Deodorant and preparation method and application thereof

A technology for deodorization and pore-forming agent, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of poor deodorization effect, high cost, poor hardness, etc., and achieve fast deodorization reaction, low cost, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a deodorant with good safety, low cost, high purification degree and good desulfurization efficiency, and the preparation method is simple. It is used for adsorption and conversion of sulfur-containing substances in oxidative atmospheres such as air. The sulfur-containing substances are enriched on the deodorizer, and then they are catalyzed and converted into oxygen-containing sulfides to achieve the purpose of deodorization.

[0036] The polycarboxylic acid mentioned in the present invention refers to citric acid, oxalic acid or tartaric acid.

[0037] The CMC refers to sodium carboxymethyl cellulose, and its English name is Sodium Carboxymethyl Cellulose;

[0038] The PEG-1000 refers to polyethylene glycol 1000;

Embodiment 1

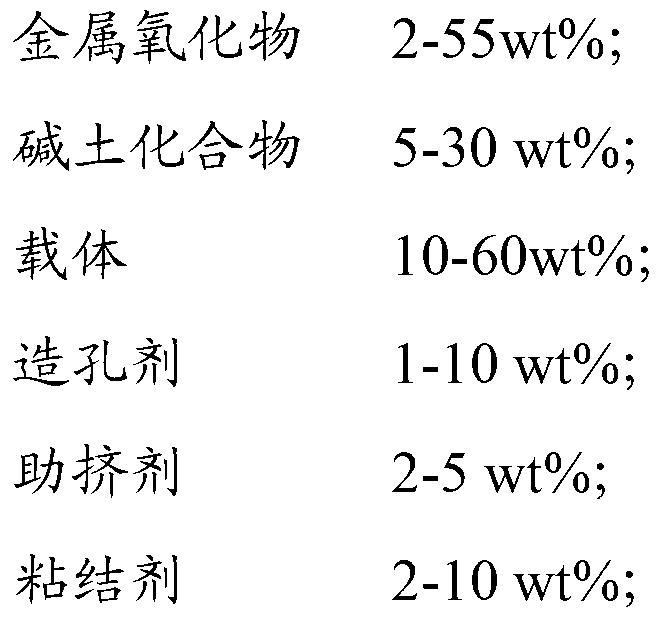

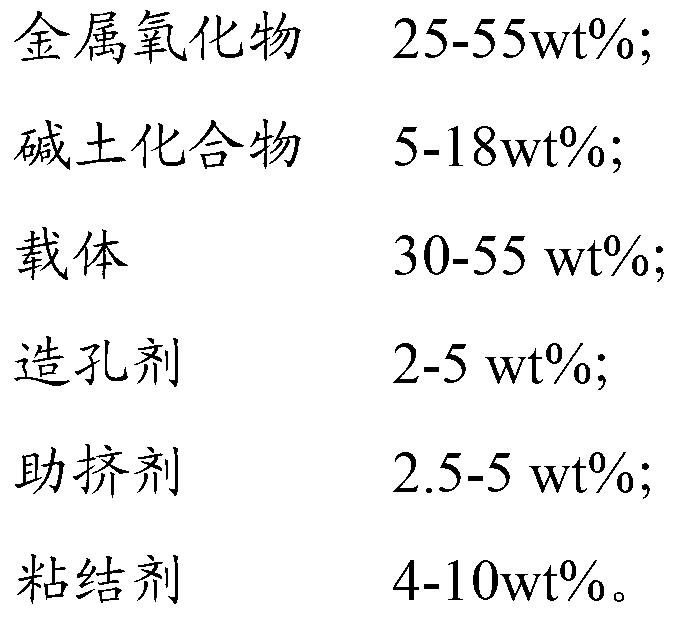

[0041] A kind of deodorizing agent, described deodorizing agent is prepared by the material of following percentage by weight:

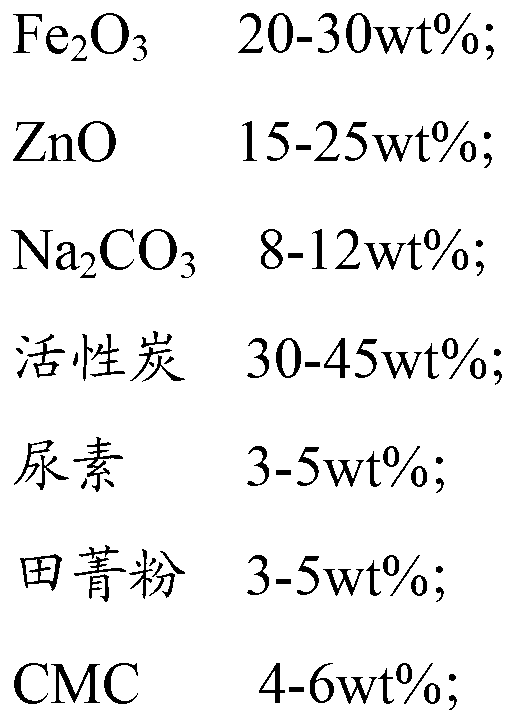

[0042] The metal oxide is: zinc oxide 25wt%;

[0043] Alkaline earth compound is: sodium hydroxide 5wt%, sodium carbonate 5wt%;

[0044] The carrier is: activated carbon 55wt%, the particle size of the activated carbon is 120 mesh, and the specific surface area is 230m 2 / g;

[0045] The pore-forming agent is: oxalic acid 3wt%;

[0046] Extrusion aid is: lubricating oil 3wt%;

[0047] The binder is: CMC4wt%;

[0048] The preparation method of described deodorant, comprises the steps:

[0049] (1) Mix the above materials evenly to obtain a mixture;

[0050] (2) Add 35wt% water to the mixture, that is, add water with a water-powder ratio of 35wt%, and put it in an extruder to knead and extrude, dry at 80°C for 6 hours, and roast at 400°C for 3 hours to obtain deodorization agent TC1.

Embodiment 2

[0052] A kind of deodorizing agent, described deodorizing agent is prepared by the material of following percentage by weight:

[0053]The metal oxides are: aluminum oxide 10wt%, calcium oxide 5wt%, manganese oxide 10wt%, magnesium oxide 10wt%, zinc oxide 10wt%;

[0054] The alkaline earth compound is: potassium hydroxide 5wt%;

[0055] The carrier is: activated carbon 30wt%, the particle size of the activated carbon is 200 mesh, and the specific surface area is 386m 2 / g;

[0056] The pore forming agent is: urea 5wt%;

[0057] Extrusion aid is: talcum powder 5wt%;

[0058] The binder is: polyvinyl alcohol 10wt%;

[0059] The preparation method of described deodorant, comprises the steps:

[0060] (1) Mix the above materials evenly;

[0061] (2) Add 40wt% water to the mixture, that is, add water with a water-powder ratio of 40wt%, and place it in an extruder to knead and extrude, dry at 50°C for 6 hours, and roast at 350°C for 4 hours to obtain deodorization agent TC2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com