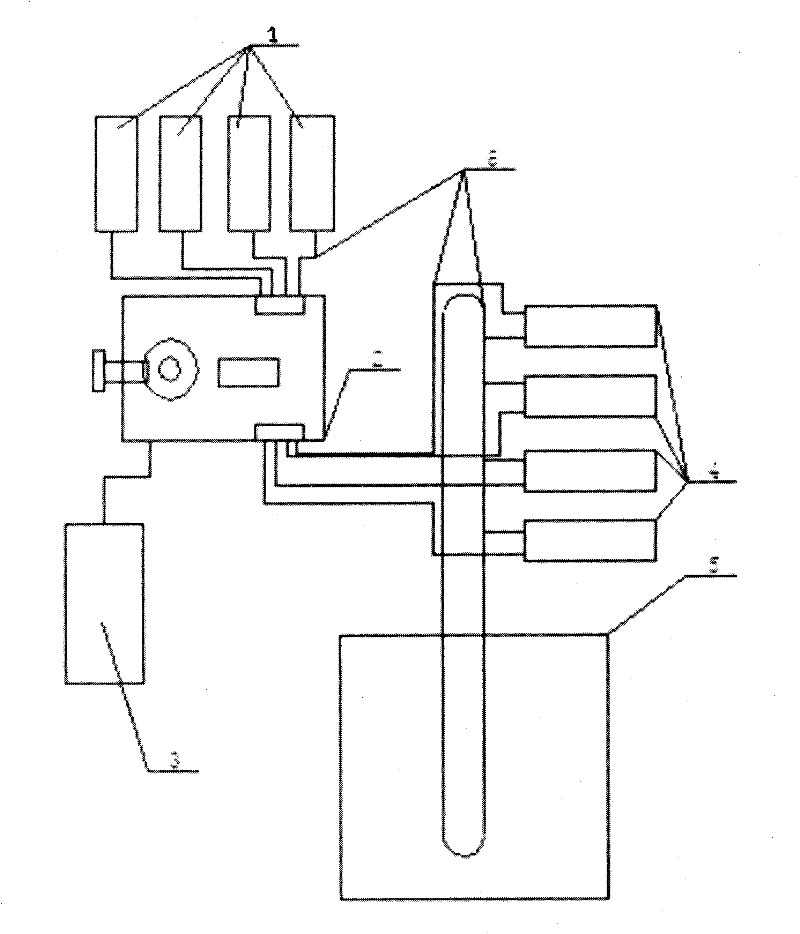

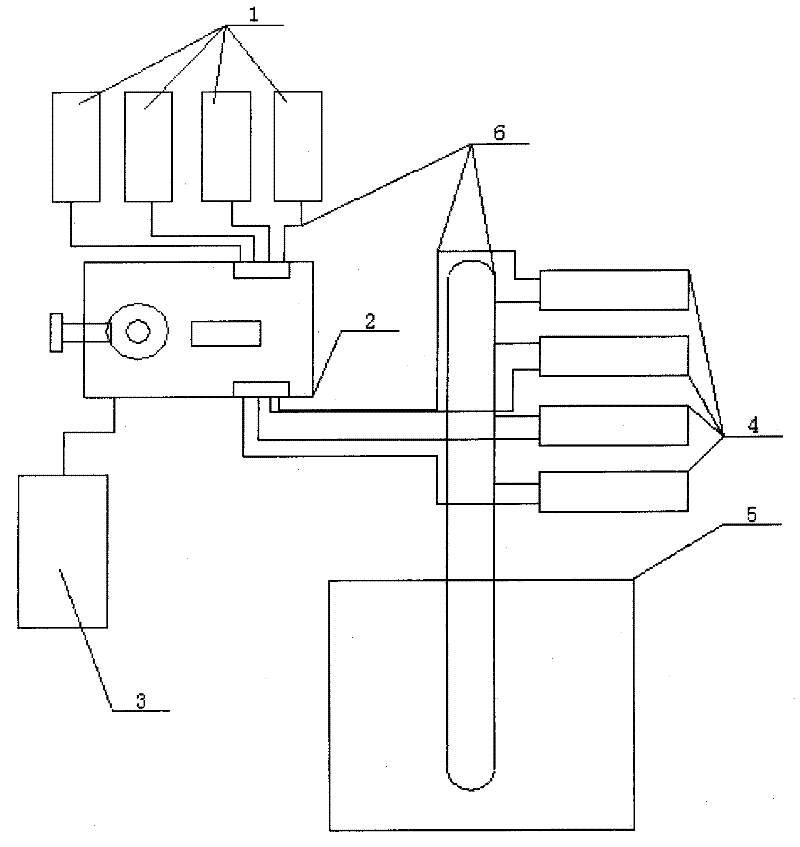

Gel foam used for preventing and treating spontaneous combustion of goaf coal and application

InactiveCN107060874ASuppress spontaneous combustionImprove stabilityDust removalFire preventionCoal spontaneous combustionFoaming agent

The invention discloses gel foam used for preventing and treating spontaneous combustion of goaf coal and application. The gel foam comprises the raw materials of, by weight, 0.4%-0.6% of a foaming agent, 2%-3% of a foam stabilizing agent, 0.6%-0.8% of a gelling substance and the balance water, wherein the foaming agent is a composite foaming agent composed by mixing lauryl sodium sulfate, sodium dodecyl benzene sulfonate and dicyl polyglycoside, the foam stabilizing agent is a mixture of water glass and xanthan gum, and the gelling substance is a mixture of polyacrylamide and guar gum. After the substances are subjected to mixing foaming, the formed gel foam has the characteristics that the water retention time is long and the half foam life period exceeds four days. After the gel foam is injected into a liable-spontaneous-combustion coal area, coal bodies can be effectively coated, residual coal is subjected to cooling, after the foam is burst, a layer of oxygen-insulating film can be formed on the surface of the residual coal to insulate the coal from making contact with oxygen, and coal spontaneous combustion can be enduringly prevented and treated.

