Patents

Literature

851results about How to "Isolated contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gastric bypass prosthesis

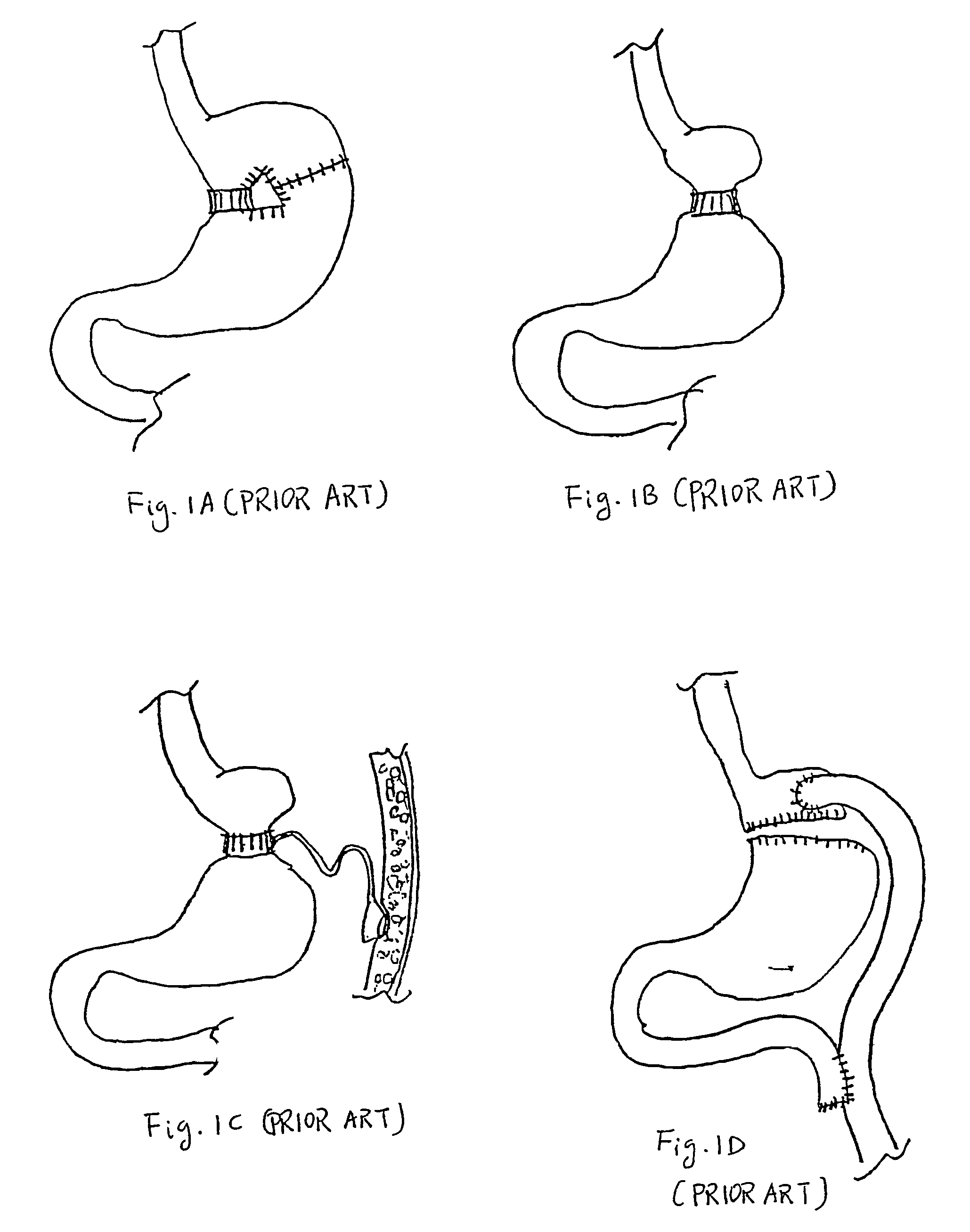

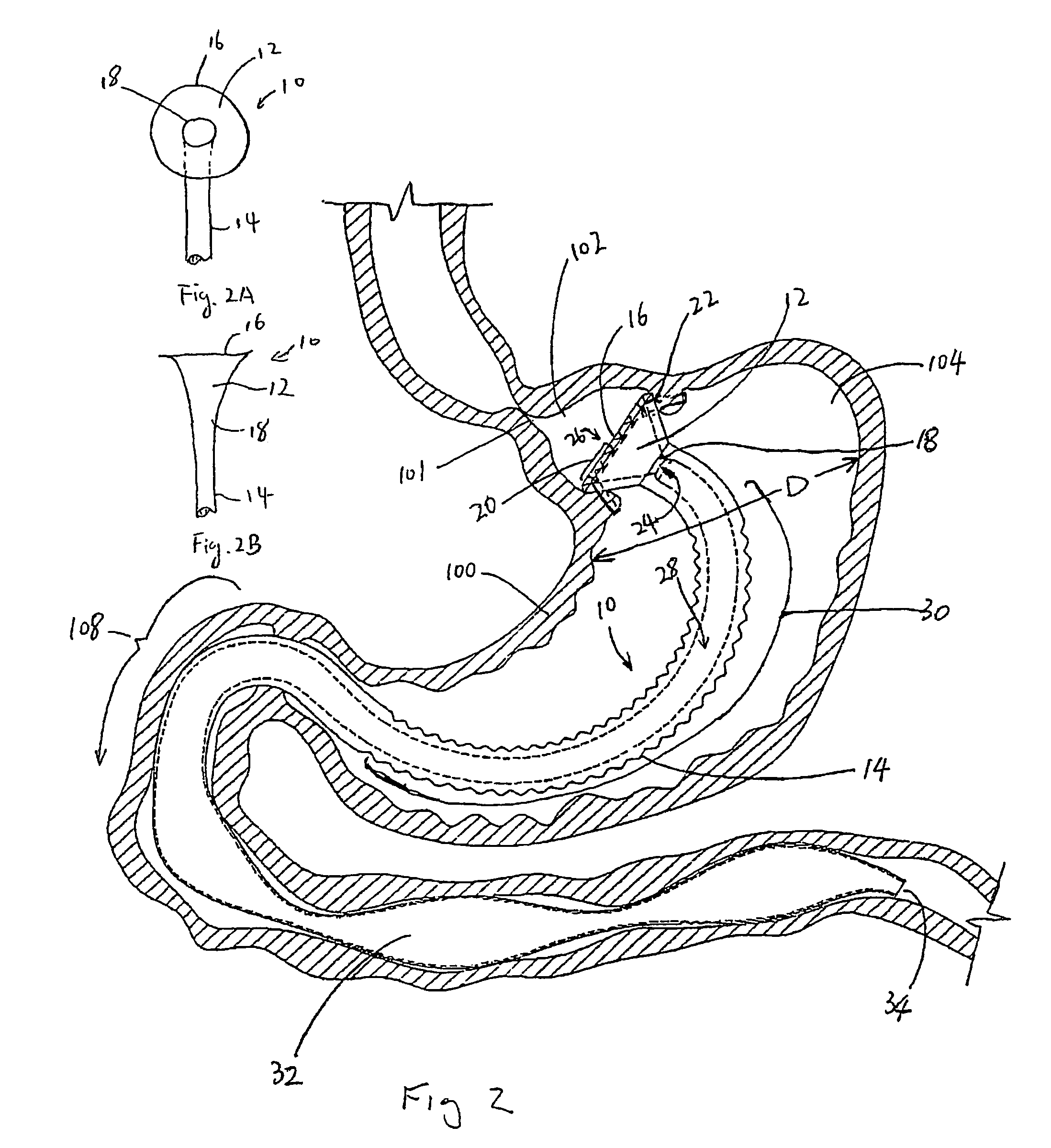

InactiveUS20050256587A1Sufficient diametric rigidityIsolated contactSuture equipmentsIntravenous devicesPylorusProsthesis

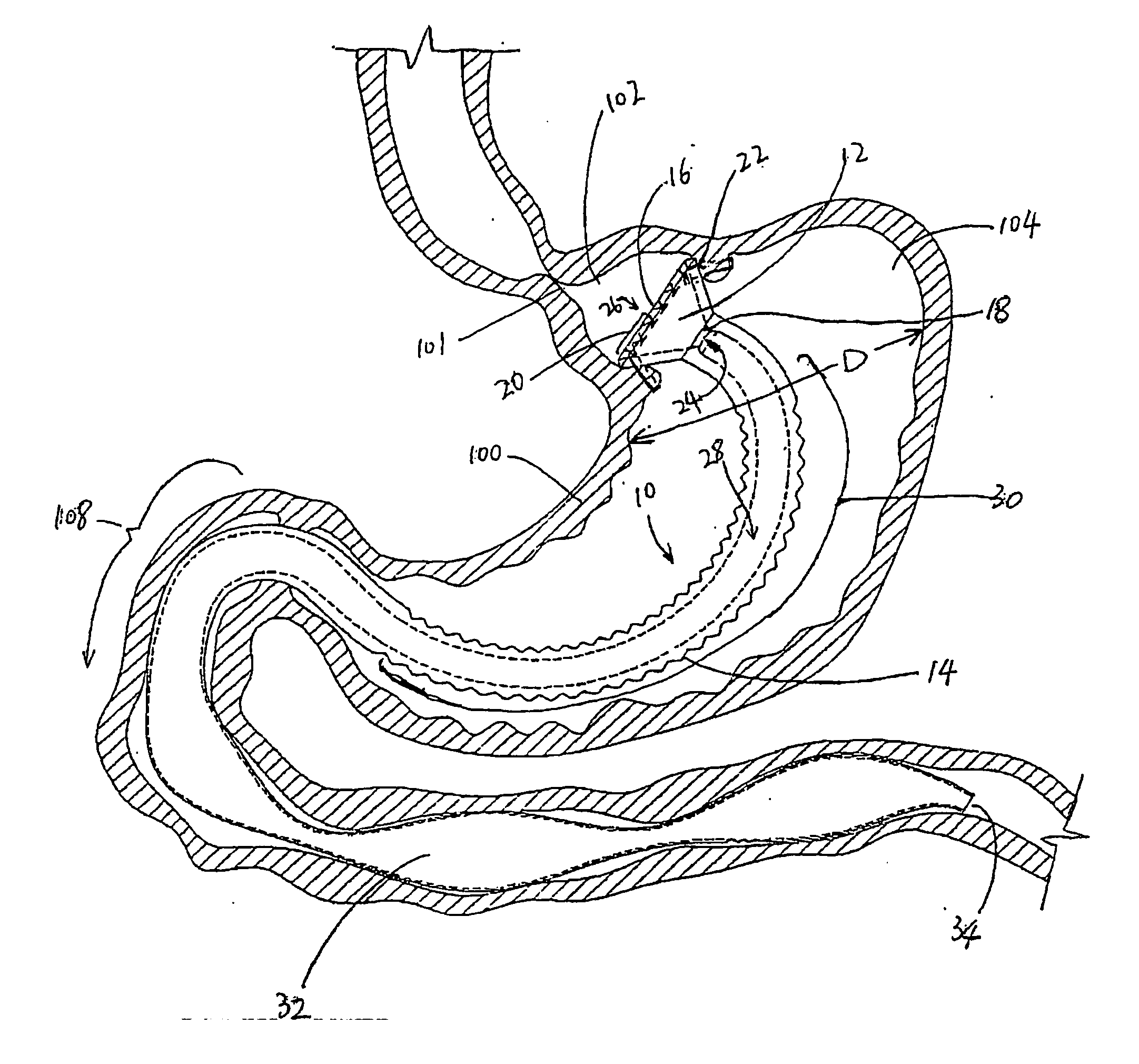

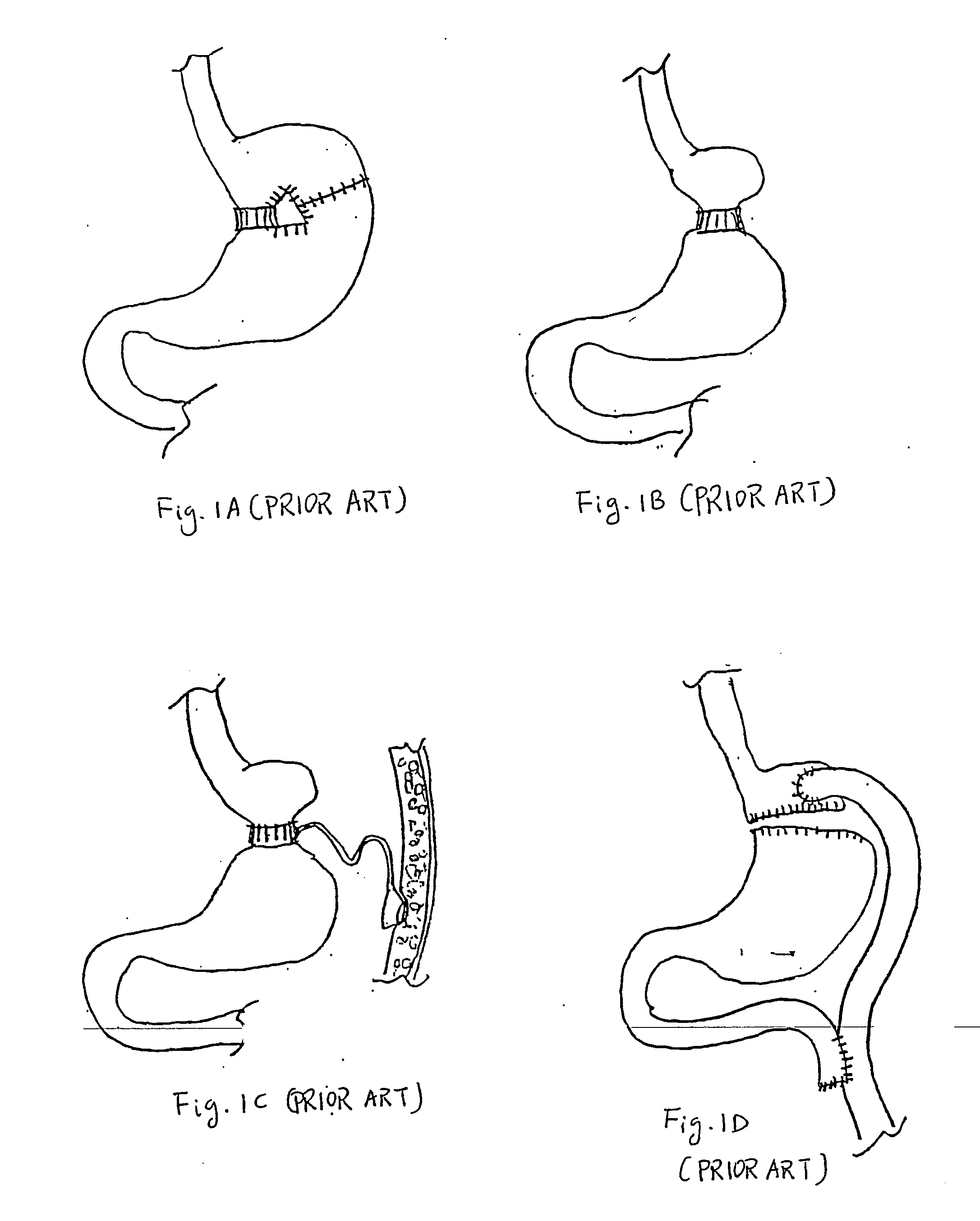

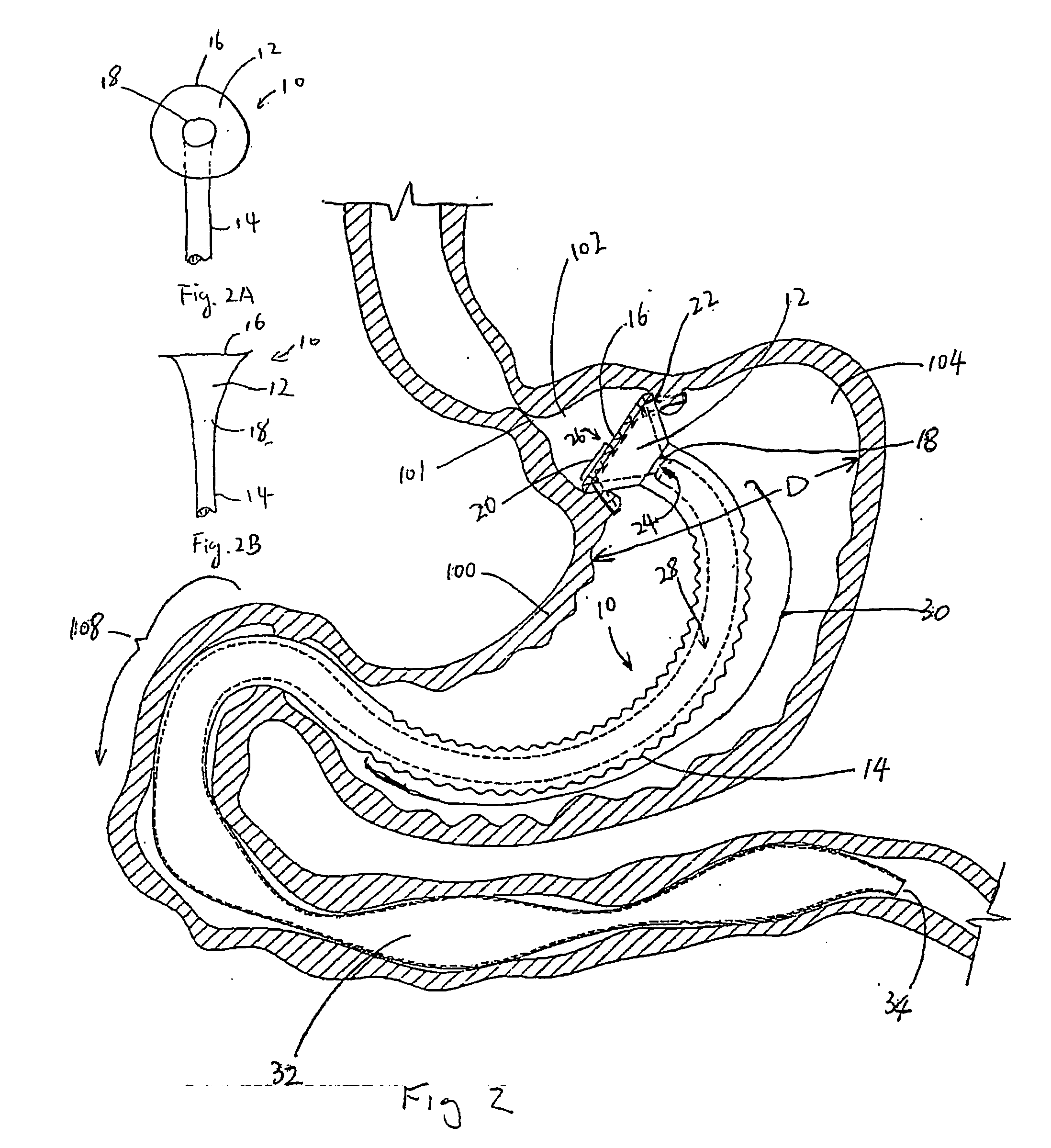

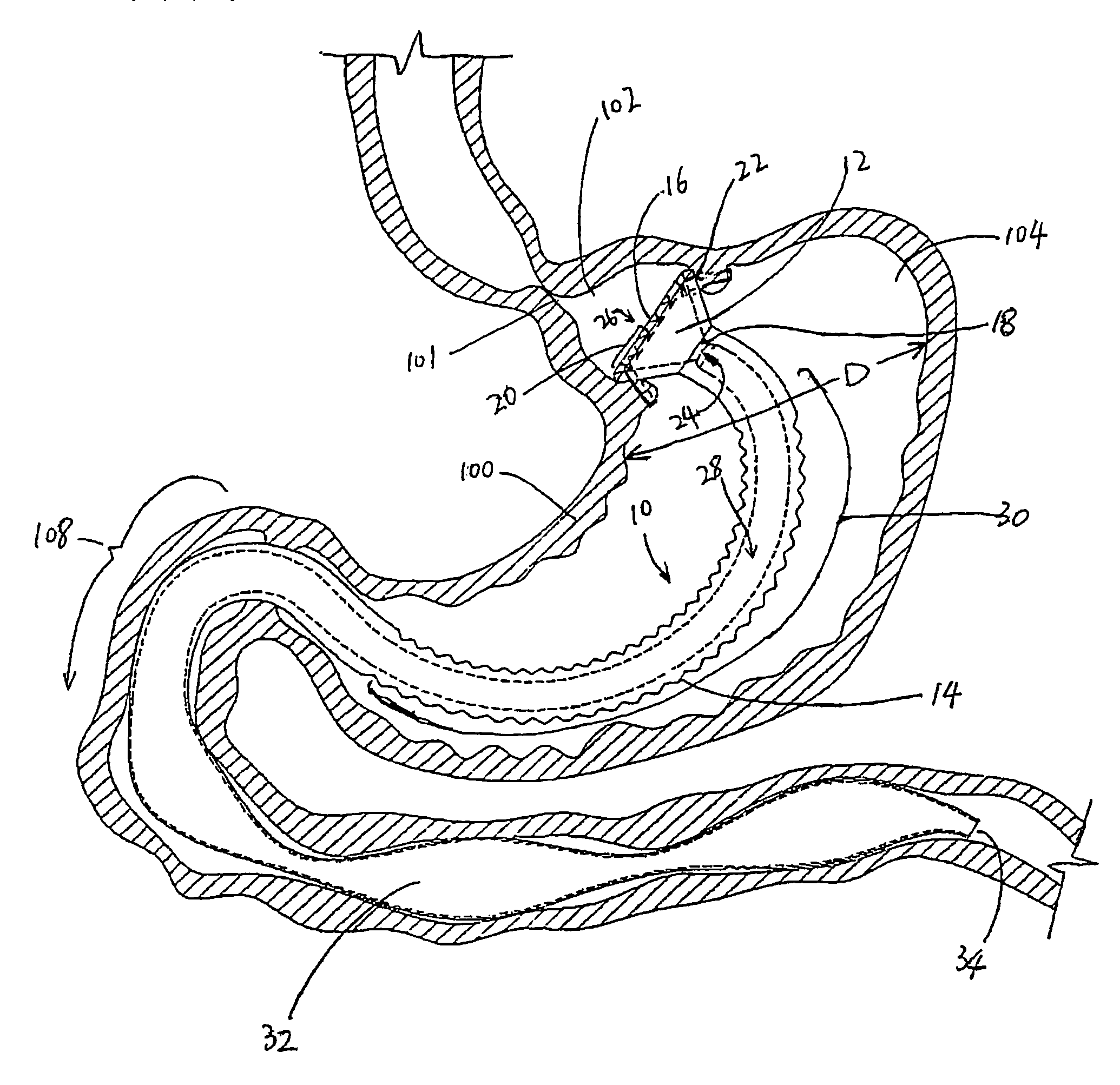

A device (10) for treatment of obesity of a patient comprises an annular element (12) having a relatively large outer boundary and a relatively small inner boundary, and an elongated flexible tube (14) extending from the relatively small inner boundary of the annular element to a distal end. The relatively large outer boundary is adapted to be attached to an inner wall of a stomach (100) of a patient, such that the annular element divides the stomach (100) into two chambers, an esophagus-end chamber close to an esophagus of the patient, and a pylorus-end chamber close to a pylorus of the patient. The invention also provides a method for treatment of obesity of a patient which includes inserting an annular element having a relatively large outer boundary and a relatively small inner boundary into a stomach of the patient, and attaching the relatively large outer boundary of the annular element to an inner circumference of the stomach of the patient.

