Controllable gas injection point gas injection device, gas injection technology and gasification method

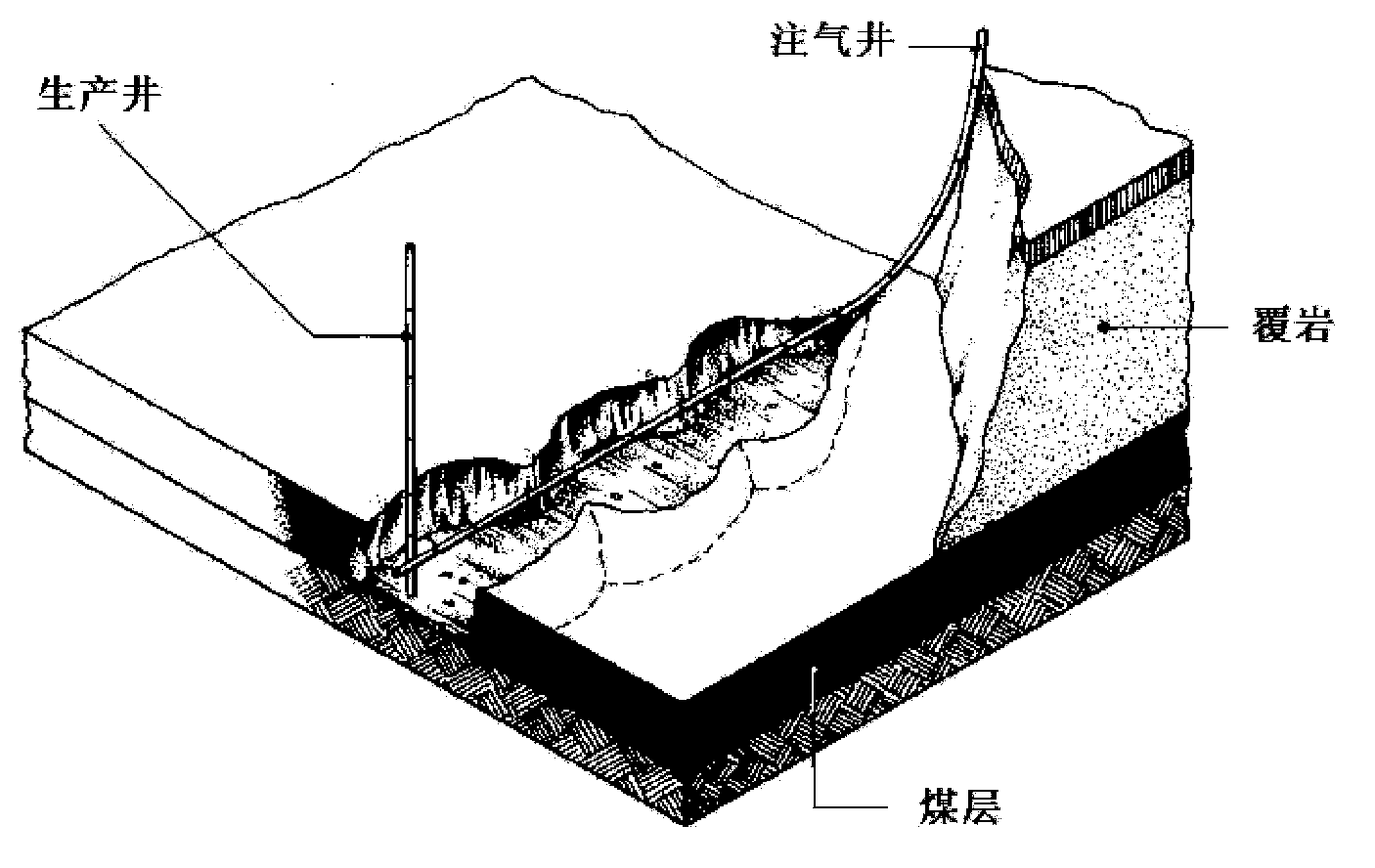

A gas injection point and gas injection technology, which is used in coal gasification, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of discontinuous movement of gas injection point position, poor stability of gasification process, and multiple ignition devices. , to reduce the blind area of coal seam gasification combustion, prevent the spontaneous combustion of coal seam in the channel, and improve the gasification recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