Owner:CHINA UNIV OF MINING & TECH

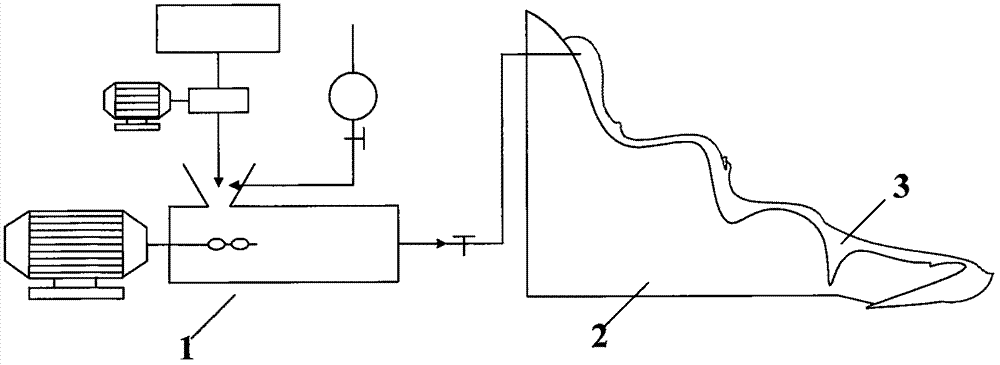

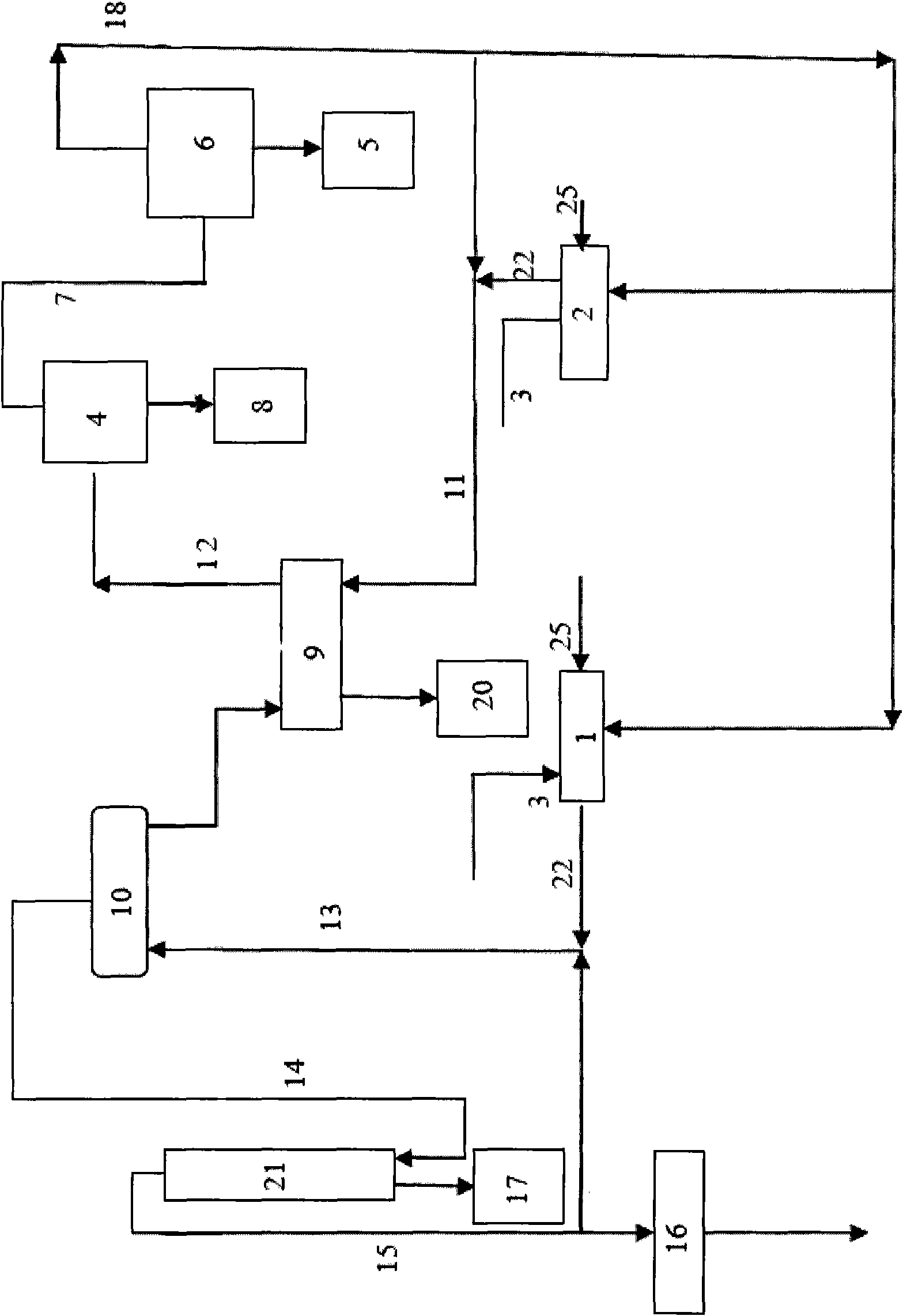

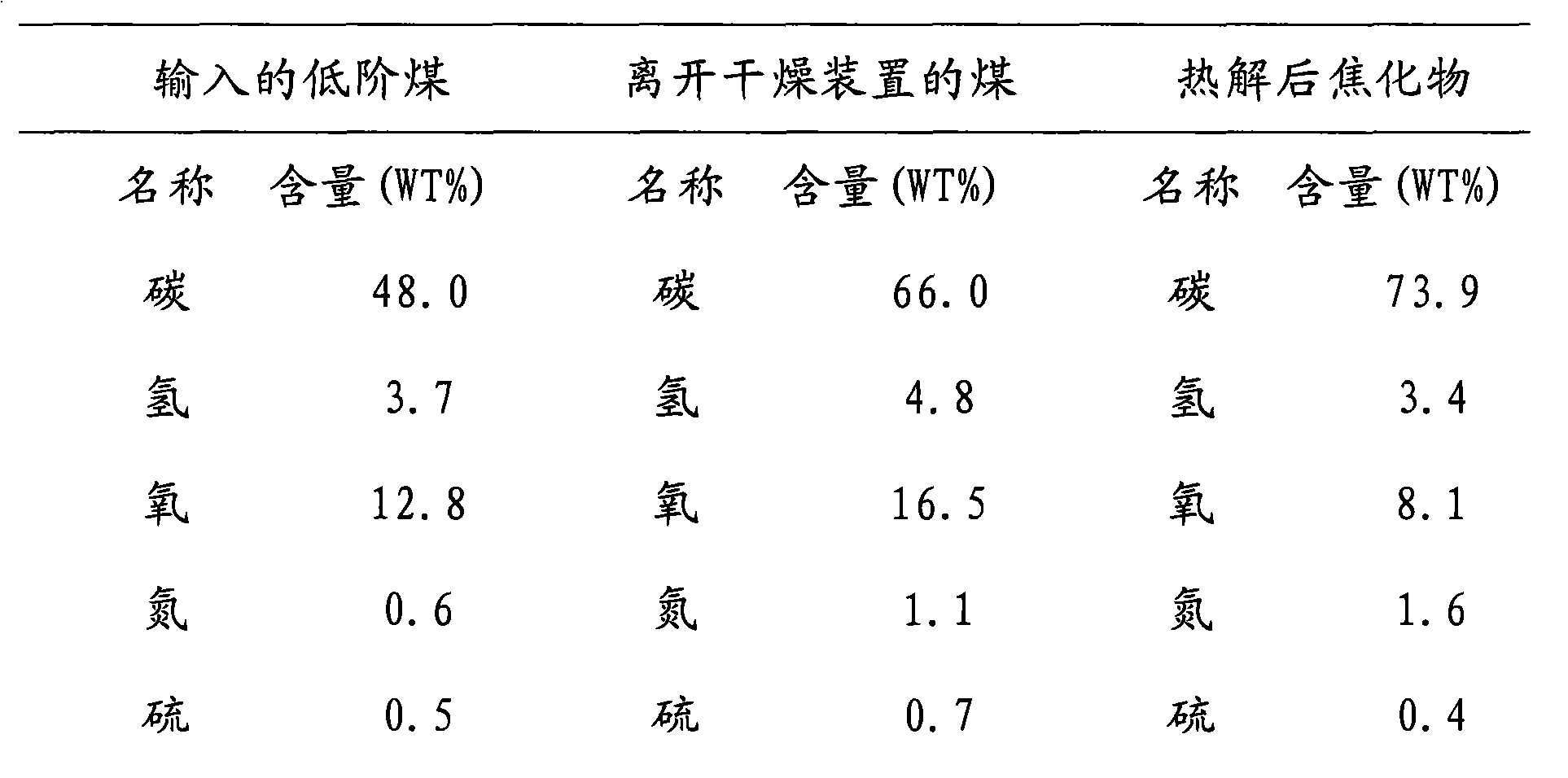

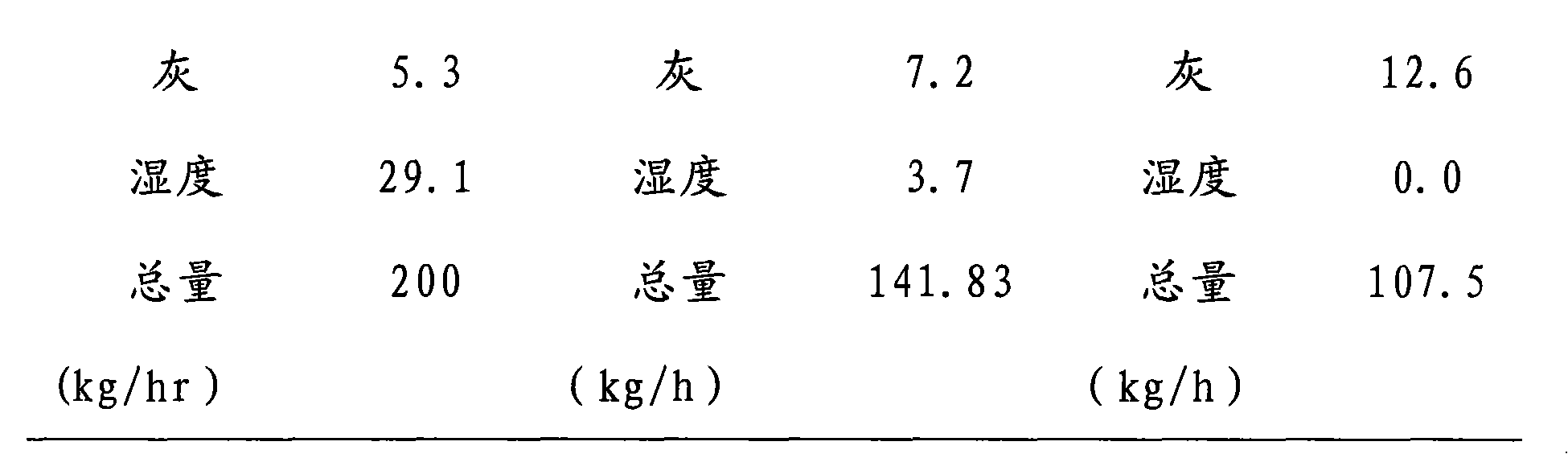

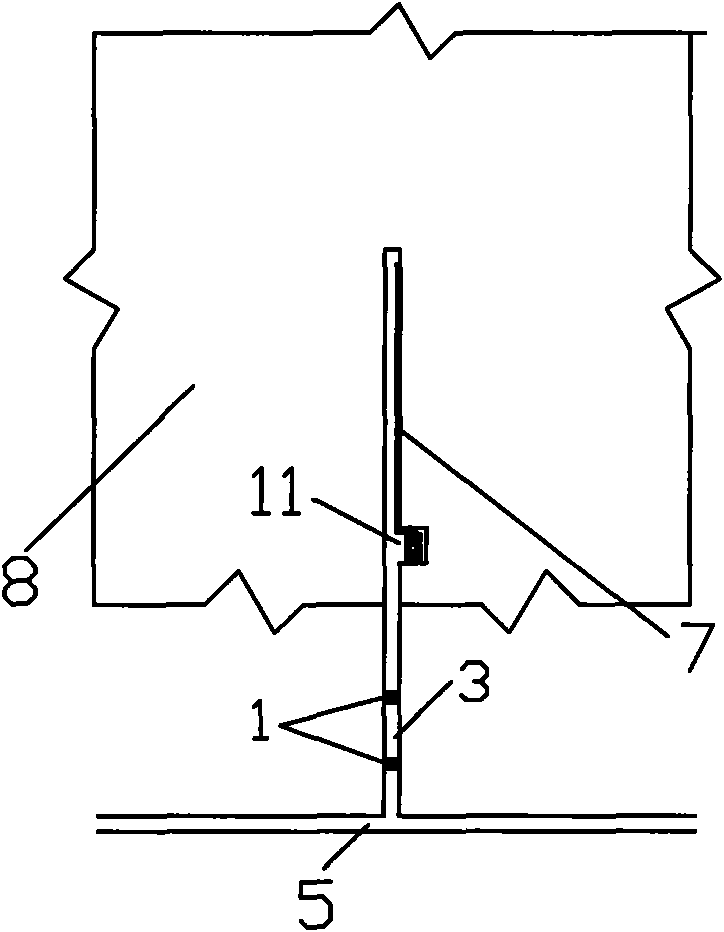

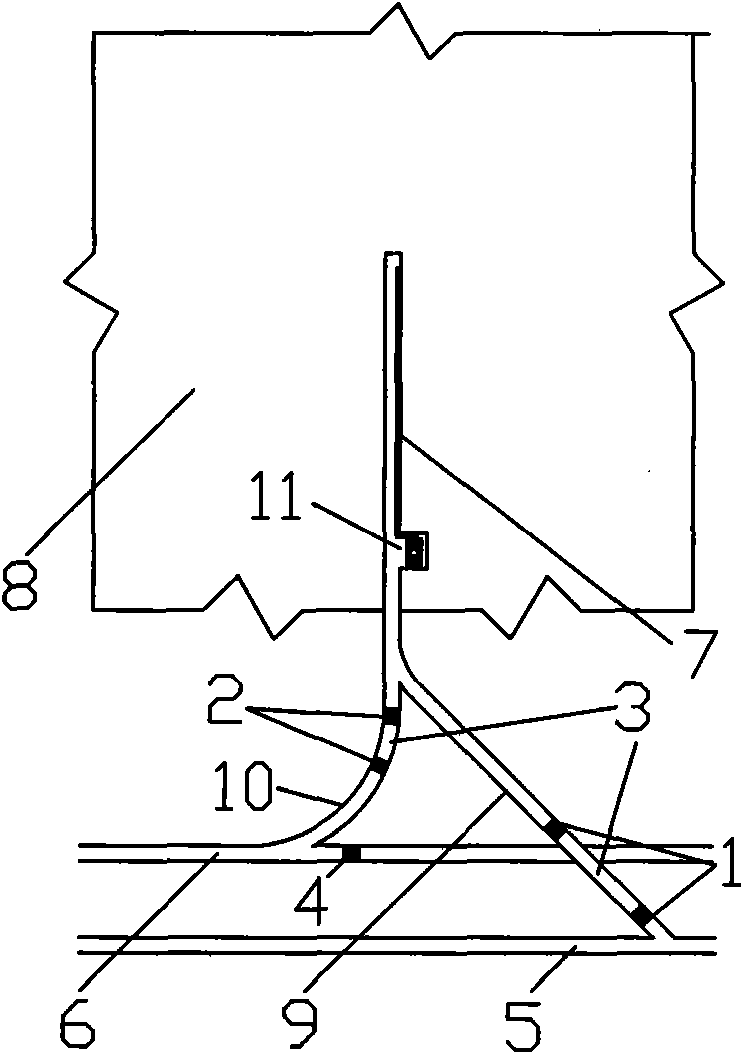

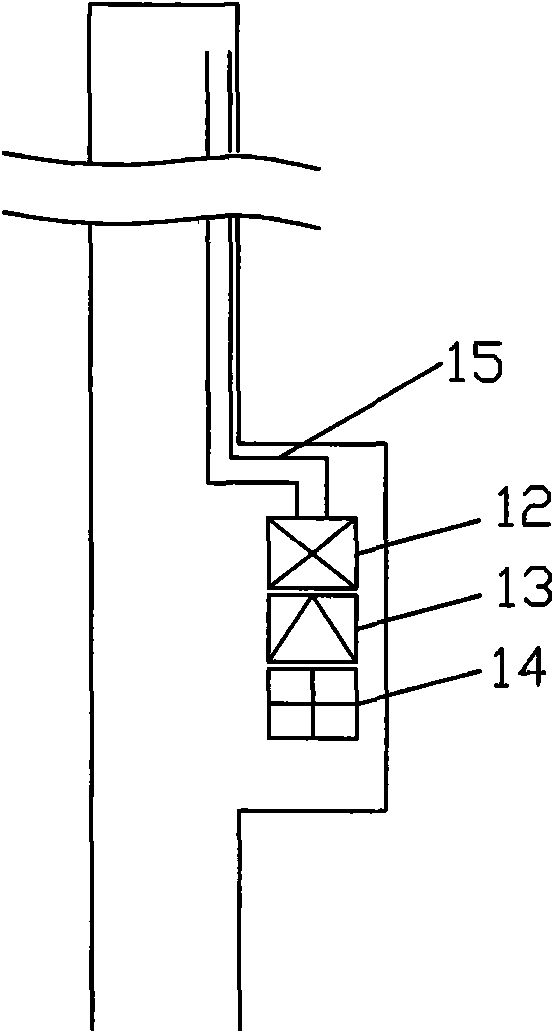

Process method and device for transformation and quality improvement of low-rank coal

InactiveCN101805628ALow selectivityEasy to industrializeDrying solid materials with heatCoke ovensTemperature controlCombustion chamber

The invention provides process method and device for the transformation and quality improvement of low-rank coal. The process method comprises the following steps of: drying the low-rank coals in a drying device by utilizing hypoxic gas supplied by a first combustion chamber; pyrolyzing the dried low-rank coals input in a pyrolysis device by utilizing the hypoxic gas supplied by a second combustion chamber; separating the pyrolysis gas generated by the pyrolysis device; and respectively transporting combustible gas obtained by separating the pyrolysis gas to the first combustion chamber and the second combustion chamber to be used as combustion gas for recycle. In the device, a combustion device respectively supplies the hypoxic gas to the drying device and the pyrolysis device through the first combustion chamber and the second combustion chamber which are mutually independent; the combustible gas obtained by separating the pyrolysis gas is respectively transported to the first combustion chamber and the second combustion chamber to be cycled as the combustion gas. The invention lowers the energy consumption, effectively controls local combustion and temperature in the drying device and the pyrolysis device and reduces the environmental pollution.