Owner:EGAN THOMAS +1

Gastric bypass prosthesis

InactiveUS7316716B2Limiting the amount of food intake of a patientReduce morbiditySuture equipmentsIntravenous devicesPylorusProsthesis

A device (10) for treatment of obesity of a patient comprises an annular element (12) having a relatively large outer boundary and a relatively small inner boundary, and an elongated flexible tube (14) extending from the relatively small inner boundary of the annular element to a distal end. The relatively large outer boundary is adapted to be attached to an inner wall of a stomach (100) of a patient, such that the annular element divides the stomach (100) into two chambers, an esophagus-end chamber close to an esophagus of the patient, and a pylorus-end chamber close to a pylorus of the patient. The invention also provides a method for treatment of obesity of a patient which includes inserting an annular element having a relatively large outer boundary and a relatively small inner boundary into a stomach of the patient, and attaching the relatively large outer boundary of the annular element to an inner circumference of the stomach of the patient.

Owner:EGAN THOMAS +1

Fruit tree protection glue for preventing fruit tree disease scar and wound generated by pruning from rot

The invention relates to a fruit tree protective agent, particularly a kind of fruit protective glue for preventing fruit tree scar and rotting wound produced by pruning. The invention solves the problems existing in present technology, for instance the traditional technology of treating fruit tree wound and cut is simple, the effect is bad, and so on. The product is composed of the following materials: 60-70 parts by weight of polyvinyl alcohol, 10-20 parts by weight of glycerol, 0.004-0.006 parts by weight of GA, 4-5 parts by weight of asomate, 85-100 parts by weight of water, heating and dissolving and at last forming a jelly solution. The product can prevent rot disease, and occurrence of new diseases, heal the wound and scar gradually, prevent the cracks between the tree bark and the xylem, make the tissue around the scar or wound heal in Jun-Jul in present year, and the efficiency is 95%. The product is applied in apple tree, pear tree, peach tree and other economic crops. The product is easy to use all year round without preparation at the scene.

