Capsule fire preventing and extinguishing material for coal bed fire and preparation method thereof

A technology for fire prevention and fire prevention. It can be used in fire prevention equipment and other directions. It can solve the problems of high stirring intensity, low water absorption of materials, and difficult to prevent and extinguish fire, and achieve good thermal stability and heat resistance, film-forming and dispersibility. Good, reduce the effect of oxidation reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

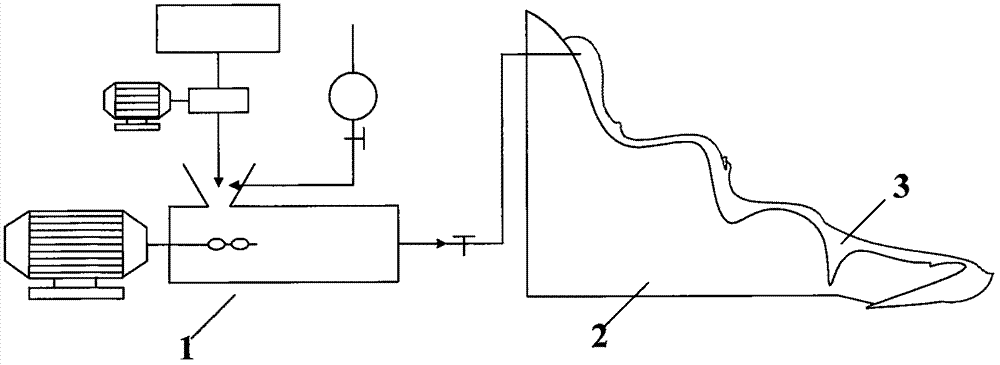

Method used

Image

Examples

Embodiment 1

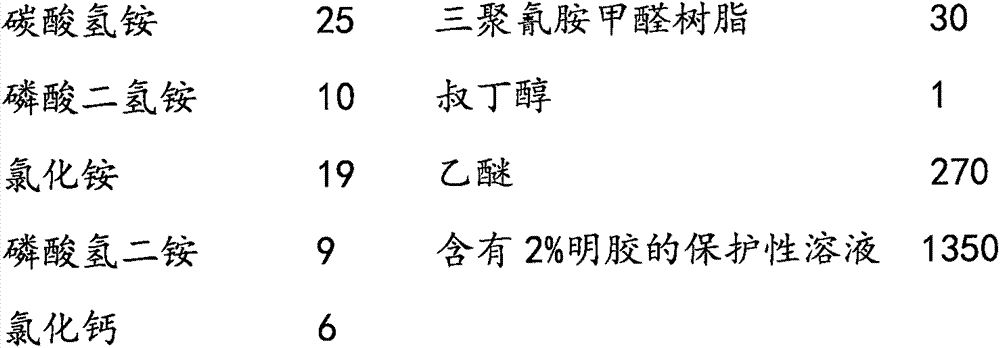

[0026] A capsule fire-proofing material for coal seam fires and a preparation method thereof, the materials required for preparing the capsule fire-proofing material for coal seam fires are as follows in terms of mass fractions:

[0027]

[0028] Follow the steps below for production:

[0029] a, take the weight of each component respectively according to the proportion;

[0030] b. Grinding ammonium bicarbonate, ammonium dihydrogen phosphate, ammonium chloride, diammonium hydrogen phosphate, calcium chloride, and melamine formaldehyde resin respectively so that the particle diameters are all less than 50 μm, and mixing ammonium bicarbonate, ammonium dihydrogen phosphate, Ammonium chloride, diammonium hydrogen phosphate, and calcium chloride are placed in a container and mixed fully and uniformly to form a mixed powder.

[0031] c. Put the melamine formaldehyde resin in ether, stir to accelerate the dissolution until it is completely dissolved, add the above mixed powder a...

Embodiment 2

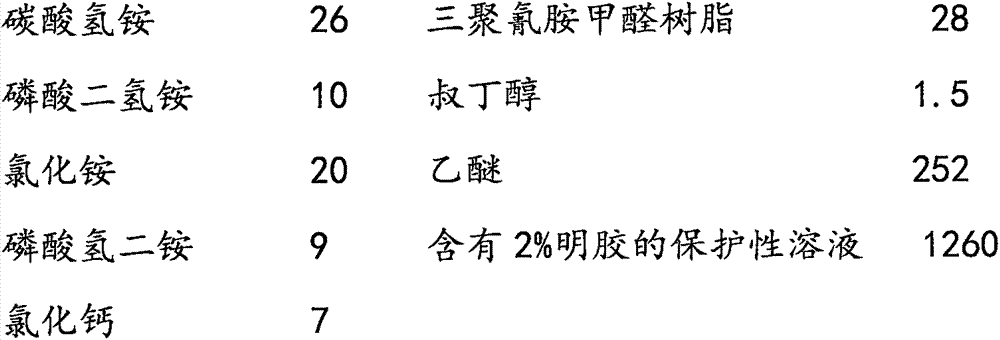

[0035] A capsule fire-proofing material for coal seam fires and a preparation method thereof, the materials required for preparing the capsule fire-proofing material for coal seam fires are as follows in terms of mass fractions:

[0036]

[0037] Follow the steps below for production:

[0038] a, take the weight of each component respectively according to the proportion;

[0039] b. Grinding ammonium bicarbonate, ammonium dihydrogen phosphate, ammonium chloride, diammonium hydrogen phosphate, calcium chloride, and melamine formaldehyde resin respectively so that the particle diameters are all less than 50 μm, and mixing ammonium bicarbonate, ammonium dihydrogen phosphate, Ammonium chloride, diammonium hydrogen phosphate, and calcium chloride are placed in a container and mixed fully and uniformly to form a mixed powder.

[0040] c. Put the melamine formaldehyde resin in ether, stir to accelerate the dissolution until it is completely dissolved, add the above mixed powder a...

Embodiment 3

[0044] A capsule fire-proofing material for coal seam fires and a preparation method thereof, the materials required for preparing the capsule fire-proofing material for coal seam fires are as follows in terms of mass fractions:

[0045]

[0046] Follow the steps below for production:

[0047] a, take the weight of each component respectively according to the proportion;

[0048] b. Grinding ammonium bicarbonate, ammonium dihydrogen phosphate, ammonium chloride, diammonium hydrogen phosphate, calcium chloride, and melamine formaldehyde resin respectively so that the particle diameters are all less than 50 μm, and mixing ammonium bicarbonate, ammonium dihydrogen phosphate, Ammonium chloride, diammonium hydrogen phosphate, and calcium chloride are placed in a container and mixed fully and uniformly to form a mixed powder.

[0049] c. Put the melamine formaldehyde resin in ether, stir to accelerate the dissolution until it is completely dissolved, add the above mixed powder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com