Owner:HUNAN HUAYIN ENERGY TECH

Co-mining tunneling method of seam roadway gas

ActiveCN102061919AAvoid it happening againAvoid lostUnderground miningSurface miningHigh concentrationRespirable dust

The invention discloses a co-mining tunneling method of seam roadway gas. The port of a roadway is sealed to form a sealed space, therefore air outside the roadway can not enter the space, so that the concentration of the gas in the roadway is above 20%, the concentration of the oxygen in the roadway is lower than 12%, and gas loses explosion capability. A drawing pipe is connected to release high-concentration gas released in a working space. In order to prevent high pressure from forming when coal and gas extrude in the roadway, a circular arc-shaped pressure relief roadway is dug on the opening end of the roadway, and high-pressure gas generated by extrusion can be removed. An air conditioning system is arranged in the roadway to guarantee proper environment in the roadway, and workerswork in the sealed space under the condition of prepared safety protection. By utilizing the roadway tunneling method, the problem of gas explosion is fundamentally solved, fire hazard danger is alsoeliminated, and the damage to a human body caused by respirable dust is eliminated; and meanwhile, because the roadway does not have explosion danger, so that the co-mining tunneling method provided by the invention has no anti-explosion requirement on equipment, and has a good popularization value.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing fireproof and explosion suppression pulverized fuel ash carbon dioxide material

InactiveCN101787289APrevent spontaneous combustionReduce the probability of ignitionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention relates to a method for preparing fireproof and explosion suppression pulverized fuel ash carbon dioxide material, which comprises the steps of: mixing 70-80% of water and 20-30% of pulverized fuel to prepare pulverized fuel ash slurry liquid according to the mass percent; mixing 94-98% of water and 2-6% of industrial sodium hydrogen carbonate to prepare industrial sodium hydrogen carbonate solution according to the mass percent; mixing 77-92% of water, 5-15% of industrial aluminum sulfate and 3-8% of polyvinyl alcohol to prepare mixed solution of the industrial aluminum sulfate and the polyvinyl alcohol according to the mass percent; and mixing the prepared pulverized fuel ash slurry liquid, the industrial sodium hydrogen carbonate solution and the mixed solution of the industrial aluminum sulfate and the polyvinyl alcohol according to the proportion of 1: 1: 1, mutually reacting to generate a great deal of carbon dioxide, and forming a great deal of foam. The foam pulverized fuel ash has good effect of preventing and extinguishing fire, releases carbon dioxide on gas phase, reduces the oxygen concentration and gas density in a mined out space, leads the mined out space for inerting, and inhibits spontaneous combustion of coal and gas explosion; the pulverized fuel ash on solid phase covers the coal body, blocks an air leakage channel and achieves the aim of preventing the spontaneous combustion of coal; and water on liquid phase can reduce the temperature of the coal body, thus reducing the ignition rate of the spontaneous combustion of coal.

Owner:CHINA UNIV OF MINING & TECH

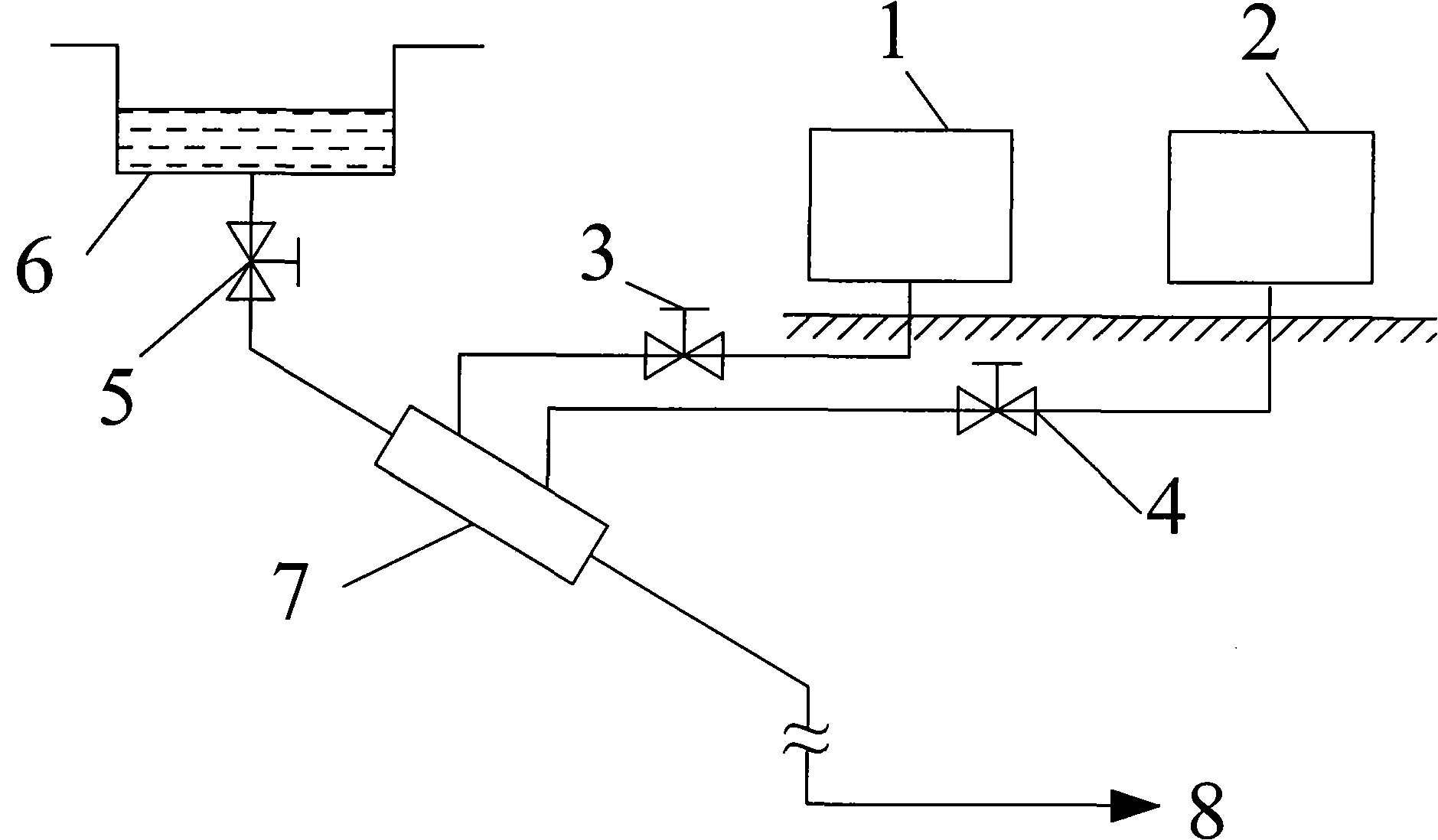

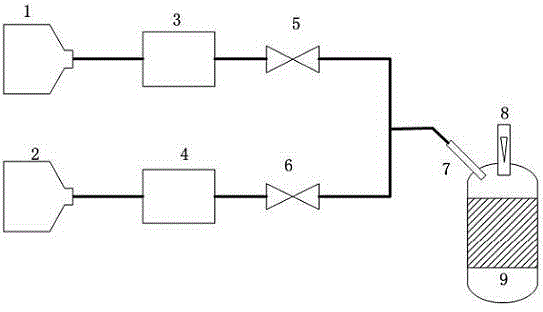

Ionic current based spark ignition engine preignition detection control device

InactiveCN103603730ASuppress spontaneous combustionAvoid super knockInternal combustion piston enginesEngine controllersSpark-ignition engineCombustion chamber

The invention discloses an ionic current based spark ignition engine preignition detection control device. Before an ionic current detection device detects spark ignition, autoignition happens in a combustion chamber, an ethanol solenoid valve is controlled in the compression stroke to be turned on to inject a certain amount of ethanol so as to lower the temperature in the combustion chamber and restrain preignition, and the ethanol solenoid valve and a gasoline solenoid valve are controlled to be turned on simultaneously according to gasoline injection pulse width in subsequent circulation, so that the ethanol is mixed in gasoline, and preignition tendency in the subsequent combustion circulation is reduced; if preignition happens continuously, the ethanol is injected in the compression stroke, if preignition does not happen in the subsequent circulation, ethanol injection amount in fuel is decreased along with circulation, and finally pure-gasoline injection is restored. The ionic current based spark ignition engine preignition detection control device has the advantages that when one cylinder is detected to be pre-ignited, fuels such as the ethanol with high latent heat of vaporization are injected into the cylinder so as to cool compressed mixed gas, the temperature in the combustion chamber at upper dead point of compression is lowered, non-combusted mixed gas is restrained from autoignition, super detonation caused by preignition is prevented, and damage to an engine is reduced.

