Inactive protect device for ball-shaped bunker

A technology of protection device and spherical bin, which is applied in the direction of packaging, transportation, packaging, containers, etc., and can solve the problems of spontaneous combustion of the coal pile in the warehouse, poor ventilation conditions, and easy accumulation of heat in the coal pile in the warehouse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

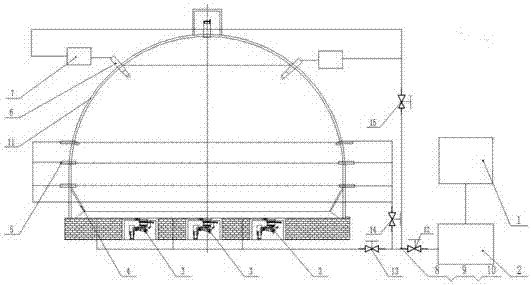

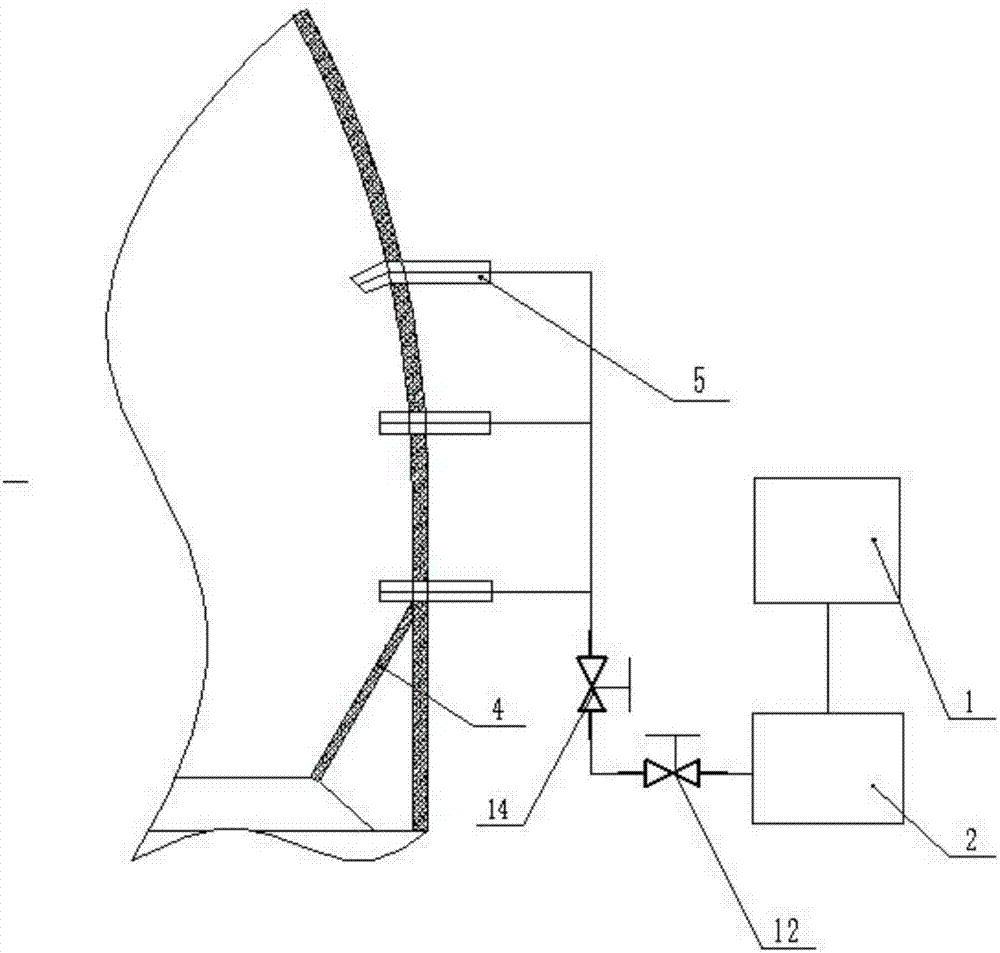

[0020] Such as figure 1 As shown, in this ball warehouse inerting protection device, the gas storage device 1 is connected to the inflation network pipes at all levels through the pressure reducing device 2. The main valve 12, the first stage inflation pipeline valve 13, and the second stage inflation pipeline valve 14 , The third-stage inflation pipeline valve 15 controls the on-off of all stages of inflation network management.

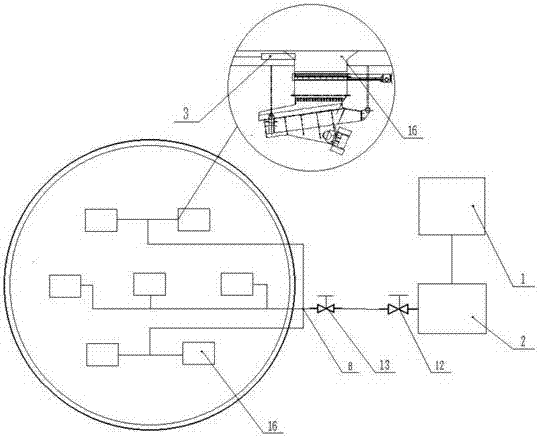

[0021] Such as figure 2 As shown, the first-stage inflatable embedded pipe 3 of the ball silo inerting protection device is arranged at all the coal outlets at the bottom of the ball silo. During inerting protection, the main valve 12 and valve 13 are opened to inert the ball silo bottom. The gaseous carbon dioxide suppresses the hot air pressure effect caused by the spontaneous combustion temperature rise of the coal pile in the ball bin, and achieves the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com