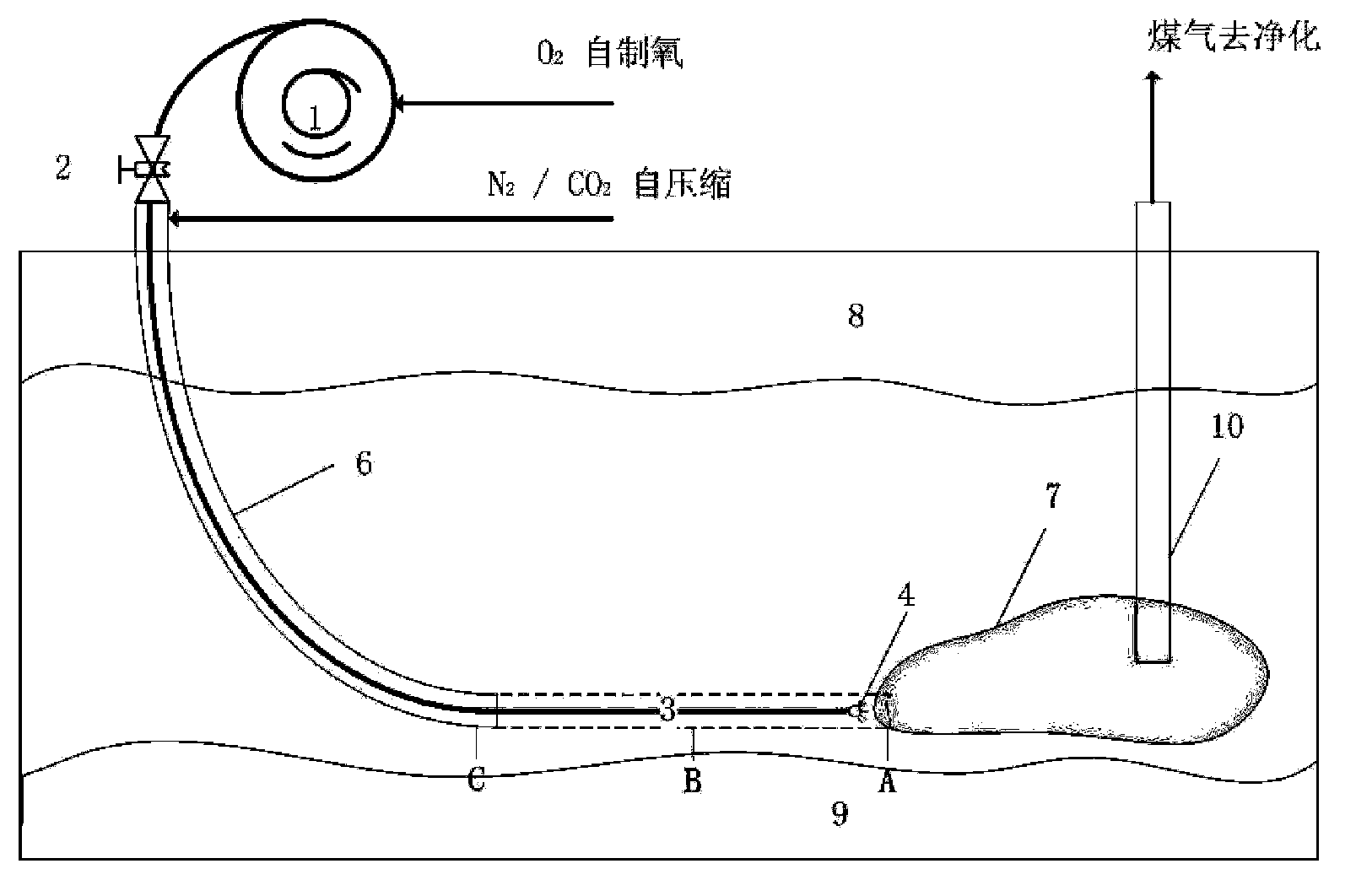

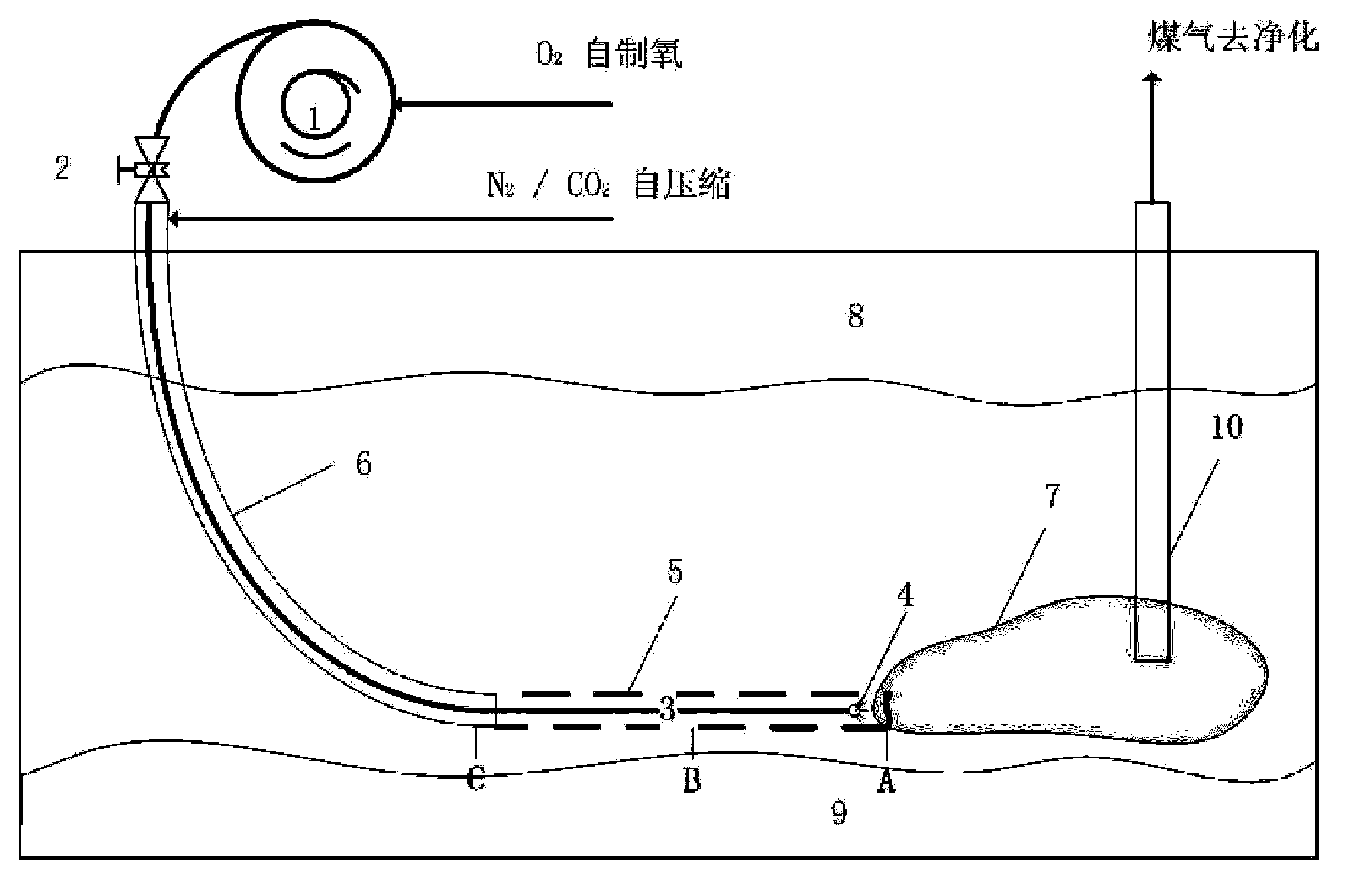

[0065] A controllable gas injection point gas injection device, the gas injection device includes a directional well channel 6, and a coiled tubing 3 is arranged in the directional well channel 6; the coiled tubing 3 communicates with an oxygen / oxygen-enriched gas pipeline; the The coiled tubing 3 and the annulus of the directional well channel 6 are connected with the auxiliary gasification agent pipeline and the steam pipeline;

[0066] The tubing drum 1 is used for carrying the coiled tubing 3 .

Embodiment 2

[0068] A gas injection process with a controllable gas injection point. The gas injection process transports oxygen / oxygen-enriched gas through coiled tubing placed in the channel of a directional well. The transported auxiliary gasification agent is mixed evenly at the nozzle position at the end of the coiled tubing, and the mixed gasification agent enters the predetermined gasification position of the coal seam through the directional well channel or the pore channel in the coal seam.

[0069] The directional well channel is formed by a directional drilling method; the directional drilling method preferably adopts directional well technology, horizontal well technology, sidetracking well technology, radial horizontal well technology, branch well technology, Any one of cluster well technology or extended reach well technology, the channel length of the directional well is greater than 10m.

[0070] The pore channel in the coal seam is formed by artificial drilling and fractur...

Embodiment 3

[0075] A gasification method with controllable gas injection point. The method realizes segmental movement of the gas injection point to a predetermined gasification position by moving the coiled tubing in stages, and then adjusts the gas injection process parameters for reverse ignition, gasification channel processing and gasification. chemical production.

[0076] Described gasification method comprises the steps:

[0077] 1) According to the parameters such as the thickness and reserves of the gasification coal seam in the gasification area, the position of the gas injection point is moved to the predetermined gasification position by moving the coiled tubing in stages according to the gas injection process;

[0078] 2) Adjust the pressure and flow rate of a single gas, control the parameters such as the flow rate, pressure and oxygen concentration of the injected gasification agent; use the reverse combustion method to gradually move the flame working surface to the prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com