Owner:TONGJI UNIV

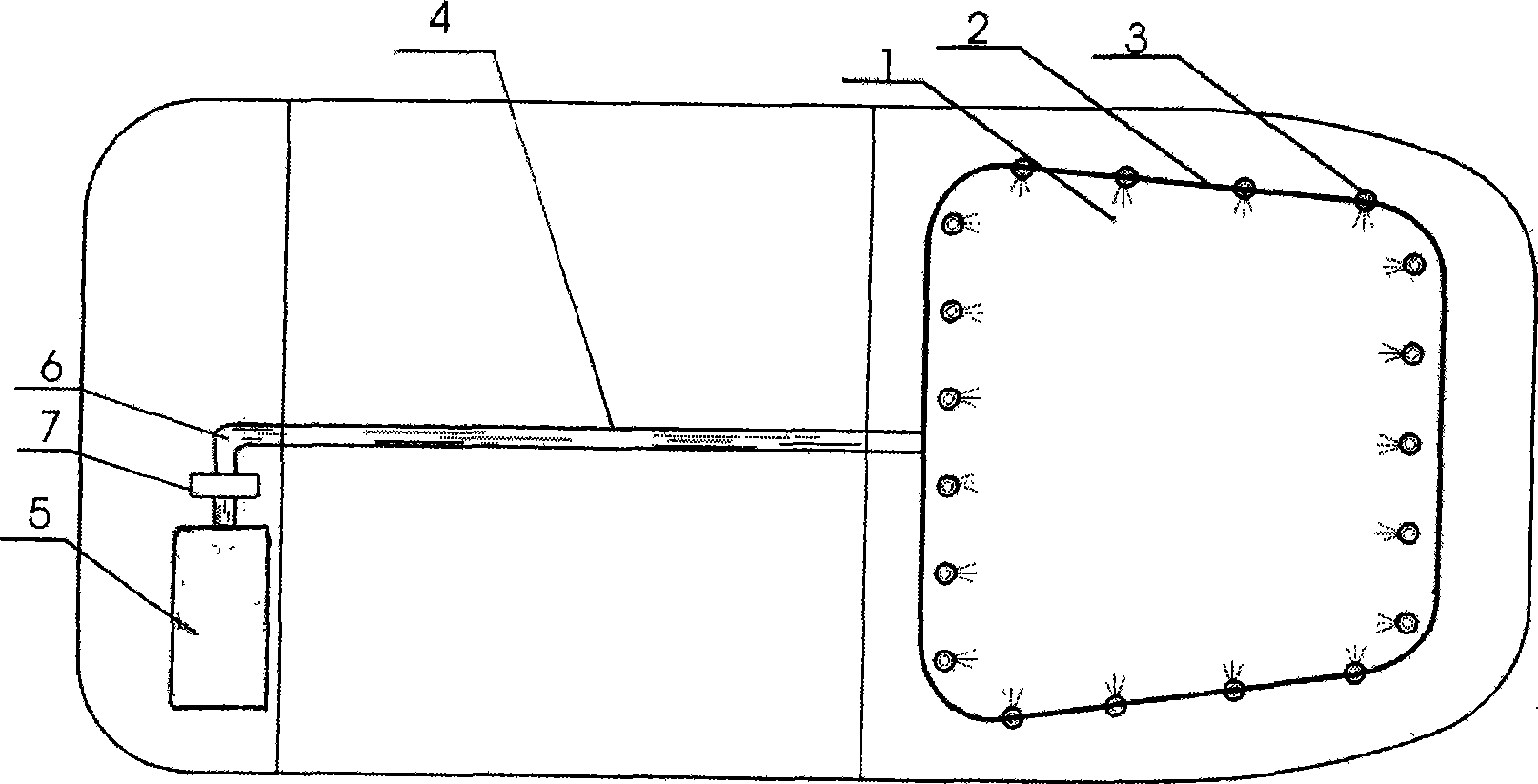

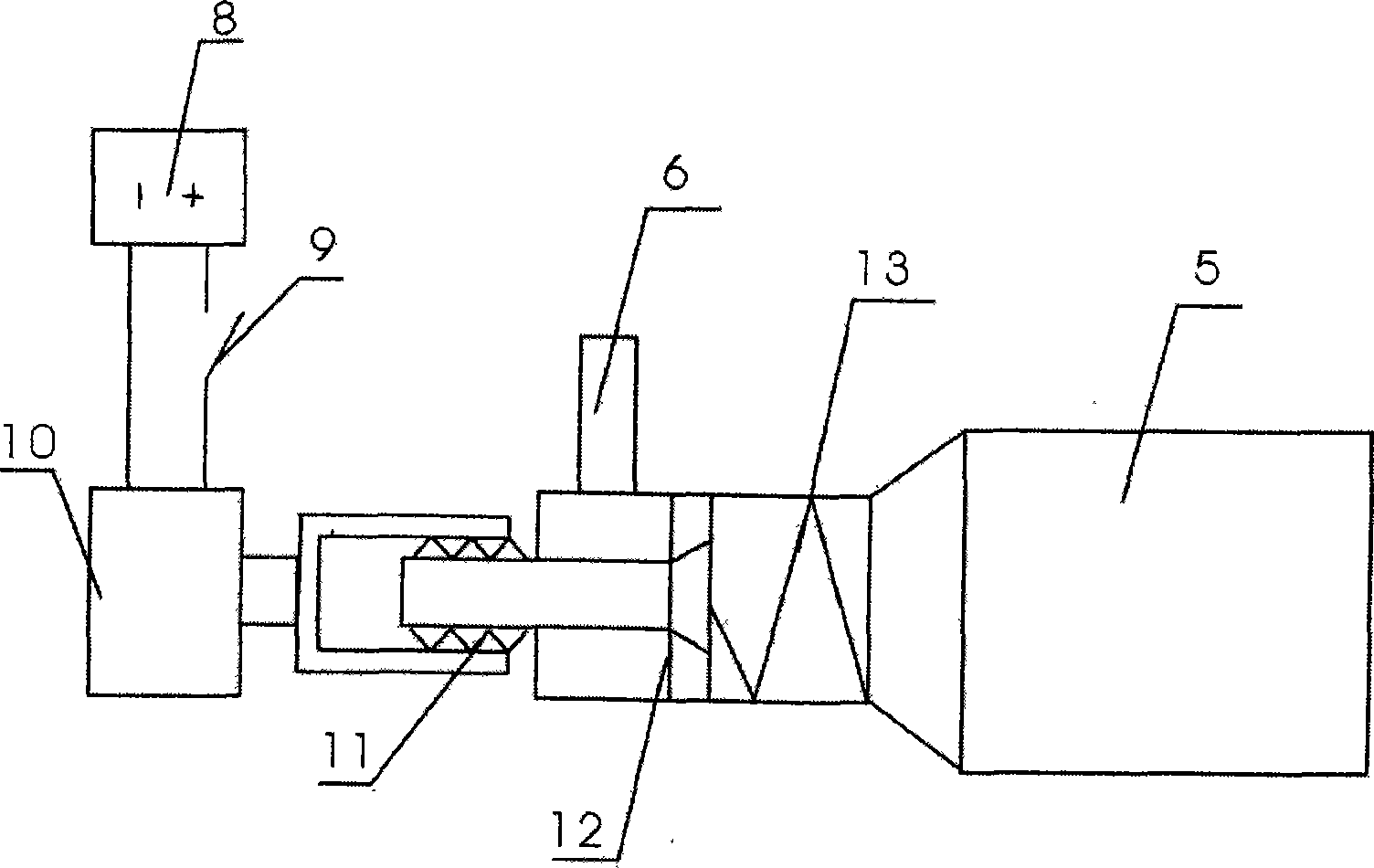

Automatic remote control extinguishing device for automobile

InactiveCN101543667APrevent car spontaneous combustionReduce property damageFire rescueDriver/operatorAutomatic control

The invention provides an automatic remote control extinguishing device for an automobile, which belongs to technology of vehicle design and manufacture and technology of fire prevention and fire fighting, and in particular relates to the technology of fire prevention and fire fighting of running automobiles. The device is characterized in that an air duct is wound on the periphery of a cover cap of an automobile engine; gas orifices towards the engine are uniformly distributed along the air duct; the air duct is connected with a jet orifice of an extinguisher through a hose; and a relay controlled by infrared ray is arranged on a control end of the extinguisher, is on a position within drivers reach, and is provided with an infrared launch button with a protective cover. The device has the advantages that the vehicular automatic remote control extinguishing device is arranged on the automobile, so when the automobile smokes and has a risk for fire, the automobile can realize automatic extinguishing only by pressing a remote control switch by the driver, and a crowd and chaotic occasion that passengers and the driver scramble for the extinguisher to extinguish fire is avoided. The method provides an effective measure for fire prevention of the automobile in China.

Owner:邵顺彬

Foamed gel for preventing and controlling spontaneous combustion of coal in goaf and application

ActiveCN108708764AThe material is non-toxic and harmlessIncrease in sizeDust removalFire preventionSpontaneous combustionPolymer science

The invention discloses foamed gel for preventing and controlling spontaneous combustion of coal in a goaf and application. The foamed gel is prepared from raw materials including a foaming agent, a foam stabilizer, a gelling substance and water, wherein the foaming agent is a composite foaming agent prepared from lauryl sodium sulfate, sodium dodecyl benzene sulfonate and dicyl polyglycoside, thefoam stabilizer is a mixture of sodium silicate and xanthan gum, and the gelling substance is a mixture of polyacrylamide and guar gum. The foamed gel has adsorptive property. After the substances are mixed and foamed, the formed foamed gel has long water retention time and long foam half-life period, and the improved foamed gel has good adsorptive property. After the foamed gel is injected intoan area where spontaneous combustion of coal is likely to occur, a coal body can be effectively coated, cooling is conducted on residual coal, a layer of oxygen isolation film can be formed on the surface of the residual coal after foam bursting to isolate contact between the coal and oxygen, and spontaneous combustion of coal can be permanently prevented and controlled.

Owner:CHINA UNIV OF MINING & TECH

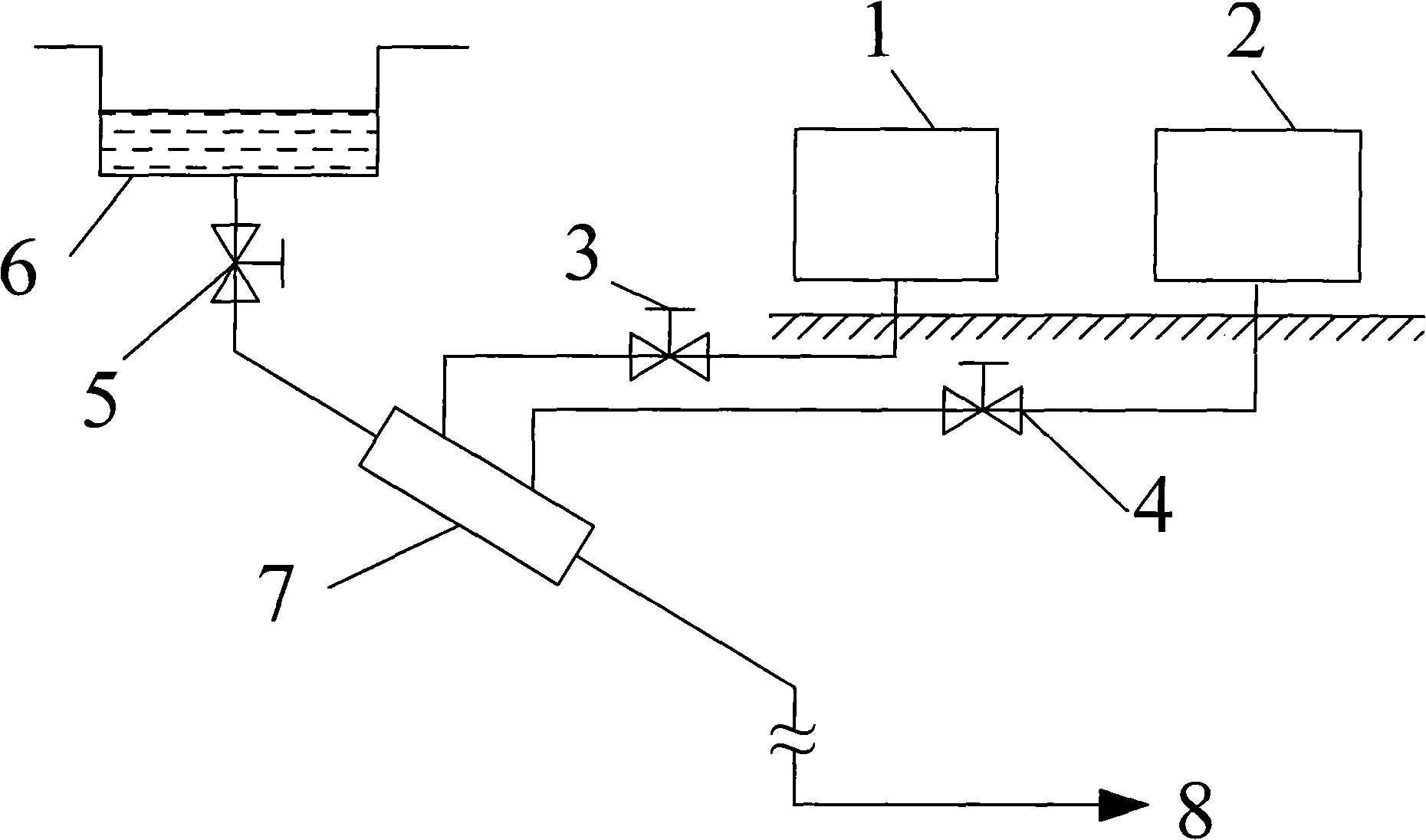

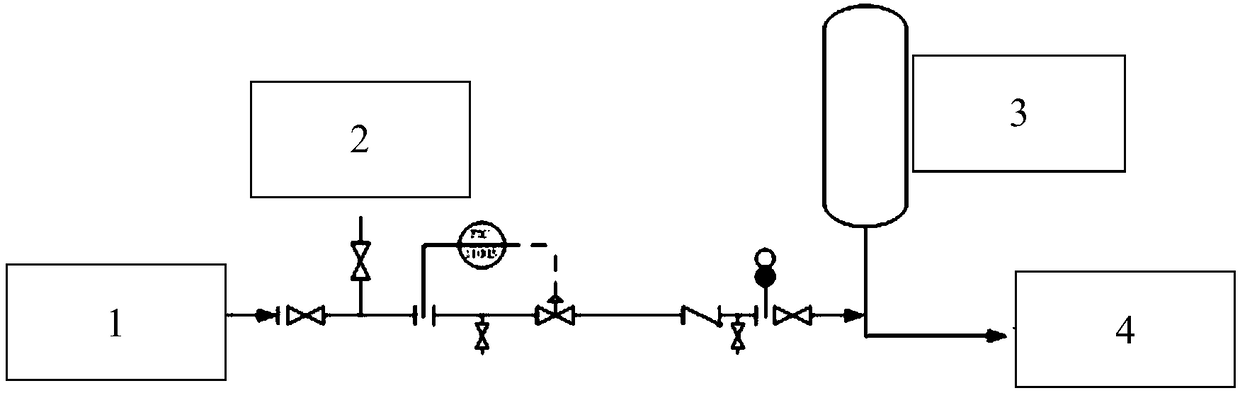

Coal mine underworkings-type coal-seam gas fracturing equipment

InactiveCN102691515AImprove permeabilityReduce rock burstGas removalLiquid storage tankHigh pressure

The invention relates to the field of coal mine acquisition technology and specifically relates to coal mine underworkings-type coal-seam gas fracturing equipment. An underground coal body (5) is connected with one end of each of a plurality of high pressure fracturing pumps (4) through high-low pressure manifolds (6); the other end of each of the plurality of the high pressure fracturing pumps (4) is connected with a fracturing-liquid mixing and proportioning mixer (2) through the high-low pressure manifolds (6); one end of the fracturing-liquid mixing and proportioning mixer (2) is connected with a plurality of liquid storage tanks (1) through the high-low pressure manifolds (6); and a lower end of the fracturing-liquid mixing and proportioning mixer(2) is connected with a control monitoring device(3). The coal mine underworkings-type coal-seam gas fracturing equipment is used for fracturing coal seams, can assist in improving coal seam permeability and can assist in reducing rock bursts of a coal body fracturing area and reducing risks of coal and gas outbursts and the rock bursts at a working face.