Owner:郑永昌

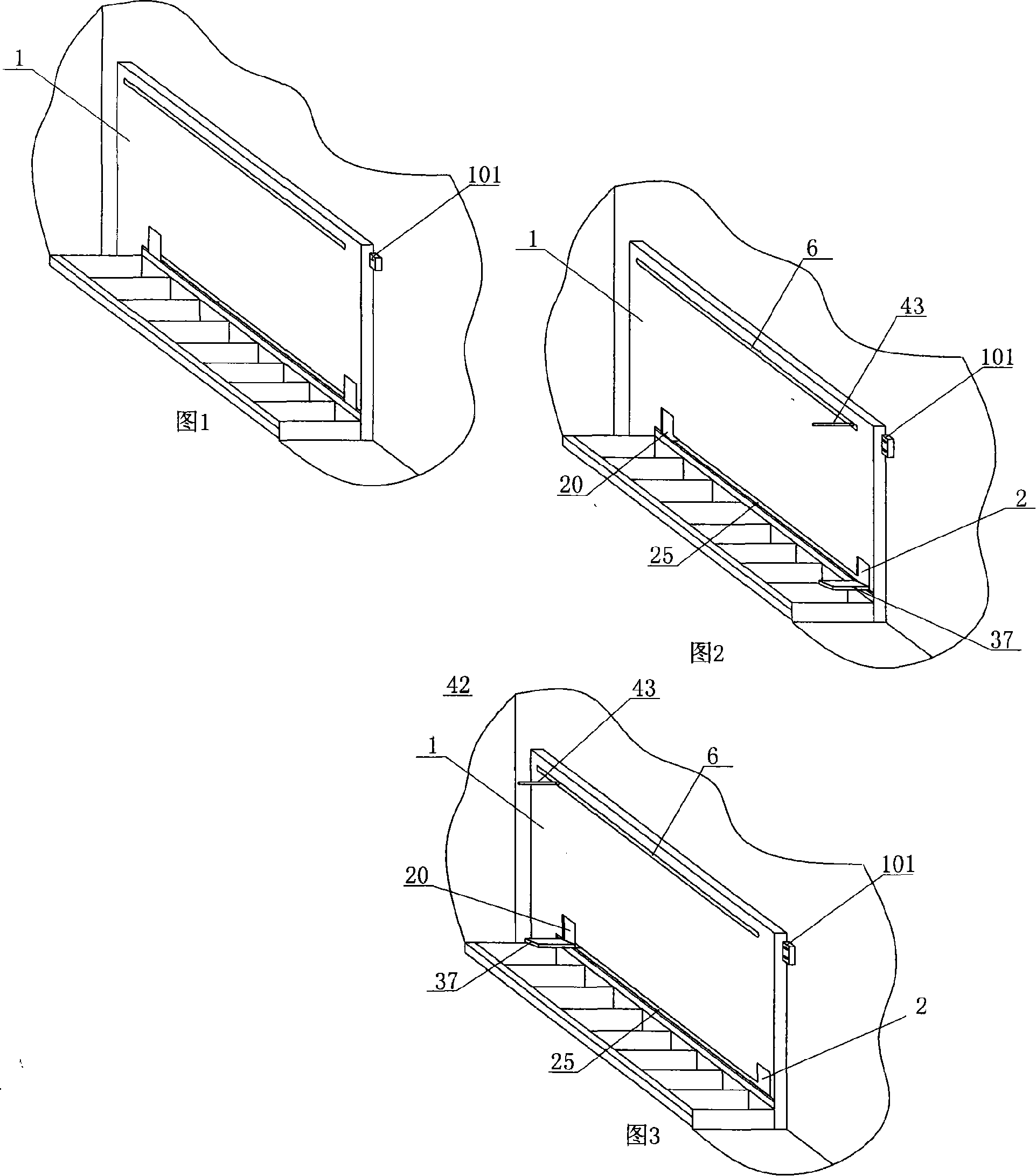

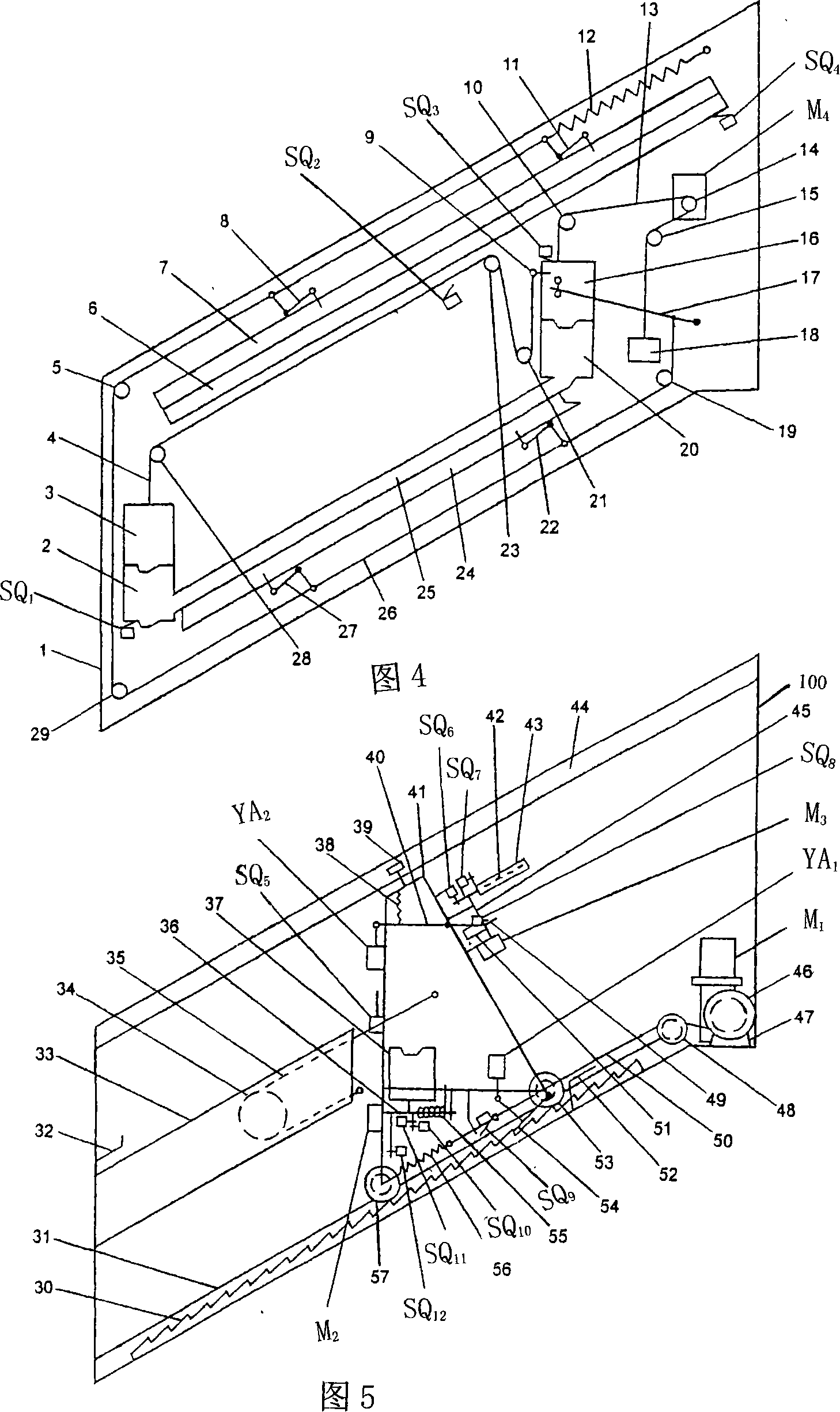

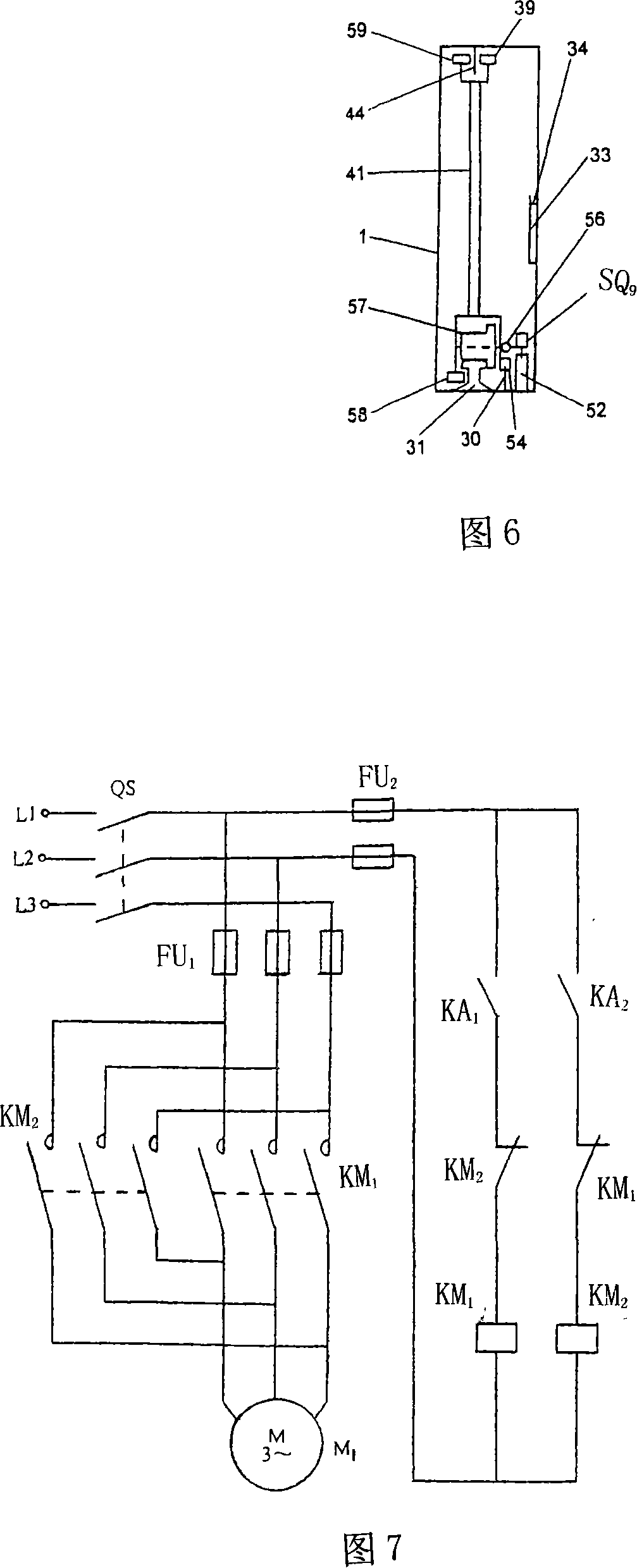

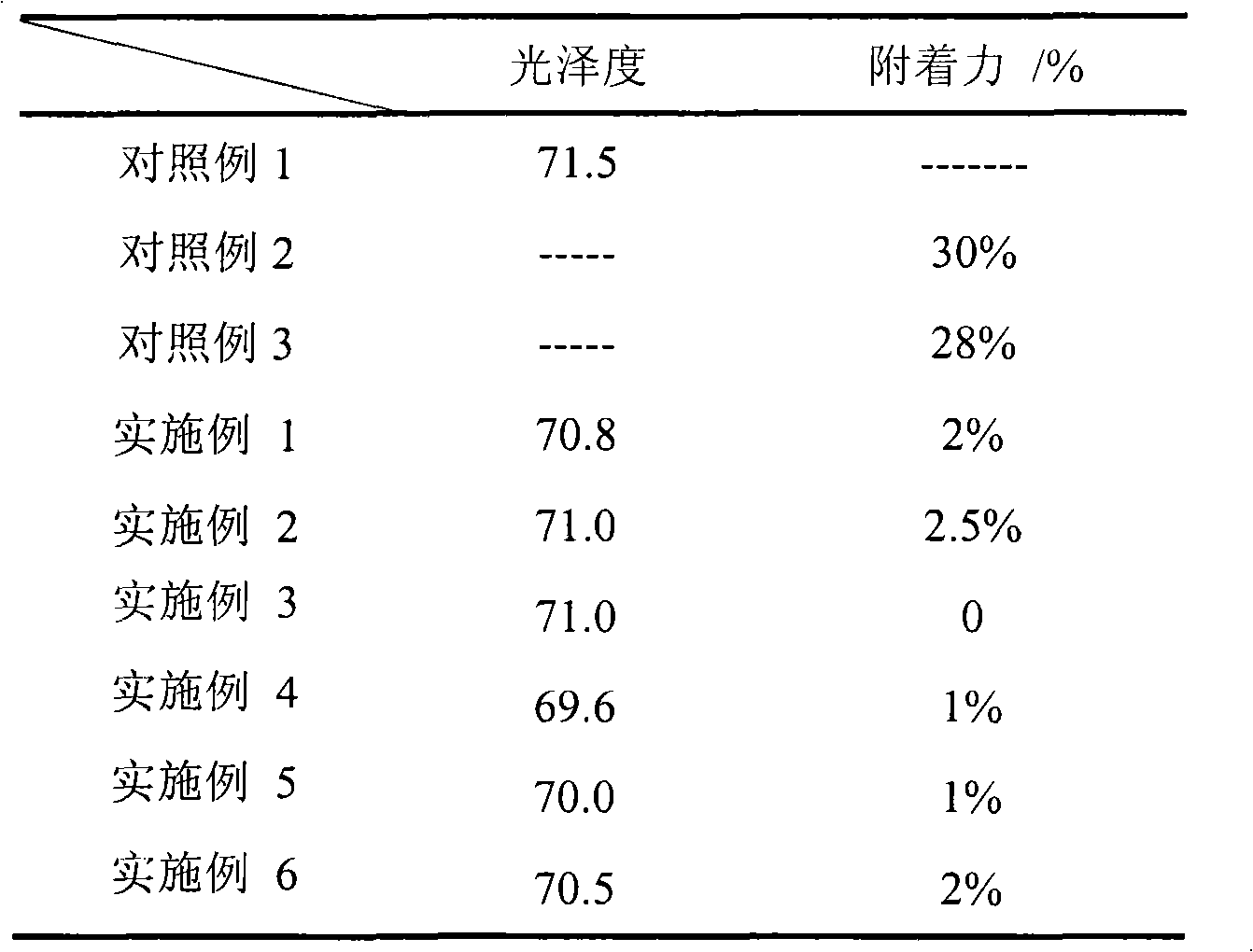

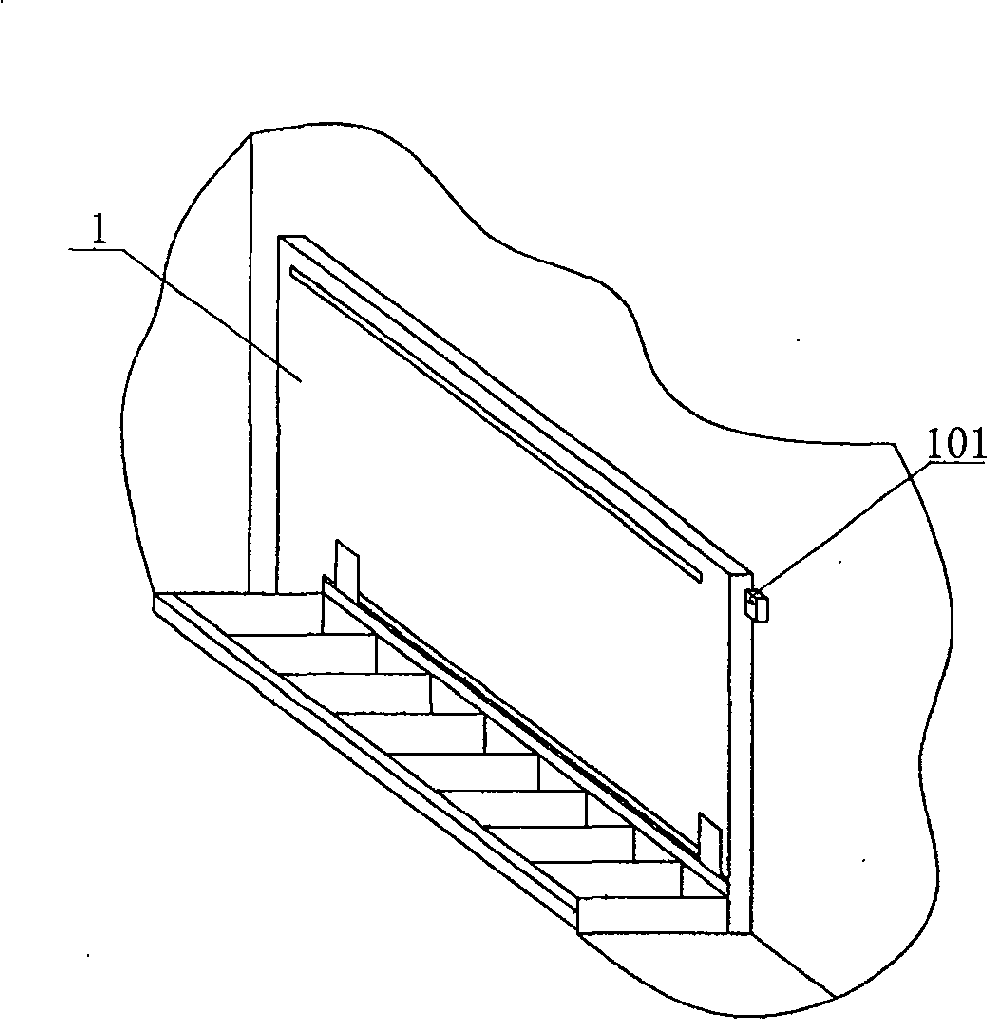

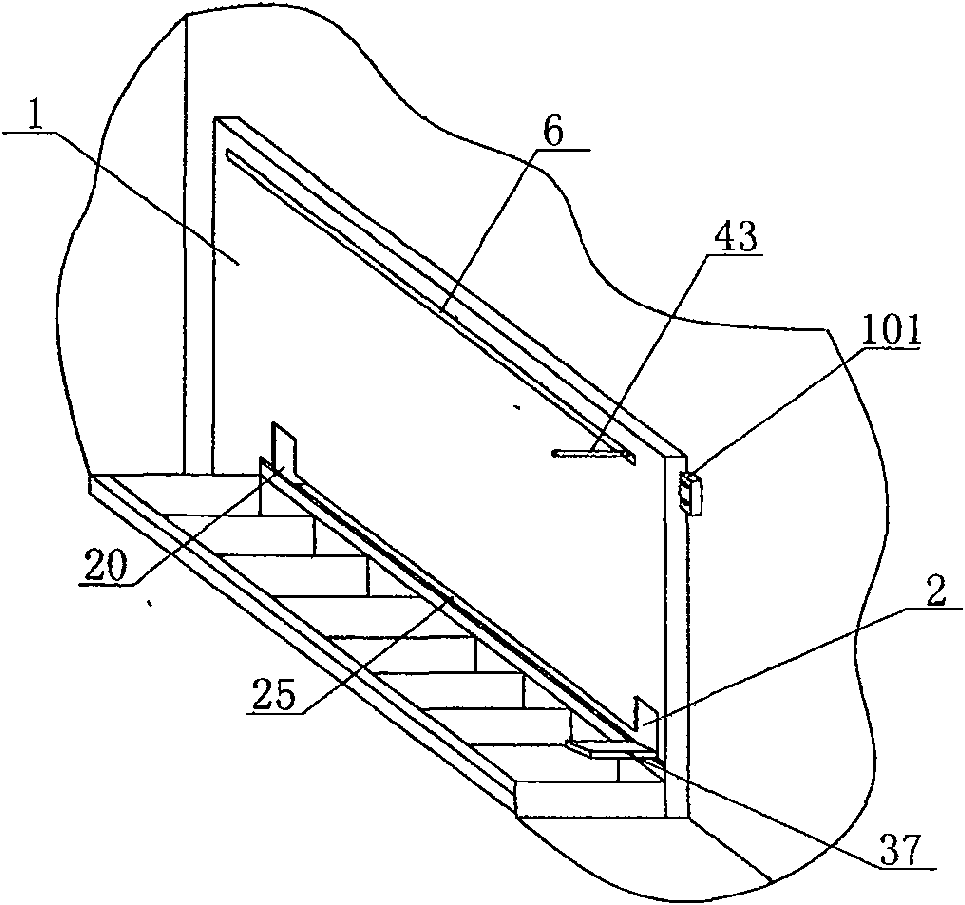

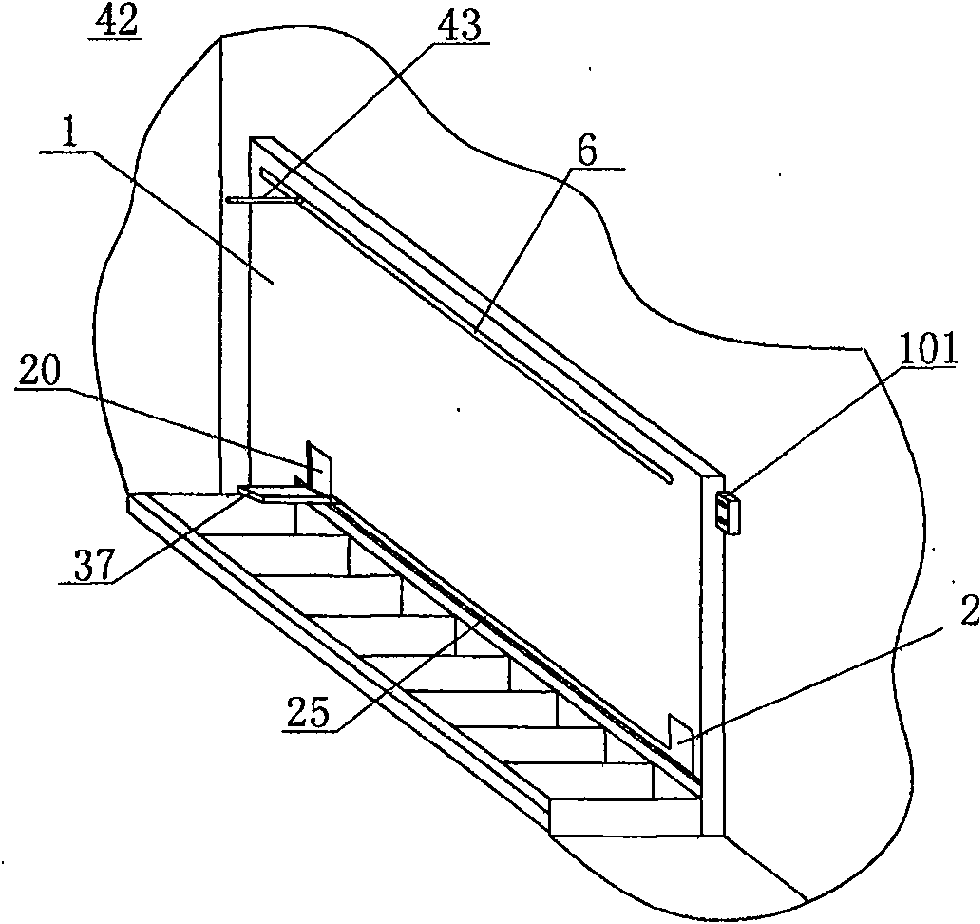

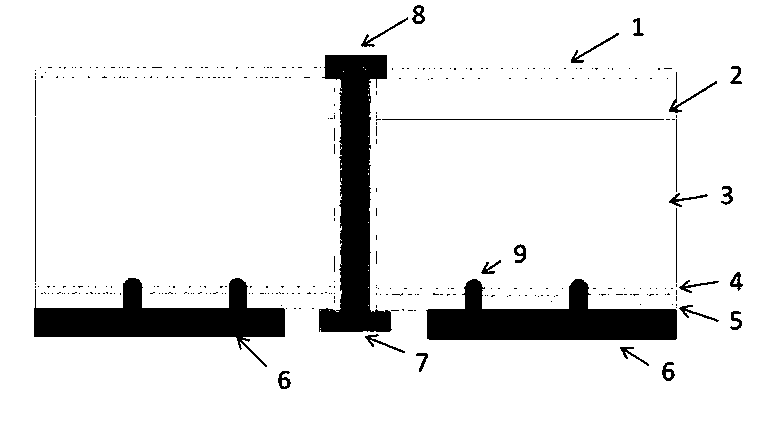

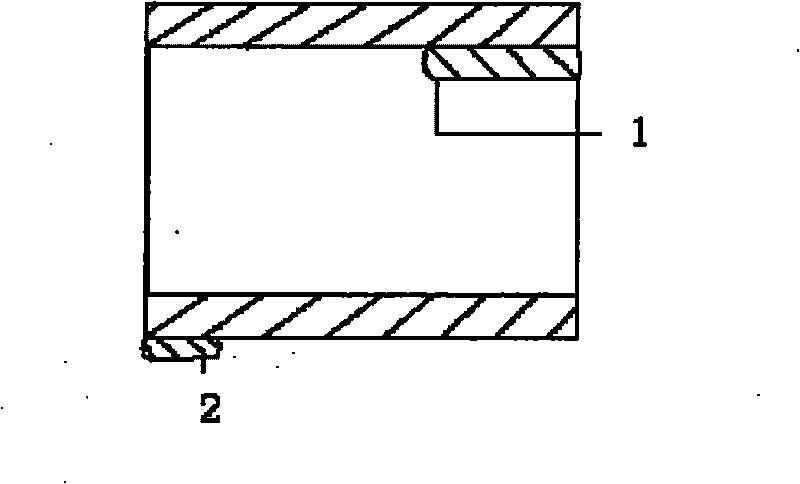

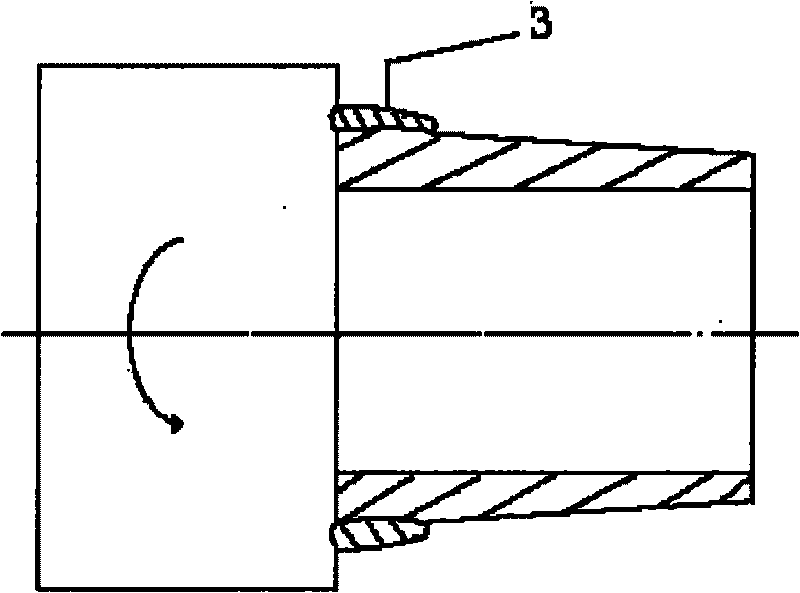

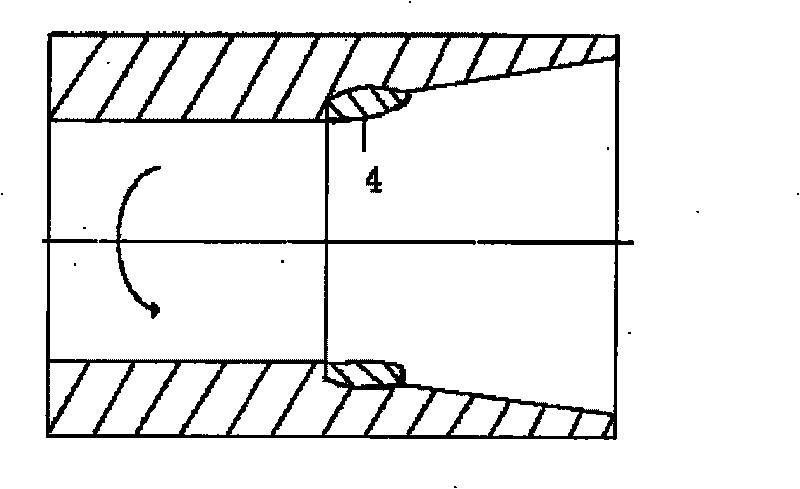

Relay type passageway lift

The invention relates to a relay type corridor elevator using each section of corridor as a unit, which are respectively provided with an independently running elevator, and the elevator is positioned on the side of the corridor, and the corridor comprises the ladder rack positioned along the inclined direction of the corridor, and the ladder rack is provided with an upper rail, a lower rail, a railcar, a hauling device, a sealing device and a control system. The upper and the lower parts of the railcar are respectively provided with a folding armrest and a folding footplate. The hauling device drives the railcar to run. The sealing device is provided with an upper groove and a lower groove, an upper door hole and a lower door hole, and the upper door hole and the lower door hole are all communicated with the lower groove. The control system controls the running and the stopping of the hauling device, and controls the folding and unfolding of the folding arm rest and the folding footplate. Each section of the corridor has an independently running elevator, and the motion amount is greatly increased. By adopting the sealing device, the invention leads the full part or partial part of the elevator to be arranged in the wall body at the side of the corridor, which does not cover or covers a little area of the corridor space.

Owner:竺圣刚 +1

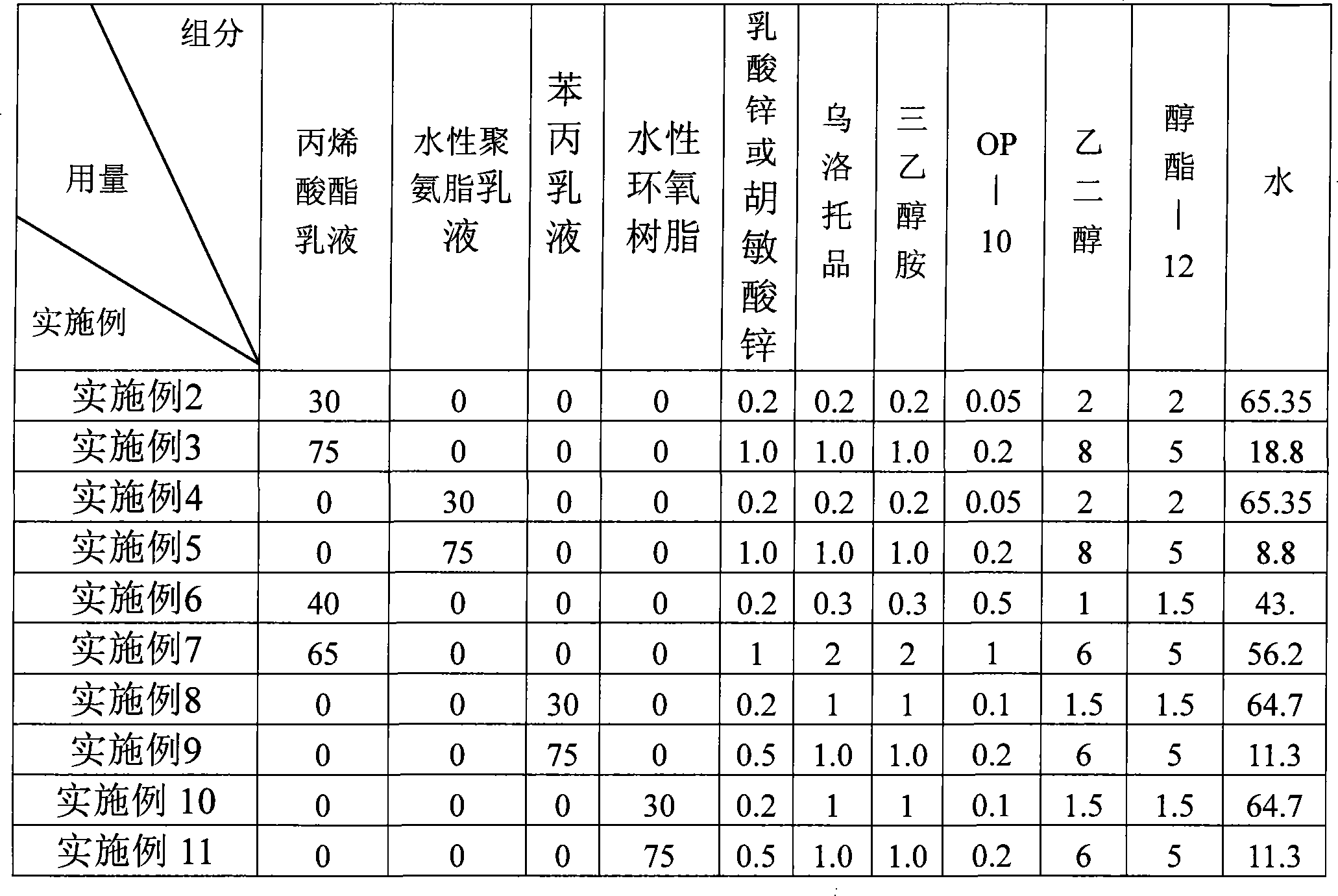

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653AGood acid and alkali resistance and water resistanceGood metallic lusterCoatingsPigment treatment with organosilicon compoundsDouble bondChemistry

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps: by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Water-based antirust agent

InactiveCN101240141AImprove bindingStay the sameLiquid surface applicatorsAnti-corrosive paintsWater basedWater vapor

The invention discloses a water-base anti-rust agent composed of 30% to 75% film-forming agent, 0.5% to 6.0% inhibitor, 2% to 16% accessory ingredient and water. Bonding force of film layer to basal body is improved by adopting acrylic ester emulsion or water-base polyurethane emulsion as film-forming substance associated with components of inhibitor, accessory ingredient, etc. The water-base anti-rust agent is brushed on steel surface to form continuous compact protection layer, isolating steel surface from oxygen and water vapor effectively, for long lasting rust prevention. The anti-rust period of steel piece might be more than one year. The protecting film is quite compact, which maintains fundamental color of steel piece invariable. User can process next step of treatment directly without removing the protecting film, which reduces tiresome process of removing anti-rust coat. Operation modes include soaking, spraying, brush coating, etc. The invention is incombustible, nontoxic and environment-friendly. Contents of free formaldehyde, heavy metal and volatile organic meet qualified criteria. Bond strength of twice-brushed deformed steel bar to concrete is more than non-brushed test piece.

