Method for preparing fireproof and explosion suppression pulverized fuel ash carbon dioxide material

A technology of carbon dioxide and fly ash, which is applied in fire prevention, dust prevention, mining equipment, etc., can solve the problem of single preventive effect of fly ash grouting, and achieve suppression of coal spontaneous combustion, inerting gobs, reduction of oxygen concentration and The effect of gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

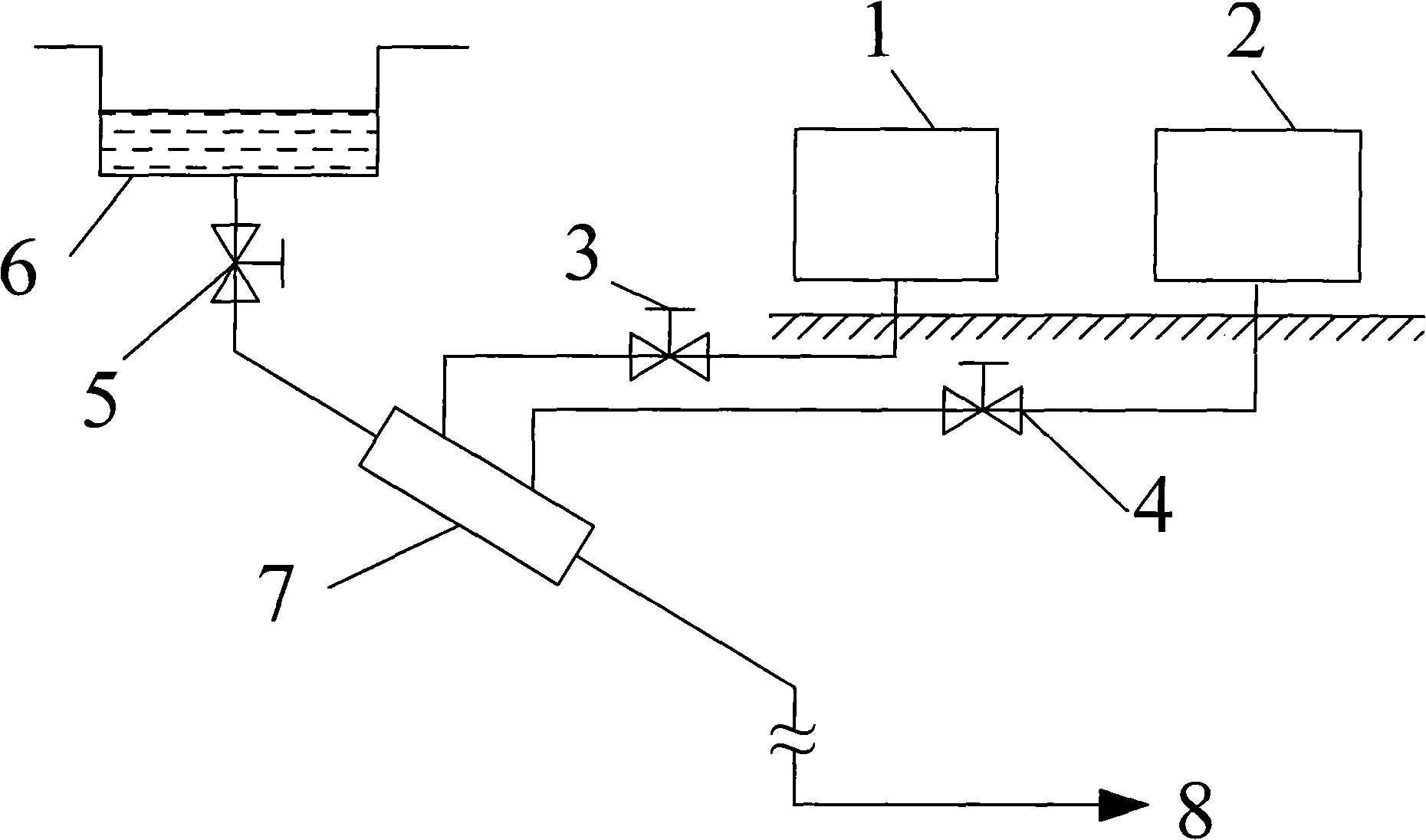

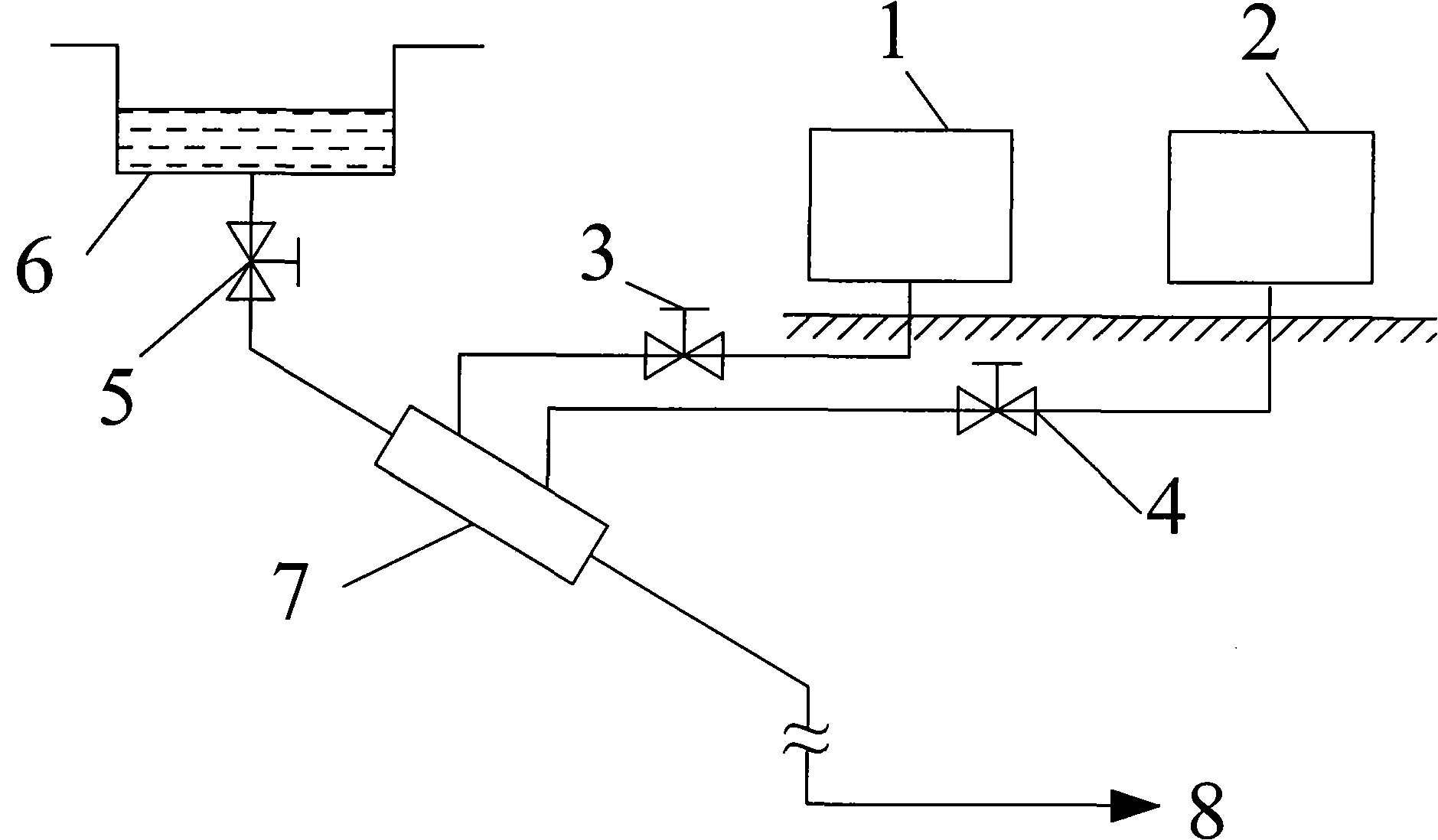

[0012] Embodiment one, at first prepare respectively fly ash slurry, industrial sodium bicarbonate solution, industrial aluminum sulfate and polyvinyl alcohol mixed solution according to mass percentage, then three kinds of different mass percentages of slurry or solution are mixed according to the ratio of 1:1:1 By mixing the mass percentages, the fire-proof and explosion-suppressing fly ash carbon dioxide material that can be directly used is obtained. Specific steps are as follows:

[0013] 1. At room temperature (about 25°C), use the local fire prevention and extinguishing grouting pool 6 of the coal mine, add 70% of water and 30% of fly ash, and fully stir according to the mass percentage to prepare a fly ash slurry;

[0014] 2. Inject 94% of water and 6% of industrial sodium bicarbonate into the industrial sodium bicarbonate solution box 1, fully stir to dissolve it according to the mass percentage, and prepare industrial sodium bicarbonate solution;

[0015] 3. Inject ...

Embodiment 2

[0020] In the mass percentage of fly ash slurry: 75% of water, 25% of fly ash; in the mass percentage of industrial sodium bicarbonate solution: 96% of water, 4% of industrial sodium bicarbonate; in the mass percentage of industrial aluminum sulfate and polyvinyl alcohol mixed solution Middle: 85% water, 10% industrial aluminum sulfate, 5% polyvinyl alcohol. Others are the same as in Embodiment 1, omitted.

Embodiment 3

[0022] In the mass percentage of fly ash slurry: 80% of water, 20% of fly ash; in the mass percentage of industrial sodium bicarbonate solution: 98% of water, 2% of industrial sodium bicarbonate solution; in the mass percentage of industrial aluminum sulfate and polyvinyl alcohol mixed solution : Water 92%, industrial aluminum sulfate 5%, polyvinyl alcohol 3%. Others are the same as in Embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com