Owner:DAQING ZHONGYOU QINGRUI GASOLINEEUM SCI & TECH

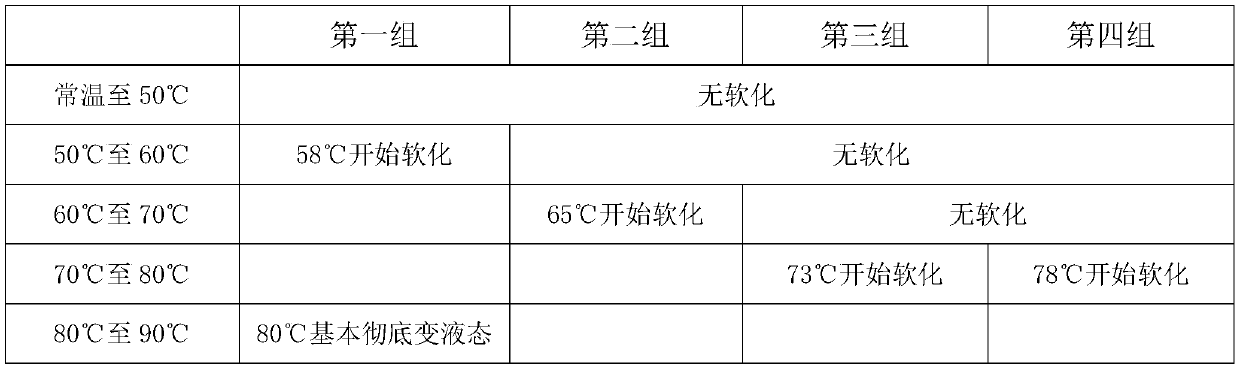

Temperature-sensitive material for predicting coal spontaneous combustion of goaf and preparation method and application of temperature-sensitive material

ActiveCN109738128ASuppress spontaneous combustionInhibition of spontaneous combustion reactionDetection of fluid at leakage pointFlavorCoal spontaneous combustion

The invention discloses a temperature-sensitive material for predicting coal spontaneous combustion of goaf and preparation method and application of the temperature-sensitive material. The temperature-sensitive material is composed of a capsule containing tracer core materials, the capsule wall of the capsule is prepared from prepared raw materials obtained by evenly mixing 70 type chlorinated paraffins and 52 type chlorinated paraffins at the ratio of 3:1 to 6:1, and the tracer core materials include SF6 and industrial flavor. The temperature-sensitive material can be directly used in a goafarea, first-phase arrangement is not required, and simplicity, convenience and practicality are achieved; the chlorinated paraffins of the capsule wall have good stability and can protect a capsule core material to remain in the goaf for a long time at room temperature, the tracer core materials are easy to prepared and obtain, when residual coal in the goaf appears high-temperature hidden dangerand the ambient temperature reaches or exceeds a critical value of capsule wall softening of the capsule, thawing and rupture of the capsule wall can be detected by the human body olfaction and an SF6 detector, thus the phenomenon of coal spontaneous combustion can be predicted stably and effectively, and major accidents caused by coal spontaneous combustion are avoided; and a metal frame can prevent damage from geological problems, and the error-tolerant rate of a system is increased.

Owner:CHINA UNIV OF MINING & TECH

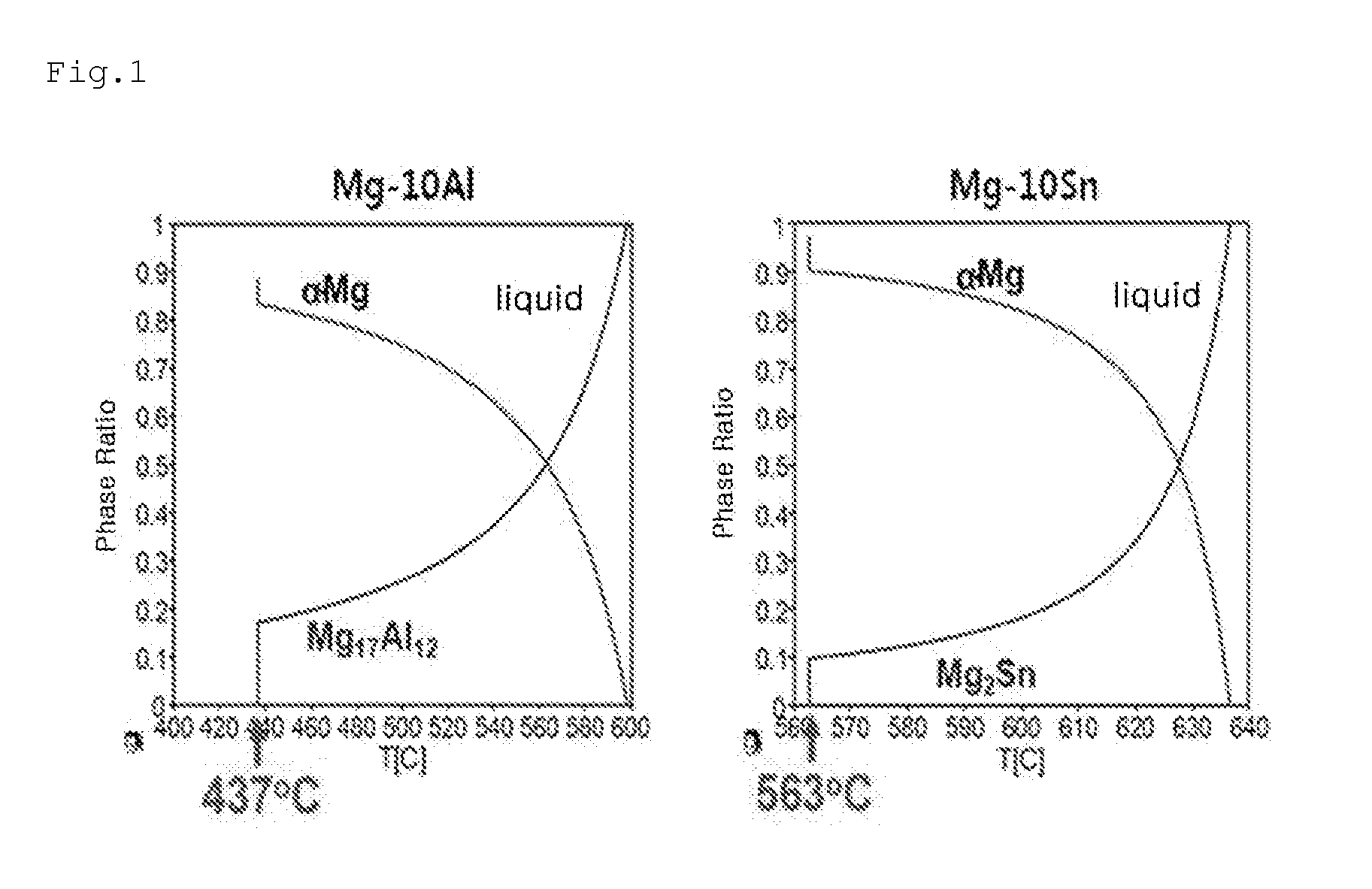

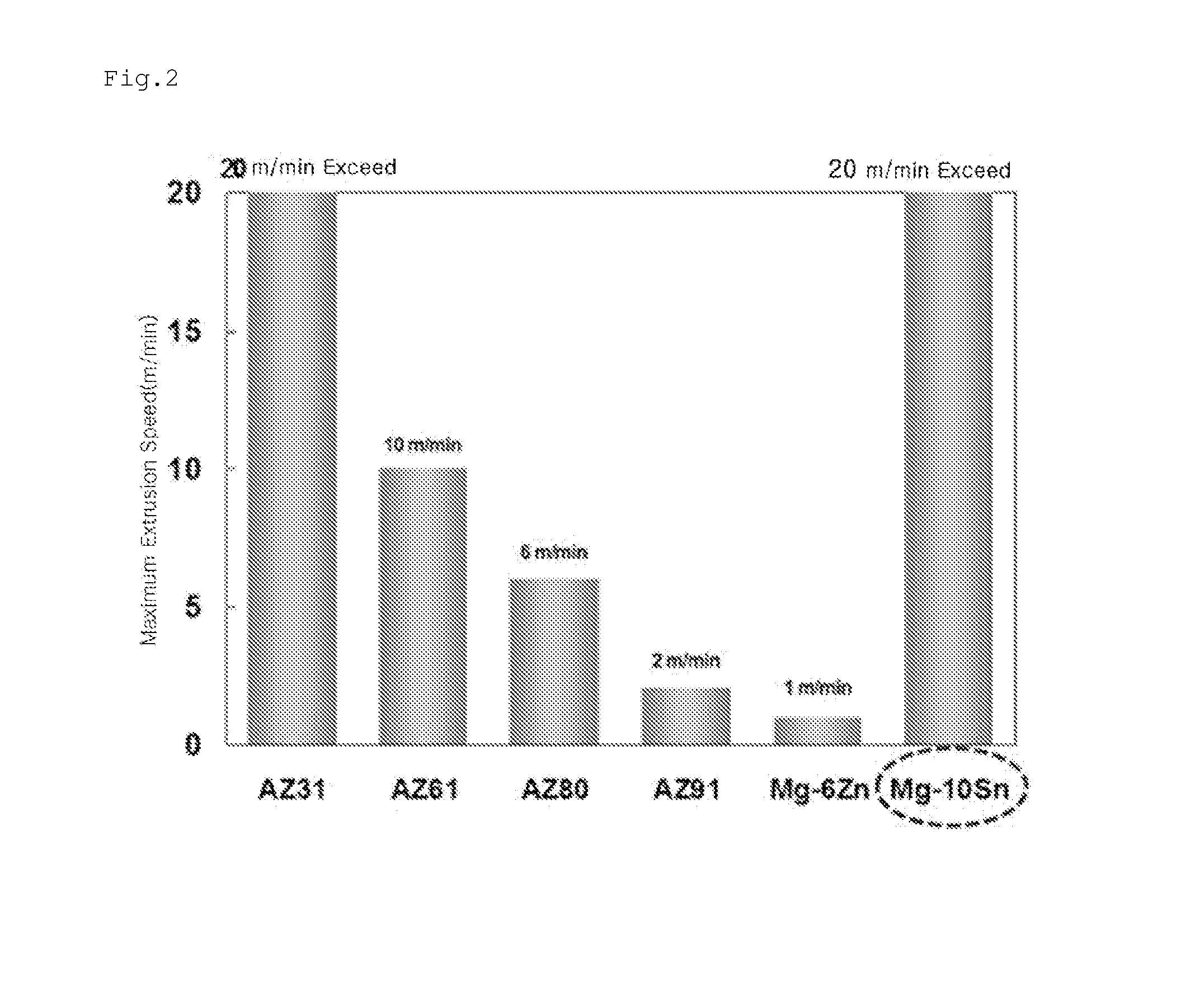

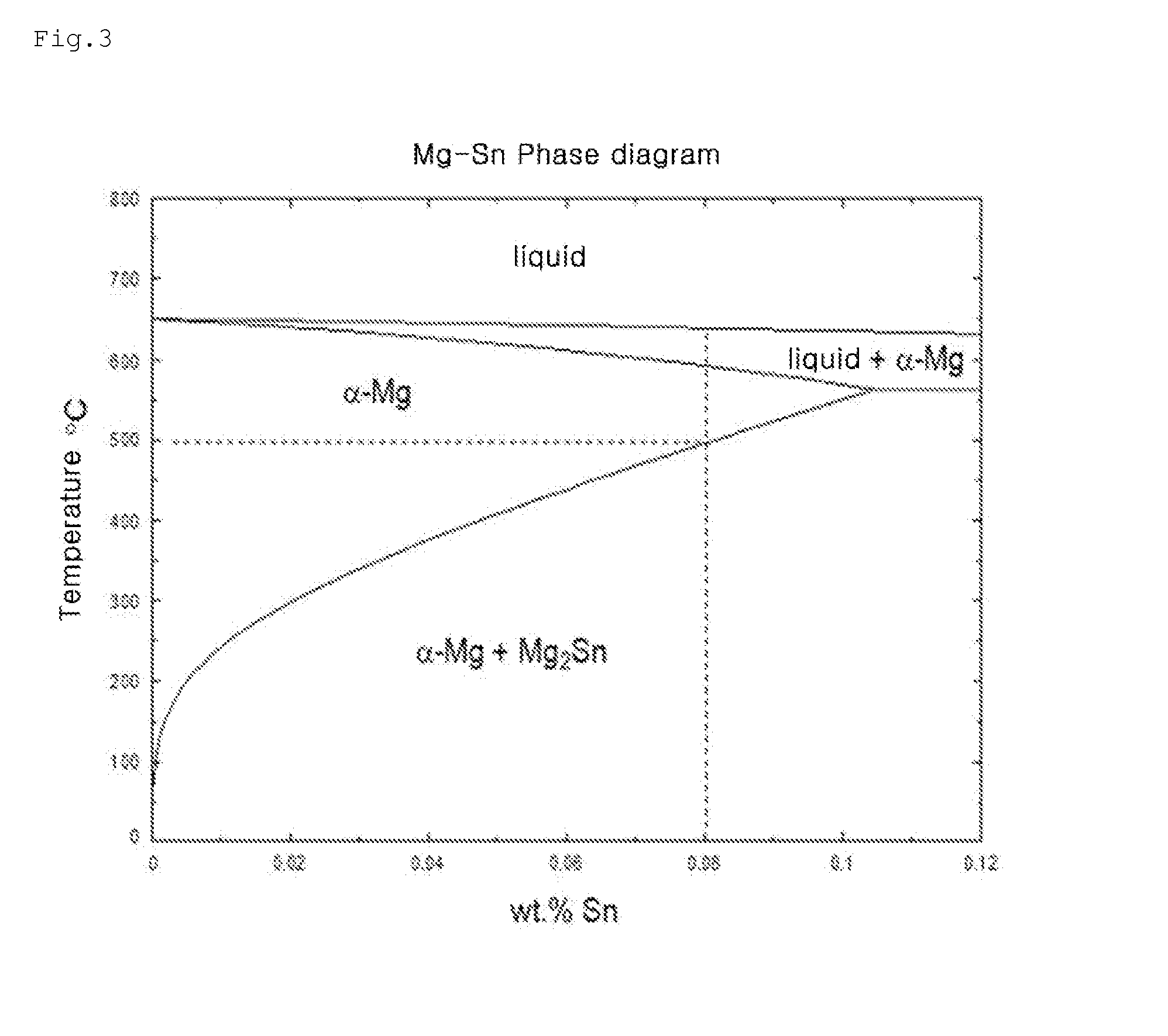

Machining magnesium alloy capable of being heat treated at high temperature

Disclosed are a magnesium (Mg) alloy and a manufacturing method thereof. The Mg alloy has a composition including, by weight, 4% to 10% of Sn, 0.05% to 1.0% of Ca, 0.1% to 2% of at least one element selected from the group including Y and Er, the balance of Mg, and the other unavoidable impurities. The Mg alloy includes an Mg2Sn phase having excellent thermal stability, and is capable of being heat treated at a temperature of 480° C. or more.

