Lithium ion battery silicon carbon composite negative electrode material and preparation method thereof

A lithium-ion battery, silicon-carbon composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as limited capacity, low high-rate charge and discharge capacity, and poor low-temperature performance, to solve safety problems and avoid environmental problems. and safety and hygiene issues, the effect of high specific surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

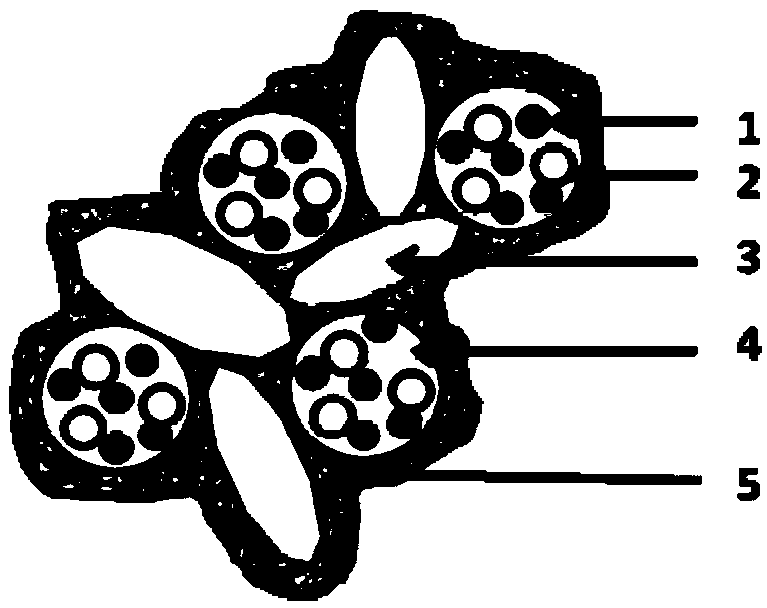

Method used

Image

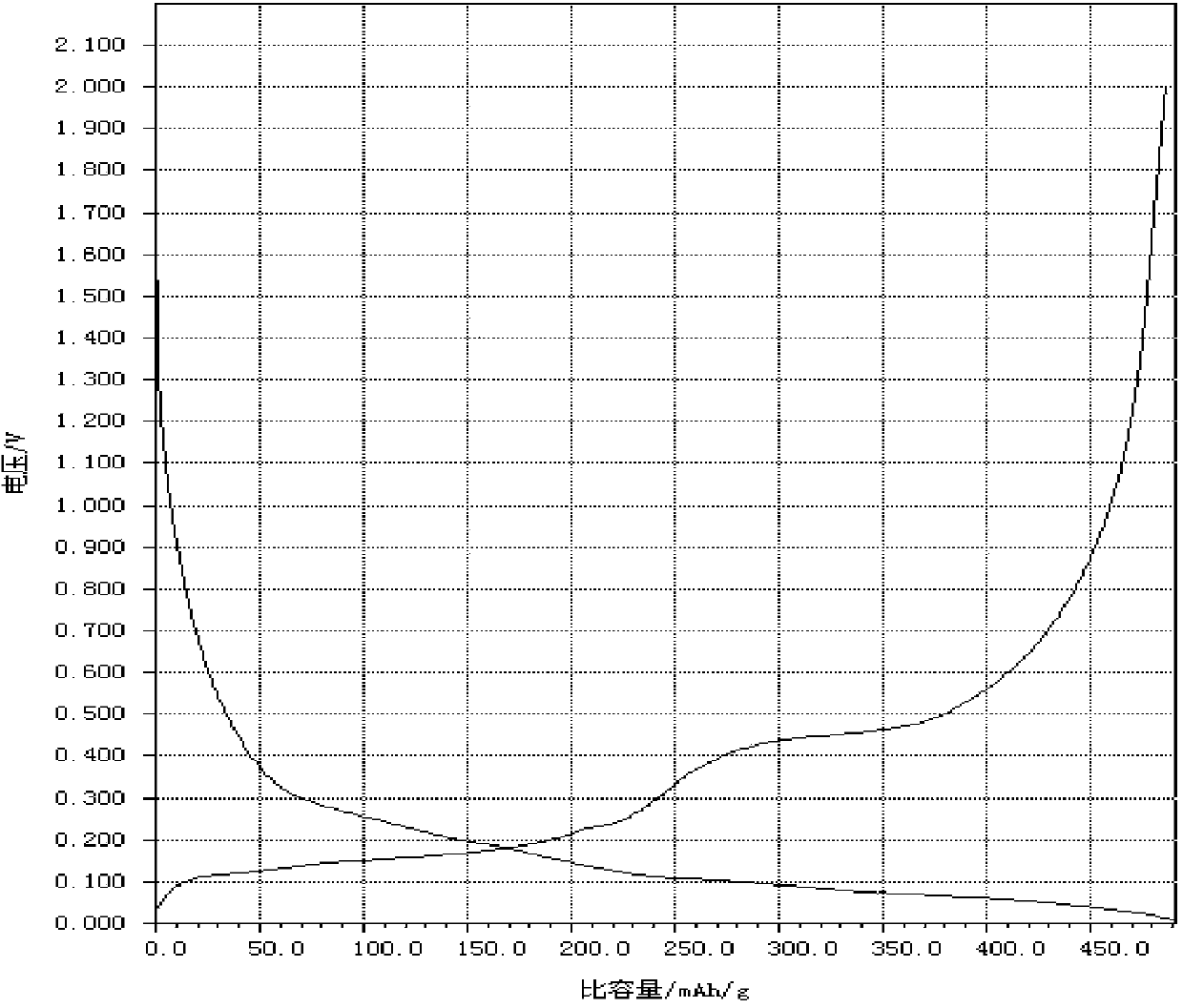

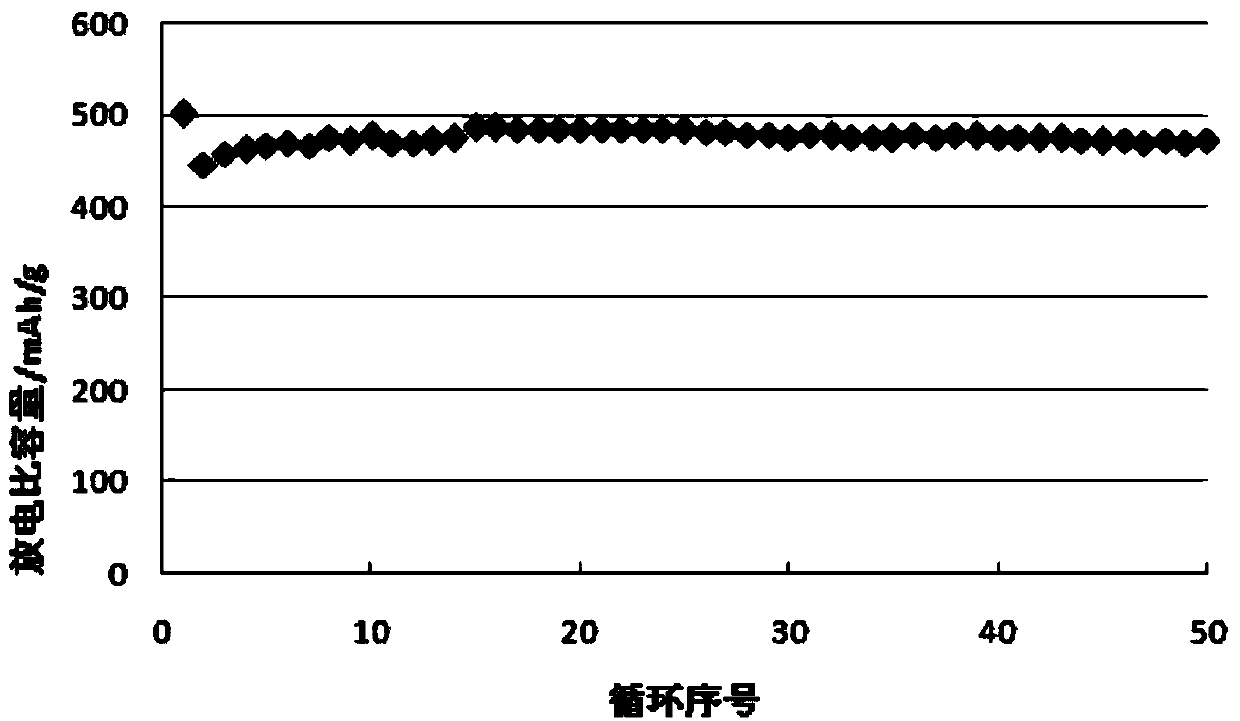

Examples

Embodiment 1

[0051] Using 80 parts by weight of styrene and 20 parts by weight of polyethylene glycol dimethacrylate as the grinding solvent, in the presence of hydroquinone accounting for 0.01% of the grinding solvent, utilize the grinding machine to grind silicon, and in the grinding liquid of silicon Inside, add fumaric acid, control the pH value of the silicon grinding dispersion below 5.5, the content of silicon is 6% of the grinding solvent, and the average particle size of silicon particles in the silicon grinding liquid is 100nm.

