Waste polymer modified asphalt composition and preparation method thereof

A technology of modifying asphalt and polymers, which is applied to building structures, building components, and building insulation materials. Facilitate industrial application and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

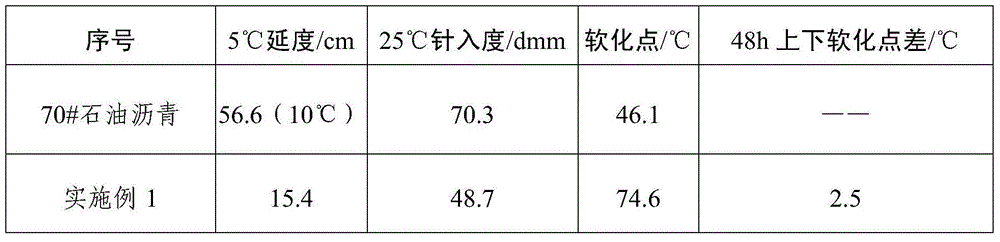

Examples

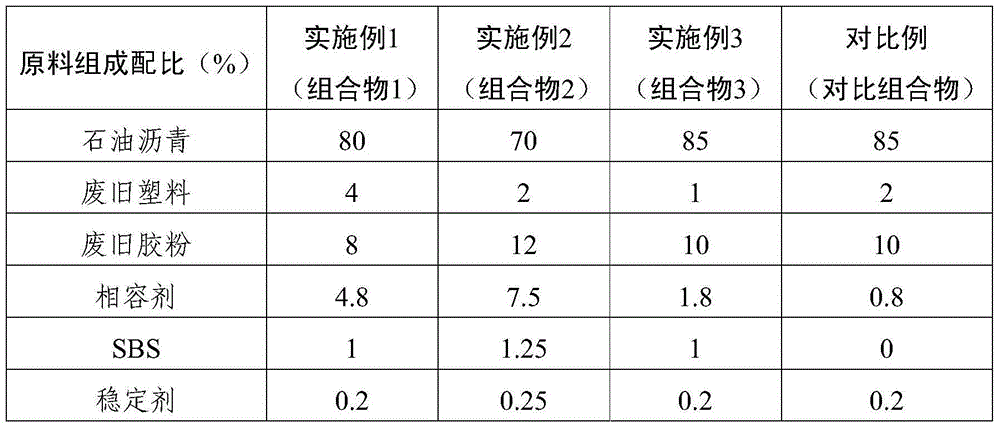

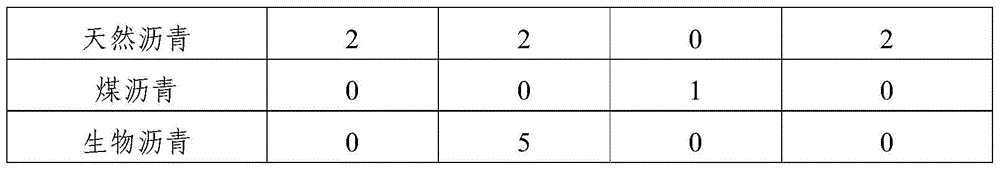

Embodiment 1

[0043] Step 1: Take 25g of aromatic oil (compatibilizer) and heat it to 140°C and stir for 5 minutes, then heat up to 166°C and add 20g of waste low-density polyethylene particles and 10g of Xinjiang rock asphalt (natural asphalt) at a shear rate of 5000r / min Cut down for 30 minutes to obtain a premix of waste plastic particles;

[0044] Step 2: Take 400g of 70# petroleum asphalt, heat it to 160°C and stir for 5 minutes, add the waste plastic granule premix prepared in Step 1, add 40g of waste rubber powder and 5g of SBS at the same time, heat up to 180°C, Shear at a rate of 5000r / min for 30min;

[0045] Step 3: Then add 1g of stabilizer (sulfur) and shear at 180°C for 30min,

[0046] The shear rate is 5000r / min. Thus, the waste polymer-modified asphalt composition 1 of the present invention was obtained.

Embodiment 2

[0048] Step 1: Take 37.5g tung oil (compatibilizer) and 25g biological asphalt and heat to 140°C and stir for 5min, then heat up to 160°C and add 10g waste high-density polyethylene particles and 10g North American rock asphalt (natural asphalt) at a shear rate Shear at 5000r / min for 30min to obtain a premix of waste plastic granules;

[0049] Step 2: Take 350g of 70# petroleum asphalt, heat it to 160°C and stir for 5 minutes, add the waste plastic granule premix prepared in Step 1, add 60g of waste rubber powder and 6.25g of SBS at the same time, heat up to 180°C, Shear at a rate of 5000r / min for 30min;

[0050] Step 3: Then add 1.25g of stabilizer (sulfur) and shear at 180°C for 45min at a shear rate of 5000r / min. Thus, the waste polymer modified asphalt composition 2 of the present invention was obtained.

Embodiment 3

[0052] Step 1: Take 9g of aromatic oil (compatibilizer) and heat it to 140°C and stir for 5min, then raise the temperature to 160°C, add 5g of waste particles, 5g of polypropylene and coal tar pitch for 45min at a shear rate of 5000r / min to obtain Premix of waste plastic granules;

[0053] Step 2: Take 425g of 70# petroleum asphalt, heat it to 160°C and stir for 5 minutes, then add the waste plastic granule premix prepared in Step 1, add 50g of waste rubber powder and 5g of SBS at the same time, heat up to 180°C, Shear at a rate of 5000r / min for 30min;

[0054] Step 3: Then add 1 g of stabilizer (sulfur) and shear at 180° C. for 45 min with a shear rate of 5000 r / min. Thus, the waste polymer modified asphalt composition 3 of the present invention was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com