Owner:KOREA INST OF MATERIALS SCI

Comprehensive treatment method for gas and coal spontaneous combustion in near-horizontal thick coal seam mining

ActiveCN110821552APrevent overrunningOverrun Problem SuppressionDust removalFire preventionCoal spontaneous combustionMining engineering

The invention provides a comprehensive treatment method for gas and coal spontaneous combustion in near-horizontal thick coal seam mining, and belongs to the technical field of mine gas and coal spontaneous combustion prevention and control. The comprehensive treatment method for gas and coal spontaneous combustion in near-horizontal thick coal seam mining comprises the following steps that gas gushing from a stope face is treated by adopting a two-inlet and one-return-deviation Y-shaped downward ventilation system, an extraction pipe is pre-buried in a connection roadway, and gas gushing fromresidual coal in a goaf is extracted through the extraction pipe; and a grouting pipeline and an air injection pipeline are arranged in an air inlet roadway of the stope face, non-combustible solidified foam is continuously injected into the goaf through the grouting pipeline, and then nitrogen is continuously injected into the goaf through the air injection pipeline. According to the comprehensive treatment method, a three-dimensional prevention and control system for gas and coal spontaneous combustion in near-horizontal thick coal seam mining is constructed, accurate prevention and controlof gas and coal spontaneous combustion coupling disasters are realized, the recovery efficiency of the stope face is improved, and the safety production of a mine is guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

A kind of preparation method of composite microcapsule inhibitor for preventing and controlling coal spontaneous combustion

ActiveCN108167016BHigh strengthHigh ignition pointDust removalFire preventionCold airCoal spontaneous combustion

The invention relates to a composite microcapsule stopping agent for preventing coal spontaneous combustion and a preparation method of the composite microcapsule stopping agent. The stopping agent comprises a wall shell and a stopping agent solution sealed in the wall shell. The wall shell is mainly prepared from the following components of, by weight, 70-80 parts of phase-change materials, 10-20parts of flame-resistant materials and 8-12 parts of reinforcing materials. The stopping agent solution is ionic liquid or a chloride solution. The stopping agent solution is evenly composited to thecomposite phase-change materials to obtain a mixed emulsion, the mixed emulsion is sprayed into a dry porous medium in an emulsion-drop mode through a spraying device to enable mixed emulsion drops to be further atomized into mist drops with the particle diameter of 30-50 [mu]m, and after the mixed emulsion which is formed into the mist drops makes contact with cold air, the composite phase-change mixed materials are quickly solidified to wrap the stopping agent solution to form the composite microcapsule stopping agent. The stopping agent can be evenly distributed in coal seams, the coveragerange is wide, accumulation of heat is prevented, coal spontaneous combustion is resisted, and the preparation method can efficiently produce and process the composite microcapsule stopping agent.

Owner:CHINA UNIV OF MINING & TECH

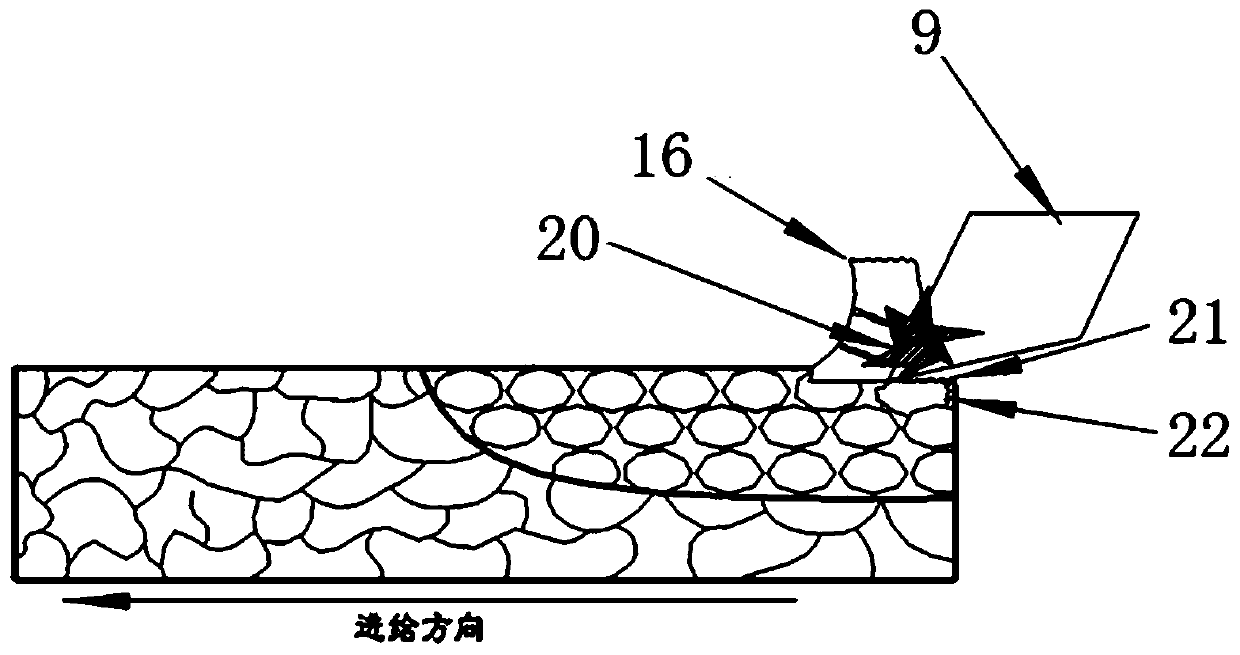

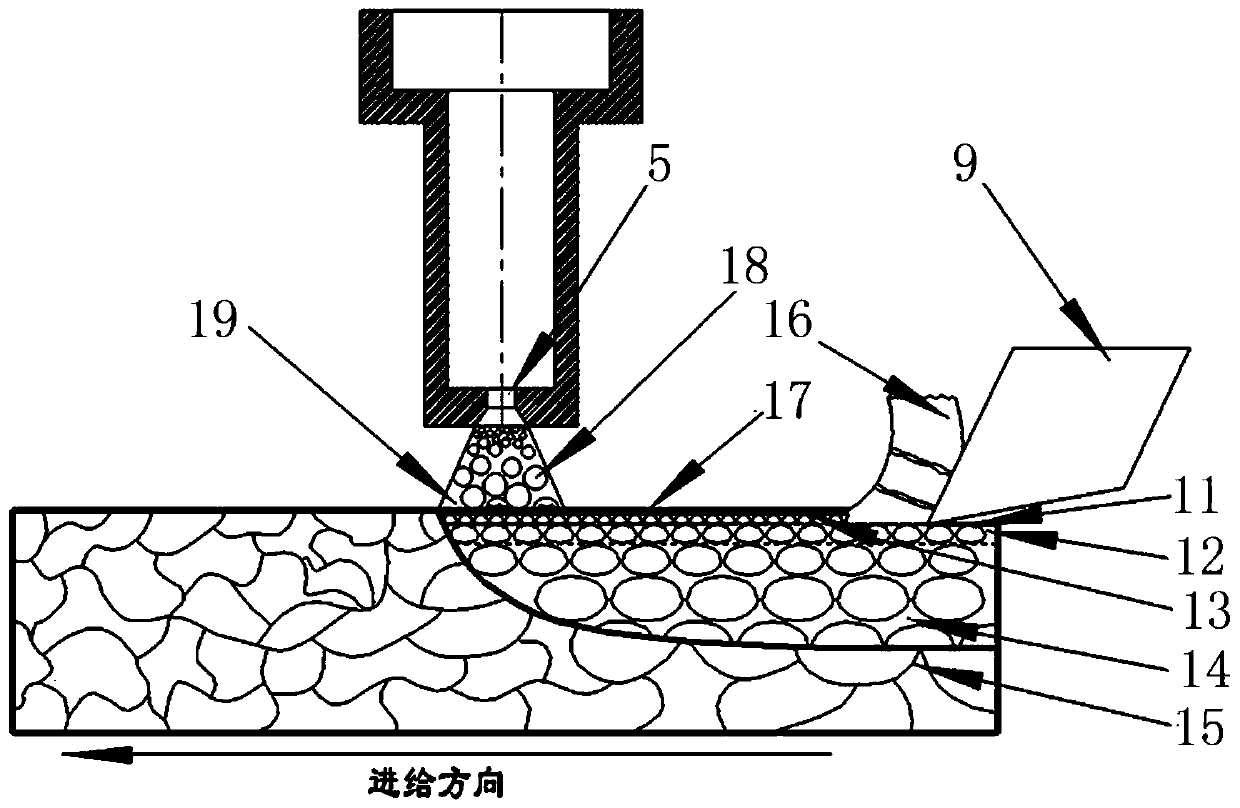

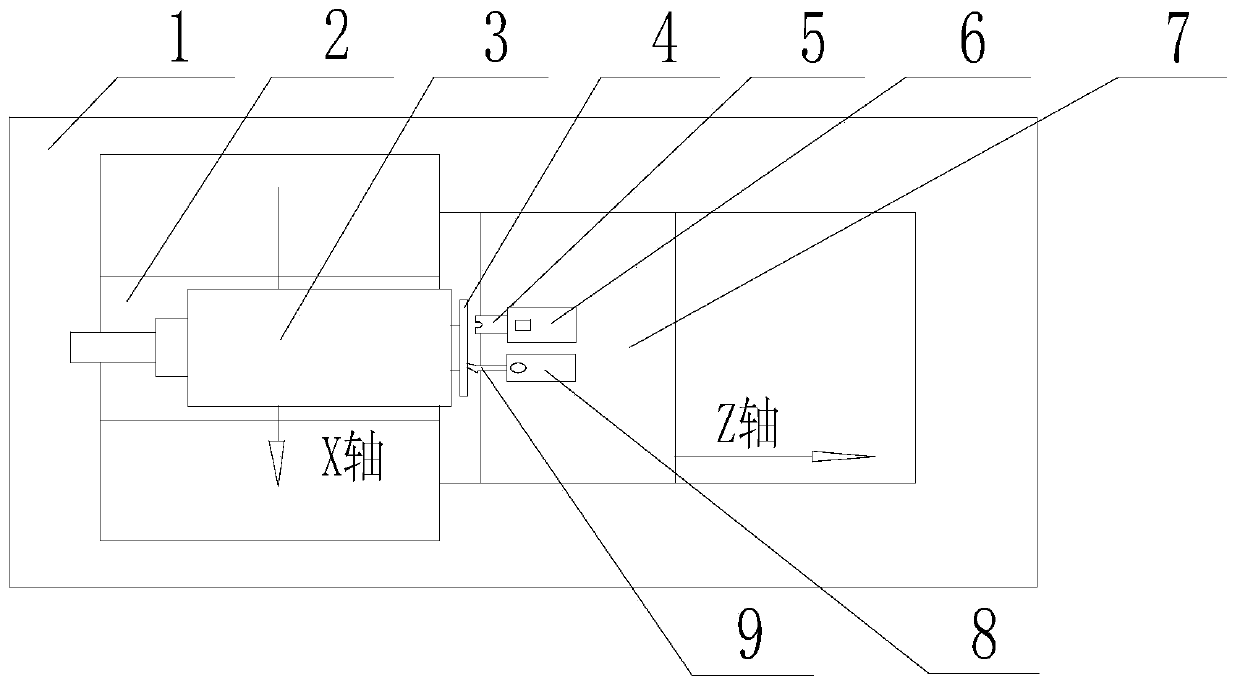

Ultra-precision machining method of cerium lanthanum alloy

The invention discloses an ultra-precision machining method of cerium-lanthanum alloy. The method comprises the following steps of, (1) Carrying out nanocrystallization treatment on the surface of thecerium lanthanum alloy : a nozzle is utilized to impact the surface of cerium-lanthanum alloy by cavitation jet bubbles, generating plastic deformation of the crystal, and realizing crystal pulverization on the surface of the material to nano-scale; and (2) Carrying out trace cutting on the surface of the cerium-lanthanum alloy subjected to nanocrystallization treatment on the surface by adoptinga single-point diamond machining tool and a machining process. According to the method disclosed by the invention, the processing stability of the cerium-lanthanum alloy can be improved; meanwhile, spontaneous combustion is inhibited, and the surface and sub-surface damage generated when the cerium-lanthanum alloy is subjected to traditional precise cutting is reduced; a compact layer is generated, the oxidation corrosion process is hindered, and the surface cleanness is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