[0052] The silicon dispersion is transferred to a container with a stirring inert gas protection, and the 3-methacryloxypropylmethyldiethoxysilane of the grinding solvent 10wt% is added to the ball-milled silicon dispersion, Stir at a speed of 1200 r / min for 60 min to obtain a hydrophobized silicon dispersion. Continue to add conductive carbon black of grinding solvent 1wt%, dibenzoyl peroxide of grinding solvent 5wt%, n-dodecyl mercaptan of grinding sol...

Embodiment 2

[0062]Use 80 parts by weight of styrene and 20 parts by weight of polyethylene glycol dimethacrylate as the grinding solvent, in the presence of 0.01% hydroquinone in the grinding solvent, use a grinding machine to grind silicon, and in the grinding liquid of silicon , add fumaric acid, control the pH value of the silicon grinding dispersion below 5.5, the content of silicon is 6% of the grinding solvent, and the average particle size of silicon particles in the silicon grinding liquid is 100nm.

[0063] The silicon dispersion is transferred to a container with a stirring inert gas protection, and the 3-methacryloxypropylmethyldiethoxysilane of the grinding solvent 10wt% is added to the ball-milled silicon dispersion, Stir at a speed of 1200 r / min for 60 min to obtain a hydrophobized silicon dispersion. Continue to add conductive carbon black of grinding solvent 1wt%, dibenzoyl peroxide of grinding solvent 5wt%, n-dodecyl mercaptan of grinding solvent 0.5wt%, stir with 1200r / m...

Embodiment 3

[0073] Use 80 parts by weight of styrene and 20 parts by weight of polyethylene glycol dimethacrylate as the grinding solvent, in the presence of a small amount of hydroquinone accounting for 0.01% of the grinding solvent, utilize a grinder to grind silicon, and in the grinding of silicon Add fumaric acid to the liquid to control the pH value of the silicon grinding dispersion below 5.5, and the silicon content is 6% of the grinding solvent. The average particle size of the silicon particles in the silicon polishing liquid is 100 nm.

[0074] The silicon dispersion is transferred to a container with a stirring inert gas protection, and the 3-methacryloxypropylmethyldiethoxysilane of the grinding solvent 10wt% is added to the ball-milled silicon dispersion, Stir at a speed of 1200 r / min for 60 min to obtain a hydrophobized silicon dispersion. Continue to add 5wt% dibenzoyl peroxide as a grinding solvent and 0.5wt% n-dodecylmercaptan as a grinding solvent to form an organic mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com