Owner:焦占付

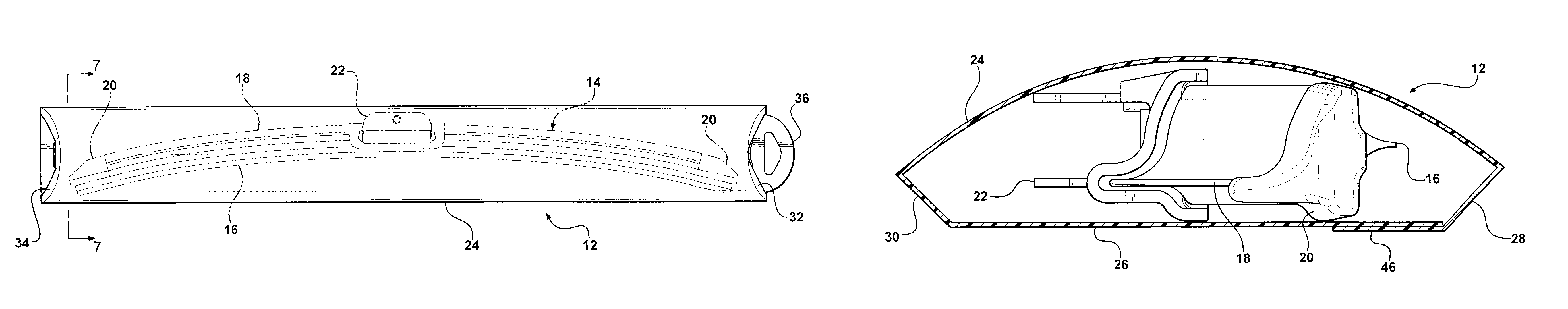

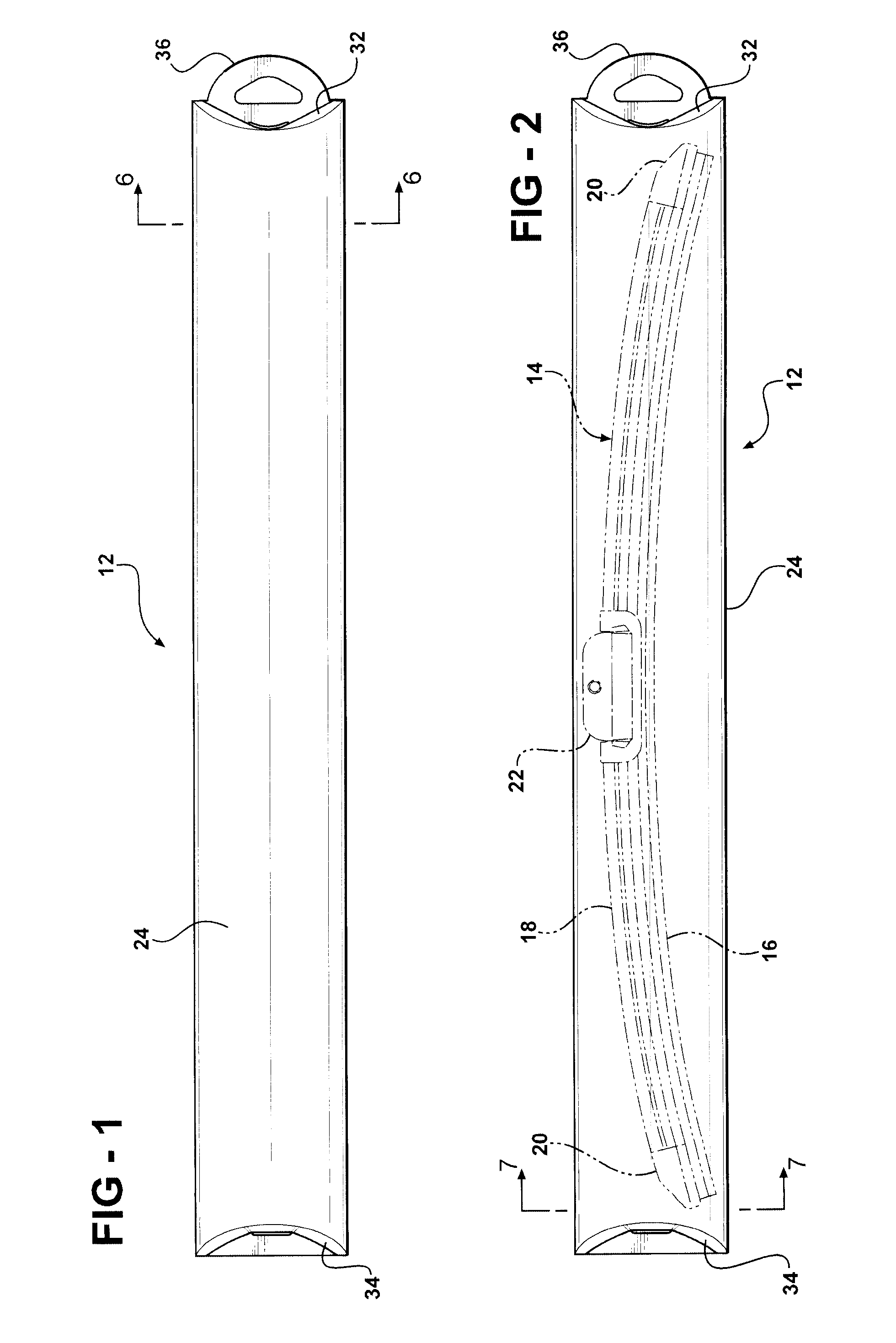

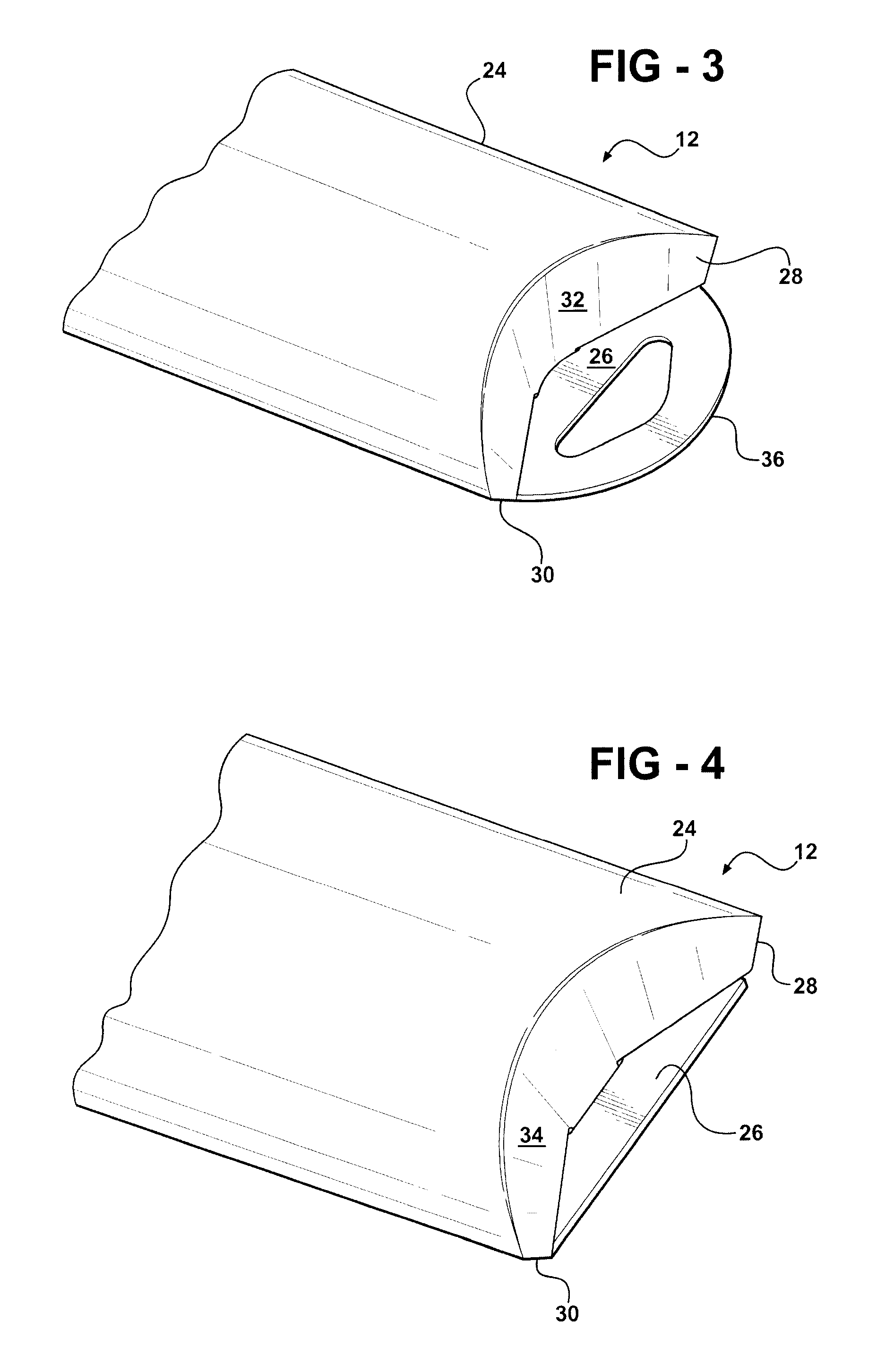

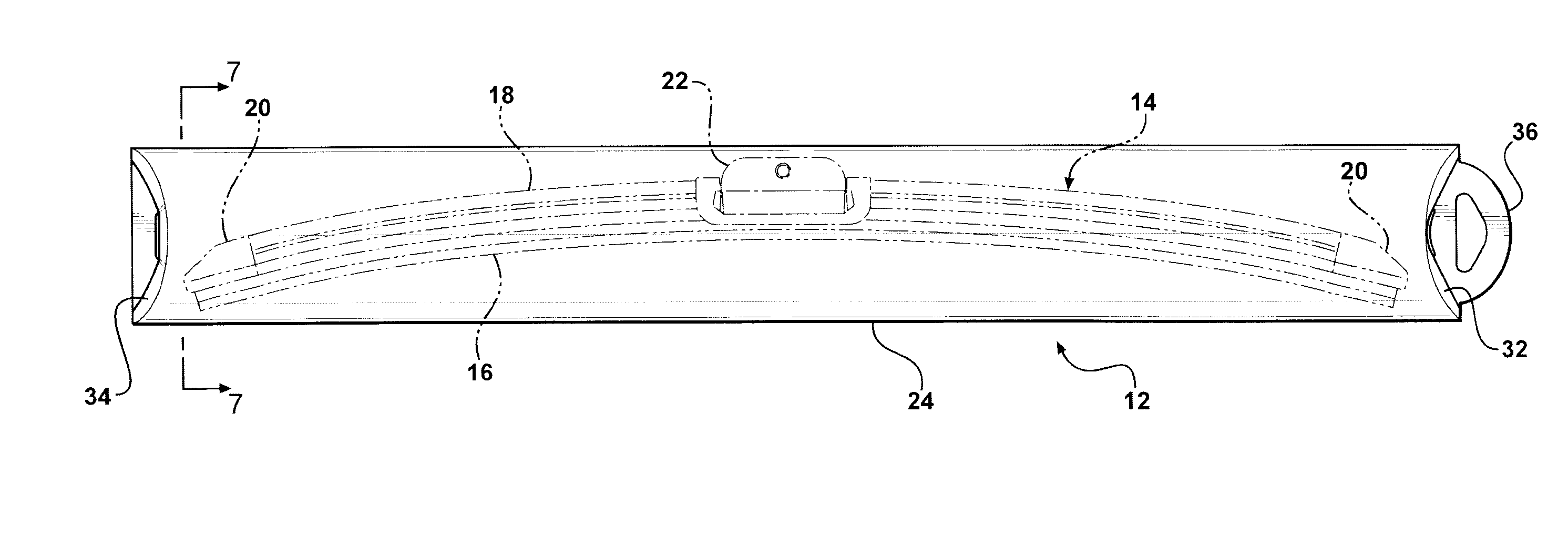

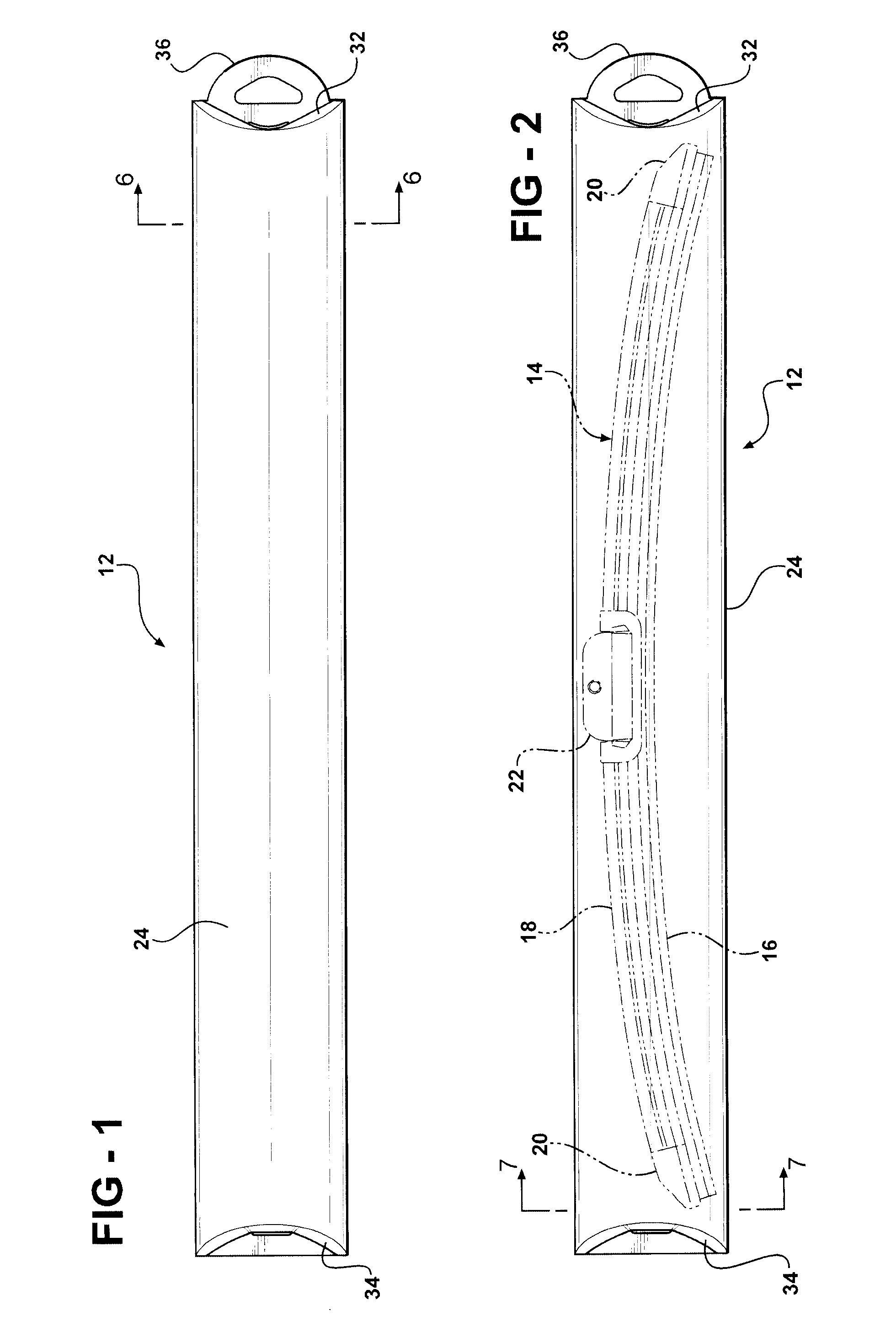

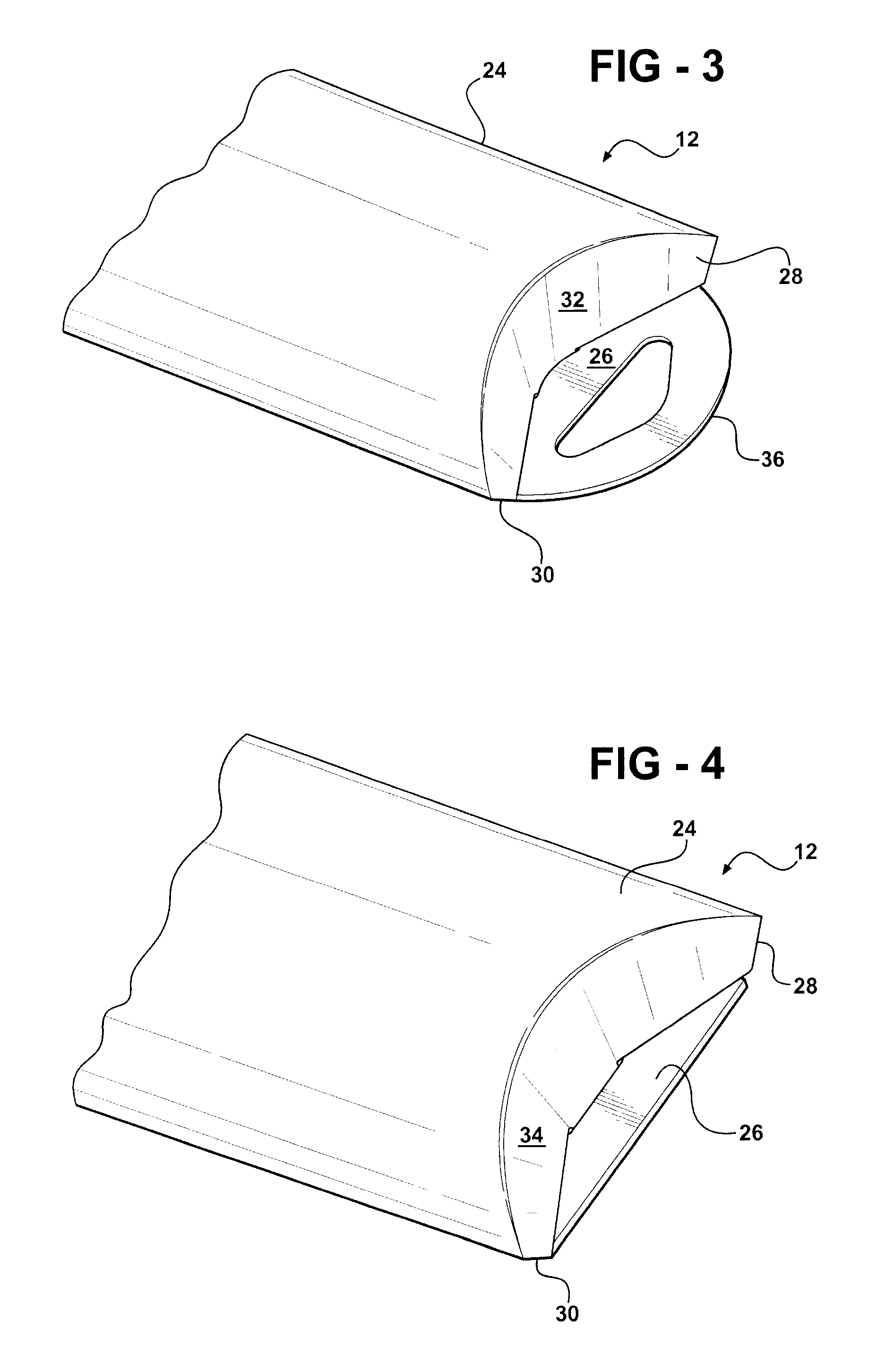

Contour flat blade packaging design

ActiveUS7690509B2Efficiently smallEasy to disassembleOther accessoriesWindow cleanersEngineeringKnife blades

Owner:TRICO PROD CORP

Preparation method for organic/inorganic hybridization cladding aluminum composite particle

InactiveCN102516831AStrong combinationGood dispersionPigment treatment with organosilicon compoundsAluminum compositesOrganosilicon

The invention discloses a preparation method for an organic / inorganic hybridization cladding aluminum composite particle, which includes mixing leafing aluminum powder and solvent alcohol evenly to be transferred to a reactor to be stirred for a period of time, then adding alcoholic solution containing an organic silicon source and an inorganic silicon source at a constant speed and mixed solution of catalyst, water and alcohol, reacting for a period of time at the constant temperature, and finally filtering, washing and vacuum drying to obtain the organic / inorganic hybridization cladding aluminum composite particle. The organic / inorganic hybridization cladding aluminum composite particle has the following advantages of being capable of scattering in hydrosolvent and the alcohol solvent well and good in compatibility with resin, keeping good metal glossy, and simultaneously having good performance for resisting acid and alkaline corrosion. The organic / inorganic hybridization cladding aluminum composite particle can be used as environment-friendly metallic pigment for water-based paint.

