Comprehensive treatment method for gas and coal spontaneous combustion in near-horizontal thick coal seam mining

A technology for comprehensive treatment and thick coal seam, which can be used in gas discharge, mining equipment, earth-moving drilling, etc., and can solve problems such as single disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

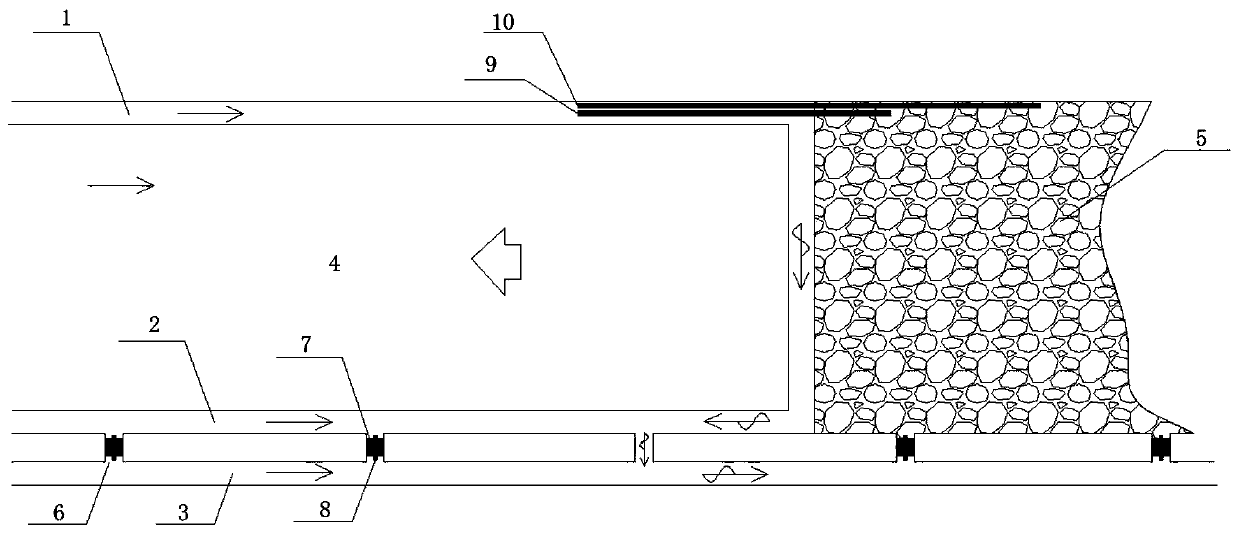

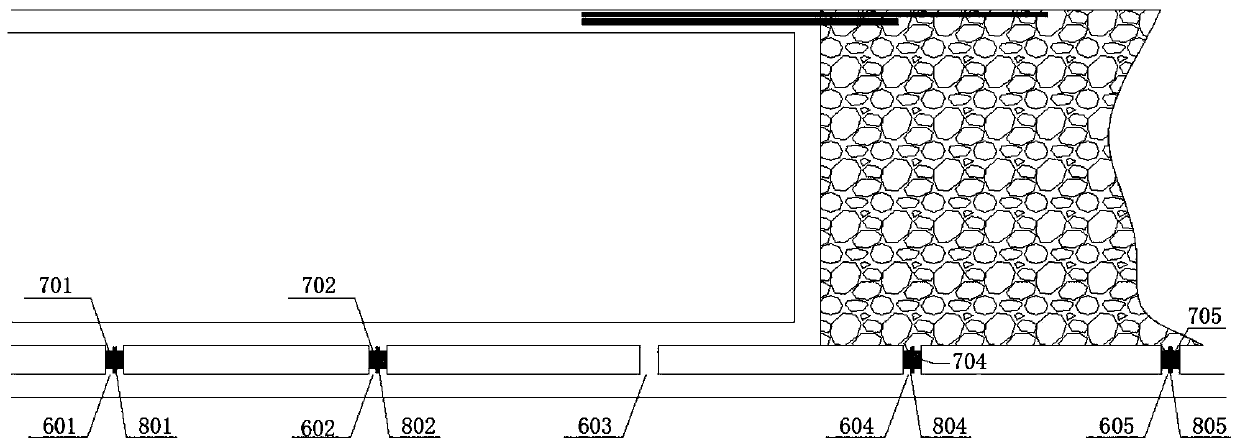

[0046] Such as Figure 1~4 As shown, a kind of near horizontal thick coal seam mining gas and coal spontaneous combustion comprehensive treatment method provided by the present invention comprises the following steps:

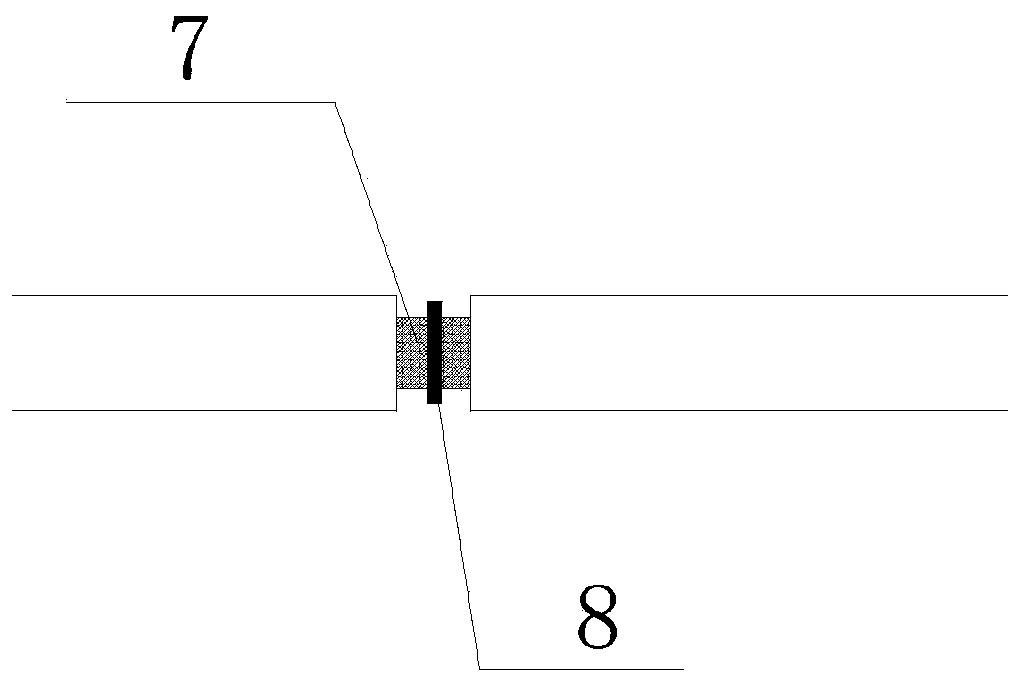

[0047] (1) Use a two-inlet and one-return partial Y-shaped downward ventilation system to control the gas gushing out of the mining face 4: use the air inlet lane 1 of the mining face and the rubber transport lane 2 of the mining face to enter the air, and the auxiliary transport lane 3 of the mining face Return air, wherein the rubber transport lane 2 of the mining face and the auxiliary transport lane 3 of the mining face are connected through the connecting lane 6 every 100m, and the communicating lane 6 is sealed by the airtight wall 7. When the mining face 4 pushes through one of the communicating lanes, Close the airtight wall of the connecting roadway, open the airtight wall of the connecting roadway in front, and have and only one airtight wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com