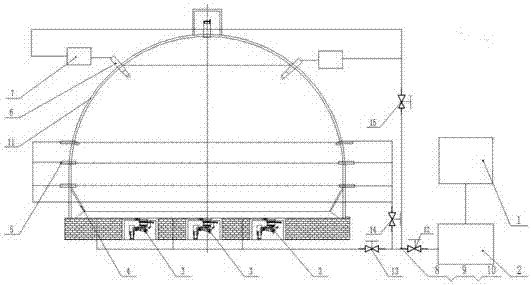

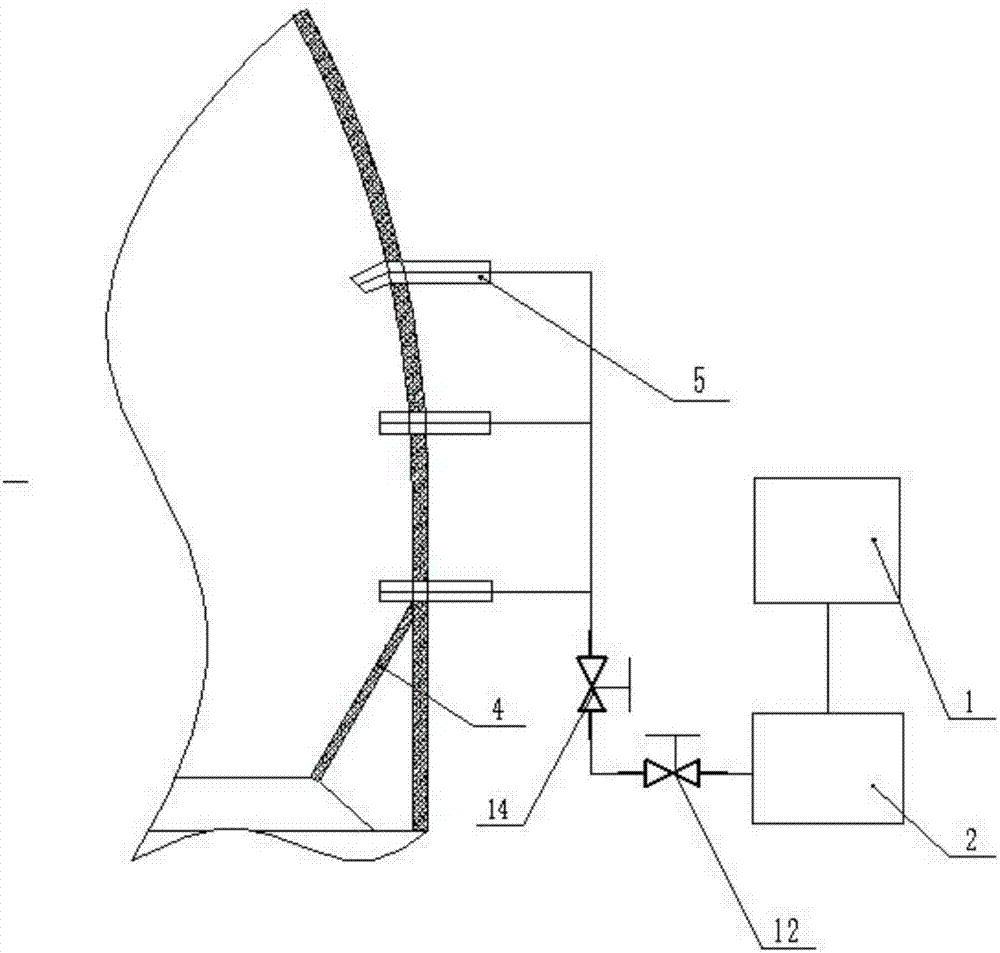

Inactive protect device for ball-shaped bunker

The invention discloses an inactive protect device for a ball-shaped bunker. The inactive protect device is used for conducting inactive protection on large-sized ball-shaped coal storage bunkers of thermal power stations and the like. According to the inactive protect device, a gas storage device is connected with multiple stages of gas filling pipelines through a decompression device, and can adjust the pressure of inert gas filling, and a main valve is arranged on a main pipeline behind the decompression device, and is used for controlling the connection and disconnection of the main pipeline; the inactive protect device is composed of the gas storage device, the decompression device, embedded pipes arranged at the coal outlet of the bottom and the wall of the ball-shaped bunker, a gas filling device arranged on the upper portion of the ball-shaped bunker, and the multiple stages of gas filling pipelines. Firstly gas filling is conducted on the bottom and the upper portion of the ball-shaped bunker, and then the effect of ''isolation-restraining'' is achieved by conducting gas filling inside a coal dump, and finally the inactive protection of a whole coal dump in the ball-shaped bunker is formed.