Owner:SUN YAT SEN UNIV

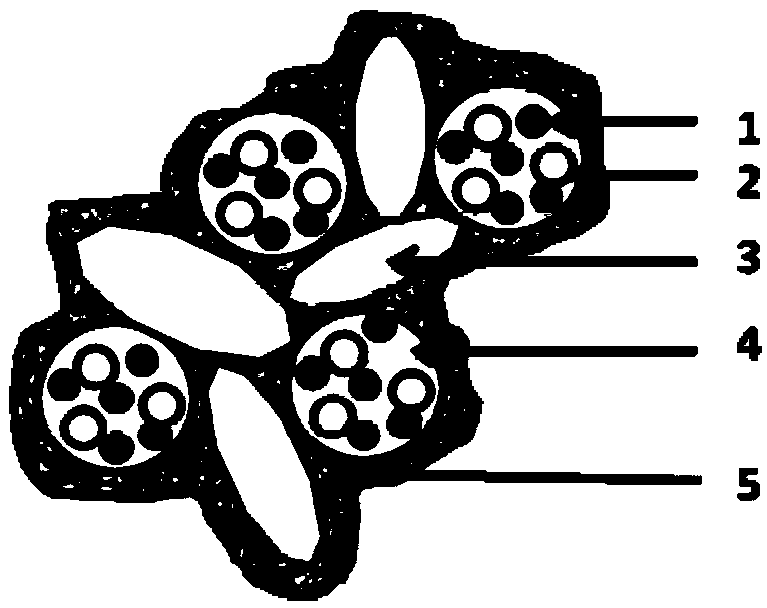

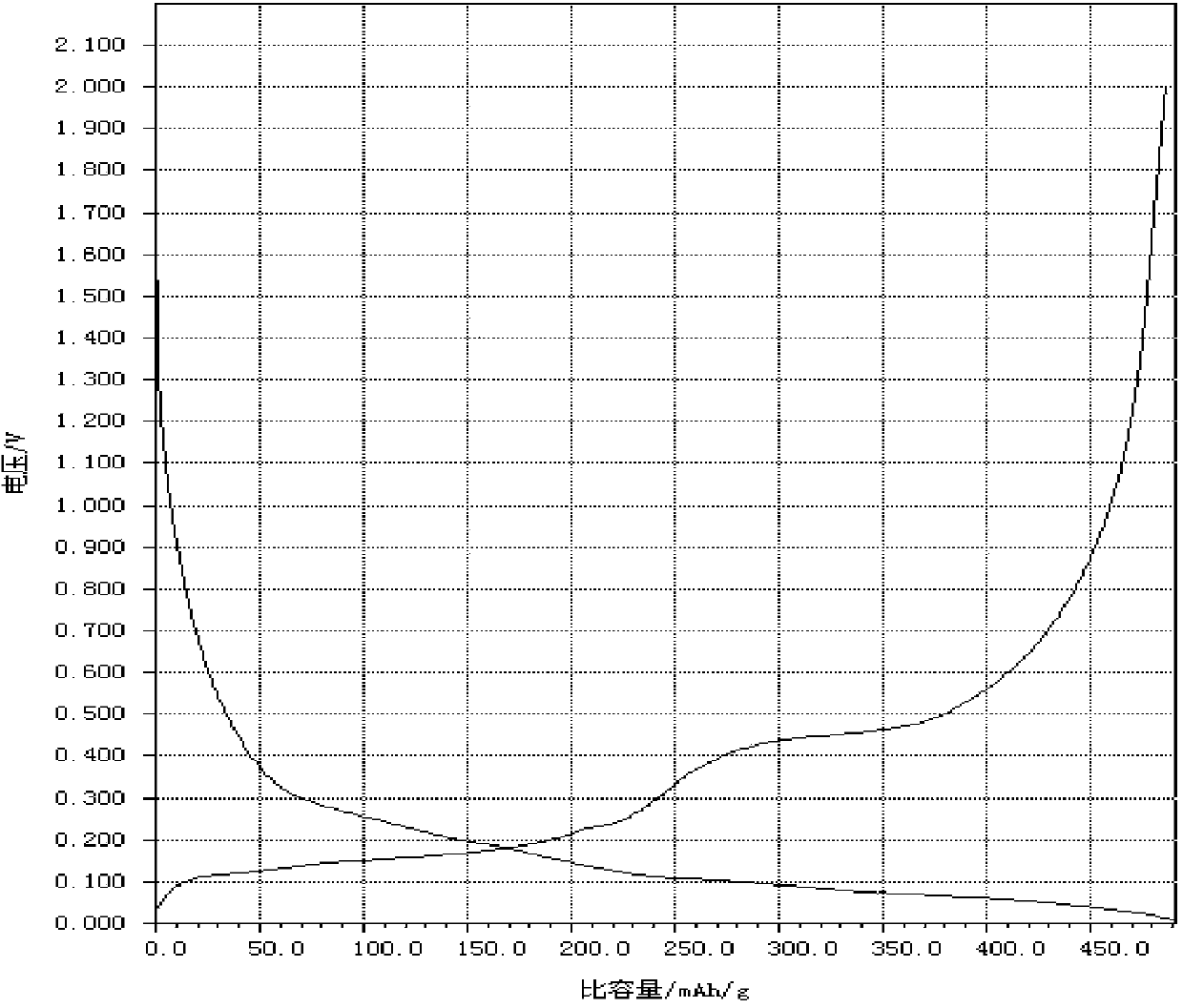

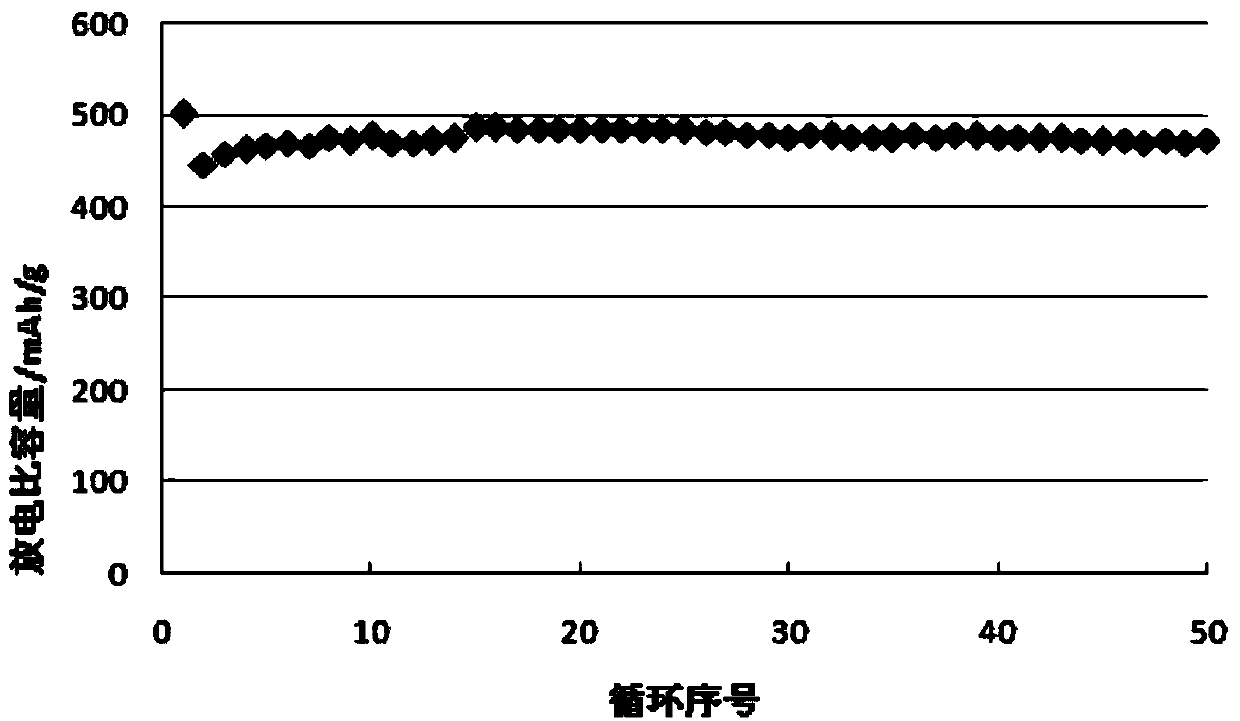

Silicon-carbon composite microsphere anode material and preparation method thereof

ActiveCN104362311ASimple processLow costSecondary cellsNegative electrodesLithium electrodeCarbon composites

The invention discloses a silicon-carbon composite microsphere anode material and its preparation method. the preparation method comprises the following steps: firstly, nano-silicon particles and a first macromolecular solution are mixed, and first composite microspheres are formed after spray drying; then, the first composite microspheres and a second macromolecular solution are mixed to carry out surface coating on the first composite microspheres, and second composite microspheres with a core-shell structure are formed after solvent evaporation; and finally, the second composite microspheres undergo oxidation and carbonization treatments to form the silicon-carbon composite microsphere anode material. By the preparation method which has a simple technology, is low-cost and is easy to operate, the silicon-carbon composite microsphere anode material is prepared. In addition, no etching operation for pore-forming is required by the preparation method. Raw materials used in the preparation method can be selected from a number of sources. According to the silicon-carbon composite microsphere anode material obtained, advantages of nano-silicon and a carbon substrate are combined effectively. Thus, electrochemical performance of the silicon-carbon composite microsphere anode material used as a negative electrode of a lithium ion battery is enhanced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

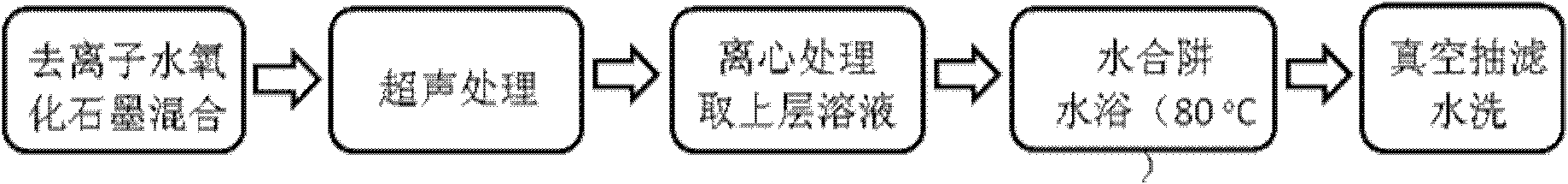

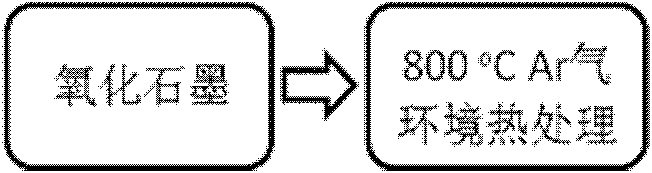

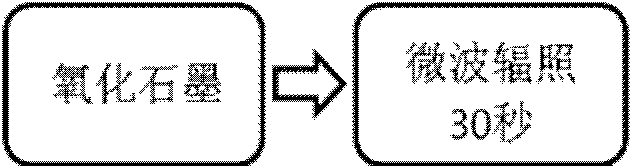

Method for preparing graphene material by microwave irradiation in vacuum or inert gas environment

InactiveCN102139873ASimple structureIsolated contactMaterial nanotechnologyGraphenePhysicsGraphite oxide

The invention relates to a method for preparing graphene material by microwave irradiation in a vacuum or inert gas environment. The method comprises the following steps: taking dry graphite particles to be placed in a vacuum cavity of a microwave chamber and closing a top cap of the vacuum cavity; pumping the air pressure in the vacuum cavity to be in an ultimate vacuum state; injecting gas into the vacuum cavity till driving residue oxygen in the vacuum cavity; starting the microwave irritation till the oxidation graphite explodes and breaks; closing the microwave irritation and filling the air pressure in the vacuum cavity to be in an atmosphere state; opening the top cap of the vacuum cavity and collecting the exploded and reduced oxidized graphite powder. The method has the advantages that the heating is concentrated due to microwave and the power is high; graphite is heated and oxidized in short time so that the oxidized graphite is heated and reduced instantly and rapidly expands to release a large quantity of gas; the vacuum cavity can effectively isolate the contact between oxygen and graphene so as to avoid the combustion of graphene in the high temperature reduction process, thereby increasing the reduction yield.

Owner:无锡第六元素高科技发展有限公司

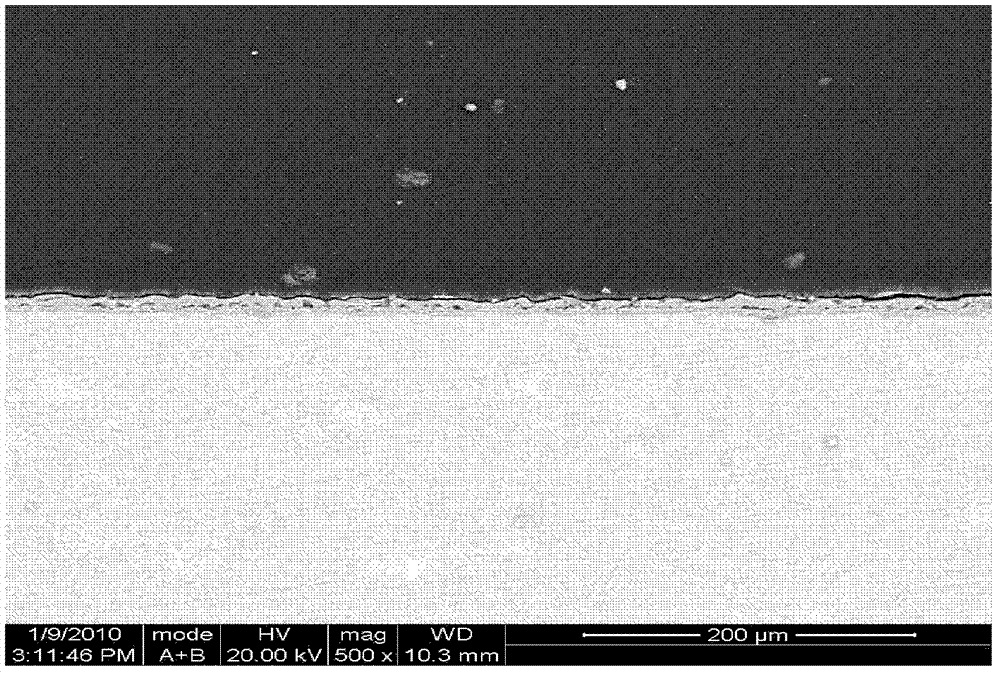

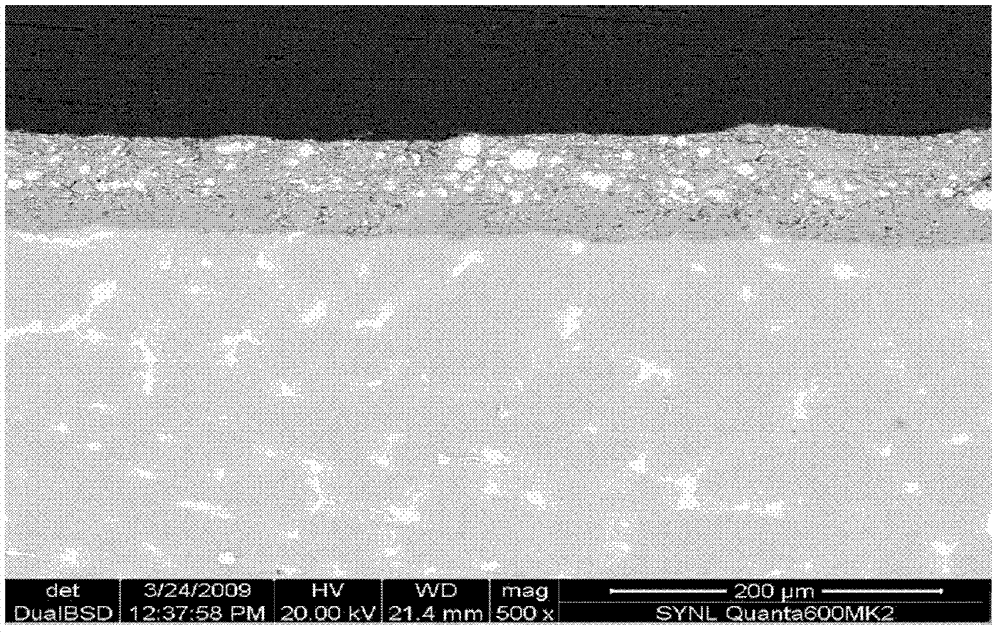

Magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and preparation method thereof

InactiveCN103085379AAchieving densification and sealingReduce defectsAnodisationCeramic layered productsCross-linkMicro arc oxidation

The present invention discloses a magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and a preparation method thereof. The coating comprises a micro-arc oxidation ceramic layer, a self-assembly nanometer film and an inorganic metal ceramic coating, wherein the micro-arc oxidation ceramic layer, the self-assembly nanometer film and the inorganic metal ceramic coating are sequentially attached on the magnesium alloy surface. The preparation method comprises: carrying out plasma electrolysis oxidation on the surface of a magnesium alloy substrate to form a micro-arc oxidation ceramic coating, then carrying out dipping or high pressure spraying of a self-assembly nanometer film as a connection layer on the surface of the ceramic layer, and adopting a low temperature sintering method to prepare an inorganic metal ceramic coating on the surface of the self-assembly nanometer film. According to the present invention, the head group of the self-assembly nanometer film and the micro-arc oxidation bottom layer ceramic layer form chemical bonding, and a sealing treatment is performed on micro-pores of the micro-arc oxidation film; a high density cross-linking effect on active function groups in the inorganic metal ceramic coating by the self-assembly nanometer film is achieved through the end group; and the magnesium alloy surface composite protection coating prepared by using the method has characteristics of good bonding strength, corrosion resistance, scratching resistance and high hardness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Contour flat blade packaging design

ActiveUS20080073246A1Efficiently smallEasily removeOther accessoriesWindow cleanersKnife bladesWindshield

A flat blade windshield wiper blade (12) has a naturally elongated curve with a delicate wiper element (16) to be protected during shipping and display for retail sales purposes. A protective package (12) surrounds the wiper (12). The package (12) is made from a single piece of sheet stock and includes a flexible, outwardly bowed front panel (24), a back panel (26), and opposing left (30) and right (28) side panels adjoining respective sides of the front (24) and back (26) panels. Top (32) and bottom (34) end flaps extend between the front (24) and back (26) panels for forcing the front (24) panel to form in a generally semi-cylindrical configuration bowed outwardly relative to the back panel (26). The wiper (12) is disposed in a shipping condition in the package (12), with a connector (22) feature of the wiper (12) bearing in direct pressing contact with the bowed front panel (24). The wiper element (16) is completely isolated from contacting the package (12) by wedging other portions of the wiper (12) in three discrete regions of direct contact against the bowed front panel (24) and three discrete regions of direct contact against the back panel (26).

Owner:TRICO PROD CORP

Anti-reburning environment-friendly power transmission line forest fire extinguishing agent

The invention discloses an anti-reburning environment-friendly power transmission line forest fire extinguishing agent. The anti-reburning environment-friendly power transmission line forest fire extinguishing agent comprises the following components in parts by weight: 5-20 parts of ammonium carbonate, 10-45 parts of ammonium polyphosphate, 10-30 parts of sodium silicate, 1-10 parts of a foaming agent, 0.5-5 parts of polyethylene glycol, 1-5 parts of a thickening agent, 4-10 parts of a composite anti-freezing agent and 55-80 parts of water, wherein the foaming agent is selected from one of alkylethoxylate carboxylate, an imidazoline amphoteric surfactant and a biological surfactant; the composite anti-freezing agent is a compound which is prepared by compounding inorganic salt and polyhydric alcohol according to a mole ratio of (1 to 3)-(1 to 9). All the raw materials of the anti-reburning environment-friendly power transmission line forest fire extinguishing agent are environment-friendly materials, so that the fire extinguishing agent is free of fluorine compound, toxicity, smell and pollution; a fire retardant is added into the fire extinguishing agent, so that the fire extinguishing agent is capable of effectively preventing the fire from spreading and is high in fire extinguishing efficiency; the environment-friendly surfactant serves as the foaming agent, so that the fire extinguishing agent is high in foaming performance and is capable of effectively isolating contact between the combustion material and the air and accelerating the fire extinguishing speed; the anti-freezing agent is compounded by the inorganic salt and polyhydric alcohol, so that the freezing point of the fire extinguishing agent is reduced to be -30 DEG C.

Owner:STATE GRID CORP OF CHINA +2

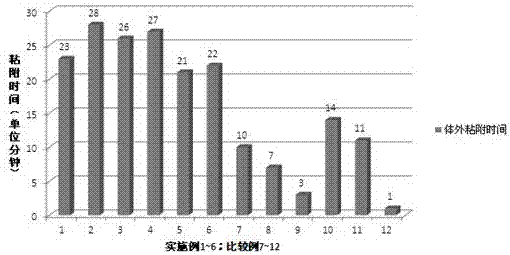

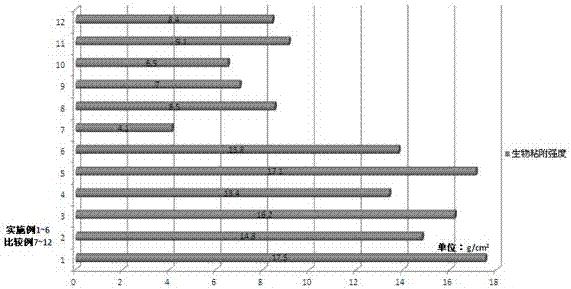

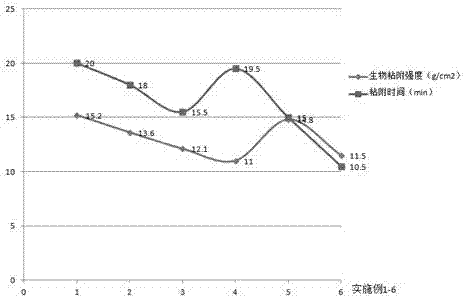

Sustained-release oral ulcer film having biological adhesion and preparation method of sustained-release oral ulcer film

ActiveCN107412200AIsolated contactHas antibacterial propertiesAntibacterial agentsAntipyreticOral ulcersIrritation

The invention relates to a sustained-release oral ulcer film having biological adhesion and a preparation method of the sustained-release oral ulcer film. According to the formula, the sustained-release oral ulcer film having the biological adhesion consists of the following components in percentage by weight: 5-50% of a bio-adhesion material, 5-80% of a sustained-release film forming material, 0.5-10% of a medicine, 1-50% of a supporting agent, 1-20% of a plasticizer, 0.1-0.5% of a bacteriostatic agent and 0.5-1% of a flavoring agent. The film provided by the invention, which is prepared in a specific production mode, is good in stability, and excellent biological adhesion and sustained-release performance of the film can be kept for a long time; a soluble sustained-release gel can be gradually formed as the film is adhered to an ulcer surface and absorbs water, so that contact of the ulcer surface with external side is prevented; the oral ulcer film provided by the invention has the characteristics of diminishing inflammation, alleviating pain, achieving an antibacterial effect and being free from toxins, irritation, mutagenic action and the like; and the oral ulcer film can promote growth of blood vessel endothelium and proliferation of fibroblasts and keratinocytes, and subsequently, the oral ulcer film can promote regeneration, repair of healing of the ulcer surface.

Owner:HARBIN QIANBAINA BIOPHARM

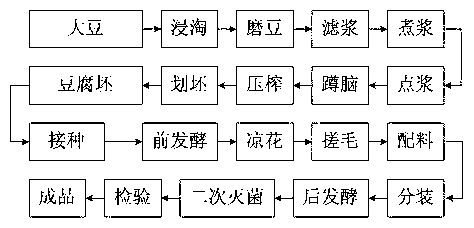

Production process of low-salt oil-free fermented bean curd

InactiveCN102696777APreserve the unique flavorGuarantee quality and safetyCheese manufactureFood scienceAlcoholHot peppers

The invention discloses a production process of low-salt oil-free fermented bean curd. The production process comprises the following steps: after performing the steps of immersing and washing soybean, grinding the soybean, filtering pulp, boiling the pulp, mixing pulp, concentrating, squeezing, dividing, inoculating, performing primary fermentation, cooling and mildewing, adding 8 to 10 percent of salt and 6 to 8 percent of alcohol; adding a proper amount of spice such as hot pepper powder, ginger powder, garlic powder and the like according to the traditional process; subpackaging into small bottles in one step; integrating fermenting, storing and finished product packaging materials; vacuumizing, so that the vacuum degree of the small bottle is 0.8 to 1.0; performing secondary fermentation for 1 to 2 months under the natural condition; performing secondary sterilization on the mature fermented bean curd, wherein the sterilization central temperature is 80 to 85 DEG C and the sterilization time is 25 to 35 minutes; and obtaining the finished products after passing inspection. The production process has the advantages that the unique flavor of the local traditional fermented bean curd is maintained; the characteristics of the times are achieved; the production process is fashionable and novel; the edible range is widened; the low-salt oil-free fermented bean curd has high nutritional value and preference, can realize industrial production and is safe and healthy; and quality safety of the oil-free fermented bean curd is effectively guaranteed.

