Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

A nano-film and coating technology is applied in the field of organic-inorganic hybrid nano-film-coated aluminum powder pigments to achieve the effects of improving compatibility, good acid and alkali resistance and water resistance, and good metallic luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

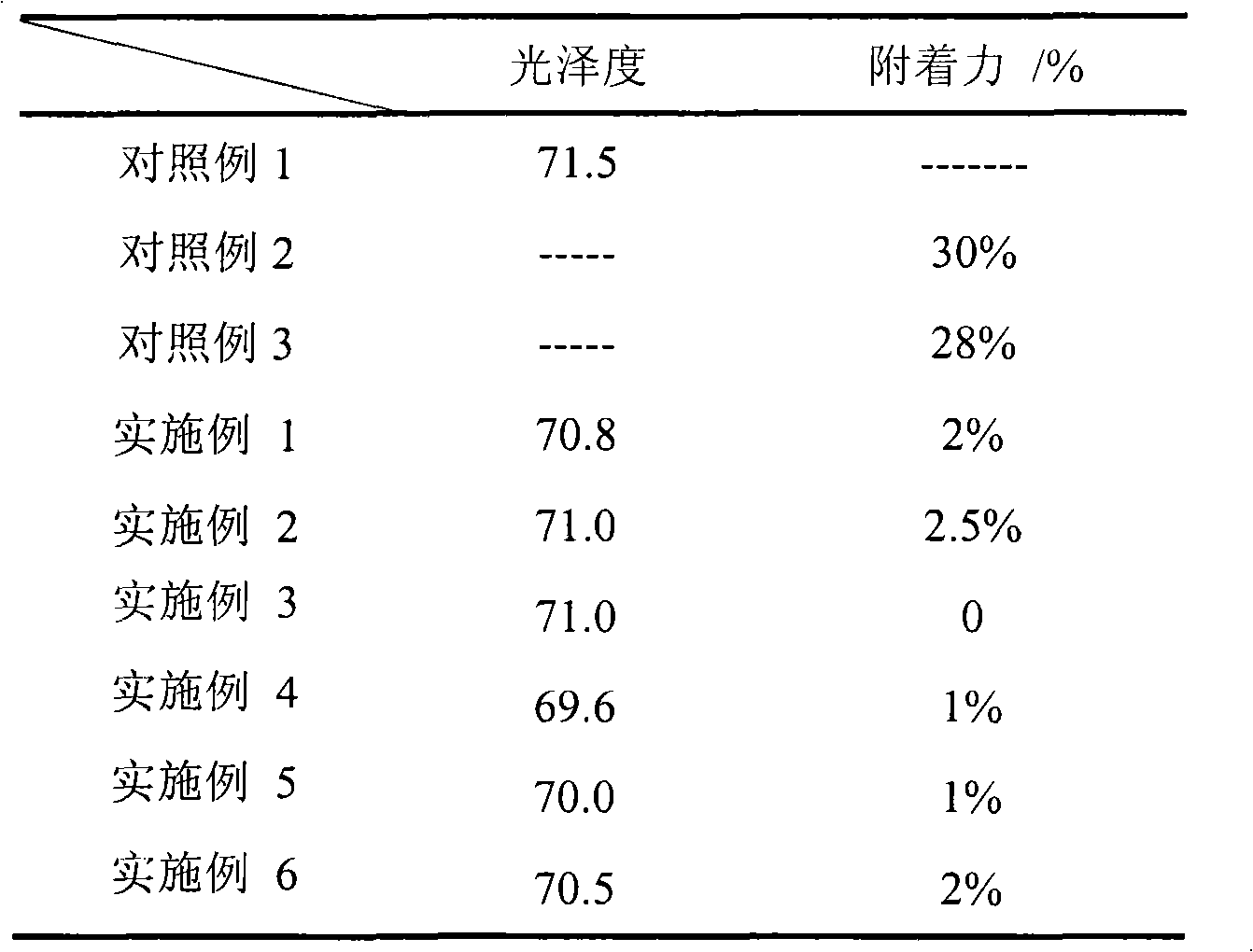

Examples

Embodiment 1-6

[0025] Embodiment 1-6 is the preparation method of organic-inorganic hybrid nano film coated aluminum powder pigment

Embodiment 1

[0027] The first step is to add 5 parts of vinyltrimethoxysilane, 6 parts of styrene, 40 parts of butyl acetate, and 1 part of azobisisobutyronitrile to the first reaction vessel under nitrogen protection, and react for 10 hours under stirring. The temperature is 60°C, and a polymer of carbon-carbon double bond organosiloxane and carbon-carbon double bond polymerizable monomer is obtained;

[0028] In the second step, in parts by mass, add 2 parts of aluminum powder pigment and 40 parts of methanol into the second reaction vessel, and stir at room temperature for 0.5 hour; 10~40nm;

[0029] In the third step, in the second reaction vessel described in the second step, add the mixture of 20 parts of polymers obtained in the first step, 5 parts of tetraethyl orthosilicate, 4 parts of water, 2 parts of ammonia and 10 parts of ethanol, Wherein the mixture of 20 parts of polymers obtained in the first step and 5 parts of tetraethyl orthosilicate and the mixture of 4 parts of water...

Embodiment 2

[0032] In the first step, in parts by mass, 3 parts of butadienyltriethoxysilane, 6 parts of butyl methacrylate, 40 parts of xylene, 0.5 part of benzene peroxide are added to the first reaction vessel under nitrogen protection Formyl was reacted under stirring for 6 hours at a reaction temperature of 110°C to obtain a polymer of carbon-carbon double bond-type organosiloxane and carbon-carbon double-bond type polymerizable monomer;

[0033] In the second step, in parts by mass, add 4 parts of aluminum powder pigment and 40 parts of propanol to the second reaction vessel, and stir for 1 hour at room temperature; 10-40nm;

[0034] In the third step, in the second reaction vessel described in the second step, add the mixture of 40 parts of polymers obtained in the first step, 5 parts of tetraethyl orthosilicate, 6 parts of water, 3 parts of ammonia and 10 parts of ethanol, Wherein the mixture of 40 parts of polymers obtained in the first step and 5 parts of tetraethyl orthosilicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com