Selective water-blocking, oil-permeable and sand-preventing proppant as well as preparation method and application thereof

A proppant and selective technology, which is applied in crude oil production of sand producing oil wells and high water content fields, can solve the problems of poor chemical water shutoff selectivity, affecting normal production of oil wells, and limited mechanical water shutoff, so as to achieve less pollution and save underground Reservoir resources, complete effect of gel breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for preparing a selective water-repelling, oil-permeable and sand-controlling proppant, wherein the preparation method includes the following steps:

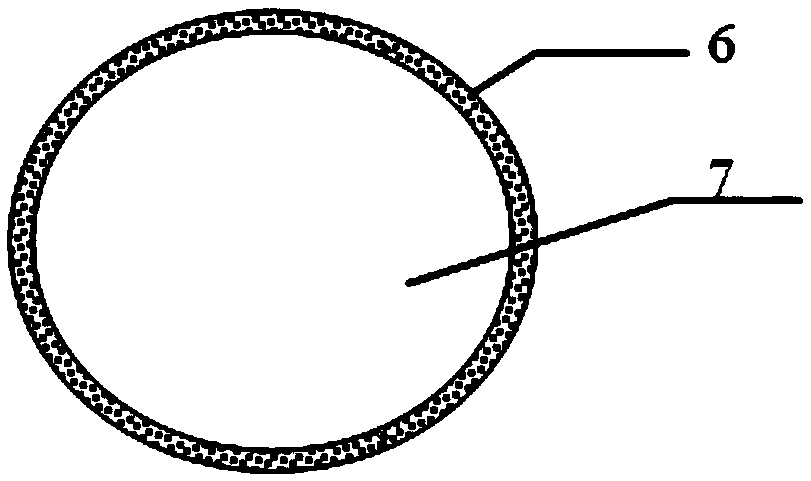

[0062] a, 2kg sintered ceramsite (particle size 0.5-0.8mm, density 1.45g / cm 3 , maximum strength 50MPa) heated to 260°C and placed in a sand mixer for stirring; when the ceramsite cools down to 200°C, add 0.1kg of phenolic resin and 0.04kg of polyvinylidene fluoride, and stir evenly to obtain a surface-coated hydrophobic and lipophilic Ceramsite of type resin film;

[0063] b. Then add 0.016kg plasticizer (dioctyl phthalate), stir evenly, add 0.005kg coupling agent (aminopropyltriethoxysilane.), stir evenly, add 0.012kg curing agent (6 Methylenetetramine), stir evenly, make hydrophobic-lipophilic resin film solidify; Add lubricant (calcium stearate) before agglomeration, and stir at hydrophobic-lipophilic resin film beginning to solidify; After the resin film is completely cured, it is ...

Embodiment 2

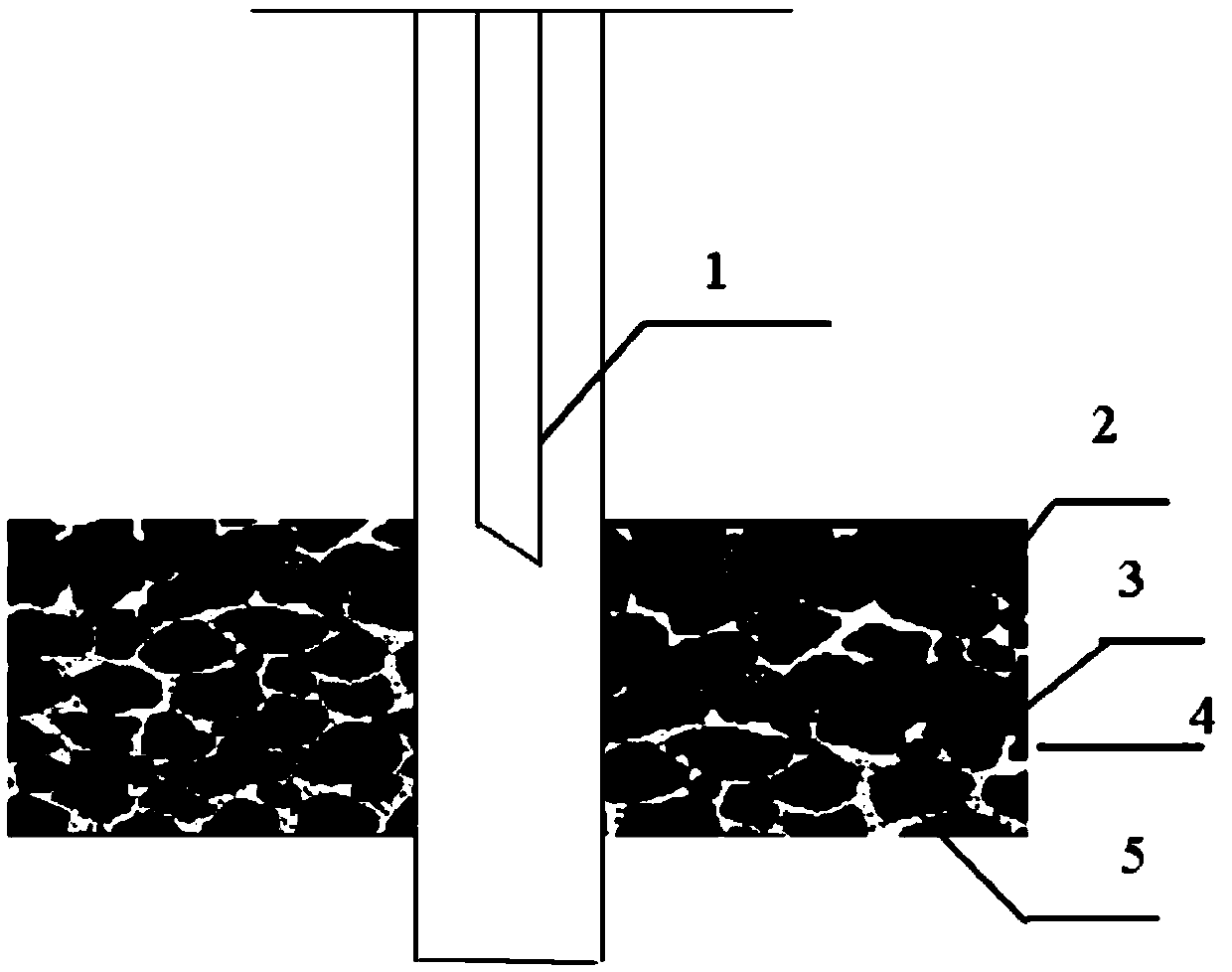

[0065] This example provides the application of the selective water-repelling, oil-permeable and sand-controlling proppant prepared in Example 1 in water plugging and sand-controlling of oil wells. The application includes the following steps:

[0066] (1), move up: wash the pressure oil well, and pull out the pipe string in the well;

[0067] (2) Sand washing: put the sand washing pipe into the oil well to detect the sand surface, if there is sand, wash the sand to the bottom of the artificial well;

[0068] (3) Drilling well: run the drilling plan to the oil well;

[0069] (4) Scraper: Scrape the well with a spring scraper in the oil well, and backwash the well with hot water for two weeks;

[0070] (5), lower construction pipe string 1: a combined pipe string with a pen tip at the bottom that is lowered into the oil well;

[0071] (6) Install high-pressure wellhead;

[0072] (7) The pipeline on the ground surface, and inject solid-free clean sand-carrying liquid into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com