Owner:WANYUAN LICHUAN FOOD COMPREHENSIVE DEV

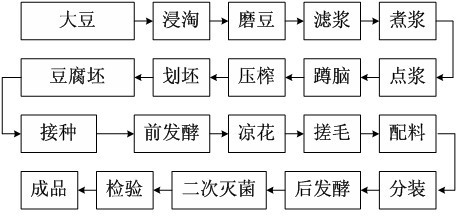

Anti-corrosive protective film agent for marine boiler

ActiveCN101498001AMaintain propertiesSolve the problem of insoluble in waterMarine engineeringAntiseptic

The invention discloses an antiseptic protective film used in a ship boiler, which comprises octadecylamine, emulsifier, stabilizer, deoxidant and water. The antiseptic protective film used in the ship boiler has good antiseptic effect, high stability, long preservation time, safety and environmental protection and can be used in both an operation condition and an idle condition when used in the ship boiler.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Lithium ion battery silicon carbon composite negative electrode material and preparation method thereof

InactiveCN103618074AImprove dispersionEfficient coatingCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention relates to a lithium ion battery silicon carbon composite negative electrode material and a preparation method thereof. The method comprises the following steps: fixing nanometer silicon in a macromolecule microsphere by preparing a micromolecule / silicon / (carbon black) composite microsphere emulsion, then compounding the microsphere emulsion and graphite, asphalt and the like, and carrying out thermal treatment, thereby obtaining the lithium ion battery silicon carbon composite negative electrode material. The macromolecule microsphere in the material has the effects that the macromolecule microsphere not only is a fixer for stabilizing and inlaying the nanometer silicon, but also is a bonding agent between the nanometer silicon and the graphite after being subjected to high-temperature sintering treatment. The method solves the problems that the nanometer silicon is high in specific surface energy and easy to agglomerate because of small granularity. The lithium ion battery silicon carbon composite negative electrode material prepared by the preparation method disclosed by the invention achieves the synergistic effect of graphite, high-dispersion silicon and carbon, and presents an excellent battery performance.

Owner:南京毕汉特威高分子材料有限公司

Method for producing fried peanut kernels with low peroxide number

The invention discloses a method for producing friend peanut kernels with low peroxide number for fried peanuts with strong oxidation resistance and long quality guarantee period. The method comprises the following steps of: (1). selecting peanut kernels; (2). charging nitrogen: continuously supplementing nitrogen for a frying pan through a nitrogen making machine, wherein the nitrogen charging time is 20-25 minutes, and the nitrogen charging purity is 98.5-99.5%; (3). frying with mixed water and oil, wherein the temperature of oil at the upper layer is within 130-200 DEG C, the temperature of oil at the lower layer is within 55-130 DEG C, and the temperature of the oil water demarcation face is controlled to be below 55 DEG C; (4) processing the fried peanut kernels; (5). coating a film:a film solution is prepared by a pea starch solution with the concentration of 5%, during preparation, the film solution needs to be gelatinized in a boiling water bath for 20 minutes, the temperature of the film solution is maintained to be within 30-40 DEG C, and then the film solution is coated on the surfaces of the fried peanut kernels; and (6). drying the fried peanut kernels subjected to film coating in a vacuum-freezing drying machine, wherein the freezing temperature is minus 35 DEG C, and the vacuum degree is 0.05 MPa.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

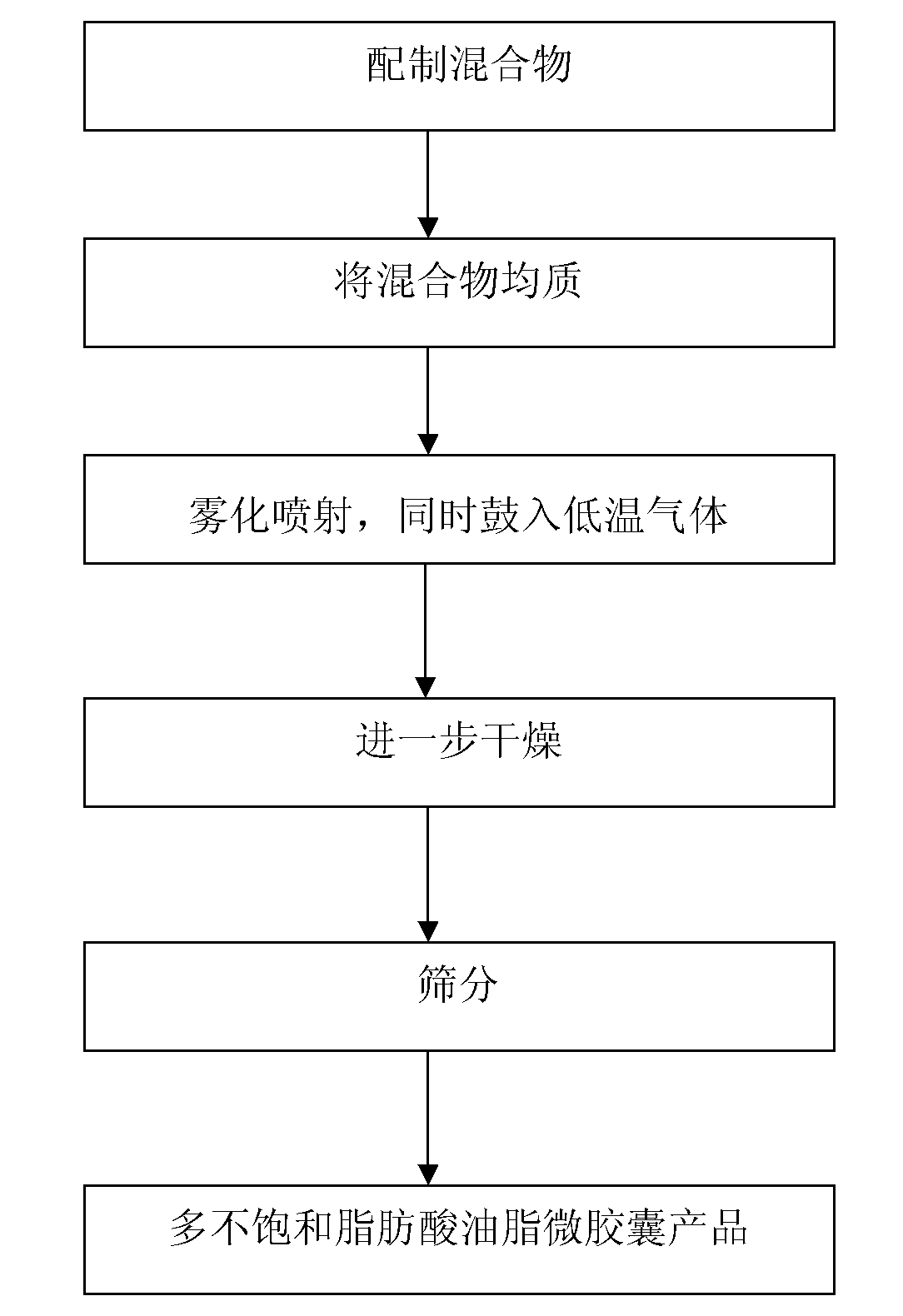

Spray freeze-drying preparation technology for polyunsaturated fatty acid oil microcapsule

The invention relates to a spray freeze-drying preparation technology for a polyunsaturated fatty acid oil microcapsule, which comprises the following technological steps: mixing oil containing polyunsaturated fatty acid with emulsifier and water to obtain mixture; homogenizing the mixture to obtain emulsion; atomizing the emulsion into liquid drops which are sprayed into a spray drying device with temperature of negative 60 DEG C to negative 10 DEG C, wherein powder embedding materials are contained at the bottom part of the spray drying device, and blasting low-temperature gas to fully mix the materials in the spray drying device and to keep the temperature in the spray drying device to be the set temperature; and further drying and screening to obtain polyunsaturated fatty acid oil microcapsule products. The invention has the advantages that the drying temperature of the preparation technology is low, the speed is fast and the nutritional ingredients are not apt to be damaged; the technology is simple and convenient and the automatic mass production can be realized; and the oil embedding rate of the obtained independent polyunsaturated fatty acid oil microcapsule particles is high, the embedding performance is good, the product shelf life is long and the stability is good.

Owner:CABIO BIOTECH WUHAN CO LTD

Method for extracting lutein from marigold particles

InactiveCN101514177AReduce consumptionReduce dosageSenses disorderOrganic chemistryFood additiveDistillation

The invention provides a method for extracting lutein from marigold particles. The method comprises the following preparation steps: (1) grinding marigold dried flower particles sifting out, placing the powder in an extraction device, continuously passing the powder through organic solvent, and collecting and filtering the extracting solution; (2) placing the extracting solution in a distillationstill for distillation and carrying out basic hydrolysis on the concentrated extracting solution with the participation of a phase transfer catalyst; (3) using acid to adjust solution pH value after saponification, and adding distilled water for stirring; (4) extracting the lutein by organic solvent, carrying out reduced pressure distilling and recovery on extract liquor, thus obtaining lutein crude product; and (5) carrying out eluviation and obtaining food or medical grade lutein by vacuum drying. The invention features simple method, low cost, easy post-processing, and achieves content of final product which reaches more than 97%, therefore, the lutein extracted by the method of the invention can be applied as food additive and raw materials of medicines and health products and is applicable to industrial mass product.

Owner:HUBEI LISANTO BIOTECH

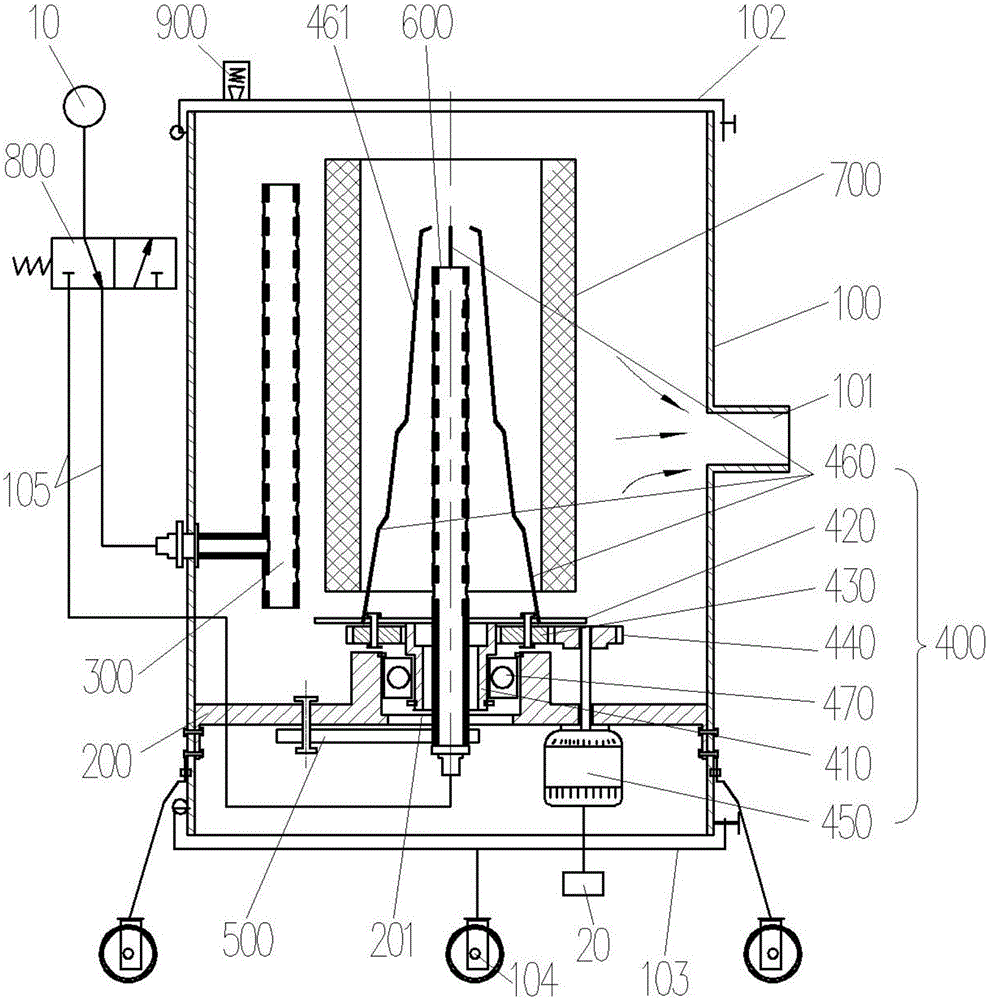

Cleaning machine for air cleaner element

ActiveCN105903274AReduce the burden onImprove sealingGas treatmentDispersed particle filtrationEngineeringAir cleaners

The invention relates to a cleaning machine for an air cleaner element. The cleaning machine comprises a closed cover and a two-position valve, wherein a chassis and an external cleaning device are arranged on the inner side of the closed cover; a rotating platform and an internal cleaning device are mounted on the chassis; the rotating platform can realize the rotating movement; a fixing clamp used for fixing the air cleaner element is mounted on the rotating platform; an air-blowing port of the internal cleaning device is opposite to an inner wall of the air cleaner element; the air-blowing port of the external cleaning device is opposite to an outer wall of the air cleaner element; the internal cleaning device is connected with the external cleaning device through the two-position valve and a compressed air source. The air cleaner element is driven to rotate by the rotating platform, the cleaning device is arranged in and out of the air cleaner element and the high-efficient environment-friendly cleaning of the air cleaner element is realized.

Owner:GUANGZHOU PORT GRP +1

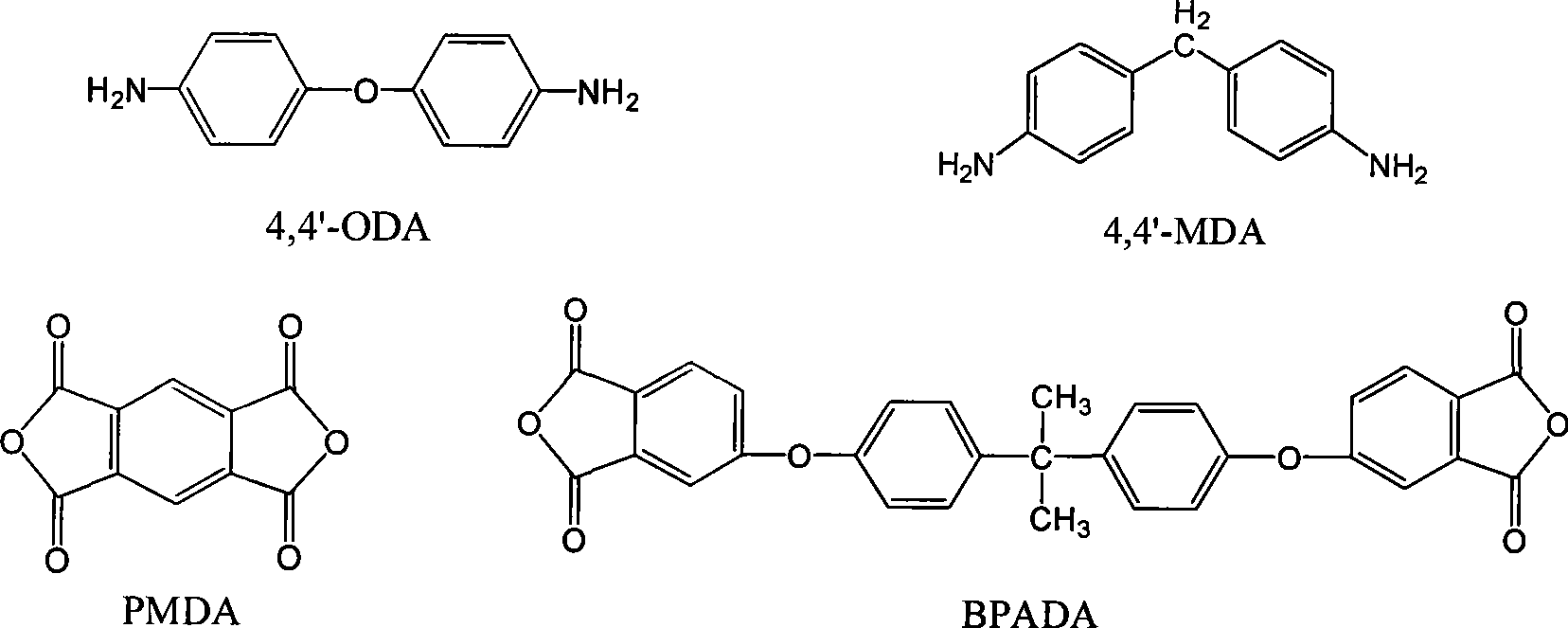

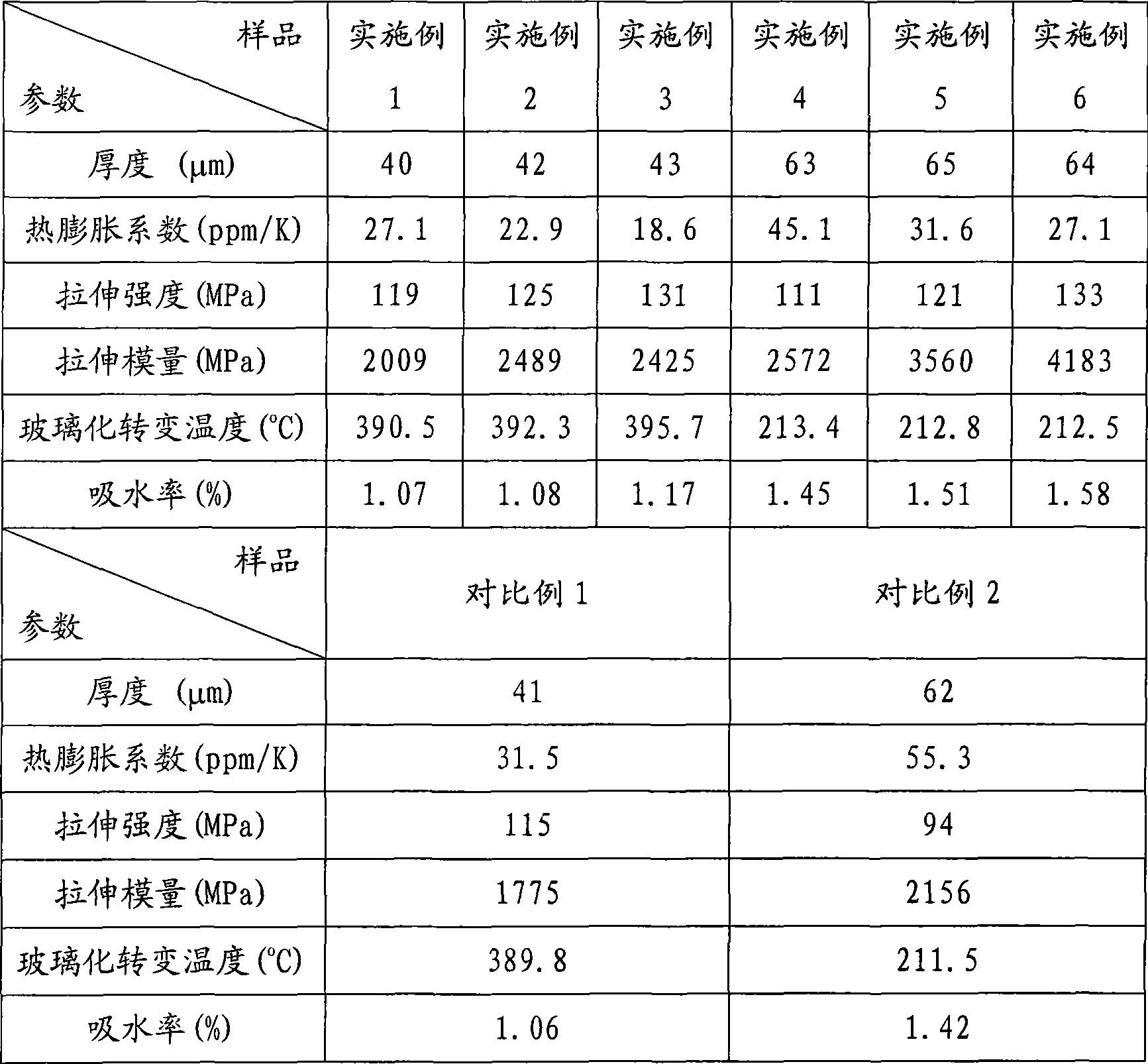

Polyimide/rod-like clay nano-composite film and preparation method thereof

The invention provides a polyimide / rod-like clay nano-composite film and a preparation method thereof, which belong to the field of polymer materials. The composite film provided by the invention takes polyimide as a matrix and takes rod-like clay as a disperse phase, wherein the mass fraction of the polyimide matrix is 70 to 99.9 percent; the mass fraction of the rod-like clay is 0.1 to 30 percent; and the rod-like clay is sepiolite, attapulgite or a mixture of the two in arbitrary mixture ratio. The preparation method obtains the polyimide / rod-like clay nano-composite film by dispersing the rod-like clay in an organic solvent, adding diamine and dianhydride to the organic solvent, mechanically stirring the organic solvent for 1 to 3 hours at a temperature of between 0 and 30 DEG C, obtaining a polyimide / rod-like clay mixed solution, smearing a glass plate with the mixed solution to form a film, volatilizing the solvent and performing hot imidization. The preparation method is simple. The obtained composite film has the advantages of excellent mechanical properties, dimension stability, good thermal stability, chemical stability and the like.