Owner:BEIJING UNIV OF TECH

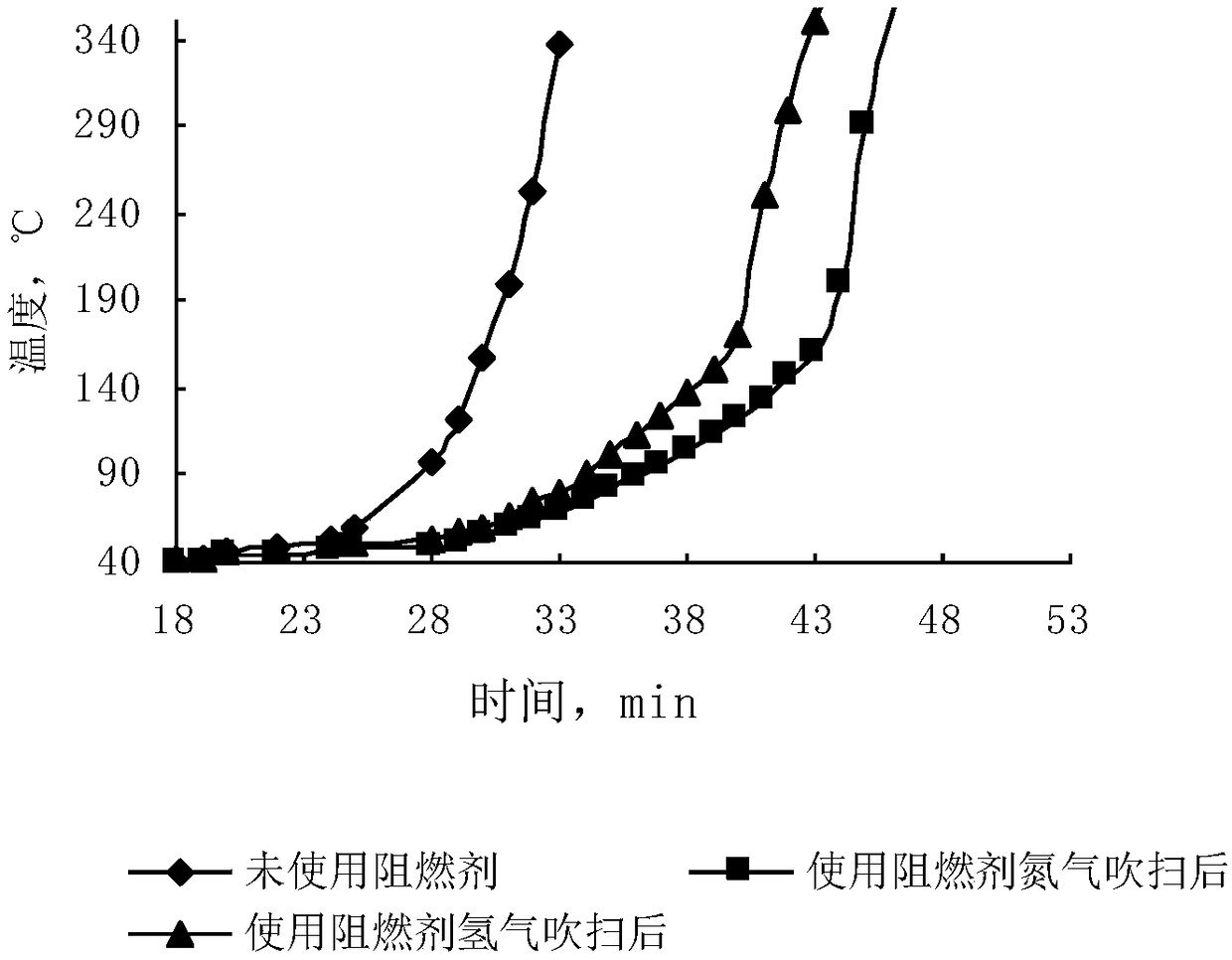

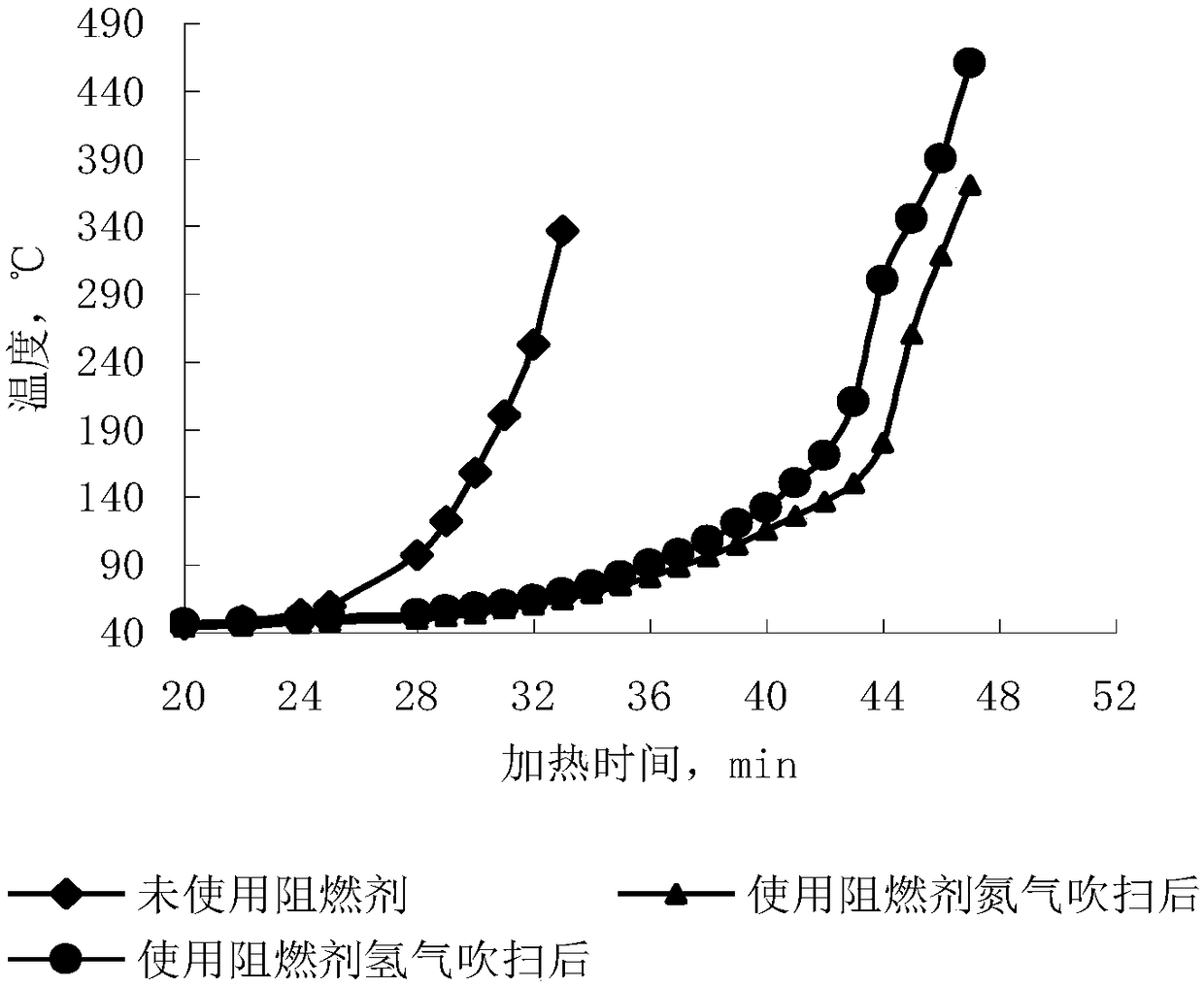

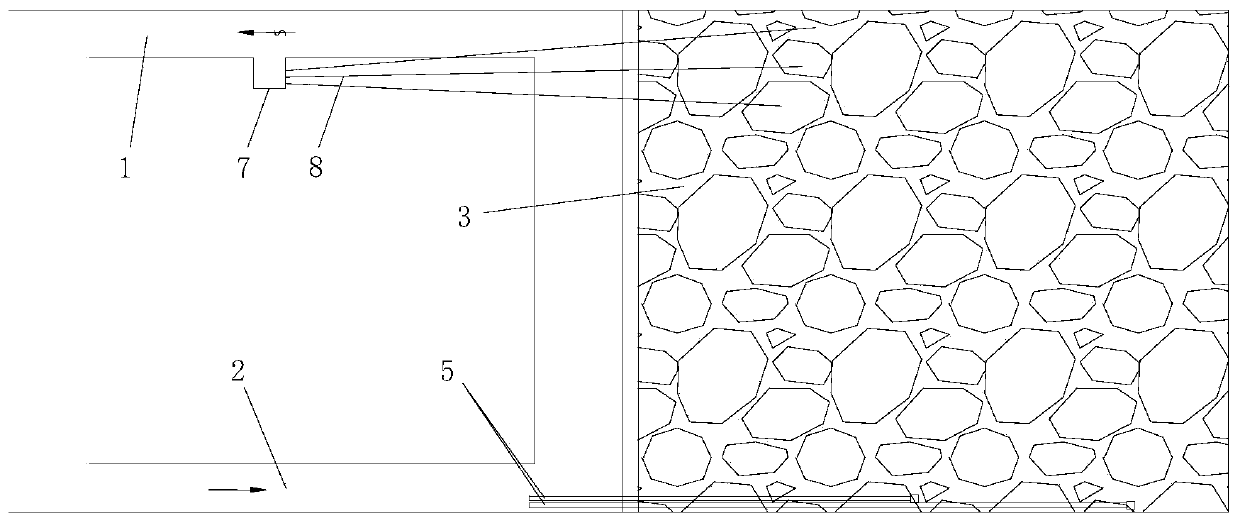

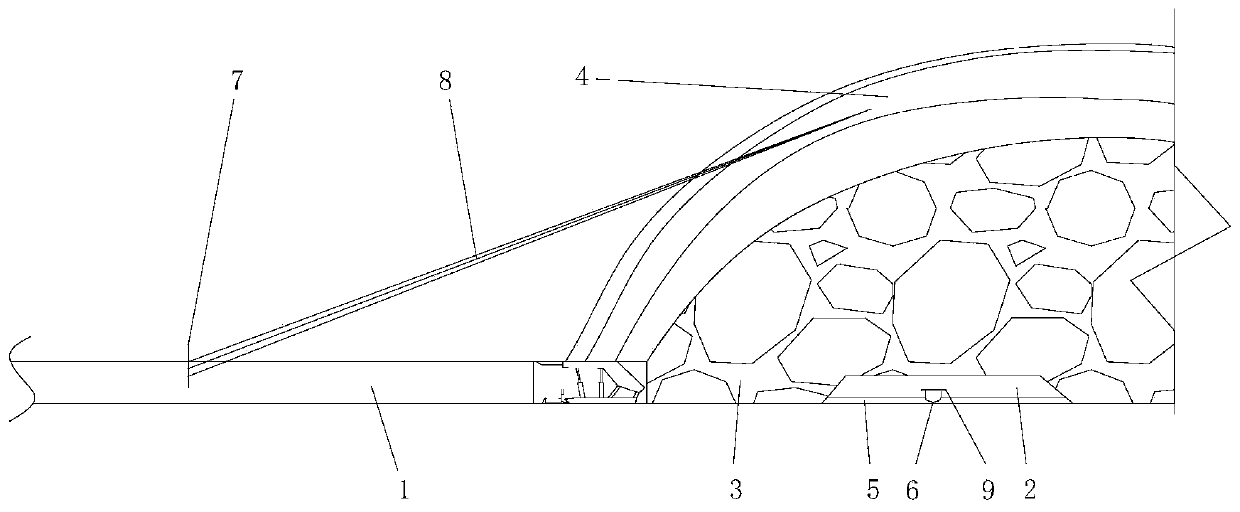

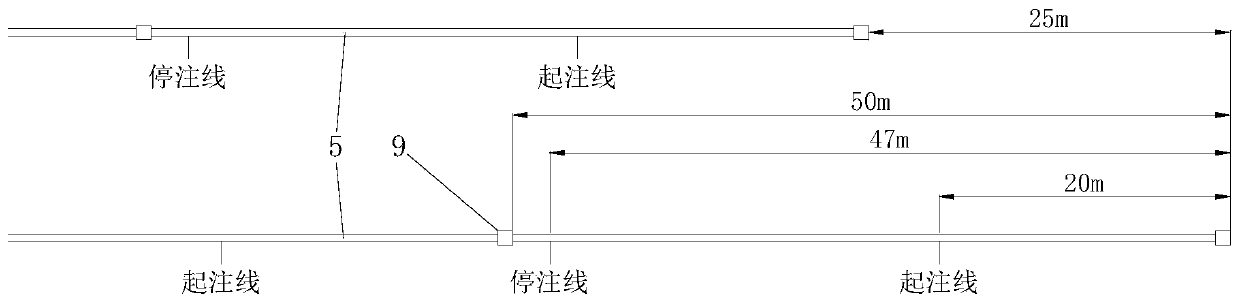

Using method of SHYZ-1 hydrogenation catalyst fire retardant

InactiveCN109135810AImprove flame retardant performanceSuppress spontaneous combustionHydrocarbon oil crackingWaxFire retardant

The invention discloses a using method of an SHYZ-1 hydrogenation catalyst fire retardant. The using method is characterized by comprising the following steps: (1) temperature reduction and quantity reduction; (2) oil replacement of wax oil; (3) diesel oil replacement; (4) fire retardant injection; (5) film formation; and (6) gas cooling replacement. The fire retardant disclosed by the invention has good fire retardant effect, and the generation of hydrogenation catalyst autoignition after the reaction in the agent discarhge process can be inhibited effectively.

Owner:上海阳申石化设备安装有限公司

Flue gas displacement reinforced goaf gas extraction and goaf fire preventing and controlling method

ActiveCN109854294AReduce pressure differenceSolve the problem of air leakageGas removalSpontaneous combustionFlue gas

The invention relates to a flue gas displacement reinforced goaf gas extraction and goaf fire preventing and controlling method. The flue gas displacement reinforced goaf gas extraction and goaf firepreventing and controlling method is suitable for underground use of a coal mine, and comprises the steps that during the stoping process, a rock stratum above a goaf is broken and moved, an annular fracture zone is formed at the position of a caving arch, gas released in the stoping process is enriched, and gas injection pipelines are arranged on a roadside of the outer side of an air inlet lanein a paved mode and buried into the goaf; a drilling field is arranged at one side of an air return lane, pumping and extracting drilling holes are formed in from a drilling field to the caving arch position of the goaf, factory waste flue gas is injected into the goaf through the gas injection pipelines, and the gas enriched in the fracture zone is pumped and extracted through the pumping and extracting drilling holes; the flue gas is used for inhibiting the spontaneous combustion of residual coal in the goaf, the flue gas is injected into the goaf to balance the air pressure in the goaf by using belt pressure, and the air leakage of a working surface to the goaf is weakened; and flue gas is used for replacing, displacing and lifting the gas in the residual coal and surrounding rock to float to the fracture zone, and the gas pumping and extracting amount and the gas pumping and extracting concentration in the pumping and extracting drilling holes are improved to achieve the effects ofthe prevention and control of the fire in the goaf and improving the quality of the gas pumping and extracting.

Owner:CHINA UNIV OF MINING & TECH

A temperature-sensitive cell coat of phase change material, composite inhibitor and preparation method thereof

ActiveCN107955632BGood effectOvercome the disadvantages of easy failureDust removalFire preventionCoal briquetteParaffin wax

The invention discloses phase change material temperature-sensitive coating as well as a composite retarder and a preparation method thereof. A temperature-sensitive phase change material is used as acoating shell, the composite retarder with high water content is directly and externally coated with a composite phase change material, and the composite material takes phase change materials such asparaffin and stearic acid as matrix, uses glass fibers, polypropylene fibers and the like as aggregates and is prepared from flame retardant materials such as magnesium hydroxide, chlorinated paraffin, expanded graphite and glass beads. The phase change material temperature-sensitive coating improves the hardness and ignition point of the phase change material, enables coal briquettes not easy tobreak when falling down, and not only overcomes the defect that the traditional fire preventing and extinguishing retarder is easy to fail, but also well maintains the properties of the retarder; furthermore, the phase change material is more sensitive to temperature rise and can be melted before the critical temperature of coal spontaneous combustion, so that the retarder in the coating can be fully released so as to inhibit the coal spontaneous combustion. The preparation system adopts a modular design, is simple in structure and easy to operate, and can be used for efficiently producing and processing the retarder for the coating.

Owner:CHINA UNIV OF MINING & TECH

Novel hydrogel coal field fire preventing and extinguishing material and using method thereof

InactiveCN111905318AImprove water retentionSuppress spontaneous combustionFire rescueFire extinguisherDehydroacetic acidCellulose

The invention discloses a novel hydrogel coal field fire preventing and extinguishing material, which is prepared by mixing a fire preventing and extinguishing dry material and water according to a material-water mass ratio of 2-3:100; wherein the fire preventing and extinguishing dry material is prepared from the following components in percentage by mass: 80 to 85 percent of composite environment-friendly hydrogel material, 5 to 10 percent of composite anti-enzyme preservative and 10 to 15 percent of composite halogen salt; the composite environment-friendly hydrogel material is prepared from the following components in percentage by mass: 40 to 60 percent of instant polyanionic cellulose, 0.5 to 1.5 percent of high-viscosity polyacrylamide and 38.5 to 58.5 percent of super absorbent resin; the compound type anti-enzyme preservative is prepared from the following components in percentage by mass: 30 to 40 percent of calcium propionate, 15 to 30 percent of potassium sorbate, 15 to 20percent of calcium benzoate and 15 to 30 percent of dehydroacetic acid. The novel hydrogel coal field fire prevention and extinguishing material provided by the invention has good water retention performance, which forms a waterproof film with a certain thickness on the surface of a coal body, so that the product can quickly reduce the temperature of a coal field fire area, and effectively prevents air flow, so that spontaneous combustion of coal is inhibited.

Owner:LIAONING TECHNICAL UNIVERSITY

Preparation method of inhibitor for spontaneous combustion of coal based on magnesium ion compound

PendingCN113789185APlay a flame retardant effectEnhanced inhibitory effectDust removalFire preventionCoal spontaneous combustionDisplacement reactions

The invention discloses a preparation method of an inhibitor for spontaneous combustion of coal based on magnesium ion oxide, and relates to the technical field of preparation of inhibitors for spontaneous combustion of coal. The method comprises the following steps: preparing a solution from a magnesium compound, adding a basic compound, carrying out a metal ion replacement reaction, conducting standing for 2-4 hours, carrying out suction filtration, and performing drying to obtain the inhibitor for spontaneous combustion of coal based on the magnesium ion compound. The preparation method is simple, green and safe in process, and a dispersing agent is added in a reaction process to modify the generated inhibitor, enhance adhesion with coal molecules and improve inhibition effect. A relatively stable magnesium hydroxide compound is generated, and redundant Mg<2+> in a solution jointly acts in the spontaneous combustion process of coal, so early-stage spontaneous combustion of coal can be effectively inhibited, and meanwhile, the service life of the inhibitor for spontaneous combustion of coal is guaranteed.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com