Owner:BEIJING UNIV OF CHEM TECH

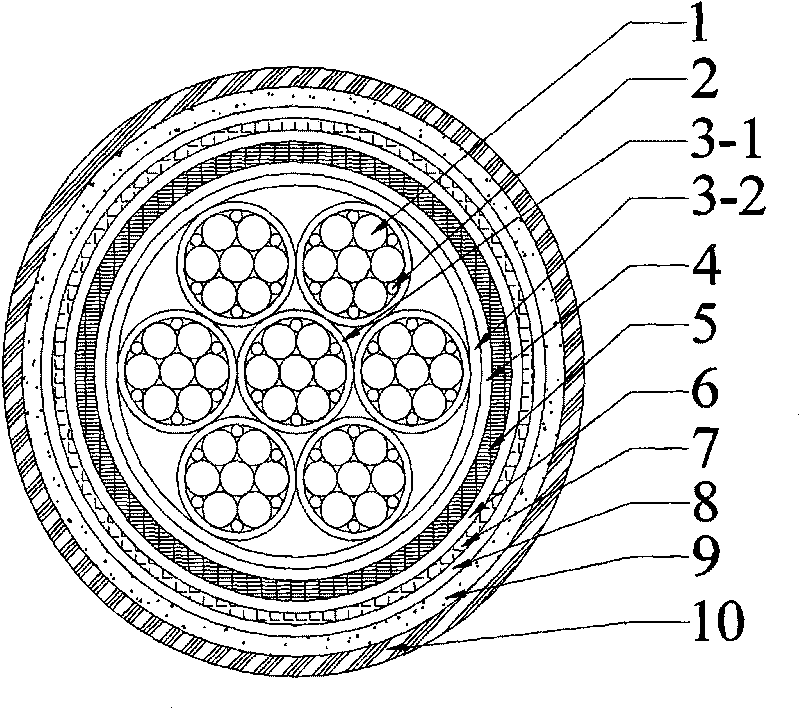

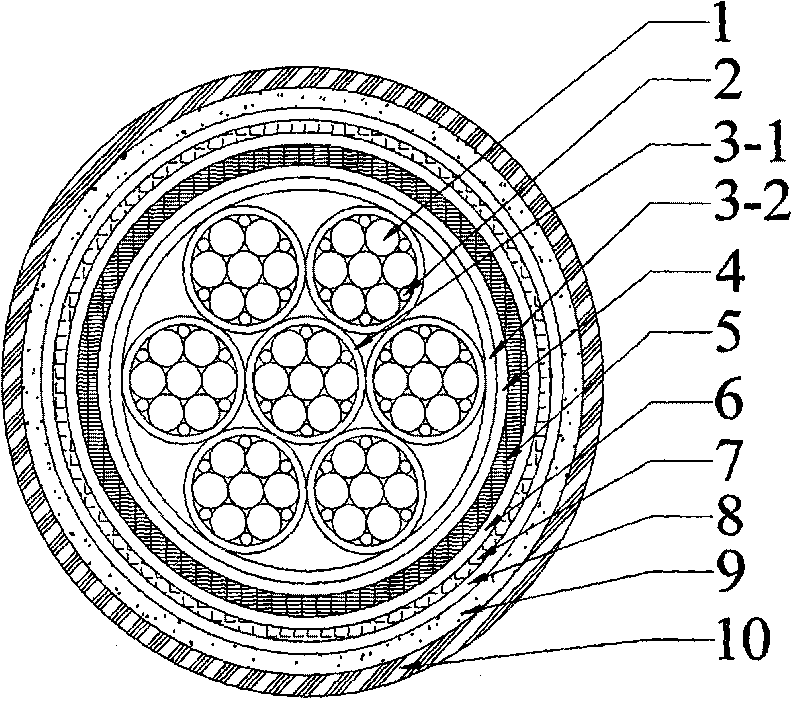

Direct current cable for subway

InactiveCN101714417AGood flexibilityHelp slipPlastic/resin/waxes insulatorsClimate change adaptationPolyesterYarn

The invention relates to a direct current cable for subway, which comprises a conductor, wherein the conductor adopts tin-plating copper wires; the strand is stranded by a plurality of tin-plating copper wires; water blocking yarns are clamped among the tin-plating copper wires; a power wire core is stranded by a plurality of strands horizontally coated with double-surface semi-conductive water blocking tapes and is coated with two layers of double-surface semi-conductive water blocking tapes outside which polyester film tapes are coated; the polyester film tapes is coated with 105 DEG C heat-resistant, high-strength and flame-retardant ethylene propylene terpolymer rubber outside which an expansion type semi-conductive water resistance tape is coated; aluminum plastic composite tapes are arranged outside the expansion type semi-conductive water resistance tapes and are overlapped, horizontally coated and welded in a lapping way; a high flame retardant oxygen-blocking layer is extruded and coated between the aluminum plastic composite tapes and a polyethylene inner sheath, wherein the high flame retardant oxygen-blocking layer is filled with a great amount of organic flame retardants, such as metal hydroxides of aluminum hydroxide, magnesium hydroxide and the like; a ratproof, termiteproof, ultraviolet-resistant, low-smoke, halogen-free and high flame retardant type polyolefine sheath is arranged outside the polyethylene inner sheath. The invention can be completely used under bad geological conditions.

Owner:兴乐电缆有限公司

Relay type passageway lift

InactiveCN100572249CRun volume increaseIsolated contactBuilding liftsControl systemTraction control system

The invention relates to a relay-type corridor elevator. Each section of the corridor is used as a unit, and independently operated elevators are respectively installed. The elevators are installed on the side of the corridor. The frame is provided with an upper rail, a lower rail, a rail car, a traction device, a closing device and a control system: the rail car is equipped with folding handrails and folding pedals above and below; the traction device drives the rail car to run; the closing device There is an upper slot and a lower slot, an upper door hole and a lower door hole, and the upper door hole and the lower door hole are connected with the lower slot; the control system controls the operation and stop of the traction device, and controls the retraction and retraction of the folding handrail and the folding pedal . Since each section of the corridor has an elevator that can operate independently, the running volume is greatly increased. A closed device is used to install all or part of the elevator in the wall on the side of the corridor, so that it does not occupy or occupy less corridor space and area.

Owner:竺圣刚 +1

MWT and passivation combined crystal silicon solar cell and manufacturing method thereof

InactiveCN103594529AConducive to removalReduce manufacturing costFinal product manufacturePhotovoltaic energy generationAluminiumSilver electrode

The invention discloses an MWT and passivation combined crystal silicon solar cell and a manufacturing method thereof. The crystal silicon solar cell comprises a passivating film, a phosphorus diffusion layer, a P-type silicon substrate, an aluminum oxide film, a laminated protective film and an aluminum printing layer structure which are sequentially superposed, and a through-hole silver electrode penetrates the crystal silicon solar cell. The manufacturing method of the crystal silicon solar cell comprises the steps of drilling, flocking, diffusing, polishing, film growth, tapping, hole filling, printing, sintering and the like. The MWT and passivation combined crystal silicon solar cell has the advantages of being low in cost and capable of being produced in a mass mode.

Owner:ALTUSVIA ENERGY TAICANG

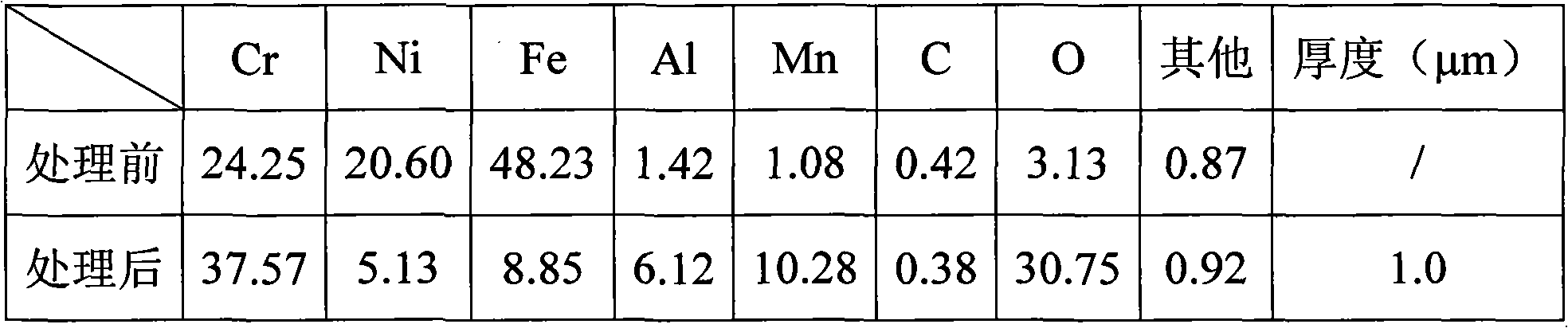

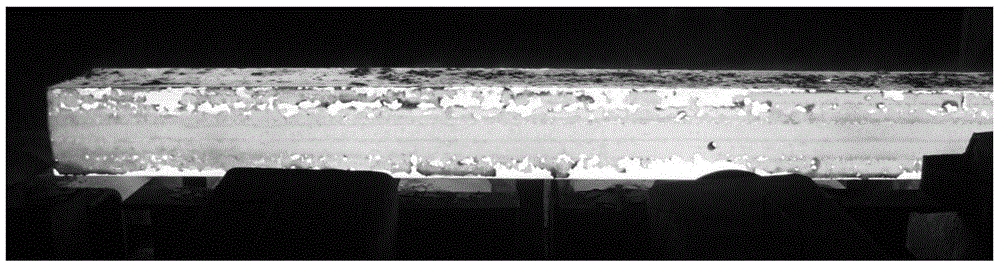

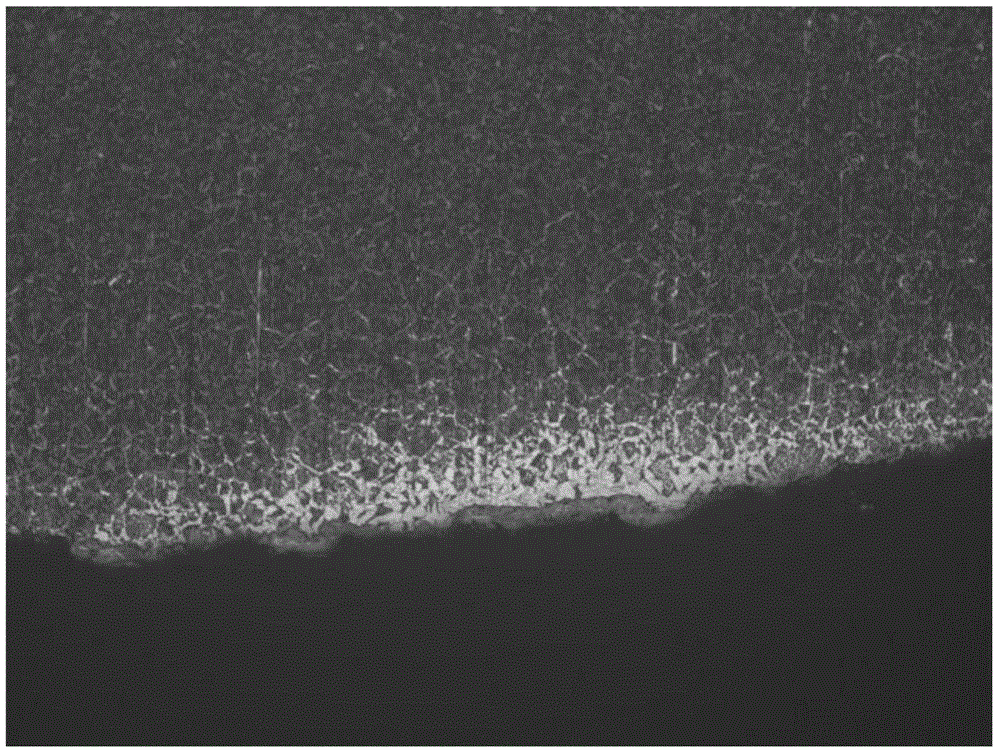

Cracking furnace tube for retarding coking and carburizing of ethylene cracking furnace tube, and manufacturing method thereof

ActiveCN102399571AInhibit cokingInhibition of carburizationThermal non-catalytic crackingCarbon numberPetroleum

The present invention relates to a cracking furnace tube for retarding coking and carburizing of an ethylene cracking furnace tube, and a manufacturing method thereof. According to the present invention, the inner surface of the cracking furnace tube is provided with a layer of an oxide film, wherein the oxide film comprises at least one element selected from Cr, Ni, Fe, Mn, Al, Si and B; the manufacturing method comprises: directly adding at least one element selected from Al, Si or B to a nickel-chromium alloy containing elements of Cr, Ni, Fe, Mn and C during the conventional cracking furnace tube manufacturing process to prepare the tube, then carrying out a heat treatment for the resulting tube under low oxygen partial pressure atmosphere to generate a layer of the metal and / or nonmetal oxide thin film on the inner surface of the tube; when the cracking furnace tube of the present invention is adopted for producing olefin with low carbon number by the petroleum hydrocarbon cracking furnace, the deposition of the coke on the inner wall of the furnace tube can be reduced by more than 70%.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for manufacturing high steel grade sulfur resistant drill pipe by laser cladding

ActiveCN101722403AIsolated contactImprove anti-H

<sub>2</sub>

S stress corrosion cracking performanceMetallic material coating processesLaser beam welding apparatusFriction weldingSulfur

The invention relates to a method for manufacturing a high steel grade sulfur-resistant drill pipe by laser cladding. In the method, in the condition of inert gas insulating air, nickel-base alloy anti-corrosion material is clad on the inner and outer pipe walls of an S135 steel grade drill pipe with conventional properties by laser, a nickel-base alloy anti-corrosion layer is clad on the non-thread area of a joint, threads are processed on the thread conical surface of the joint after a nickel-base alloy anti-corrosion layer is clad on the thread conical surface of the joint, and the end part of a pipe body is oppositely connected with the joint through friction welding; the output power of the laser is 3.5-4.5kW; laser beam spot size is not more than Phi 3mm; defocusing amount is 25-35mm; laser beam scanning line speed is 6.5-7.5mm / s; the inclined angle between the laser beam and the long axis direction of the pipe body is 40-50 degree; and the delivery rate of cladding wire material is 15-20g / s. The drilling pipe reaches the property of the S135 steel grade drilling pipe by the APE Spec standard. The cladding layer can effectively prevent a base body from contacting natural gas to improve the H2S-resistant stress corrosion cracking performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

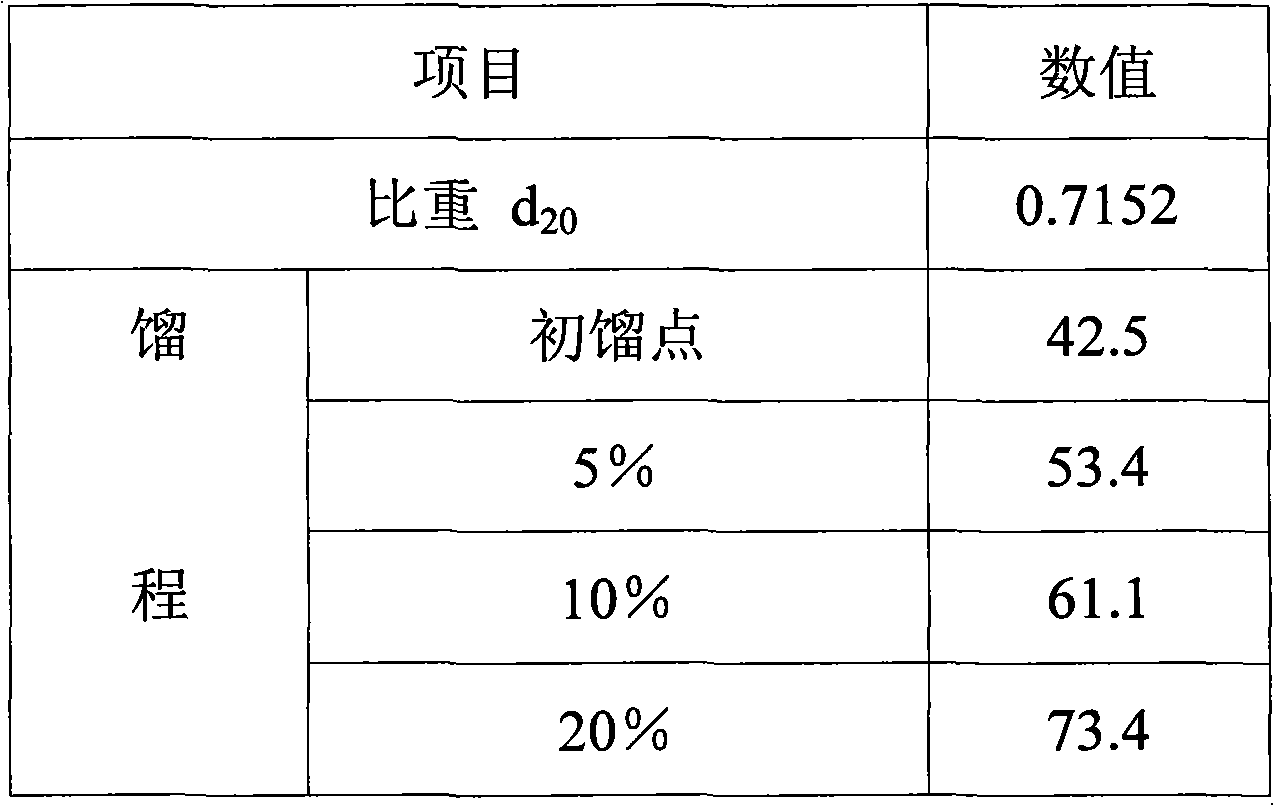

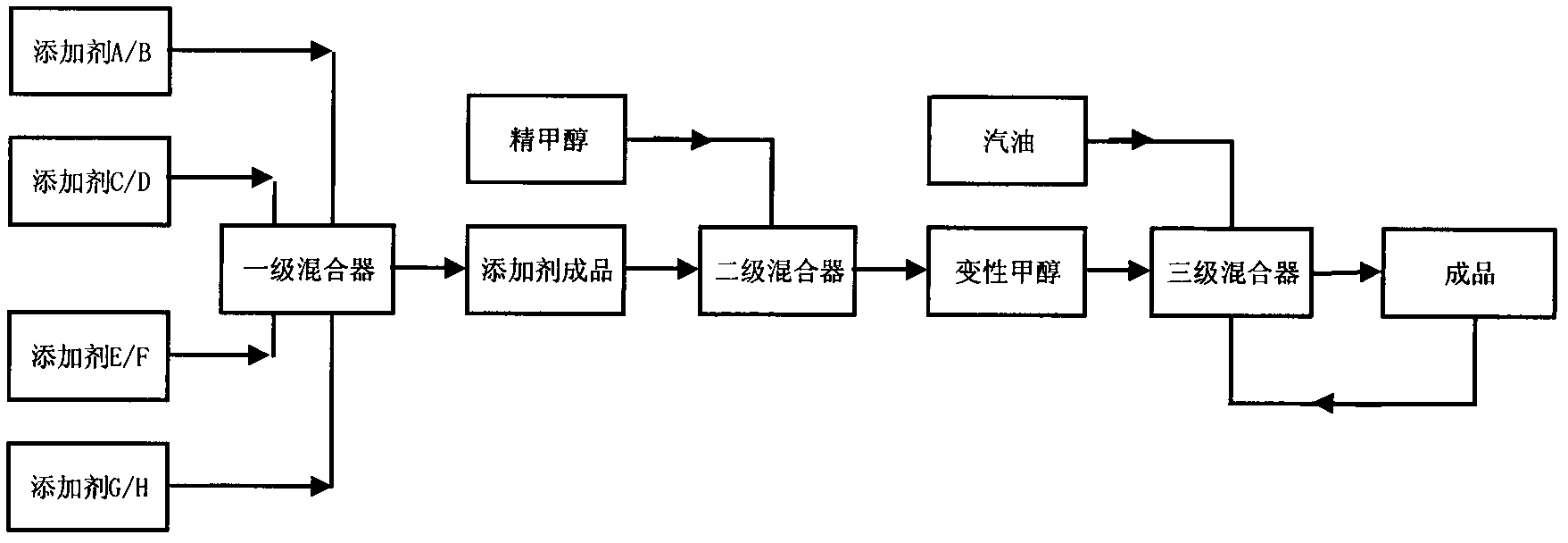

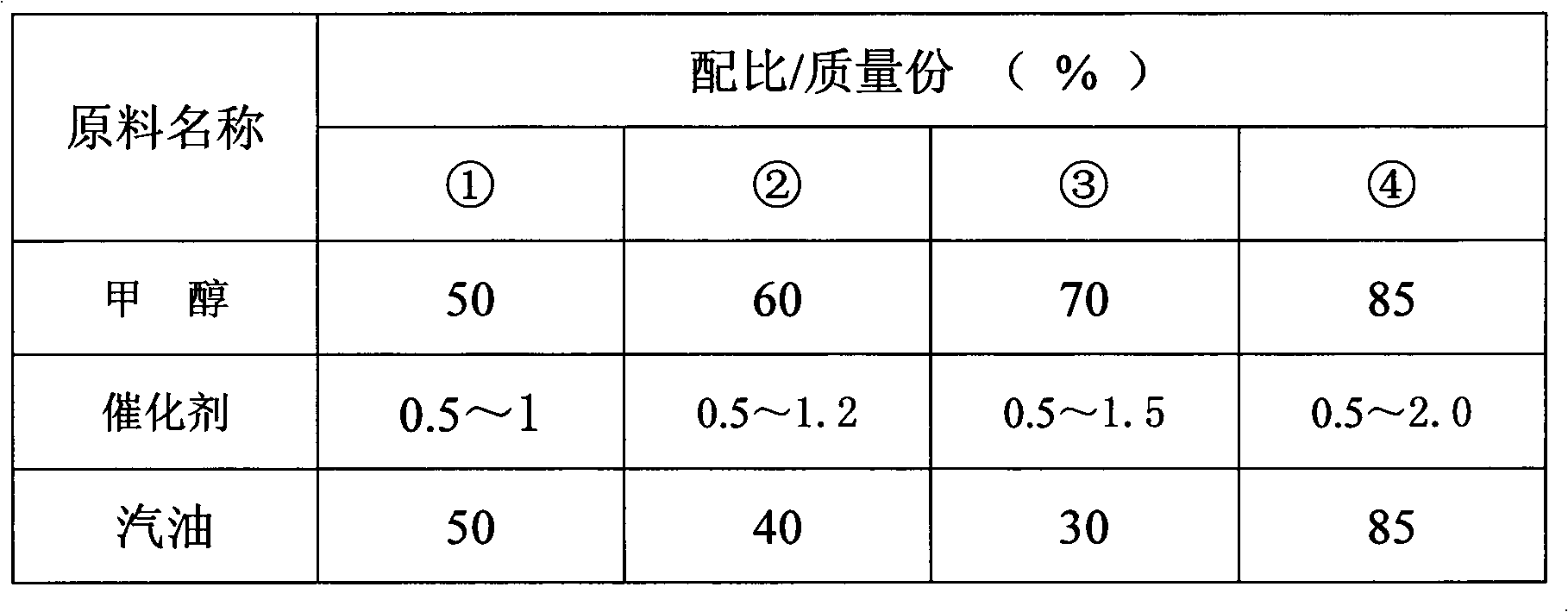

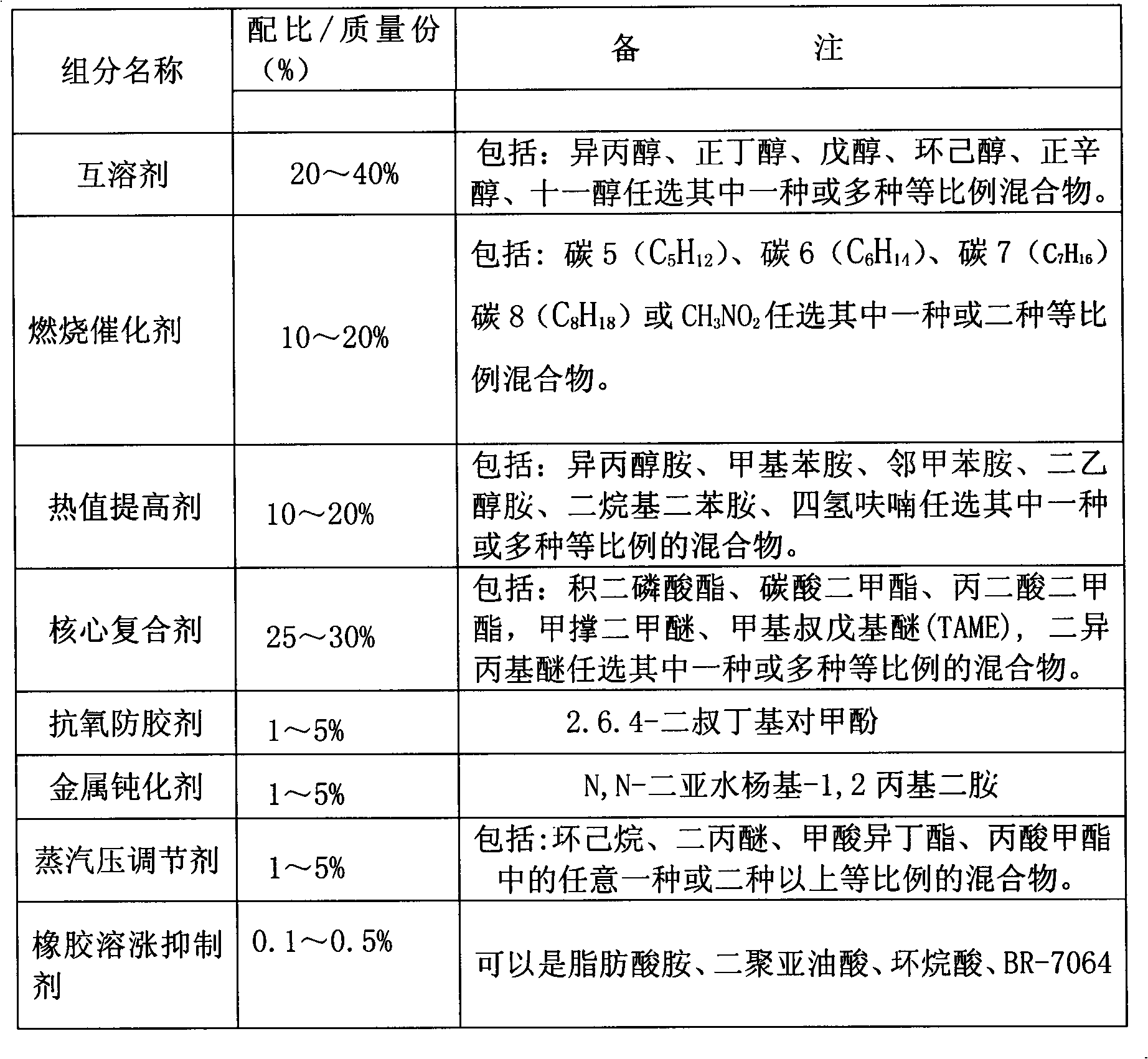

Large-proportion methanol gasoline catalyst and preparation method

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

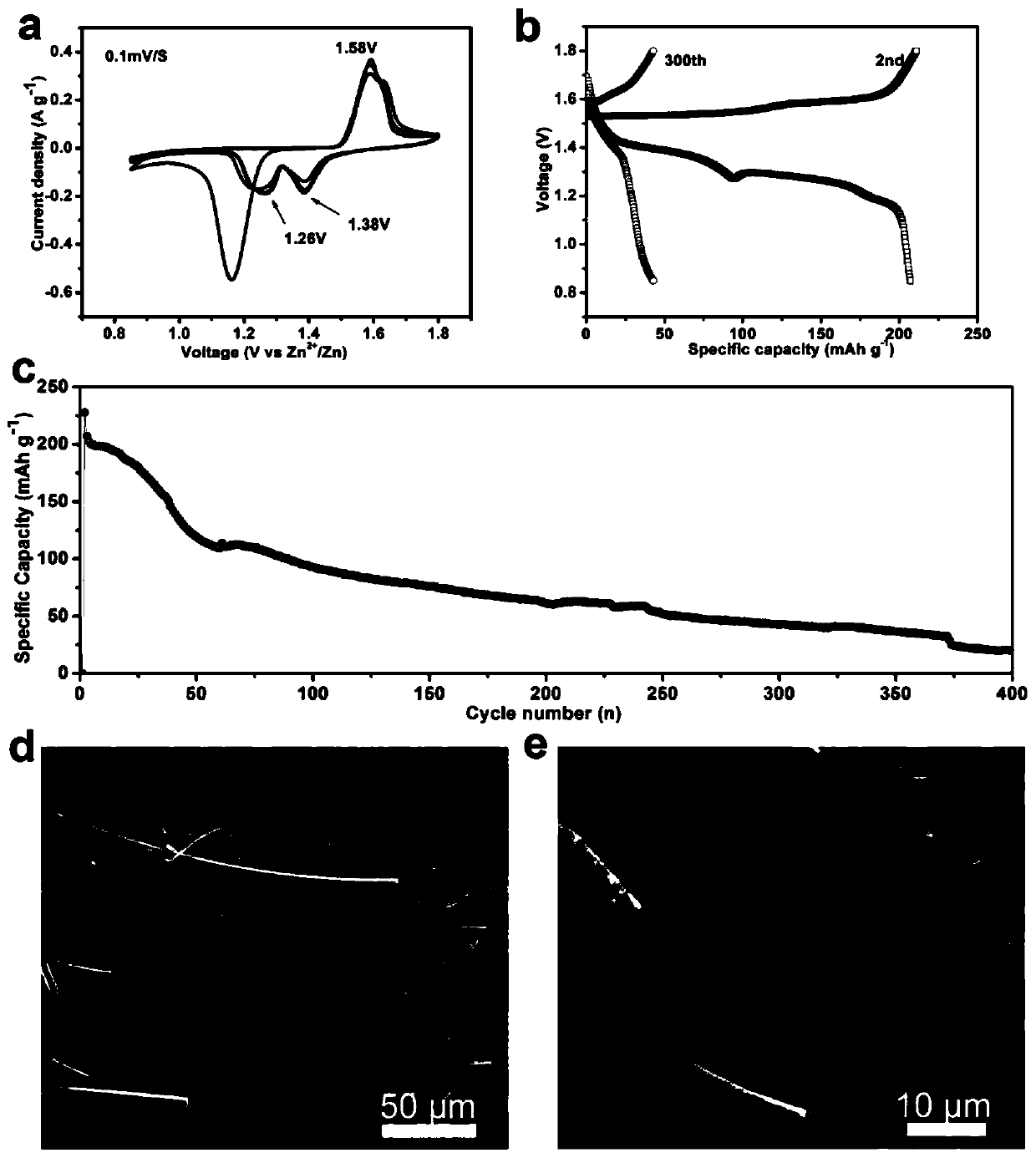

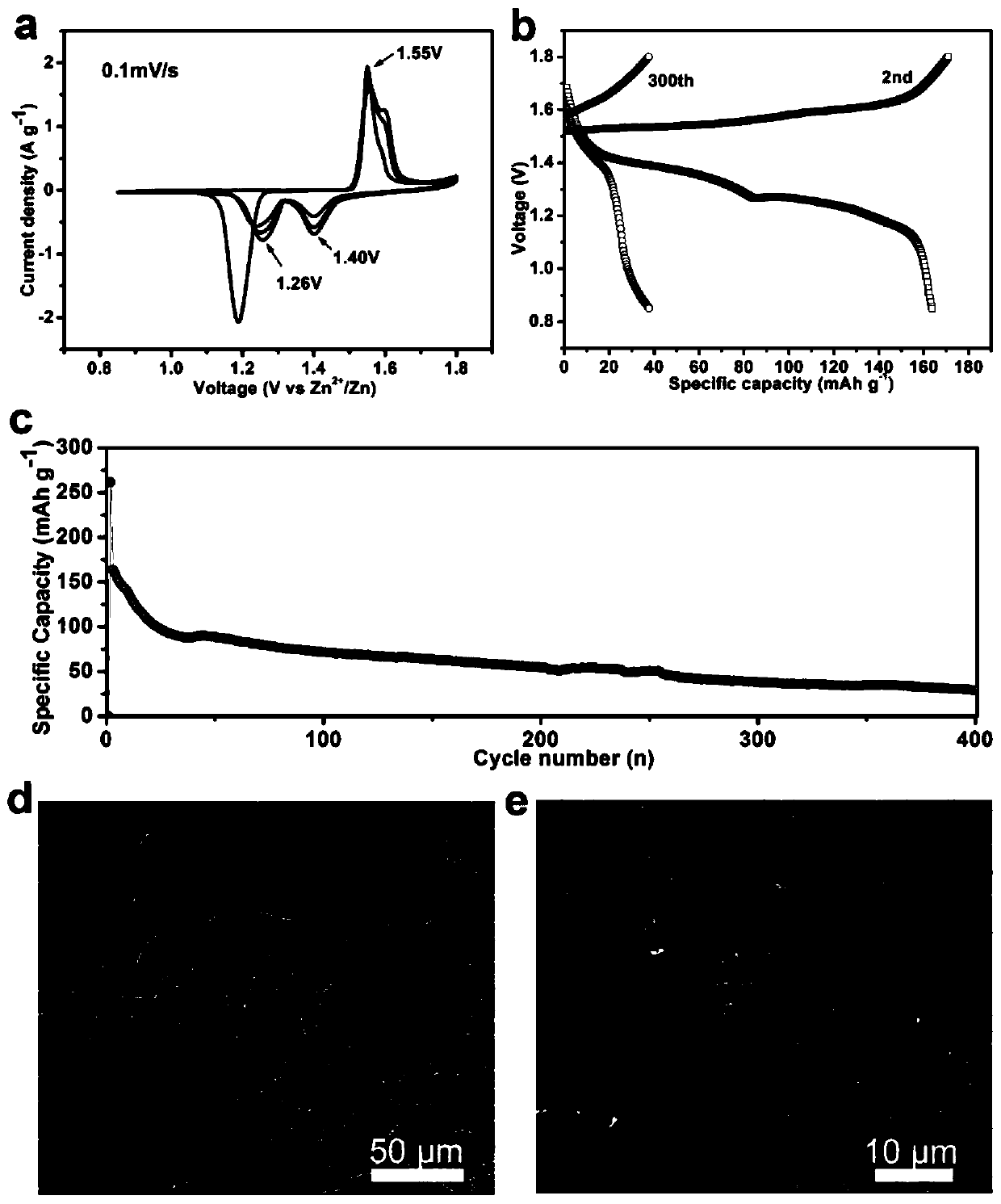

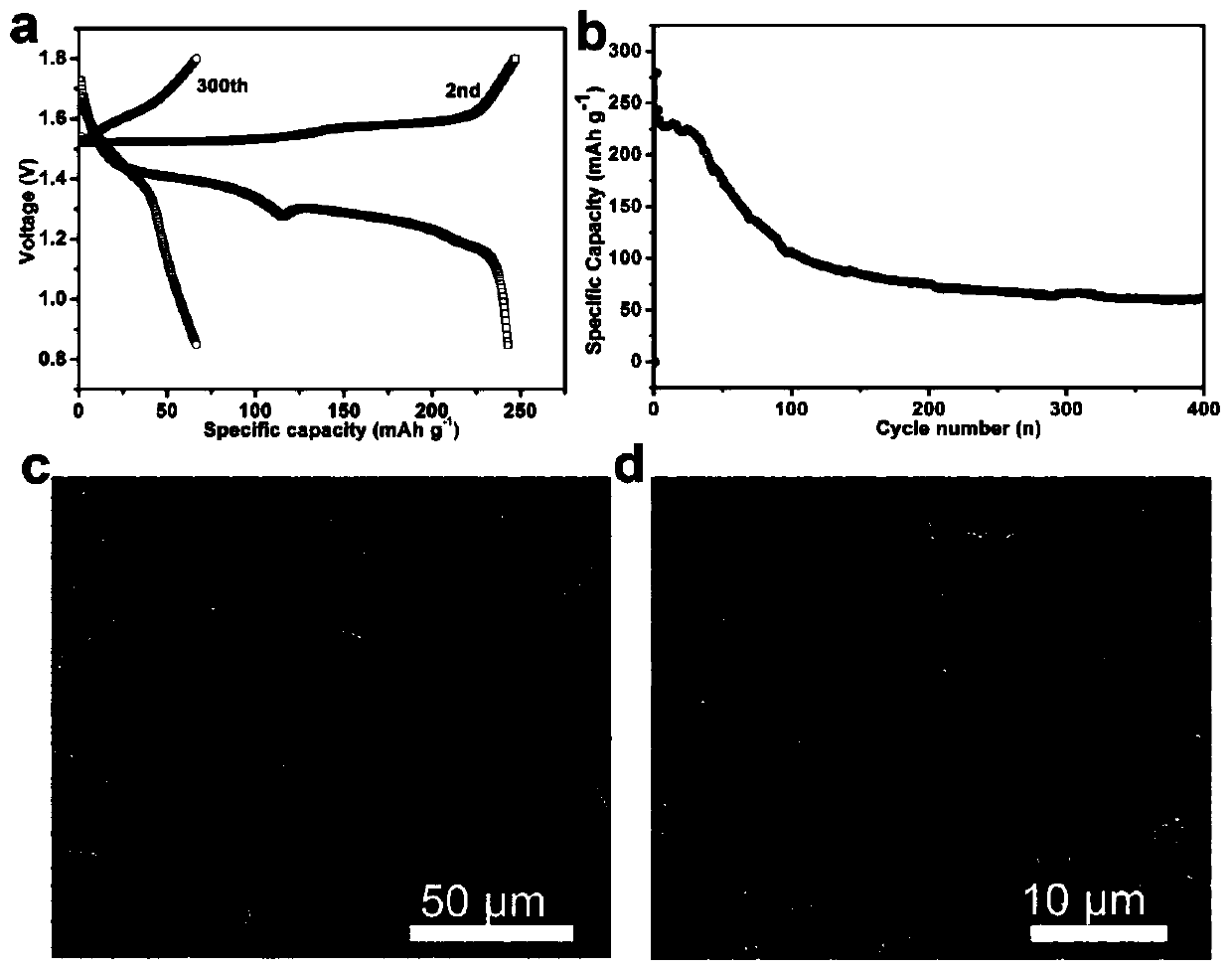

Metal zinc negative electrode with uniform mesoporous structure coating and preparation method and application thereof

ActiveCN110416549AReduce short circuitAlleviate volume expansionElectrode manufacturing processesNegative electrodesPorositySlurry

The invention discloses a metal zinc negative electrode with a uniform mesoporous structure coating and a preparation method and application thereof, belonging to the technical field of aqueous zinc ion batteries. The metal zinc negative electrode comprises a zinc negative electrode and a clay slurry layer, and is prepared by pre-embedding zinc. The raw material powder of the clay slurry includes1-20wt% of polyvinylidene fluoride and 80-90wt% of clay material. The aqueous zinc ion battery negative electrode coating presented in the invention can play a role of a protective layer, isolate thedirect contact between the zinc negative electrode and the electrolyte to a certain extent, reduce the side reaction between the electrode and the electrolyte and improve the cycle stability. The layered porosity of the material itself can prevent dendrites from being generated and penetrating a diaphragm in the cycle process, alleviate the volume expansion of the negative electrode, reduce the occurrence of short circuit of the battery and improve the safety performance.

Owner:CENT SOUTH UNIV

High-temperature protective coating for steel billets and applications thereof

ActiveCN104877397AOvercoming the difficulty of descalingProtection billetCoatingsSlagDecarburization

The invention discloses a high-temperature protective coating for steel billets and applications thereof, relates to a coating or cladding material temporarily applied before the heat treatment of alloys, and particularly relates to a coating or cladding material which is temporarily applied before the heat treatment of alloys and used for preventing the high-temperature decarburization of steel billets and reducing the difficulty of dephosphorization. The invention is designed for providing a high-temperature protective coating for steel billets, which can effectively reduce the surface decarburization layers of special steel billets. The high-temperature protective coating for steel billets disclosed by the invention comprises the following components in parts by mass: 15-50 parts of SiC, 10-25 parts of SiO2, 5-20 parts of Al2O3, 3-10 parts of Cr2O3, 5-15 parts of granulated blast furnace slags, 0.2 part of sodium hexametaphosphate and 0.2 part of celluloses. The coating of the invention can reduce the high-temperature oxidation burning loss of steel billets in a furnace, and meanwhile, alleviate the high-temperature dilution and decarburization of alloying elements on the surfaces of steel billets, and solve the problem that the difficulty of surface descaling of special steel is large; and an iron scale generating structure is modified by the coating, so that the high-pressure water descaling effect after steel billets are discharged out of a furnace is greatly increased. The coating disclosed by the invention is applied to the field of steel rolling.

Owner:SHIJIAZHUANG BINGXIN METALLURGICAL CHARGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com